Treatments Technology and Mechanisms of East Asia Black Cotton Soil

Abstract

:1. Introduction

2. Performance Test

2.1. Materials

2.2. Test Plan

2.2.1. Specimen Preparation

2.2.2. Test Program

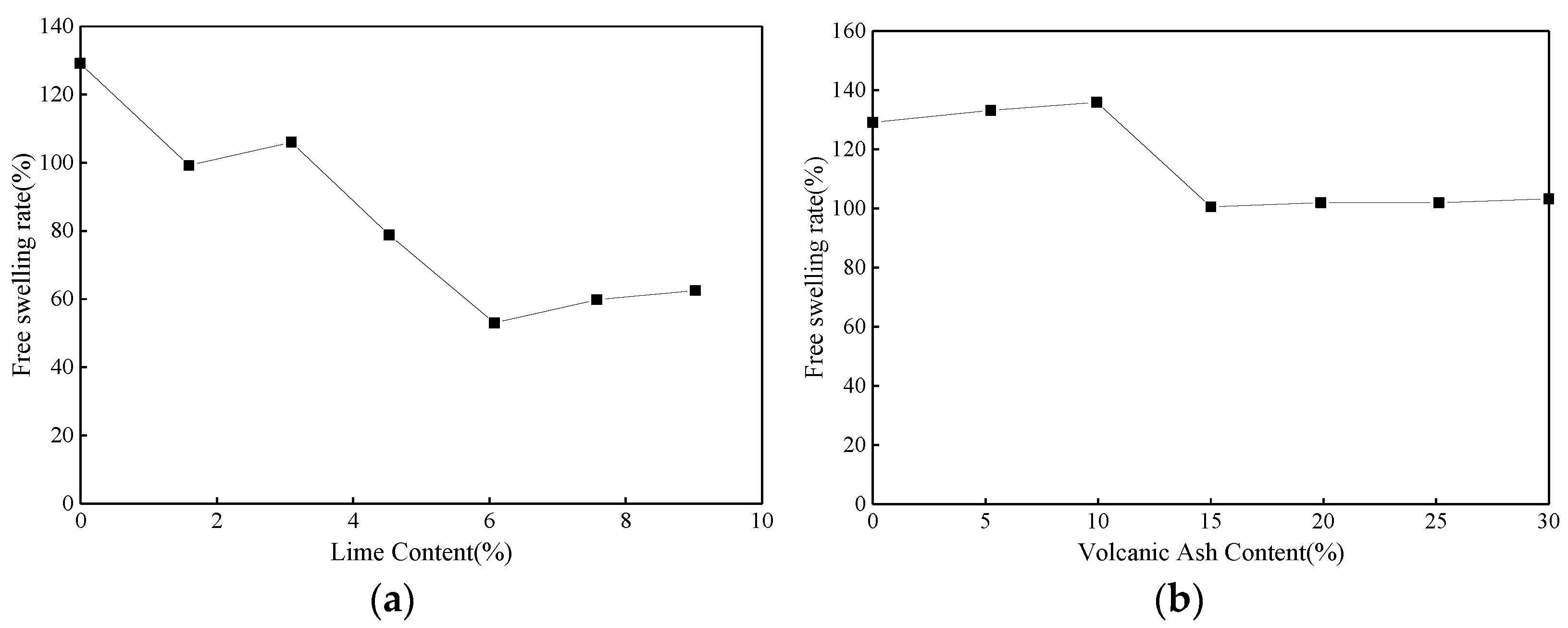

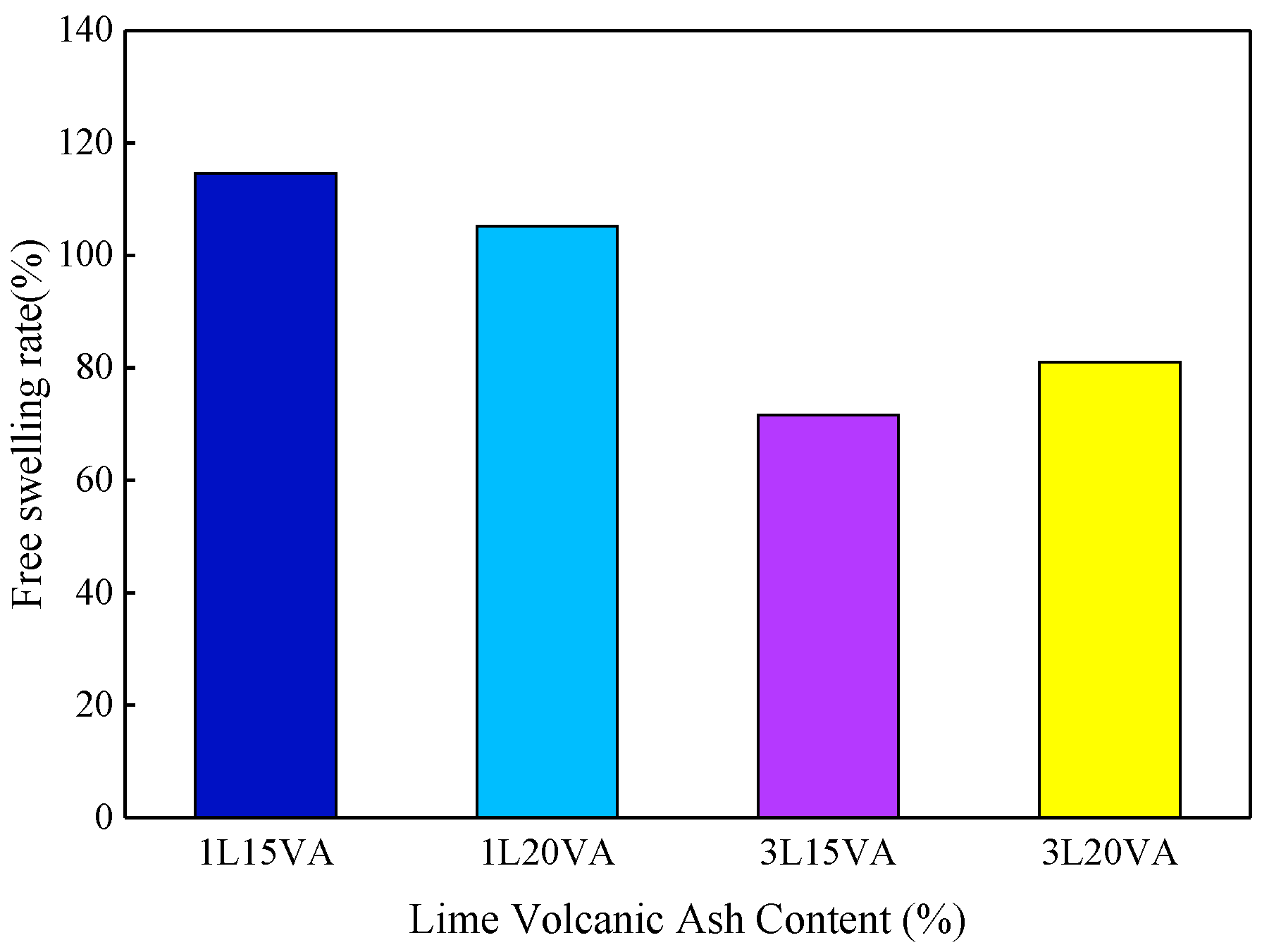

