Advanced Analysis of Structural Performance in Novel Steel-Plate Concrete Containment Structures

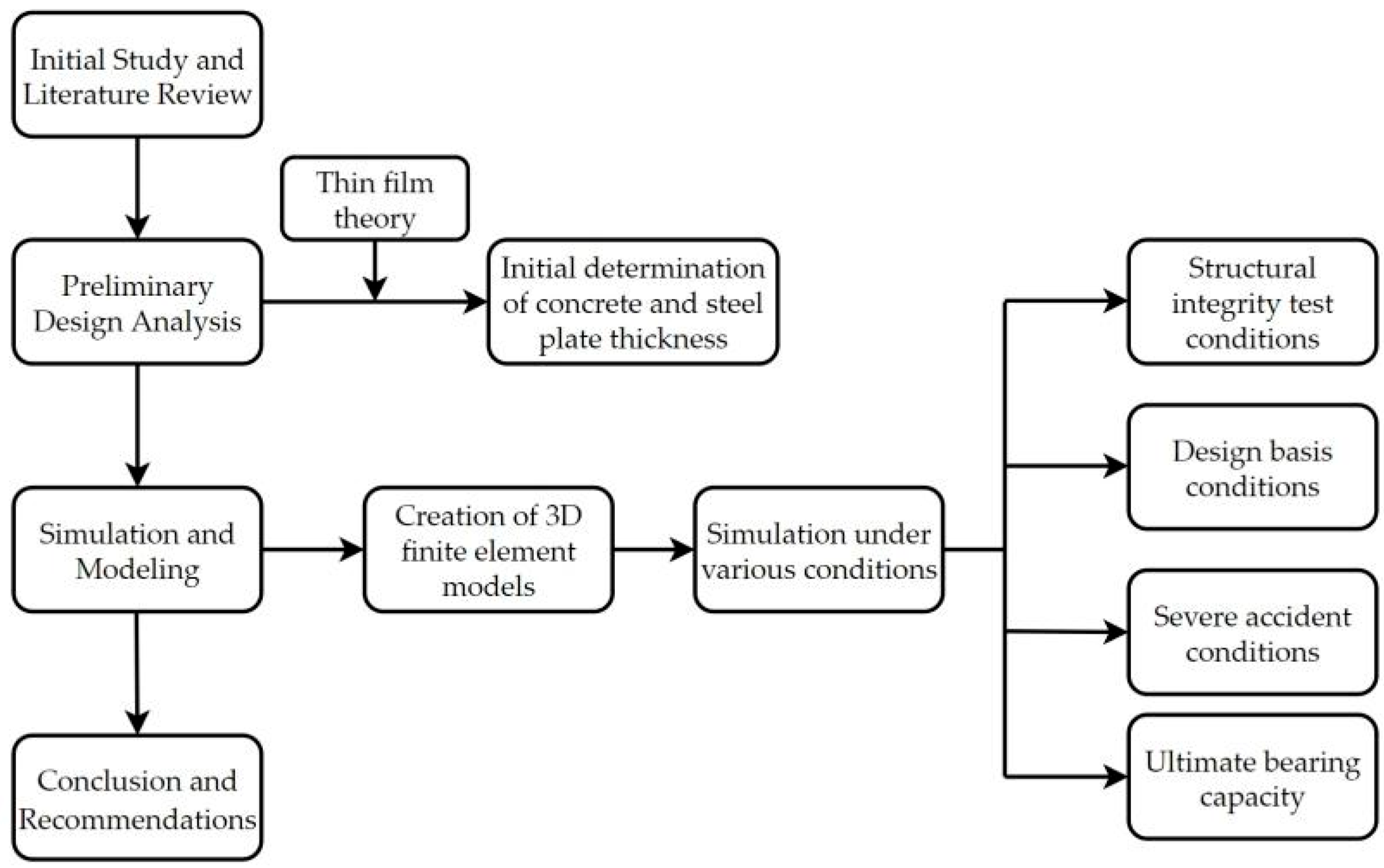

Abstract

1. Introduction

2. The Determination of SC Containment Scheme

2.1. The Main Types of Containment at Present

2.1.1. CPR1000 [28]

2.1.2. HPR1000 [36]

2.1.3. EPR [37]

2.1.4. VVER [38]

2.1.5. CAP1400 [39]

2.1.6. BWRX-300 [40]

2.2. Thin Film Stress Theory

2.3. Scheme Determination

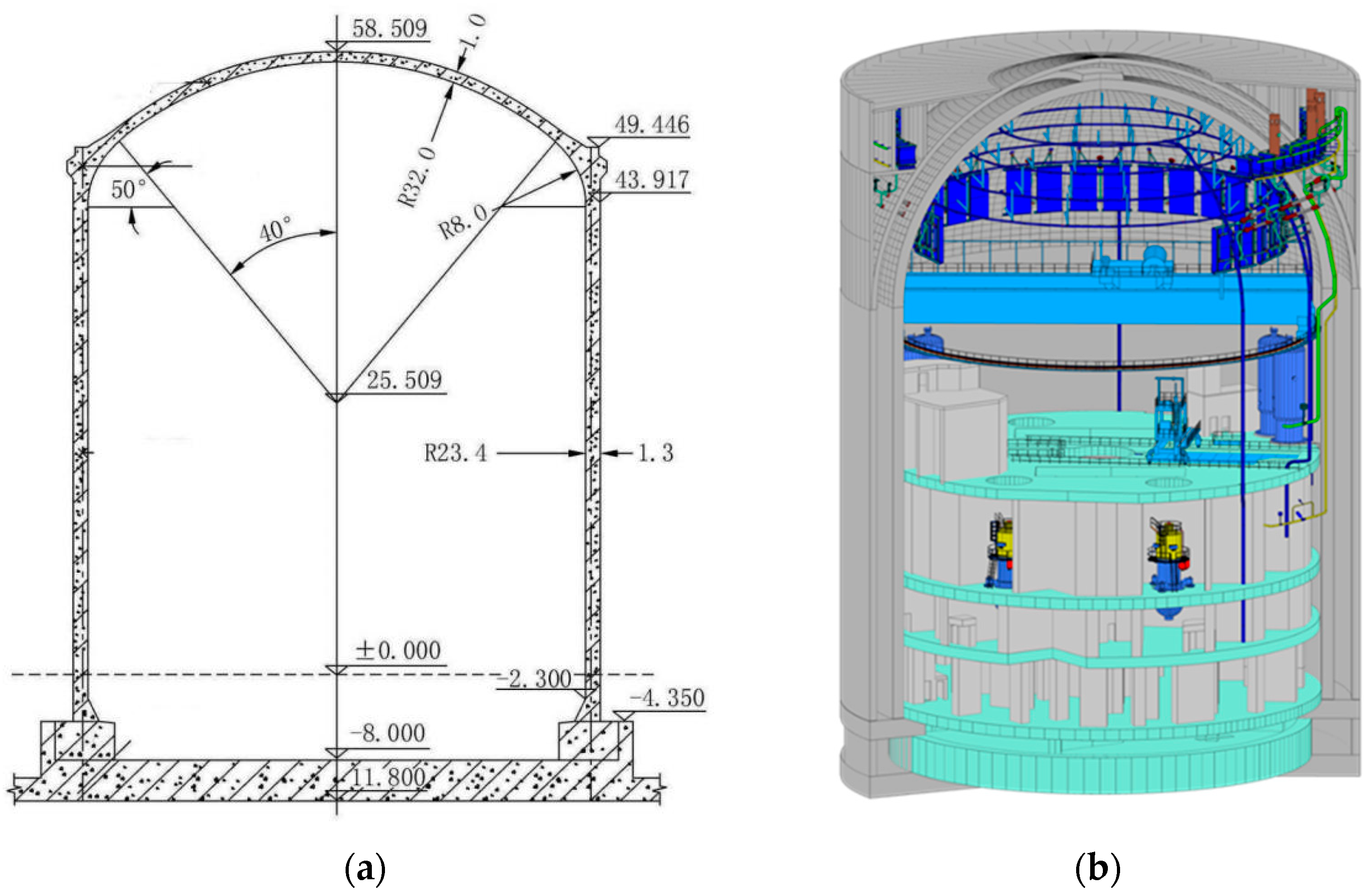

3. Structural Configuration

3.1. Steel-Plate Containment Model

3.2. Material Properties

3.2.1. Concrete

3.2.2. Steel

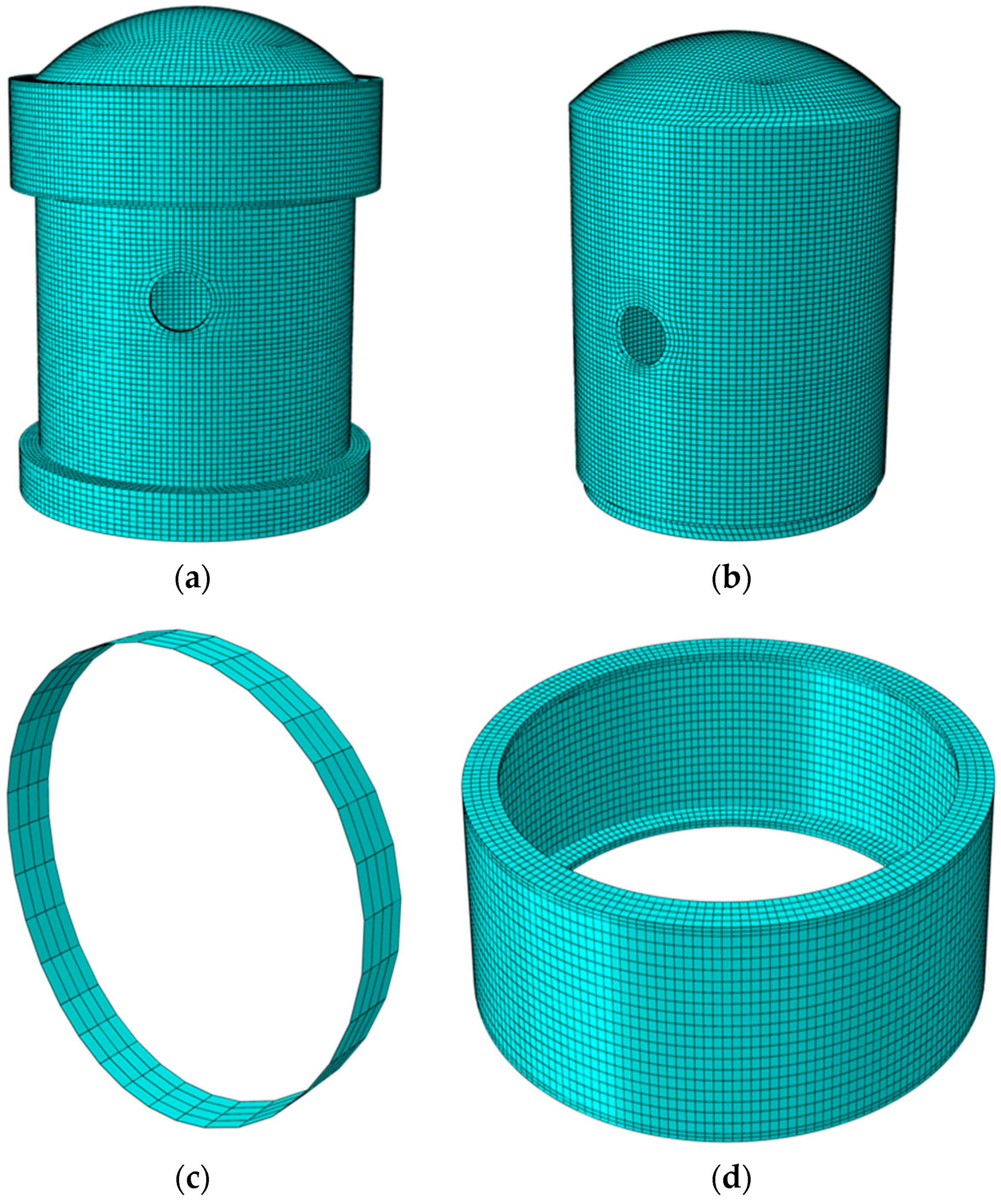

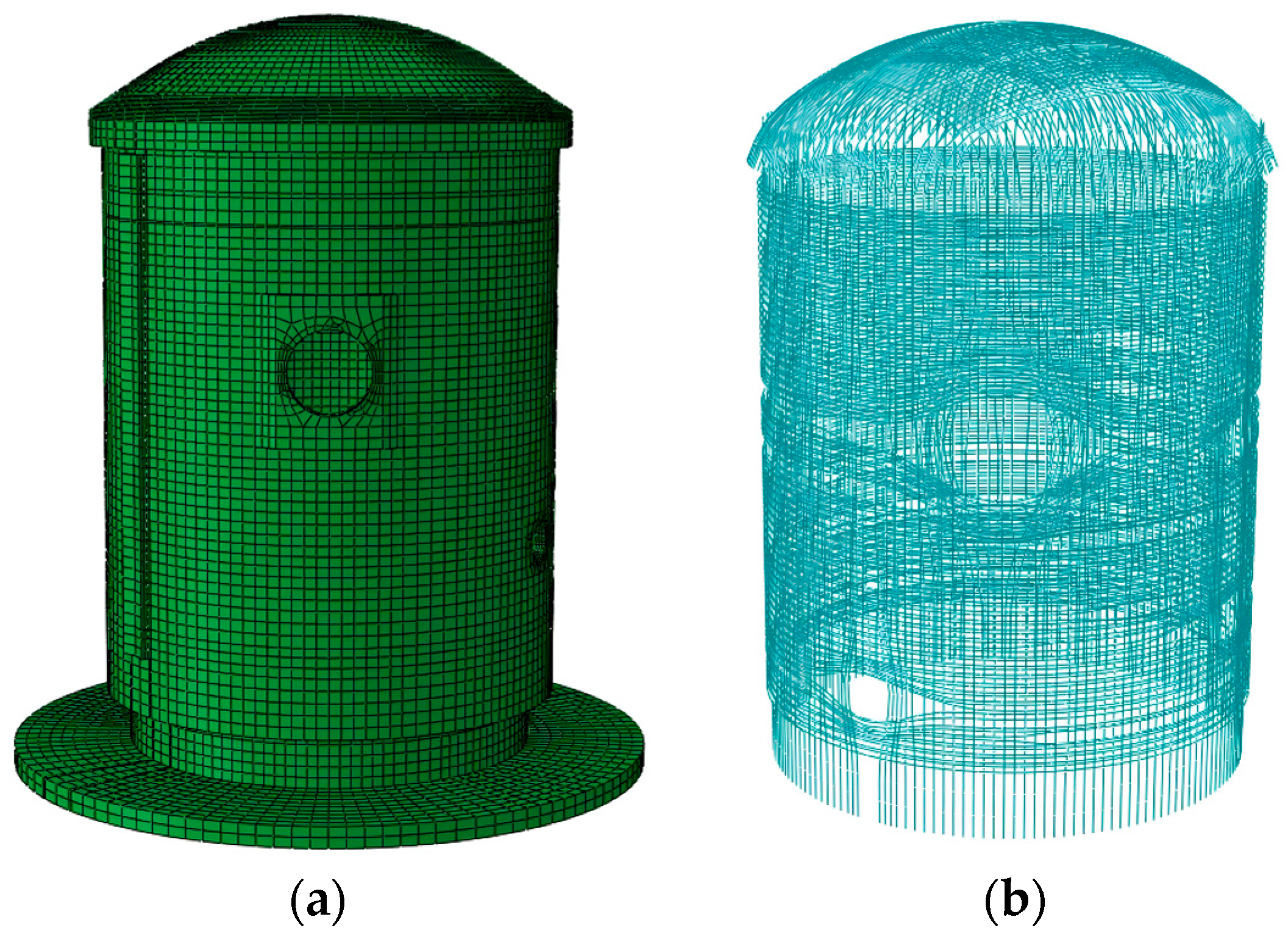

3.3. FE Model of the SC Containment

3.4. Load Conditions and Analysis Methods

3.4.1. Load Conditions

3.4.2. Analysis Methods

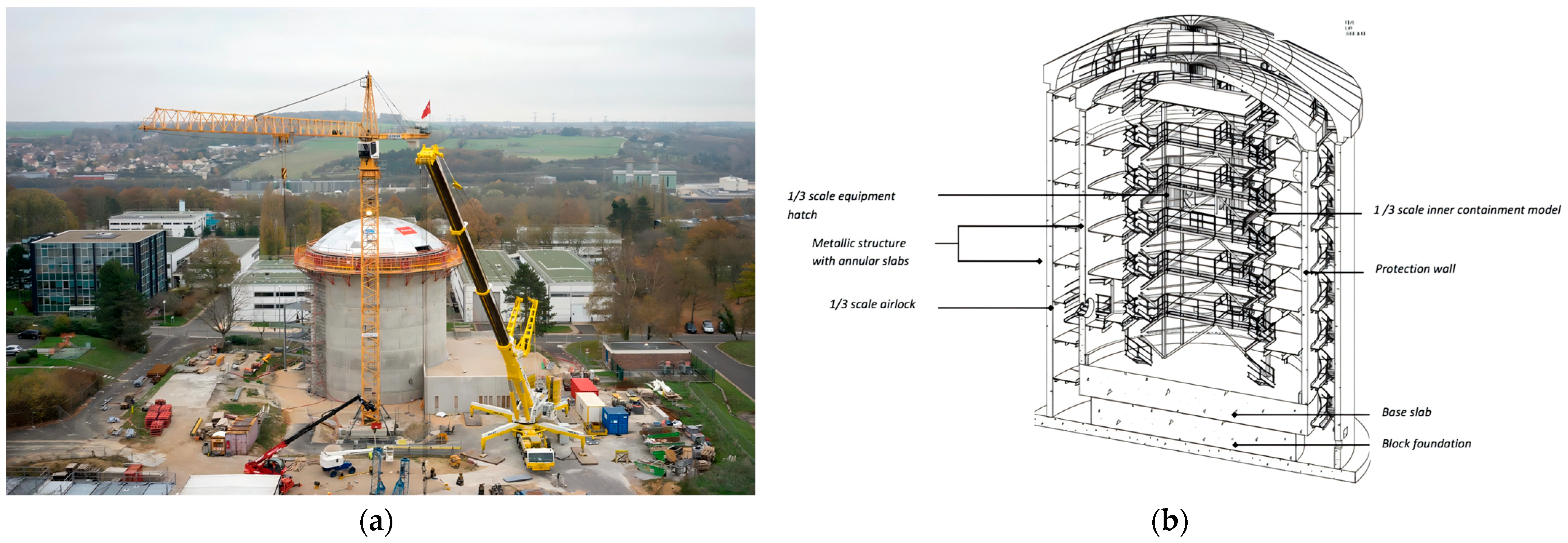

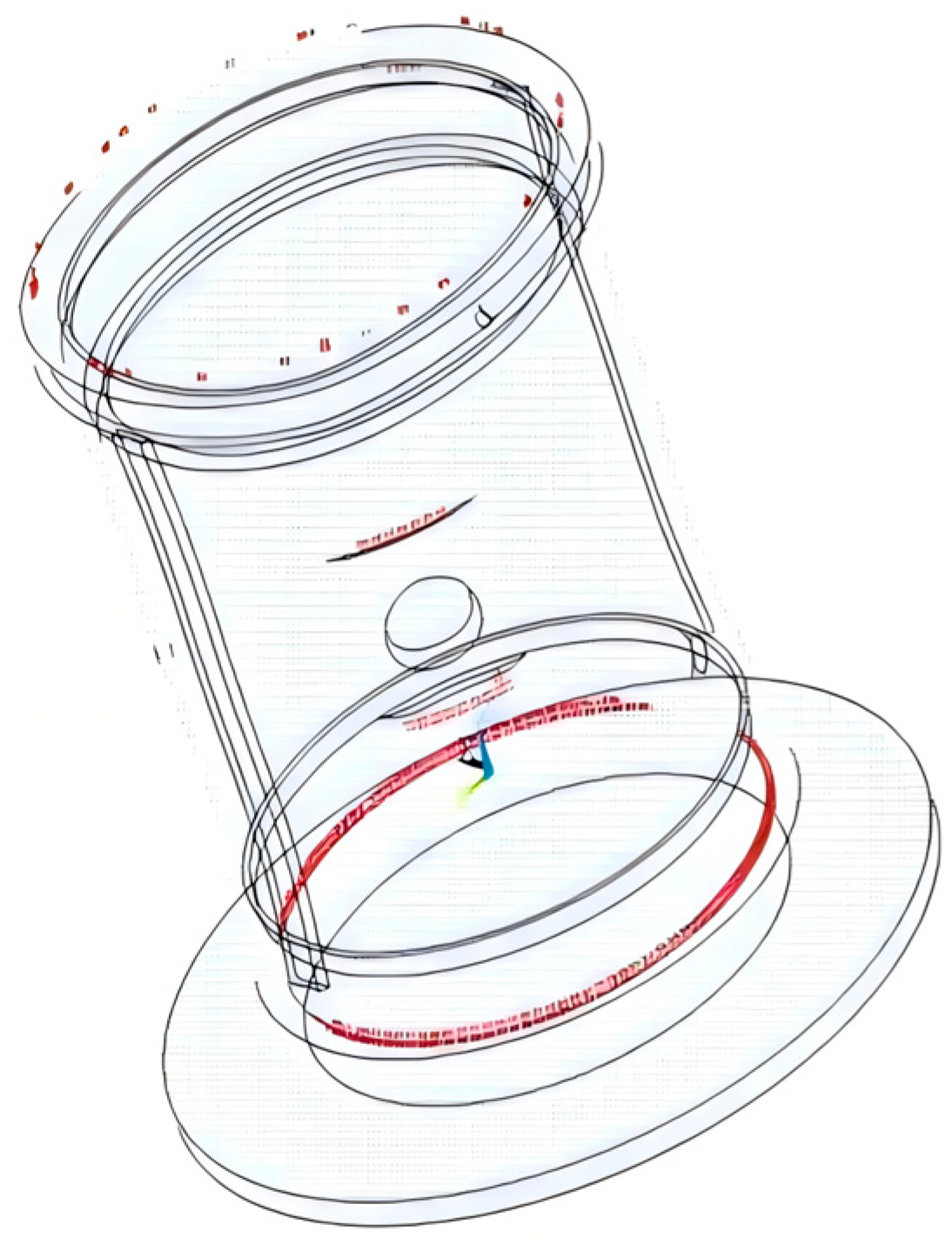

3.4.3. Validation of Modeling and Analysis Methods

4. Results

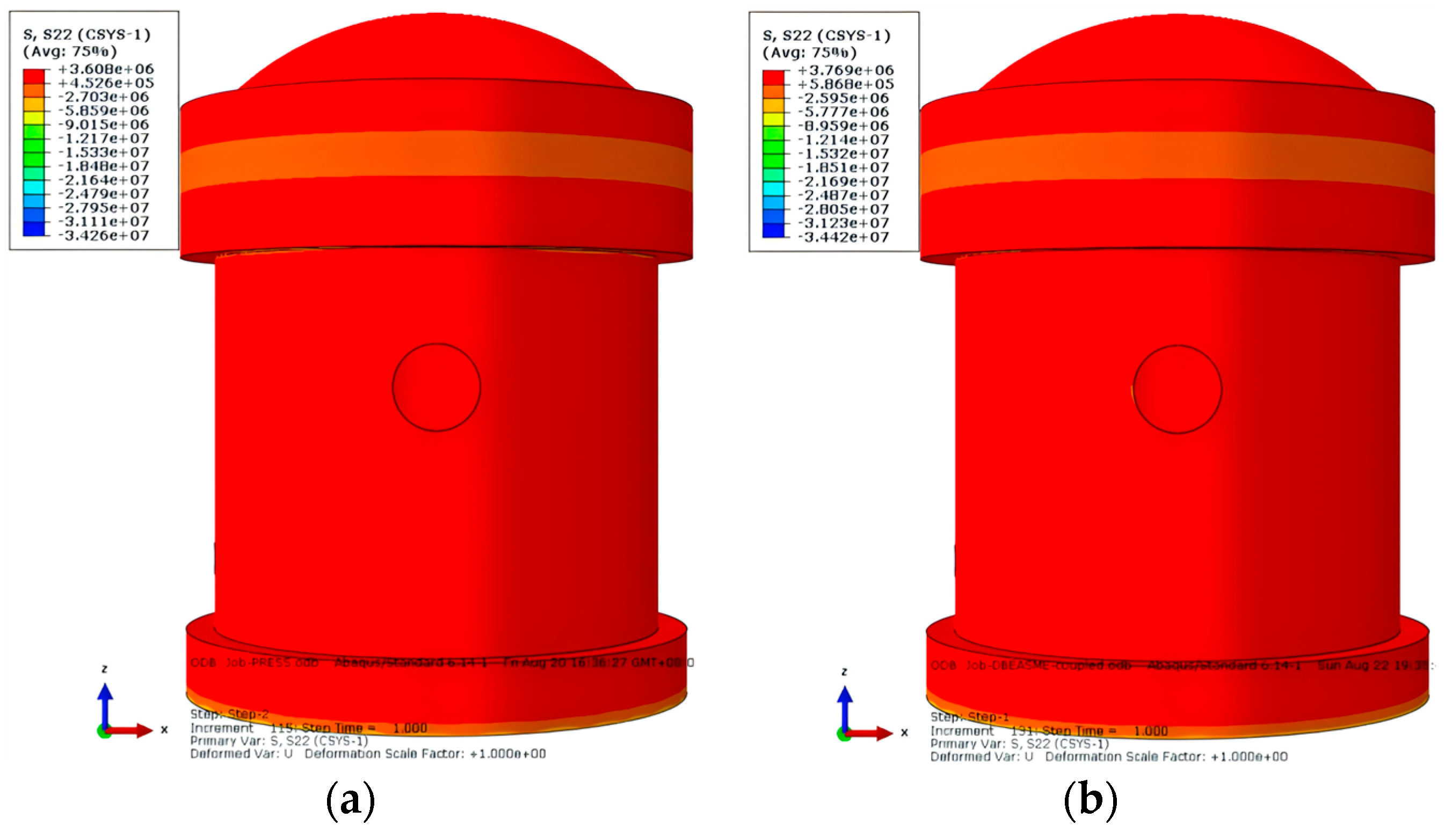

4.1. Structural Integrity Test Conditions

