Laboratory-Scale Limestone Rock Linear Cutting Tests with a Conical Pick: Predicting Optimal Cutting Conditions from Tool Forces

Abstract

1. Introduction

2. Rock Linear Cutting Test

2.1. Laboratory-Scale Linear Cutting Machine

2.2. Conical Pick and Rock Sample

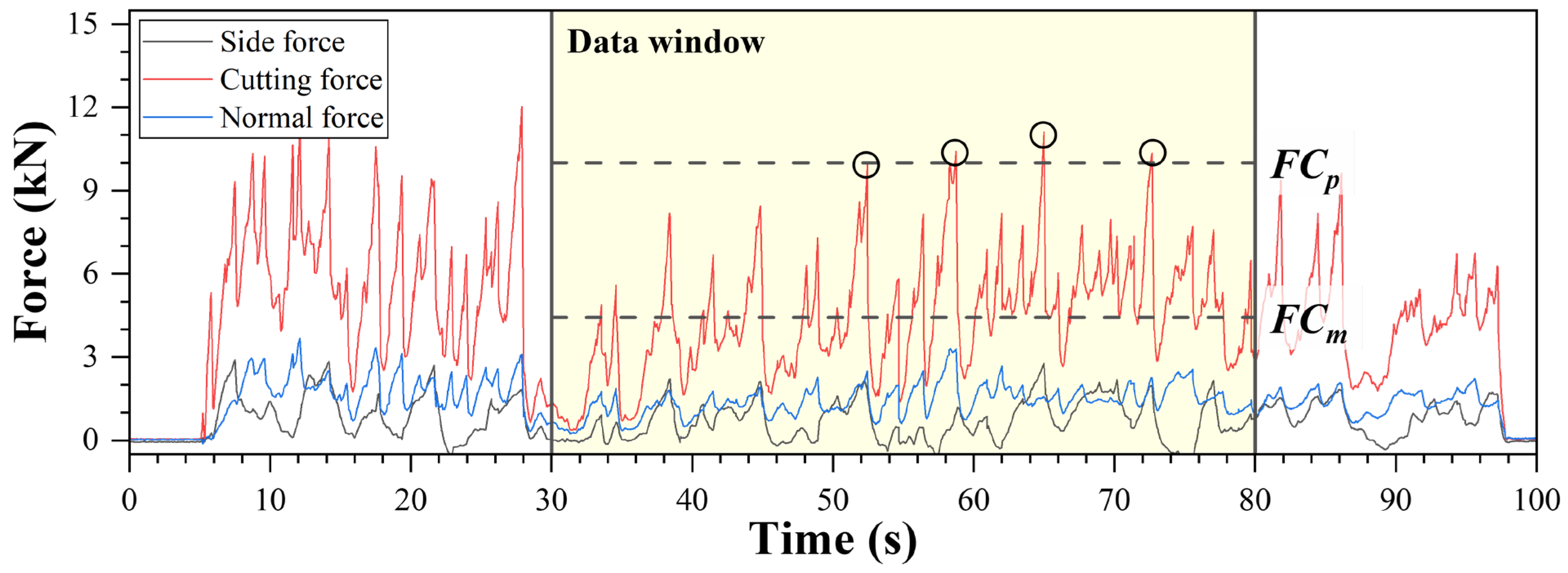

2.3. Cutting Parameters and Data Processing

3. Results and Discussions

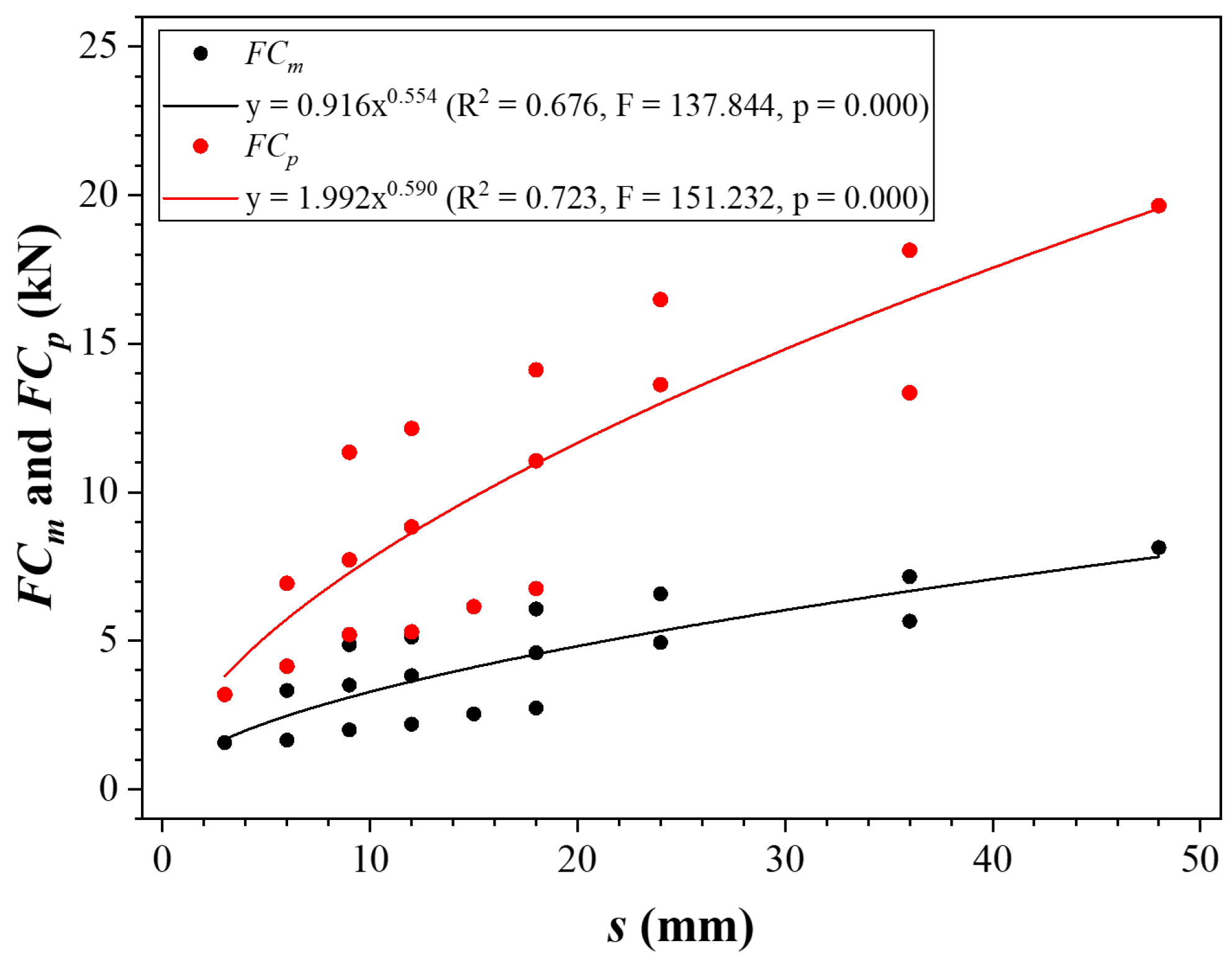

