Experimental Study on the Photothermal Properties of Thermochromic Glass

Abstract

1. Introduction

1.1. Development Overview of Thermochromic Glazing (TCG)

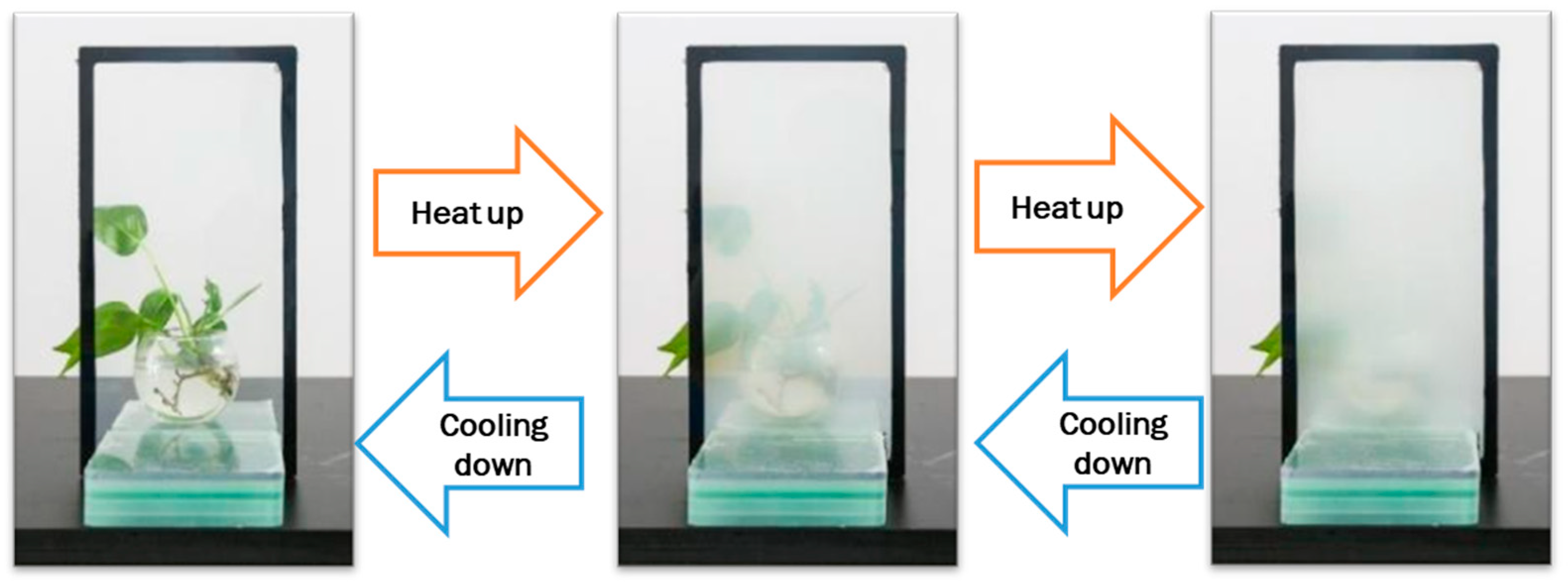

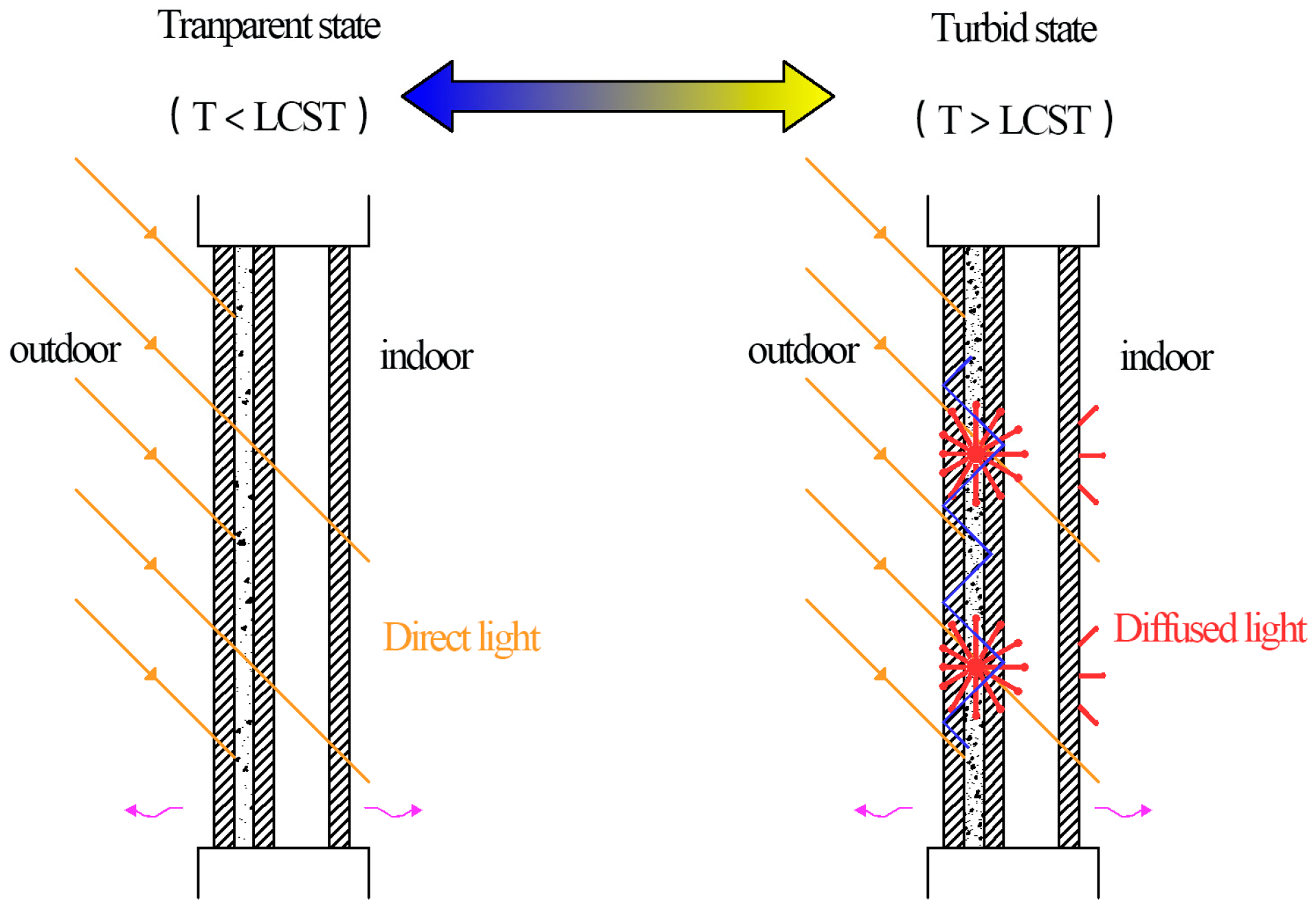

1.2. Characteristics of Hydrogel-Based Thermochromic Glazing

2. Methodology

2.1. Workflow

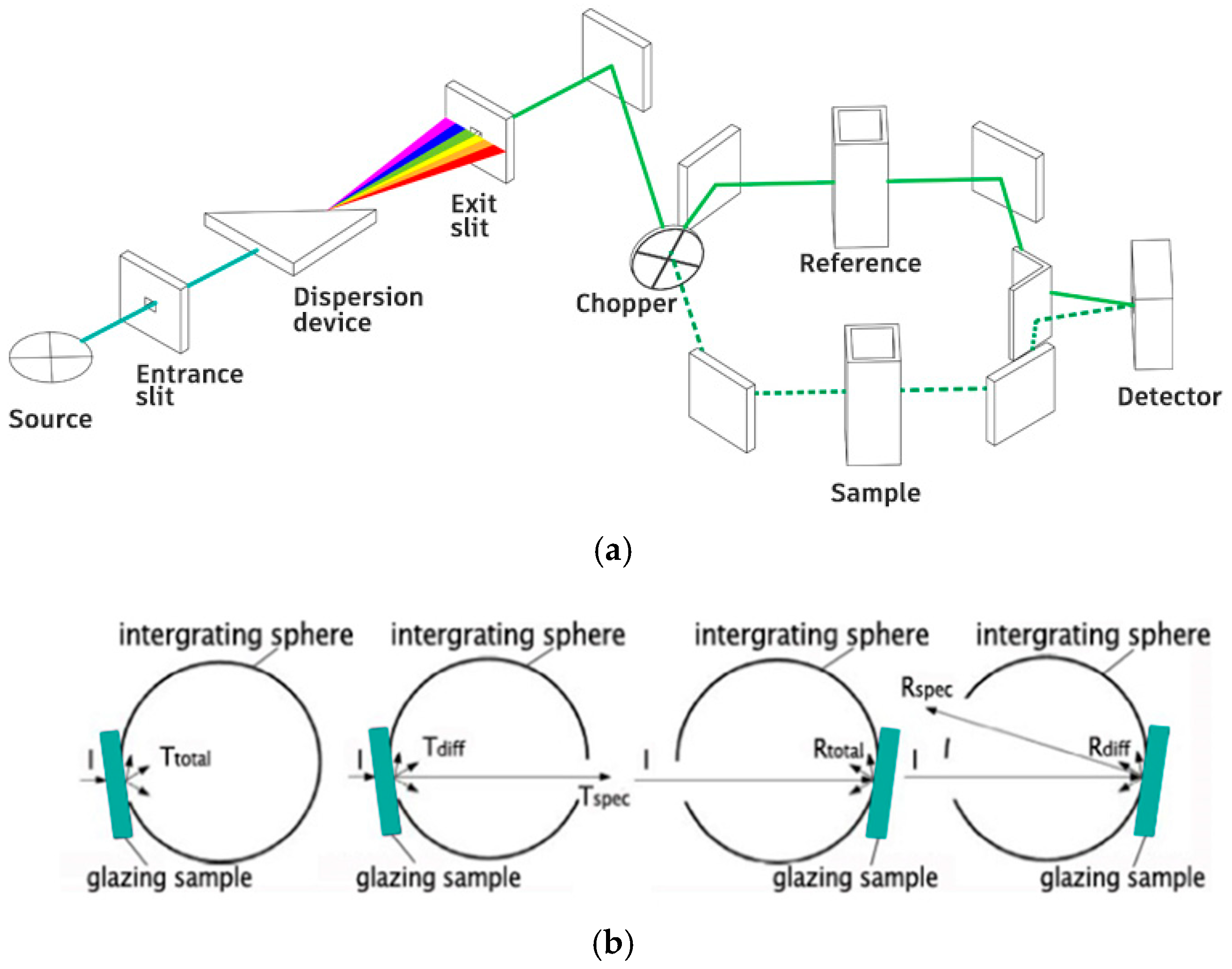

