Abstract

The distinctly shaped steel-reinforced concrete (SRC) column–beam framing system offers an innovative and tailored structural solution that combines load-bearing capabilities with architectural esthetics. This study introduces an innovative joint design methodology, focusing on examining the seismic responsiveness of the uniquely designed SRC columns when interconnected with reinforced concrete (RC) beams, subjected to bidirectional low cycle loading patterns through precisely calibrated pseudo-static evaluations with varied stirrup spacing. A comparative assessment was undertaken, comparing the joints of SRC test specimens with their RC counterparts, ensuring equivalency in steel and reinforcement area to maintain fairness. The evaluation encompassed a thorough examination of hysteresis loop backbone curves, as well as load–strain hysteresis patterns. It was found that the specimens incorporating structural steel and tubes demonstrated enhanced energy dissipation capabilities, surpassing other specimens in this critical performance aspect. An in-depth analysis was also conducted by comparing the ductility coefficient and the equivalent viscous damping coefficient to evaluate the joints’ performance in dissipating energy, coupled with a thorough examination of their stiffness deterioration behavior. The conclusion is that the energy dissipation capacity and stiffness degradation of distinctly shaped SRC column joints are superior to those of conventional, distinctly shaped concrete column joints, indicating promising application prospects.

1. Introduction

Steel-reinforced concrete (SRC) columns, featuring distinctive shapes, offer an esthetically superior alternative to the conventional rectangular columns typically utilized in frame structures. These innovative configurations, specifically the L-shaped, cross-shaped, T-shaped, and Z-shaped designs, substitute the conventional rectangular cross-section. This substitution underscores the paramount importance of their enhanced ductility, structural robustness, and seismic resilience. These attributes are vital considerations in the realm of architectural design, as they significantly contribute to the overall safety and durability of structures during seismic events. A joint is an important part connecting and working together with beams and columns [1]. The joints of a frame are an important part of the seismic performance of a building, and fracturing of the joints is usually one of the causes of damage to the entire structure. The earthquake performance of the joints directly affects the seismic resistance of the entire structure [2,3].

Earthquake records indicate that the majority of damage sustained by frame structures is concentrated at or originates from the failure of the joints [4,5,6]. Recognizing the vulnerability of joints during seismic events, the investigation into their behaviors has garnered widespread interest among researchers globally. Consequently, conducting experimental analyses to evaluate the shear resistance and seismic responses of reinforced concrete beam–column connections is imperative [7,8,9]. A significant number of researchers have undertaken experimental studies to comprehensively explore the multifaceted characteristics of reinforced concrete (RC) columns, encompassing their shear resistance [10], seismic responses [8,11], and mechanical capabilities. The examination is particularly focused on square-shaped columns, along with unconventional geometries such as T-shaped [11], L-shaped [12,13], and other configurations, when they are interconnected with RC beams. The objective is to gain a comprehensive understanding of their structural behaviors and performances under various conditions.

Distinctly shaped SRC columns, renowned for their robust seismic performance, must satisfy not only the operational load demands but also maintain the competency to transmit vertical loads and predetermined seismic forces, even as the joint connections transition into inelastic or elasto-plastic states following repetitive deformations. Hence, examining the mechanical behavior of composite structures subjected to low cycle loads becomes paramount. Feng [14] and colleagues conducted an experimental investigation into the shear reinforcement of CRTS II slab ballastless tracks under such loads. To comprehensively assess the seismic resilience and hysteretic characteristics of structural joints, cyclic loading tests have emerged as a proven methodology across numerous studies [15,16,17,18,19]. Researchers have extensively applied cyclic loading tests to various composite structures, including reinforced concrete T-columns integrated with RC beams [20], precast concrete beam–column joints reinforced with strands [21], non-core-anchored concrete-encased joints [22], concrete-encased steel structure joints [23], steel truss reinforced composite joints [24], and a diverse array of other composite configurations [25,26,27].

When the frame attains an elasto-plastic state, characterized by pronounced deformations and cracking at the joints, it retains the ability to transmit stresses, shear forces, and bending moments. Research into the degradation of load-bearing capacity, ductility, and reinforcement strength post yielding at the joints are necessary to guarantee structural safety. Joints play a pivotal role in shaped column–beam frames, facilitating moment distribution, force transmission, and collapse resistance during seismic events. To understand the seismic response of combined structures, various hybrid frame joints were investigated, including those connecting composite columns with steel beams [28], precast concrete columns featuring grouted corrugated sleeves and decoupled longitudinal reinforcement [29], reinforced concrete cruciform columns [30], and shear walls interconnected with steel trusses [31]. Notably, shear walls reinforced with steel trusses connecting beams exhibited significantly enhanced hysteresis behaviors under seismic loads, and the joints, in general, demonstrated robust performance during seismic excitation. Modeling studies and experiments are also conducted around the investigation of the temperature behaviors of joints and fatigue performance under cyclic flexural strains [32,33,34]. Strengthening schemes have also been proposed [35,36].

By simulating bidirectional loading, this study aimed to achieve a more realistic representation of the seismic forces experienced by buildings during earthquakes. Earthquakes are inherently multi-directional phenomena. In a seismic event, structures are subjected to ground motions that can vary in direction, intensity, and frequency, resulting in complex loading patterns. Therefore, evaluating the seismic performances of structural components under bidirectional loading is crucial to understanding their behaviors in real-world scenarios. The existing literature has extensively examined the seismic behaviors of RC columns and their joints, focusing primarily on conventional shapes like square or rectangular cross-sections. However, there is a notable gap in understanding the seismic responsiveness of distinctly shaped SRC columns interconnected with RC beams, particularly under bidirectional low cycle loading conditions. These distinctly shaped columns, such as L-shaped, cross-shaped, T-shaped, and Z-shaped configurations, offer superior architectural esthetics while also enhancing ductility, structural integrity, and resilience against seismic events. Yet, the behaviors of these unique joints under seismic loading remain understudied.