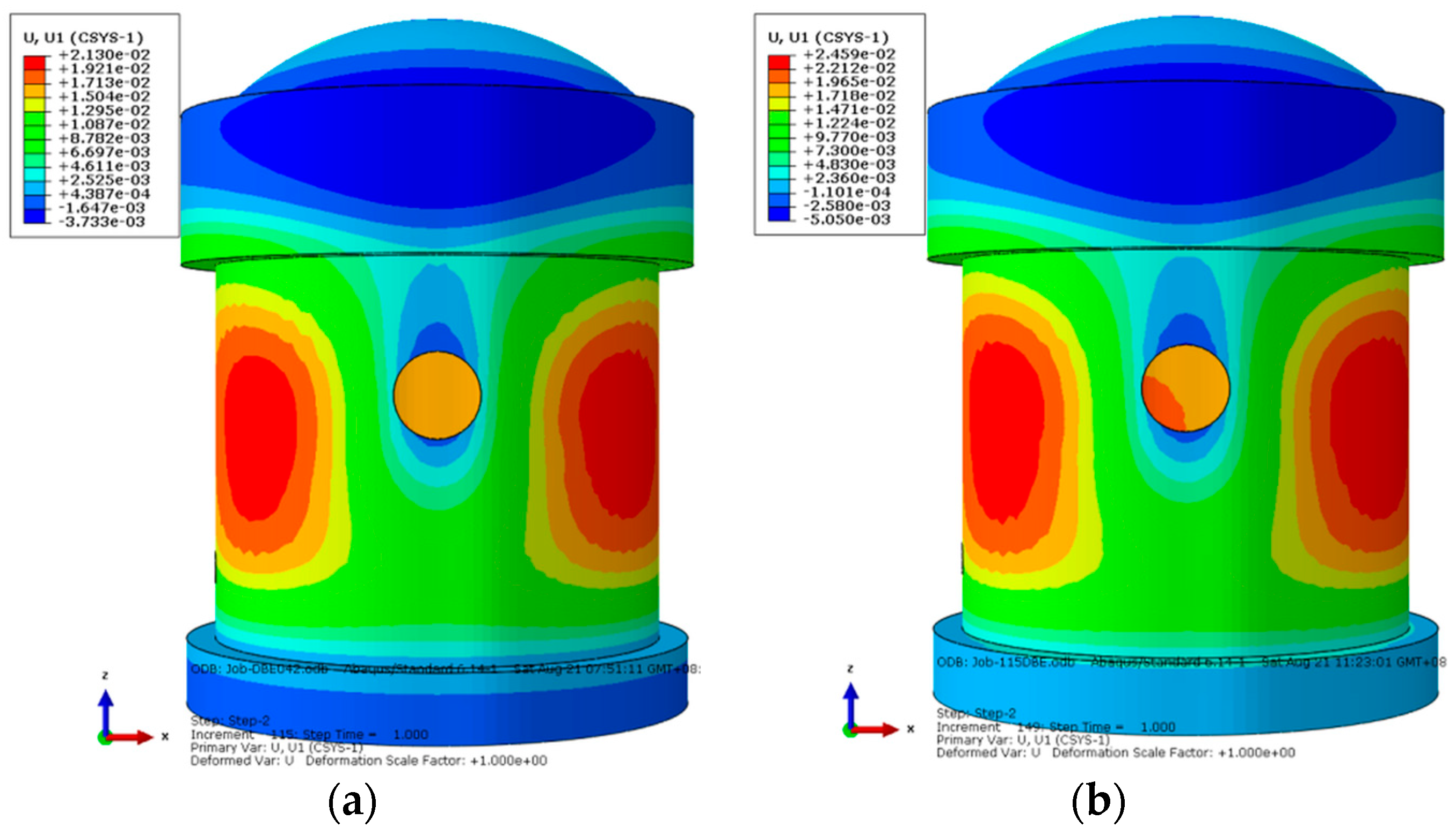

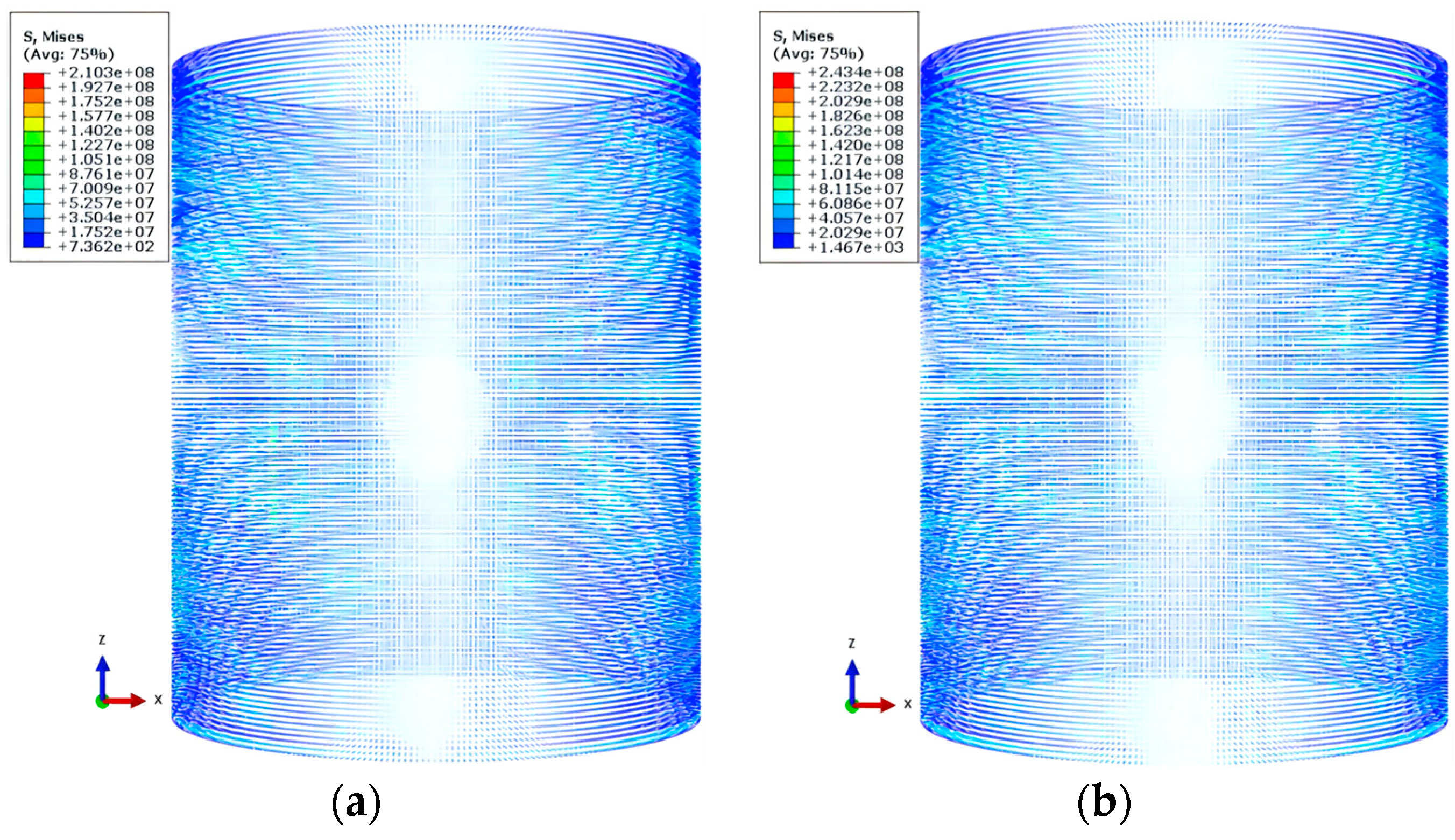

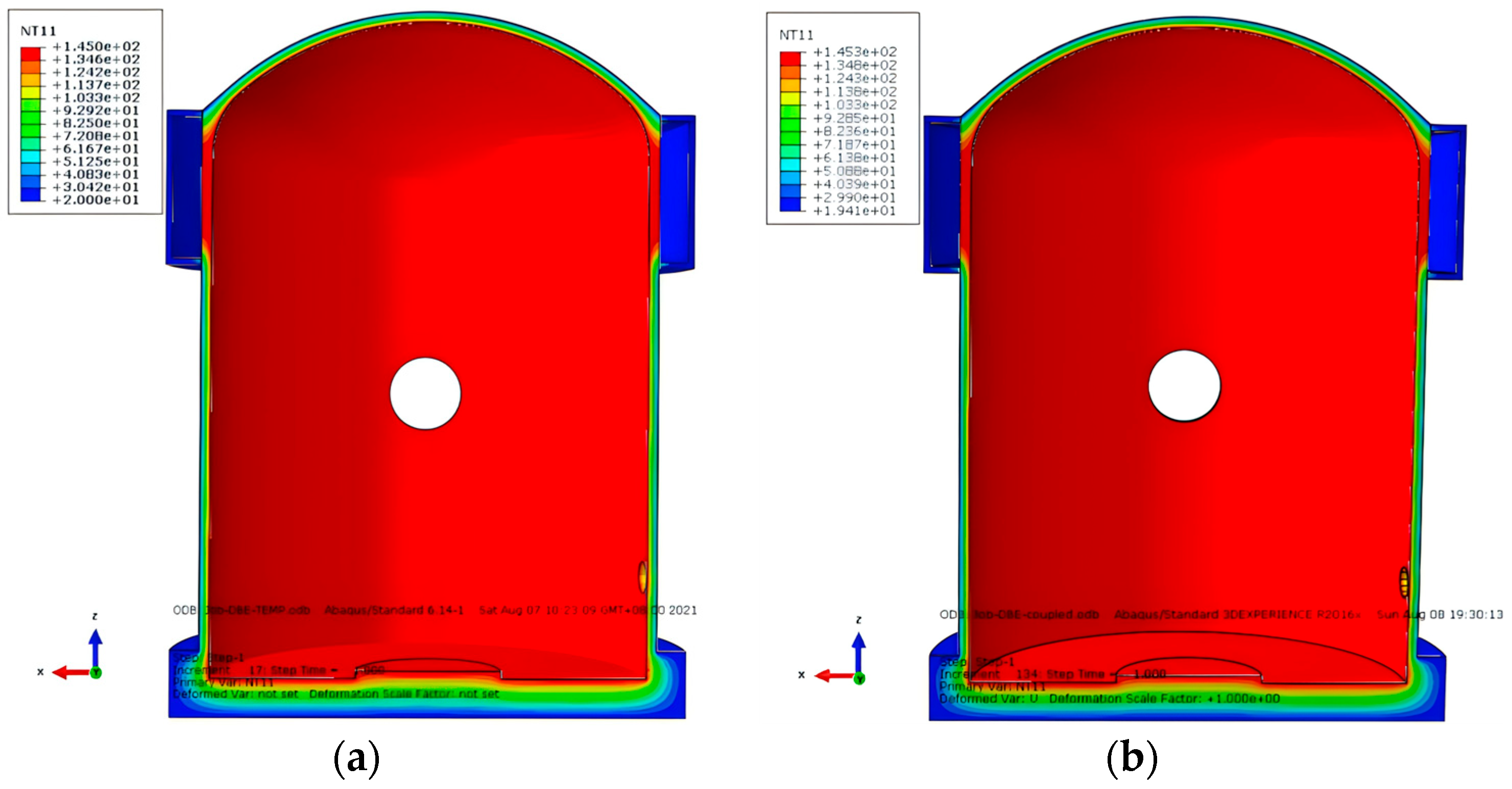

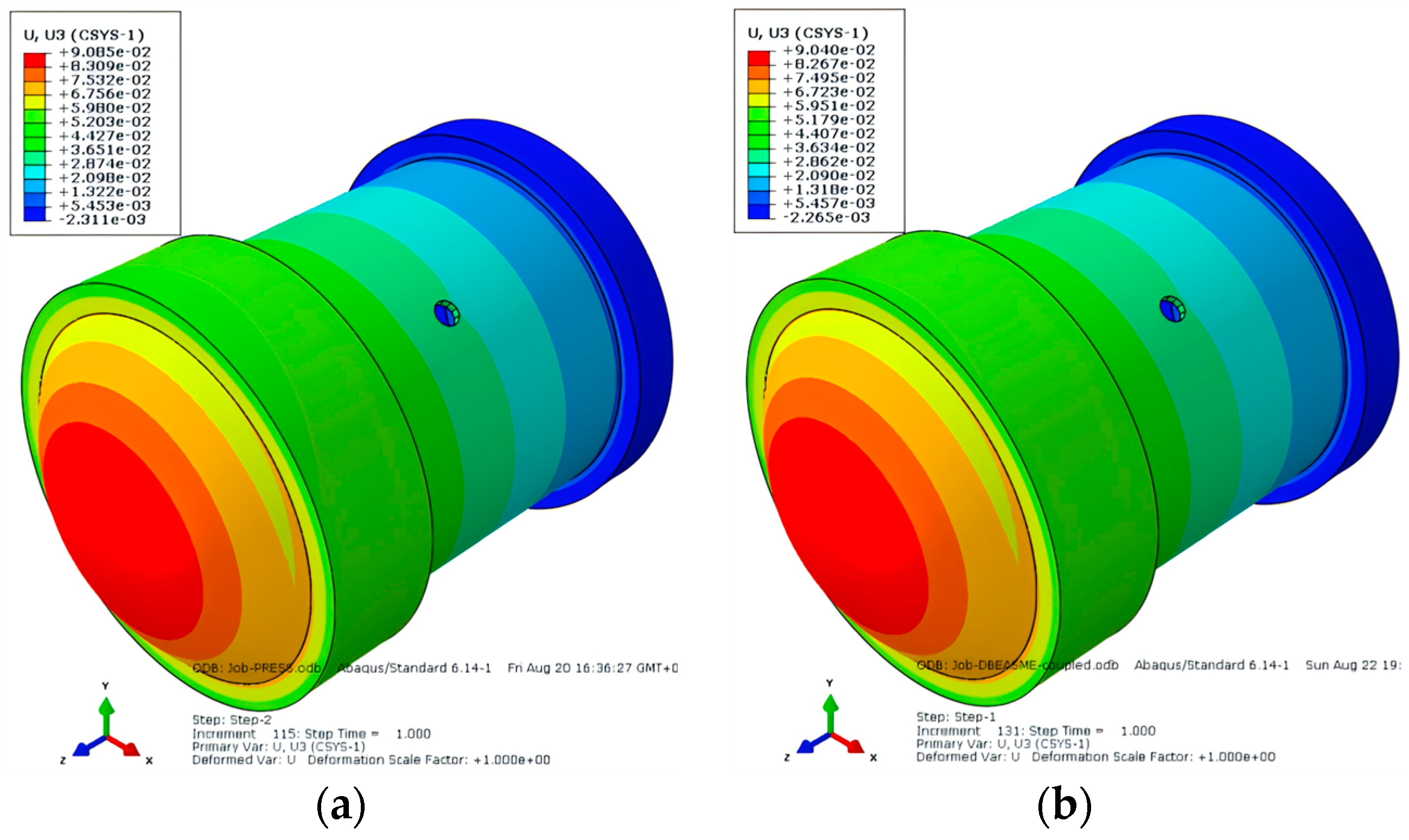

4.1.1. Deformation Analysis

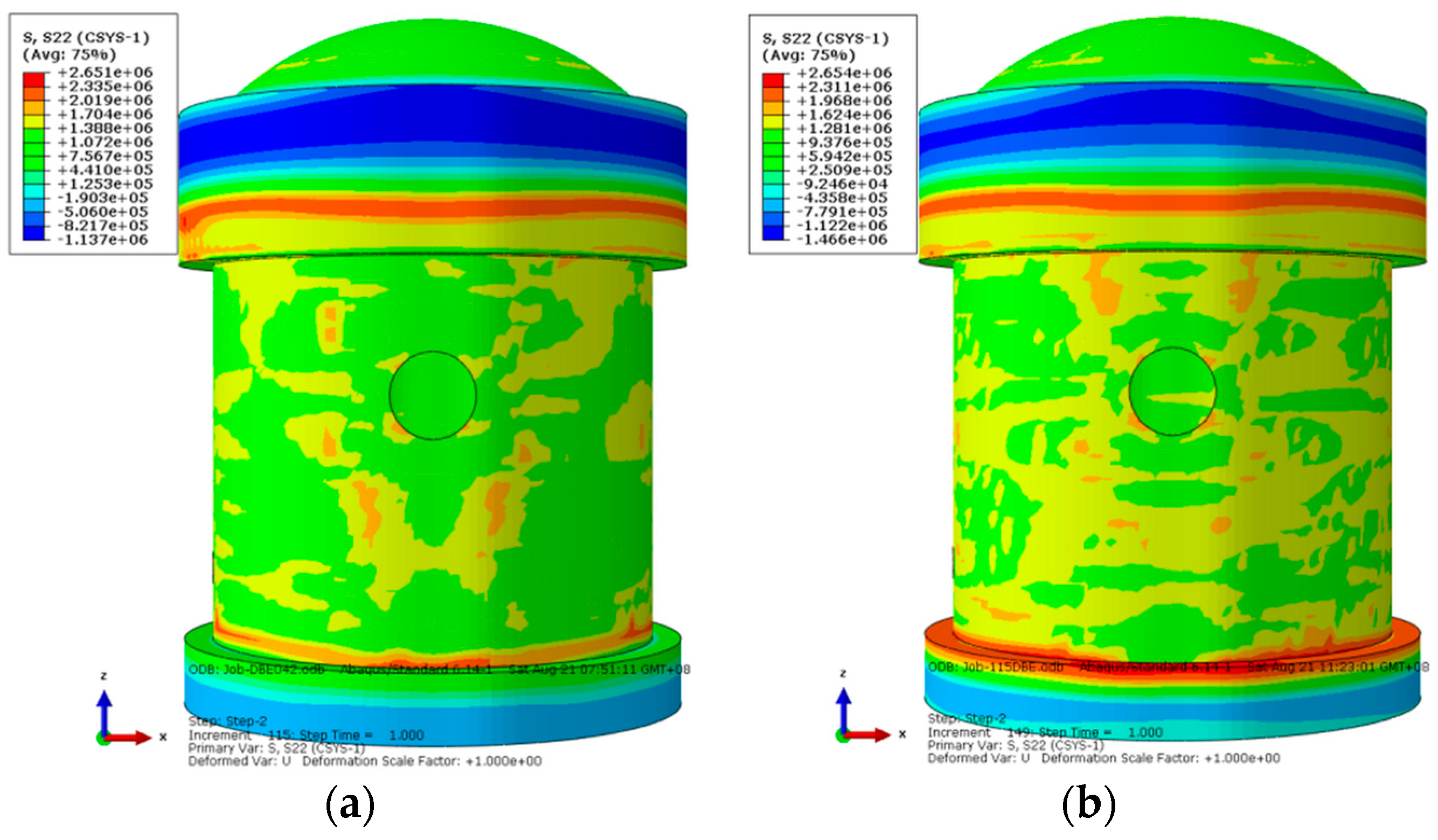

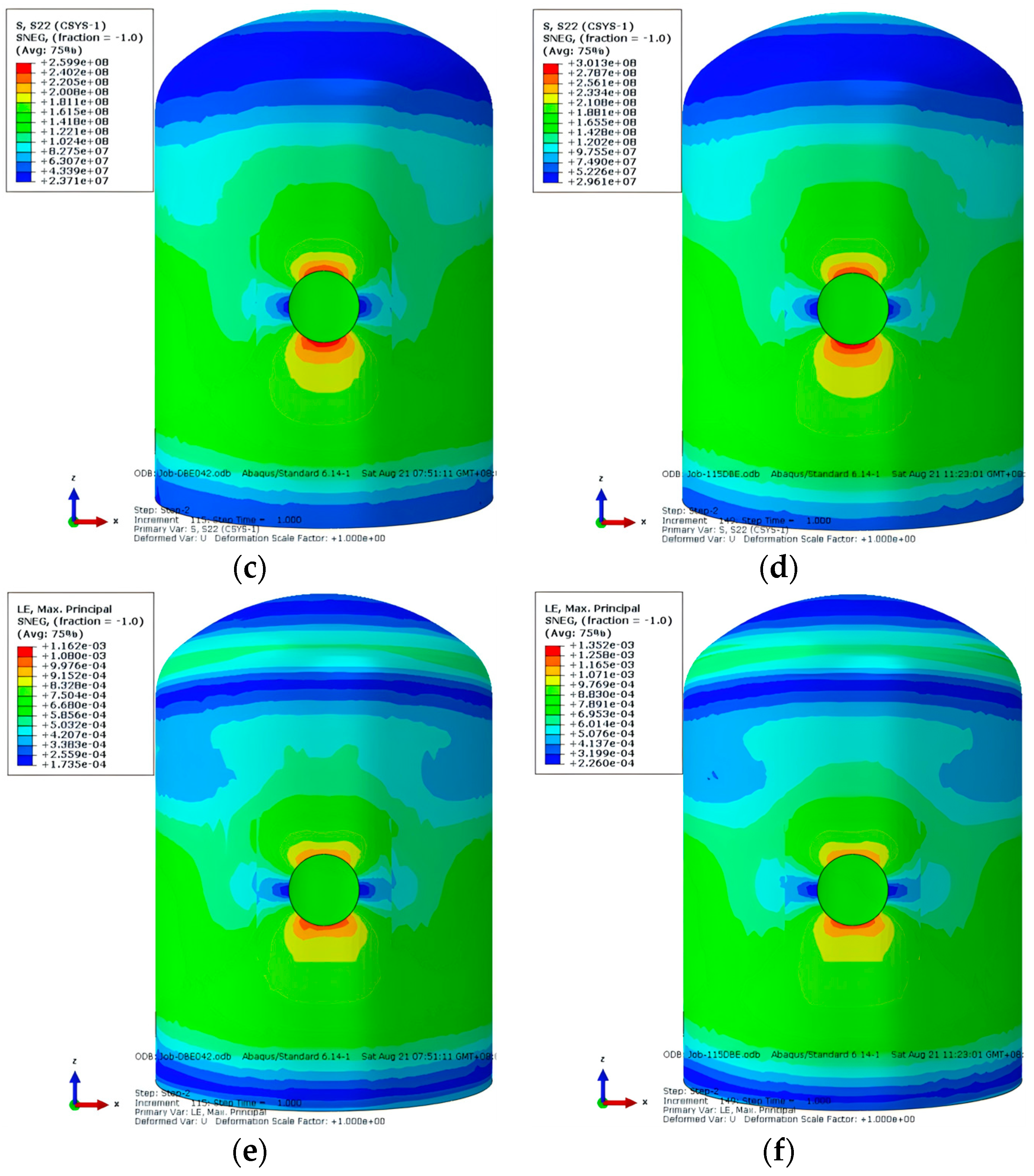

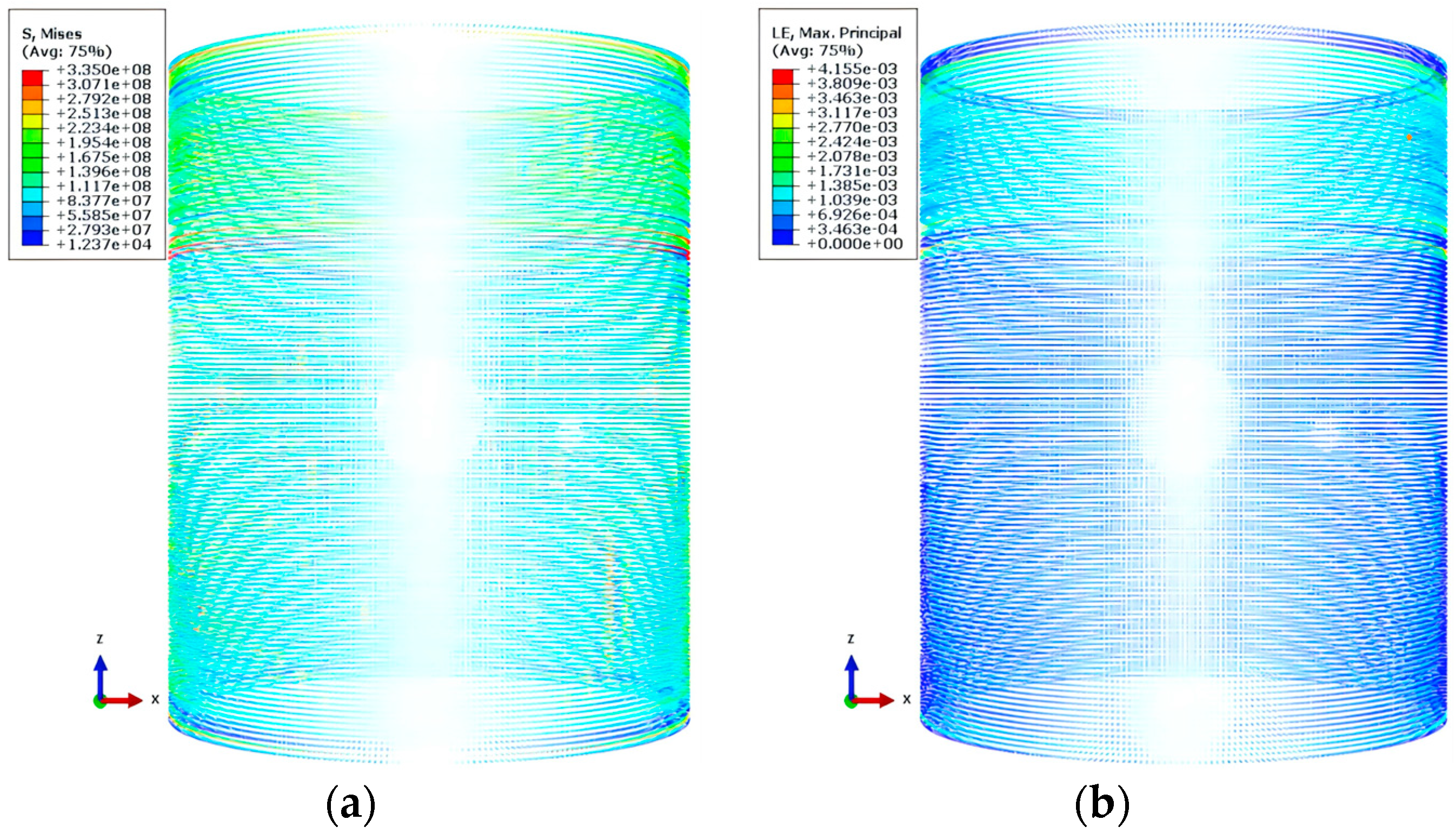

4.1.2. Stress and Strain Analysis

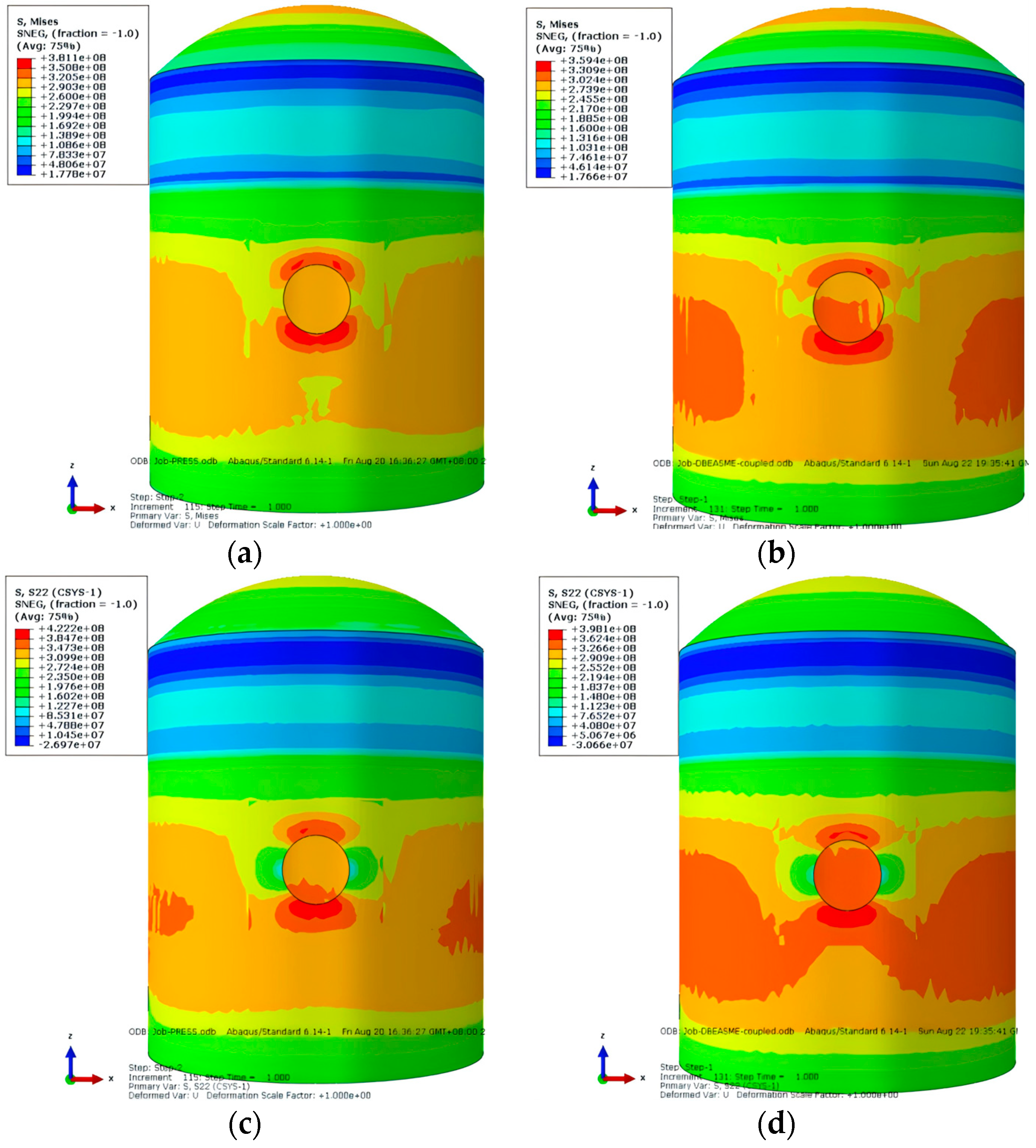

4.2. Design Basis Conditions

4.2.1. Deformation Analysis

4.2.2. Stress and Strain Analysis

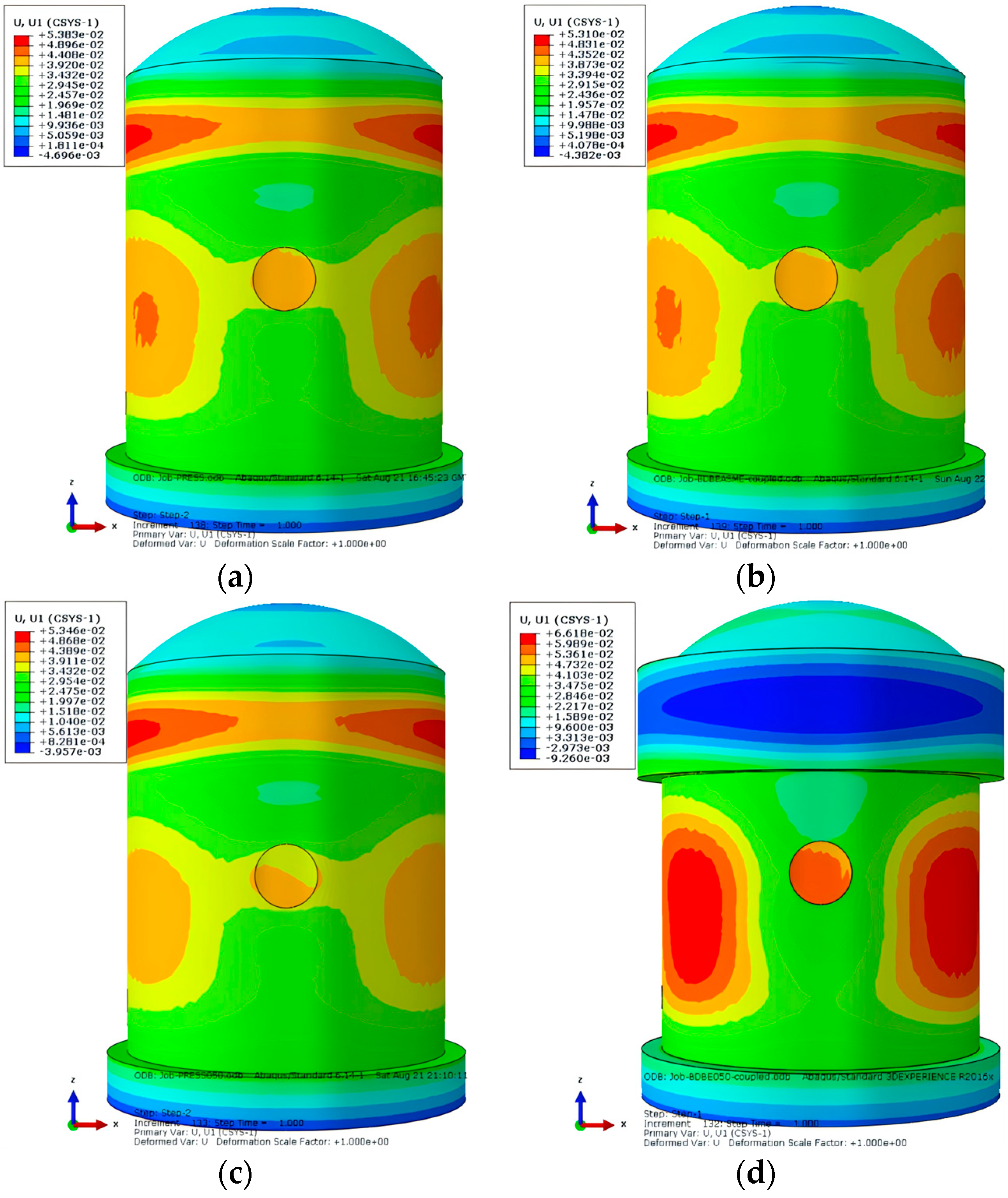

4.3. Severe Accident Conditions

4.3.1. Deformation Analysis

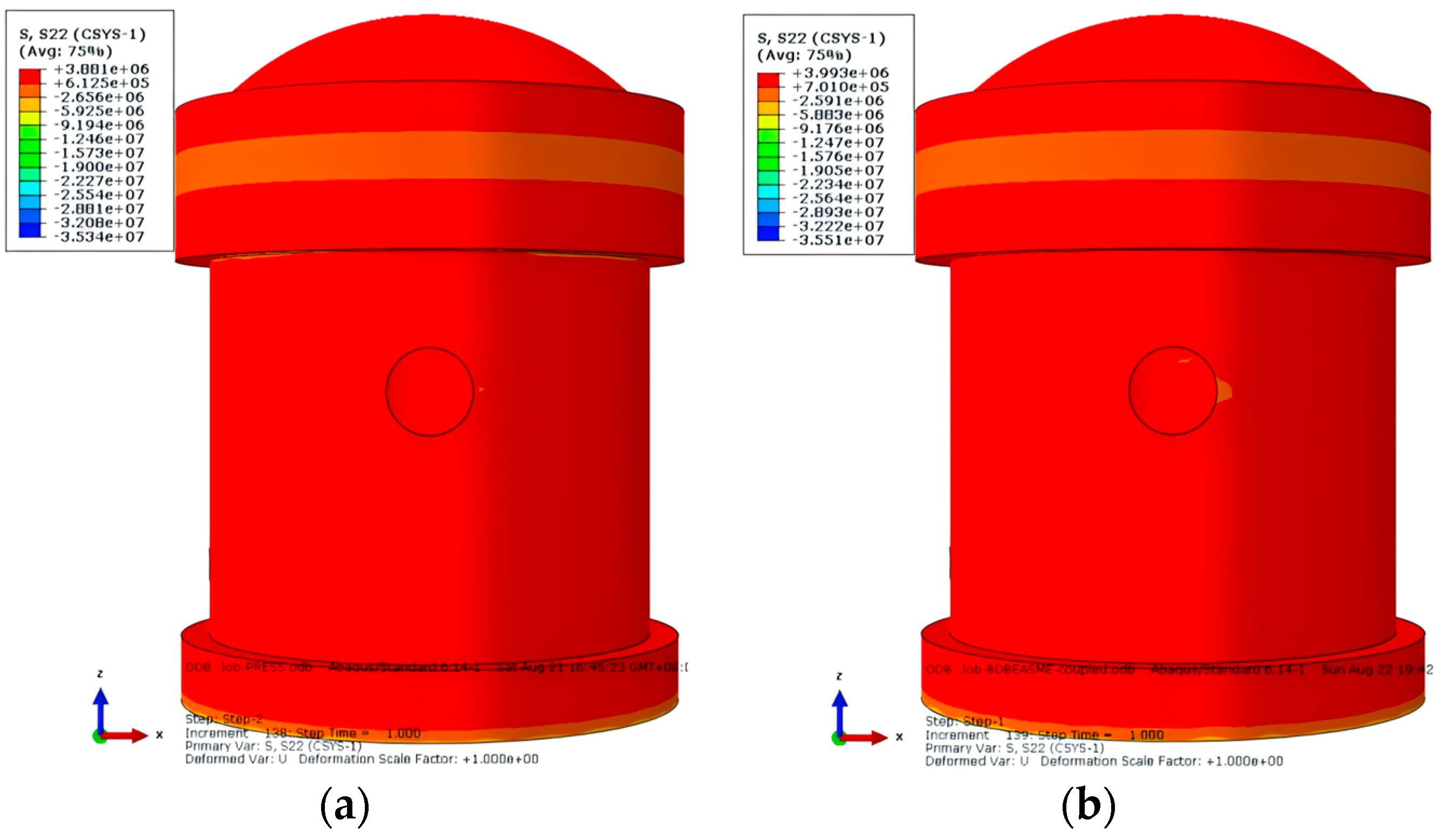

4.3.2. Stress and Strain Analysis

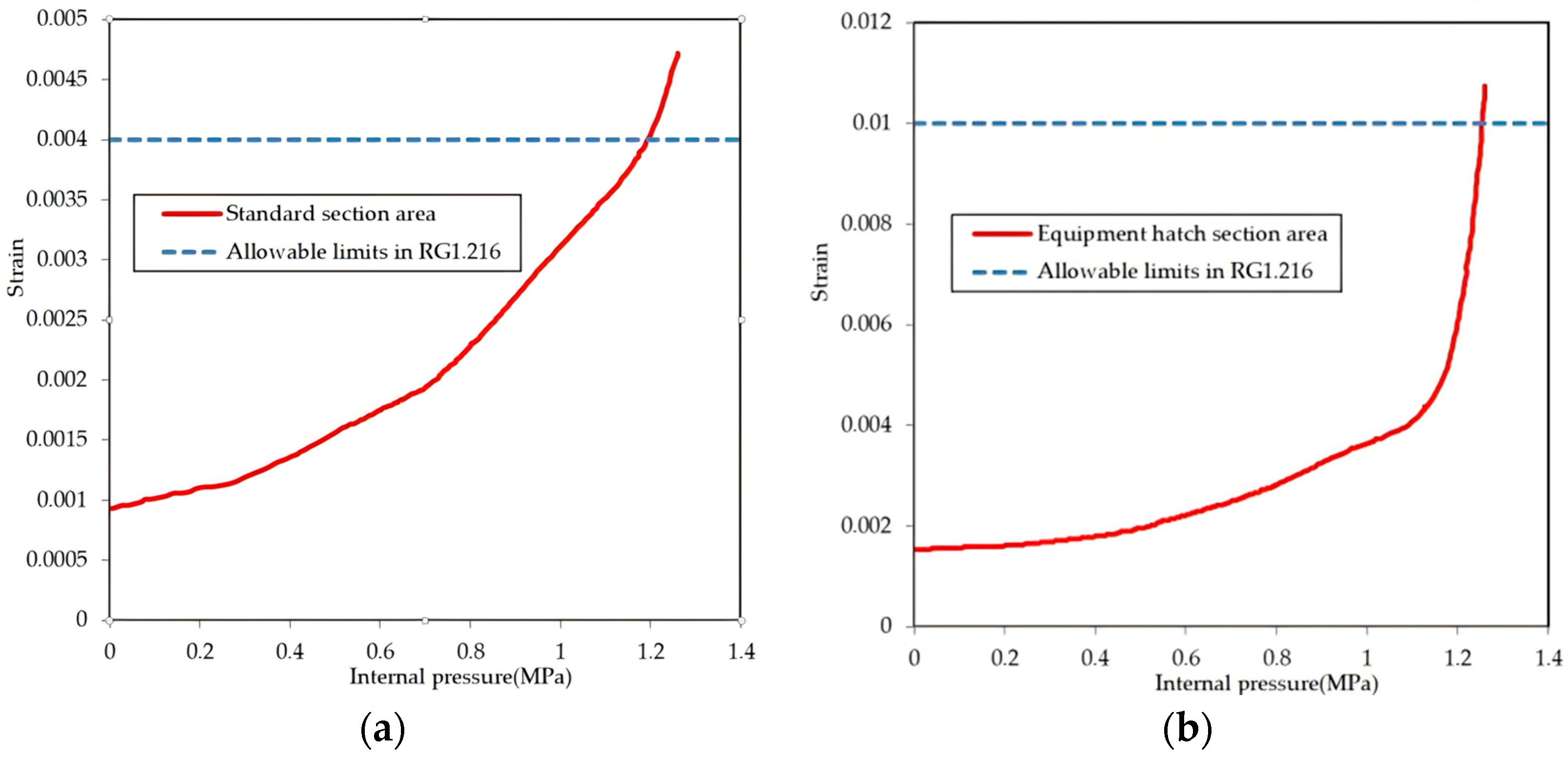

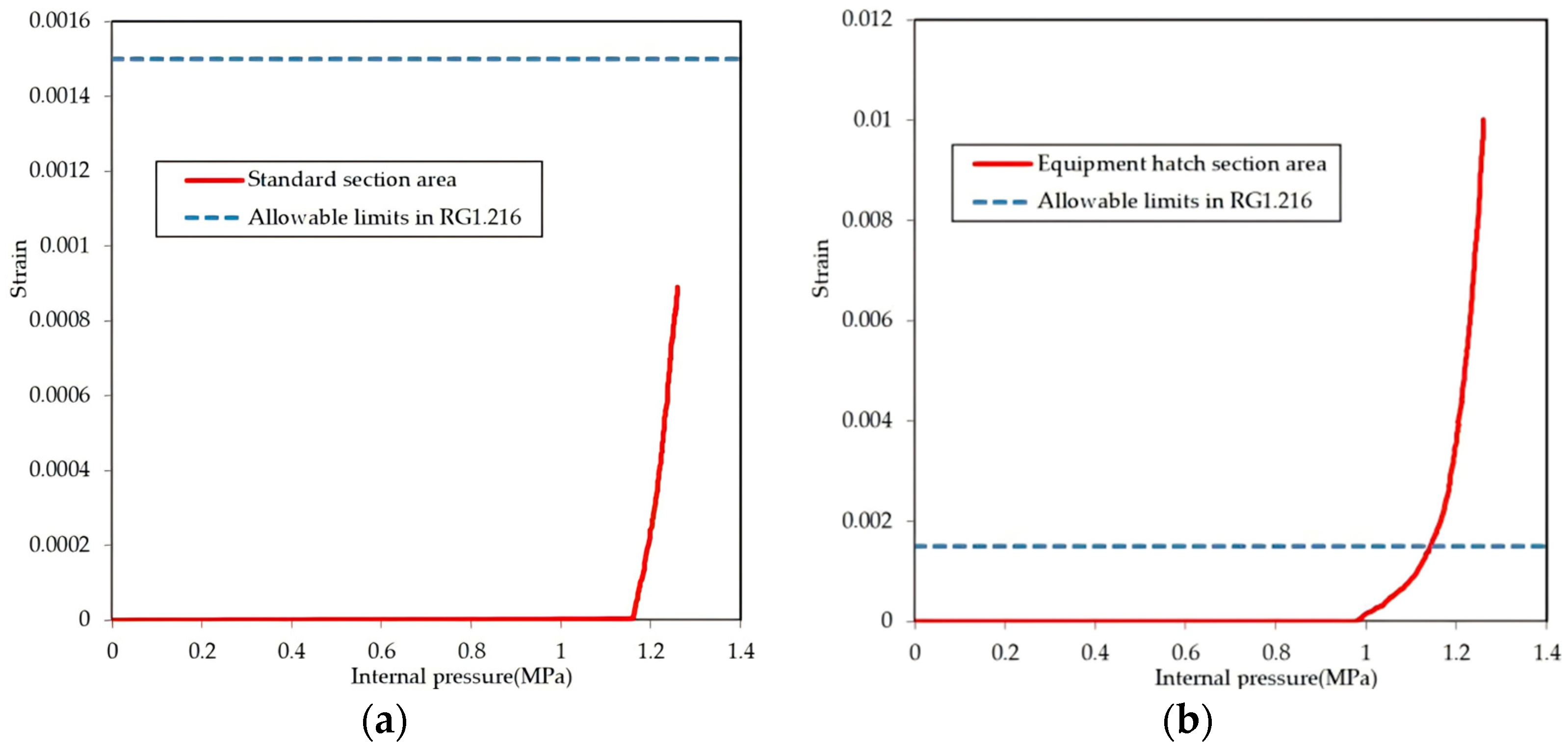

4.4. Failure Criterion and Ultimate Bearing Capacity

4.4.1. Failure Criterion

4.4.2. Ultimate Bearing Capacity