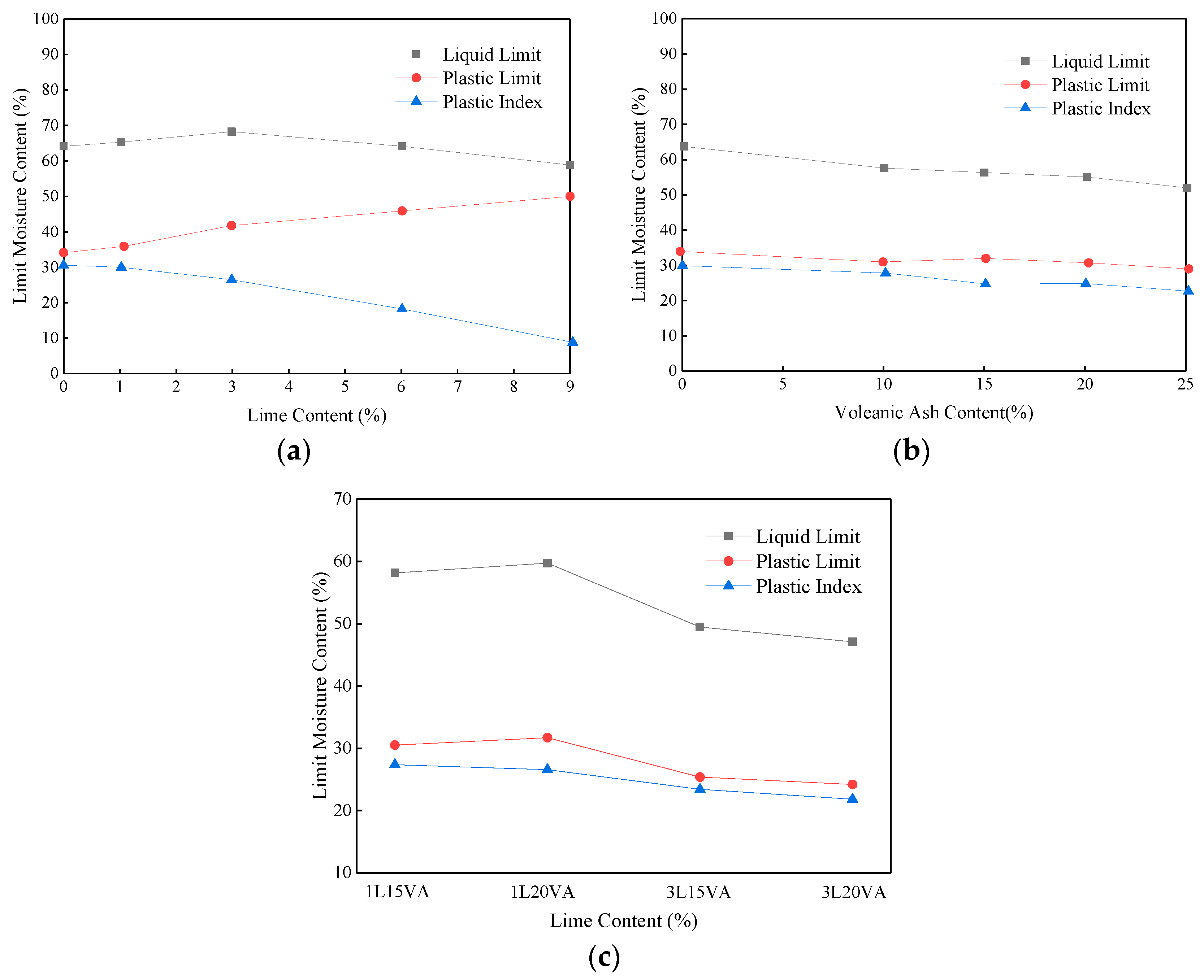

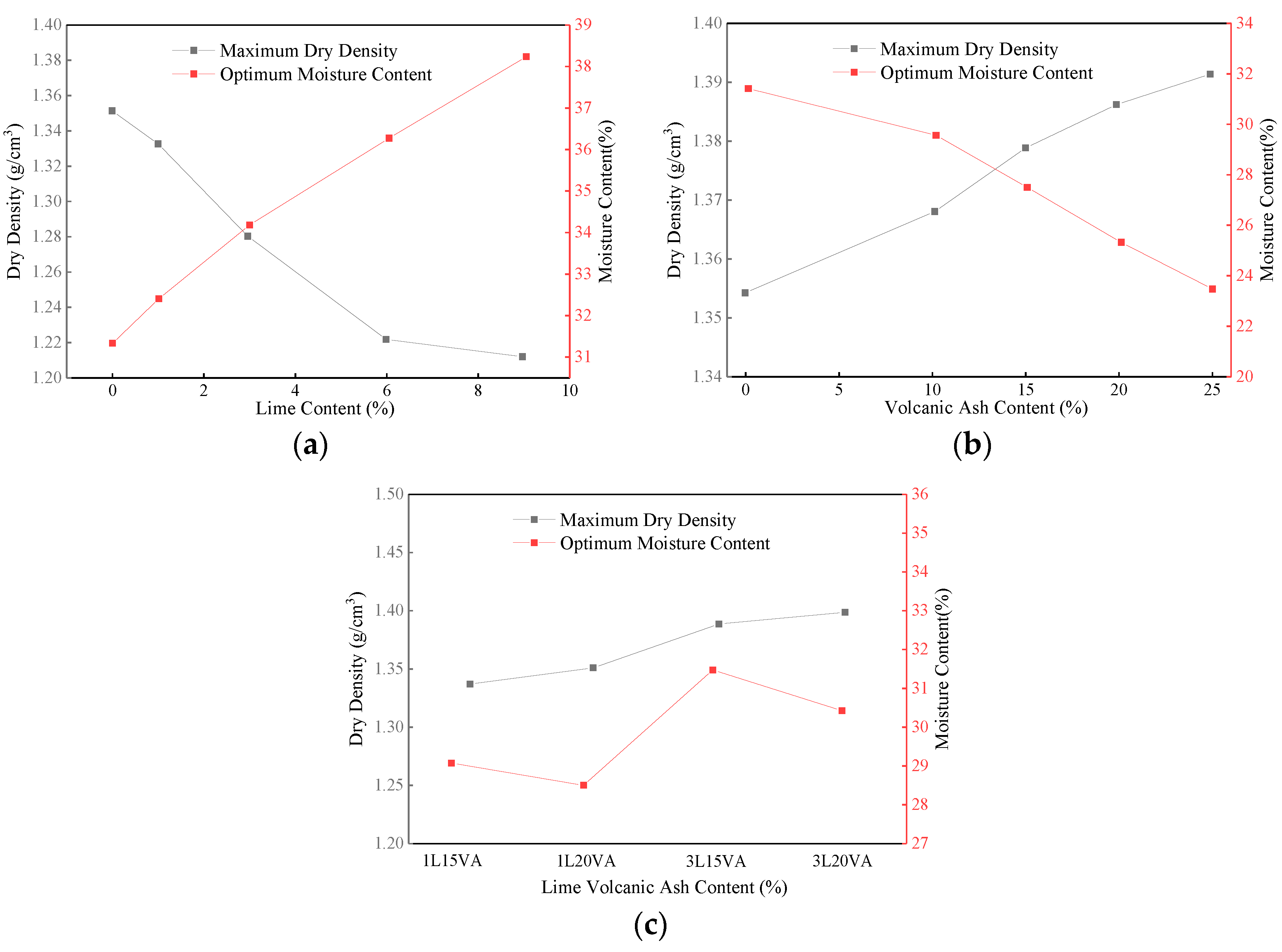

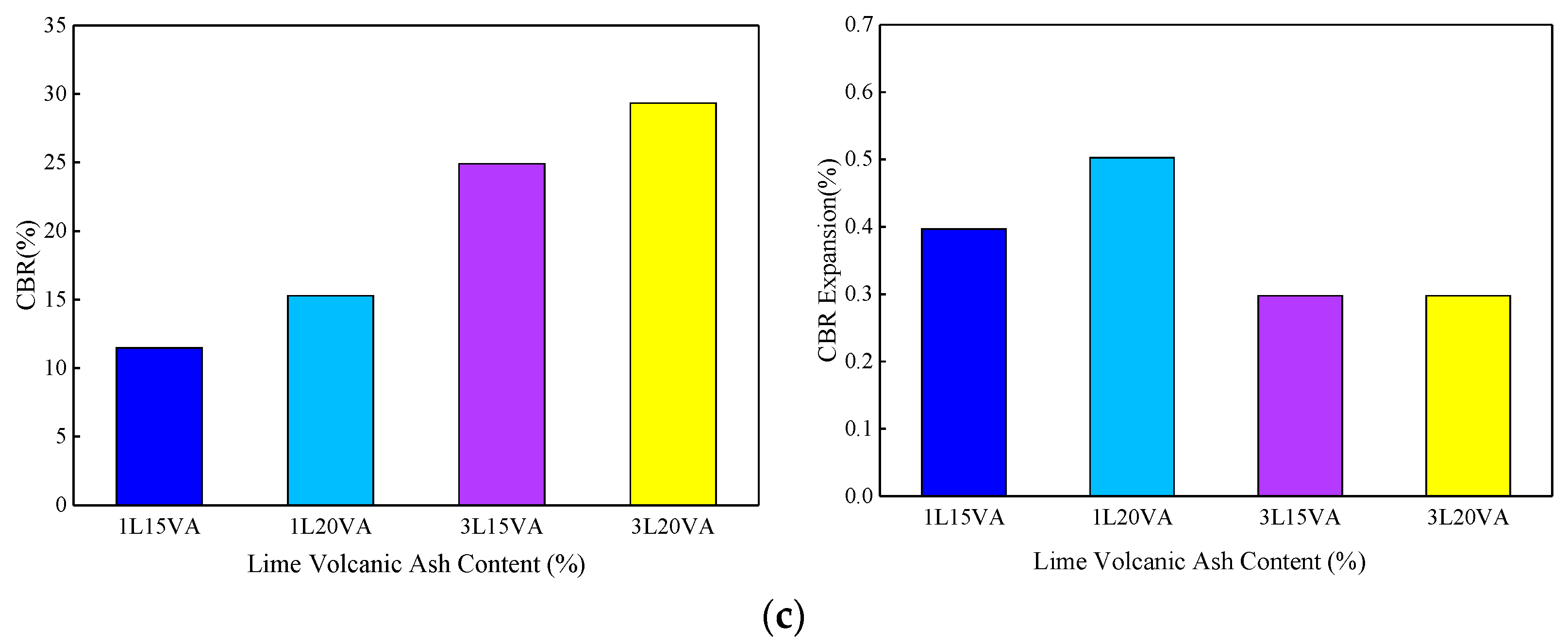

2.2.3. Testing Results

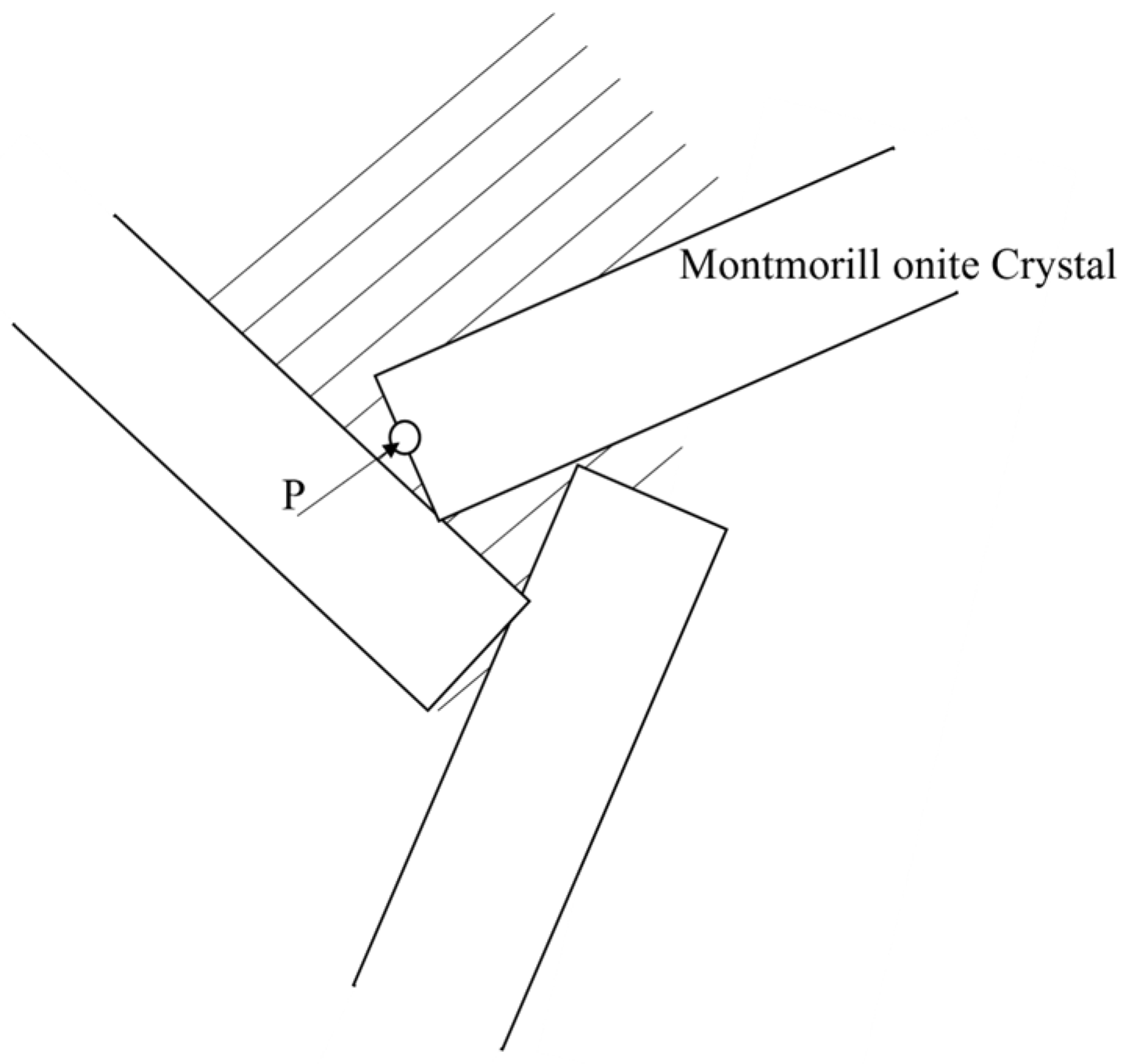

3. Mechanism of Performance Improvement

3.1. Hydration Exothermic Reaction

3.2. Volcanic Ash Reaction

