Abstract

Despite the growing adoption of modular construction (MC) to enhance productivity, sustainability and industrialization in the building sector, critical terminological inconsistencies and conceptual ambiguities persist across academic, professional and regulatory domains. This study conducts a systematic literature review to investigate how the key terms modular, module, modularity, modularization and modular coordination are defined and applied in the recent literature. Following the PRISMA protocol, 85 peer-reviewed articles were selected from an initial pool of 4832 Scopus records. Bibliometric and thematic analyses reveal a lack of conceptual consistency in the application of key terms, most notably the frequent misuse of module to describe non-volumetric components. Beyond identifying these ambiguities, this study maps the most recurrent definitional patterns to outline potential pathways toward conceptual consensus. It clarifies the boundaries between modular (a system attribute), modularization (a design strategy), modularity (a system property), module (a prefabricated, spatially autonomous, functionally complete, and volumetric unit) and modular coordination (a dimensional grid system). Based on these insights, it proposes a conceptual hierarchy, and a set of propositions integrated into a structured glossary that contribute to terminological clarity, foster standardization, and improve communication in the Architecture, Engineering, and Construction (AEC) sector.

1. Introduction

The construction industry is globally recognized for its disproportionate consumption of natural resources, high carbon footprint, and persistent inefficiencies in productivity and project delivery [1,2,3,4]. These limitations, rooted in traditional, on-site, labor-intensive workflows, hinder quality control, increase operational risks, and constrain innovation [5,6,7]. In response, off-site strategies such as modular construction (MC) have emerged as promising alternatives. By shifting substantial portions of the building process to controlled factory environments, MC enables parallel task execution, tighter tolerances, repeatable quality, and accelerated schedules, while reducing material waste and improving safety through prefabricated volumetric units with integrated MEP systems [8,9,10,11,12,13].

Despite these technical advantages, MC still faces a critical and often overlooked barrier: the absence of clear, shared definitions for its foundational concepts. While this definitional instability has been recognized for years [14,15], Tan et al. (2023) [16] confirmed that “the non-consistent definitions of modules” persist across disciplinary boundaries, continuing to hinder both theoretical clarity and practical alignment in modular construction.

Multiple recent studies also document that the term module is applied inconsistently to a broad range of elements, from 1D beams and 2D panels to 3D volumetric units and even temporary storage containers, often without reference to volumetry, functional autonomy, or standardized interfaces [17].

This instability extends to related concepts: Tan et al. (2023) [16] report that “terms such as module, modular, modularity, and modularization are often used interchangeably across various academic papers spanning different subjects”, and Dong et al. (2023) [18] are explicit that “there is no consistent definition of modularity in the construction literature,” while Cao et al. (2022) [19] note that the term modular system is used in ways ranging from volumetric “boxes” to partial assemblies.

Even at the institutional level, normative standards diverge. ISO 21723:2019 defines a module as a dimensional increment of 100 mm [20], whereas ISO 20887:2020 describes it as an autonomous volumetric unit designed for disassembly and reuse [21]. Draft ISO standards under development, such as ISO/WD 25084.2 (Prefabricated Building: Terminology and General Principles) and ISO/WD 25192 (Prefabricated Building, Modular Building, Part 1: Concepts and General Principles), further underscore the lack of harmonized guidance and terminological consensus at the institutional level [22,23].

Evidence from practice confirms that this problem is not confined to academia. The McKinsey & Company report Modular Construction: From Projects to Products (2019) [24] shows that practitioners adopt modular to refer interchangeably to complete volumetric units, flat-packed panelized systems, or partially assembled kits. Such inconsistencies have been linked to scope misalignment, incompatible BIM object libraries, and disputes over quality assurance responsibilities, issues that directly affect cost, schedule, and compliance.

Attempts to define more precisely what qualifies as a module have emerged, such as Ginidahara et al. (2022) [25], who, drawing on a Delphi expert panel, confined the term module to prefabricated, self-contained volumetric units with integrated service systems. While valuable, such definitions remain the exception rather than the rule, raising a fundamental question for the AEC sector: are there established criteria that determine what can legitimately be considered a module, or can virtually any element be labeled as such depending on project-specific choices?

In other words, is this designation an arbitrary decision, or should a module necessarily comply with a defined set of technical and functional requirements? However, to date, no study has systematically mapped and clarified the meanings and interrelations of these foundational terms within the recent construction literature.

This definitional instability also cascades into related concepts. Modularization (the process of decomposing a system into modules) cannot be clearly understood if the core concept of a module is unclear. Similarly, modularity (the degree to which a system is composed of modules) relies on a shared and consistent definition, yet such consensus is often missing. As Tan et al. (2023) [26] observe, “as a multi-faceted concept, there is little consensus on the definition of product modularity.” Even terms like modular coordination, which aims to standardize dimensions, and modular construction itself, depend on stable conceptual anchors. Without a coherent foundation for what constitutes a module, the entire lexicon surrounding modular construction becomes unstable.

This terminological fluidity has resulted in a fragmented and ambiguous conceptual landscape, undermining cross-study comparability, obstructing theoretical development, and impairing the standardization of modular practices. These are not merely semantic variations; they represent foundational principles of modular construction whose inconsistent usage compromises conceptual coherence and limits the scalability of modular strategies across the AEC sector [16].

This scenario creates difficulties for practitioners, obstructs regulatory alignment, and impedes the production of rigorous and comparable academic research. These tensions raise fundamental research questions: what precisely qualifies as a module in modular construction, and how do related terms interrelate and diverge?

To answer these questions, this study conducts a PRISMA-based systematic review of the academic literature published between March 2020 and April 2025, aiming to establish a unified, theory-driven framework that clarifies and standardizes the terminology associated with MC. Specifically, the study (1) defines each core term based on its usage in the recent literature, (2) maps their conceptual relationships and hierarchical structure, and (3) synthesizes these findings into a comprehensive glossary. The outcome is a consolidated framework accompanied by a set of propositions to guide future empirical testing and support standardization efforts.

By offering a shared lexicon for design variables, performance metrics, and compliance criteria, this framework reduces entrenched ambiguities, bridges a major literature gap, and lays the foundation for interoperable BIM libraries, consistent procurement practices, and scalable innovation. Terminological clarity also supports contract drafting, regulatory alignment, and rigorous academic inquiry, ultimately facilitating the broader adoption of modular methodologies across the construction sector.

2. Research Methodology

Building on the conceptual gap identified in the previous section, this chapter outlines the methodological procedures adopted to examine how key terms related to modular construction are defined and applied in recent academic publications. The review included four structured phases: identification, screening, eligibility, and inclusion. To ensure transparency and replicability, the study followed the PRISMA protocol (Preferred Reporting Items for Systematic Reviews and Meta-Analyses).