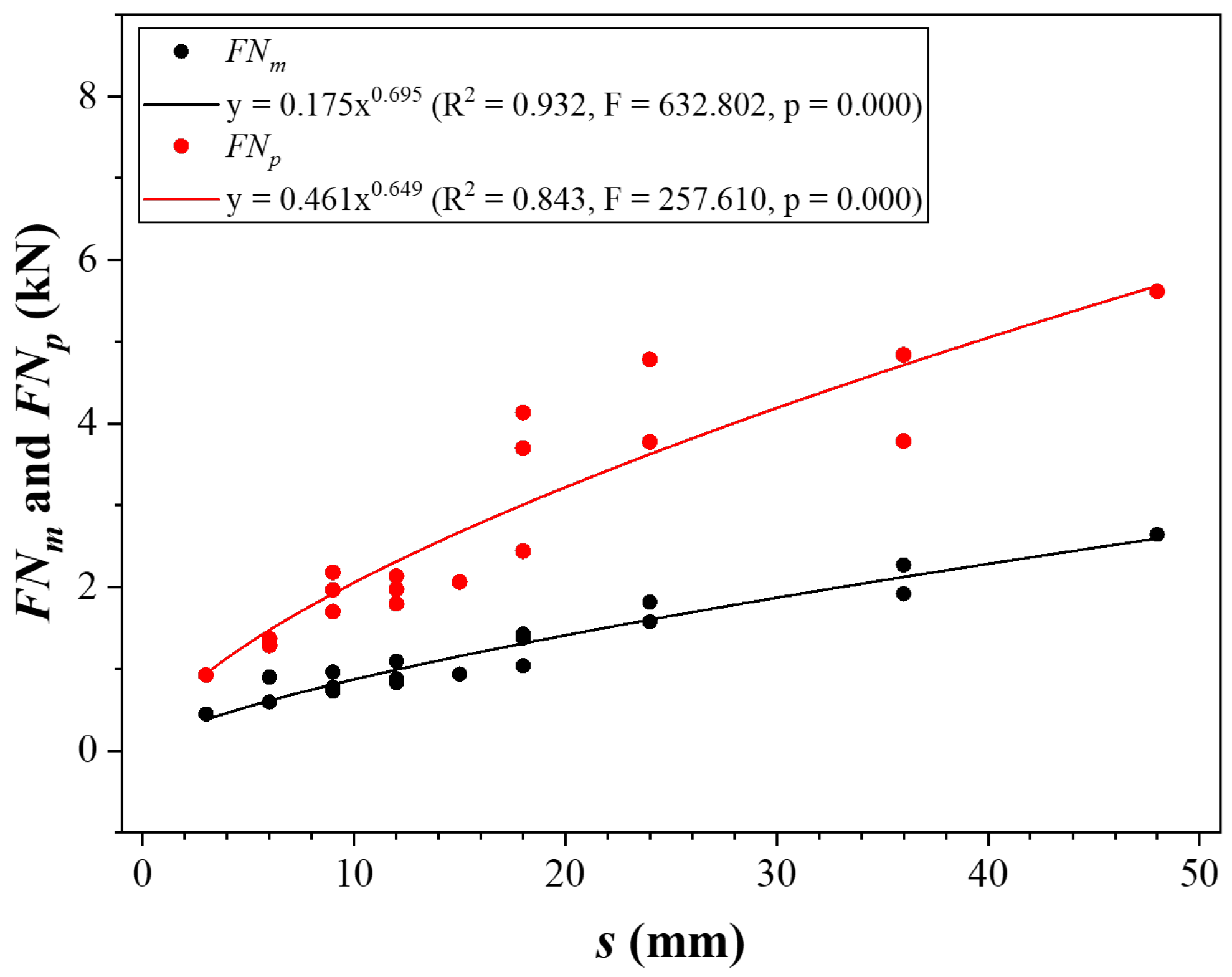

3.1. Analysis of Tool Forces

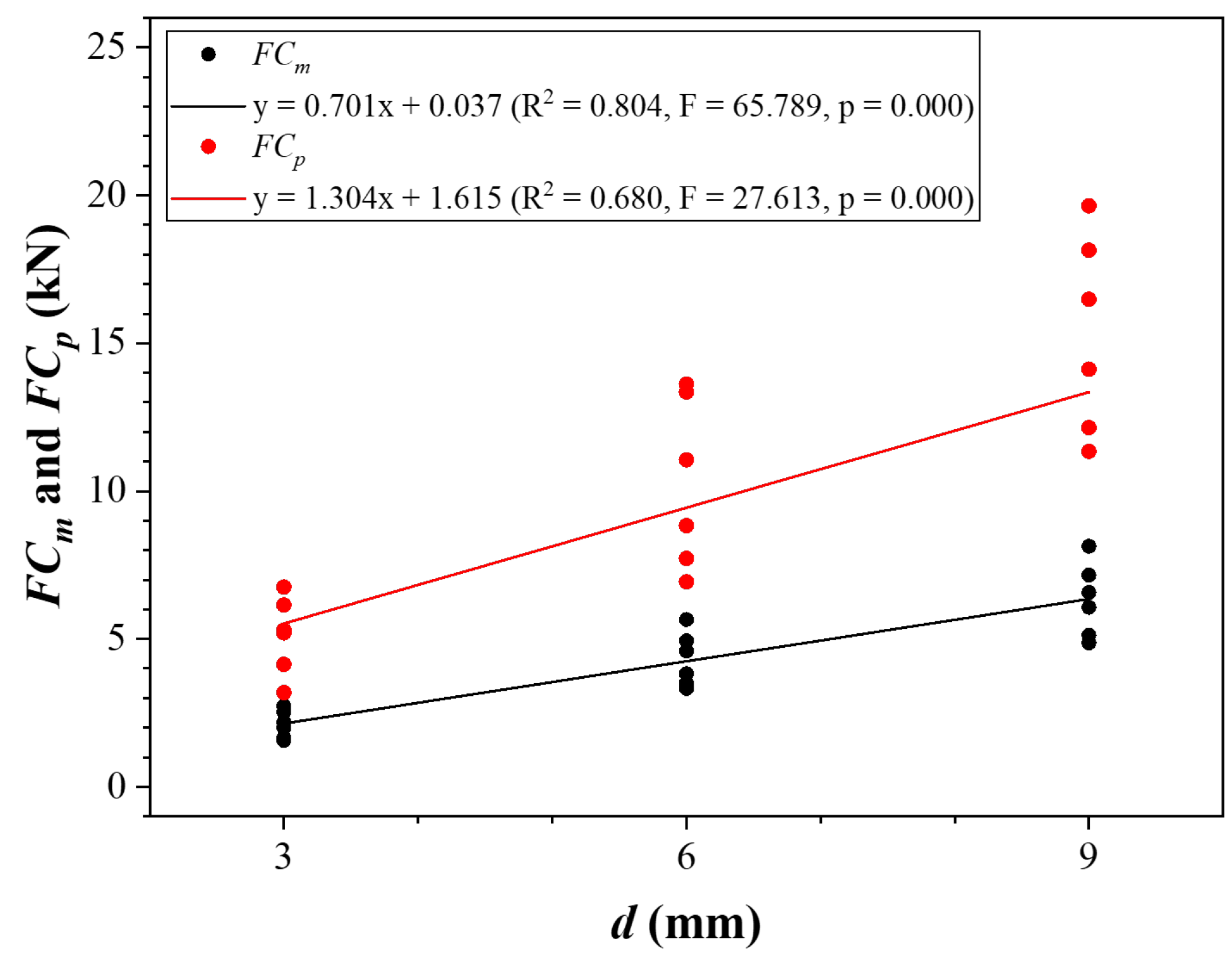

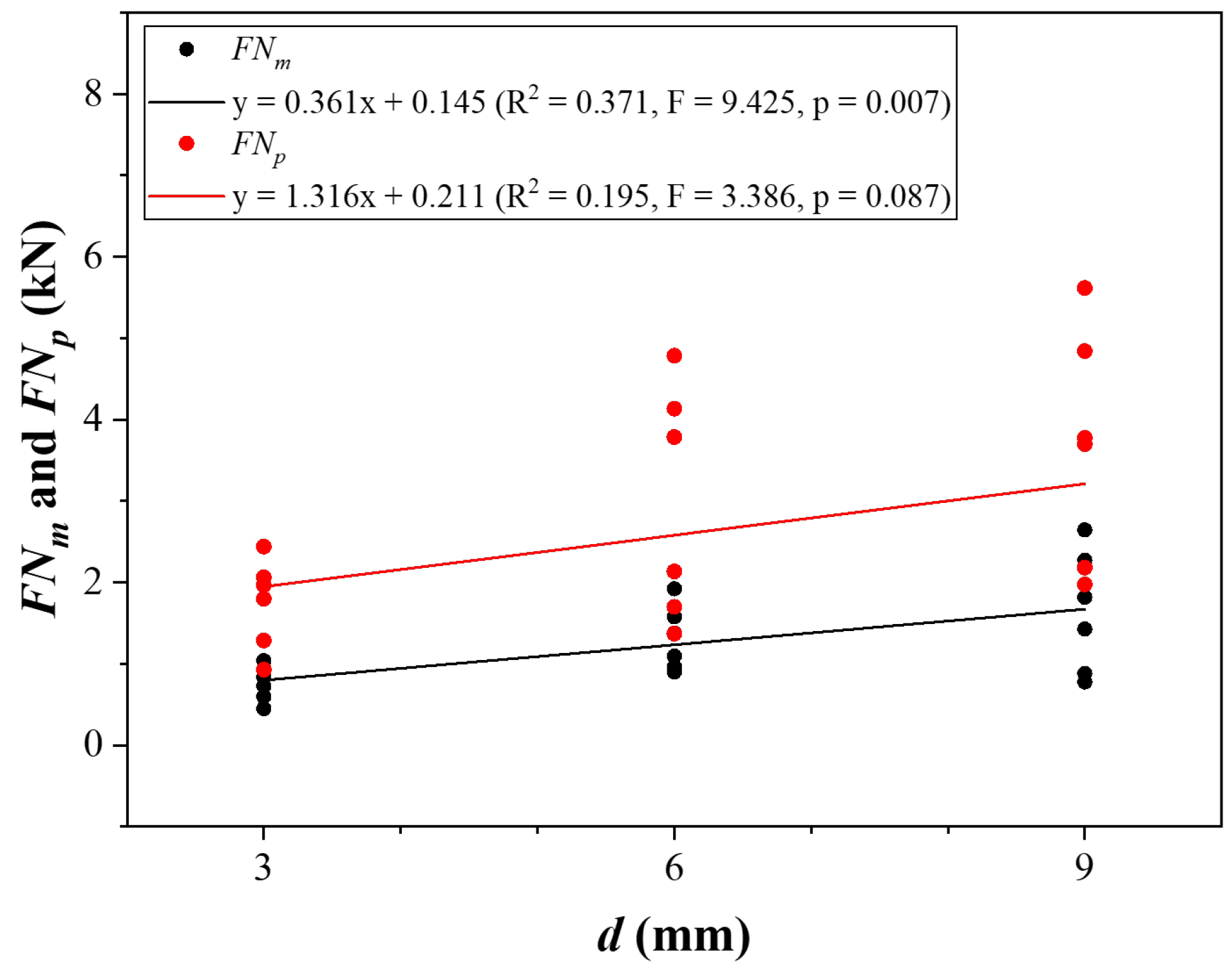

3.1.1. Correlation between Tool Forces and Cutting Conditions

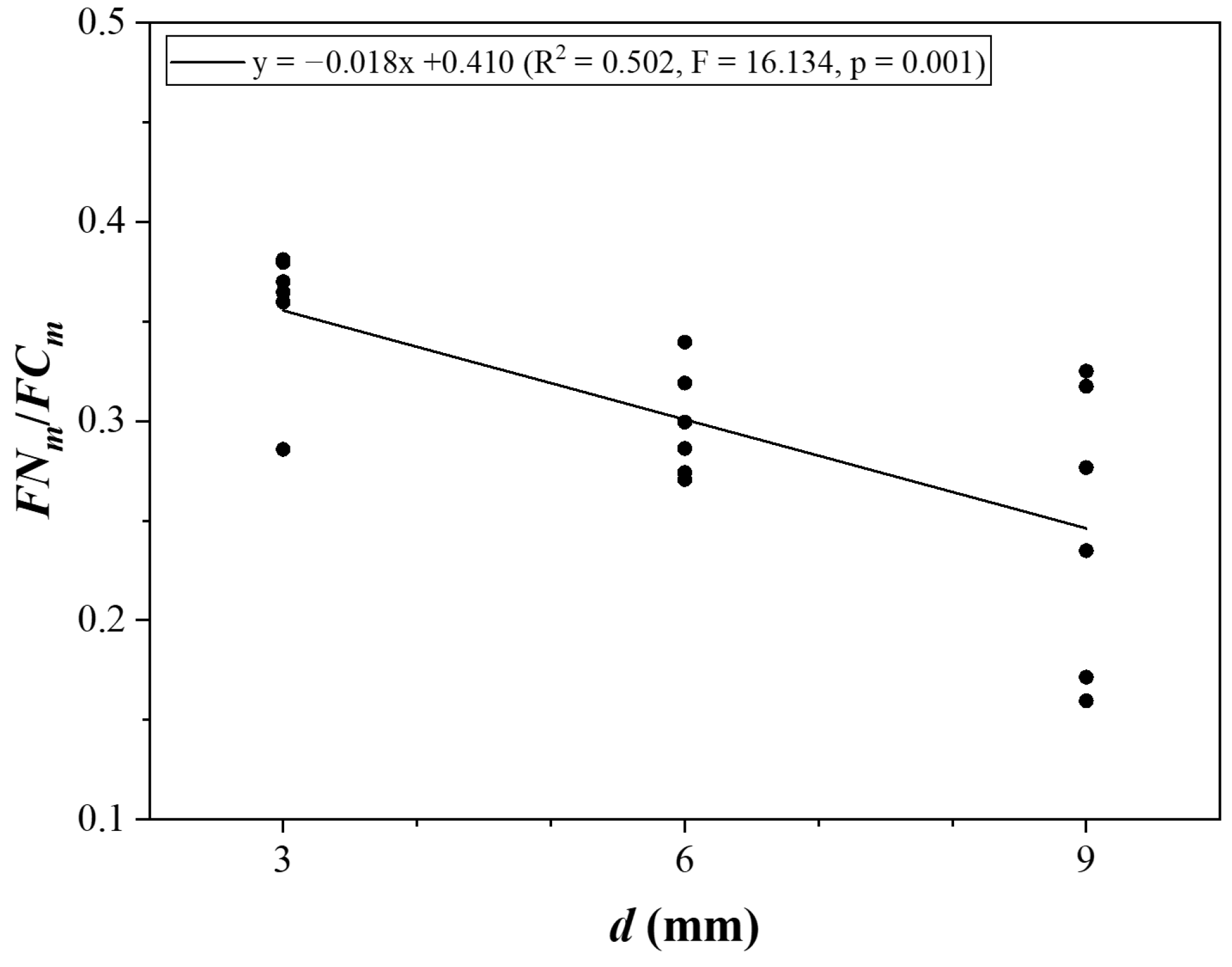

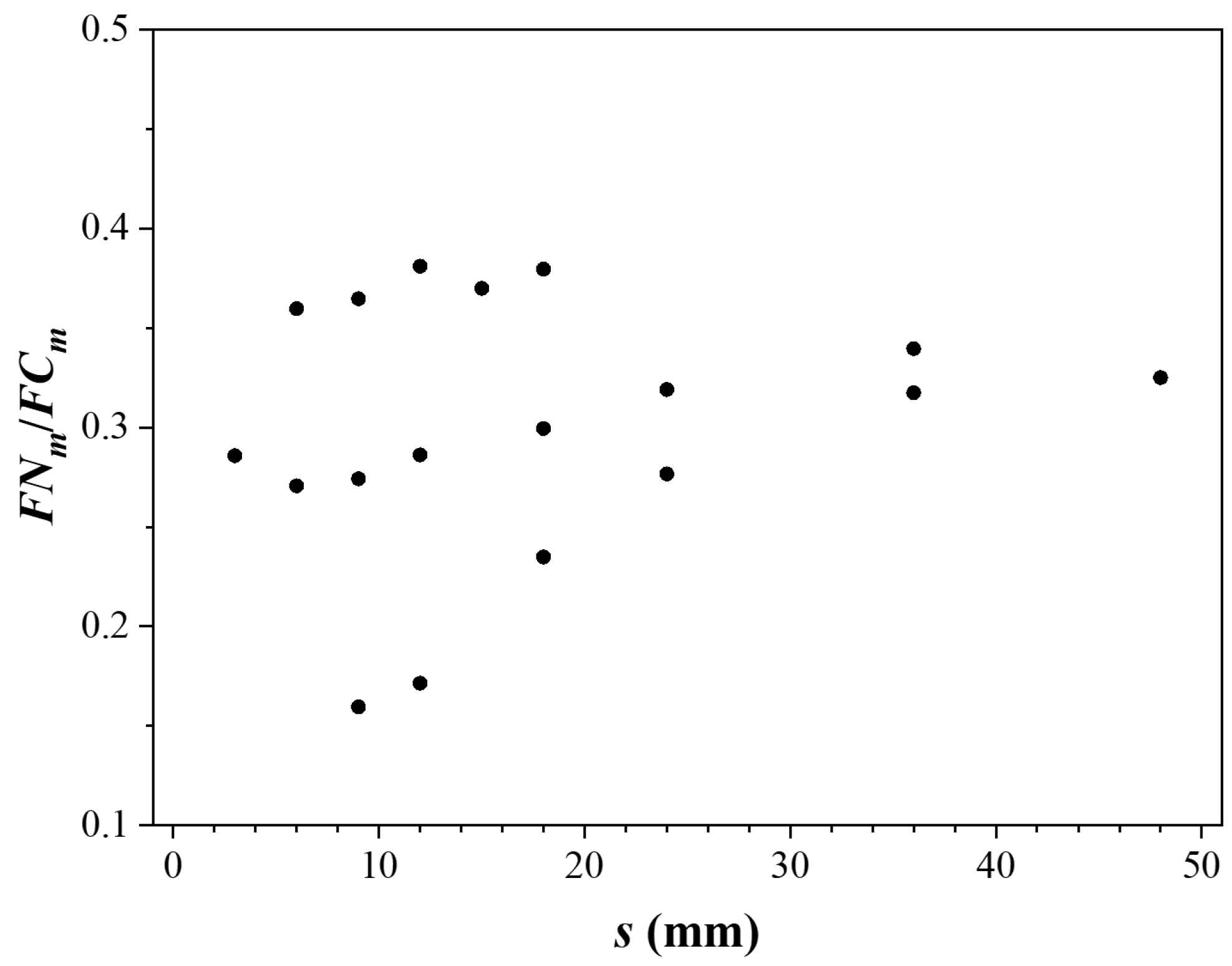

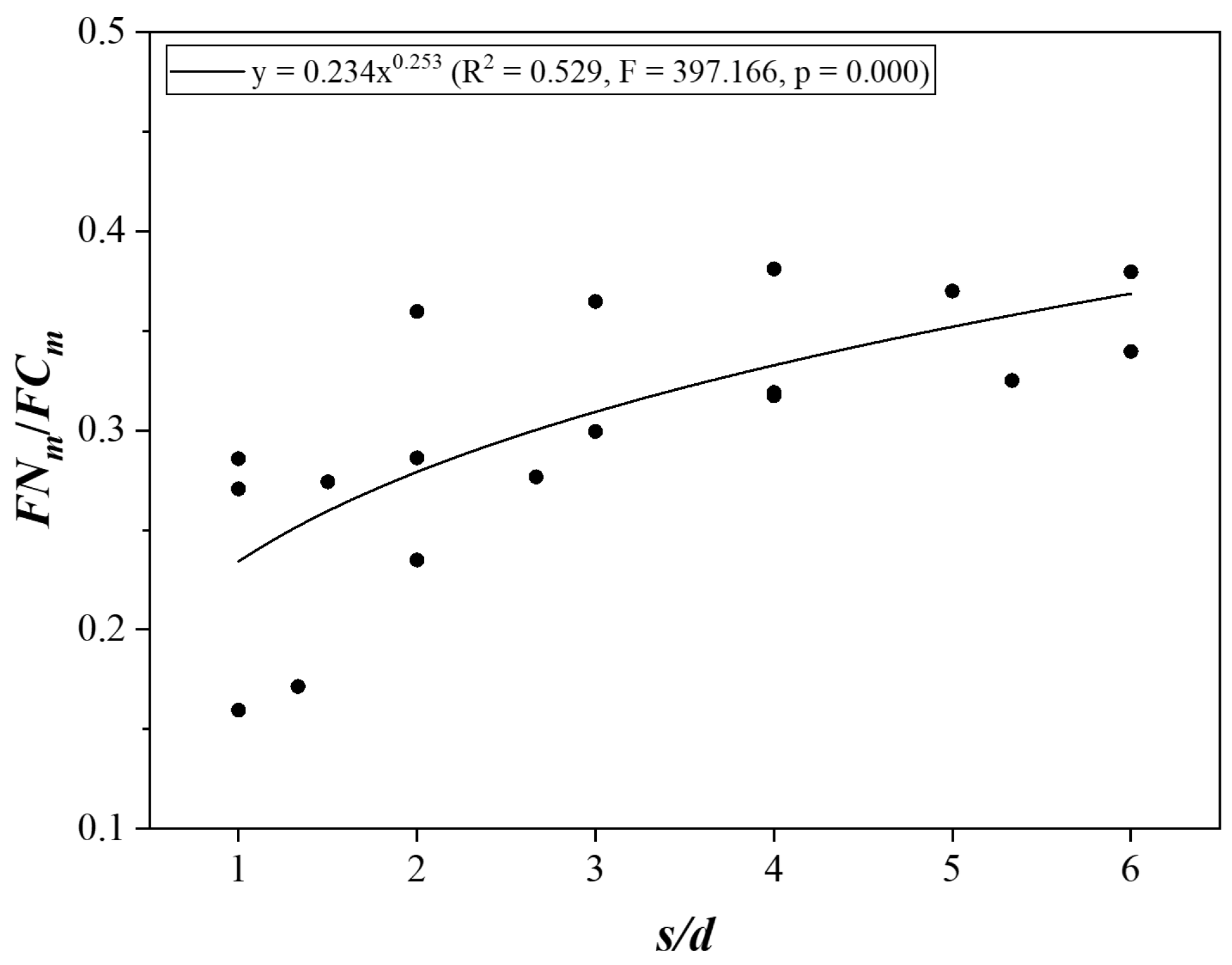

3.1.2. Correlation between Ratio of Normal to Cutting Force and Cutting Condition

