Numerical Stability Analysis of Sloped Geosynthetic Encased Stone Column Composite Foundation under Embankment Based on Equivalent Method

Abstract

:1. Introduction

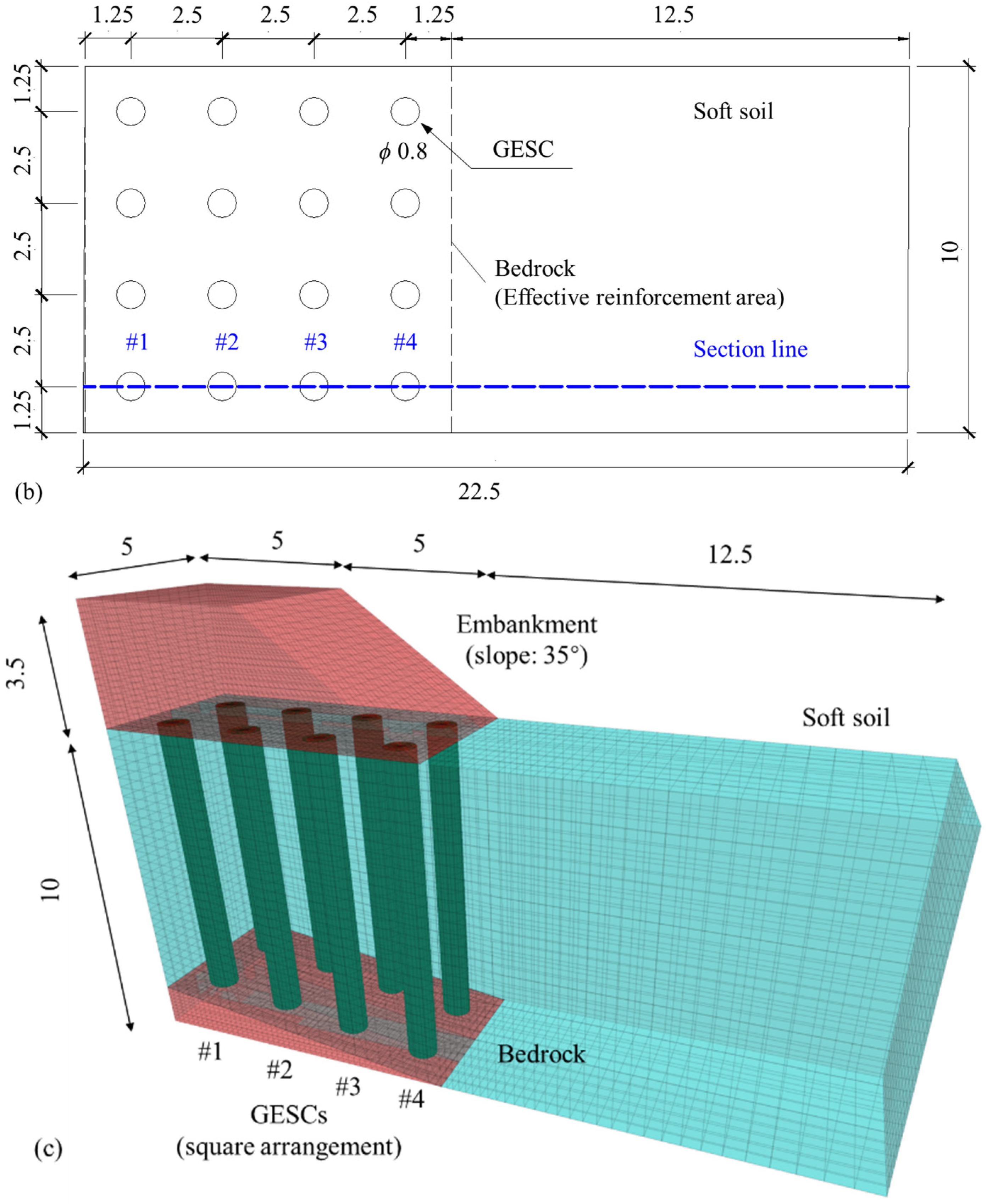

2. FDM Molding and Validation

2.1. Details of the FDM Model