This study introduces a unique joint design comprising distinctly shaped SRC columns and an RC beam, featuring a novel reinforcement technique. This technique utilizes a circular steel tube as the core, surrounded by structural steel, forming the core reinforcement. The beam reinforcement is strategically positioned along both its vertical sides, extending into the column for anchoring purposes and adhering to the structural steel within the joint. The experimental setup encompassed four specifically designed specimens: three were distinctly shaped SRC column joints, and the remaining one was a distinctly shaped RC column. A pivotal design parameter in this study was the proportion of the stirrup, which was varied among the specimens. Low cycle loading tests were subsequently performed, and the outcomes were analyzed by considering the hysteresis curves and assessing the energy dissipation capabilities. Through pseudo-static testing, we comprehensively evaluate the seismic performances of these joints, focusing on their energy dissipation capabilities, stiffness degradation behaviors, and ductility. By comparing SRC joints against conventional RC joints under equivalent conditions, we demonstrated the advantages of the proposed design. This analysis provided insights into the energy dissipation capacity of the proposed joints. Additionally, a comprehensive seismic performance assessment was undertaken to demonstrate the efficacy and robustness of the proposed joint design.

2. Experimental Design and Preparation

2.1. Materials and Specimens

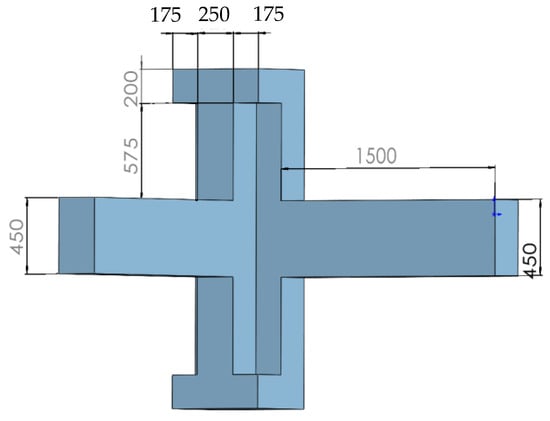

As earthquakes generate forces in multiple directions, bidirectional loading patterns can better simulate the actual seismic forces experienced by buildings during earthquakes. For anti-seismic performance evaluation and achieving a more nuanced recreation of the stress performance at corner joints during bidirectional earthquakes, twin-beam specimens with mid-side joints were designed, which were subjected to a bidirectional, low-frequency cyclic loading regime. This experimental setup comprised four such specimens, each designed to simulate the stress environment of corner joints under the influence of bidirectional seismic forces. Figure 1 presents the schematic diagram of these specimens, while Table 1 outlines the key parameters and their corresponding explanations utilized in this study. There are four specimens involved, numbered JD-1, JD-2, JD-3, and JD-4, all designed in accordance with the Chinese Code for the design of concrete structures [37] and the Chinese Code for the Seismic Design of Buildings [38]. Each specimen incorporates two beams that connect to an SRC column, forming a joint core area at their intersection, which are designated as beam ① and beam ②, based on their respective loading positions. The dimensions of the sections and the material specifications of the reinforcing bars used are detailed in Table 2. All specimens, including the cubic standard test specimens and the main specimens, were constructed using the same C30 concrete mix design. This mix was carefully formulated to meet the specified strength requirements and ensure consistent performances across all specimens. The concrete mix design was verified by both laboratory tests and field application to ensure its suitability for the intended purpose. All specimens underwent a standardized 28-day curing process to ensure optimal strength development. To further guarantee consistency in strength, both the cubic standard test specimens and the main specimens were cured outdoors under identical conditions. This included maintaining similar temperature and humidity levels during the entire curing period. By curing the specimens together, the potentials for variability due to differences in environmental factors were minimized. Cubic standard test specimens (each measuring 150 mm × 150 mm × 150 mm) were retained during the pouring of each specimen. To guarantee consistency in strength, compressive strength measurements and tests were conducted on the same day. A series of strain gauges, comprising both concrete and rebar gauges, were affixed to strategic locations on each specimen, including fracture-prone joint areas, longitudinal rebars within the beams, stirrups, and steel ribs at the joints. The actual mechanical property indices of these tests are summarized in Table 3.

Figure 1.

The stereogram of the specimens.

Table 1.

Terms covered in this article.

Table 2.

Details of the specimens.

Table 3.

Mechanical properties of the concrete.

To facilitate loading, each specimen was equipped with a rectangular capital, within which closely spaced ϕ12@60 and ϕ12@80 bar mats were arranged in a crisscross pattern, ensuring efficient force transmission to the column. All specimens incorporated bars with diameters of 25 mm and 20 mm at the beam’s top and bottom, respectively. This arrangement ensured that the loads remained within the servo-loaded actuator’s capacity even during failure of the beam’s end or joint.

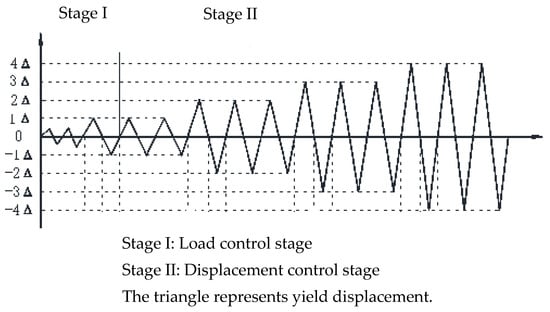

2.2. Loading System and Measurement

The test setup is illustrated in Figure 2, utilizing a pseudo-static testing methodology. To guarantee unrestrained horizontal movement of the specimens under both vertical and horizontal loads, a freely sliding hinge was incorporated, supplying vertical load at the column capital and the upper rigid beam. To precisely and efficiently simulate the bidirectional earthquake effects, subjecting the joint region to the most severe conditions, this test employed a system where a low-frequency cyclic load was incrementally applied from both ends of the beam. To ensure the accurate application of the axial force centered precisely on the cross-section, a geometric alignment procedure was adopted. This ensured that the predetermined axial force was evenly and fully applied to the cross-section. In the experiment, to ensure uniform and centered loading, preloading was conducted from one to two times. The specific loads applied to the four specimens were 1000 kN, 800 kN, and 800 kN for JD-2, JD-3, and JD-4, respectively, while specimen JD-1 received no axial force. Specimens D-3 and JD-4 were under the same axial load of 800 kN, which enabled the comparison of the SRC joint and normal RC joint subjected to same loading conditions. A load–displacement hybrid control scheme was adopted as the loading criterion, divided into two distinct stages, as illustrated in Figure 3. The first stage was the load control stage, which was the small deformation stage before applying the yielding load to the specimen. The second stage was the displacement control stage, which occurred after the specimen yielded. In addition, each displacement level was subjected to three load cycles.

