Abstract

The improper treatment of steel slag (SS) will cause serious environmental problems. Therefore, appropriate management and disposal practices are essential to mitigate the potential environmental risks. This paper delineated the impact of steel slag on cement-based materials’ working performances. The paper provides an exhaustive overview of the mechanical properties, encompassing flexural strength, compressive strength, etc. Finally, the frost resistance, sulfate attack resistance, and seepage resistance of steel slag cement were outlined. This literature review found that steel slag increases the fluidity of cement-based materials, with a setting time approximately 210% to 300% longer than that of Portland cement (PC). When the replacement rate is 50%, the compressive strength can reach 60–80 MPa and the bending strength can reach 6–9 MPa. An optimal replacement of steel slag improved concrete’s frost resistance by 15–20% and reduced permeability by up to 30%.

1. Introduction

The ecological environment is one of the critical problems in the field of civil engineering. With the human economy’s rapid development and public health improvement, the production of bulk solid waste is increasing daily [,]. The safety and stability of the ecological environment are seriously threatened []. Steel slag and fly ash are bulk waste, and their disposal and utilization are essential to understanding issues such as ecological stability and environmental safety. Different from blast furnace slag, steel slag is the waste slag produced in the process of iron and steel smelting. It is mainly composed of ferrite and calcium barium produced in the process of cooling and solidification of molten steel in steel furnaces. Different treatment and utilization methods need to be carried out according to different components and characteristics [,]. Most steel slag and fly ash are dumped, discarded, or stored in different non-environmentally friendly forms [,,]. They will release trace elements and leach out high-alkalinity water [,]. These not only harm surface- and groundwater but also seriously endanger human health and the growth and survival of plants and animals [,]. Consequently, it is imperative to implement strategies for the appropriate disposal and sensible usage of this solid waste. It is essential to preserve the health of water sources, safeguard plant and animal development, and preserve the well-being of humans [,,].

Materials containing cement emerged as the predominant choice for construction materials in civil engineering. The production of silicate cement leads to a significant consumption of land, mineral resources, and energy in cement making [,]. Concurrently, a significant release of carbon dioxide and other harmful gasses will occur, resulting in considerable ecological pollution. Related research indicates that each ton of cement releases approximately 0.79 tons of CO2 [,,]. About 8–9% of global CO2 emissions come from the concrete industry [,].

As a result, discussions about the sustainability of cement concrete have been initiated [,]. On the one hand, the cement industry must undergo industrial restructuring [,]. On the other hand, human beings must vigorously develop eco-friendly and sustainable cement-based materials [,,,,]. We should endeavor to minimize the consumption of natural resources and energy throughout the life cycle of cement materials, from production to utilization [,]. This even enables cement materials to be recycled after disposal [,,]. Consequently, initiating energy conservation and embracing sustainable development has emerged as an indispensable trend in the cement industry to ensure its vitality [].

The chemical composition of steel slag exhibits remarkable diversity, primarily comprising metallic elements such as Fe, Ca, Mg, and Si, as well as trace amounts of MnO2 and Al2O3 [,,]. Additionally, it encompasses compounds like CaSiO3 and FSCA, along with SiO2, which has a resemblance to the chemical composition of Portland cement [,,,,,]. Notably, steel slag has the potential to facilitate cement hydration, including dicalcium silicate (C2S), tricalcium silicate (C3S), and calcium ferric aluminate (C4AF) [,,,]. Therefore, steel slag could potentially impart a favorable effect on the properties of cement-based materials [,,]. Furthermore, steel slag contains SiO2, which has a particular strength in terms of chemical composition. Therefore, it could be utilized as a filler for strength enhancement in composites [,].

Some researchers have explored the effects of chemical exposure on the durability of geopolymer concrete incorporating silica fumes and nano-sized silica at different curing temperatures []. Additionally, the strength and flexural behavior of self-compacting concrete with steel fibers and silica fumes have been investigated []. A comprehensive review has also been conducted on the use of waste slags as sustainable construction materials, analyzing their physico-mechanical properties []. Furthermore, the impact of nanomaterials on the properties and performance of geopolymer concrete has been extensively reviewed []. These studies provide valuable insights into the potential benefits and limitations of using steel slag in cement-based materials.

To summarize, using steel slag concrete might improve the overall effective use of resources. Forming a harmonious alliance between the steel and building materials industries was key in reducing pollution, protecting the environment, and achieving emissions’ reduction [,,].

At present, little research exists on the impact of steel slag in steel slag concrete on the working performance of cement-based materials and the related corrosion resistance. The main research question of this paper is how to effectively use steel slag as a component of cement-based materials to reduce its potential environmental impact. This overview systematically presented the primary studies and advances in steel slag’s working performance, mechanical performance, and durability. In addition, the development of steel slag cement-based materials and prospective challenges were discussed. It established a theoretical basis for the practical application of steel slag concrete.

2. Steel Slag Cement-Based Materials’ Working Performance

The working performance of steel slag concrete has been extensively discussed by numerous scholars. The well-designed mixture should not exhibit water exudation and segregation issues. It should also meet the requirements of fluidity, cohesiveness, and water retention. Many scholars have reached the consensus that achieving the optimal working performance of cement-based materials requires controlling steel slag admixture [,,,,,,,,,,,,,,,,,,]. Table 1 summarizes the impact of different utilization categories of steel slag on the working performance of cement-based materials.

Table 1.

Influence of different utilization categories of SS on the working performance of cement-based materials.

2.1. Steel Slag as Cementing Material

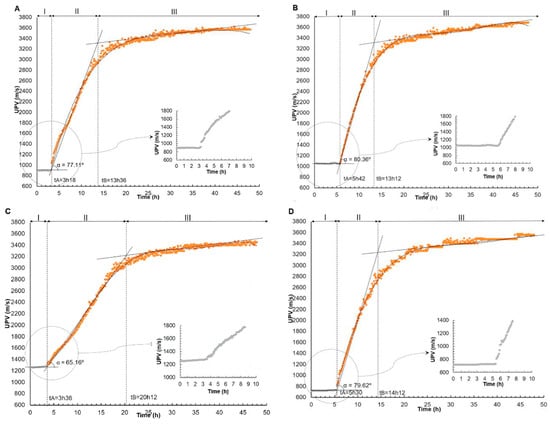

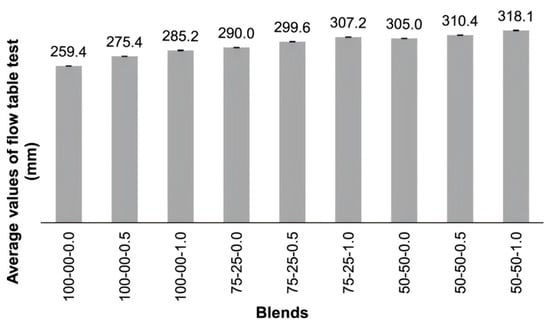

Martins [] utilized steel slag powder (SSP), linear alkyl benzene sodium sulfonate (LAS), and cement to fabricate a composite cementitious material. It was found that steel slag powder can delay the hydration process and affect the hydration kinetics (as shown in Figure 1). Moreover, it was noteworthy that steel slag powder boosts fluidity with the freshly mixed cementitious material in Figure 2. The maximum increase in spread diameter values of cement-based materials incorporating steel slag was observed to be 58.1 mm when compared with Portland cement. These observations aligned with the findings of a study conducted by Frank [].

Figure 1.