5. Conclusions and Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Frano, R.L.; Forasassi, G. Dynamic Response of a Nuclear Power Plant Subjected to External Accident Event. In Proceedings of the 18th International Conference on Nuclear Engineering, Xi’an, China, 17–21 May 2010; pp. 607–615. [Google Scholar]

- Ryzhov, S.B.; Mokhov, V.A.; Nikitenko, M.P.; Bessalov, G.G.; Podshibyakin, A.K.; Anufriev, D.A.; Gadó, J.a.; Rohde, U. VVER-Type Reactors of Russian Design. In Handbook of Nuclear Engineering; Cacuci, D.G., Ed.; Springer: Boston, MA, USA, 2010; pp. 2249–2320. [Google Scholar] [CrossRef]

- Sener, K.C.; Varma, A.H.; Wang, S.; Bhardwaj, S.R.; Gallocher, S. Modular steel-plate composite (SC) wall steelbricks: Experimental and numerical evaluations. Nucl. Eng. Des. 2019, 350, 224–233. [Google Scholar] [CrossRef]

- Zhu, X.; Li, J.; Lin, G.; Pan, R.; Li, L. Sensitivity Analysis of Steel-Plate Concrete Containment against a Large Commercial Aircraft. Energies 2021, 14, 2829. [Google Scholar] [CrossRef]

- Pan, R.; Wu, J.; Zhang, X. Application and development of steel plate reinforced concrete structure in nuclear power engineering. Ind. Constr. 2014, 44, 1–6. [Google Scholar]