Figure 2.

Test field loading devices.

Figure 3.

Loading patterns.

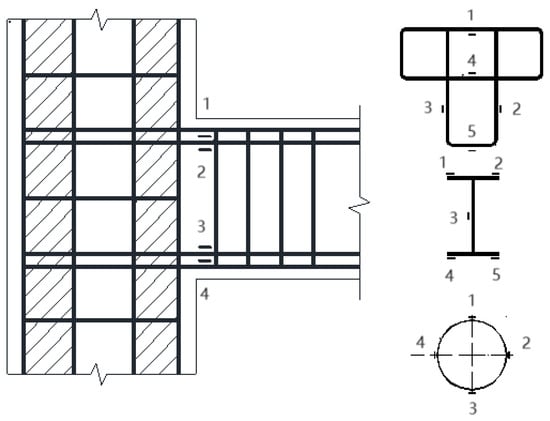

Strain gauges were strategically positioned at the bars, I-steel, and tubes, as shown in Figure 4. To assess the stress state of the stirrups, additional resistance strain gauges were utilized to measure their strains within the plastic hinge zone and the joint’s core area. To obtain a clear understanding of how the steel forces were distributed within the joint area, strain gauges were strategically placed along the two vertical directions outside the steel tube and also on the flange and web sections of the structural steel. This arrangement allowed for the precise measurement of the strains, providing valuable insights into the force distributions. Deflection measurements were obtained using displacement sensors mounted on the actuator, with the collected data subsequently transmitted to a computer for automated gathering under varying load conditions.

Figure 4.

Distribution of strain gauges in the specimens.

3. Test Procedures and Crack Observation

3.1. Specimen JD-1

The distance between the stirrups located within the joint core area measured 100 mm for JD-1, and the column capital experienced no axial forces. During the initial loading cycle, beam ① experienced a downward force, whereas beam ② experienced an upward force. In the initial stage, when the force reached 70 kN, we found that the specimen had some rigid body displacement together with the loading device, and some parts tended to overturn. Therefore, we adjusted the displacement-controlling value in the displacement-controlling stage to make it agree with the actual yielding displacement. In the first circulation, when the load reached about 75% of the yielding load and some cracks were going to appear, the readings of the displacement and strain were growing linearly. It proved that the specimen was at the elastic stage, and the diagonal cracks appeared early. When the loads reached 35 kN, which were in a downward direction on beam ① and in an upward direction on beam ②, some cracks appeared at end of the beam and tended to expand to the core area. These cracks belonged to curved shear cracks. Initially, the width of cracks was about 0.02 mm. When the applied loads reached the maximum specified controlling load, the specimen was unloaded and subjected to reversed loads that were approximately 75% of its yielding capacity. During this process, the load at which reversed cracks initially appeared was recorded. Subsequently, testing continued with the application of a second load cycle, ultimately leading to the yielding of the beam. Specifically, at the point of yielding, the downward displacement for beam ① was measured as 18.4 mm, while the upward displacement for beam ② was 12.5 mm. Following this, the specimen was once again unloaded and subjected to reversed loading conditions until it yielded again, resulting in a yield displacement of 19.1 mm for beam ① in the upward direction and a downward yield displacement of 13.8 mm for beam ②.

When the loads entered reversed circulation, some subtle cracks appeared on the diagonal of the core area and gathered. At that time, shear deformation at the joint and strains of the stirrups far from end of the beam were small. The strains of the stirrups were less than 600 με. Next, some crossed diagonal cracks appeared in core area in the displacement-controlling circulation. The cracks were about 0.1~0.2 mm wide and did not cut through the whole joint. The widths of the cracks at the end of the beam grew noticeably faster than those in the core area.

3.2. Specimen JD-2

In the load-controlling stage, the maximum controlling load was 100 kN. When the load at the end of the beam was exerted at 35 kN in a downward direction, the first crack appeared at the beam end near the joint area. At the time, no crack had appeared in the joint area. The maximum stretching strain and compressive strain of the longitudinal reinforcement were 382 με and −283 με in beam ① and 267 με and −271 με in beam ②. The maximum strain of concrete reached 206 με. Arranged at the intersection of the distinctly shaped column and far from the end section of the beam, the steel tubes had small strains: 54 με for the section near the beam and 46 με for the section far from the beam. Structural steel had a larger strain than steel tubes, which reached 106 με. The first time when the load at the beam end reached the reversed value of 50 kN, a subtle reversed crack appeared under the bottom part of the beam. This crack was a bending crack.

As the load grew, the first crack appeared in the core area when the load at the beam end reached 110 kN. The crack appeared along the diagonal of the core area and tended to expand. At that time, the maximum stretching strain and compressive strain of longitudinal reinforcement were 1452 με and −1101 με in beam ① and 1019 με and −970 με in beam ②. The maximum strain of concrete reached 842 με. The steel tubes had small strains: 388 με for the section near the beam and 266 με for the section far from the beam. Structural steel had a larger strain than the steel tubes, reaching 920 με.

The loading test went on, and the second time loads made the specimen yield. Then, the test transferred from the displacement- controlling stage to the controlling load stage. The whole process was similar to joint JD-1’s test.

3.3. Specimen JD-3

Among the specimens, specimen JD-3 possessed the largest stirrup spacing of 200 mm within the joint core. Maintaining a constant axial compression ratio, a force of 800 kN was applied on top of the column. We kept loading until the specimen yielded, and the load criterion had no apparent difference from the first two. In the next displacement-controlling circulations, several crossed diagonal cracks appeared in the core area. The widths of the cracks were too small to cut through the joint. However, the widths of the cracks at the beam end grew fast and were apparently wider than those in the core area. When the displacement ductility factor μΔ reached 3, the cracks in the core area would not grow any more. At that time, destructions mainly happened at the end of the beam. Although the plastic hinges underwent significant damage, the level of destruction within the core area remained relatively unchanged. Consequently, the core area retained an ample shear capacity, ensuring continued structural integrity.