The setting time and the hydration kinetic process at (A) 100 (PC%)-00 (SSP%)-0.0 (LAS%); (B) 100 (PC%)-00 (SSP%)-0.5 (LAS%); (C) 75 (PC%)-25 (SSP%)-0.0 (LAS%); and (D) 75 (PC%)-25 (SSP%)-0.5 (LAS%) [].

Figure 2.

Average spread diameter values from the flow table tests performed in all the mortars evaluated [].

Tian [] pointed out that some of the steel slag could be used as a cement substitute and researched the working performance of steel slag cement-based materials. Varying proportions of steel slag (0%, 10%, 15%, and 20%) were utilized. The fluidity of the cement slurry and the slump of the concrete mix were also evaluated experimentally. The slump and spread diameter are corresponding relations. As the steel slag content increased, the slump of the concrete mix initially decreased by 48.6%, then increased by 63%, and ultimately decreased again by 26.5%. The decline in slump could be attributed to the filler effect, which imparts supplementary surface sites for the nucleation of hydrates, because as the water requirement of steel slag powder is larger than that of cement, with the further increase in steel slag powder content, the free water in concrete decreases with the increase in steel slag powder content under a certain water consumption condition, resulting in the decrease in the slump value of steel slag concrete [,,,,]. Moreover, the increase in slump could be ascribed to the ball effect. When the content of steel slag powder is small, mixing a certain amount of steel slag powder with cement can improve the particle composition of the cementing material. Well-graded cementite materials can improve the water leakage of concrete, thereby improving the slump of concrete [,,,,,].

2.2. Steel Slag as Aggregates

Wang [] adopted the orthogonal experimental design method in their study. Steel slag was used instead of sand to compare steel slag concrete with regular concrete. The findings showed that the steel slag concrete has good compatibility and can meet the requirements of concrete. Both the steel slag admixture and the water–cement ratio had an influence on the slump. Among them, the steel slag admixture had the most significant effect on the concrete slump. The findings suggest that utilizing steel slag as an admixture in concrete mixtures can improve its workability and overall quality. Additionally, optimizing the water–cement ratio is crucial for achieving the desired consistency in structural applications. Further research into these factors could lead to advancements in sustainable construction practices using industrial by-products like steel slag.

Subathra Devi [] studied the influence of steel slag substitution for coarse or fine aggregates on concrete’s working performance. The results revealed a decrease in concrete compatibility as the substitution ratio increased. Fine aggregate substitution had a better compatibility than coarse aggregate substitution (as shown in Table 2).

Table 2.

Slump of different proportions of steel slag substitutions for coarse or fine aggregates.

2.3. Steel Slag Carbonization

Luan [] carbonated steel slag for 60 min and 120 min, while different steel slag admixtures were then made by grinding. Then, the standard consistency water consumption and the cement mortar flow rate were determined. Results showed that the uncarbonated steel slag almost did not affect the cement’s standard consistency water consumption. With the gradual increase in the carbonization weight gain rate, the water consumption required to achieve the standard consistency increases gradually when the cement is mixed with carbonized steel slag. With the carbonation weight gain rate escalating, a gradual augmentation was observed in the water consumption required to meet standard coherence in cement mixed with carbonated steel slag.

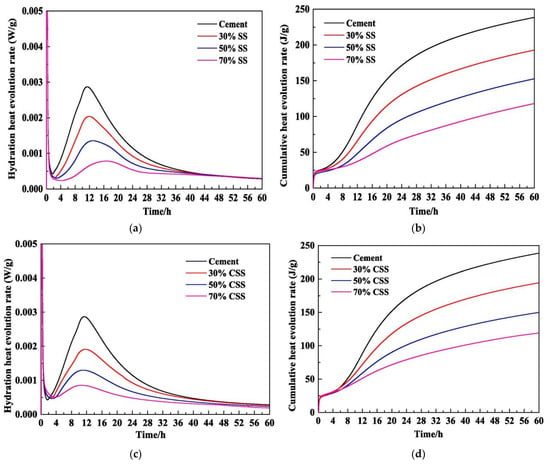

Rui [] compared the impact of the CO2-immobilized steel slag on the hydration properties of cement concrete. The findings demonstrated that the CO2-fixed steel slag facilitated the early hydration process of cement-based materials. Figure 3 illustrates the impact of SSP on the hydration heat and cumulative heat of cement-based materials. The results indicated that SSP delayed exothermic process of cement concrete. The carbonized steel slag expedited the hydration of cement concrete. Therefore, the hardening of cement concrete was accelerated and thus, the setting time was decreased []. The surface of porous carbonized products was formed by the CO2 fixation process’ chemical reaction, which increased the specific surface area. As a result, the water absorption rate was increased, while the free water content was diminished.

Figure 3.

Impact of SSP on hydration heat and cumulative heat of cement-based materials. (a) Hydration heat evolution rate of cement-based material mixed with SS; (b) cumulative heat evolution rate of cement-based material blended with SS; (c) hydration heat evolution rate of cement-based material mixed with CSS; and (d) cumulative heat evolution rate of cement-based material blended with CSS [].

3. Steel Slag Cement-Based Materials’ Mechanical Performance

In civil engineering, the mechanical performance of materials is usually regarded as the most paramount part and is an essential basis for designers in material selection. Scholars used test data to evaluate their merits. The strength of concrete served as a vital assurance for the safety and stability of a structure, both under load-bearing conditions and non-load effects. The strength tested for concrete encompasses various types, including compressive strength, tensile strength, and flexural strength [,,,,,,,,,,]. Table 3 summarizes the impact of different steel slag utilization categories on the mechanical performance of cement-based materials.

3.1. Steel Slag as a Cementing Material

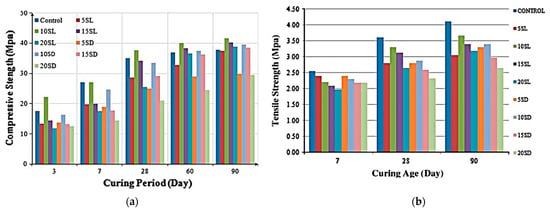

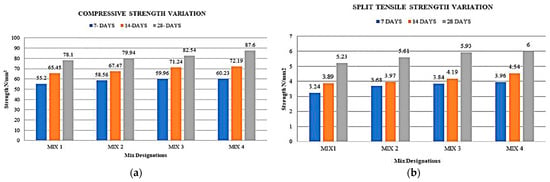

Roslan [] replaced cement with a 5%, 10%, 15%, and 20% proportion of steel slag separately. The results demonstrated that incorporating steel slag enhanced cement concrete’s compressive strength. The addition of 10% steel slag was the optimum dose. At the age of 3 days, the early compressive strength of the specimen was 27%, which was greater than the control sample. At 28 days, the specimen with 10% doping attained its maximum compressive strength of 42 MPa (Figure 4a). The splitting tensile strength results are shown in Figure 4b []. The results indicated that adding steel slag positively improved the flexural strength. This improvement can be attributed to the filling effect and pozzolanic activity of steel slag in the concrete mixture [,,,,].

Figure 4.

Mechanical performance of steel slag and steel sludge. (a) Compressive strength and (b) splitting tensile strength [].

Zhu [] prepared concrete specimens of steel slag by substituting 10%, 20%, and 30% of the cement. Experiments of compressive strength and flexural strength were conducted. It was observed that as the steel slag powder content increased, the concrete’s compressive and flexural strength exhibited an initial increase followed by a subsequent decrease at all ages. The optimum amount of steel slag powder admixture was 10%. At the age of 28 days, the compressive and flexural strengths of the specimens were 51.3 MPa and 5.21 MPa, respectively. These values were 6.9% and 8.31% higher than the control specimens.