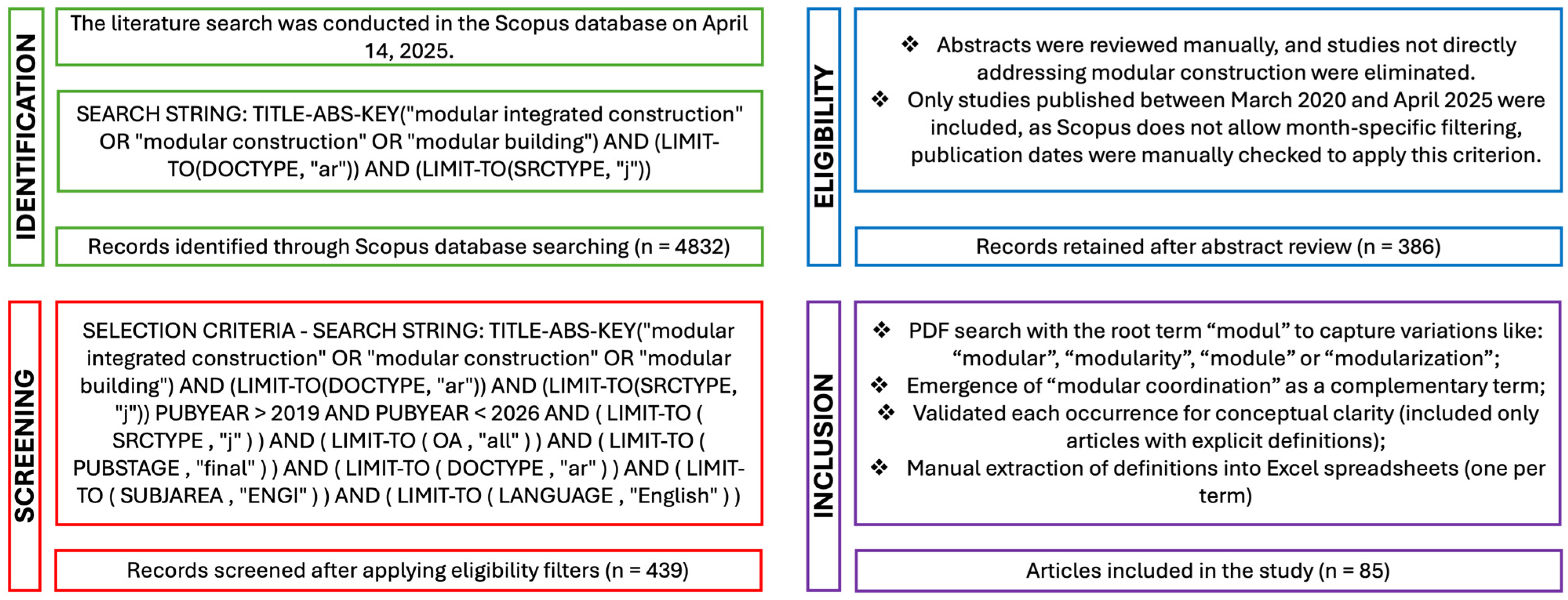

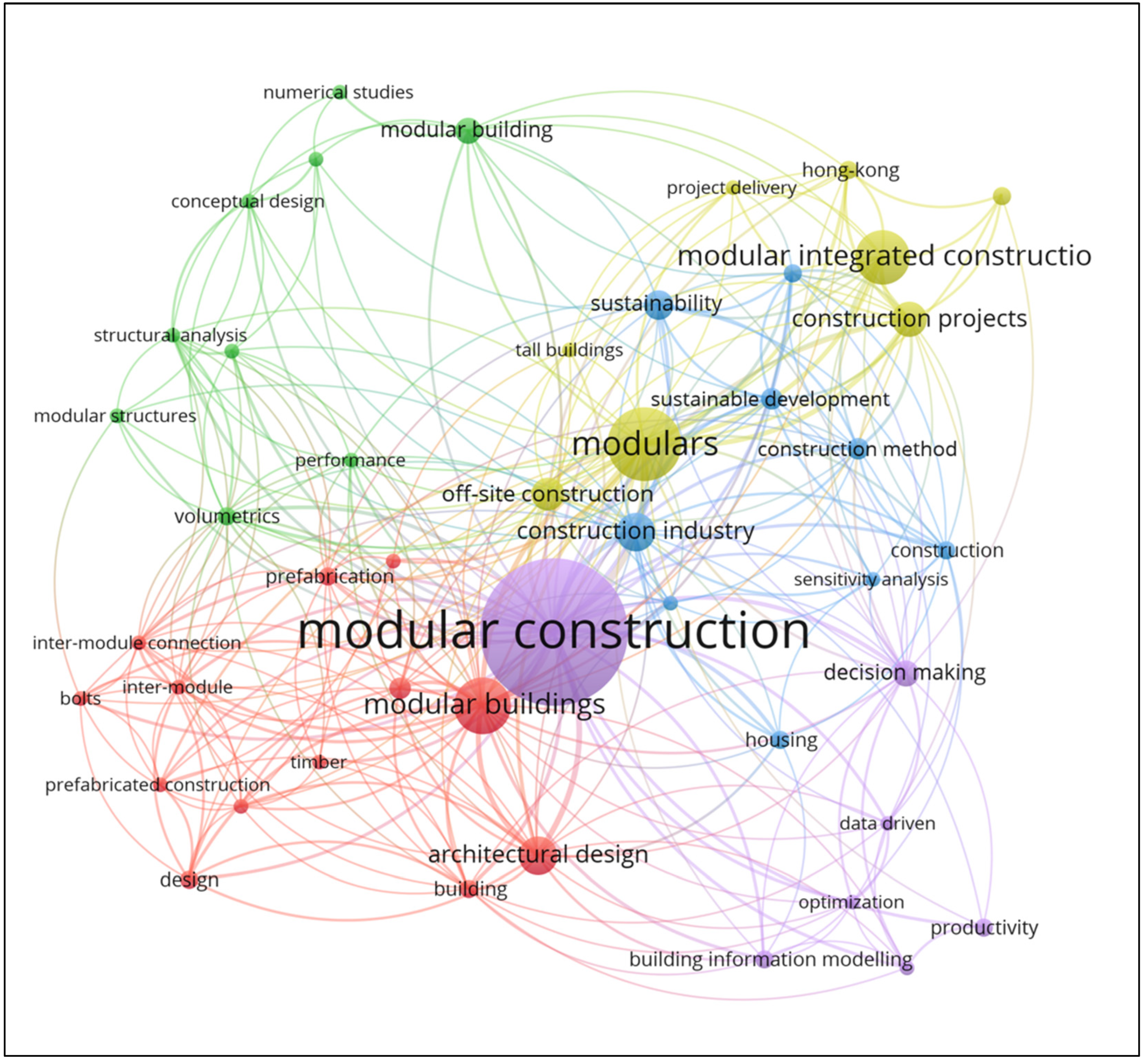

In accordance with the PRISMA 2020 guidelines [27], the systematic review process was conducted in four stages. First, 4832 records were retrieved through Scopus using a targeted search strategy (identification). Second, the initial results were refined by applying more restrictive filters (screening). Third, the temporal range (March 2020–April 2025) was manually applied and article abstracts were reviewed to assess compliance with the inclusion criteria (eligibility). Finally, 85 articles that met all criteria were selected for final analysis (inclusion). The complete process is visually represented in the PRISMA flow diagram (Figure 1).

Figure 1.

Literature selection process adopted in this systematic review.

Once the final corpus was established, qualitative content analysis was applied to extract and compare terminological patterns across studies.

2.1. Identification

A preliminary review of systematic literature studies in the field of modular construction was conducted to guide the formulation of the search strategy. Seminal works such as Khan et al. [28] and Wuni et al. [2] commonly employ broad descriptors such as “prefabrication”, “prefab”, “pre-fabricated”, “offsite”, “precast”, and “industrialized”. These terms were initially tested in exploratory searches and yielded an excessively large volume of results, many of which only mentioned modular-related concepts tangentially and lacked explicit definitions modular-related terms.

To maintain conceptual focus and analytical precision, the present review deliberately adopted a narrower search scope, using only terms that directly reflect the notion of modular associated with building and construction practices. Additionally, the search string detected occurrences of these expressions in the title, abstract, or keywords, ensuring that retrieved publications explicitly addressed the terminology of interest.

This strategy was intended to avoid semantic ambiguity, reduce noise from the unrelated literature, and retrieve articles most relevant to the discourse on conceptual clarity and terminological standardization.

The conceptual focus was further refined based on the contribution of Tan et al. [16], who identified “modular”, “modularity”, “module”, and “modularization” as foundational constructs, frequently used across disciplines such as engineering, industrial design, and construction. These terms, although closely related, are often applied inconsistently and interchangeably, contributing to conceptual fragmentation and terminological ambiguity.

Building on this insight, the present review examines how these four terms are defined and operationalized in the recent academic literature within the construction sector, targeting not only relevant studies, but also the core conceptual issues that hinder clarity and standardization in the field. Rather than attempting to develop a comprehensive glossary, this study focuses exclusively on the conceptual foundations of these key terms. The findings are intended to support future efforts toward terminological standardization in the field.

The literature search was carried out using the Scopus database, which is widely regarded for its comprehensive coverage and reliability in academic indexing. On 14 April 2025, the following query was executed:

TITLE-ABS-KEY(“modular integrated construction” OR “modular construction” OR “modular building”) AND LIMIT-TO(DOCTYPE, “ar”) AND LIMIT-TO(SRCTYPE, “j”)

Despite its concise formulation, the query yielded a total of 4832 journal articles. This substantial number of results not only underscores the widespread academic interest in the topic, but also highlights the need for a carefully structured filtering process, as detailed in the following sections.

2.2. Screening

The screening phase was conducted to ensure the relevance, recency, and quality of the studies included in the review. Only journal articles published between March 2020 and April 2025 were considered. Additional inclusion criteria required that articles be peer-reviewed, published in their final version, classified under the subject area of Engineering, written in English, and available in full-text open access format. This five-year window was adopted to capture the most up-to-date and representative research on modular construction.

Since the Scopus platform does not support filtering by publication month, a broader temporal string was applied during the database query. This initial search retrieved all journal articles published between 2020 and 2025 that met the general inclusion parameters. The following query was used:

TITLE-ABS-KEY(“modular integrated construction” OR “modular construction” OR “modular building”) AND LIMIT-TO(DOCTYPE, “ar”) AND LIMIT-TO(SRCTYPE, “j”) AND PUBYEAR > 2019 AND PUBYEAR < 2026 AND LIMIT-TO(SRCTYPE, “j”) AND LIMIT-TO(OA, “all-open”) AND LIMIT-TO(PUBSTAGE, “final”) AND LIMIT-TO(DOCTYPE, “ar”) AND LIMIT-TO(SUBJAREA, “ENGI”) AND LIMIT-TO(LANGUAGE, “English”)

The precise temporal range defined for this review (March 2020 to April 2025) was subsequently applied during the eligibility assessment. After executing the query, a total of 439 journal articles were retrieved. These records were then forwarded to the eligibility phase for further refinement.

2.3. Eligibility

The eligibility assessment was conducted through a preliminary review of article abstracts. This step aimed to exclude studies that were thematically unrelated to modular construction or published outside the defined timeframe (i.e., before March 2020). All retained studies met the following eligibility criteria: (i) thematic relevance to modular construction; (ii) publication between March 2020 and April 2025; (iii) peer-reviewed journal article in its final version; (iv) written in English; (v) full-text availability under open access; and (vi) classified under the subject area of Engineering. A total of 386 articles met these requirements and were selected for full-text review in the subsequent phase.

2.4. Inclusion

Following the eligibility assessment, a structured reading of the 386 retained articles was conducted to identify how the terms “modular”, “module”, “modularity”, and “modularization” were defined or discussed conceptually within the context of the construction sector. To minimize the risk of missing relevant definitions, each article was examined in full using the “search” function of the PDF reader. The root term “modul” was systematically entered into the search bar to retrieve all lexical variations in interest, such as “modular”, “modularity”, “module”, “modularization”, and related compounds. This strategy enabled consistent navigation across the documents and ensured that definitions embedded in less prominent sections (e.g., footnotes, figures, or appendices) were not overlooked.

Although the initial scope was limited to four core terms, the expression “modular coordination” emerged incidentally through this search method. Due to its frequent occurrence and conceptual relevance, it was included as a complementary focus in the analysis.

For each relevant occurrence, the surrounding context was reviewed to assess conceptual clarity. Only articles that offered explicit definitions or substantial conceptual discussions of at least one target term were included in the final corpus.

To support rigorous analysis, the identified definitions were manually extracted and recorded in separate spreadsheets, one for each term containing two columns: (i) article source and (ii) corresponding definition or conceptual excerpt. These data formed the empirical basis for the qualitative synthesis presented in Section 4, allowing the identification of semantic patterns, convergences, and inconsistencies across the literature.

In total, 85 articles met these criteria and were included in the final dataset. Each of these contributed at least one definition or substantive conceptual discussion extracted into the spreadsheets used for analysis. The remaining studies, although broadly related to modular construction, were excluded for lacking direct terminological input. The full methodological flow, from identification to inclusion, is summarized in Figure 1 (PRISMA), and the complete list of selected articles is presented in Table 1.

Table 1.

