Environmental Effects in Life Cycle Assessment of Machine-Vision-Driven Spall Repair Material Estimation for Sustainable Road Maintenance

Abstract

:1. Introduction

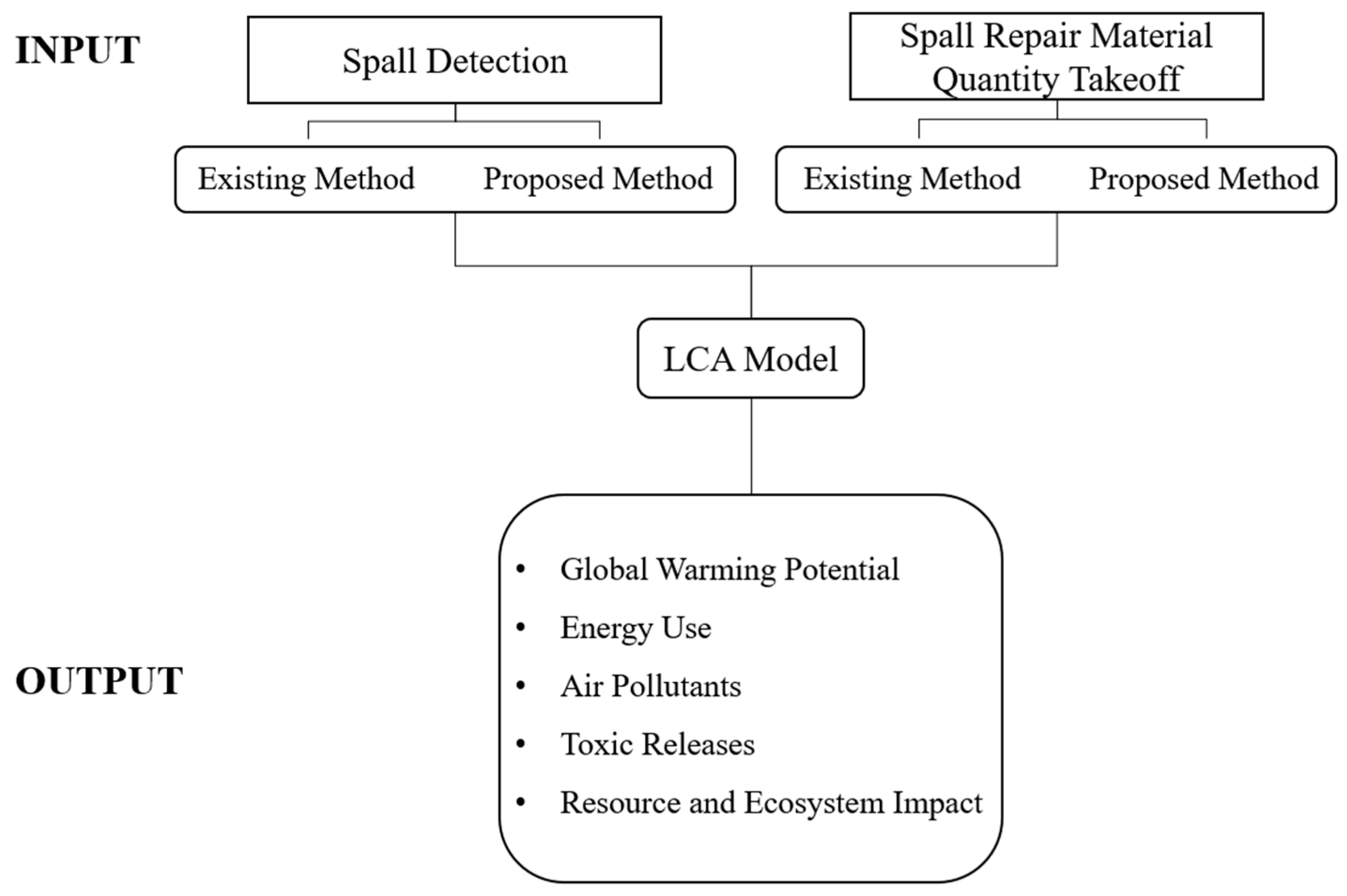

2. Methodology

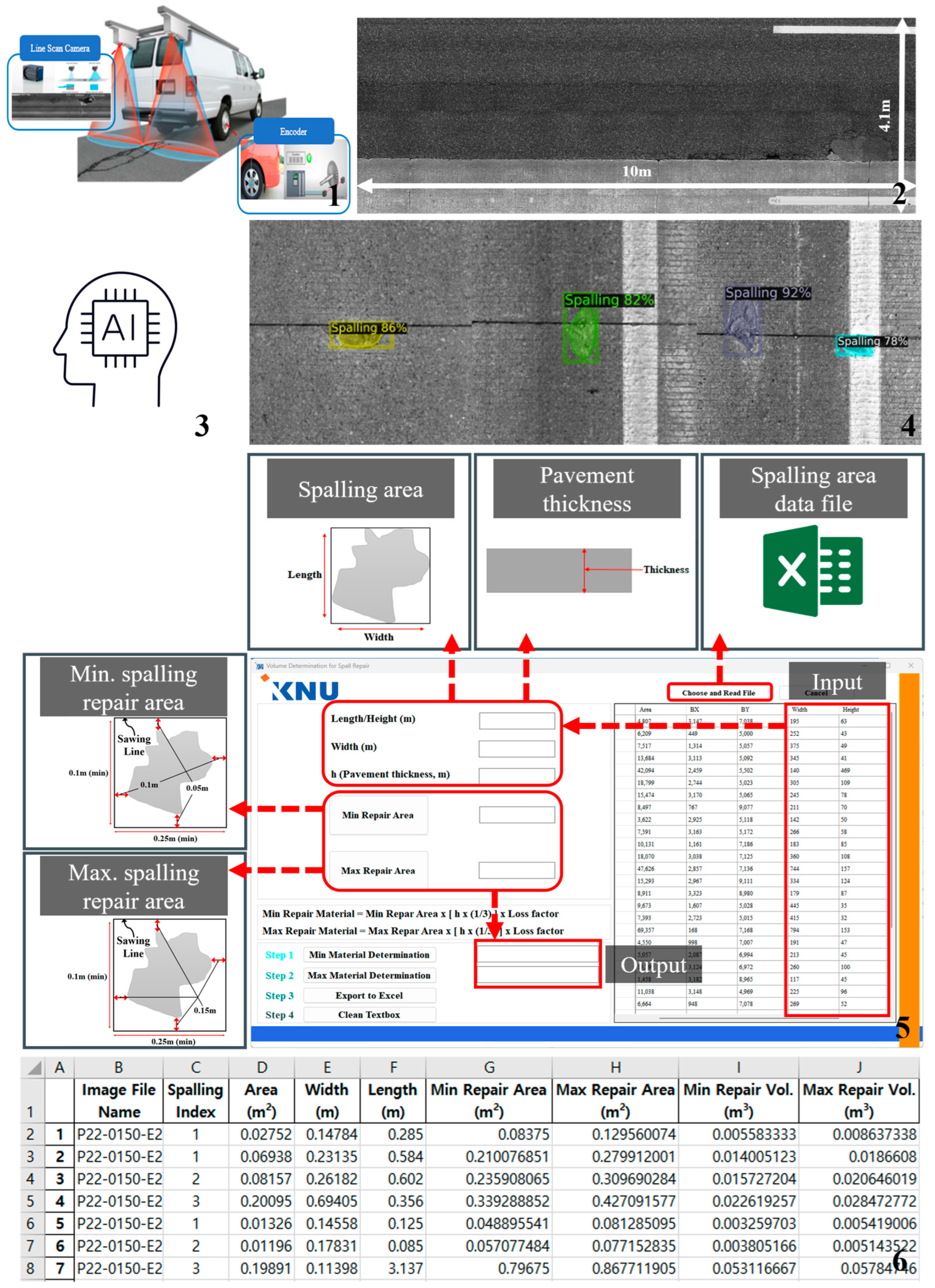

2.1. Overview of Proposed Spall Material Quantity Takeoff Method

- Energy and fuel consumption: The existing method involves high fuel consumption due to road closures and heavy machinery usage, while the proposed method minimizes fuel use during the spall detection phase without requiring road closures.

- Material use: The proposed method allows for precise calculation of the required repair materials, reducing waste compared to existing methods.

- Traffic emissions: Emissions from idling vehicles due to road closures are included for the existing method, whereas the proposed method assumes no idling emissions.

- Impact assessment framework: Environmental impacts, global warming, resource usage, and pollution are evaluated using OpenLCA software v2.3.0 [32].

2.2. Inventory Analysis

- Vehicle fuel consumption: In the existing method, the idling time caused by traffic congestion during road closure is included as a factor affecting fuel consumption. In the proposed method, energy consumption by the line-scan camera and vehicle is only used during the spall detection phase, with no idling assumed.

- Energy consumption and material input: Given that the line-scan camera and vehicle consume far less energy compared to heavy machinery, it is assumed that the proposed method uses minimal energy and materials during the repair process.

- Material usage: Material use is based on the amount of PCC required by each method, and it is assumed that the proposed method results in more accurate material quantities, reducing waste.

- Traffic congestion and emissions: The analysis assumes an average traffic density in a congested urban section to estimate the additional emissions during road closure. The increase in global warming due to traffic congestion is factored in, quantifying the environmental impact of congestion on emissions.