3.2. Steel Slag as Aggregates

Yang [,,] formulated concrete with steel slag coarse aggregates by substituting natural stones with steel slag of equivalent quality. The concrete’s short-term and long-term compressive and splitting tensile strengths were investigated. The results demonstrated that the compressive and splitting tensile strengths initially increased and then decreased as the steel slag substitution rate increased. This could be due to after the hydration reaction, the calcium hydroxide can not only promote the hydration of steel slag powder, but also rehydrate with steel slag powder to produce calcium aluminosilicate. The calcium aluminosilicate binds closely to cement slurry, which improves the compressive strength of concrete, but too much steel slag powder reduces the C-S-H hydrate of the cement slurry, which leads to a decrease in the compressive strength of concrete [,,]. Steel slag had better compressive and tensile properties in the short and long term at a 50% replacement rate. At 120 days of age, the compressive strength of the specimen reached 67 MPa, which exhibited an 18.2% increase (ordinary concrete was the control group).

Keertan [] employed steel slag to replace coarse aggregates at varying percentages, specifically 40%, 45%, and 50%. The mechanical performance of concrete was investigated. The findings indicated that 50% of the steel slag admixture performed better in compressive strength and splitting tensile strength (Figure 5) []. The compressive strength of the specimen was 87.6 MPa at the age of 120 days, which was 12.2% higher than that of the control specimen.

Figure 5.

Mechanical performance of cement-based material mixed with steel slag. (a) Compressive strength and (b) splitting tensile strength [].

Lai [] replaced coarse and fine aggregates with steel slag in 0~80% and 0~60% proportions. The results revealed that the optimum substitution rates for coarse and fine aggregates were 50% and 30%. With this ratio, compared to Portland concrete, the compressive strengths at 7, 28, and 90 days were increased by 5.32%, 5.76%, and 19.32%. The compressive strength of concrete increased significantly in the later stage.

3.3. Steel Slag Carbonization

Mo [] conducted CO2 carbonation curing (at 0.1 MPa gas pressure) of pure steel slag specimens and mixed specimens of steel slag blended with 20% Portland cement for 14 days. The mechanical performance was studied quantitatively. The results demonstrated an obvious increase in the compressive strength of the specimens following carbonation, with respective values of 44.1 MPa and 72.0 MPa. As the carbonation time increased, the amount of calcium carbonate formed and the compressive strength of the specimens also increased [,,]. These findings were consistent with the results obtained by Bukowski and Zhang [,].

Liu [] carried out a comparative study on the mechanical performance of low-carbonated steel slag specimens (carbonized for 15 min) and high-carbonated steel slag specimens (carbonized for 240 min). The compressive strengths of the steel slag (SS), low-carbonated steel slag (LCSS), and high-carbonated steel slag (HCSS) cement mortars at 3, 7, 28, and 90 days of age are provided in Table 4. The findings showed that the compressive strength of the low-carbonated steel slag specimens exhibited increases at all tested ages. At ages 7 and 28 days, it increased by 5.3% and 8% compared to the uncarbonized specimens. In contrast, the high-carbonated steel slag was reduced approximately by 11.1% in the early compressive strength of the cement-based materials. However, the compressive strength of the cement pastes at later ages, precisely 7 days and 28 days, experienced increases of approximately 2.1% and 14.7%, respectively [,]. On the one hand, overconsumption of CaSiO3 diminished the reactiveness of hydration. On the other hand, the rich formation of SiO2 gels increased the reactivity of the volcanic ash and facilitated the progress of compressive strength, especially in the later stages [,].

Table 4.

Effect of carbonated steel slag on the compressive strengths of cement mortars.

Table 3.

Effect of different utilization categories of steel slag on the mechanical performance of cement-based materials.

Table 3.

Effect of different utilization categories of steel slag on the mechanical performance of cement-based materials.

| Category | Cement Replacement | Test Content | Test Result | Author |

|---|---|---|---|---|

| Cementitious material | 5%, 10%, 15%, 20% | Flexural strength, compressive strength, and splitting tensile strength test | 10% was the optimal dosage, ft = 5.3 MPa, fcu = 42 MPa, fts = 4.10 MPa | Nurul Hidayah Roslan [] |

| 10%, 20%, 30% | Flexural strength and compressive strength test | 10% was the optimal dosage, ft = 5.59 MPa, fcu = 59.3 MPa | Jianhua Zhu [] | |

| Coarse and fine aggregate | 25%, 50%, 100% | Compressive strength and splitting tensile strength test | 50% was the optimal dosage, fcu = 67 MPa, fts = 4.2 MPa | Chen Yang, Linlin Xing, Yanli Han [,,] |

| 40%, 45%, 50% | Compressive strength and splitting tensile strength test | 50% was the optimal dosage, fcu = 87.6 MPa, fts = 6 MPa | Tirukovela Sai Keertan [] | |

| coarse aggregate (0~80%) fine aggregate (0~60%) | Compressive strength test | The optimal replacement rate of coarse aggregate was 50%, fcu = 73.5 MPa; the optimal replacement rate of fine aggregate was 30%, fcu = 74.9 MPa | M.H. Lai [] | |

| Carbonization | 80%, 100% (0.1 MPa 14 d) | Compressive strength test | Increased compressive strength, fcu = 72.0 MPa | Liwu Mo, J.M. Bukowski, Feng Zhang [] |

| 30% (0.25 MPa 15 min, 240 min) | Compressive strength test | Increased compressive strength (15 min); compressive strength showed a decrease followed by an increase. (240 min) | Peng Liu [] |

In addition to fulfilling the working and mechanical performance requirements, steel slag cement-based materials should also exhibit excellent durability. Concrete’s durability directly affects the safety of building structures. Therefore, research on the durability properties of new materials is also more important [,,,,,,,]. Table 5 summarizes the influence of steel slag on the durability of cement-based materials.

Table 5.

Influence of steel slag on the durability of cement-based materials.

4. Steel Slag on the Durability of Cement-Based Materials

4.1. Freeze–Thaw Cycle

Wang [] conducted tests by using the rapid freeze–thaw method, which studied the frost resistance of steel slag fine aggregate concrete. After freeze–thaw cycles, they tested the mass loss rate, strength loss rate, and relative dynamic elastic modulus of concrete with different acceptable aggregate replacement rates for steel slag. The findings indicated that the steel slag fine aggregate underwent significant damage due to the freeze–thaw action. The concrete specimens with a 60% steel slag replacement demonstrated the lowest mass loss and strength loss, exhibiting only 4.06% and 44.2% reductions, respectively. The concrete specimens with a 100% slag replacement rate exhibited the highest mass loss and strength loss, amounting to 6.05% and 58%, respectively. When freeze–thaw cycles were more than 50 times, the relative dynamic modulus of elasticity of the concrete with 60% steel slag was higher than the rest of the dosing group. This may be due to the fact that active minerals such as C2S, C3S, and C2F in steel slag aggregates are similar to cement due to their gelling properties. Under the influence of the hydration reaction, a more dense structure is formed between these active minerals and the cement slurry, thus reducing the formation of pores. These pore reductions further restrict the flow of aqueous solution inside the concrete, reduce the static water pressure or permeability pressure caused by the aqueous solution, reduce the stress damage inside the concrete, and indirectly improve the frost resistance of the concrete [].