Studies included in the final corpus of the systematic review.

Despite the structured selection process, potential biases should be acknowledged. The inclusion criteria, limited to English-language journal articles in the field of Engineering, may have excluded relevant studies from other languages or disciplines. Additionally, as Scopus favors journals from North America, Europe, and parts of Asia, some regions may be underrepresented. These limitations reflect the chosen scope and suggest directions for broader future reviews.

3. Results and Discussion

3.1. Bibliometric Analysis

Understanding how the academic community engages with modular construction terminology requires more than identifying isolated definitions; it demands a comprehensive view of the scholarly structure that shapes this discourse. In this context, bibliometric analysis serves as a strategic method to map the intellectual landscape of the field, uncover thematic clusters, and identify influential authors, journals, countries, and temporal trends.

This approach is especially pertinent given the increasing complexity and interdisciplinary nature of modular construction research, which spans domains such as engineering, architecture, project management, and digital technologies. By analyzing publication patterns, citation impact, author networks, and keyword co-occurrence, the bibliometric analysis offers both quantitative and qualitative insights into how modular construction terminology has developed over time and across geographic regions.

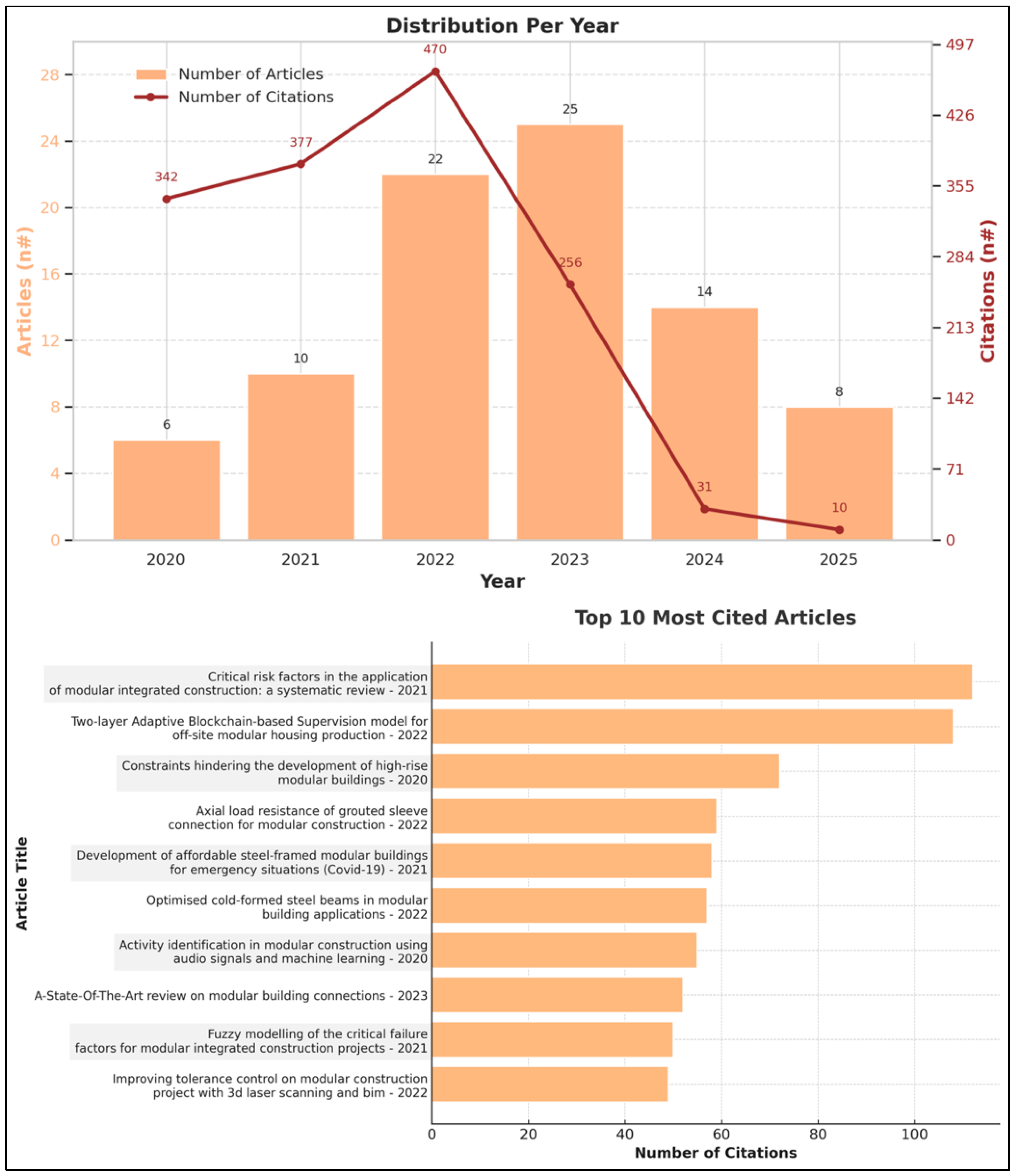

3.1.1. Temporal Distribution and Influence of Conceptually Focused Publications

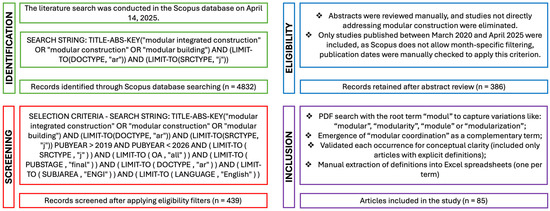

The distribution of articles and citations per year (Figure 2) reveals important trends in the development of the conceptual discourse on modular construction. Between 2020 and 2023, there was a steady increase in the number of publications, culminating in a peak of 25 articles in 2023. This period reflects the expansion of academic interest in refining the definitions and theoretical boundaries of modular construction. Notably, 2022 stands out as a pivotal year, combining high productivity (22 articles) with the highest citation count (470), which suggests both volume and significant academic influence.

Figure 2.

Distribution of articles and citations per year, along with the top 10 most cited articles in the systematic review. Source: elaborated by the authors (2025). This chart was generated using Python (v.3.11.8), Matplotlib (v.3.6.3), and Pandas (v.1.5.3). The script used to produce this visualization is available upon request.

A cross-analysis between annual publication trends and the top 10 most cited articles (Figure 2) reinforces this pattern. Most of the highly cited works were published between 2020 and 2022, with 2022 alone contributing four of the ten. These studies focus on themes such as risk factors, design tolerances, failure modes, and systemic constraints, which are all topics that influence how modular construction is understood and operationalized. This indicates that the conceptual discourse has been significantly shaped during this period by academically impactful contributions. Although 2023 marked the highest number of publications, only one article from that year appears among the most cited, reflecting the expected citation lag.

Despite the low publication count in 2020, early contributions proved highly influential, suggesting a pioneering role in reframing modular construction in the post-pandemic context. Thematically, highly cited works have emphasized technical and operational challenges, reflecting the sector’s focus on performance and implementation over conceptual refinement.

Importantly, this analysis is based on a dataset restricted to articles that directly engage with conceptual definitions, particularly those addressing the meanings and distinctions of “module”, “modular construction”, “modularity”, “modularization”, and “modular coordination”. As such, the observed trends reflect the evolution of terminological clarity, rather than the overall volume of modular construction research. The recent decline in article and citation counts should be interpreted with caution, considering the inherent delay in citation cycles and the incomplete representation of 2025.

Nevertheless, the drop in conceptually focused publications after 2022 may also signal a turning point: a potential stabilization or pacification of the core terminology used in the field. This reinforces not only the relevance of the definitions proposed in this study but also the study’s potential to serve as a reference for future research, fostering terminological consistency and interdisciplinary alignment in modular construction.

Notably, even though this study focuses on the core terminology of modular construction, none of the ten most cited articles provides a systematic terminological review. Despite their significant influence, particularly in areas such as performance evaluation, risk mitigation, and system implementation, these works prioritize application over conceptual clarity.