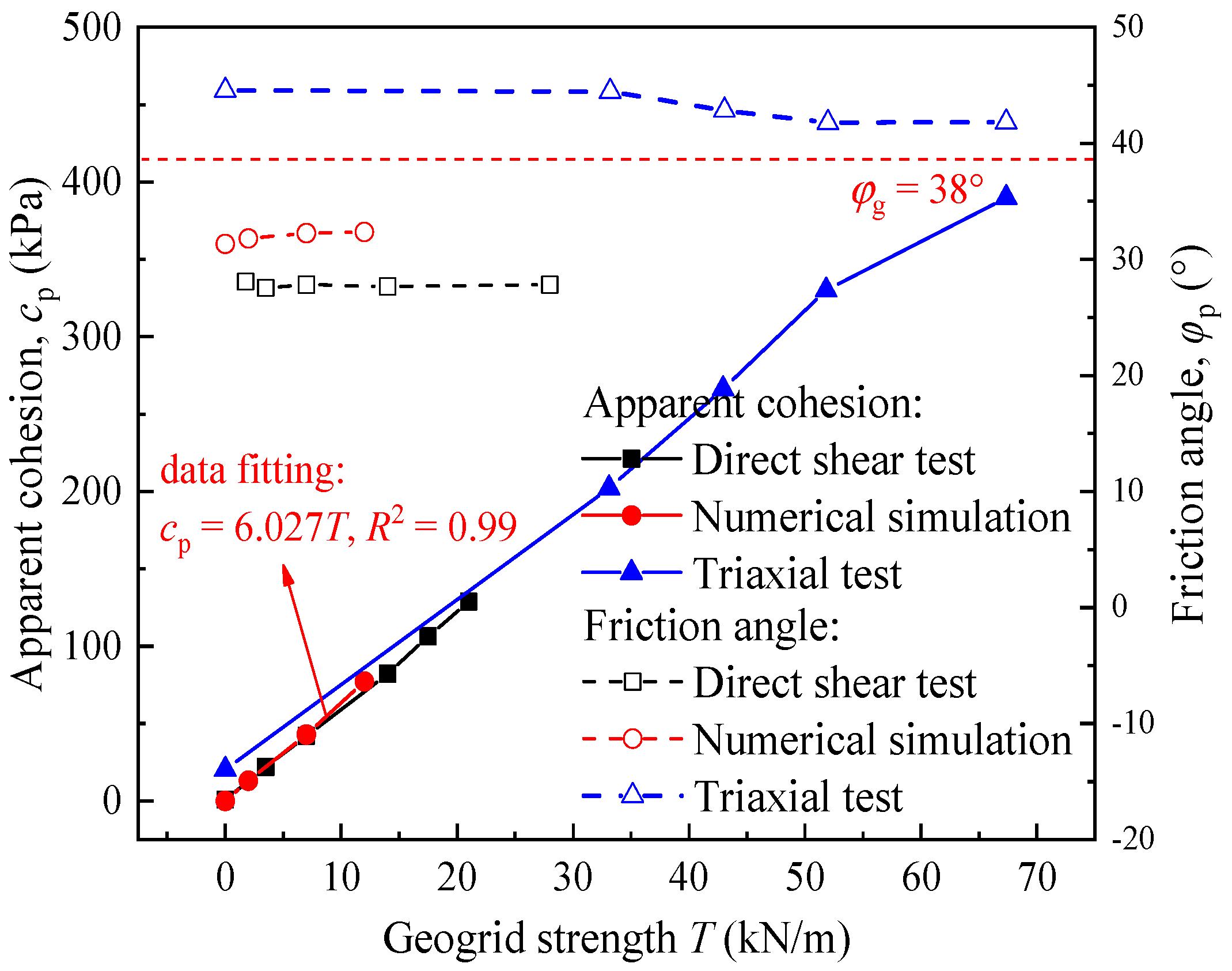

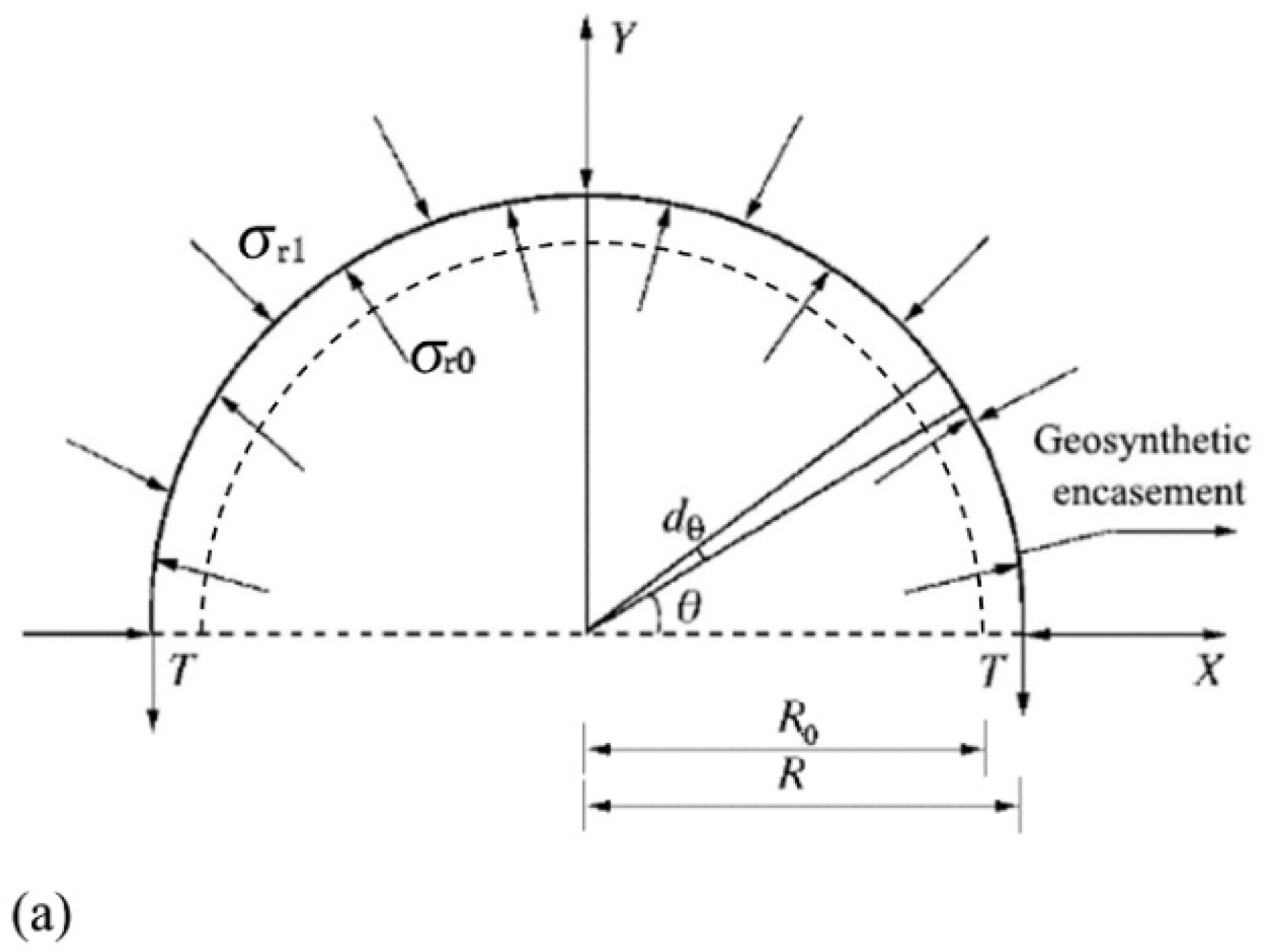

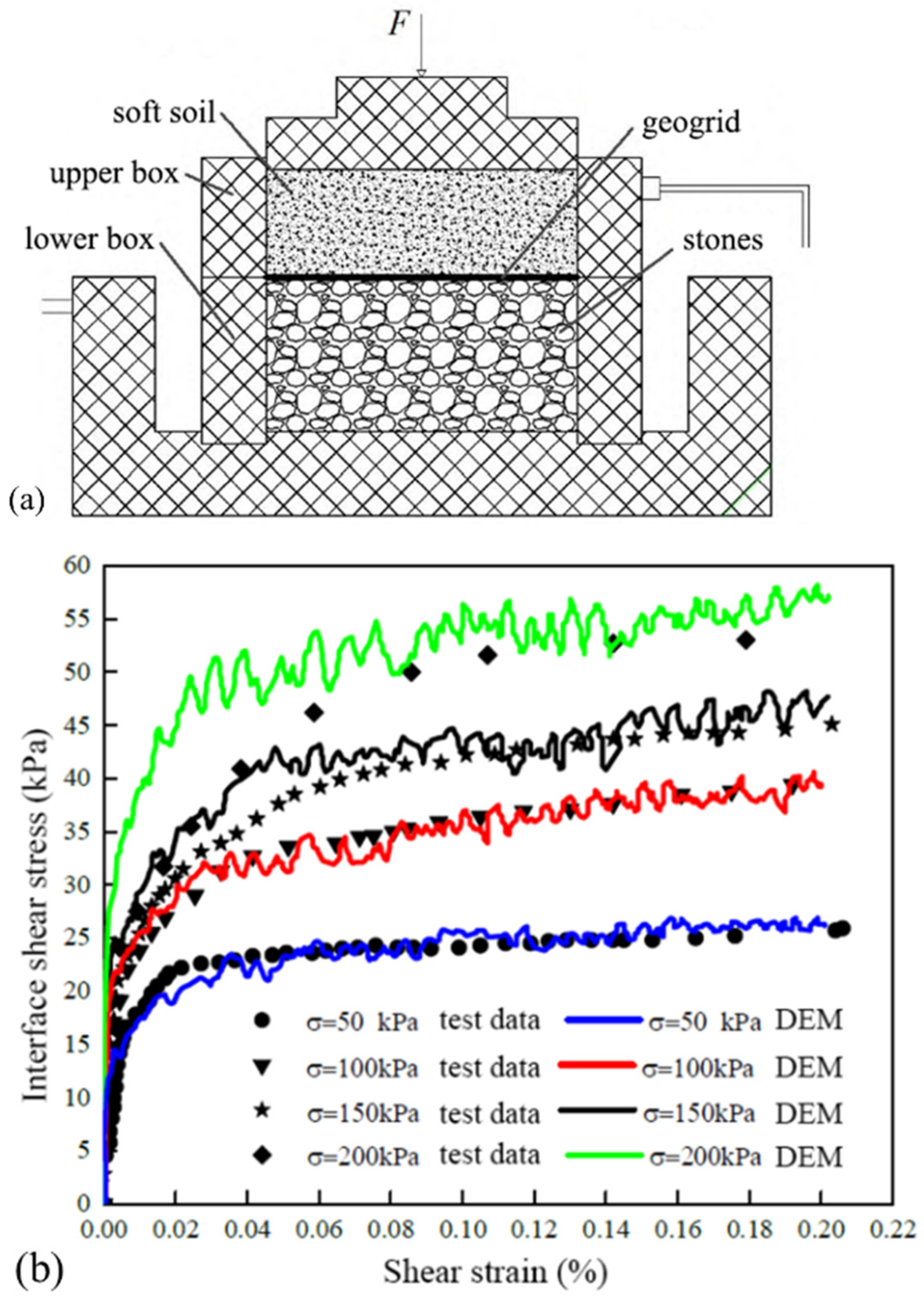

2.2. Material Properties and Equivalent Method

- establish the basic geometric model;

- determine the material parameters for all components except the GESCs;

- adopt the Mohr–Coulomb model for GESCs and calculate the equivalent parameters through Equations (1), (2), (10), and (11);

- create the interfaces between different materials and determine the interface parameters.