Zhu [] researched the influence of steel slag mixture in steel slag concrete on the frost and seepage resistance of concrete specimens. The experimental results showed that the seepage resistance of concrete was related to the amount of steel slag admixture while maintaining the same water-to-cement ratio. The seepage and frost resistance of the specimens improved significantly with the increase in the steel slag dosing. These findings align with the conclusions reached by Santamaría [].

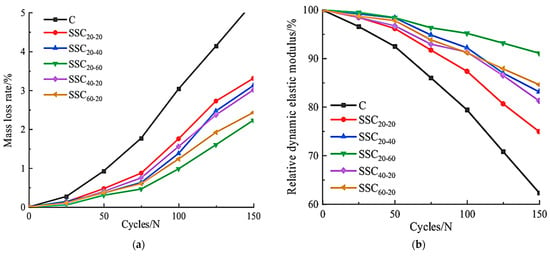

Wen [] studied the freezing resistance of steel slag concrete. The results showed that ordinary concrete exhibited more severe damage phenomena. Figure 6 and Figure 8 shows the relationship between the mass loss rate and the number of freeze–thaw cycles. It was evident that the mass loss diminished with increased slag content. As the slag content increased, the mass loss decreased.

Figure 6.

Freezing–thawing cycles of steel slag concrete. (a) Mass loss rate and (b) relative dynamic elastic modulus [].

Furthermore, the steel slag specimens exhibited a more minor relative dynamic elastic modulus reduction. The specimens demonstrated a higher resistance to freezing. The weight loss rate ranged from 2.233 to ~3.024%, and the relative dynamic elastic modulus ranged from 74.92 to ~91.09% (as shown in Figure 6). When the ratio of steel slag to coarse aggregate was 20% and that of fine aggregate was 60%, the frost durability of the specimens was better. The frost resistance life of these specimens was more than twice that of ordinary concrete.

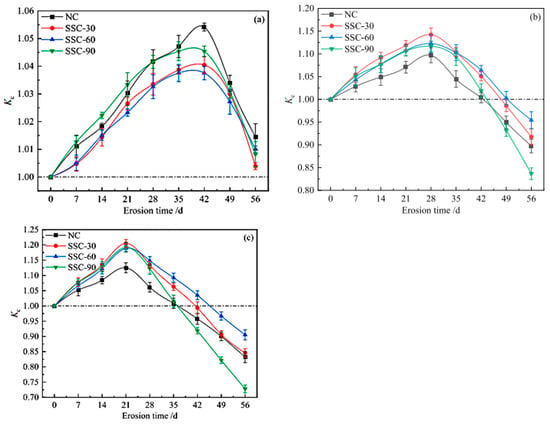

4.2. Sulfate Dry and Wet Alternation

Cheng [] conducted erosion and material mechanics tests on SS coarse aggregate concrete in different mass fraction sulfate solutions. Figure 7 illustrated the Kc (crack resistance coefficient) variation in concrete containing steel slag coarse aggregate in different sulfate concentrations. The results indicated that steel slag can significantly reduce the damage caused by sulfate solution corrosion. When the steel slag replacement rate in concrete reached 60%, the concrete exhibited a better resistance to sulfate attack. This may be due to the fact that calcium hydroxide and AFt formed by f-CaO hydration in steel slag fill the internal pores of concrete, promote the internal structure to be dense, and thus enhance the resistance to the sulfate corrosion of concrete.

Figure 7.

Change of Kc with time in a sulfate solution with a mass fraction of (a) 5%; (b) 10%; and (c) 15% [].

Feng [] immersed steel slag concrete specimens in a solution of sulfate at a concentration of 8000 mg/L and a solution of magnesium ions at 3000 mg/L. They studied the erosion performance of each specimen after six months. The results demonstrated that the steel slag’s particle size impacts the corrosion resistance of steel slag concrete. The concrete specimens exhibited the highest mass and strength loss, 6.05% and 58%, respectively. It was observed that as the particle size of steel slag decreased, the free active ingredients of the specimens also decreased.

4.3. Permeability Resistance

Van Tran [] investigated the use of steel slag as a replacement for coarse aggregate and conducted a series of experiments. The experiments included strength loss, charge passage rate, and chloride ion penetration resistance. The results indicated that the effect of steel slag on concrete strength was insignificant. However, the use of steel slag could increase chloride permeation resistivity [].

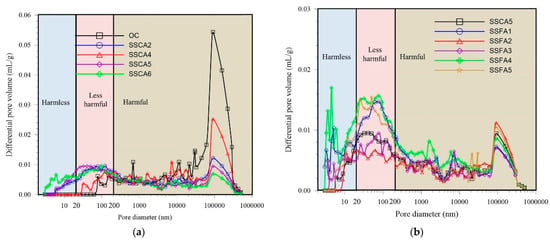

M.H. Lai [] investigated the effect of steel slag replacements of coarse and fine aggregates on the porosity of concrete. Figure 8 shows the pore size distribution of hardened concrete for specimens. The results showed that the optimal substitution ratio of steel slag fine aggregates and steel slag coarse aggregates significantly reduced the harmful pore volume, average pore size, and total pore volume of the concrete. It effectively improved the bulk concrete capacity and impermeability durability.

Figure 8.

Hardened concrete pore size distribution. (a) Group no. 1 and (b) Group no. 2 [].

5. Conclusions

This paper made a series of generalizations about the working performance, mechanical properties, and durability of cement-based materials mixed with steel slag. Some of the findings can be summarized as follows:

(1) A certain amount of steel slag would reduce cement concrete’s hydration heat with a slow-setting effect. The setting time of steel slag cement concrete was two to three times longer than Portland cement. Steel slag had both a filling effect and a ball effect. An acceptable aggregate substitution had better compatibility than a coarse aggregate substitution. Notably, after the CO2 curing, steel slag speeds up the setting time for cement-based materials and improves water consumption’s standard consistency.

(2) When steel slag is used as a substitute for cementing materials, the optimal amount of steel slag was 10%. By incorporating this proportion, the specimen reached a compressive strength of 40–50 MPa, approximately 10% higher than the control specimen. When steel slag replaced aggregates, the optimal amount of steel slag powder was determined to be 50%. With this proportion, the specimen exhibited a compressive strength of 60–80 MPa, approximately 15% higher than the control specimen. Carbonation improved the mechanical performance of steel slag cement concrete. The mechanical properties of the steel slag cement-based specimens were improved. The compressive strength of the carbonated steel slag concrete was about 10% higher than the control specimen.

(3) When the substitution rate is 60%, steel slag could maximally improve the frost resistance, impermeability, and sulfate attack resistance of concrete. And under the same replacement rate, steel slag shows better frost resistance than sulfate corrosion resistance. In addition, the trends in erosion degree and compressive strength and the erosion coefficient of concrete with different steel slag replacement rates were consistent.

6. Outlook

Steel slag concrete has the advantages of a high working performance, good mechanical performance, and good durability. Therefore, it has many applications in civil infrastructure, such as buildings, highways, bridges, and airport runways. Especially in reducing resource and energy consumption, steel slag concrete is a “smart” choice for the sustainable development of concrete materials and structures. It will bring a massive revolution to the field of traditional concrete materials. It provides new ideas for the resource utilization of steel slag solid waste. It is important for the steel and building materials industry to achieve synergy to promote pollution reduction and carbon reduction, as well as environmental protection and emission reduction. At the same time, it will benefit the economy, society, and the environment. These findings also furnish valuable insights for the trajectory of eco-friendly building materials. This pioneering methodology not just accelerates resource recycling but also presents an efficacious and sustainable architectural resolution. In the future, this research could be expanded to encompass other waste materials, with the objective of enhancing the performance of cement-based composites even further.