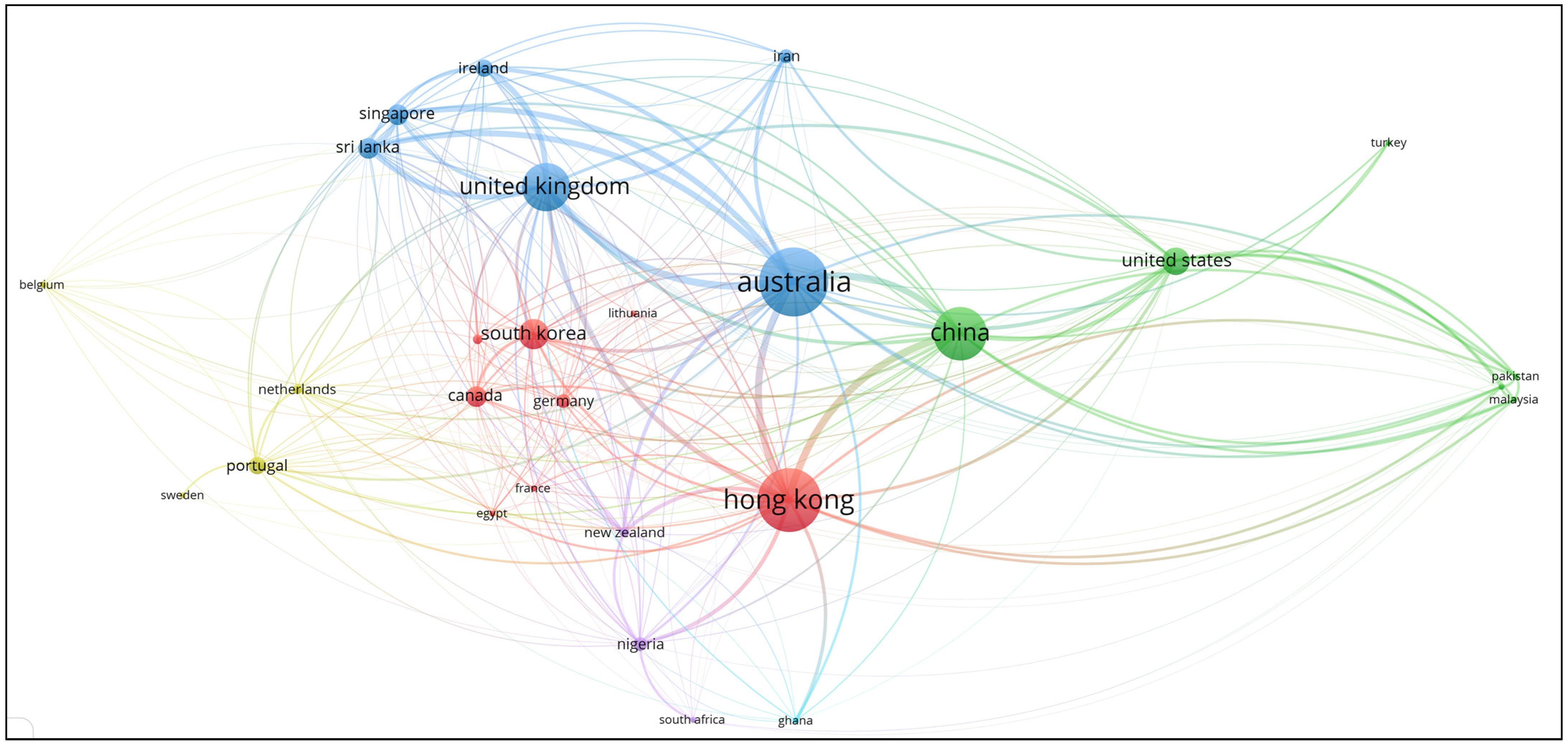

3.1.2. Country Distribution and Implications for Glossary Development

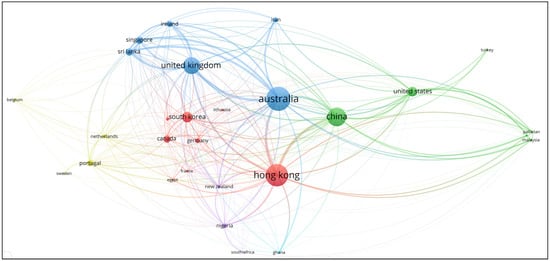

The country-based bibliometric analysis (Figure 3) highlights Australia, the United Kingdom, Hong Kong, and China as leading contributors to modular construction research. These countries not only have the highest number of publications but also form the strongest international collaboration networks. Their prominence is driven by factors such as rapid urbanization, innovation policies, and investments in industrialized building systems.

Figure 3.

Country co-authorship network of the studies included in the systematic review. Source: elaborated by the authors (2025). Visualization generated using VOSviewer (v.1.6.19), with a minimum co-authorship threshold of 2. The full counting method and default clustering algorithm were applied. Country names were standardized.

A dense international collaboration network also reinforces the global scope of modular construction research. Australia shows strong ties with the United Kingdom, China, and Hong Kong, while the United States maintains relevant (though less central) connections. Asian countries such as South Korea, Malaysia, and Pakistan also demonstrate growing academic engagement, suggesting a broadening of the research landscape beyond traditional Western centers.

Importantly, regional differences in language, building culture, and policy priorities may influence how core terms are defined and interpreted. For instance, while Hong Kong and China focus on high-rise modular systems, Australia and the UK emphasize low- and mid-rise applications. These contextual distinctions may shape terminology usage and create semantic variations even when terms are translated into English.

European countries such as Portugal, the Netherlands, and France are present but play a secondary role in international collaboration. Similarly, the absence of South American countries and the limited presence of African nations like Nigeria and South Africa suggest opportunities to expand terminological frameworks into underrepresented regions.

Despite Japan’s well-known modular housing industry, its absence from the dataset likely reflects barriers such as language, proprietary research, and publication in local outlets not indexed by Scopus.

Even with these regional asymmetries and linguistic particularities, the selected articles demonstrate broad geographic representation and include contributions from diverse academic and cultural contexts. This diversity enhances the robustness of the review and suggests that, despite terminological inconsistencies, there is potential to establish a globally relevant conceptual foundation for modular construction. As such, the analyzed corpus provides a strong empirical basis for identifying shared definitions and proposing terminology capable of supporting international standardization efforts and future glossary development.

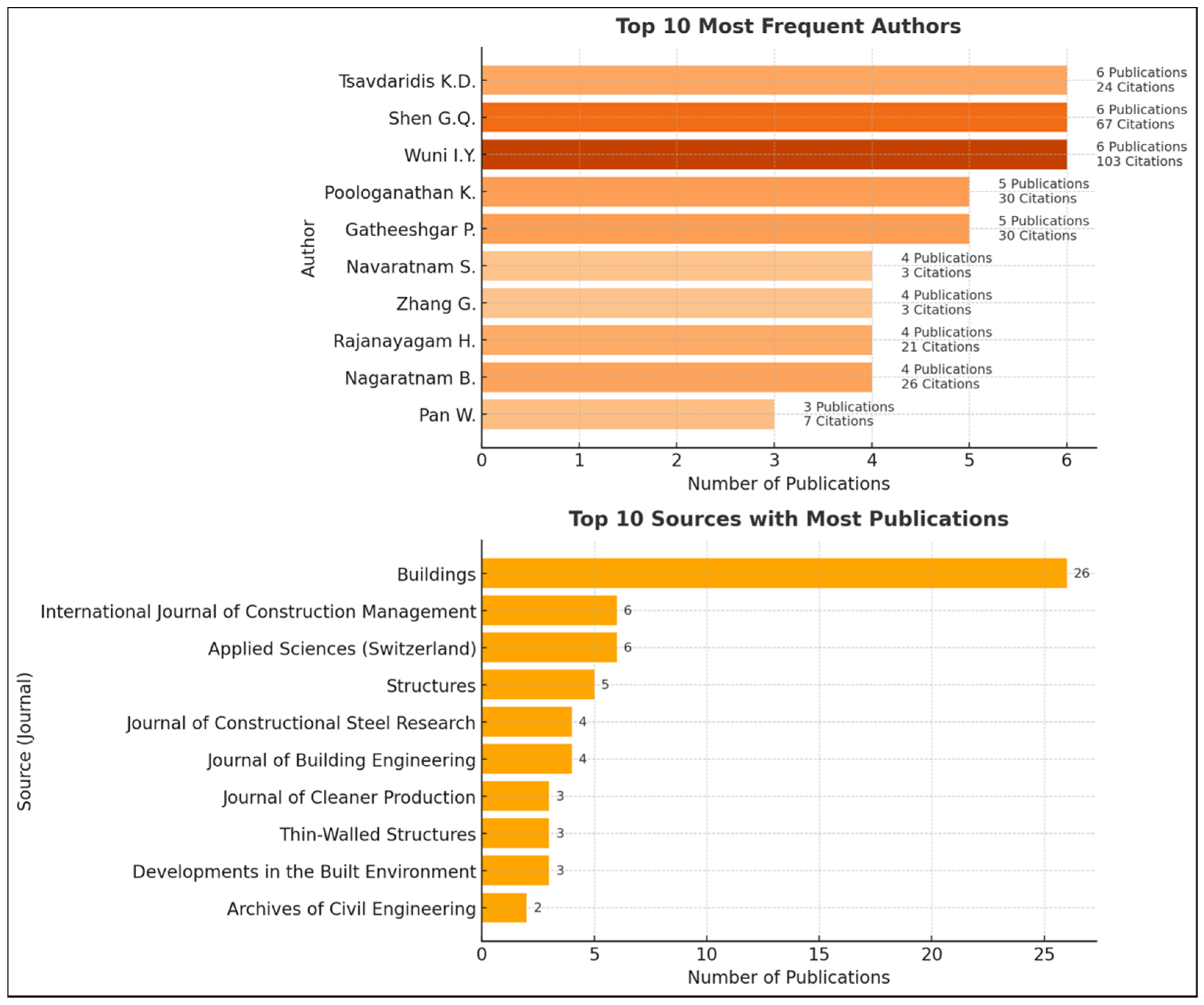

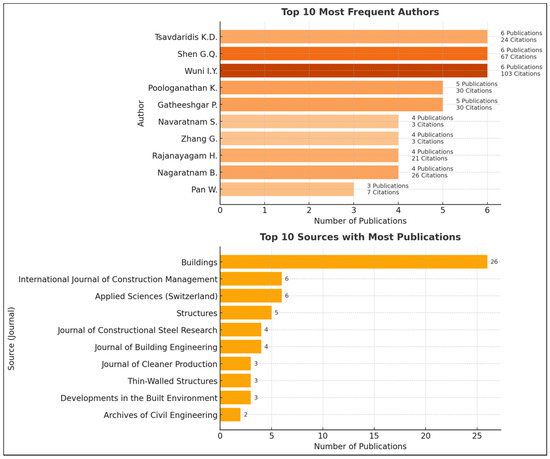

3.1.3. Journal and Author Distribution

The included studies were published across 30 journals, with Figure 4 displaying the 10 journals that contributed the largest number of articles addressing the research topic. The prominence of Buildings as a journal reflects not only its editorial alignment with modular construction research, particularly its focus on innovation, sustainability, and technological advancement in the built environment, but also its open access publication model. This model enhances the visibility, accessibility, and dissemination of research outputs, making it an attractive venue for scholars working in this domain.

Figure 4.

Most productive authors and journals in the corpus of the systematic review. Source: elaborated by the authors (2025). This chart was generated using Python (v.3.10), Matplotlib, and Pandas libraries. The script used to produce this visualization is available upon request.

Likewise, the presence of Applied Sciences and the International Journal of Construction Management among the top sources reinforces the multidisciplinary and managerial dimensions of the field. Journals such as Structures and Thin-Walled Structures emphasize the structural engineering perspective, highlighting the technical depth involved in modular system design.

This journal distribution not only highlights the fragmentation and specialization of modular construction research but also provides strategic guidance for researchers seeking venues aligned with terminological studies and system-level innovations in the field.