3.4. Specimen JD-4

Specimen JD-4 is the only comparative specimen among the four specimens. Rebars that had a section with an equal area of steel ribs were arranged inside the distinctly shaped column as longitudinal reinforcement. Throughout the test process, the force on the column capital was kept at 800 kN. When the application of loads commenced, the joint remained in an elastic state. The loads were applied in a gradual, incremental manner. Initially, beam ① was subjected to a downward force, while beam ② experienced an upward force. As the magnitude of the loads increased, specifically when beam ① endured a downward load of 40 kN, fine cracks with a width of 0.02 mm emerged at the intersection between the beam and column, subsequently propagating towards the joint. As the loads further intensified, minor rigid body displacements were observed in certain regions. Upon completion of the second loading cycle, the transition to the displacement-controlling stage ensued. Beam ① was subjected to a downward force of 127 kN while beam ② to an upward force of 141 kN. When the specimen yielded for the first time, plenty of diagonal cracks appeared and extended from the load actuator to the joint core area. Then, some cracks appeared in the core area along the diagonal and passed through the intersection of the diagonals of the joint core area. At that time, the strain of beam ① reached 2755 με, while the strain of beam ② reached 2483 με. The strain exhibited by the stirrups located near the end of the beam was notably higher, reaching 1140 με, though this level of strain was insufficient to induce yielding in the stirrups. Conversely, stirrups positioned further away from the beam end displayed lower strain levels, approximately 500 με. At this stage, the stirrups were subjected to some shearing forces within the joint area. It is noteworthy that the strain distributions across the entire length of the stirrups were uneven. Strains of the cracking section were larger than those far from the cracking section. The stress differences in one limb, which were caused by uneven strains were transmitted by the adhesive property of concrete. At that time, the adhesive property was determined to be good, and there was essentially no sliding failure. The anchoring of the longitudinal reinforcement worked well in the joint core area. When the specimen began to yield, we unloaded it and exerted reversed loads. When the reversed load on beam ① reached an upward force of 125 kN and beam ② received a downward force of 155 kN, the beam yielded in a reverse manner, and some visible cracks appeared.

Diagonal cracks appeared in the joint core area: these were about 0.5 mm wide and noticeably larger than those from the joint test on the distinctly shaped steel-reinforced concrete column and reinforcement concrete beam at the same stage.

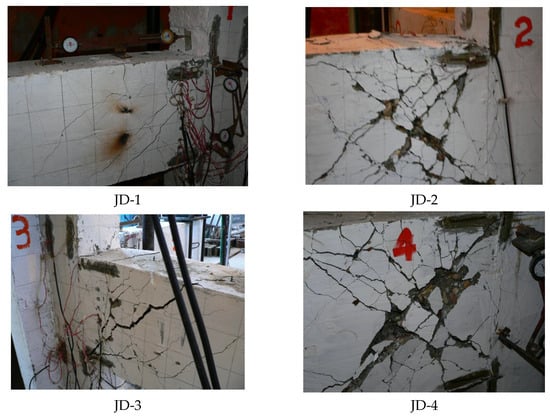

In the yielding displacement control phase, during the initial cycle, beam ① was subjected to a downward force of 133 kN, while beam ② was subjected to an upward force of 177 kN, reaching the peak load capacity. Subsequently, the load direction was reversed, with beam ① receiving an upward force of 137 kN and beam ② a downward force of 151 kN, achieving the reversed peak load capacity. Throughout subsequent cycles, the peak load capacity gradually decreased, indicating a degradation in the overall bearing capacity of the specimen. The crack propagation and damage of specimens JD-1~JD-4 are shown in Figure 5.

Figure 5.

Crack propagation and damage of specimens JD-1~JD-4.

4. Results and Hysteresis Analysis

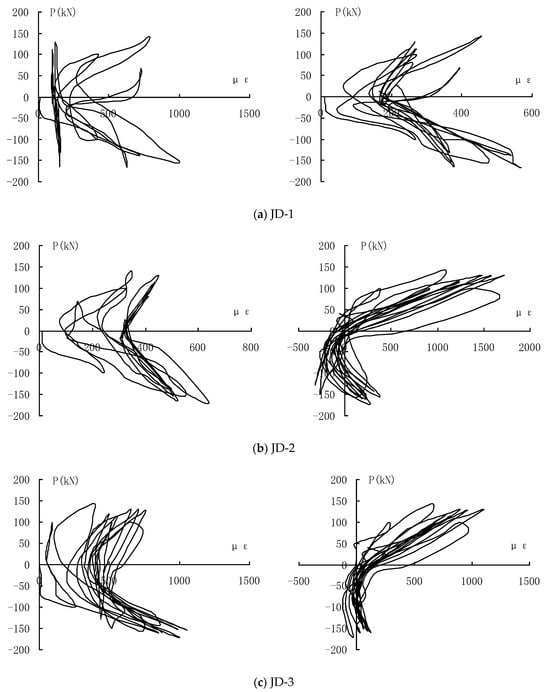

Under the effect of repetitive loads, hysteresis curves comprehensively portray crucial parameters such as the bearing capacity, stiffness, and ductility, as well as energy absorption and dissipation capacities, which are fundamental criteria in the evaluation of seismic resistance. The strain experienced by structural steel (I-beam steel) varies in accordance with alternating loads, and this hysteretic behavior is depicted in Figure 6. Observation of the figure reveals that, during the initial loading phase, the strain remains minimal and grows linearly. As the loads are repeatedly applied, the steel’s strains undergo a cyclic process, diminishing and then augmenting as the load alternates. This underscores that structural steel exerts a confinement effect akin to that of stirrups on concrete. Irrespective of whether the loads are applied in the forward or reverse direction, when they attain their peaks, the confinement effectiveness of both structural steel and stirrups reaches its maximum. With the repetitive application of loads, the confinement capacity of structural steel and the shear forces undergo cyclical variations.