The methodology mentioned in this paper is scientific and systematic in studying the influence of steel slag on the properties of cement-based materials. However, in practical applications, there are still some areas that can be improved.

1. Sample selection and processing: The current research may have the problem of an insufficient sample size or unrepresentative sample selection. It is suggested to add more steel slag samples from different sources and properties to improve the universality and reliability of the research results.

2. Long-term performance testing: Current research mainly focuses on short-term performance testing. It is recommended to increase the evaluation of long-term properties of cement-based materials, such as durability and stability tests, to more fully understand how steel slag behaves in practical applications (especially when it comes to durability experiments).

Author Contributions

Conceptualization, H.W. and Z.C.; methodology, X.C.; validation, Z.C. and H.W.; formal analysis, X.C. and H.W.; investigation, Z.C., X.C. and J.S.; resources, X.C.; data curation, Z.C. and X.C.; writing—original draft preparation, H.W. and X.C.; writing—review and editing, H.W., X.C., Z.C., J.S. and S.W.; visualization, X.C.; supervision, Z.C.; project administration, H.W. and S.W.; funding acquisition, H.W. and J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Zhejiang Provincial Natural Science Foundation of China (No. LY22E080005, No. LY24E080010).

Data Availability Statement

The data used to support the findings of this study are available on request.

Conflicts of Interest

Authors Jian Sun and Songhua Wu were employed by the company China Construction Eighth Engineering Division Corp., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Chen, J.J.; Sun, Y.Q.; Zhang, Z.T. Evolution of trace elements and polluting gases toward clean co-combustion of coal and sewage sludge. Fuel 2020, 280, 118685. [Google Scholar] [CrossRef]

- Bao, Z.K.; Lu, W.S.; Peng, Z.Y.; Ng, S.T. Balancing economic development and construction waste management in emerging economies: A longitudinal case study of Shenzhen, China guided by the environmental Kuznets curve. J. Clean. Prod. 2023, 396, 136547. [Google Scholar] [CrossRef]

- Chen, G.Y.; Liu, X.Y.; Sun, Y.N.; Du, C.M.; Wang, X.H.; Yan, B.B.; Cheng, Z.J.; Lin, F.W. Current status of research on co-disposal of municipal solid waste and corrosion risk in boilers and industrial kilns. Environ. Eng. 2022, 40, 11. [Google Scholar]

- Liu, X.; Zhang, C.; Yu, H.; Qian, G.; Zheng, X.; Zhou, H.; Huang, L.; Zhang, F.; Zhong, Y. Research on the Properties of Steel Slag with Different Preparation Processes. Materials 2024, 17, 1555. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Nguyen, H.T.; Ahmed, S.F.; Rajamohan, N.; Yusuf, M.; Sharma, A.; Arunkumar, P.; Deepanraj, B.; Tran, H.; Al-Gheethi, A.; et al. Emerging waste-to-wealth applications of fly ash for environmental remediation: A review. Environ. Res. 2023, 227, 115800. [Google Scholar] [CrossRef]

- Baalamurugan, J.; Kumar, V.; Padmapriya, R.; Raja, V. Recent applications of steel slag in construction industry. Environ. Dev. Sustain. 2024, 26, 2865–2896. [Google Scholar] [CrossRef]

- Zhao, J.; Hu, W.; Ni, W.; Guo, J.; Zhu, W.; Su, S. The Effect of Removing Hard-to-Grind Minerals from Steel Slag on Efficient Grinding and Hydration Activity. J. Sustain. Metall. 2023, 9, 1315–1328. [Google Scholar] [CrossRef]

- Baalamurugan, J.; Ganesh Kumar, V.; Naveen Prasad, B.S.N.; Padmapriya, R.; Karthick, V.; Govindaraju, K. Recycling of induction furnace steel slag in concrete for marine environmental applications towards ocean acidification studies. Int. J. Environ. Sci. Technol. 2022, 19, 5039–5048. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, C.X. Current status and development trend of comprehensive utilization of iron and steel slag. Miner. Compr. Util. 2019, 2, 21–25. [Google Scholar]

- Li, Y.; Liu, F.; Yu, F.; Du, T. A review of the application of steel slag in concrete. Structures 2024, 63, 106352. [Google Scholar] [CrossRef]

- Li, X.H.; Gu, X.; Zhang, W.; Liu, J.; Li, Z.; Liu, B. An ecological composites for a novel class of solid waste concrete. Mater. Lett. 2024, 361, 136082. [Google Scholar] [CrossRef]

- Lv, S.; He, T.; Wei, D.; Gan, Z. Make full using coal chemical solid waste to prepare coal goaf filling concrete and its structure and properties. Arch. Civ. Mech. Eng. 2024, 24, 210. [Google Scholar] [CrossRef]

- Wang, J.; Ren, C.; Huang, T.; Li, X.; Cao, W.L.; Zhu, Y.; Wei, P.; Wang, D.; Liu, Z. Performances of concrete with binder and/or aggregates replacement by all-solid waste materials. J. Clean. Prod. 2024, 450, 141929. [Google Scholar] [CrossRef]

- Zhang, T.S.; Peng, H.; Wu, C.; Guo, Y.Q.; Wang, J.W.; Chen, X.Z.; Wei, J.X.; Yu, Q.J. Process compatible desulfurization of NSP cement production: A novel strategy for efficient capture of trace SO2 and the industrial trial. J. Clean. Prod. 2023, 411, 137344. [Google Scholar] [CrossRef]

- Costa, F.N.; Ribeiro, D.V. Reduction in CO2 emissions during production of cement, with partial replacement of traditional raw materials by civil construction waste (CCW). J. Clean. Prod. 2020, 276, 123302. [Google Scholar] [CrossRef]

- Weng, Y.; Liu, Y.; Liu, J. Study on mathematical model of hydration expansion of steel slag-cement composite cementitious material. Environ. Technol. 2021, 42, 2776–2783. [Google Scholar] [CrossRef]

- Li, H.; Zhang, R.; Wang, T.; Wu, Y.; Xu, R.; Wang, Q.; Tang, Z. Performance evaluation and environment risk assessment of steel slag enhancement for seawater to capture CO2. Energy 2022, 238, 121861. [Google Scholar] [CrossRef]

- Li, D.; Rong, P.; Yao, L.; Liu, S.; Zhang, S.; Guan, X.; Zhu, J.; Lu, J.; Poon, C. Tailoring high-magnesium cements for enhanced carbonation hardening and CO2 sequestration. Constr. Build. Mater. 2024, 435, 136849. [Google Scholar] [CrossRef]

- Qian, C.; Yu, X.; Zheng, T.; Chen, Y. Review on bacteria fifixing CO2 and bio-mineralization to enhance the performance of construction materials. J. CO2 Util. 2021, 55, 101849. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Liu, R. The Capture and Transformation of Carbon Dioxide in Concrete: A Review. Symmetry 2022, 14, 2615. [Google Scholar] [CrossRef]

- Liu, J.W.; Zhang, H.T.; Shen, J.M.; Yu, W.J. Current situation and new countermeasures for development of cement concrete pavement at home and abroad. Chin. Foreign Highw. 2016, 36, 73–77. [Google Scholar]

- Yang, J.; He, X. Durability and Sustainability of Cement and Concrete Composites. Materials 2023, 16, 5693. [Google Scholar] [CrossRef] [PubMed]

- Belaïd, F. How does concrete and cement industry transformation contribute to mitigating climate change challenges? Resour. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Liu, L.F. Deeply promote the pilot cement industry restructuring. China Cem. 2020, 6, 17–19. [Google Scholar]