2.3. Life Cycle Impact Assessment

3. Results and Discussion

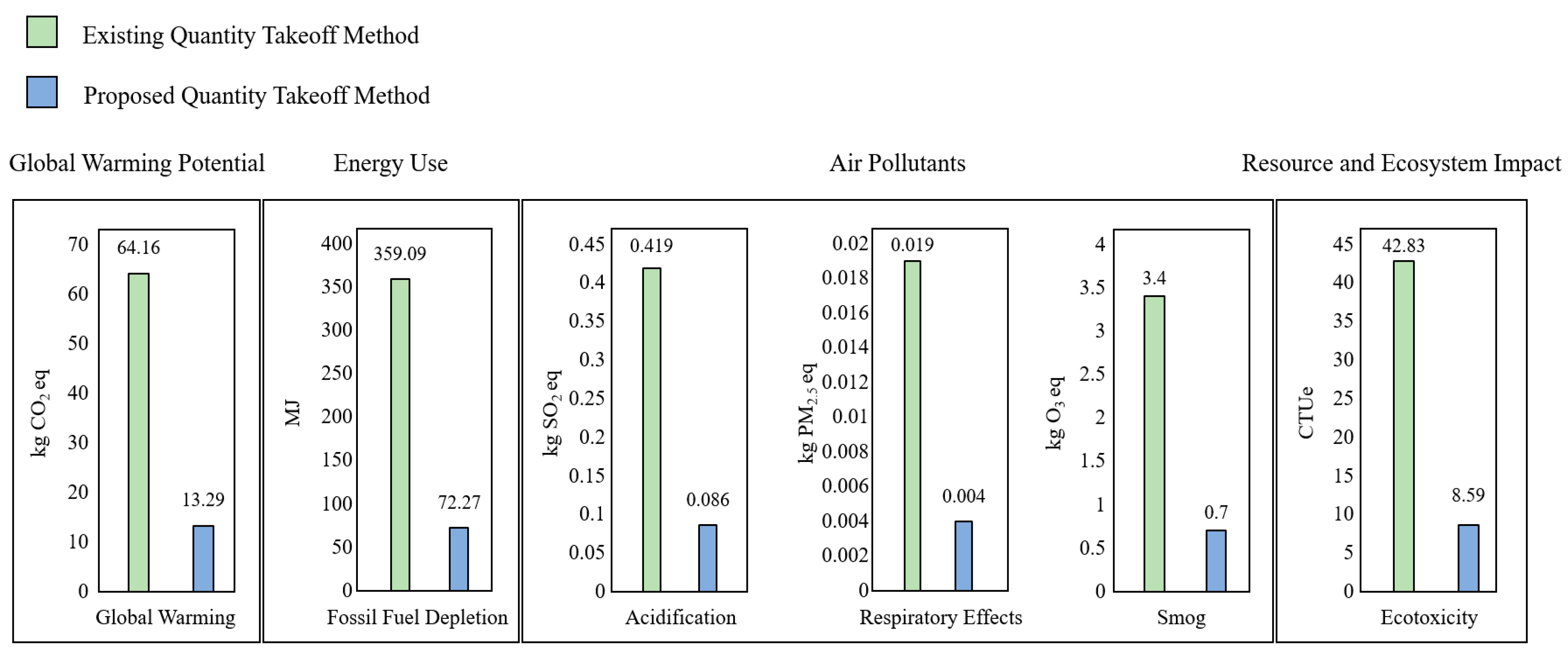

- Global warming potential: Global warming (kg CO2 equivalent (eq)).

- Energy use: Fossil fuel depletion (megajoule (MJ)).

- Air pollutants: Acidification (kg sulfur dioxide (SO2) eq), respiratory effects (kg particulate matter (PM) 2.5 eq), and smog (kg ozone (O3) eq).

- Resource and ecosystem impact: Ecotoxicity (comparative toxic unit equivalent (CTUe)).

- The integration of machine vision (MV) technology allows for real-time detection of spall without necessitating road closures. This efficiency not only reduces the time required for inspections but also minimizes the operational downtime of repair crews, leading to significant fuel savings and lower CO2 emissions.

- Accurate estimation of repair materials through MV technology minimizes overestimation and underestimation, leading to reduced material waste and lower environmental footprints. This precision ensures that only the necessary amount of Portland cement concrete (PCC) is used, which directly contributes to the observed reductions in ecotoxicity and resource depletion.

- By streamlining the repair process, the proposed method reduces the reliance on heavy machinery and extensive labor hours, further decreasing the energy consumption and associated emissions. This optimization not only enhances environmental performance but also improves overall project timelines and cost-effectiveness.

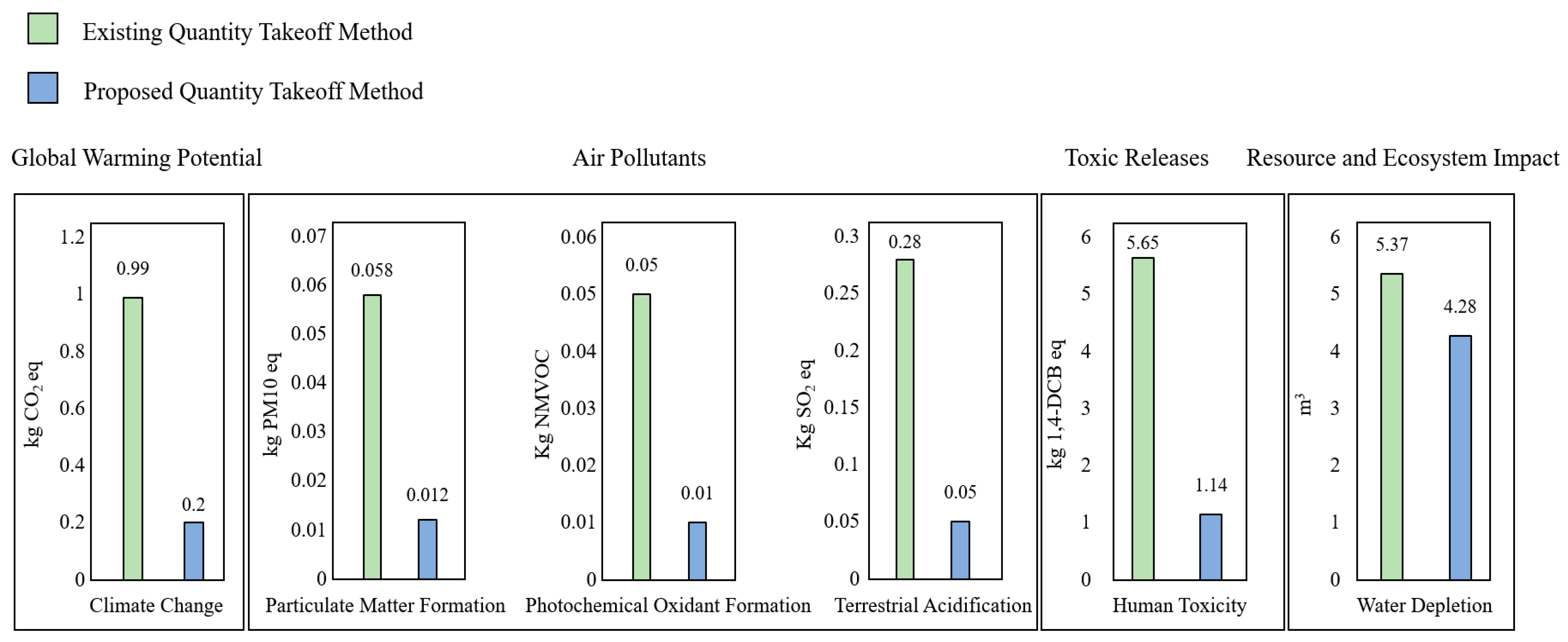

- Global warming potential: Climate change (kg CO2 eq).

- Air pollutants: Particulate matter formation (kg PM10 eq), photochemical oxidant formation (kg non-methane volatile organic compounds (NMVOC)), and terrestrial acidification (kg SO2 eq).