- Ning, J.; Bao, F.; Fang, J. Experimental research on seismic behavior of low shear-span ratio composite shear wall with double steel plates and infill concrete. J. Build. Struct. 2011, 32, 74–81. [Google Scholar] [CrossRef]

- Chen, J.; Jun, Z. Construction Technology of Composite Structure of Double Steel Plate and Shear Wall in Yancheng Broadcast Television Tower. Constr. Technol. 2011, 40, 17–20. [Google Scholar]

- Tokyo Electric Power Company (TEPCO). Improved Construction and Project Management; TEPCO: Tokyo, Japan, 2001. [Google Scholar]

- JEAG 4618-2005; Technical Guidelines for Aseismic Design of Steel Plate Reinforced Concrete Structures: Buildings and Structures. Japan Electric Association: Tokyo, Japan, 2005.

- JEAG 4618-2009; Technical Code for Seismic Design of Steel Plate Reinforced Concrete Structures: Buildings and Structures. Japan Electric Association Nuclear Safety: Tokyo, Japan, 2009.

- Korea Electric Power Industry Code-Structural Nuclear Grade. Specification for Safety-Related Steel Plate Concrete Structures for Nuclear Facilities. Board of KEPIC Policy, Structural Committee; Korea Electric Association: Seoul, Republic of Korea, 2010. [Google Scholar]

- ANSI/AISC N690s1-15; Specification for Safety-Related Steel Structures for Nuclear Facilities. American Institute of Steel Construction: Chicago, IL, USA, 2015; pp. 1–15.

- Ministry of Housing and Urban Development–Regulation Construction. GB/T 51340-2018; Technical Standard for Steel Plate Concrete Structures of Nuclear Power Plants. China Planning Press: Beijing, China, 2018.

- Zhang, J.-L.; Liu, B.-D.; Zhang, P.-Y.; Wang, Z.-H. Small-scale test and analysis of corrugated-steel-plate–concrete composite member adopting novel shear connectors. Eng. Struct. 2019, 184, 369–383. [Google Scholar] [CrossRef]

- Wang, Q. The Structural Design and Shock-Resistant Performance of Steel Beam-Concrete Column Frame Structure; Springer: Cham, Switzerland, 2020; pp. 1020–1026. [Google Scholar]