- Kemer, H.; Bouras, R.; Mesboua, N.; Sonebi, M.; Kinnane, O. Shear-thickening behavior of sustainable cement paste-Controlling physical parameters of new sources of supplementary cementitious materials. Constr. Build. Mater. 2021, 310, 125277. [Google Scholar] [CrossRef]

- Xi, B.; Huang, Z.; Al-Obaidi, S.; Ferrara, L. Predicting ultra high-performance concrete self-healing performance using hybrid models based on metaheuristic optimization techniques. Constr. Build. Mater. 2023, 381, 131261. [Google Scholar] [CrossRef]

- Cabral, J.S.; Menegatti, C.R.; Nicolodelli, G. Laser-induced breakdown spectroscopy in cementitious materials: A chronological review of cement and concrete from the last 20 years. TrAC Trends Anal. Chem. 2023, 160, 116948. [Google Scholar] [CrossRef]

- Deng, F.; Ye, J.; Liu, Y.L.; Zhang, T.X.; Liao, Y.S.; Tang, S.W. Influence of cement on properties of calcined phosphogypsum based composite cementitious materials. J. Mater. Res. Technol. 2023, 24, 3145–3156. [Google Scholar] [CrossRef]

- Ruviaro, A.S.; Lima, G.; Silvestro, L.; Barraza, M.T.; Rocha, J.C.; Brito, J.D.; Gleize, P.; Pelisser, F. Characterization and investigation of the use of oat husk ash as supplementary cementitious material as partial replacement of Portland cement: Analysis of fresh and hardened properties and environmental assessmen. Constr. Build. Mater. 2023, 363, 129762. [Google Scholar] [CrossRef]

- Kroumian, C.; Maier, J.; Scheffknecht, G. Oxyfuel combustion experiments to reduce CO2 emissions in the cement production process. Chem. Ing. Tech. 2022, 94, 9. [Google Scholar] [CrossRef]

- Guo, Z.H.; Bai, X.X.; Liu, S.H.; Luo, L.N.; Hao, Y.; Lv, Y.Q.; Xiao, Y.F.; Yang, J.Q.; Tian, H.Z. Heterogeneous Variations on Historical and Future Trends of CO2 and Multiple Air Pollutants from the Cement Production Process in China: Emission Inventory, Spatial-Temporal Characteristics, and Scenario Projections. Environ. Sci. Technol. 2022, 56, 14306–14314. [Google Scholar] [CrossRef] [PubMed]

- El Messiry, M.; Al-Oufy, A. Investigations of the recycling of airbag filters from the cement industry into fabric/polymer or fabric/cement composite materials. Discov. Appl. Sci. 2024, 6, 42. [Google Scholar] [CrossRef]

- Lee, J.B.; Kim, J.; Min, B.; Woo, B.; Raganati, F. Performance Assessment of Carbon Dioxide Sequestration in Cement Composites with a Granulation Technique. Materials 2024, 17, 53. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; Yang, Y.; Lu, J.H. Development dynamics and prospect of decorative concrete at home and abroad. World Concr. 2021, 7, 48–53. [Google Scholar]

- Barbhuiya, S.; Kanavaris, F.; Das, B.; Idrees, M. Decarbonising cement and concrete production: Strategies, challenges and pathways for sustainable development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Xiao, Y.; Sakurai, Y.; Hisaka, Y.; Tsukihashi, F. Recycling of Steelmaking Slag in Seawater as an Iron Supplier: Effects of Slag Composition, Carbonation and Usage of Gluconic Acid:Environment. Mater. Trans. 2021, 62, 1253–1262. [Google Scholar]

- Tyutrin, A.; Nemchinova, N.; Baranov, A.N. Analysis of Steel Slag Composition and Properties to Facilitate the Search for Rational Slag Recycling Methods. IOP Conf. Ser. Mater. Sci. Eng. 2020, 969, 012042. [Google Scholar] [CrossRef]

- Hao, S.; Luo, G.; Lu, Y.; An, S.; Chai, Y.; Song, W. Effect of High Temperature Reconstruction and Modification on Phase Composition and Structure of Steel Slag. Minerals 2023, 13, 67. [Google Scholar] [CrossRef]

- Zhao, D.Q.; Shen, W.G.; Wang, Y.N.; Yang, Y.; Zhang, W.S.; Shi, Q.L.; Deng, Y.L.; Lu, J.C.; Deng, Y. Direct use of original granular steel slag to prepare multi-phased clinker: Sintering mechanism and properties. Constr. Build. Mater. 2023, 390, 131575. [Google Scholar] [CrossRef]

- Shi, K.Y.; Deng, H.Y.; Hu, J.X.; Zhou, J.Q.; Cai, X.H.; Liu, Z.W. Effects of Steel Slag Powder Content and Curing Condition on the Performance of Alkali-Activated Materials Based UHPC Matrix. Materials 2023, 16, 3875. [Google Scholar] [CrossRef]

- Iacobescu, R.I.; Pontikes, Y.; Koumpouri, D.; Angelopoulos, G.N. Synthesis, Characterization and properties of calcium ferroaluminate belite cements produced with electric arc furnace steel slag as raw material. Cem. Concr. Compos. 2013, 44, 1–8. [Google Scholar] [CrossRef]

- Faraone, N.; Tonello, G.; Furlani, E.; Maschio, S. Steelmaking slag as aggregate for mortars: Effects of particle dimension on compression strength. Chemosphere 2009, 77, 1152–1156. [Google Scholar] [CrossRef] [PubMed]

- Tüfekçi, M.; Demirbaş, A.; Genç, H. Evaluation of steel furnace slags as cement additives. Cem. Concr. Res. 1997, 11, 1713–1717. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.C.; Shi, C.; Pan, S.Y. Characteristics of steel slags and their use in cement and concrete-A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Ma, L.T.; Sheng, G.H.; Wang, X.Y.; Wang, J.H.; Li, J.Y.; Ma, Y.; Wang, Z.H. Experimental study on the compressive strength of ultra-high-doped steel slag cement matrix composites. Concrete 2022, 8, 102–104+124. [Google Scholar]

- Kriskova, L.; Pontikes, Y.; Cizer, Ö.; Mertens, G.; Veulemans, W.; Geysen, D.; Jones, P.T.; Vandewalle, L.; Balen, K.V.; Blanpain, B. Effect of mechanical activation on the hydraulic properties of stainless steel slags. Cem. Concr. Res. 2012, 42, 778–788. [Google Scholar] [CrossRef]

- Muhmood, L.; Vitta, S.; Venkateswaran, D. Cementitious and pozzolanic behavior of electric arc furnace steel slags. Cem. Concr. Res. 2009, 39, 102–109. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, D.; Yan, P.; Zhang, D.; Wang, H. Self-cementitious property of steel slag powder blended with gypsum. Constr. Build. Mater. 2016, 113, 835–842. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, Q.; Wei, J.; Li, J.; Zhang, P. Preparation of high performance blended cements and reclamation of iron concentrate from basic oxygen furnace steel slag. Resour. Conserv. Recycl. 2011, 56, 48–55. [Google Scholar] [CrossRef]

- Xue, P.; Xu, A.J.; He, D.F.; Yang, Q.X.; Liu, G.Q.; Engström, F.; Björkman, B. Research on the sintering process and characteristics of belite sulphoaluminate cement produced by BOF slag. Constr. Build. Mater. 2016, 122, 567–576. [Google Scholar] [CrossRef]