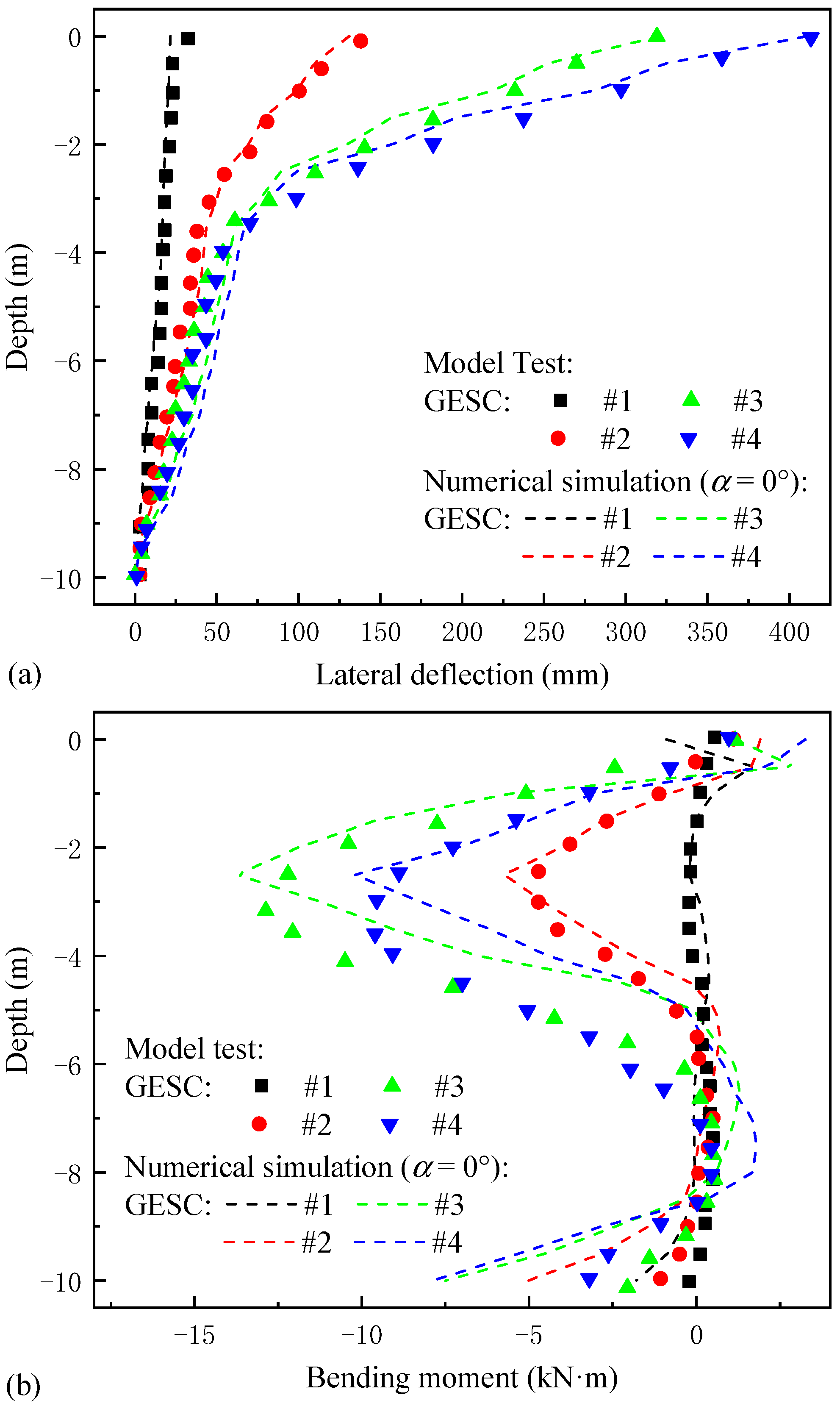

2.3. Model Verification

3. Test Scheme

4. Test Results

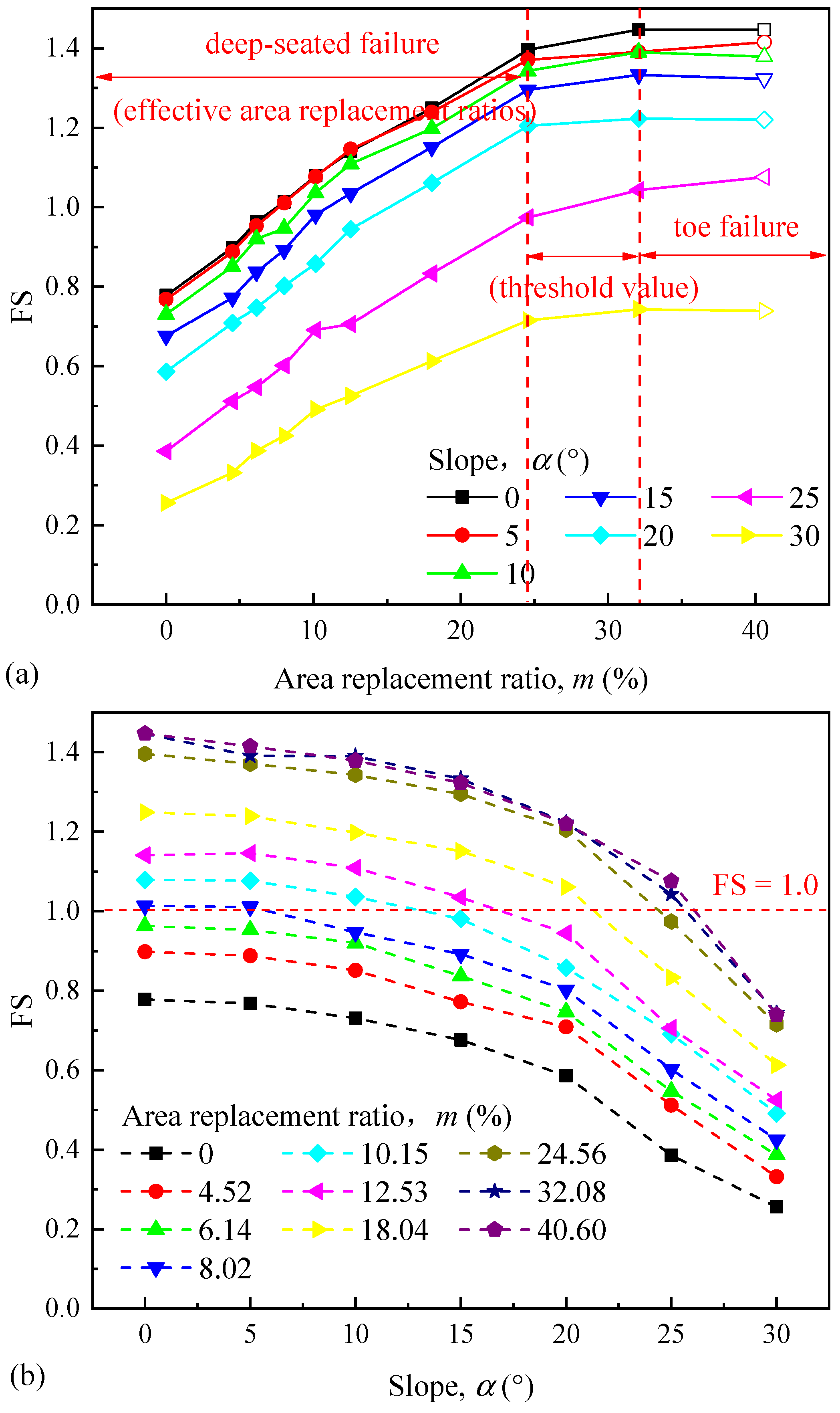

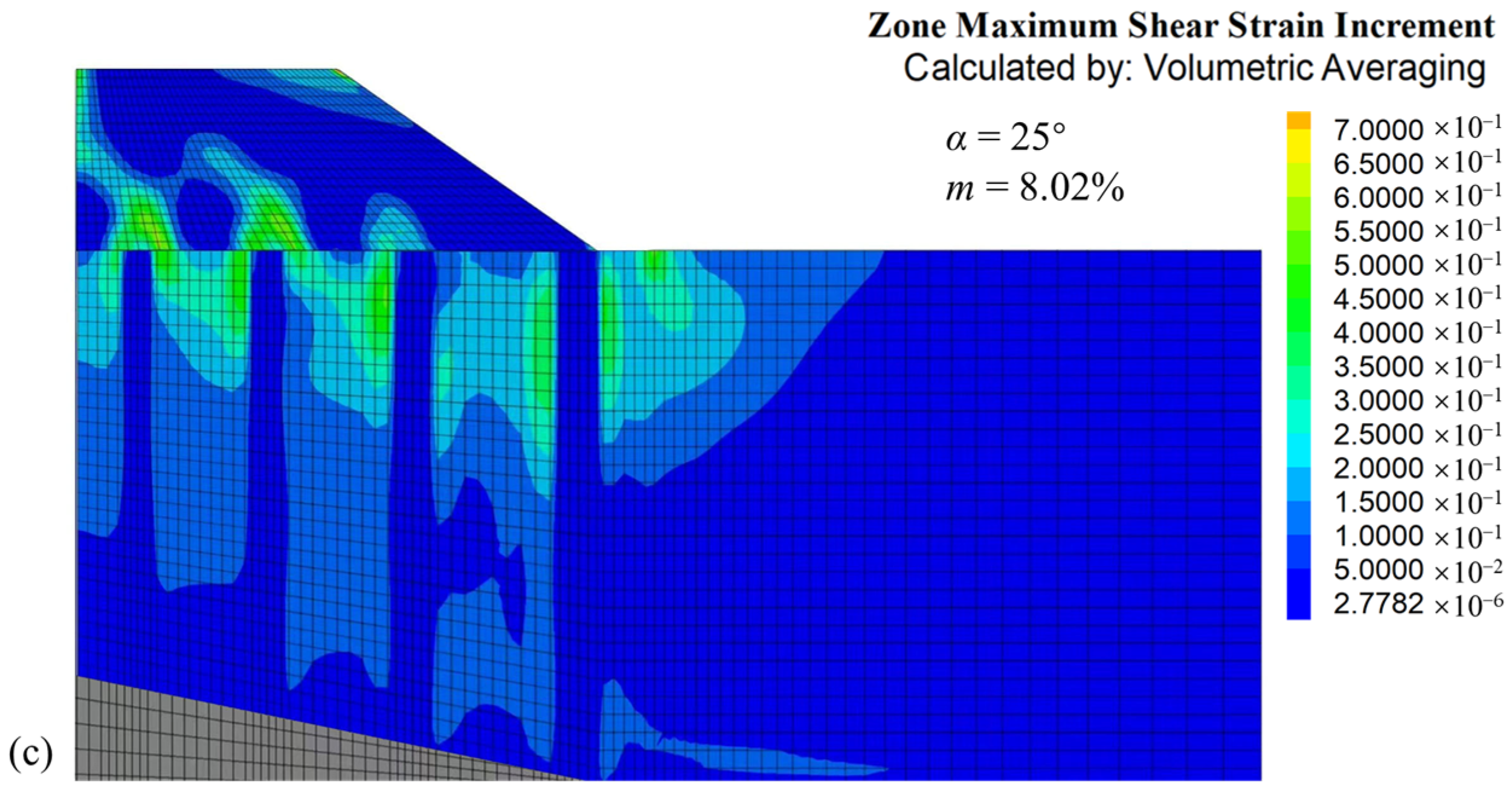

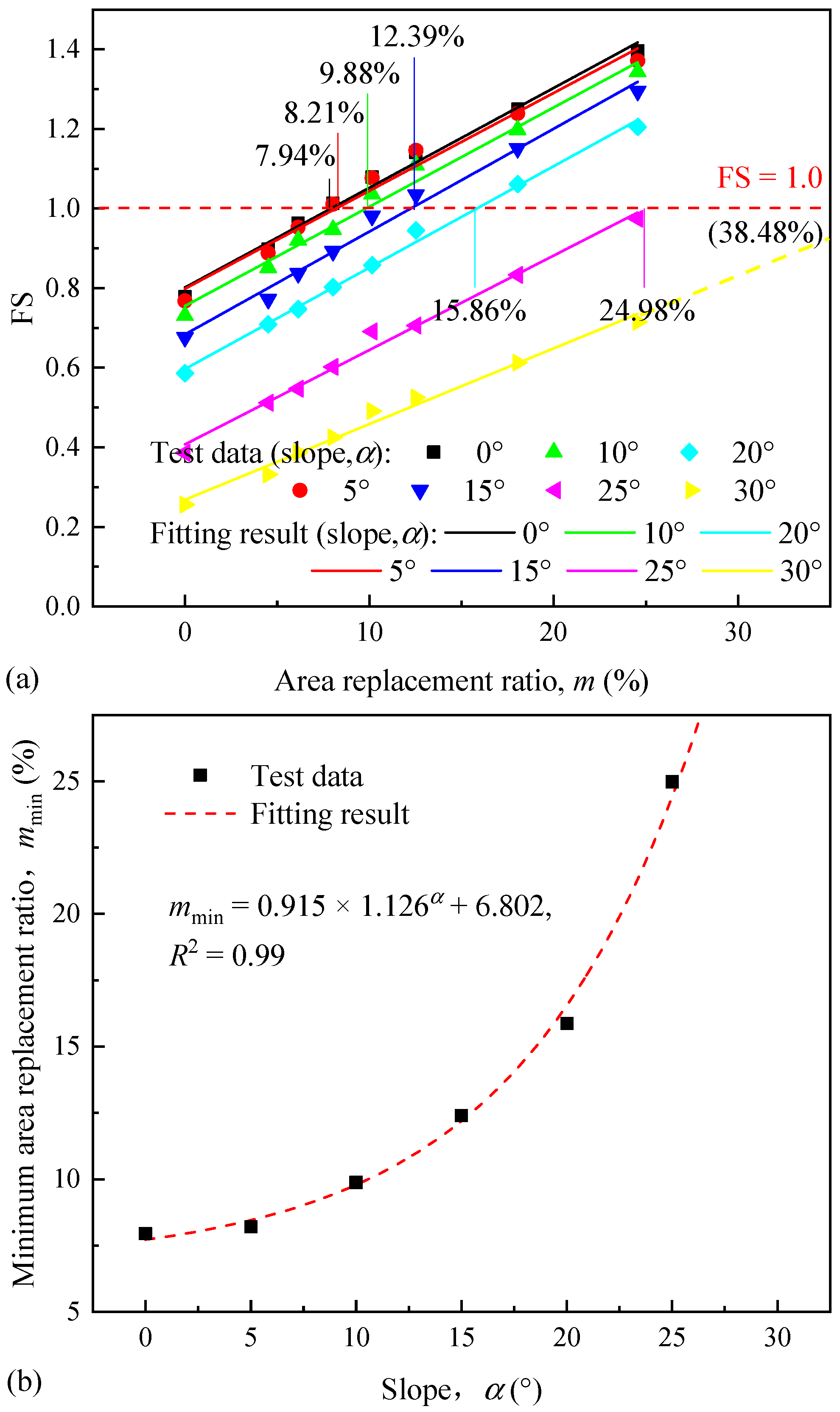

4.1. Effect of Area Replacement Ratio under Different Slopes

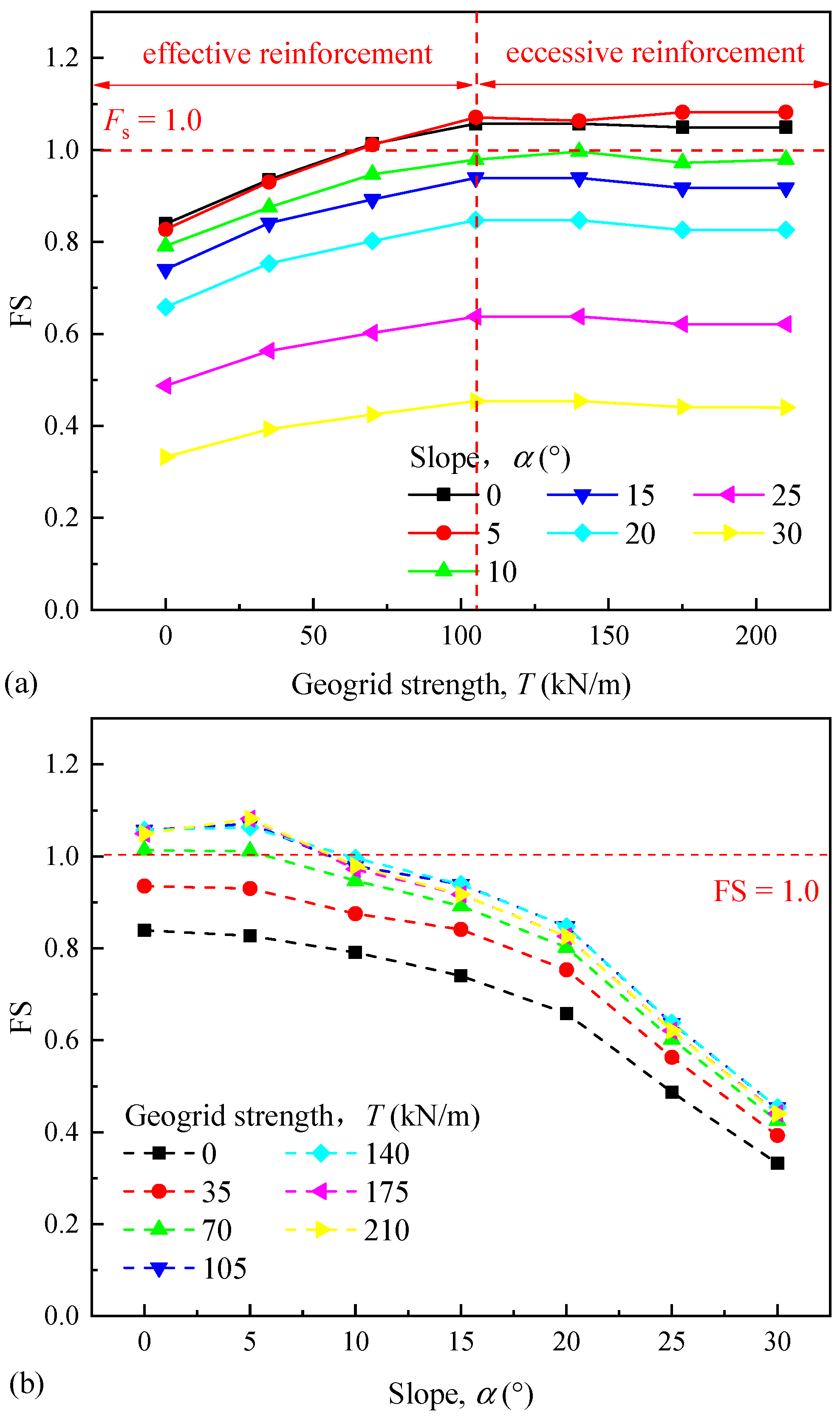

4.2. Effect of Geogrid Strength under Different Slopes

5. Determination of Minimum Area Replacement Ratio

6. Conclusions

- (1)

- The equivalent method, which treats the GESC as a homogeneous material, is rational and effective, offering simplicity and computational efficiency without compromising precision. The method could be recommended for practical applications where simplicity and computational efficiency are prioritized, ensuring accurate results without the need for overly complex calculations;

- (2)

- The FS increases nonlinearly with the area replacement ratio (m). Within an effective range (e.g., m = 0~24.56% in this study), the FS increases approximately linearly with the area replacement ratio. Beyond this range, the increase tends to diminish and stabilize. There exists an optimal area replacement ratio (m = 24.56%) to ensure slope stability while minimizing