In parallel, the analysis of authorship reveals several prominent contributors. Three authors, Tsavdaridis K.D., Shen G.Q., and Wuni I.Y., each authored six of the included studies. However, citation metrics provide further nuance: Wuni’s publications have accumulated 103 citations, followed by Shen and Tsavdaridis. Additional prolific authors include Poologanathan K. and Gatheeshgar P., each with five publications, primarily between 2020 and 2021.

These patterns suggest that Wuni’s work resonates strongly within the academic community, especially in shaping the conceptual foundations of modular construction. Unlike many authors who focus solely on application, Wuni consistently introduces explicit definitions of key terms alongside his empirical or analytical findings, contributing to greater clarity and a consolidation of modular construction terminology.

3.1.4. Keyword Co-Occurrence Analysis and Thematic Clusters

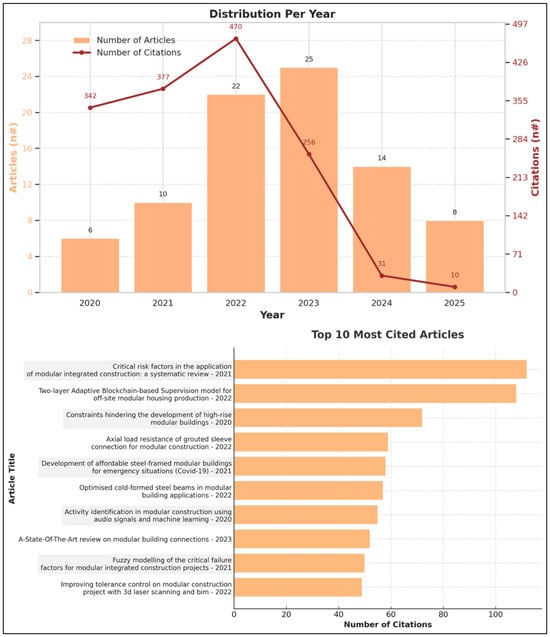

The keyword co-occurrence map (Figure 5) reveals four major thematic clusters: “modular buildings and architectural design” (purple), “construction systems and prefabrication” (red), “structural analysis and modular building techniques” (green), and “modular integrated construction and project management” (yellow). At the center of the network lies “modular construction”, underscoring its semantic dominance and broad relevance across disciplinary boundaries. This centrality also reflects the search terms adopted in this review.

Figure 5.

Keyword co-occurrence network based on the studies included in the systematic review. Source: elaborated by the authors (2025). The visualization was generated using VOSviewer (v.1.6.19). A minimum co-occurrence threshold of 3 was applied. The full counting method and the default clustering algorithm were used. Only author-supplied keywords were considered.

Interestingly, keywords such as “off-site construction” “prefabrication” and “prefabricated construction” appear conceptually adjacent but distinct from “modular construction,” suggesting that while modular approaches are part of the off-site paradigm, they possess unique features that justify terminological differentiation. This is an essential distinction for the development of a glossary.

The yellow cluster highlights the influence of Asian research, particularly from Hong Kong, where “modular integrated construction” (MiC) has emerged as a policy-driven term. This reinforces the idea that regional frameworks and institutional contexts shape both practice and terminology. The map also shows the increasing convergence of modular construction with digital tools such as “building information modeling”, “decision-making”, and “optimization”, pointing to a shift toward integrated and data-informed approaches.

Notably, only one of the five central terms appear in the co-occurrence map. This omission likely reflects the technical orientation of the reviewed articles, which tend to focus on applied challenges, such as implementation barriers, performance assessment, and risk management, rather than engaging in conceptual or terminological discussions.

The preeminent use of “modulars” as a keyword suggests a generic or inconsistent application across studies, as the term lacks specificity and may ambiguously refer to systems, components, or practices. Its diffuse presence within the network points to semantic overlap and reinforces the absence of consolidated terminological standards in the field. This issue is further compounded by the disjointed use of related terms such as “modular buildings” and “modular construction”, which, despite their proximity, are applied inconsistently, contributing to terminological fragmentation.

3.2. Thematic Analysis of Terminological Usage

To complement the bibliometric findings and address terminological nuances not captured by keyword co-occurrence analysis, this section introduces additional terms that emerged during the full-text review of the selected articles. Although these expressions stem from the term ‘modular construction’, they reflect region-specific practices, regulatory frameworks, and construction typologies.

A central finding is the widespread semantic overlap between modular-related concepts and adjacent terminologies, such as off-site construction, prefabrication, industrialized building systems, and modern methods of construction (MMCs). In some studies, these terms appear as direct synonyms for modular construction, while in others, they are treated as distinct yet overlapping concepts, often without explicit clarification. This variability contributes to conceptual dilution and hinders cross-study comparability.

A closer examination of the literature shows that the use of the terms “modular” and “module” also varies considerably depending on disciplinary orientation. Engineering and construction management papers frequently frame these terms in technical or logistical terms, while architectural studies tend to associate them with spatial design, user flexibility, or esthetic modularity.

This issue is compounded by the proliferation of region-specific terminologies that orbit the concept of modular construction (Table 2). In Hong Kong, for example, the term Modular Integrated Construction (MiC) refers to a highly regulated, volumetric, and prefabricated construction model institutionalized by the Construction Industry Council [61,76,92,93,103,109]. In Singapore, Prefabricated Prefinished Volumetric Construction (PPVC) carries similar connotations and legal requirements [53]. In North America, the distinction between Permanent Modular Construction (PMC) and Temporary Modular Construction (TMC) emphasizes whether modular systems are designed for long-term use or relocatability [59,78]. Meanwhile, Industrialized Building Systems (IBS), widely used in Malaysia, cover a broad range of prefabrication strategies, although only some of them are modular in the strict sense [32,113].

Table 2.

Regional variants of modular construction terminology and their key characteristics.

Additional expressions include Volumetric Modular Construction (VMC), commonly used in the United Kingdom [69,100,114]; Modular Building Systems (MBS), a general term often applied in the United States and Australia [64,72]; and material-specific variants such as Steel-Framed Modular Structures, and Timber Volumetric Structures, which reflect typological differences in structural systems [31,88,106].

Although these variants differ markedly in terminology, material logic, and regulatory frameworks, they often rely on foundational principles articulated through core modular terms, such as module (as a discrete unit), modularization (as a process of decomposition and assembly), and modularity (as a system property related to separability and reconfigurability). This lexical convergence suggests a shared conceptual aspiration.

In sum, while these region-specific expressions are not the central focus of this review, they exemplify the broader phenomenon of terminological drift that surrounds the concept of modular construction. While many of them implicitly rely on core concepts such as module and modularization, the absence of consistent definitions across regions and disciplines reinforces the need for a shared and critically examined vocabulary. By clarifying the semantic foundations of the five core terms analyzed in this study, we seek to provide a conceptual anchor amid this lexical variability.

4. Contributions Toward a Glossary for Modular Construction

4.1. Introduction and Scope

This section presents a critical synthesis of terminological insights derived from a systematic review of the academic literature on modular construction. Rather than producing an exhaustive glossary, it focuses on five foundational terms—modular, module, modularity, modularization, and modular coordination—examining how they are defined, interpreted, and applied in the construction sector. Emphasis is placed on identifying conceptual convergence, inconsistencies, and disciplinary nuances. By consolidating recurring patterns and clarifying ambiguities, this synthesis seeks to establish a conceptual foundation that can inform future glossary development and contribute to terminological standardization in modular construction research.

4.2. Analysis of Key Terms

4.2.1. Module

The term “module” is one of the most frequently used and often inconsistently defined concepts in the discourse on modular construction. Grammatically, the term functions as a concrete, countable noun that denotes a discrete unit within a larger construction system. It refers not to a process or property (as in modularization or modularity), but to a physical and manipulable entity.

The terminological complexity surrounding the concept is further compounded by its widespread use across other disciplines. In fields such as manufacturing, and software design, module may refer to any discrete, functional, and interchangeable unit regardless of physical dimensions or spatial embodiment, resulting in conceptual spillover and ambiguity when transposed to the built environment [29,30,91].

A key point emerging from the review is the terminological contradiction surrounding what qualifies as a module. Table 3 illustrates the ambiguous landscape found in the literature regarding its definition. While some authors adopt a broader interpretation, referring to two-dimensional panels, prefabricated beams, or linear components as modules [30,34,50,51,56,57,62,77,83,86,90,98,102,108], others restrict it as a three-dimensional, prefabricated, and functionally autonomous unit that typically includes internal finishes, integrated equipment, and utility connections, and is transported to the construction site as a complete volumetric entity, ready for installation [28,29,31,32,33,35,36,38,39,40,41,42,43,44,45,46,47,48,49,52,53,54,55,58,59,60,61,63,64,65,66,67,68,69,70,71,72,74,75,76,78,79,80,81,82,84,85,87,88,89,92,93,94,95,96,97,99,100,103,104,105,106,107,109,110,111,112].

Table 3.

Conceptual interpretations of “Module” found in the literature.

In between these positions, several studies also use the term simultaneously to refer to both volumetric units and non-volumetric components [37,73,91,101], resulting in a hybrid classification that further reinforces the conceptual ambiguity observed across the field.

To address this ambiguity, and in alignment with the prevailing literature, this study adopts a stricter definition: a module in construction must meet four cumulative criteria: it must be volumetric, prefabricated, functionally autonomous, and capable of integration through standardized and reversible interfaces. The association between module and volume is not incidental, since the fundamental objective of the AEC sector is the creation of inhabitable spatial units.

In this perspective, a module is not merely a prefabricated component, but a spatially autonomous, load-bearing or inhabitable unit that integrates structural, architectural, and service functions [29,53,69,81,93,112]. Labeling flat or linear components as modules without satisfying these conditions dilutes the conceptual clarity of modular construction and risks conflating it with generic prefabrication. Therefore, while every module is necessarily prefabricated, not every prefabricated component meets the criteria to be considered a module.

In the construction sector, typical examples include bathroom pods, kitchen units, bedrooms, or entire room-sized blocks that leave the factory fully equipped and ready for integration on-site [29,53,69,80,81,104], even though some publications still classify non-volumetric elements, such as beams, columns, façades and flooring systems, equipment racks, prefabricated pods, or MEP assemblies as modules [30,34,51,98,102], despite their lack of spatial autonomy and volumetric integrity.