3.3. Semipermeable Membrane Effect

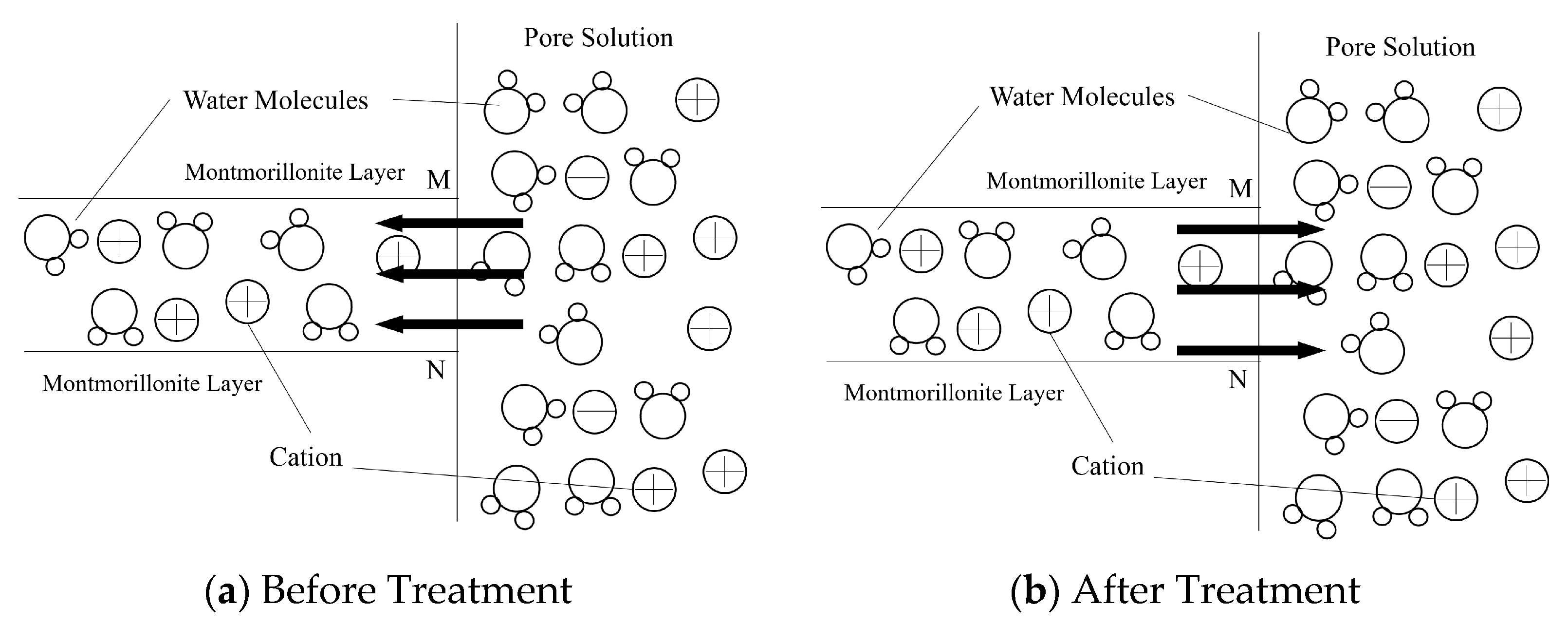

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, Z.X.; Tang, K.; Zhang, X.J.; He, W.; Hou, L. Research on survey methods and engineering properties of black cotton soil of ethiopian railway. J. Railw. Eng. Soc. 2014, 31, 15–18. [Google Scholar]