material costs. Increasing the shear strength of embankment fills will be more effective for the further improvement of slope stability than continuously increasing the area replacement ratio. Additionally, multiple reinforcement techniques, such as combining GESCs with anti-slide piles, are necessary for high-angle sloped GESC composite foundations;

- (3)

- The FS also increases linearly with the tensile strength of geosynthetic encasement (T) at lower strength levels (e.g., T = 0~105 kN/m in this study), but beyond a threshold, the FS immediately stops increasing and remains constant, indicating an excessive reinforcement. Increasing the tensile strength of geosynthetic encasement benefits the low-angle (α ≤ 5°) sloped GESC composite foundations more than the modest or high-angle (α > 5°) ones, where increasing the area replacement rate is more effective;

- (4)

- The connection between the minimum area replacement ratio (mmin) and the foundation slope (α) can be expressed by an exponential function, allowing for the determination of the area replacement ratio for various sloped GESC composite foundations, and providing practical use for achieving safety requirements and economic efficiency;

- (5)

- Further research could focus on refining the parameter study by involving additional influencing factors, such as column diameter, column spacing, and soil strength. Additionally, research could consider the effects of an additional strip load on soil foundations reinforced layer-by-layer with geomaterials. Investigating the stability of sloped GESC composite foundations using various analysis methods, including finite-element, discrete-element, and theoretical methods, will also be valuable.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- De Mello, L.G.; Mondolfo, M.; Montez, F.; Tsukahara, C.N.; Bilfinger, W. First use of geosynthetic encased sand columns in South America. In Proceedings of the 1st Pan-American Geosynthetics Conference, Cancun, Mexico, 2–5 March 2008. [Google Scholar]

- Gniel, J.; Bouazza, A. Construction of geogrid encased stone columns: A new proposal based on laboratory testing. Geotext. Geomembr. 2010, 28, 108–118. [Google Scholar] [CrossRef]

- Almeida, M.S.S.; Hosseinpour, I.; Riccio, M.; Alexiew, D. Behavior of geotextile-encased granular columns supporting test embankment on soft deposit. J. Geotech. Geoenviron. Eng. 2015, 141, 04014116. [Google Scholar] [CrossRef]