Figure 6.

Hysteretic loops of load–strain curves of the shape steel at the joint core.

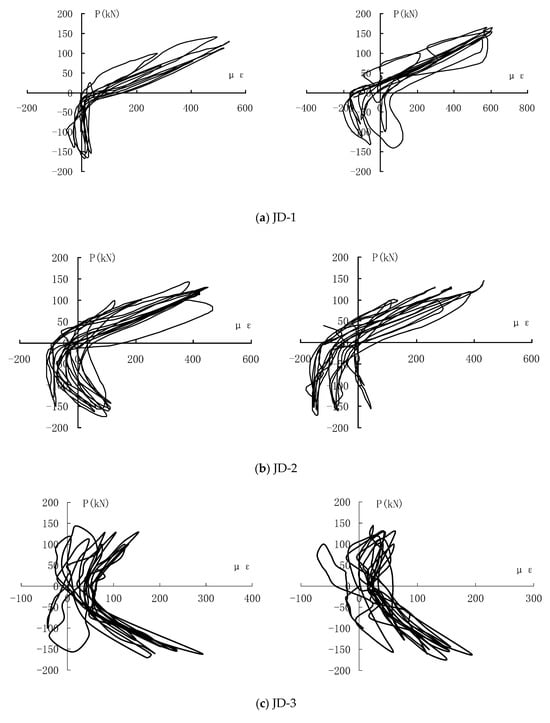

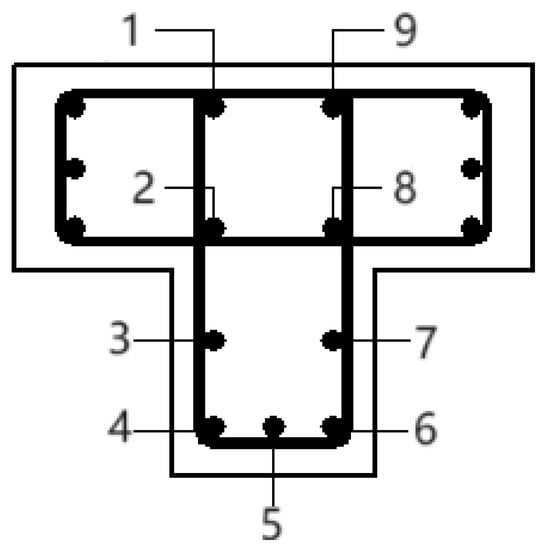

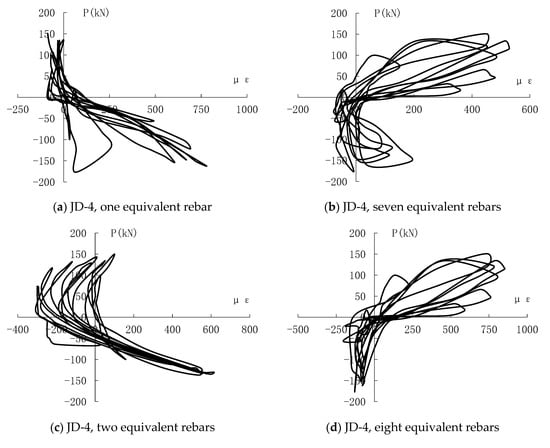

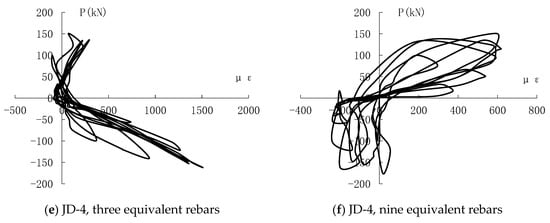

The hysteretic loops of the load–strain curves of the tube at the joint core drawn based on the test are shown in Figure 7. The strains of the steel tube have a special process, where they decrease and then increase without negative growth during each circulation when the loads are alternately exerted. Specimen JD-4 is a common joint of a distinctly shaped reinforced concrete column without structural steel and a steel tube. Based on the equivalent cross-section method, longitudinal rebars (HRB335, diameter 20 mm) with a cross-section area equivalent to JD-1~JD-3 are arranged. Equivalent longitudinal rebars are numbered 1~9. The numbers are shown in Figure 8. The hysteretic loops of the load–strain curves of joint JD-4’s equivalent steel bars under repeated loads are shown in Figure 9.

Figure 7.

Hysteretic loops of load–strain curves of the tube at the joint core.

Figure 8.

Serial numbers of JD-4 equivalent bars.

Figure 9.

Hysteretic loops of load–strain curves of the equivalent steel bars of joint JD-4.

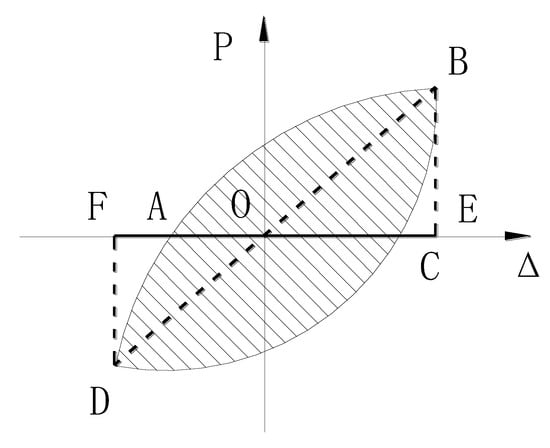

5. Seismic Energy Dissipation Analysis

The energy dissipation of structures and components is usually considered ductile energy expression. The fullness of the hysteresis loops can be understood as the energy dissipation capacity of the component, while the area of a loop is usually considered to be the energy absorbed in said loop. To clarify the calculation of the equivalent viscous damping coefficient (), the areas enclosed within the curve-shaped regions of the ABCD depicted in Figure 10 should be considered. This comprehensive area comprises two distinct subsections, ABC and CDA, as shown in Figure 10. The equivalent viscous damping coefficient () can be calculated to reflect the energy dissipation capacity of the structure.