- Carvalho, S.Z.; Vernilli, F.; Almeida, B.; Oliveira, M.D.; Silva, S.N. Reducing environmental impacts: The use of basic oxygen furnace slag in portland cement. J. Clean. Prod. 2018, 172, 385–390. [Google Scholar] [CrossRef]

- Wang, Q.; Li, M.y.; Shi, M.X. Hydration characteristics of cement-steel slag-slag composite cementitious materials. J. Silic. 2014, 42, 629–634. [Google Scholar]

- Kourounis, S.; Tsivilis, S.; Tsakiridis, P.E.; Papadimitriou, G.D.; Tsibouki, Z. Properties and hydration of blended cements with steelmaking slag. Cem. Concr. Res. 2007, 37, 815–822. [Google Scholar] [CrossRef]

- Paruthi, S.; Rahman, I.; Husain, A.; Hasan, M.; Khan, A. Effects of Chemicals Exposure on the Durability of Geopolymer Concrete Incorporated with Silica Fumes and Nano-Sized Silica at Varying Curing Temperatures. Materials 2023, 16, 6332. [Google Scholar] [CrossRef] [PubMed]

- Abdalla, S.; Afzal, K.; Mohammad, A.; Nadeem, K.; Seyed, K.; Michal, P.; Neyara, R. Strength and flexural behavior of steel fiber and silica fume incorporated self-compacting concrete. J. Mater. Res. Technol. 2021, 12, 1380–1390. [Google Scholar]

- Meshram, S.; Raut, S.; Ansari, K.; Madurwar, M.; Daniyal, M.; Khan, M.; Katare, V.; Khan, A.; Khan, N.; Hasan, M. Waste slags as sustainable construction materials: A compressive review on physico mechanical properties. J. Mater. Res. Technol. 2023, 23, 5821–5845. [Google Scholar] [CrossRef]

- Sagar, P.; Ibadur, R.; Asif, H.; Afzal, K.; Ana-Maria, M.; Ehab, S. A comprehensive review of nano materials in geopolymer concrete: Impact on properties and performance. Dev. Built Environ. 2023, 16, 100287. [Google Scholar]

- He, K.; Wang, L.; Li, X. Review of the Energy Consumption and Production Structure of China’s Steel Industry: Current Situation and Future Development. Metals 2020, 10, 302. [Google Scholar] [CrossRef]

- Zhao, S.W.; Shi, Y.; Xu, J.P. Carbon emissions quota allocation based equilibrium strategy toward carbon reduction and economic benefits in China’s building materials industry. J. Clean. Prod. 2018, 189, 307–325. [Google Scholar] [CrossRef]

- Yin, S.; Li, B.Z.; Xing, Z.Y. The governance mechanism of the building material industry (BMI) in transformation to green BMI: The perspective of green building. Sci. Total Environ. 2019, 677, 19–33. [Google Scholar] [CrossRef]

- Martins, A.; Carvalho, J.; Duarte, M.; Lima, G.; Pedroti, L.G.; Peixoto, R. Influence of a LAS-based modifying admixture on cement-based composites containing steel slag powder. J. Build. Eng. 2022, 53, 104517. [Google Scholar] [CrossRef]

- Frank, B.; Gerd, B. Composition of the reactivity of engineered slags from bauxite residue and steel slag smelting and use as SCM for Portland cement. Constr. Build. Mater. 2022, 321, 126331. [Google Scholar]

- Tian, E.B.; Kang, H.X.; Zhuang, Z.P. Analysis of fluidity and mechanical properties of steel slag micronized pavement concrete. J. Sanming Coll. 2021, 38, 87–92+101. [Google Scholar]

- Guang, W.; Jia, Z.; Yan, M.; Xu, W.; Jin, L.; Dong, P.; Yang, J.; Wen, W. Effect of pyroligneous acid as a novel bio-additive on the hydration mechanism of calcium sulfoaluminate cement and ordinary Portland cement. Constr. Build. Mater. 2024, 439, 137261. [Google Scholar]

- Jun, J.; Jia, W.; Qing, Y.; Quan, L.; Xiao, L.; Zheng, Y. Hydration of Portland cement in the presence of triethanolamine and limestone powder: Mechanical properties and synergistic mechanism. Constr. Build. Mater. 2024, 438, 137323. [Google Scholar]

- Gutteridge, W.A.; Dalziel, J.A. Filler cement—The effect of the secondary component on the hydration of Portland cement part 1: Fine nonhydraulic filler. Cem. Concr. Res. 1990, 20, 778–782. [Google Scholar] [CrossRef]

- Gutteridge, W.A.; Dalziel, J.A. Filler cement: The effect of the secondary component on the hydration of Portland cement: Part 2: Fine hydraulic binders. Cem. Concr. Res. 1990, 20, 853–861. [Google Scholar] [CrossRef]

- Zhi, C.; Hai, W.; Jian, Z.; Xiao, S. Simulation analysis of microstructure development of tricalcium silicate using the needle model of calcium silicate hydrate. Cem. Concr. Res. 2024, 183, 107589. [Google Scholar]

- Jian, L.; Meng, W.; Nan, L.; Le, T.; Yi, W.; Zheng, C.; Cai, S. Development of ultra-fine SAP powder for lower-shrinkage and higher-strength cement pastes made with ultra-low water-to-binder ratio. Compos. Part B Eng. 2023, 262, 110810. [Google Scholar]

- Justs, J.; Wyrzykowski, M.; Winnefeld, F.; Bajare, D.; Lura, P. Influence of superabsorbent polymers on hydration of cement pastes with low water-to-binder ratio: A calorimetry study. J. Therm. Anal. Calorim. 2014, 115, 425–432. [Google Scholar] [CrossRef]

- Baert, G.; Hoste, S.; De Schutter, G.; De Belie, N. Reactivity of fly ash in cement paste studied by means of thermogravimetry and isothermal calorimetry. J. Therm. Anal. Calorim. 2008, 94, 485–492. [Google Scholar] [CrossRef]

- Wolf, S.; Christian, P.; Reinhard, T.; Jörn, G. Cement hydration kinetics followed by electron spin resonance. Cem. Concr. Res. 2024, 181, 107548. [Google Scholar]

- Jun, H.; Rui, X.; Qing, N.; Jing, Z.; Bao, H. High-volume coal gasification fly ash–cement systems: Experimental and thermodynamic investigation. Constr. Build. Mater. 2023, 377, 131082. [Google Scholar]

- Zhuang, S.Y.; Wang, Q. Inhibition mechanisms of steel slag on the early-age hydration of cement. Cem. Concr. Res. 2021, 140, 106283. [Google Scholar] [CrossRef]

- Wang, C.; Qi, Y.M.; He, J.Y. Experimental study on steel slag and slag replacing sand in concrete. In Proceedings of the 2008 International Workshop on Modelling, Simulation and Optimization, Hong Kong, China, 27–28 December 2008; pp. 451–455. [Google Scholar]

- Devi, V.S.; Gnanavel, B.K. Properties of Concrete Manufactured Using Steel Slag. Procedia Eng. 2014, 97, 95–104. [Google Scholar] [CrossRef]

- Luan, N.; Yin, M.; Chen, K.; Zhang, H.T.; Zhu, Y.C. Experimental study on carbonation of steel slag and its effect on the performance of cement mortar. China Nonferrous Metall. 2023, 52, 107–113. [Google Scholar]

- Rui, Y.F.; Qian, C.X. CO2-fixing steel slag on hydration characteristics of cement-based materials. Constr. Build. Mater. 2022, 354, 129193. [Google Scholar] [CrossRef]