The only recognized exception to this volumetric requirement is the case of foldable or articulated modules, which may lack volume during transportation but are specifically designed to deploy into fully functional three-dimensional units on-site [69]. These systems preserve the essential attributes of modules like spatial autonomy, functional completeness, and systemic integration while adding logistical flexibility.

This high level of completion contributes not only to logistical efficiency but also unlocks the potential for disassembly, reuse, and lifecycle optimization, especially when standardized interfaces support interoperability [66]. Furthermore, modules have been shown to serve as operational units in planning, scheduling, and productivity monitoring, especially in projects that emphasize modular logistics and performance benchmarking [44].

The notion of function is another critical, yet often overlooked, aspect in defining what constitutes a module. Across the literature, variations in definition frequently stem from differences in building typology, project scale, and regulatory or logistical contexts [30,36,50,77]. Unlike in manufacturing or software domains where a module may perform a single, narrowly defined function (e.g., a mouse or a microservice), modules in construction are expected to deliver multiple, integrated roles (spatial, structural, mechanical, and architectural) within a single unit [50,105].

This added complexity reinforces the understanding that a construction module must embody a complete and autonomous functional space, rather than serve as a mere structural fragment. Nevertheless, the association between module and volume allows each unit to retain a clearly identifiable programmatic function such as a bathroom, kitchen, or bedroom, despite its multifunctional nature.

Beyond function, the presence of standardized interfaces plays a central role in defining what qualifies as a module [3,6,8,54]. Regardless of its form or structural logic, it is the ability to connect, detach, or replace the unit within a broader system that distinguishes a module from a prefabricated object [8,54]. Moreover, several authors emphasize that these interfaces must allow for reversibility, meaning that modules should be removable or replaceable without compromising their structural or functional integrity [6,8,28].

Without such flexibility, the component loses the operational independence and systemic adaptability expected of modular systems. Modules that rely on irreversible connections, such as permanent welds, may violate this criterion and therefore should not be classified as modules even if they encompass a volume.

An exception to this rule is the case of standalone modules such as single-module dwellings, which may not require reversible interfaces in practice, since they are not intended to connect with other units. However, they must still conform to modular construction principles in their design, particularly regarding prefabrication, spatial autonomy, and functional completeness. Nevertheless, they do not constitute modular construction in the strict sense, as they neither result from modularization nor exhibit systemic modularity.

This conceptual refinement is essential to achieve terminological precision, especially in interdisciplinary projects, regulatory classifications, and design communication. Recognizing the distinction between a module, a component, and a prefabricated part allows for more accurate categorization of construction systems and avoids semantic ambiguity in both the academic literature and professional practice.

4.2.2. Modular

Widely used across the discourse on construction industrialization, modular serves as a versatile yet often ambiguous descriptor. Its meaning tends to vary depending on context, and its application across publications is frequently inconsistent [59,98]. Unlike module, which refers to a tangible, three-dimensional building unit, modular operates primarily as an adjective qualifying systems, processes, layouts, components, and even overarching design philosophies [88,90].

This semantic elasticity contributes to a fragmented and often ambiguous conceptual landscape regarding its meaning. As summarized in Table 4, the literature reflects five predominant patterns in how the term is interpreted, each grounded in a distinct conceptual framework.

Table 4.

Conceptual grouping of “Modular” definitions in the literature.

A review of the literature shows that modular is frequently employed to describe systems that exhibit properties such as repeatability, standardization, interchangeability, and off-site fabrication [69,102,104,110]. However, these characteristics do not always imply the use of volumetric modules.

A system may be described as modular based solely on its design logic, even when composed of 2D elements, panelized systems, or technical subassemblies. This becomes particularly evident when modular is used as an umbrella term encompassing diverse off-site strategies, such as panelized construction, kit-of-parts, hybrid prefabrication, or modularized service cores [102,104,105,110]. Numerous studies also apply modular to façades, walls, roofs, or floor systems [97,109,111]. In these cases, the term captures a logic of decomposition, interface coordination, and prefabrication rather than the presence of volumetric modules in the strict sense [73,88,95].

This inconsistency extends to research on hybrid structural systems, where modular may describe prefabricated assemblies, including steel-framed volumetric units with enhanced seismic properties or technical components like INNO3DJOINTS [73], whether or not they fully adhere to strict volumetric logic [86,94].

Furthermore, modular principles are frequently associated with sustainability outcomes, including carbon reduction, waste minimization, and lifecycle efficiency [69,102,105,110]. These studies show that modular design thinking can serve broader environmental and logistical goals, even when the components differ in form or autonomy [104].

To address this inconsistency, this study proposes a clearer conceptual boundary: when the adjective modular is used to qualify an entire construction product or building such as in modular construction, modular housing, or modular building, it should explicitly imply the presence of volumetric modules [39,66,94,101,106,108]. This interpretation reflects the dominant usage in the academic literature and aligns with international regulatory frameworks and industry standards.

Therefore, when applied to a building or construction system, the term should convey not merely a design philosophy but an actual composition of volumetric modules. In this sense, expressions like volumetric modular construction are conceptually redundant, since the literature overwhelmingly defines module as volumetric [39,66,94,101].

In this logic, a single-module building may qualify as a module, but it does not constitute a modular system. Accordingly, describing it as “modular” is inaccurate, as the term implies systemic integration: the capacity to connect, detach, or replace units within a larger configuration.

Conversely, systems that adopt modular principles but are not composed of volumetric units should be described with greater specificity using terms like panelized industrialized systems, component-based off-site construction, or functional modularization to prevent semantic confusion [88,97,109,111].

This conceptual clarification is not merely a linguistic refinement; it is a necessary alignment with the spatial, functional, and systemic logic of architecture and construction. In this context, modular construction cannot be conflated with generic prefabrication, panelized assemblies, or component-based strategies. It must be reserved for building systems composed of volumetric, prefabricated, and functionally autonomous modules, interconnected through standardized interfaces, as rigorously defined in this study.

4.2.3. Modularity

Modularity is frequently defined in the literature as a structural and functional property of systems that enables the separation, recombination, and substitution of components without compromising overall performance [30,36,45]. Originally rooted in engineering design and systems theory, the concept has been adapted in construction to describe how systems can be broken down into coordinated, semi-independent components [37,41].

From an engineering perspective, modularity denotes the degree to which units can be independently created and still be integrated to generate diversified configurations using common design principles, offering flexibility, adaptive reuse, and the capacity for recombination [32,36].

Grammatically, modularity functions as an abstract, uncountable noun that denotes a systemic property or condition emerging from modular design. It is distinct from modular, an adjective used to qualify systems, layouts, or components that exhibit modular characteristics, and from modularization, which refers to the deliberate process of decomposing complex systems into coordinated parts [36].

However, the term also exhibits considerable semantic elasticity. Some sources describe modularity as a qualitative design approach, while others frame it as a measurable property expressed through metrics such as the degree of coupling or the number of standardized interfaces. A recurring source of confusion lies in the conceptual overlap with modularization: while modularity refers to a system’s inherent configuration, modularization denotes the deliberate process through which modularity is achieved [36].

In the broader context of systems engineering and manufacturing, modularity can be applied to a wide range of products and subsystems, including technical systems such as HVAC, plumbing, façades, and panelized assemblies. It refers to a systemic property that allows the separation, recombination, and substitution of components while preserving overall functionality.

Across the reviewed publications, several interpretations converge on the idea that modularity facilitates architectural flexibility, parallel production, and easier maintenance by promoting independence among parts [45,77]. In this sense, modularity supports core principles such as scalability, customizability, and reconfigurability, which are clearly aligned with the broader goals of industrialized construction [29,45,104].

These strategic advantages are reinforced by studies that highlight how modularity enables independent fabrication, flexible sequencing, and reconfiguration in both design and production workflows [46,110]. Additionally, decision-making frameworks for MiC adoption frequently emphasize modularity as a foundational enabler of standardization, lifecycle optimization, and early-stage integration strategies [36].

However, within the specific context of the AEC sector, and particularly in discussions related to modular construction, the use of the term modularity is more precisely associated with buildings composed of volumetric, prefabricated, and functionally autonomous modules interconnected through a standardized interface, as defined in Section 4.2.1.

This sector-specific proposal does not deny the existence of modularity in complementary technical systems, but it establishes a conceptual boundary aligned with the architectural and spatial logic that underpins volumetric modular construction. Accordingly, in this study, modularity is primarily discussed in reference to buildings assembled from volumetric modules rather than to modular subsystems.

In this sense, the definition of modularity adopted in this study consolidates its role as a systemic property that, within the context of the AEC sector, is intrinsically linked to volumetric modular construction. This distinction provides the necessary conceptual foundation for the subsequent discussion on modularization.

4.2.4. Modularization

Modularization refers fundamentally to the process of simplifying complexity. In the construction literature, it is commonly described as a strategic method of decomposing complex systems into smaller, manageable, and coordinated parts, with the purpose of optimizing design, production, and on-site assembly [28,30,35,90].

One prominent interpretation of modularization is its treatment as a multidimensional decomposition process, applicable not only to the physical configuration of a building but also to its underlying functions, design stages, and production workflows [30,35,37,67].

Several authors define modularization as a systematic planning strategy that structures the project and supply chain into discrete, rational units, enabling greater control, parallel execution, and standardization across different domains [35,37,67]. In particular, studies on MiC adoption emphasize modularization as a prerequisite for enabling standardized coordination and early design integration [93,112].

Despite its frequent use, the term remains conceptually fragmented, with variations in scope and emphasis across different studies [77,90,112]. Linguistically, modularization is a nominalized action noun derived from the verb “to modularize”, denoting the act or strategy of breaking down a whole into coordinated parts [30,35].

It stands in contrast to modularity, which refers not to the process itself but to the resulting systemic condition characterized by separability, reconfigurability, and interface compatibility [28,35]. Accordingly, “modular” functions as an adjective for entities that embody the principles of decomposition, standardization, and coordinated interfaces, typically, but not exclusively, as outcomes of a modularization process.