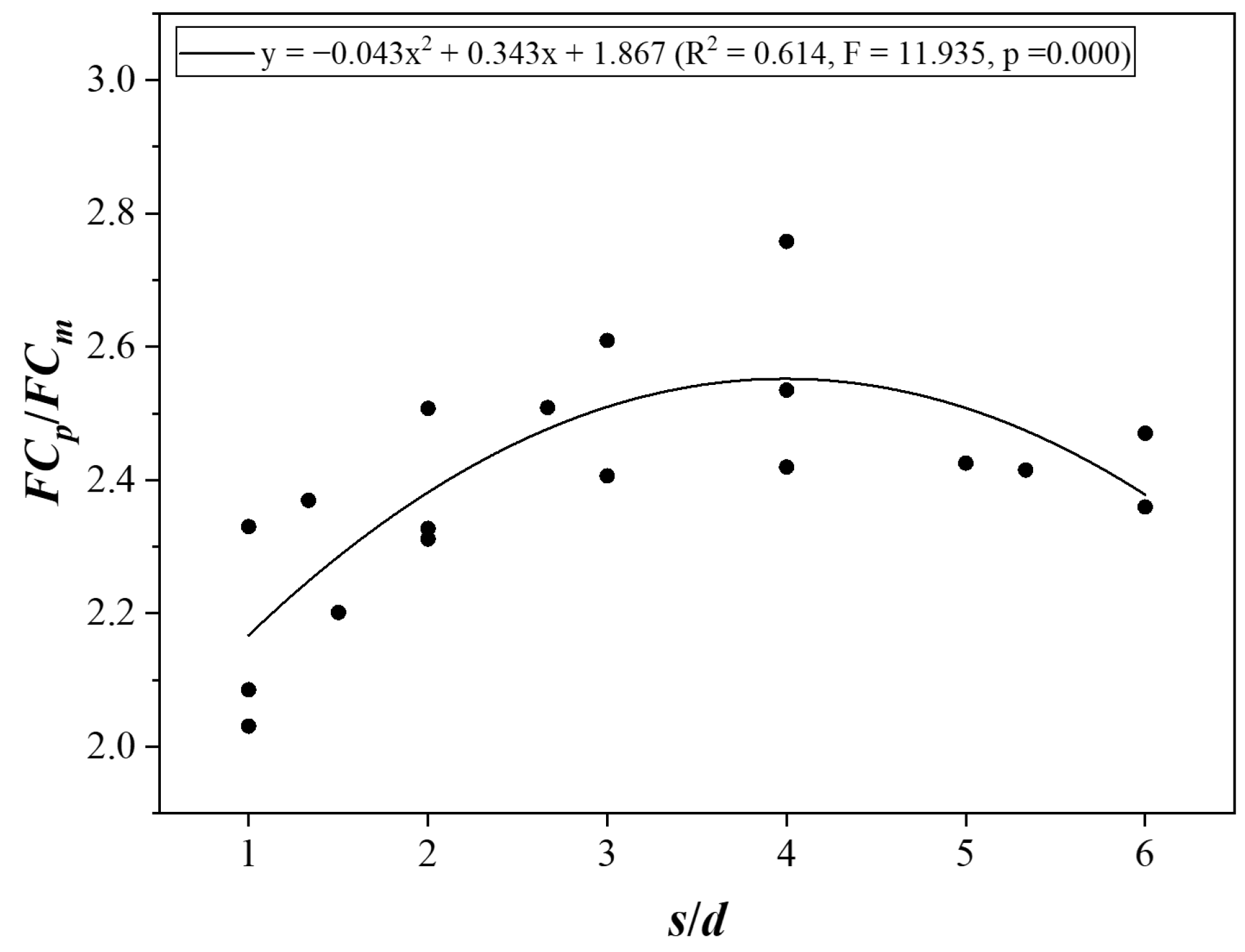

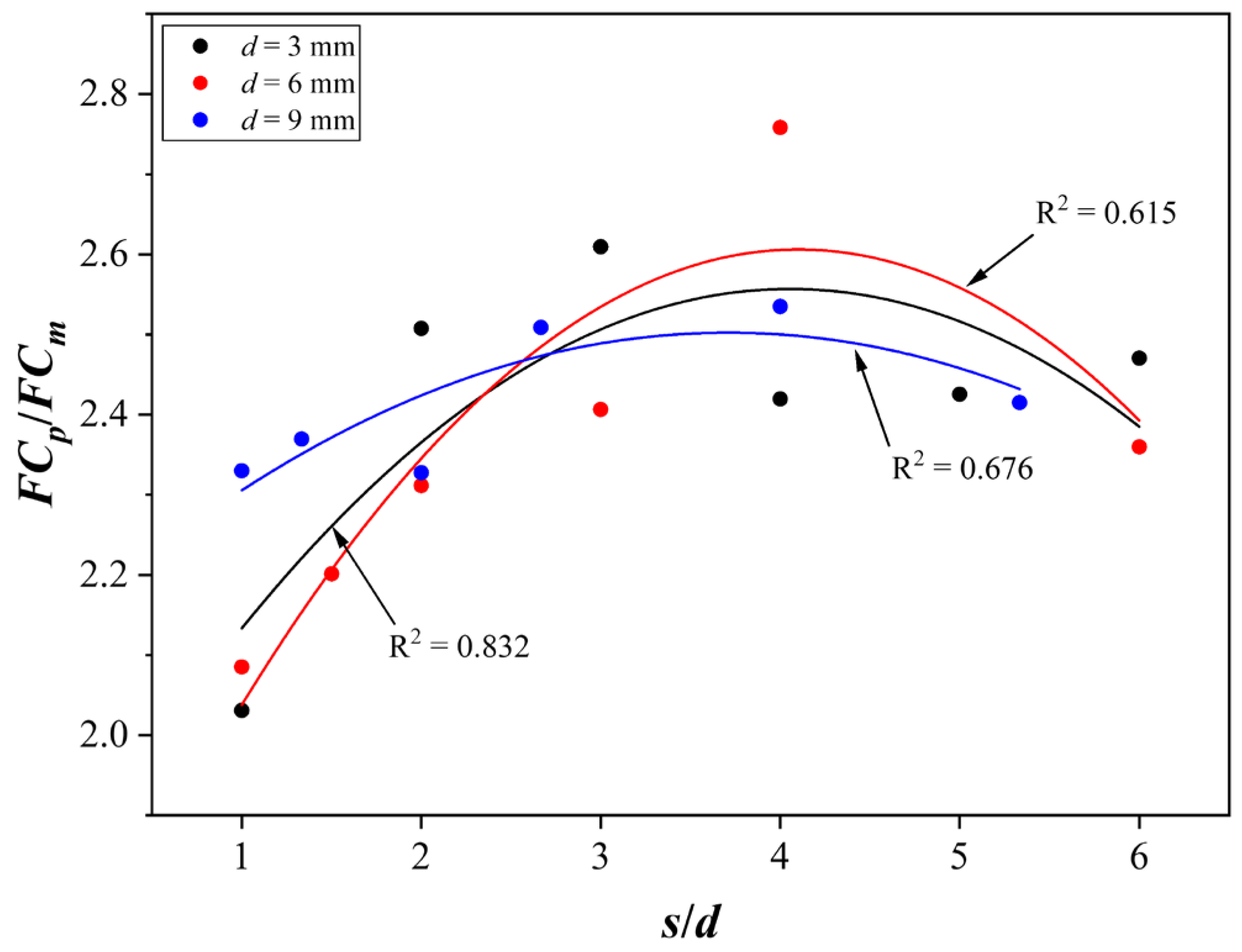

3.1.3. Correlation between Ratio of Peak-to-Mean Tool Force and Cutting Condition

3.2. Simplified Approach to Predicting Optimal Cutting Conditions

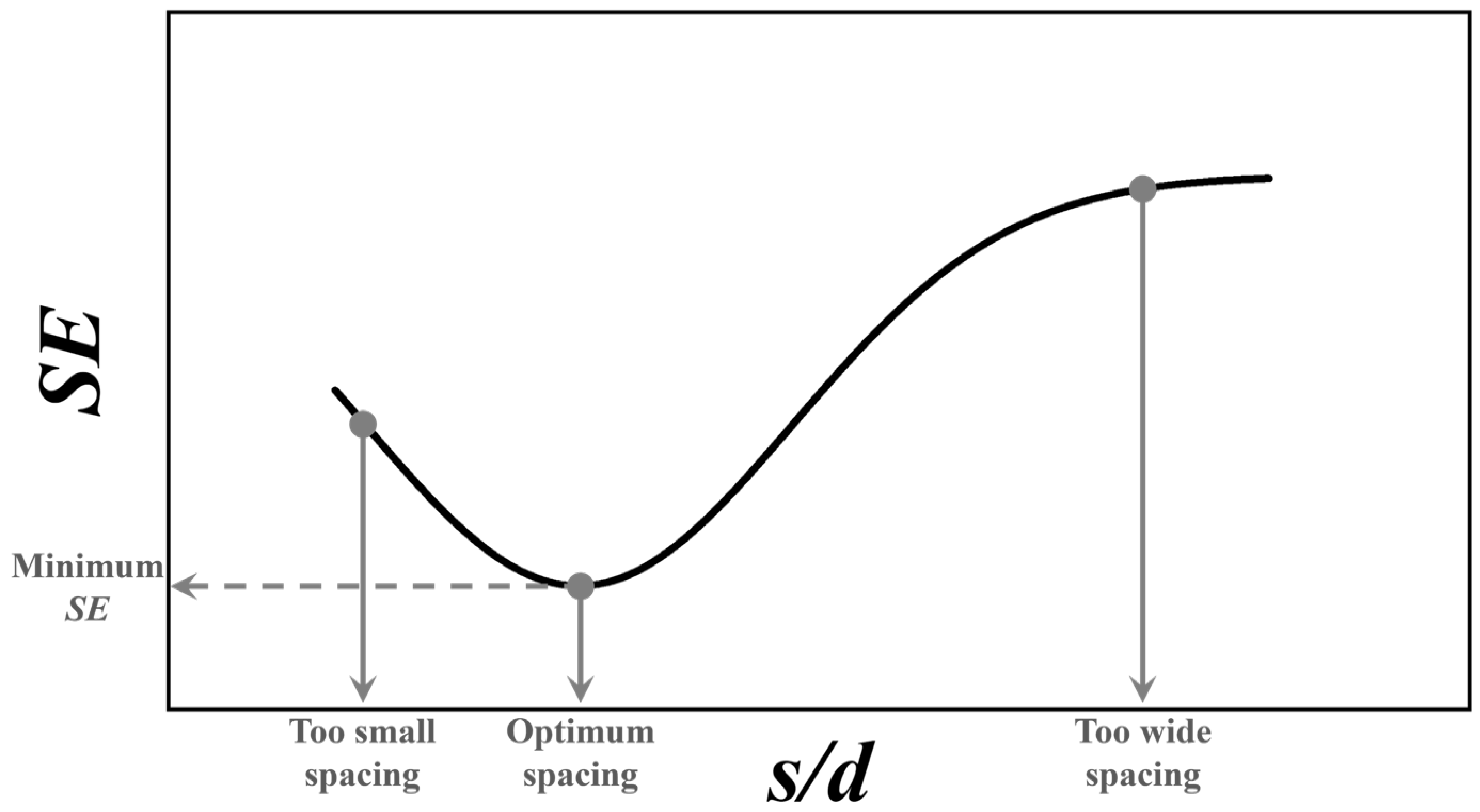

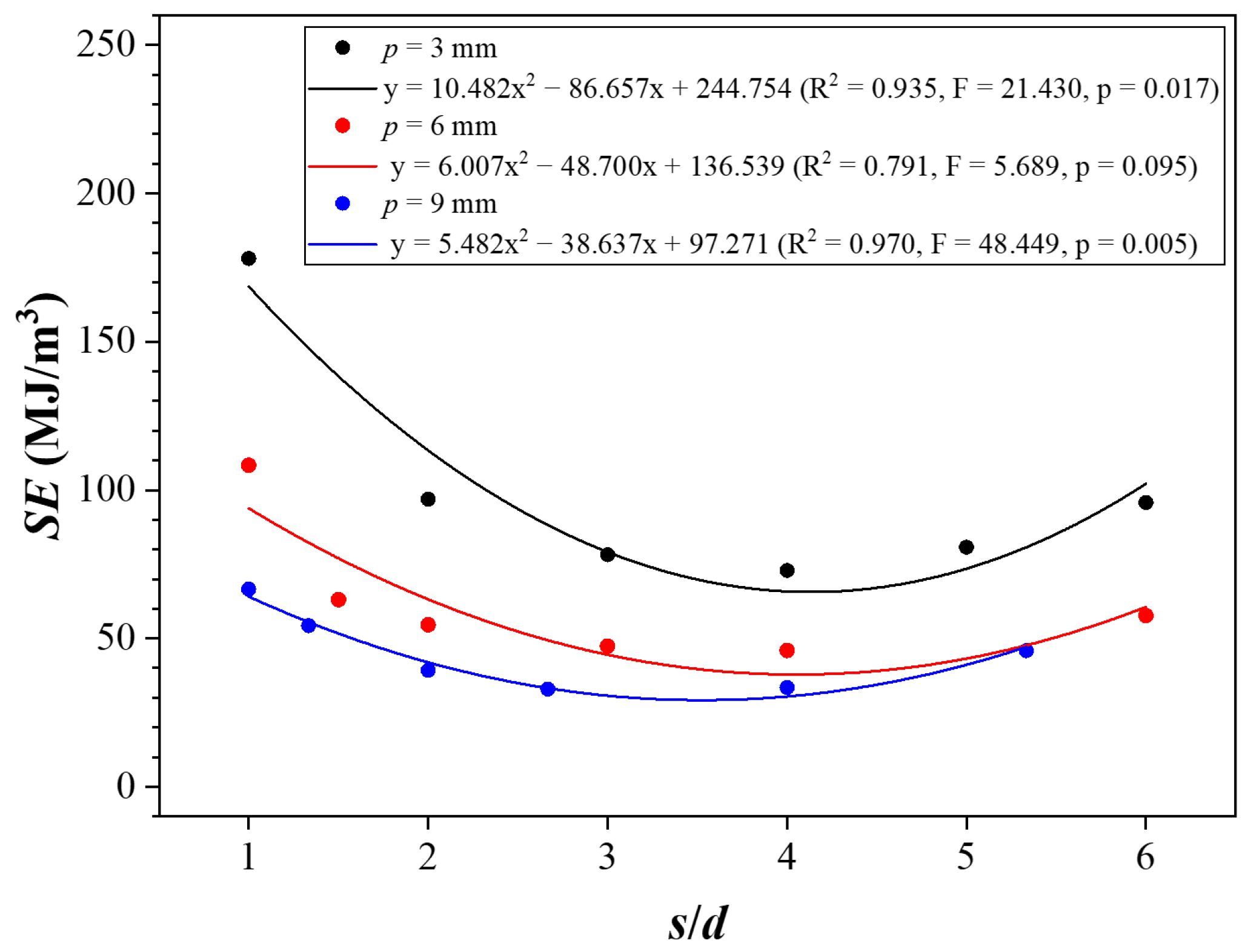

3.2.1. Optimal Cutting Conditions Using SE Methodology

3.2.2. Comparison with SE Methodology

3.2.3. Assessment of Proposed Methodology

4. Conclusions

- FC and FN exhibited linear and power function relationships, respectively, with increasing penetration depth and spacing. Spacing more significantly influenced both FC and FN than did penetration depth. However, the optimal cutting conditions could not be predicted based on the relationship between the tool forces and cutting parameters.

- FNm/FCm exhibited a linear decrease as the penetration depth increased, but it did not show any correlation with the spacing. Additionally, FNm/FCm demonstrated the strongest correlation with s/d, increasing within the power function relationship as s/d increased. However, the optimal cutting conditions could not be predicted, even for the relationship between FNm/FCm and the cutting parameters.