- Wagner, G.H.; Stevenson, F.J. Structural Arrangement of Functional Groups in Soil Humic Acid as Revealed by Infrared Analyses. Soil Sci. Soc. Am. J. 1965, 29, 43–48. [Google Scholar] [CrossRef]

- Shao, W.M.; Tan, L.R.; Zhang, M.Y.; Hua, L.L. Experimental Study on Relationship between Mineral Composition and Swelling Characteristics of Expansive Soil. Rock Soil Mech. 1994, 2, 11–19. [Google Scholar]

- Gao, D.P. Study of Properties of Expansive Soil on the Ethiopia to Djibouti Railway (Dire Dawa-Dawanle Segment). Railw. Investig. Surv. 2015, 3, 13–15. [Google Scholar]

- Zhao, P.; Xu, Z.X.; Tang, L.; Zeng, D.L. Research on the Black Cotton Soil Swell-shrink Characteristics and the Depth of Black Cotton Soil Influenced by the Atmosphere in Ethiopia. J. Railw. Eng. Soc. 2014, 4, 46–50. [Google Scholar]

- Mahjoory, R.A. Occurrence and mineralogy of a deposit of shampoo-clay in southern Iran. Appl. Clay Sci. 1996, 11, 69–76. [Google Scholar] [CrossRef]

- Xu, Z.X.; Zhang, K.; Tang, L. Comments on Engineering Geological Investigation of Ethiopian Railway. J. Railw. Eng. Soc. 2012, 29, 26–29+39. [Google Scholar]