- Toxic releases: Human toxicity (kg 1,4-dichlorobenzene (DCB) eq).

- Resource and ecosystem impact: Water depletion (m3).

- Although lower than the other categories, the 20.27% reduction in water use aligns with sustainable water management practices, which is especially critical in regions facing water scarcity.

- The 79.68% reduction in NMVOC emissions indicates a substantial decrease in the precursors of ground-level ozone formation, enhancing both air quality and public health outcomes.

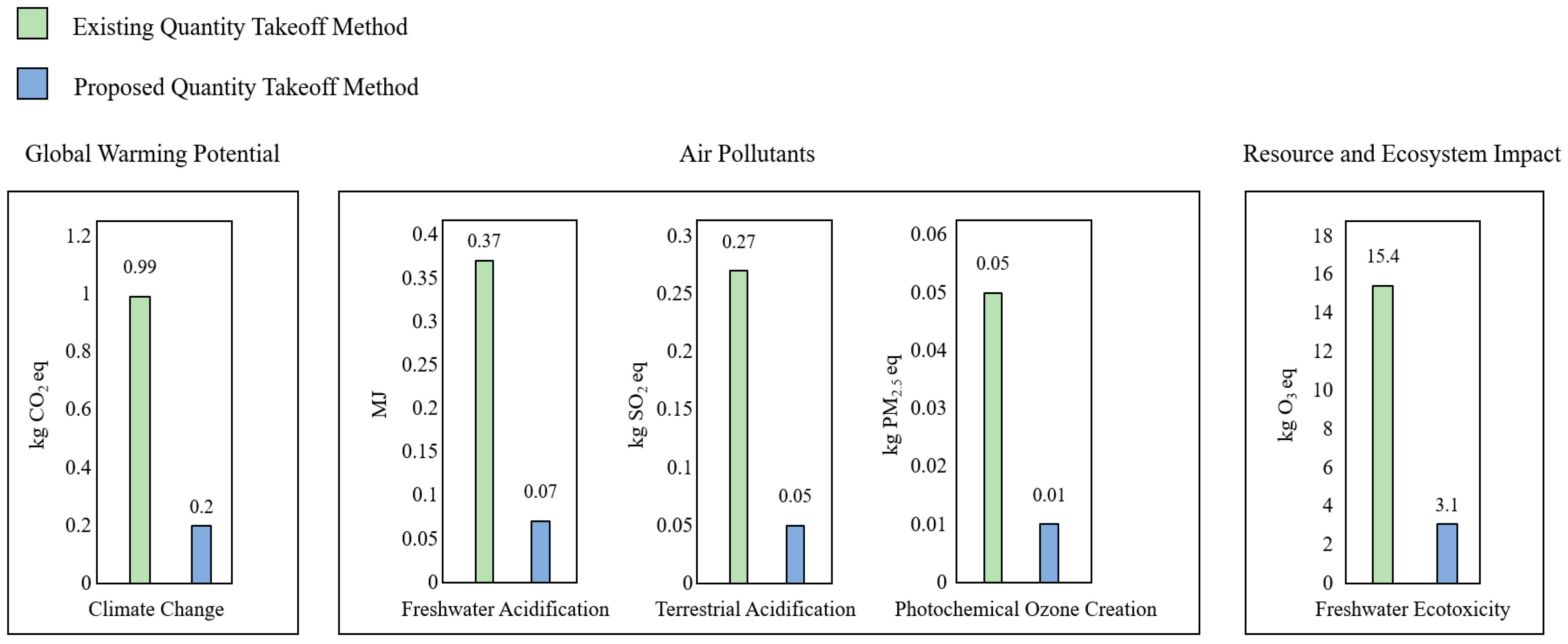

- Global warming potential: Climate change (kg CO2 eq).

- Air pollutants: Freshwater acidification (mol Hydron (H+) eq), terrestrial acidification (mol N eq), and photochemical ozone creation (kg NMVOC eq).

- Resource and ecosystem impact: Freshwater ecotoxicity (comparative toxic unit (CTU)).

- Reduced CO2 emissions (global warming): The lower CO2 eq in the proposed method can be attributed to less idling traffic and minimized material waste through consistent output, reducing errors in PCC usage. Existing methods often lead to excessive PCC production, where the calcination of limestone (CaCO3 → CaO + CO2) in cement kilns is a major CO2 source [43]. By minimizing material overestimation, the proposed approach reduces the volume of PCC produced and transported, thus cutting down the CO2 released during calcination and fossil fuel combustion in cement plants.

- Acidification (SO2 and NOx): The acidification potential is driven by the release of sulfur and nitrogen oxides during fuel combustion and certain industrial processes. Reduced machinery operation times, fewer detours, and less congestion in the proposed method mean fewer instances of incomplete combustion in vehicles and machinery. This reduces NOx emissions and, consequently, the formation of nitric acid (HNO3) in the atmosphere [44].

- Respiratory effects and smog (PM2.5, O3 precursors): Particulate matter (PM2.5) and ozone (O3) precursors such as volatile organic compounds (VOCs) and NOx are byproducts of combustion processes and asphalt/tire wear under congested conditions [45]. Minimizing road closures reduces the prolonged stop-and-go traffic scenario, cutting down incomplete combustion and the formation of secondary pollutants. This leads to fewer fine particulates and ozone-forming reactions in the troposphere, directly improving air quality and reducing health-related burdens.

- Human toxicity and ecotoxicity (1,4-DCB eq): The proposed method’s lower ecotoxicity and human toxicity indicators arise from the reduced use of PCC and associated raw materials. Cement and aggregate extraction involves quarrying and processing, potentially introducing heavy metals and other toxic substances into ecosystems [46]. By using a consistent estimation of PCC quantities, the method diminishes the overall cradle-to-gate resource extraction and related pollution. This reduces chemical leachates and runoff containing substances that can be toxic to aquatic and terrestrial organisms.