Figure 10.

Calculation of the coefficient .

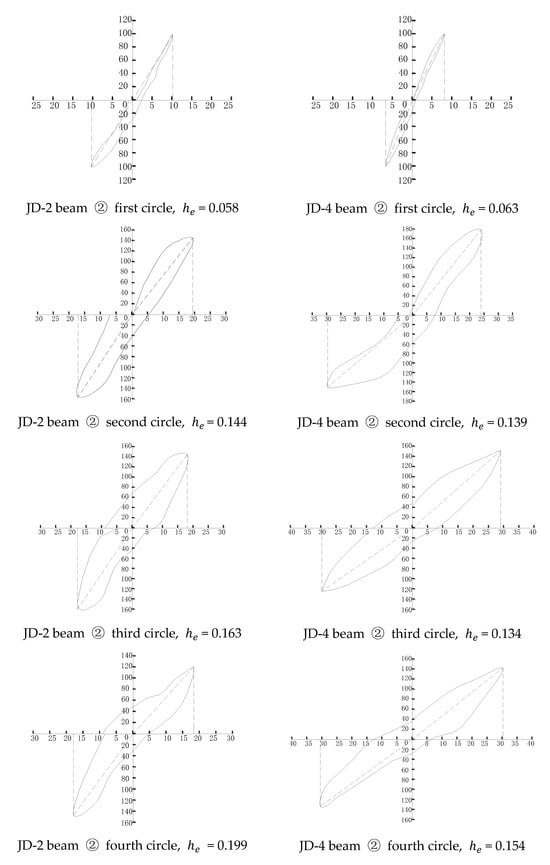

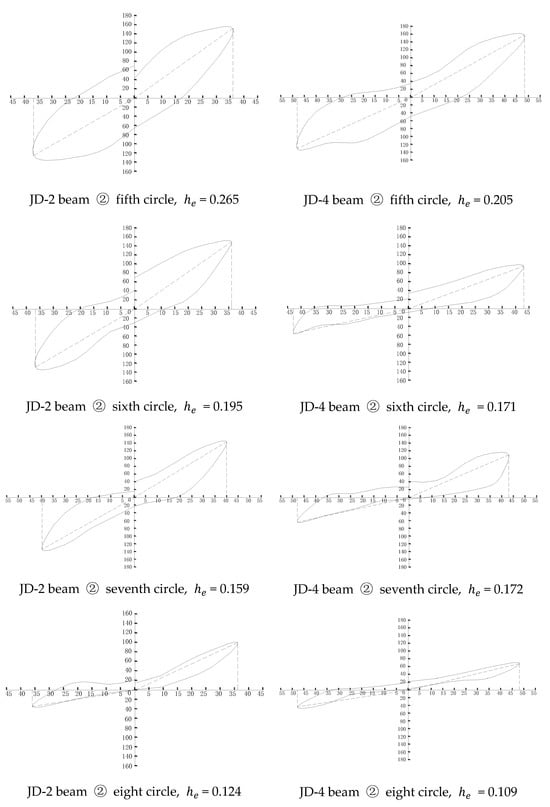

In this test, specimens JD-2 and JD-4 had the same rate of stirrups, and the column reinforcements of JD-2 and JD-4 were made of steel sections and steel bars, respectively. It is noteworthy that the areas of the sections and steel bars are the same. Therefore, specimens JD-2 and JD-4 were compared to reflect the force, energy dissipation, and damage characteristics of shaped column joints with concrete containing steel sections or steel bars. As shown in Figure 11, the equivalent viscous damping coefficients of the first eight cycles of the hysteresis curves of specimens JD-2 and JD-4 were compared in this study.

Figure 11.

Coefficient values of all circles.

In the initial stage, the specimen was in the elastic stage, was small, and the hysteresis curve was not sufficiently plump. The difference between the values of specimen JD-2 and specimen JD-4 was not significant. As the loading cycles progressed, initially rose steadily and attained its maximum value during the fifth cycle, wherein the hysteresis loop resembled a full and rounded shuttle shape.

The equivalent viscous damping coefficients of JD-2 and JD-4 were 0.265 and 0.205, respectively, which proved that the energy dissipation capacity of the reported concrete column joint was better than that of the ordinary reinforced concrete column joint.

During the testing process, the equivalent viscous damping coefficient exhibited a consistent trend for each hysteresis loop, initially increasing and subsequently decreasing in value. Table 4 shows the equivalent viscous damping coefficients for each cycle. Through careful observation, it is apparent that the equivalent viscous damping coefficient exhibited by JD-2 during each cycle surpasses that of JD-4, suggesting a greater capacity for dampening vibrations. Additionally, an examination of Figure 11 reveals that the load–displacement curve traced by JD-2 is more pronounced, and the area encompassed within the coordinate axes, which represents the energy dissipated during each cycle, is consistently larger compared to JD-4. This graphical representation visually underscores the fact that the distinctly shaped SRC columns of JD-2 possess superior energy dissipation properties, indicating their ability to more effectively absorb and dissipate energy during dynamic loading conditions, thereby enhancing the overall structural performance and resilience.

Table 4.

Comparison of coefficient values.

From the results above, the use of a circular steel tube as the core reinforcement in our SRC joints has been proven to significantly enhance their energy dissipation capabilities. The steel tube acts as a restraint, improving the confinement effect of the concrete, which leads to a more ductile failure mode and increased energy absorption during cyclic loading. The hysteresis curves produced during our pseudo-static tests clearly demonstrate the presence of wider loops, suggesting superior energy dissipation capabilities. Furthermore, the strategic positioning of the beam reinforcement extending into the column for anchoring purposes ensures better load transfer and distribution. This reinforcement strategy, combined with the use of structural steel surrounding the steel tube, results in a more robust joint capable of dissipating more energy under seismic loads. Compared to previous studies that used different reinforcement techniques or materials, our SRC joint design exhibits superior energy dissipation due to its integrated multi-material reinforcement system, which benefits from the synergy between steel and concrete.