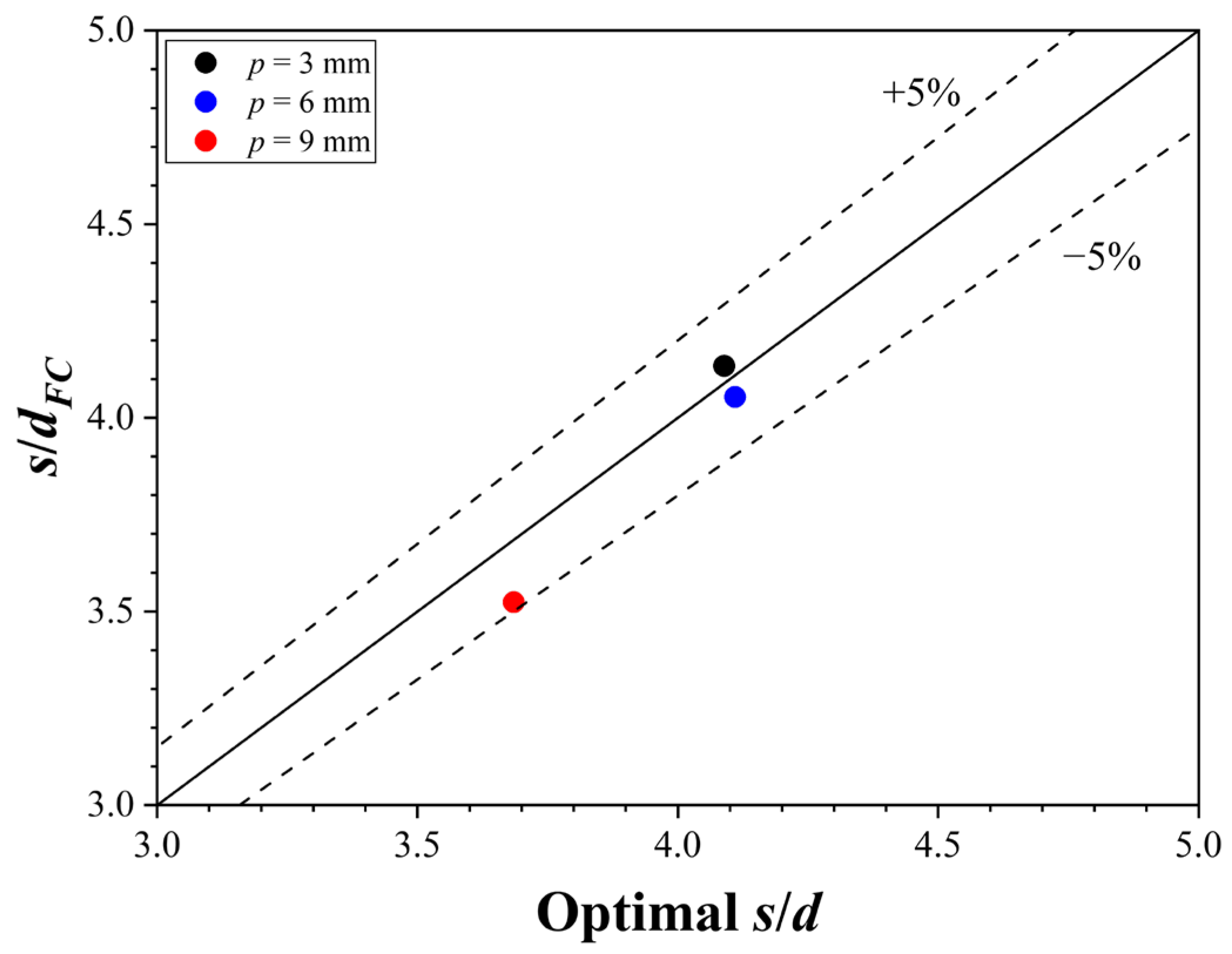

- FNp/FNm and FCp/FCm exhibited a parabolic relationship with s/d. They increased as s/d increased up to a certain point, after which they decreased, behavior similar to that observed for the relationship between SE and s/d. However, the relationship between FNp/FNm and s/d was not significant. Therefore, it was assumed that the optimal cutting conditions could be predicted based on the relationship between FCp/FCm and s/d.

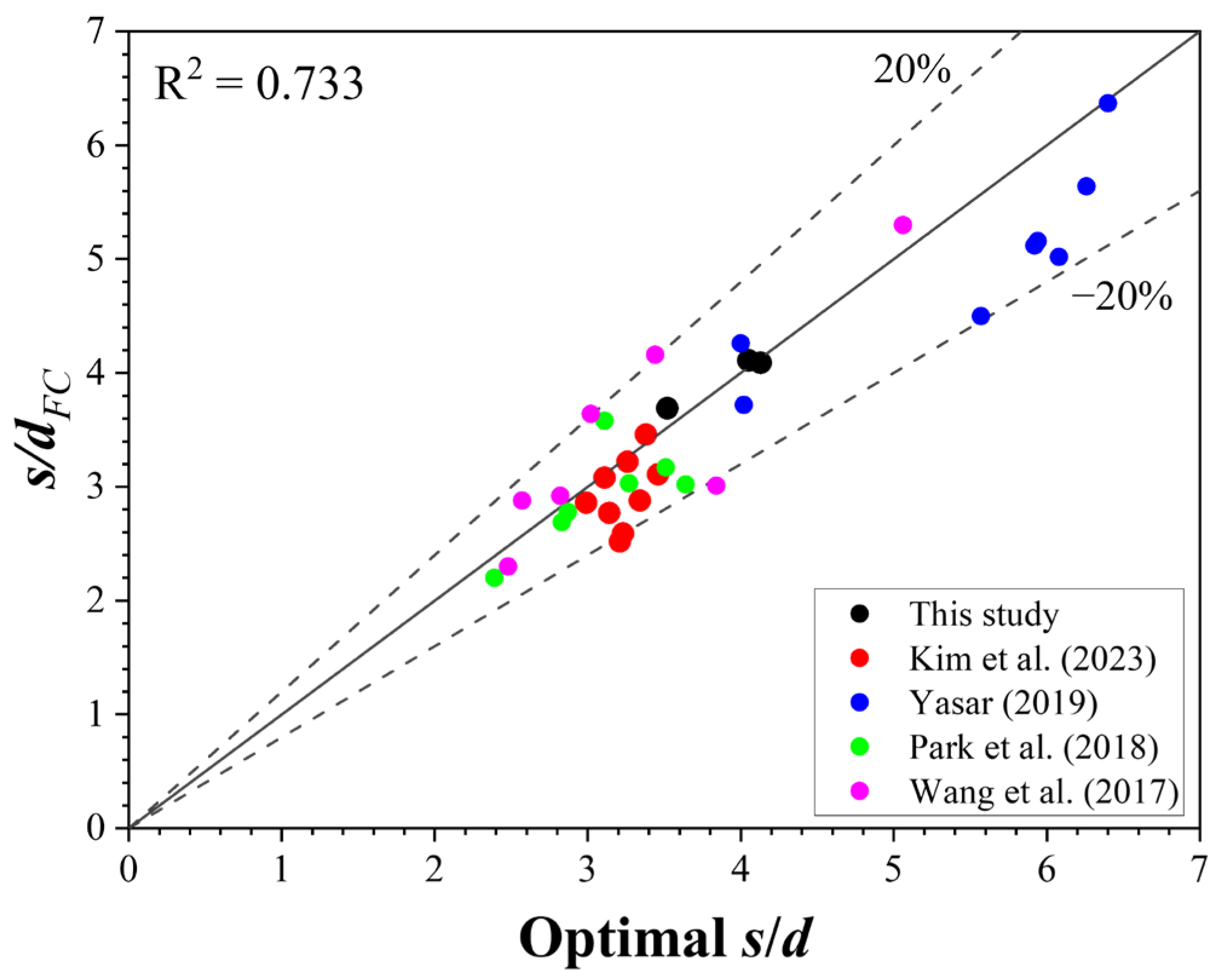

- The optimal s/d for the conical pick in Finike limestone was between 3 and 5, and FCp/FCm reached its maximum value when s/d was between 3 and 5. The difference between the optimal s/d and s/dFC was less than 5%. Furthermore, the proposed methodology showed reasonable agreement with the results of standard techniques, with a margin of error within 20%, when compared with the results of the LCM test performed in previous studies that employed drag-type tools.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bao, R.H.; Zhang, L.C.; Yao, Q.Y.; Lunn, J. Estimating the peak indentation force of the edge chipping of rocks using single point-attack pick. Rock Mech. Rock Eng. 2011, 44, 339–347. [Google Scholar] [CrossRef]

- Balci, C.; Bilgin, N. Correlative study of linear small and full-scale rock cutting tests to select mechanized excavation machines. Int. J. Rock Mech. Min. Sci. 2007, 44, 468–476. [Google Scholar] [CrossRef]

- Bilgin, N.; Demircin, M.A.; Copur, H.; Balci, C.; Tuncdemir, H.; Akcin, N. Dominant rock properties affecting the performance of conical picks and the comparison of some experimental and theoretical results. Int. J. Rock Mech. Min. Sci. 2006, 43, 139–156. [Google Scholar] [CrossRef]

- Vogt, D. A review of rock cutting for underground mining: Past, present, and future. J. S. Afr. Inst. Min. Metal. 2016, 116, 1011–1026. [Google Scholar] [CrossRef]

- Ayawah, P.E.A.; Kaba, A.G.A.; Gertsch, L.S. A novel approach for determining cutting geometry for TBM using full-scale laboratory linear rock cutting and PFC3D-based numerical simulations. Tunn. Undergr. Space Technol. 2024, 144, 105559. [Google Scholar] [CrossRef]

- Gertsch, R.; Gertsch, L.; Rostami, J. Disc cutting tests in Colorado Red Granite: Implications for TBM performance prediction. Int. J. Rock Mech. Min. Sci. 2007, 44, 238–246. [Google Scholar] [CrossRef]

- Rostami, J.; Ozdemir, L.; Nilson, B. Comparison between CSM and NTH hard rock TBM performance prediction models. In Proceedings of the Annual Technical Meeting of the Institute of Shaft Drilling Technology, Las Vegas, NV, USA, 1–3 May 1996. [Google Scholar]

- Chang, S.-H.; Choi, S.-W.; Bae, G.-J.; Jeon, S. Performance prediction of TBM disc cutting on granitic rock by the linear cutting test. Tunn. Undergr. Space Technol. 2006, 21, 271. [Google Scholar] [CrossRef]

- Copur, H.; Bilgin, N.; Balci, C.; Tumac, D.; Avunduk, E. Effects of Different Cutting Patterns and Experimental Conditions on the Performance of a Conical Drag Tool. Rock Mech. Rock Eng. 2017, 50, 1585–1609. [Google Scholar] [CrossRef]

- Abu Bakar, M.Z.; Gertsch, L.S. Evaluation of saturation effects on drag pick cutting of a brittle sandstone from full scale linear cutting tests. Tunn. Undergr. Space Technol. 2013, 34, 124–134. [Google Scholar] [CrossRef]

- Balci, C. Correlation of rock cutting tests with field performance of a TBM in a highly fractured rock formation: A case study in Kozyatagi-Kadikoy metro tunnel, Turkey. Tunnl. Undergr. Space Technol. 2009, 24, 423–435. [Google Scholar] [CrossRef]