Conversely, other studies use the term as a near-synonym for prefabrication or off-site construction, reducing its meaning to a production method without addressing the underlying conceptual rationale [93,112]. This conceptual dilution has been identified as a barrier to effective implementation in modular high-rise projects, where precise modularization strategies are often lacking [90,112].

A core enabler of modularization is the standardization of interfaces, which ensures seamless integration, interchangeability, and system flexibility [28,30,35,37]. Several authors emphasize that the effectiveness of modularization depends not only on the act of decomposition itself but also on the degree to which interfaces are standardized, coordinated, and decoupled from system-specific constraints [30,37,77]. Digital modeling and AI-driven coordination tools have further enhanced this capacity by enabling more granular control over modular workflows and interface management [37].

Furthermore, the literature highlights a critical trade-off intrinsic to modularization decisions. The efficiency of modularization depends on the level, scale, and granularity of module division: while finer decomposition may facilitate design optimization and flexibility, it also increases the number of components, logistical complexity, and associated costs. Conversely, larger module scales may limit customization but improve economies of scale and assembly efficiency [77]. This balance must be carefully managed according to project-specific goals, production capabilities, and economic constraints. Thus, modularization should be understood not only as a matter of part separation but as the intelligent planning of interconnections [30,37].

Although modularization techniques have been employed in various industries for centuries, the building industry continues to struggle with achieving high levels of modularization [105]. This persistent difficulty may stem, at least in part, from a lack of conceptual clarity regarding what exactly is being decomposed through product modularization.

A critical review of the literature reveals that the term is applied to at least three distinct decomposition strategies, often without explicit differentiation. Some studies emphasize the decomposition of volumetric entities, such as fully enclosed and self-supporting three-dimensional units like pods, rooms, or similar elements [35,81]. Others refer to two-dimensional panelized components, including walls, slabs, and façades, as the primary objects of modularization [35,90]. In parallel, a third group of studies focuses on functional decomposition, wherein systems such as HVAC, plumbing, or electrical networks are broken down into modular functions or subsystems to be coordinated independently [30,37,90].

Several modularization schemes have been proposed across different levels of the building system and for different types of components [67]. These interpretations reflect the broad applicability of the term and its conceptual elasticity in construction practice, with some studies identifying modularization as a key success factor in project performance, especially when supported by clear metrics and decision frameworks [37,67,112].

This plurality contributes directly to terminological fragmentation within the AEC sector. Rather than representing a well-defined process, modularization often serves as an umbrella term encompassing fundamentally different decomposition logics. While each serves distinct purposes, the lack of precision leads to confusion, miscommunication, and implementation challenges.

To contribute toward greater conceptual clarity, this study proposes a stricter distinction: the term “modularization”, within the context of building construction (AEC sector), should refer specifically to the decomposition of a building into modules, volumetric, prefabricated, and functionally autonomous units with standardized interfaces. This definition does not deny the existence or validity of modularization in other industries or technical domains, such as HVAC, electrical, plumbing, or façade systems, where modular thinking follows rules, constraints, and standards specific to those manufacturing sectors. However, such practices follow a distinct logic rooted in system engineering and should not be conflated with modularization in the architectural and spatial sense of building construction.

This distinction aligns with the stricter definition of ‘module’ adopted in Section 4.2.1 and represents a necessary step toward reducing conceptual ambiguity, improving communication, and advancing both research and industrial practice in the AEC sector. Furthermore, it brings the construction terminology into alignment with that of other industries such as automotive and aerospace, where modularization consistently refers to the decomposition of systems into autonomous, interoperable units governed by standardized interfaces.

4.2.5. Modular Coordination

The term modular coordination refers primarily to the dimensional and spatial organization of building components based on a standardized grid or coordination module. Unlike the other terms analyzed in this section, it does not inherently imply off-site construction, prefabrication, or volumetric assembly. Instead, its conceptual foundation is rooted in design rationalization, standardization, and interface compatibility, serving as a fundamental principle for enabling industrialized construction methods.

In technical standards such as ISO 21723:2019, modular coordination is defined as a methodology for establishing dimensional compatibility between building elements, typically based on a basic unit or “module” of 100 mm (or its multiples). These guidelines aim to optimize manufacturing, transportation, and on-site assembly by ensuring interoperability between prefabricated components, regardless of the degree of modularity or automation.

The reviewed literature reinforces the strategic role of modular coordination in aligning spatial logic with industrial production. As described in the study Research on the Modular Design Method and Application of Prefabricated Residential Buildings [77], modular coordination is presented as “an effective method to realize the standardized design of prefabricated buildings by using the modular coordination mechanism to coordinate the dimensional relationship between the structure and various parts and to complete the reasonable modular design”. The authors further state that “the modular application of new building industrialization solves the modular coordination of various parts and components, makes building manufacturing scientific and technical, and ensures quality and efficiency”.

Despite being referred to as a “module” in technical norms, the coordination unit (e.g., 100 mm) does not meet the essential criteria of a construction module. It is not a prefabricated entity, nor is it volumetric, autonomous, or equipped with standardized interfaces. It serves purely as a dimensional pattern or measurement convention, a modular grid unit, not as a physical or functional unit of construction.

Nonetheless, the term “modular coordination” reinforces the association between module and volume, as it prescribes the systematic repetition of three-dimensional increments, typically cubes or prisms, structured around a basic coordination unit. This reinforces one of the core defining criteria of the term module, as discussed in Section 4.2.1.

For this reason, it may be more accurate to describe it as a dimensional standard and refer to the methodology as “dimensional coordination”, rather than as “modular coordination” in the sense used throughout the modular construction literature. Recognizing this distinction is key to avoiding terminological confusion, particularly in interdisciplinary discussions that involve both design systematization and modular construction technologies.

Throughout the literature, modular coordination appeared as a complementary but conceptually distinct term. It was frequently discussed in relation to design systematization, grid-based planning, and spatial efficiency. In some cases, however, it was loosely conflated with broader terms such as modular construction or modularization, contributing to semantic ambiguity. Its normative and historical relevance, particularly in European and Brazilian contexts, justifies its inclusion in this study as a term closely linked to modular thinking, albeit not interchangeable with the other four core terms.

By addressing modular coordination alongside modular, module, modularity, and modularization, this study acknowledges the layered complexity of the modular discourse. It also highlights the importance of delineating where design rationalization ends and modular construction, understood as a production and assembly strategy, begins. Clarifying these conceptual boundaries is essential to achieving terminological coherence and effective implementation in both design and construction workflows.

4.3. Epistemological Implications and Disciplinary Displacements

These findings suggest the need for a unified theory for modularity in AEC sector, grounded not in analogies with manufacturing or software, but in the spatial, functional, and systemic realities of the built environment. The proposed hierarchy lays the conceptual foundations for such a theory. The following epistemological implications and disciplinary displacements emerge from this analysis:

- The module is not merely one among several related concepts; it is the conceptual pivot around which the entire terminology of modular construction revolves. All other terms, whether procedural, systemic, or dimensional, derive their meaning through the existence and definition of module.

- The module is conceptually ambivalent: it is both a unit and a microcosm. While structurally integrated into a larger system, it maintains operational and spatial autonomy, a duality that sets it apart from panels, components, or coordination grids.

- Volumetricity is not a typological preference, but a disciplinary necessity. Unlike in software or manufacturing, where modularity is defined by function or process, construction modularity is inherently spatial. It reflects not only how systems are produced, but how space is organized, inhabited, and reconfigured.

- A single-module building may qualify as a module, but it constitutes an exception within modular construction. It lacks modular integration, systemic modularity, and is not the result of modularization.

- The so-called “module” of modular coordination, commonly defined as a 100 mm dimensional increment, does not meet the criteria of a construction module. It should instead be considered a dimensional standard or coordination unit. Distinguishing this from the physical module is critical for avoiding conceptual conflation and for promoting terminological precision across design, engineering, and regulatory domains.

- Modularity may be an emergent property of system organization, but modular construction is a deliberate act that integrates spatial, regulatory, and industrial decisions into a coherent construction logic.

- Although modularity may exist in subsystems through separability and reconfigurability, its architectural significance emerges only when such logic derives from modularization, that is, when the overall system is deliberately decomposed into spatially autonomous volumetric units.

- Modularization, in this context, is not simply a strategy of decomposition; it is a spatialization process that translates systemic logic into architectural form. It enables modularity not merely as technical separability, but as the inhabitable articulation of spaces.

- While modularization produces discrete volumetric units as a design strategy, modular coordination merely regulates dimensional alignment, often without implying prefabrication, functional autonomy, or system separability. This epistemological gap reinforces the need to distinguish physical modules from abstract coordination units.

- Although reversibility is a defining criterion of modularity, most modular buildings are designed for permanence. This reveals a conceptual gap between what modularity enables and how it is commonly realized, suggesting that the full potential of modular systems remains underutilized in practice.

- The field still lacks a typological matrix that classifies modules beyond form and size, according to behavior, connectivity, functional autonomy, and adaptability. A more rigorous modular taxonomy could enable consistency across design practices, digital tools, regulatory models, and academic discourse.

- Modular construction reconfigures architectural temporality. It enables not just accelerated construction, but the possibility of reversibility, reassembly, and cyclical building lifespans, disrupting the traditional linear model of conception, execution, use, and demolition.

- By delegating formal, spatial, and functional decisions to prefabricated systems, modular construction transforms the role of the architect from autonomous author to orchestrator of pre-established configurations. This shift mirrors broader changes in authorship in the age of digital and parametric design.

- The drive for modular standardization often collides with construction’s inherent contextuality. Cultural, climatic, and social particularities resist full integration into prefabricated logics, exposing the limits of universalization in modular design.

- Modular construction occupies a disciplinary blind spot: it is too technical for architectural theory, too spatial for engineering, and too infrastructural for product design. This epistemological orphanhood underscores the urgency of establishing modularity as a domain of theoretical inquiry in its own right.