- Wang, T.; Fan, Q.B.; Liu, X.; Wang, Y. Black Cotton Subgrade Treatment in East Africa. Master’s Thesis, Chang’an University, Xi’an, China, 2014. [Google Scholar]

- Chen, S.X.; Li, F.B.; Kong, L.W. Engineering behaviors of weak expansive soil and its treatment measures for roadbed filling. Rock Soil Mech. 2006, 27, 353–359. [Google Scholar]

- Zhang, D.F.; Yang, J.; Li, L.Y.; Shen, Z.P. Engineering properties of black cotton soil in East Africa and pile foundation disease treatment. Build. Struct. 2015, 45, 72–76. [Google Scholar]

- Li, S.D.; Zhao, Z.X. Improvement of Engineering Properties of Expansive Soil by Using Mineral Slurry Composites. Chin. J. Geotech. Eng. 1993, 15, 11–23. [Google Scholar]

- Li, X.Y.; Zhang, X.H. Lime Improved Expansive Soil Filling Subgrade Construction Technology. Subgrade Eng. 2001, 3, 47–49. [Google Scholar]

- Oriola, F.; Moses, G. Groundnut Shell Ash Stabilization of Black Cotton Soil. Electron. J. Geotech. Eng. 2010, 15, 415–428. [Google Scholar]

- Santhi, K.K.; Sayida, M.K. Behavior of Black Cotton Soil Reinforced with Sisal Fibre. In Proceedings of the 10th National Conference on Technological Trends(NCTT09), Trivandrum, India, 6–7 November 2009; pp. 88–93. [Google Scholar]

- Shi, B.; Li, S.L.; Tolkachev, M. Quantitative Study on SEM Images of Microstructure of Clay. Sci. China (Ser. A) 1995, 6, 666–672. [Google Scholar]

- Tovey, N.K. A digital computer technique for orientation analysis of micrographs of soil fabric. J. Microsc. 1980, 120, 303–315. [Google Scholar] [CrossRef]

- TB 10077-2001; Code for Rock and Soil Classification of Railway Engineering. China Railway First Survey and Design Institute Group. Beijing China Railway Press: Beijing, China, 2001.

- JTG E40-2007; Test Method of Soils for Highway Engineering. Ministry of Communications Highway Research Institute. Beijing China Communications Press: Beijing, China, 2007.

- ASTM D4318; Standard Test Method for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- JTG D30-2015; Specifications for Design of Highway Subgrades. Ministry of Communications Highway Research Institute. Beijing China Communications Press: Beijing, China, 2015.

- Zheng, J.L. Theory and Technology for Highway Expansive Soil Engineering; Beijing China Communications Press: Beijing, China, 2013. [Google Scholar]

| Ash Sample Number | CaO | MgO | Fe2O3 | Al2O3 | SiO2 | K2O | Na2O | SO3 | P2O5 | MnO | TiO2 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample 1 | 10.69 | 11.69 | 12.43 | 13.35 | 43.26 | 1.29 | 2.76 | 0.065 | 0.54 | 0.17 | 2.85 | 0.32 |

| Sample 2 | 10.88 | 12.18 | 12.41 | 13.07 | 43.08 | 1.26 | 2.75 | 0.061 | 0.54 | 0.17 | 2.81 | 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, X.; Wang, J.; Chang, H.; Zhang, W. Treatments Technology and Mechanisms of East Asia Black Cotton Soil. Buildings 2024, 14, 2679. https://doi.org/10.3390/buildings14092679

Shang X, Wang J, Chang H, Zhang W. Treatments Technology and Mechanisms of East Asia Black Cotton Soil. Buildings. 2024; 14(9):2679. https://doi.org/10.3390/buildings14092679

Chicago/Turabian StyleShang, Xin, Jiansheng Wang, Haolei Chang, and Weiguang Zhang. 2024. "Treatments Technology and Mechanisms of East Asia Black Cotton Soil" Buildings 14, no. 9: 2679. https://doi.org/10.3390/buildings14092679