- Balci, C.; Tumac, D. Investigation into the effects of different rocks on rock cuttability by a V-type disc cutter. Tunn. Undergr. Space Technol. 2012, 30, 183–193. [Google Scholar] [CrossRef]

- Ma, H.; Gong, Q.; Wang, J.; Yin, L.; Zhao, X. Study on the influence of confining stress on TBM performance in granite rock by linear cutting test. Tunn. Undergr. Space Technol. 2016, 57, 145–150. [Google Scholar] [CrossRef]

- Shaterpour-Mamaghani, A.; Copur, H.; Gumus, A.; Tumac, D.; Balci, C.; Erdogan, T.; Dogan, E.; Kocbay, A. Full-Scale linear cutting tests using a button cutter and deterministic performance prediction modeling for raise boring machines. Tunn. Undergr. Space Technol. 2022, 127, 104609. [Google Scholar] [CrossRef]

- Tumac, D.; Balci, C. Investigations into the cutting characteristics of CCS type disc cutters and the comparison between experimental, theoretical and empirical force estimations. Tunn. Undergr. Space Technol. 2015, 45, 84–98. [Google Scholar] [CrossRef]

- Copur, H.; Shaterpour-Mamaghani, A.; Tumac, D.; Balci, C. Relationships between performances of a button cutter and a disc cutter based on full-scale linear cutting tests. Acta Geotech. 2023, 19, 2731–2752. [Google Scholar] [CrossRef]

- Cho, J.W.; Jeon, S.; Jeong, H.Y.; Chang, S.H. Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement. Tunn. Undergr. Space Technol. 2013, 35, 37–54. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, Q.; Peng, X.; Liu, Q.; Liu, J.; Huang, X.; Cui, X.; Cai, T. Full-Scale Linear Cutting Tests to Propose Some Empirical Formulas for TBM Disc Cutter Performance Prediction. Rock Mech. Rock Eng. 2019, 52, 4763–4783. [Google Scholar] [CrossRef]

- Copur, H. Linear stone cutting tests with chisel tools for identification of cutting principles and predicting performance of chain saw machines. Int. J. Rock Mech. Min. Sci. 2010, 47, 104–120. [Google Scholar] [CrossRef]

- Jeong, H.; Jeon, S. Characteristic of size distribution of rock chip produced by rock cutting with a pick cutter. Geomech. Eng. 2018, 15, 811–822. [Google Scholar]

- Kim, H.E.; Ha, S.G.; Rehman, H.; Yoo, H.K. Analysis of Mechanical Excavation Characteristics by Pre-Cutting Machine Based on Linear Cutting Tests. Appl. Sci. 2023, 13, 1205. [Google Scholar] [CrossRef]

- Copur, H.; Balci, C.; Tumac, D.; Bilgin, N. Field and laboratory studies on natural stones leading to empirical performance prediction of chain saw machines. Int. J. Rock Mech. Min. Sci. 2011, 48, 269–282. [Google Scholar] [CrossRef]

- Choi, S.-W.; Kang, T.-H.; Lee, C.; Chang, S.-H. Measurement of Pick Cutting Volumes by a 3D Scanner. In Proceedings of the KSCE 2016 Convention, Jeju, Republic of Korea, 19–21 October 2016. [Google Scholar]

- Kim, H.E. Proposal of Optimum Cutting Condition for Pre-Cutting Machine and Indicator of Excavation Efficiency Based on Linear Cutting Tests. Ph.D. Thesis, Hanyang University, Seoul, Republic of Korea, 2023. [Google Scholar]

- Cho, J.W.; Jeon, S.; Yu, S.H.; Chang, S.H. Optimum spacing of TBM disc cutters: A numerical simulation using the three-dimensional dynamic fracturing method. Tunn. Undergr. Space Technol. 2010, 25, 230–244. [Google Scholar] [CrossRef]

- Moon, T.; Oh, J. A study of optimal rock-cutting conditions for hard rock TBM using the discrete element method. Rock Mech. Rock Eng. 2012, 45, 837–849. [Google Scholar] [CrossRef]

- Zhou, P.; Guo, J.; Sun, J.; Zou, D. Theoretical Research and Simulation Analysis on the Cutter Spacing of Double Disc Cutters Breaking Rock. KSCE J. Civ. Eng. 2019, 23, 3218–3227. [Google Scholar] [CrossRef]

- Gong, Q.M.; Zhao, J.; Hefny, A.M. Numerical simulation of rock fragmentation process induced by two TBM cutters and cutter spacing optimization. Tunn. Undergr. Space Technol. 2006, 21, 263. [Google Scholar] [CrossRef]

- Choi, S.O.; Lee, S.J. Three-dimensional numerical analysis of the rock-cutting behavior of a disc cutter using particle flow code. KSCE J. Civ. Eng. 2015, 19, 1129–1138. [Google Scholar] [CrossRef]

- Naghadehi, M.Z.; Mikaeil, R. Optimization of tunnel boring machine (TBM) disc cutter spacing in jointed hard rock using a distinct element numerical simulation. Period. Polytech. Civ. Eng. 2017, 61, 56–65. [Google Scholar] [CrossRef]

- Jiang, B.; Zhao, G.F.; Gong, Q.; Zhao, X.B. Three-dimensional coupled numerical modelling of lab-level full-scale TBM disc cutting tests. Tunn. Undergr. Space Technol. 2021, 114, 103997. [Google Scholar] [CrossRef]

- Tang, M.; Huang, X.; Wang, S.; Zhai, Y.; Zhuang, Q.; Zhang, C. Study of the cutter-rock interaction mechanism during TBM tunnelling in mudstone: Insight from DEM simulations of rotatory cutting tests. Bull. Eng. Geol. Environ. 2022, 81, 298. [Google Scholar] [CrossRef]

- Wang, T.; Yan, C.; Zheng, H.; Ke, W.; Ali, S. Optimum spacing and rock breaking efficiency of TBM double disc cutters penetrating in water-soaked mudstone with FDEM. Tunn. Undergr. Space Technol. 2023, 138, 105174. [Google Scholar] [CrossRef]

- Jeong, H.; Choi, S.; Jeon, S. Effect of skew angle on the cutting performance and cutting stability of point-attack type picks. Tunn. Undergr. Space Technol. 2020, 103, 103507. [Google Scholar] [CrossRef]

- ASTM D7012-14; Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D3967-08; Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens with Flat Loading Platens. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C97/C97M-15; Standard Test Methods for Absorption and Bulk Specific Gravity of Dimension Stone. ASTM International: West Conshohocken, PA, USA, 2015.

- He, X.; Xu, C. Specific energy as an index to identify the critical failure mode transition depth in rock cutting. Rock Mech. Rock Eng. 2016, 49, 1461–1478. [Google Scholar] [CrossRef]

- Wang, X.; Su, O.; Wang, Q.F.; Liang, Y.P. Effect of cutting depth and line spacing on the cuttability behavior of sandstones by conical picks. Arab. J. Geosci. 2017, 10, 525. [Google Scholar] [CrossRef]

- Yang, W.; Xue, Y.; Zhang, X. Experimental study on rock fragmentation by the 19-inch TBM cutter and statistical analysis of debris. In Proceedings of the ISRM International Symposium—8th Asian Rock Mechanics Symposium (ARMS 2014), Sapporo, Japan, 14–16 October 2014. [Google Scholar]

- Gong, Q.M.; Zhao, J.; Jiang, Y.S. In situ TBM penetration tests and rock mass boreability analysis in hard rock tunnels. Tunn. Undergr. Space Technol. 2007, 22, 303–316. [Google Scholar] [CrossRef]

- Bilgin, N.; Copur, H.; Balci, C. Mechanical Excavation in Mining and Civil Industries, 1st ed.; CRC Press: New York, NY, USA, 2013; pp. 1–355. [Google Scholar]

- Khair, A.W. The Effect of Bit Geometry on Rock Cutting Efficiency. Appl. Occup. Environ. Hyg. 1996, 11, 695–700. [Google Scholar] [CrossRef]

- Cook, N.G.W. Analysis of hard-rock cuttability for machines. In Proceeding of the Tunnel and Shaft Conference, Minneapolis, MN, USA, 15–17 May 1968. [Google Scholar]

- Barker, J.S. A laboratory investigation of rock cutting using large picks. Int. J. Rock Mech. Min. Sci. 1964, 1, 519–534. [Google Scholar] [CrossRef]

- Park, J.Y.; Kang, H.; Lee, J.W.; Kim, J.H.; Oh, J.Y.; Cho, J.W.; Rostami, J.; Kim, H.D. A study on rock cutting efficiency and structural stability of a point attack pick cutter by lab-scale linear cutting machine testing and finite element analysis. Int. J. Rock Mech. Min. Sci. 2018, 103, 215–229. [Google Scholar] [CrossRef]