- Alexiew, D.; Moormann, C.; Jud, H. Foundation of a coal/coke stockyard on soft soil with geotextile encased columns and horizontal reinforcement. In The 17th International Conference on Soil Mechanics and Geotechnical Engineering; IOS Press: Tepper Drive Clifton, VA, USA, 2009; Volume 1–4, pp. 2236–2239. [Google Scholar]

- Alexiew, D.; Raithel, M. Geotextile-Encased Columns: Case Studies over Twenty Years. Embankments with Special Reference to Consolidation and Other Physical Methods; Butterworth-Heinemann: Oxford, UK, 2015; pp. 451–477. [Google Scholar]

- Michalowski, R.L.; Wojtasik, A.; Duda, A.; Florkiewicz, A.; Park, D. Failure and remedy of column-supported embankment: Case study. J. Geotech. Geoenviron. Eng. 2018, 144, 05017008. [Google Scholar] [CrossRef]

- Shukla, A.; Pandey, B.K.; Ingale, R.; Vivek, A.K.; Meshram, K. Effect of construction time on the behavior of embankment constructed on ESC-improved clayey soil. Indian Geotech. J. 2023, 54, 1538–1548. [Google Scholar] [CrossRef]

- Ouyang, F.; Wu, Z.; Wang, Y.; Wang, Z.; Cao, J.; Wang, K.; Zhang, J. Field tests on partially geotextile encased stone column-supported embankment over silty clay. Geotext. Geomembr. 2024, 52, 95–109. [Google Scholar] [CrossRef]

- Akosah, S.; Chen, J.; Bao, N. Reinforcement of problematic soils using geotextile encased stone/sand columns. Arab. J. Geosci. 2022, 15, 1371. [Google Scholar] [CrossRef]

- Gu, Z.-A.; Niu, F.-J.; Chen, J.-F.; Yoo, C. Centrifuge investigation on behavior of geosynthetic-encased stone column supported embankment under freeze-thaw cycles. Geotext. Geomembr. 2024, 52, 2–11. [Google Scholar] [CrossRef]

- Chen, J.-F.; Li, L.-Y.; Xue, J.-F.; Feng, S.-Z. Failure mechanism of geosynthetic-encased stone columns in soft soils under embankment. Geotext. Geomembr. 2015, 43, 424–431. [Google Scholar] [CrossRef]

- Zhang, L.; Peng, B.; Xu, Z.; Zhou, S. Shear performance of geosynthetic-encased stone column based on 3D-DEM simulation. Comput. Geotech. 2022, 151, 104952. [Google Scholar] [CrossRef]

- Yang, X.-L.; Wang, Z.-B.; Zou, J.-F.; Li, L. Bearing capacity of foundation on slope determined by energy dissipation method and model experiments. J. Cent. South Univ. Technol. 2007, 14, 125–128. [Google Scholar] [CrossRef]

- Qiu, Y.; Wei, Y.; Luo, Q. Highway embankments over sloped ground and influence on pavement responses. In Proceedings of the First International Conference on Transportation Engineering, Chengdu, China, 22–24 July 2007; pp. 1615–1620. [Google Scholar]

- Jiang, X.; Qiu, Y.J.; Wei, Y.X.; Ling, J. Application of SSRM in stability analysis of subgrade embankments over sloped weak ground with FLAC3D. In Landslides and Engineered Slopes. From the Past to the Future; CRC Press: Boca Raton, FL, USA, 2008; pp. 763–768. [Google Scholar]

- Baah-Frempong, E.; Shukla, S.K. Stability analysis and design charts for a sandy soil slope supporting an embedded strip footing. Int. J. Geo-Eng. 2018, 9, 13. [Google Scholar] [CrossRef]

- Zhang, O.; Yang, G.; Zhao, Y.; Lu, H.; Hou, L. Parametric Influences of Stability and Settlement Pattern of Embankment on Slope Foundation. IOP Conf. Ser. Earth Environ. Sci. 2020, 560, 012047. [Google Scholar] [CrossRef]

- Castro, J.; Sagaseta, C. Deformation and consolidation around encased stone columns. Geotext. Geomembr. 2011, 29, 268–276. [Google Scholar] [CrossRef]

- Rajesh, S.; Jain, P. Influence of permeability of soft clay on the efficiency of stone columns and geosynthetic-encased stone columns—A numerical study. Int. J. Geotech. Eng. 2015, 9, 483–493. [Google Scholar] [CrossRef]

- Chen, J.-F.; Li, L.-Y.; Zhang, Z.; Zhang, X.; Xu, C.; Rajesh, S.; Feng, S.-Z. Centrifuge modeling of geosynthetic-encased stone column-supported embankment over soft clay. Geotext. Geomembr. 2021, 49, 210–221. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, L.; Peng, B.; Zhou, S. DEM-FDM numerical investigation on load transfer mechanism of GESC-supported embankment. Comput. Geotech. 2021, 138, 104321. [Google Scholar] [CrossRef]

- Fan, K.; Liu, S.H.; Cheng, Y.P.; Wang, Y. Sliding stability analysis of a retaining wall constructed by soilbags. Geotech. Lett. 2019, 9, 211–217. [Google Scholar] [CrossRef]

- Liu, F.; Wang, J.; Zhou, B.; Wu, M.; He, J.; Bin, J. Shaking table study on rubber-sand mixture cored composite block as low-cost isolation bearing for rural houses. J. Build. Eng. 2023, 76, 107413. [Google Scholar] [CrossRef]

- Wang, J.; Wu, M.; Liu, F.; Bin, J.; He, J. Rubber-sand infilled soilbags as seismic isolation cushions: Experimental validation. Geosynth. Int. 2024, 23, 1–4. [Google Scholar] [CrossRef]

- Jiang, X.; Liang, D.W.; Liu, J.N. Working mechanism of embankment over sloped weak ground reinforced by combination of gravel piles and slide-resistant piles. J. China Railw. Soc. 2015, 37, 81–87. [Google Scholar]

- Chen, J.F.; Wang, X.T.; Zeng, Y. Large triaxial compression tests on geosynthetic-encased granular columns. Chin. J. Geotech. Eng. 2017, 39, 2212–2218. [Google Scholar] [CrossRef]

- Fan, K.; Yang, G.; Zou, W.; Han, Z.; Shen, Y. Lateral earth pressure of granular backfills on retaining walls with expanded polystyrene geofoam inclusions under limited surcharge loading. J. Rock Mech. Geotech. Eng. 2024, 16, 1388–1397. [Google Scholar] [CrossRef]