- Particulate matter (PM10) and photochemical oxidant formation (NMVOC): Analogous to the TRACI’s PM2.5 and O3 categories, the ReCiPe’s PM10 and NMVOC metrics reinforce how the reduced operational times of construction machinery and lower traffic congestion curb combustion-related emissions.

- Water depletion and resource use: Accurate PCC usage reduces not only chemical emissions but also the energy and water needed for cement production. Cement milling, aggregate washing, and concrete mixing all consume water [47]. By curbing material overuse, the proposed method indirectly lowers the demand for resource-intensive upstream processes, ultimately mitigating freshwater depletion and related habitat disturbances.

- Freshwater acidification and terrestrial acidification: These metrics underscore the importance of controlling SO2, NOx, and ammonia-related emissions. Reduced machinery operation and minimized PCC production translate into fewer nitrogen- and sulfur-based emissions. Chemically, lowering NOx and SO2 outputs curtails the formation of acids (HNO3, H2SO4) in atmospheric reactions, diminishing acid deposition in soils and freshwater bodies [48].

- Photochemical ozone creation (NMVOC eq): Similar to the ReCiPe category, the ILCD’s focus on NMVOCs emphasizes that fewer congested conditions and less heavy machinery lead to diminished VOC releases. VOCs, reacting with NOx in sunlight, form tropospheric ozone. Thus, the improved traffic flow and shorter repair durations in terms of the proposed method ensure fewer VOC precursors in the atmosphere, reducing the rate of ozone formation and thereby lessening related respiratory risks.

4. Conclusions

- Global warming potential: The proposed method reduced CO2 emissions by 79.28%, primarily through shorter road closures and reduced vehicle idling. This reduction is critical for mitigating climate change impacts, particularly in urban areas with heavy traffic.

- Air pollution: Significant decreases in particulate matter (79.21%), smog-related emissions (79.44%), and acidification potential (79.53%) were achieved. These reductions enhance air quality and contribute to public health improvements in densely populated regions.

- Resource optimization: Accurate material estimation resulted in a 79.94% reduction in ecotoxicity and a 20.27% reduction in water depletion, underscoring the method’s efficiency in resource utilization.

- Traffic and operational efficiency: The elimination of road closures during the detection phases led to improved traffic flow, reducing congestion-related emissions and enhancing the overall operational efficiency.

- Incorporate LCCA to explore the economic benefits, such as reduced labor costs and minimized energy use.

- Investigate the method’s applicability across diverse regions with varying traffic densities, climate conditions, and material availability.

- Evaluate social factors, including improved user experiences due to fewer delays and enhanced roadway safety.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abdelkader, E.M.; Moselhi, O.; Marzouk, M.; Zayed, T. Entropy-Based Automated Method for Detection and Assessment of Spalling Severities in Reinforced Concrete Bridges. J. Perform. Constr. Facil. 2021, 35, 04020132. [Google Scholar] [CrossRef]

- Yeon, G.; Yoo, H.; Hong, S.; Cho, J.; Kim, I. Development of an Estimation Method for Depth of Spalling Damage in Concrete Pavement by Ultrasonic Velocity Measurement. Appl. Sci. 2022, 12, 9881. [Google Scholar] [CrossRef]

- Smith, K.D.; Harrington, D.S.; Pierce, L.; Ram, P.; Smith, K.L. Concrete Pavement Preservation Guide; United States, Federal Highway Administration, National Concrete Pavement Technology Center: Washington, DC, USA, 2014.

- Alabduljabbar, H.; Alyousef, R.; Mohammadhosseini, H.; Topper, T. Bond Behavior of Cleaned Corroded Lap Spliced Beams Repaired with Carbon Fiber Reinforced Polymer Sheets and Partial Depth Repairs. Crystals 2020, 10, 1014. [Google Scholar] [CrossRef]

- Kim, D.-H.; Choi, M.-K.; Han, S.-H.; Jeong, J.-H. Determination of Partial Depth Repair Size for Spalling of Jointed Concrete Pavements Using the Impact Echo Method. Sustainability 2022, 14, 8143. [Google Scholar] [CrossRef]

- Robbins, D.B.; Lebel, L.B. Developing State-of-the-Art Marine Concrete Repair. In Proceedings of the Ports 2016, Seattle, WA, USA, 6 June 2016; American Society of Civil Engineers: New Orleans, LA, USA, 2016; pp. 441–450. [Google Scholar]

- Hager, I.; Mróz, K. Role of Polypropylene Fibres in Concrete Spalling Risk Mitigation in Fire and Test Methods of Fibres Effectiveness Evaluation. Materials 2019, 12, 3869. [Google Scholar] [CrossRef] [PubMed]

- Rezvan, P.; Azadnia, A.H.; Noordin, M.Y.; Seyedi, S.N. Sustainability Assessment Methodology for Concrete Manufacturing Process: A Fuzzy Inference System Approach. Adv. Mater. Res. 2013, 845, 814–818. [Google Scholar] [CrossRef]

- Kim, C.; Butt, A.A.; Harvey, J.T.; Ostovar, M. Environmental Impacts from Traffic on Highway Construction Work Zones: Framework and Simulations. Int. J. Sustain. Transp. 2024, 18, 680–694. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X. Comparison and Analysis of International Construction Waste Management Policies. In Proceedings of the Construction Research Congress 2012: Construction Challenges in a Flat World, West Lafayette, IN, USA, 21–23 May 2012; pp. 1672–1681. [Google Scholar] [CrossRef]

- Macioszek, E.; Granà, A.; Fernandes, P.; Coelho, M.C. New Perspectives and Challenges in Traffic and Transportation Engineering Supporting Energy Saving in Smart Cities—A Multidisciplinary Approach to a Global Problem. Energies 2022, 15, 4191. [Google Scholar] [CrossRef]