- Yasar, S. Determination of optimum rock cutting data through single pick cutting tests. Geotech. Lett. 2019, 9, 8–14. [Google Scholar] [CrossRef]

| Rock Name | ρ (g/cm3) | E (GPa) | ν | σc (MPa) | σt (MPa) |

|---|---|---|---|---|---|

| Finke limestone | 2.22 | 21.1 | 0.13 | 49 | 5 |

| d (mm) | s (mm) | s/d | FCm (kN) | FNm (kN) | FCp (kN) | FNp (kN) | FCp/FCm | FNp/FNm | FNm/FCm | FNp/FCp | SE (MJ/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 3 | 1 | 1.567 | 0.448 | 3.183 | 0.925 | 2.031 | 2.066 | 0.286 | 0.291 | 178.02 |

| 6 | 2 | 1.650 | 0.594 | 4.139 | 1.284 | 2.508 | 2.164 | 0.360 | 0.310 | 96.91 | |

| 9 | 3 | 1.994 | 0.727 | 5.204 | 1.965 | 2.610 | 2.701 | 0.365 | 0.378 | 78.22 | |

| 12 | 4 | 2.187 | 0.834 | 5.294 | 1.796 | 2.419 | 2.154 | 0.381 | 0.339 | 72.89 | |

| 15 | 5 | 2.533 | 0.937 | 6.114 | 2.062 | 2.425 | 2.200 | 0.370 | 0.336 | 80.75 | |

| 18 | 6 | 2.733 | 1.037 | 6.752 | 2.440 | 2.470 | 2.352 | 0.380 | 0.361 | 95.80 | |

| 6 | 6 | 1 | 3.325 | 0.900 | 6.933 | 1.369 | 2.085 | 1.521 | 0.271 | 0.197 | 108.33 |

| 9 | 1.5 | 3.506 | 0.961 | 7.718 | 1.699 | 2.201 | 1.768 | 0.274 | 0.220 | 63.04 | |

| 12 | 2 | 3.820 | 1.093 | 8.830 | 2.135 | 2.312 | 1.953 | 0.286 | 0.242 | 54.57 | |

| 18 | 3 | 4.594 | 1.376 | 11.055 | 4.135 | 2.406 | 3.005 | 0.299 | 0.374 | 47.37 | |

| 24 | 4 | 4.937 | 1.575 | 13.618 | 4.783 | 2.758 | 3.036 | 0.319 | 0.351 | 45.95 | |

| 36 | 6 | 5.656 | 1.921 | 13.346 | 3.786 | 2.360 | 1.971 | 0.340 | 0.284 | 57.71 | |

| 9 | 9 | 1 | 4.868 | 0.777 | 11.342 | 2.182 | 2.330 | 2.809 | 0.160 | 0.192 | 66.61 |

| 12 | 1.33 | 5.125 | 0.878 | 12.144 | 1.972 | 2.370 | 2.247 | 0.171 | 0.163 | 54.26 | |

| 18 | 2 | 6.066 | 1.425 | 14.188 | 3.699 | 2.328 | 2.597 | 0.235 | 0.262 | 39.21 | |

| 24 | 2.67 | 6.570 | 1.818 | 16.483 | 3.774 | 2.509 | 2.076 | 0.277 | 0.229 | 32.89 | |

| 36 | 4 | 7.157 | 2.271 | 18.141 | 4.840 | 2.535 | 2.131 | 0.317 | 0.267 | 33.46 | |

| 48 | 5.33 | 8.135 | 2.644 | 19.646 | 5.615 | 2.415 | 2.123 | 0.325 | 0.286 | 45.87 |

| Regression Equation | R2 | F-Value | p-Value |

|---|---|---|---|

| 0.804 | 65.789 | 0.000 | |

| 0.680 | 27.613 | 0.000 | |

| 0.371 | 9.425 | 0.007 | |

| 0.195 | 3.386 | 0.087 |

| Regression Equation | R2 | F-Value | p-Value |

|---|---|---|---|

| 0.676 | 137.844 | 0.000 | |

| 0.723 | 151.232 | 0.000 | |

| 0.932 | 632.802 | 0.000 | |

| 0.843 | 257.610 | 0.000 |

| Regression Equation | R2 | F-Value | p-Value | Coefficient | |||||

|---|---|---|---|---|---|---|---|---|---|

| d | s | Constant | |||||||

| t | p-Value | t | p-Value | t | p-Value | ||||

| 0.995 | 1454.468 | 0.000 | 30.820 | 0.000 | 23.698 | 0.000 | −2.442 | 0.027 | |

| 0.977 | 320.838 | 0.000 | 13.412 | 0.000 | 12.259 | 0.000 | −1.498 | 0.155 | |

| 0.961 | 183.104 | 0.000 | 3.099 | 0.007 | 14.996 | 0.000 | 2.606 | 0.020 | |

| 0.839 | 39.189 | 0.000 | 1.557 | 0.140 | 6.859 | 0.000 | 1.429 | 0.173 | |

| Regression Equation | R2 | F-Value | p-Value |

|---|---|---|---|

| 0.502 | 16.134 | 0.001 | |

| 0.529 | 397.166 | 0.000 | |

| 0.154 | 1.367 | 0.285 | |

| 0.614 | 11.935 | 0.000 |

| Regression Equation | R2 | F-Value | p-Value | Coefficient | |||||

|---|---|---|---|---|---|---|---|---|---|

| d | s | Constant | |||||||

| t | p-Value | t | p-Value | t | p-Value | ||||

| 0.892 | 62.024 | 0.000 | −10.882 | 0.000 | 7.364 | 0.000 | 27.853 | 0.000 | |

| 0.665 | 14.898 | 0.000 | −5.410 | 0.000 | 3.264 | 0.005 | 14.641 | 0.000 | |

| 0.195 | 1.818 | 0.196 | −0.892 | 0.386 | 1.906 | 0.076 | 22.626 | 0.000 | |

| 0.004 | 0.027 | 0.974 | 0.179 | 0.860 | 0.042 | 0.967 | 8.056 | 0.000 | |

| d (mm) | Regression Equation | R2 | F-Value | p-Value |

|---|---|---|---|---|

| 3 | 0.935 | 21.430 | 0.017 | |

| 6 | 0.791 | 5.689 | 0.095 | |

| 9 | 0.970 | 48.449 | 0.005 |

| No. | References | Cutting Tools | Rock Types | σc (MPa) | d (mm) | Optimal s/d | s/d FC |

|---|---|---|---|---|---|---|---|

| 1 | This study | Conical pick | Finike limestone | 49.00 | 3 | 4.13 | 4.09 |

| 6 | 4.05 | 4.11 | |||||

| 9 | 3.52 | 3.69 | |||||

| 2 | Kim et al. [21] | Chisel pick | Cement mortar | 18.00 | 3 | 3.34 | 2.88 |

| 6 | 3.26 | 3.22 | |||||

| 9 | 3.38 | 3.46 | |||||

| 29.30 | 9 | 3.21 | 2.52 | ||||

| 42.00 | 3 | 3.46 | 3.11 | ||||

| 6 | 2.99 | 2.86 | |||||

| 9 | 3.23 | 2.59 | |||||

| 51.80 | 6 | 3.11 | 3.08 | ||||

| 9 | 3.14 | 2.77 | |||||

| 3 | Wang et al. [39] | Conical pick | Sandstone | 17.91 | 3 | 5.06 | 5.30 |

| 6 | 2.48 | 2.30 | |||||

| 9 | 2.57 | 2.88 | |||||

| 12 | 3.02 | 3.64 | |||||

| 79.20 | 3 | 2.82 | 2.92 | ||||

| 6 | 3.44 | 4.16 | |||||

| 9 | 3.84 | 3.01 | |||||

| 4 | Park et al. [46] | Conical pick | Cement mortar | 21.00 | 4 | 3.51 | 3.17 |

| 3.11 | 3.58 | ||||||

| 6 | 3.27 | 3.03 | |||||

| 41.00 | 4 | 3.64 | 3.02 | ||||

| 6 | 2.82 | 2.92 | |||||

| 57.00 | 4 | 3.44 | 4.16 | ||||

| 2.39 | 2.20 | ||||||

| 6 | 2.87 | 2.78 | |||||

| 2.83 | 2.69 | ||||||

| 5 | Yasar [47] | Conical pick | Red andesite | 72.85 | 9 | 4.02 | 3.72 |

| Grey andesite | 99.92 | 9 | 5.94 | 5.16 | |||

| Green tuff | 51.65 | 9 | 5.92 | 5.12 | |||

| Grey tuff | 62.63 | 9 | 6.26 | 5.64 | |||

| Brown vitric tuff | 88.15 | 9 | 6.08 | 5.02 | |||

| Yellow vitric tuff | 62.48 | 9 | 3.68 | 2.59 | |||

| Metasiltstone | 1.89 | 9 | 5.57 | 4.50 | |||

| Crystal tuff | 2.44 | 9 | 4.00 | 4.26 | |||

| Volcanic sandstone | 12.34 | 9 | 6.40 | 6.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-e.; Hwang, S.-p.; Yoo, W.-k.; Kim, W.-s.; Kim, C.-y.; Yoo, H.-k. Laboratory-Scale Limestone Rock Linear Cutting Tests with a Conical Pick: Predicting Optimal Cutting Conditions from Tool Forces. Buildings 2024, 14, 2772. https://doi.org/10.3390/buildings14092772

Kim H-e, Hwang S-p, Yoo W-k, Kim W-s, Kim C-y, Yoo H-k. Laboratory-Scale Limestone Rock Linear Cutting Tests with a Conical Pick: Predicting Optimal Cutting Conditions from Tool Forces. Buildings. 2024; 14(9):2772. https://doi.org/10.3390/buildings14092772

Chicago/Turabian StyleKim, Han-eol, Sung-pil Hwang, Wan-kyu Yoo, Woo-seok Kim, Chang-yong Kim, and Han-kyu Yoo. 2024. "Laboratory-Scale Limestone Rock Linear Cutting Tests with a Conical Pick: Predicting Optimal Cutting Conditions from Tool Forces" Buildings 14, no. 9: 2772. https://doi.org/10.3390/buildings14092772

APA StyleKim, H.-e., Hwang, S.-p., Yoo, W.-k., Kim, W.-s., Kim, C.-y., & Yoo, H.-k. (2024). Laboratory-Scale Limestone Rock Linear Cutting Tests with a Conical Pick: Predicting Optimal Cutting Conditions from Tool Forces. Buildings, 14(9), 2772. https://doi.org/10.3390/buildings14092772