- Zhou, T.; Wang, J.; Sawab, J.; Chen, H.; Mo, Y.L. Biaxial steel plated concrete constitutive models for composite structures: Implementation and validation. J. Constr. Steel Res. 2021, 177, 106452. [Google Scholar] [CrossRef]

- Wu, L.; Wang, H.; Lin, Z. Ultimate strength behavior of steel plate-concrete composite slabs: An experimental and theoretical study. Steel Compos. Struct. 2020, 37, 741–759. [Google Scholar] [CrossRef]

- Liu, R.; Yang, Y. Research on fatigue performance of steel-plate-concrete composite slab. Thin-Walled Struct. 2021, 160, 107339. [Google Scholar] [CrossRef]

- Szewczyk, P.; Szumigała, M. Optimal Design of Steel–Concrete Composite Beams Strengthened Under Load. Materials 2021, 14, 4715. [Google Scholar] [CrossRef]

- Ma, Z.; Wu, Y.; Zhang, J.; Zhang, M. Experimental Study on Seismic Behavior of Coupled Steel Plate and Reinforced Concrete Composite Wall. Buildings 2022, 12, 2036. [Google Scholar] [CrossRef]

- Liu, A.; Wu, Y.; Wang, B.; Chen, X. Seismic Design and Performance Evaluation of Coupled Steel Plate and Reinforced Concrete Composite Walls. Buildings 2023, 13, 2242. [Google Scholar] [CrossRef]

- Wang, B.; Chen, P.; Jiang, H.; Wang, J. Performance of steel-plate-reinforced concrete composite walls in tall structures. Proc. Inst. Civ. Eng.—Civ. Eng. 2024, 177, 118–125. [Google Scholar] [CrossRef]

- Appa Rao, T.V.S.R. Behavior of Concrete Nuclear Containment Structures up to Ultimate Failure with Special Reference to MAPP-1 Containment, Inelastic Behavior; Structural Engineering Research Centre: Madras, India, 1975. [Google Scholar]

- Donten, K.; Knauff, M.; Sadowski, A.; Scibak, W. Tests on Model of Prestressed Reactor Containment; Institute of Nuclear Research: Otwock, Poland, 1980; pp. 231–245. [Google Scholar]

- NUREG/CR-5825; Post-Test Report on Testing and Analysis of the Sizewell-B 1:10-Scale Containment Model. ANATECH Research Corp.: San Diego, CA, USA, 1991.

- NUREG/CR-6810; Overpressurization Test of a 1:4-Scale Prestressed Concrete Containment Vessel Model. Sandia National Laboratories: Albuquerque NM, USA, 2003.