- Le, T.-T.; Nguyen, V.-H.; Le, M.V. Development of Deep Learning Model for the Recognition of Cracks on Concrete Surfaces. Appl. Comput. Intell. Soft Comput. 2021, 2021, 8858545. [Google Scholar] [CrossRef]

- Yu, Y.; Rashidi, M.; Samali, B.; Mohammadi, M.; Nguyen, T.N.; Zhou, X. Crack Detection of Concrete Structures Using Deep Convolutional Neural Networks Optimized by Enhanced Chicken Swarm Algorithm. Struct. Health Monit. 2022, 21, 2244–2263. [Google Scholar] [CrossRef]

- Wu, W.; Qurishee, M.A.; Owino, J.; Fomunung, I.; Onyango, M.; Atolagbe, B. Coupling deep learning and UAV for infrastructure condition assessment automation. In Proceedings of the 2018 IEEE International Smart Cities Conference (ISC2), Kansas City, MO, USA, 16–19 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. Comparison of deep convolutional neural networks and edge detectors for image-based crack detection in concrete. Constr. Build. Mater. 2018, 186, 1031–1045. [Google Scholar] [CrossRef]

- Doshi, K.; Yilmaz, Y. Road Damage Detection Using Deep Ensemble Learning. In Proceedings of the 2020 IEEE International Conference on Big Data (Big Data), Atlanta, GA, USA, 10 December 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 5540–5544. [Google Scholar] [CrossRef]

- Mandal, V.; Uong, L.; Adu-Gyamfi, Y. Automated road crack detection using deep convolutional neural networks. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 5212–5215. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, S.; Du, Y. Automatic Detection Method for Concrete Spalling and Exposed Steel Bars in Reinforced Concrete Structures Based on Machine Vision. Buildings 2024, 14, 1580. [Google Scholar] [CrossRef]

- Kumar, P.; Sharma, A.; Kota, S.R. Automatic multiclass instance segmentation of concrete damage using deep learning model. IEEE Access 2021, 9, 90330–90345. [Google Scholar] [CrossRef]

- Idjaton, K.; Janvier, R.; Balawi, M.; Desquesnes, X.; Brunetaud, X.; Treuillet, S. Detection of limestone spalling in 3D survey images using deep learning. Autom. Constr. 2023, 152, 104919. [Google Scholar] [CrossRef]

- Yasmin, T.; La, D.; La, K.; Nguyen, M.T.; La, H.M. Concrete spalling detection system based on semantic segmentation using deep architectures. Comput. Struct. 2024, 300, 107398. [Google Scholar] [CrossRef]

- Hoang, N.-D.; Huynh, T.-C.; Tran, V.-D. Concrete Spalling Severity Classification Using Image Texture Analysis and a Novel Jellyfish Search Optimized Machine Learning Approach. Adv. Civ. Eng. 2021, 2021, 5551555. [Google Scholar] [CrossRef]

- Cho, J.; Kang, J.; Song, Y.; Lee, S.; Yeon, J. Innovative Imaging and Analysis Techniques for Quantifying Spalling Repair Materials in Concrete Pavements. Sustainability 2023, 16, 112. [Google Scholar] [CrossRef]

- Aryan, Y.; Dikshit, A.K.; Shinde, A.M. A critical review of the life cycle assessment studies on road pavements and road infrastructures. J. Environ. Manag. 2023, 336, 117697. [Google Scholar] [CrossRef] [PubMed]

- Lei, B.; Kong, L.; Guo, Y.; Sun, B.; Li, X.; Wu, K.; Tam, V.W.; Li, W. Optimizing decarbonation and sustainability of concrete pavement: A case study. Case Stud. Constr. Mater. 2024, 21, e03574. [Google Scholar] [CrossRef]

- Finnveden, G.; Potting, J. Life Cycle Assessment. In Encyclopedia of Toxicology, 3rd ed.; Wexler, P., Ed.; Academic Press: Oxford, UK, 2014; pp. 74–77. ISBN 978-0-12-386455-0. [Google Scholar]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Hong, T.; Ji, C.; Jang, M.; Park, H. Assessment Model for Energy Consumption and Greenhouse Gas Emissions During Building Construction. J. Manag. Eng. 2014, 30, 226–235. [Google Scholar] [CrossRef]

- De Wolf, C.; Cordella, M.; Dodd, N.; Byers, B.; Donatello, S. Whole Life Cycle Environmental Impact Assessment of Buildings: Developing Software Tool and Database Support for the EU Framework Level(s). Resour. Conserv. Recycl. 2023, 188, 106642. [Google Scholar] [CrossRef]

- Celauro, C.; Corriere, F.; Guerrieri, M.; Casto, B.L. Environmentally appraising different pavement and construction scenarios: A comparative analysis for a typical local road. Transp. Res. Part D Transp. Environ. 2015, 34, 41–51. [Google Scholar] [CrossRef]

- Celauro, C.; Corriere, F.; Guerrieri, M.; Lo Casto, B.; Rizzo, A. Environmental Analysis of Different Construction Techniques and Maintenance Activities for a Typical Local Road. J. Clean. Prod. 2017, 142, 3482–3489. [Google Scholar] [CrossRef]

- Mohd Azman, M.A.H.; Ahmad Sobri, S.; Norizan, M.N.; Ahmad, M.N.; Wan Ismail, W.O.A.S.; Hambali, K.A.; Hairi, M.H.; Hermawan, A.; Mohamed, M.; Teo, P.T. Life cycle assessment (LCA) of particleboard: Investigation of the environmental parameters. Polymers 2021, 13, 2043. [Google Scholar] [CrossRef] [PubMed]

- Kong, L.; Wang, L.; Li, F.; Guo, J. Toward product green design of modeling, assessment, optimization, and tools: A comprehensive review. Int. J. Adv. Manuf. Technol. 2022, 122, 2217–2234. [Google Scholar] [CrossRef]