2.2. Test Method for Optical Properties of TCG

2.2.1. Thermochromic Glass Testing Standards

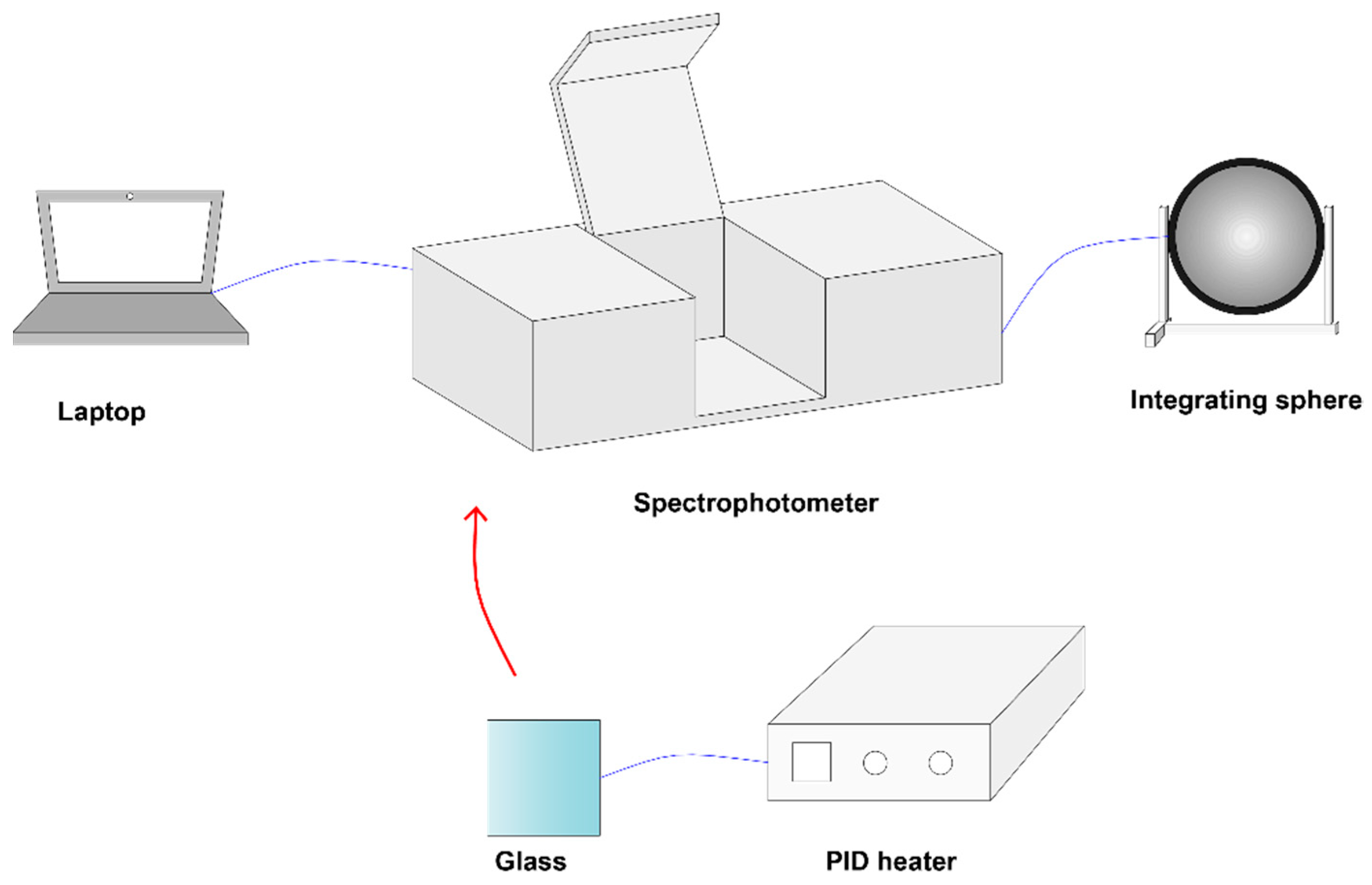