6. Conclusions

In this study, an innovative joint design methodology for distinctly shaped SRC column–beam framing systems is presented, demonstrating enhanced energy dissipation capabilities, improved ductility, and gradual stiffness degradation under cyclic loading. Through precisely calibrated pseudo-static tests, we comprehensively evaluate the seismic responsiveness of SRC joints and validate their superiority over conventional RC joints. Conclusions can be drawn as follows.

- The distinctly shaped column design addresses the limitations of conventional frame columns, where their oversized sections and sharp edges often detract from architectural esthetics. Consequently, this innovative structure holds immense potential for extensive application in practical engineering projects. However, distinctly shaped SRC column joints sometimes fall short in terms of mechanical performance, prompting the urgency to investigate and enhance joint design techniques in order to facilitate the wider acceptance and implementation of these cutting-edge designs. This study involved low-frequency cyclic load tests on the proposed distinctly shaped SRC column beam joints, offering a more precise simulation of bidirectional seismic forces compared to conventional unidirectional testing methods. The proposed testing approach offers a marked improvement over conventional unidirectional testing methods, leading to insightful and practical findings that contribute to our understanding of the seismic behavior of SRC joints.

- It was revealed in this investigation that the design approach for distinctly shaped SRC column–beam joints, incorporating steel tubes and structural steel, exhibits remarkable seismic resilience. The I-steel and tubes positioned at the joints exhibit a positive constraining effect on the core concrete, enhancing both the structural integrity and seismic performance of the overall structure. Additionally, the joint proposed in this study demonstrates reduced stiffness degradation, minimal load-bearing capacity deterioration, and superior ductility under bidirectional low-cyclic reversed-loading conditions, indicating its potential for improved seismic performance.

- This study also delineates the progression of crack formation and subsequent structural collapse. It portrays pertinent hysteresis curves and compares the hysteretic behaviors of SRC joints with those of conventional RC joints. This comparison underscores SRC joints’ more complete hysteresis loops, indicative of their superior energy dissipation efficiency and ductility in contrast to RC joints. Additionally, this study explores the strain hysteresis characteristics of structural steel and tubes under operational settings. Conclusively, the incorporation of structural steel and concrete within the core steel tube is found to significantly bolster the load-bearing capacity of joints during seismic events. Looking ahead, future endeavors may involve incorporating finite element analysis to further investigate the energy dissipation mechanisms of SRC joints.

Author Contributions

Conceptualization, P.X.; methodology, X.L.; investigation, D.Y.; writing—original draft preparation, J.D.; writing—review and editing, P.X.; supervision, P.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China grant number 11972379.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

Special thanks given to Deng Zhiheng from Guangxi University for his strong support.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Park, R. A summary of results of simulated seismic load tests on reinforced concrete beam-column joints, beams and columns with substandard reinforcing details. J. Earthq. Eng. 2002, 6, 147–174. [Google Scholar] [CrossRef]

- Luo, X.; Cheng, J.; Xiang, P.; Long, H. Seismic behavior of corroded reinforced concrete column joints under low-cyclic repeated loading. Arch. Civ. Mech. Eng. 2020, 20, 40. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Ding, F.; Xiang, P.; Yang, C.; Liu, Y.; Xu, F. Mechanical performance of overlap connections with grout-filled anchor reinforcements in embedded metal corrugated pipe. Arch. Civ. Mech. Eng. 2020, 20, 128. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, Q.; Ye, B.; Yan, W.; Deng, Z.; Xiang, P. Seismic Performances of SRC Special-Shaped Columns and RC Beam Joints Under Double-Direction Low-Cyclic Reversed Loading. Front. Mater. 2021, 8, 761376. [Google Scholar] [CrossRef]

- Xiang, P.; Lin, Y.; Huang, W.; Ding, F.; Ye, B.; Deng, Z. Investigation on Shear Capacity of Joints between Steel Reinforced Concrete Special-Shaped Column and Reinforced Concrete Beam. Front. Mater. 2020, 7, 588296. [Google Scholar] [CrossRef]

- Deng, X.; Wang, S.; Chen, J.; Ding, F.; Zhang, Q.; Xiang, P. Experimental investigation on the effect of local debonding of longitudinal reinforcement on seismic performance of precast concrete columns. J. Build. Eng. 2022, 46, 103131. [Google Scholar] [CrossRef]

- Cao, D.; Liu, J.; Ge, W.; Qian, R. Experimental study on the shear performance of steel-truss-reinforced concrete beam-column joints. Adv. Civ. Eng. 2021, 2021, 5580581. [Google Scholar] [CrossRef]

- Deng, Z.; Xu, C.; Zeng, J.; Wang, H.; Wu, X.; Xiang, P. Seismic performance and shear bearing-capacity of truss SRC beam-column frame joints. Adv. Struct. Eng. 2021, 24, 1311–1325. [Google Scholar] [CrossRef]

- Ma, D.-Y.; Han, L.-H.; Zhao, X.-L. Seismic performance of the concrete-encased CFST column to RC beam joint: Experiment. J. Constr. Steel Res. 2019, 154, 134–148. [Google Scholar] [CrossRef]

- Huang, H.; Hao, R.; Zhang, W.; Huang, M. Experimental study on seismic performance of square RC columns subjected to combined loadings. Eng. Struct. 2019, 184, 194–204. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, J.; Wen, W.; Cui, H. Investigation on the bending and tensile performances of the T-shaped hook-connected structure made of laminated composites and TC4 alloy. Polym. Test. 2019, 80, 106083. [Google Scholar] [CrossRef]

- Chen, Z.; Ning, F.; Chen, J.; Liu, X.; Xu, D. Test on mechanical behavior of SRC L-shaped columns under combined torsion and bending moment. Earthq. Eng. Eng. Vib. 2021, 20, 161–177. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, D.; Xu, J.; Wang, N. Seismic behavior and strength of L-shaped steel reinforced concrete column- concrete beam planar and spatial joints. Steel Compos. Struct. 2021, 39, 337–352. [Google Scholar]