- Bare, J.C. Traci. J. Ind. Ecol. 2002, 6, 49–78. [Google Scholar] [CrossRef]

- Chester, M.; Horvath, A. High-Speed Rail with Emerging Automobiles and Aircraft Can Reduce Environmental Impacts in California’s Future. Environ. Res. Lett. 2012, 7, 034012. [Google Scholar] [CrossRef]

- Greer, F.; Horvath, A.; Rakas, J. Life-Cycle Approach to Healthy Airport Terminal Buildings: Spatial-Temporal Analysis of Mitigation Strategies for Addressing the Pollutants That Affect Climate Change and Human Health. Transp. Res. Rec. J. Transp. Res. Board 2023, 2677, 797–813. [Google Scholar] [CrossRef]

- Dekker, E.; Zijp, M.C.; van de Kamp, M.E.; Temme, E.H.; van Zelm, R. A taste of the new ReCiPe for life cycle assessment: Consequences of the updated impact assessment method on food product LCAs. Int. J. Life Cycle Assess. 2020, 25, 2315–2324. [Google Scholar] [CrossRef]

- Pešta, J.; Pavlů, T.; Fořtová, K.; Kočí, V. Sustainable Masonry Made from Recycled Aggregates: LCA Case Study. Sustainability 2020, 12, 1581. [Google Scholar] [CrossRef]

- Palacios-Munoz, B.; Peuportier, B.; Gracia-Villa, L.; López-Mesa, B. Sustainability Assessment of Refurbishment vs. New Constructions by Means of LCA and Durability-Based Estimations of Buildings Lifespans: A New Approach. Build. Environ. 2019, 160, 106203. [Google Scholar] [CrossRef]

- Ekvall, T.; Azapagic, A.; Finnveden, G.; Rydberg, T.; Weidema, B.P.; Zamagni, A. Attributional and Consequential LCA in the ILCD Handbook. Int. J. Life Cycle Assess. 2016, 21, 293–296. [Google Scholar] [CrossRef]

- Toumi, Y.; Mezhoud, S.; Boukendakdji, O.; Hadjadj, M. Impact of Recycled Aggregate Brick on the Physical-Mechanical and Environmental Characteristics of Cement Treated Bases. Bud. Archit. 2023, 22, 27–44. [Google Scholar] [CrossRef]

- Hajibabaei, M.; Hesarkazzazi, S.; Lima, M.; Gschösser, F.; Sitzenfrei, R. Environmental Assessment of Construction and Renovation of Water Distribution Networks Considering Uncertainty Analysis. Urban Water J. 2020, 17, 723–734. [Google Scholar] [CrossRef]

- Bosoaga, A.; Masek, O.; Oakey, J.E. CO2 capture technologies for cement industry. Energy Procedia 2009, 1, 133–140. [Google Scholar] [CrossRef]

- Larki, I.; Zahedi, A.; Asadi, M.; Forootan, M.M.; Farajollahi, M.; Ahmadi, R.; Ahmadi, A. Mitigation approaches and techniques for combustion power plants flue gas emissions: A comprehensive review. Sci. Total Environ. 2023, 903, 166108. [Google Scholar] [CrossRef]

- Mayer, P.M.; Moran, K.D.; Miller, E.L.; Brander, S.M.; Harper, S.; Garcia-Jaramillo, M.; Carrasco-Navarro, V.; Ho, K.T.; Burgess, R.M.; Hampton, L.M.T. Where the rubber meets the road: Emerging environmental impacts of Tire Wear particles and their chemical cocktails. Sci. Total Environ. 2024, 927, 171153. [Google Scholar] [CrossRef] [PubMed]

- Přikryl, R. Geomaterials as construction aggregates: A state-of-the-art. Bull. Eng. Geol. Environ. 2021, 80, 8831–8845. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; de Azevedo, A.R.G.; Klyuev, S.; Vatin, N.; Karelina, M. Capacity to develop recycled aggregate concrete in South East Asia. Buildings 2021, 11, 234. [Google Scholar] [CrossRef]

- Zannetti, P. Air Pollution Modeling: Theories, Computational Methods and Available Software; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Shang, Y. Subgraph robustness of complex networks under attacks. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 821–832. [Google Scholar] [CrossRef]

| Authors | Methods | Results | Limitations | Research Gap |

|---|---|---|---|---|

| Wu et al. [14] | Combined UAVs with CNNs for damage classification and structural health assessment | Achieved efficient crack and spall detection | Potential limitations in UAV image resolution and data quality; scalability issues not addressed | Need for scalable and accurate UAV-based inspection methods |

| Dorafshan et al. [15] | Compared deep CNNs and edge detectors for image-based crack detection in concrete | Achieved higher accuracy using deep CNNs compared to traditional edge detectors | May require extensive training data; higher computational cost for CNNs compared to simpler edge detectors | Optimize computational efficiency and reduce dependency on large labeled datasets |

| Manda et al. [17] | Automated road crack detection using deep CNNs | Achieved high accuracy in classifying road cracks | High computational demand; sensitivity to image quality and lighting conditions | Develop more robust models that handle varying image conditions and reduce computational requirements |

| Doshi and Yilmaz [16] | Implemented deep ensemble learning models for road damage detection | Enhanced accuracy and robustness in classifying various road damages | May require significant computational resources; ensemble methods can be complex to deploy | Enhance ensemble methods to cover broader damage classifications effectively |

| Le et al., [12] | Developed CNNs for crack recognition | Achieved high accuracy in detecting cracks | Dependency on labeled data; potential overfitting to specific datasets | Need for objective and consistent crack detection methods, reducing reliance on subjective manual inspections |

| Kumar et al. [19] | Employed Mask R-CNN for multiclass instance segmentation of concrete damage | Enhanced detection precision, especially at the pixel level | High computational cost; may require extensive training data for accurate segmentation | Improve detection precision for spalling at the pixel level to ensure more accurate assessments |