- Zhao, X.; Yao, D.; Gao, J.; Tan, J.; Hao, X. A simulation research on thermal-pressure coupling loading of a 1:3.2 containment model. J. Nucl. Sci. Technol. 2024, 150, 1–14. [Google Scholar] [CrossRef]

- Zhao, C.; Li, Z.L.; Dong, Z. Ultimate bearing capacity analysis on containment structure of CPR1000. Comput. Aided Eng. 2013, 22, 393–398. [Google Scholar]

- Song, C.; Hou, G.; Zhou, G. Ultimate Capacity and Influenced Factors Analysis of Nuclear RC Containment Subjected to Internal Pressure. Chin. J. Nucl. Sci. Eng. 2014, 34, 228–235. [Google Scholar]

- Ren, G.; Pan, R.; Sun, F. Imulation of behaviors of a one-third scale containment model test. In Proceedings of the 25th International Conference on Nuclear Engineering, Shanghai, China, 15–19 April 2017. [Google Scholar]

- Chakraborty, M.K.; Acharya, S.; Pisharady, A.S.; Roshan, A.D.; Bishnoi, L.R. Assessment of Ultimate Load Capacity of concrete containment structures against structural collapse. Nucl. Eng. Des. 2017, 323, 417–426. [Google Scholar] [CrossRef]

- Tong, L.; Zhou, X.; Cao, X. Ultimate pressure bearing capacity analysis for the prestressed concrete containment. Ann. Nucl. Energy 2018, 121, 582–593. [Google Scholar] [CrossRef]

- Nuclear Energy Agency/Committee on the Safety of Nuclear Installations. International Standard Problem No. 48 Containment Capacity; Nuclear Energy Agency/Committee on the Safety of Nuclear Installations: Paris, France, 2005. [Google Scholar]

- Huang, X.; Kwon, O.-S.; Bentz, E.; Tcherner, J. Evaluation of CANDU NPP containment structure subjected to aging and internal pressure increase. Nucl. Eng. Des. 2017, 314, 82–92. [Google Scholar] [CrossRef]

- Mahida, P.A.; Desai, D. Structural response evaluation of reinforced-concrete nuclear containment structure subjected to internal overpressure with high-temperature loading. Int. J. Nucl. Energy Sci. Technol. 2020, 14, 281–290. [Google Scholar] [CrossRef]

- Yuqin, G. The Study on the Ultimate Bearing Capability of Nuclear Power Plant’s Containment with Temperature Effect; Harbin Engineering University: Harbin, China, 2015. [Google Scholar]

- Lin, S.; Hu, Z.; Han, J. Experimental Studies on Friction Loss of Prestress of Containment Vessel in an EPR Nuclear Power Plant. Spec. Struct. 2022, 39, 57–60. [Google Scholar]

- Asmolov, V.G.; Gusev, I.N.; Kazanskiy, V.R.; Povarov, V.P.; Statsura, D.B. New generation first-of-the kind unit—VVER-1200 design features. Nucl. Energy Technol. 2017, 3, 260–269. [Google Scholar] [CrossRef]

- Liu, J.; Han, P. Numerical Analyses of a Shield Building Subjected to a Large Commercial Aircraft Impact. Shock. Vib. 2018, 2018, 7854969. [Google Scholar] [CrossRef]

- GE-Hitachi Nuclear Energy Americas, LLC. BWRX-300 Steel-Plate Composite Containment Vessel (SCCV) and Reactor Building (RB) Structural Design–Non-Proprietary Information; GE-Hitachi Nuclear Energy Americas, LLC: Wilmington, NC, USA, 2023. [Google Scholar]

- GB-50010-2010; Specification for Design of Concrete Structures. China Construction Industry Press: Beijing, China, 2011.

- EN1994-1-2; Eurocode 4-Design of Composite Steel and Concrete Structures-Part 1-2: General Rules—Structural Fire Design. British Standards Institution: London, UK, 2005.

- The American Society of Mechanical Engineers. ASME Boiler & Pressure Vessel Code II Part A; The American Society of Mechanical Engineers: New York, NY, USA, 2007. [Google Scholar]

- GB 51249-2017; Code for Fire Safety of Steel Structures in Buildings. China Planing Press: Beijing, China, 2017.

- Jin, S.; Li, Z.; Lan, T.; Dong, Z.; Gong, J. Nonlinear Finite Element Analysis of Prestressed Concrete Containment Vessel under Severe Accident Loads. KSCE J. Civ. Eng. 2020, 24, 816–825. [Google Scholar] [CrossRef]

- Federal Association of Fire Protection Engineers Design. Rules for Design and Construction of PWR Nuclear Civil Works: RCC-CW. Paris; French Association for Design: Paris, France, 2015; pp. 7–8. [Google Scholar]

- American Society of Mechanical Engineers. ASME Boiler & Pressure Vessel Code III Division 2-Code for Concrete Containments:ACI 359; The American Society of Mechanical Engineers: New York, NY, USA, 2004. [Google Scholar]

- Nuclear Regulatory Commission. Rule 1.206, Revision. Containment Structural Integrity Evaluation for Internal Pressure Loadings above Design Basis Pressure; Nuclear Regulatory Commission: Rockville, MD, USA, 2010. [Google Scholar]

| Material Parameter | Room Temperature | High Temperature |

|---|---|---|

| Elastic modulus (MPa) | 3.60 × 104 | 3.38 × 104 |

| Compressive strength (MPa) | 38.50 | 33.88 |

| Tensile strength (MPa) | 2.85 | 2.51 |

| Density (kg/m3) | 2400 | |

| Poisson ratio | 0.2 | |

| Temperature, °C | Thermal Conductivity, W/m·°C | Specific Heat Capacity, J/Kg·°C | Coefficient of Thermal Expansion |

|---|---|---|---|

| 20 | 1.95 | 900 | 9.20 × 10−9 |

| 40 | 1.90 | 900 | 4.54 × 10−6 |

| 60 | 1.86 | 900 | 6.08 × 10−6 |

| 80 | 1.81 | 900 | 6.90 × 10−6 |

| 100 | 1.77 | 900 | 7.43 × 10−6 |

| 120 | 1.72 | 920 | 7.83 × 10−6 |

| 140 | 1.68 | 940 | 8.17 × 10−6 |

| 160 | 1.64 | 960 | 8.46 × 10−6 |

| 180 | 1.59 | 980 | 8.75 × 10−6 |

| 200 | 1.55 | 1000 | 9.02 × 10−6 |

| Temperature, °C | Steel Plate | Anchors and Tendons | ||

|---|---|---|---|---|

| Yield Strength (MPa) | Elastic Modulus (MPa) | Yield Strength (MPa) | Elastic Modulus (MPa) | |

| 20 | 415 | 2.06 × 105 | 335 | 2.00 × 105 |

| 40 | 2.05 × 105 | 1.99 × 105 | ||

| 60 | 2.04 × 105 | 1.98 × 105 | ||

| 80 | 2.03 × 105 | 1.97 × 105 | ||

| 100 | 2.02 × 105 | 1.96 × 105 | ||

| 120 | 2.01 × 105 | 1.95 × 105 | ||

| 140 | 2.00 × 105 | 1.94 × 105 | ||

| 160 | 1.98 × 105 | 1.93 × 105 | ||

| 180 | 1.97 × 105 | 1.91 × 105 | ||

| 200 | 1.96 × 105 | 1.90 × 105 | ||

| Temperature, °C | Thermal Conductivity, W/m·°C | Specific Heat Capacity, J/Kg·°C | Coefficient of Thermal Expansion |

|---|---|---|---|

| 20 | 53.33 | 439.80 | 1.36 × 10−21 |

| 40 | 52.67 | 453.36 | 6.12 × 10−6 |

| 60 | 52.00 | 465.78 | 8.21 × 10−6 |

| 80 | 51.34 | 477.16 | 9.30 × 10−6 |

| 100 | 50.67 | 487.62 | 9.98 × 10−6 |

| 120 | 50.00 | 497.26 | 1.05 × 10−5 |

| 140 | 49.34 | 506.19 | 1.08 × 10−5 |

| 160 | 48.67 | 514.51 | 1.11 × 10−5 |

| 180 | 48.01 | 522.33 | 1.14 × 10−5 |

| 200 | 47.34 | 529.76 | 1.16 × 10−5 |

| Mesh Size, mm | Maximum Radial Displacement (mm) | Concrete Circumferential Stress (MPa) | Maximum Mises Stress (MPa)—Inner Steel Plate | Maximum Mises Stress (MPa)—Outer Steel Plate | Maximum Strain—Inner Steel Plate | Maximum Strain—Outer Steel Plate |

|---|---|---|---|---|---|---|

| 1000 | 22.5 | 2.712 | 250.5 | 210.6 | 1.231 × 10−3 | 1.002 × 10−3 |

| 800 | 21.3 | 2.651 | 240.2 | 204.3 | 1.162 × 10−3 | 9.736 × 10−3 |

| 500 | 21.0 | 2.635 | 239.1 | 203.8 | 1.150 × 10−3 | 9.654 × 10−3 |

| Deformation History in μm/m | |||||

|---|---|---|---|---|---|

| Sensor | Direction | End of Prestressing | At 0.52 MPa (abs.) | ||

| Test Result | Numerical Analysis | Test Result | Numerical Analysis | ||

| H1 | T | −487.77 | −405.45 | −315.95 | −244.45 |

| V | −271.83 | −218.11 | −230.71 | −132.85 | |

| H2 | V | −470.94 | −347.14 | −425.40 | −262.70 |

| H5 | T | −551.17 | −445.97 | −369.32 | −243.08 |

| V | −286.46 | −165.31 | −245.53 | −139.27 | |

| H6 | T | −574.84 | −489.54 | −391.03 | −282.19 |

| F1 | T | −10.73 | −6.36 | −17.67 | −33.41 |

| F2 | T | −39.76 | −24.42 | −41.08 | −35.71 |

| G1 | V | −338.02 | −369.54 | −262.33 | −163.53 |

| Level, m | Position, ° | The Measured Radial Displacement during Pressurization Test, mm | The Calculated Radial Displacement during Pressurization Test, mm |

|---|---|---|---|

| 4.0 | 60 | 1.6 | 1.44 |

| 160 | 1.8 | 1.35 | |

| 260 | 1.4 | 1.23 | |

| 360 | 1.6 | 1.40 | |

| 9.0 | 60 | 1.4 | 1.36 |

| 160 | 1.5 | 1.38 | |

| 260 | 1.6 | 1.13 | |

| 360 | 1.4 | 1.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, G.; Pan, R.; Sun, F.; Dong, Z.; Lan, T. Advanced Analysis of Structural Performance in Novel Steel-Plate Concrete Containment Structures. Buildings 2024, 14, 2771. https://doi.org/10.3390/buildings14092771

Ren G, Pan R, Sun F, Dong Z, Lan T. Advanced Analysis of Structural Performance in Novel Steel-Plate Concrete Containment Structures. Buildings. 2024; 14(9):2771. https://doi.org/10.3390/buildings14092771

Chicago/Turabian StyleRen, Guopeng, Rong Pan, Feng Sun, Zhanfa Dong, and Tianyun Lan. 2024. "Advanced Analysis of Structural Performance in Novel Steel-Plate Concrete Containment Structures" Buildings 14, no. 9: 2771. https://doi.org/10.3390/buildings14092771

APA StyleRen, G., Pan, R., Sun, F., Dong, Z., & Lan, T. (2024). Advanced Analysis of Structural Performance in Novel Steel-Plate Concrete Containment Structures. Buildings, 14(9), 2771. https://doi.org/10.3390/buildings14092771