- Feng, Y.; Jiang, L.; Zhou, W.; Han, J.; Zhang, Y.; Nie, L.; Tan, Z.; Liu, X. Experimental investigation on shear steel bars in CRTS II slab ballastless track under low-cyclic reciprocating load. Constr. Build. Mater. 2020, 255, 119425. [Google Scholar] [CrossRef]

- Chun, S.C.; Lee, S.H.; Kang, T.H.K.; Oh, B.; Wallace, J.W. Mechanical anchorage in exterior beam-column joints subjected to cyclic loading. ACI Struct. J. 2007, 104, 102–112. [Google Scholar]

- Karabinis, A.I. Reinforced concrete beam-column joints with lap splices under cyclic loading. Struct. Eng. Mech. 2002, 14, 649–660. [Google Scholar] [CrossRef]

- Metelli, G.; Messali, F.; Beschi, C.; Riva, P. A model for beam-column corner joints of existing RC frame subjected to cyclic loading. Eng. Struct. 2015, 89, 79–92. [Google Scholar] [CrossRef]

- Said, A.M. Damage characterization of beam-column joints reinforced with GFRP under reversed cyclic loading. Smart Struct. Syst. 2009, 5, 443–455. [Google Scholar] [CrossRef]

- Sasmal, S.; Novak, B.; Ramanjaneyulu, K. Numerical analysis of under-designed reinforced concrete beam-column joints under cyclic loading. Comput. Concr. 2010, 7, 203–220. [Google Scholar] [CrossRef]

- Xiang, P.; Deng, Z.H.; Su, Y.S.; Wang, H.P.; Wan, Y.F. Experimental investigation on joints between steel-reinforced concrete T-shaped column and reinforced concrete beam under bidirectional low-cyclic reversed loading. Adv. Struct. Eng. 2017, 20, 446–460. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, W.; Tang, Z.; Guo, X.; Pospisil, S. Seismic behavior of precast concrete beam-column joints with steel strand inserts under cyclic loading. Eng. Struct. 2020, 216, 110766. [Google Scholar] [CrossRef]

- Zhou, J.; Fang, X.; Jiang, Y.; Yang, J. Cyclic experiments on concrete-encased CFST wall-RC coupling beam joints with non-through-core anchorages. J. Earthq. Eng. 2020, 26, 1518–1542. [Google Scholar] [CrossRef]

- Chu, L.; Li, D.; Ma, X.; Zhao, J. Cyclic behaviour of concrete encased steel (CES) column-steel beam joints with concrete slabs. Steel Compos. Struct. 2018, 29, 731–744. [Google Scholar]

- Deng, Z.; Hu, Q.; Zeng, J.; Xiang, P.; Xu, C. Structural performance of steel-truss-reinforced composite joints under cyclic loading. Proc. Inst. Civ. Eng. -Struct. Build. 2018, 171, 130–148. [Google Scholar] [CrossRef]

- Chen, Z.P.; Xu, J.J.; Chen, Y.L.; Xue, J.Y. Seismic behavior of steel reinforced concrete (SRC) T-shaped column-beam planar and 3D hybrid joints under cyclic loads. Earthq. Struct. 2015, 8, 555–572. [Google Scholar] [CrossRef]

- Chen, Z.P.; Xu, J.J.; Xue, J.Y. Hysteretic behavior of special shaped columns composed of steel and reinforced concrete (SRC). Earthq. Eng. Eng. Vib. 2015, 14, 329–345. [Google Scholar] [CrossRef]

- Xu, C.X.; Sheng, P.S.; Wan, C.C. Experimental and theoretical research on shear strength of seismic-damaged SRC frame columns strengthened with enveloped steel jackets. Adv. Civ. Eng. 2019, 2019, 6401730. [Google Scholar] [CrossRef]

- Chu, L.; Li, Q.; Zhao, J.; Li, D. Seismic behavior of hybrid frame joints between composite columns and steel beams. Shock Vib. 2020, 2020, 8870582. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, C.; Ding, F.; Xiang, P. Experimental study on the seismic behavior of precast concrete column with grouted corrugated sleeves and debonded longitudinal reinforcements. Adv. Struct. Eng. 2019, 22, 3277–3289. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X. Seismic behavior of steel reinforced concrete cross-shaped column under combined torsion. Steel Compos. Struct. 2018, 26, 407–420. [Google Scholar]

- Deng, Z.; Xu, C.; Hu, Q.; Zeng, J.; Xiang, P. Investigation on the structural behavior of shear walls with steel truss coupling beams under seismic loading. Adv. Mater. Sci. Eng. 2018, 2018, 5602348. [Google Scholar] [CrossRef]

- Akduman, S.; Karalar, M.; Mert, N.; Ozturk, H. Investigation of the post-fire behavior of different end-plated beam-column connections. Buildings 2024, 14, 1013. [Google Scholar] [CrossRef]

- Stel’Makh, S.A.; Shcherban, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Veremeenko, A.; Shilov, A.V.; Ananova, O.; Karalar, M.; Aksoylu, C.; Onuralp Özkılıç, Y. Modeling and calculation of improved centrifuged reinforced concrete columns with variotropic structure. Buildings 2023, 13, 2005. [Google Scholar] [CrossRef]

- Karalar, M.; Dicleli, M. Effect of pile orientation on the fatigue performance of jointless bridge H-piles subjected to cyclic flexural strains. Eng. Struct. 2023, 276, 115385. [Google Scholar] [CrossRef]

- Murad, Y.Z.; Alseid, B.H. Retrofitting interior RC beam-to-column joints subjected to quasi-static loading using NSM CFRP ropes. Structures 2021, 34, 4158–4168. [Google Scholar] [CrossRef]

- Zapris, A.G.; Kytinou, V.K.; Gribniak, V.; Chalioris, C.E. Novel approach for strengthening T-beams deficient in shear with near-surface mounted CFRP ropes in form of closed stirrups. Dev. Built Environ. 2024, 18, 100394. [Google Scholar] [CrossRef]

- GB 50010-2002; Code for Design of Concrete Structures. Ministry of Construction of the People’s Republic of China: Beijing, China, 2002.

- GB 50010-2001; Code for Seismic Design of Buildings. Ministry of Construction of the People’s Republic of China: Beijing, China, 2001.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).