- Beyond its logical structure, the proposed hierarchy also reflects a temporal sequence: coordination precedes modularization, which generates modules, the organization of which results in modularity, ultimately giving rise to modular construction as a systemic outcome.

Together, these insights lay the groundwork for a theory of architectural modularity that is not only terminologically rigorous, but conceptually robust and disciplinarily consequential. By articulating the spatial, systemic, and epistemic foundations of modular construction, this framework advances a critical understanding of modularity as both a building logic and a contemporary design paradigm.

Beyond their theoretical relevance, the proposed hierarchy and conceptual distinctions offer tangible benefits for practice. They provide a basis for reducing contractual ambiguities, standardizing technical specifications in procurement processes, aligning digital object libraries in BIM platforms, and mitigating disputes between designers, contractors, and suppliers. By clarifying the scope and relationships of core terms, this framework can also guide regulatory updates, inform prefabrication guidelines, and support the integration of modular logic into digital and parametric design workflows.

Taken together, the proposed hierarchy and glossary constitute a conceptual framework for terminological standardization in modular construction, transferable across diverse contexts within the Architecture, Engineering, and Construction (AEC) sector. This dual structure, theoretical foundation and practical instrument, ensures that the field can pursue efficiency and innovation without sacrificing disciplinary coherence.

4.4. Glossary of Core Terms

To consolidate the definitions discussed, Table 5 presents a glossary proposal of the five core terms analyzed in this review—modular, module, modularity, modularization, and modular coordination—structured for clarity and future standardization efforts.

Table 5.

Glossary framework based on five propositions for standardizing key terms in modular construction.

5. Conclusions

Addressing the gap identified in the introduction, this study critically examined the inconsistent use of modular-related terminology in the recent construction literature through a systematic literature review encompassing 85 peer-reviewed articles published between 2020 and 2025, following a PRISMA-based selection protocol. The analysis of five key terms (modular, module, modularity, modularization, and modular coordination) reveals a persistent lack of standardization and recurring conceptual ambiguities that hinder effective communication across academic, professional, and regulatory domains.

Despite their widespread use, these terms are rarely defined with precision. Modular is often applied to systems that do not contain modules in the strict volumetric sense, while module is frequently misused to describe components lacking spatial autonomy or functional completeness. These inconsistencies dilute the technical specificity of modular construction discourse and contribute to confusion with adjacent concepts such as prefabrication and industrialized building systems.

As a response to these challenges, this study proposes a refined semantic framework and set of propositions that establish clear hierarchical relationships among the terms. This contribution differs from prior studies that focused on broader technical mappings [116,117] or descriptive regional glossaries [118] by offering a conceptually grounded synthesis aimed at resolving semantic ambiguities and redefining core terms.

Modularization is defined as the strategic process of decomposition; modularity is defined as the systemic property that results from this process; and module is defined as the physical volumetric outcome characterized by four essential criteria: prefabrication, spatial autonomy, functional completeness, and standardized, reversible interfaces.

This framework also clarifies that modular construction, by definition, refers exclusively to systems composed of volumetric modules, rendering common expressions such as “volumetric modular construction” technically redundant. It also repositions modular coordination not as a construction method, but as a dimensional planning tool, the so-called “module” of which is, in fact, a coordination unit rather than a construction entity.

This conceptual clarification goes beyond terminology: it reflects the spatial logic that underpins the architectural and constructive nature of buildings. The ultimate objective of any building system is the creation of usable, habitable, and functional volume. This spatial logic is not ancillary; it is a defining condition that shapes the very purpose of architectural production.

Consequently, the association of modularity with volumetric modules is not simply a technical preference but a conceptual necessity that reflects the functional, spatial, and systemic essence of the AEC sector. The volumetric condition, therefore, becomes the associative criterion that guides not only the definition of module, but also the broader terminological boundaries of modular construction.

These clarifications are not purely semantic; they have practical implications for how modular systems are designed, regulated, and evaluated. By offering sharper conceptual distinctions and resolving common ambiguities, this study contributes to the ongoing effort to standardize terminology in modular construction research and practice. It provides a theoretical foundation for the development of an international glossary that can support interoperability across design disciplines, manufacturing processes, project delivery models, regulatory frameworks, and the drafting of contracts and service specifications.

Furthermore, the proposed framework aligns conceptually with Design for Assembly (DFA) principles, which promote constructability, standardization, and reduced on-site labor. By clarifying the ontological status of terms such as module and modularity, this study complements DFA’s performance-oriented perspective with a conceptual foundation that supports terminological consistency and design coherence. This convergence strengthens both the theoretical and practical articulation of modular construction.

Future research may extend these insights through qualitative methodologies, such as case studies, interviews with industry professionals, and analysis of institutional standards, to test the applicability of the proposed definitions across diverse design typologies and regulatory contexts. To support the practical implementation of a standardized glossary, such efforts should be complemented by collaborative mechanisms involving researchers, practitioners, and regulatory agencies.

Reconciling conflicting definitions in daily professional practice may require participatory processes, including Delphi panels, consensus-building workshops, or interdisciplinary working groups. These approaches can assess how semantic clarity, or its absence, impacts decision-making in modular project planning, procurement, and policy, while ensuring that the glossary evolves into a usable and adaptive tool.

As modular construction evolves toward more sophisticated, hybrid, and integrated models, terminological clarity becomes essential. Precision in language is the first step toward precision in design. The consolidated definitions and hierarchy proposed here offer not only conceptual rigor but also tangible benefits for practice, such as by reducing contractual ambiguities, ensuring consistency in technical specifications, aligning BIM object libraries, and guiding regulatory updates. This dual role, bridging theoretical foundations and practical tools, ensures that efficiency, innovation, and disciplinary coherence advance together in the built environment. Ultimately, a standardized, internationally shared vocabulary is not merely an academic aspiration; it is a structural condition for interoperability, design quality, and the sustainable advancement of the AEC sector.

Author Contributions

Conceptualization, B.J.O.P., R.M.S.F.A. and J.D.M.M.; methodology, B.J.O.P. and R.M.S.F.A.; validation, R.M.S.F.A. and J.D.M.M.; formal analysis, R.M.S.F.A.; investigation, B.J.O.P.; writing; original draft preparation, B.J.O.P.; writing; review and editing, R.M.S.F.A. and J.D.M.M.; visualization, B.J.O.P.; supervision, R.M.S.F.A. and J.D.M.M.; project administration, B.J.O.P.; funding acquisition, B.J.O.P. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financed by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Data Availability Statement

The bibliometric data used in this study were retrieved from Scopus (https://www.scopus.com, accessed on 14 April 2025). Access to Scopus requires an institutional subscription or individual license.

Acknowledgments

During the preparation of this manuscript, the authors used ChatGPT (version 4o, OpenAI) to assist with translations and graphic production. The output was reviewed and edited by the authors, who take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest in conducting this research.

Abbreviations

The following abbreviations are used in this manuscript:

| MC | Modular Construction |

| MiC | Modular Integrated Construction |

| PPVC | Prefabricated Prefinished Volumetric Construction |

| PMC | Permanent Modular Construction |

| TMC | Temporary Modular Construction |

| IBS | Industrialized Building System |

| VMC | Volumetric Modular Construction |

| MBS | Modular Building Systems |

| BIM | Building Information Modeling |

| SLR | Systematic Literature Review |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| HVAC | Heating, Ventilation, and Air Conditioning |

| AEC | Architecture, Engineering, and Construction |

| MEP | Mechanical, Electrical, and Plumbing |

| DFA | Design for Assembly |

References

- Wang, Y. Exploring the Importance of Sustainability in the Construction Industry. Appl. Comput. Eng. 2023, 9, 312–318. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the Adoption of Modular Integrated Construction: Systematic Review and Meta-Analysis, Integrated Conceptual Framework, and Strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Famakin, I.O.; Othman, I.; Kineber, A.F.; Oke, A.E.; Olanrewaju, O.I.; Hamed, M.M.; Olayemi, T.M. Building Information Modeling Execution Drivers for Sustainable Building Developments. Sustainability 2023, 15, 3445. [Google Scholar] [CrossRef]

- Oke, A.E.; Arowoiya, V.A. An Analysis of the Application Areas of Augmented Reality Technology in the Construction Industry. Smart Sustain. Built Environ. 2022, 11, 1081–1098. [Google Scholar] [CrossRef]

- Livio Rossini, F.; Novembri, G. Construction Productivity Graph: A Comprehensive Methodology Based on BIM and AI Techniques to Enhance Productivity and Safety on Construction Sites. Riv. Tema 2023, 9, 1–13. [Google Scholar] [CrossRef]

- Jayawardana, J.; Zhang, G.; Kulatunga, A.K.; Sandanayake, M.; Jayasinghe, J.A.S.C. Life Cycle Sustainability Assessment for Modular Construction—A Proposed Conceptual Framework. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 042039. [Google Scholar] [CrossRef]

- Sotorrío Ortega, G.; Cobo Escamilla, A.; Tenorio Ríos, J.A. Industrialized Construction and Sustainability: A Comprehensive Literature Review. Buildings 2023, 13, 2861. [Google Scholar] [CrossRef]

- Mischke, J.; Stokvis, K.; Vermeltfoort, K.; Biemans, B. Delivering on Construction Productivity is No Longer Optional; McKinsey & Company: Zurich, Switzerland, August 2024; Available online: https://www.mckinsey.com/capabilities/operations/our-insights/delivering-on-construction-productivity-is-no-longer-optional (accessed on 20 August 2025).

- Hosny, M. Global Value Chains Participation and Economic Upgrading: Evidence from Developing Countries. Econ. Bull. 2023, 43, 1626–1641. [Google Scholar]

- Hsu, P.-Y.; Angeloudis, P.; Aurisicchio, M. Optimal Logistics Planning for Modular Construction Using Two-Stage Stochastic Programming. Autom. Constr. 2018, 94, 47–61. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Hwang, B.-G. Risks of Modular Integrated Construction: A Review and Future Research Directions. Front. Eng. Manag. 2020, 7, 63–80. [Google Scholar] [CrossRef]