- Fan, K.; Zou, W.; Zhang, P.; Wang, X.; Shen, Y.; Fan, K.; Zou, W.; Zhang, P.; Wang, X.; Shen, Y. Laboratory investigation and theoretical analysis of lateral pressure exerted by expansive soils on retaining walls with expanded polystyrene geofoam block upon water infiltration. Geotext. Geomembr. 2024, 52, 332–341. [Google Scholar] [CrossRef]

- Frikha, W.; Tounekti, F.; Kaffel, W.; Bouassida, M. Experimental study for the mechanical characterization of Tunis soft soil reinforced by a group of sand columns. Soils Found. 2015, 55, 181–191. [Google Scholar] [CrossRef]

- Malarvizhi, S.N.; Ilamparuthi, K.O. Numerical analysis of encapsulated stone columns. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics, Goa, India, 1–6 October 2008; pp. 3719–3726. [Google Scholar]

- Gu, M.; Han, J.; Zhao, M. Three-dimensional discrete-element method analysis of stresses and deformations of a single geogrid-encased stone column. Int. J. Géoméch. 2017, 17, 04017070. [Google Scholar] [CrossRef]

- Gu, M.; Han, J.; Zhao, M. Three-dimensional DEM analysis of single geogrid-encased stone columns under unconfined compression: A parametric study. Acta Geotech. 2017, 12, 559–572. [Google Scholar] [CrossRef]

- Zhou, Z.G.; Zhang, Q.S.; Zheng, J.L. Analysis of mechanism of improved ground with stone columns reinforced by geogrids. China Civ. Eng. J. 1998, 31, 21–26. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, Z.; Yao, P.; Zhao, M.; Chen, L. Experimental study and discrete element simulation on interface friction of geo-encased stone columns. Chin. J. Geotech. Eng. 2022, 44, 72–81. [Google Scholar] [CrossRef]

- Dawson, E.M.; Roth, W.H.; Drescher, A. Slope stability analysis by strength reduction. Geotechnique 1999, 49, 835–840. [Google Scholar] [CrossRef]

- Itasca. Fast Lagrangian Analysis of Continua (FLAC3D 6.00); Itasca Consulting Group Inc.: Minneapolis, MN, USA, 2017. [Google Scholar]

- Zheng, G.; Yu, X.; Zhou, H.; Wang, S.; Zhao, J.; He, X.; Yang, X. Stability analysis of stone column-supported and geosynthetic-reinforced embankments on soft ground. Geotext. Geomembr. 2020, 48, 349–356. [Google Scholar] [CrossRef]

| Variable | Embankment Soil | Surrounding Soft Soil | Bedrock |

|---|---|---|---|

| Bulk density (kN/m3) | 20 | 17 | 22 |

| Young’s Modulus (MPa) | 20 | 3 | 300 |

| Cohesion (kPa) | 0.5 | 1 | 200 |

| Friction angle (°) | 30 | 15 | 50 |

| Dilation angle (°) | 10 | 0 | 0 |

| Poisson’s ratio | 0.3 | 0.3 | 0.25 |

| Slope, α (°) | Area Replacement Ratio, m (%) | Geogrid Strength, T (kN/m) |

|---|---|---|

| 0 | 0, 4.51, 6.14, 8.02, 10.15, 12.53, 18.04, 24.56, 32.08 | 70 |

| 8.02 | 0, 35, 70, 105, 140, 175, 210 | |

| 5 | 0, 4.51, 6.14, 8.02, 10.15, 12.53, 18.04, 24.56, 32.08 | 70 |

| 8.02 | 0, 35, 70, 105, 140, 175, 210 | |

| 10 | 0, 4.51, 6.14, 8.02, 10.15, 12.53, 18.04, 24.56, 32.08 | 70 |

| 8.02 | 0, 35, 70, 105, 140, 175, 210 | |

| 15 | 0, 4.51, 6.14, 8.02, 10.15, 12.53, 18.04, 24.56, 32.08 | 70 |

| 8.02 | 0, 35, 70, 105, 140, 175, 210 | |

| 20 | 0, 4.51, 6.14, 8.02, 10.15, 12.53, 18.04, 24.56, 32.08 | 70 |

| 8.02 | 0, 35, 70, 105, 140, 175, 210 | |

| 25 | 0, 4.51, 6.14, 8.02, 10.15, 12.53, 18.04, 24.56, 32.08 | 70 |

| 8.02 | 0, 35, 70, 105, 140, 175, 210 | |

| 30 | 0, 4.51, 6.14, 8.02, 10.15, 12.53, 18.04, 24.56, 32.08 | 70 |

| 8.02 | 0, 35, 70, 105, 140, 175, 210 |

| Foundation Slope, α (°) | Area Replacement Ratio, m (%) | Foundation Slope, α (°) | Area Replacement Ratio, m (%) |

|---|---|---|---|

| 2.5 | 8.03 | 17.5 | 14.10 |

| 5 | 8.46 | 20 | 16.62 |

| 7.5 | 9.03 | 22.5 | 20.02 |

| 10 | 9.80 | 25 | 24.58 |

| 12.5 | 10.84 | 27.5 | 30.72 |

| 15 | 12.23 | 30 | 38.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, B.-C.; Zhang, L.; Xu, Z.-Y.; Cui, P.-L.; Liu, Y.-Y. Numerical Stability Analysis of Sloped Geosynthetic Encased Stone Column Composite Foundation under Embankment Based on Equivalent Method. Buildings 2024, 14, 2681. https://doi.org/10.3390/buildings14092681

Peng B-C, Zhang L, Xu Z-Y, Cui P-L, Liu Y-Y. Numerical Stability Analysis of Sloped Geosynthetic Encased Stone Column Composite Foundation under Embankment Based on Equivalent Method. Buildings. 2024; 14(9):2681. https://doi.org/10.3390/buildings14092681

Chicago/Turabian StylePeng, Bo-Cheng, Ling Zhang, Ze-Yu Xu, Peng-Lu Cui, and Yang-Yang Liu. 2024. "Numerical Stability Analysis of Sloped Geosynthetic Encased Stone Column Composite Foundation under Embankment Based on Equivalent Method" Buildings 14, no. 9: 2681. https://doi.org/10.3390/buildings14092681