| Yu et al. [13] | Utilized deep convolutional neural networks optimized by the enhanced chicken swarm algorithm for crack detection | Demonstrated effective crack detection capabilities | Optimization process may be time-consuming; applicability to varied datasets not tested | Enhance detection algorithms to achieve better precision and reliability |

| Idjaton et al. [20] | Applied advanced deep learning techniques to 3D survey images for limestone spalling detection | Achieved pixel-level precision; integrated high-resolution data with AI algorithms to detect and classify structural defects in complex environments | Challenges of 3D spatial data processing; potential computational intensity | Enhance integration of high-resolution 3D data with AI algorithms for more efficient processing and detection |

| Yasmin et al. [21] | Utilized semantic segmentation using deep architectures for spall severity classification in concrete structures | Provided granular understanding of damage severity; enabled targeted repair strategies that optimize material usage and reduce unnecessary interventions | Dependency on large annotated datasets | Optimize material usage and reduce unnecessary interventions through targeted repair strategies |

| Wang et al. [18] | Automatic detection method for concrete spalling and exposed steel bars in reinforced concrete structures based on machine vision | Achieved high accuracy in automatically detecting and classifying concrete spalling and exposed steel bars | High computational cost for processing high-resolution images; limited model generalization across varied environmental conditions | Enhance computational efficiency for real-time application and improve model generalization across diverse environments |

| 1. Detection | 2. Repair | 3. Traffic Impact | |||||

|---|---|---|---|---|---|---|---|

| Flow | Unit | Proposed | Existing | Proposed | Existing | Proposed | Existing |

| Diesel | L | 10 | 50 | 38 | 38 | 1000 | 1624 |

| Labor | Person | 1 | 8 | 10 | 10 | - | - |

| Electricity | kWh | 1.5 | - | - | - | - | - |

| Line-Scan Camera Truck | Vehicle/h | 1/0.5 | - | - | - | - | - |

| Air Compressor Cutter | h | - | - | 20 | 20 | - | - |

| PCC Dry | kg | - | - | 346 | 352 | - | - |

| Traffic Signal Truck | Vehicle/h | - | 3/32 | 3/72 | 3/72 | - | - |

| Impact Category | Existing Method | Proposed Method | Reduction (%) |

|---|---|---|---|

| Acidification (kg SO2 eq) | 0.419996325 | 0.086008587 | 79.53 |

| Ecotoxicity (CTUe) | 42.83626922 | 8.592969417 | 79.94 |

| Fossil Fuel Depletion (MJ) | 359.0908967 | 72.2753667 | 79.87 |

| Global Warming (kg CO2 eq) | 64.16456518 | 13.29106932 | 79.28 |

| Respiratory Effects (kg PM2.5 eq) | 0.019476133 | 0.004050296 | 79.21 |

| Smog (kg O3 eq) | 3.445408793 | 0.707922127 | 79.44 |

| Impact Category | Existing Method | Proposed Method | Reduction (%) |

|---|---|---|---|

| Climate Change (kg CO2 eq) | 0.991615037 | 0.201467337 | 79.69 |

| Human Toxicity (kg 1,4-DCB eq) | 5.65768497 | 1.141349174 | 79.83 |

| Particulate Matter Formation (kg PM10 eq) | 0.05817287 | 0.011958033 | 79.44 |

| Photochemical Oxidant Formation (kg NMVOC) | 0.04961962 | 0.010083596 | 79.68 |

| Terrestrial Acidification (kg SO2 eq) | 0.281497097 | 0.057449052 | 79.60 |

| Water Depletion (m3) | 5.369538262 | 4.282614698 | 20.27 |

| Impact Category | Existing Method | Proposed Method | Reduction (%) |

|---|---|---|---|

| Climate Change (kg CO2 eq) | 0.992339757 | 0.201610086 | 79.69 |

| Freshwater Acidification (mol H+ eq) | 0.368968452 | 0.0752992 | 79.59 |

| Freshwater Ecotoxicity (CTU) | 15.46663303 | 3.103744042 | 79.94 |

| Terrestrial Acidification (mol N eq) | 0.272625077 | 0.054561223 | 79.99 |

| Photochemical Ozone Creation (kg NMVOC eq) | 0.049935326 | 0.01014676 | 79.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, J.; Rodrigazo, S.A.; Kim, H.-H.; Lee, S.-J.; Park, C.G.; Yeon, J. Environmental Effects in Life Cycle Assessment of Machine-Vision-Driven Spall Repair Material Estimation for Sustainable Road Maintenance. Buildings 2025, 15, 162. https://doi.org/10.3390/buildings15020162

Cho J, Rodrigazo SA, Kim H-H, Lee S-J, Park CG, Yeon J. Environmental Effects in Life Cycle Assessment of Machine-Vision-Driven Spall Repair Material Estimation for Sustainable Road Maintenance. Buildings. 2025; 15(2):162. https://doi.org/10.3390/buildings15020162

Chicago/Turabian StyleCho, Junhwi, Shanelle Aira Rodrigazo, Hwang-Hee Kim, Su-Jin Lee, Chan Gi Park, and Jaeheum Yeon. 2025. "Environmental Effects in Life Cycle Assessment of Machine-Vision-Driven Spall Repair Material Estimation for Sustainable Road Maintenance" Buildings 15, no. 2: 162. https://doi.org/10.3390/buildings15020162

APA StyleCho, J., Rodrigazo, S. A., Kim, H.-H., Lee, S.-J., Park, C. G., & Yeon, J. (2025). Environmental Effects in Life Cycle Assessment of Machine-Vision-Driven Spall Repair Material Estimation for Sustainable Road Maintenance. Buildings, 15(2), 162. https://doi.org/10.3390/buildings15020162