- Rui, Y.; Qian, C.; Zhang, X.; Ma, Z. Different carbon treatments for steel slag powder and their subsequent effects on properties of cement-based materials. J. Clean. Prod. 2022, 362, 132407. [Google Scholar] [CrossRef]

- Nurul, H.R.; Mohammad, I.; Zaiton, A.; Seyedmojtaba, G.; Bala, M. Performance of steel slag and steel sludge in concrete. Constr. Build. Mater. 2016, 104, 16–24. [Google Scholar]

- Zhu, J.H.; Wang, D.L.; Chai, G.G. Study on the effect of steel slag powder admixture on mechanical properties and durability of concrete. Compr. Util. Fly Ash 2022, 36, 97–101. [Google Scholar]

- Yang, C.; Liu, H.W. Research on mechanical properties and durability of steel slag coarse aggregate concrete. Concrete 2016, 3, 102–105. [Google Scholar]

- Xing, L.L.; Shang, J.L. Study on the effect of steel slag coarse aggregate on the performance of concrete. Concrete 2017, 9, 105–107. [Google Scholar]

- Han, Y.L.; Feng, Y.; Xiao, L. Effect of coarse and fine steel slag replacement of natural aggregates on the mechanical properties of concrete. Concr. Cem. Prod. 2015, 2, 96–98. [Google Scholar]

- Keertan, T.S.; Kumar, V.P.; Bommisetty, J.; Ramanjaneyulu, B.; Kumar, M.A. High strength fiber reinforced concrete with steel slag as partial replacement of coarse aggregate: Overview on mechanical and microstructure analysis. Mater. Today Proc. 2023. [CrossRef]

- Lai, M.H.; Zou, J.J.; Yao, B.Y.; Ho, J.C.M.; Zhuang, X.; Wang, Q. Improving mechanical behavior and microstructure of concrete by using BOF steel slag aggregate. Constr. Build. Mater. 2021, 277, 122269. [Google Scholar] [CrossRef]

- Mo, L.W.; Zhang, F.; Deng, M. Mechanical performance and microstructure of the calcium carbonate binders produced by carbonating steel slag paste under CO2 curing. Cem. Concr. Res. 2016, 88, 217–226. [Google Scholar] [CrossRef]

- Men, P.; Wang, X.; Liu, D.; Zhang, Z.; Zhang, Q.; Lu, Y. On use of polyvinylpyrrolidone to modify polyethylene fibers for improving tensile properties of high strength ECC. Constr. Build. Mater. 2024, 417, 135354. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Liu, C.; Cheng, P.; Li, Z.; Han, Y.; Wang, X. Enhancing the Interfacial Compatibility and Self-Healing Performance of Microbial Mortars by Nano-SiO2-Modified Basalt Fibers. Cem. Concr. Compos. 2024, 152, 105650. [Google Scholar] [CrossRef]

- Peng, X.; Shi, F.; Yang, J.; Yang, Q.; Wang, H.; Zhang, J. Modification of construction waste derived recycled aggregate via CO2 curing to enhance corrosive freeze-thaw durability of concrete. J. Clean. Prod. 2023, 405, 137016. [Google Scholar] [CrossRef]

- Bukowski, J.M.; Berger, R.L. Reactivity and strength development of CO2 activated non-hydraulic calcium silicates. Cem. Concr. Res. 1979, 9, 57–68. [Google Scholar] [CrossRef]

- Zhang, F.; Mo, L.W.; Deng, M. Effect of carbonation conservation on strength and volumetric stability of steel slag concrete. J. Silic. 2016, 44, 640–646. [Google Scholar]

- Liu, P.; Mo, L.W.; Zhang, Z. Effects of carbonation degree on the hydration reactivity of steel slag in cement-based materials. Constr. Build. Mater. 2023, 370, 130653. [Google Scholar] [CrossRef]

- Su, W.; Liu, C.; Bao, W. Study on the Mechanical Performance, Durability, and Microscopic Mechanism of Cement Mortar Modified by a Composite of Graphene Oxide and Nano-Calcium Carbonate. Buildings 2024, 14, 2236. [Google Scholar] [CrossRef]

- Ma, J.; Yu, Z.; Shi, H. Long-term hydration behavior and pore structure development of cement–limestone binary system. J. Therm. Anal. Calorim. 2021, 143, 843–852. [Google Scholar] [CrossRef]

- Xiao, H.; Bo, Y.; Gang, P. Investigation on hydration behavior and microscopic pore structure of early-age cement-based grouting material. J. Build. Eng. 2023, 80, 108050. [Google Scholar]

- Yang, B.; Zhang, Y.; Zhang, W. Recycling lithium slag into eco-friendly ultra-high performance concrete: Hydration process, microstructure development, and environmental benefits. J. Build. Eng. 2024, 91, 109563. [Google Scholar] [CrossRef]

- Wang, C.X.; Zhou, Y.S.; Wang, G.F.; Liu, T.; Wang, X.Y.; Cao, F.B. Microstructure and damage evolution model of steel slag fine aggregate concrete under freeze-thaw environment. J. Appl. Mech. 2023, 41, 585–593. [Google Scholar]

- Shan, L.; Li, H.; Zhao, J.; Zhang, X.; Kang, X.; Gao, X.; Zhou, Z. Investigating on the Pavement Performance of Multi-Source Solid Wastes by Cement and Fly Ash. Materials 2023, 16, 6556. [Google Scholar] [CrossRef]

- Zhu, X.G.; Wang, Z.Y.; He, C.Q.; Wang, L.F.; Zhao, S.; Liu, X.C. Experimental study on the compressive and seepage resistance of low strength steel slag concrete. J. Xi’an Univ. Technol. 2019, 35, 256–263. [Google Scholar]

- Santamaría, A.; Orbe, A.; José, J.T.S.; González, J.J. A study on the durability of structural concrete incorporating electric steelmaking slags. Constr. Build. Mater. 2018, 161, 94–111. [Google Scholar] [CrossRef]

- Wen, Y.; Sun, H.; Hu, S.D.; Xu, G.M.; Wu, X.Z.; Song, C.C.; Liu, Z.; Li, Z.J. Microstructure and life prediction model of steel slag concrete under freezing-thawing environment. Nanotechnol. Rev. 2021, 10, 1776–1788. [Google Scholar] [CrossRef]

- Cheng, X.; Tian, W.; Gao, J.F.; Gao, Y. Performance evaluation and lifetime prediction of steel slag coarse aggregate concrete under sulfate attack. Constr. Build. Mater. 2022, 344, 128203. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Zhang, Y.Z.; Guo, C.; Xing, H.W. Effect of steel slag microbeads replacing fine aggregates on the durability performance of concrete. Steel Vanadium Titan. 2020, 41, 102–106. [Google Scholar]

- Feng, Y.; Han, Y.L. Experimental analysis of the resistance of steel slag concrete to sulfate and magnesium salt erosion. Silic. Bull. 2015, 34, 3345–3351. [Google Scholar]

- Tran, M.V.; Nguyen, C.V.; Nawa, T.; Stitmannaithum, B. Properties of high strength concrete using steel slag coarse aggregate. ASEAN Eng. J. 2014, 4, 22–32. [Google Scholar] [CrossRef]

- Chi, L.; Huang, C.; Li, Z.; Ruan, S.; Peng, B.; Li, M.; Liang, Q.; Yin, K.; Lu, S. Heavy metals immobilization of LDH@biochar-containing cementitious materials: Effectiveness and mechanisms. Cem. Concr. Compos. 2024, 152, 105776. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).