2.2.2. Thermochromic Glass Experimental Testing System

Spectrophotometer

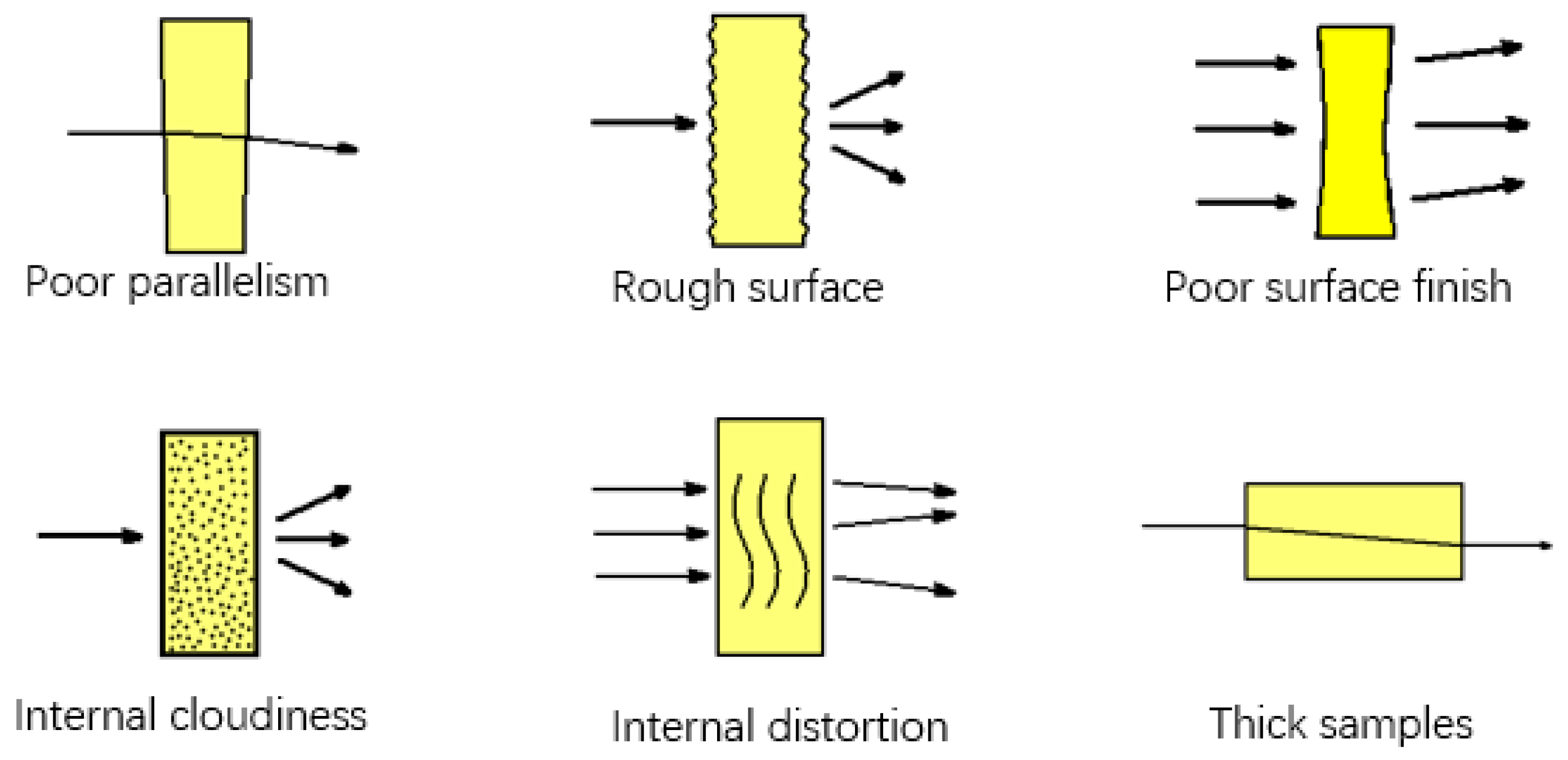

Integrating Sphere

PID Heater

A Test Sample of TCG

2.2.3. Test Procedure

3. Results

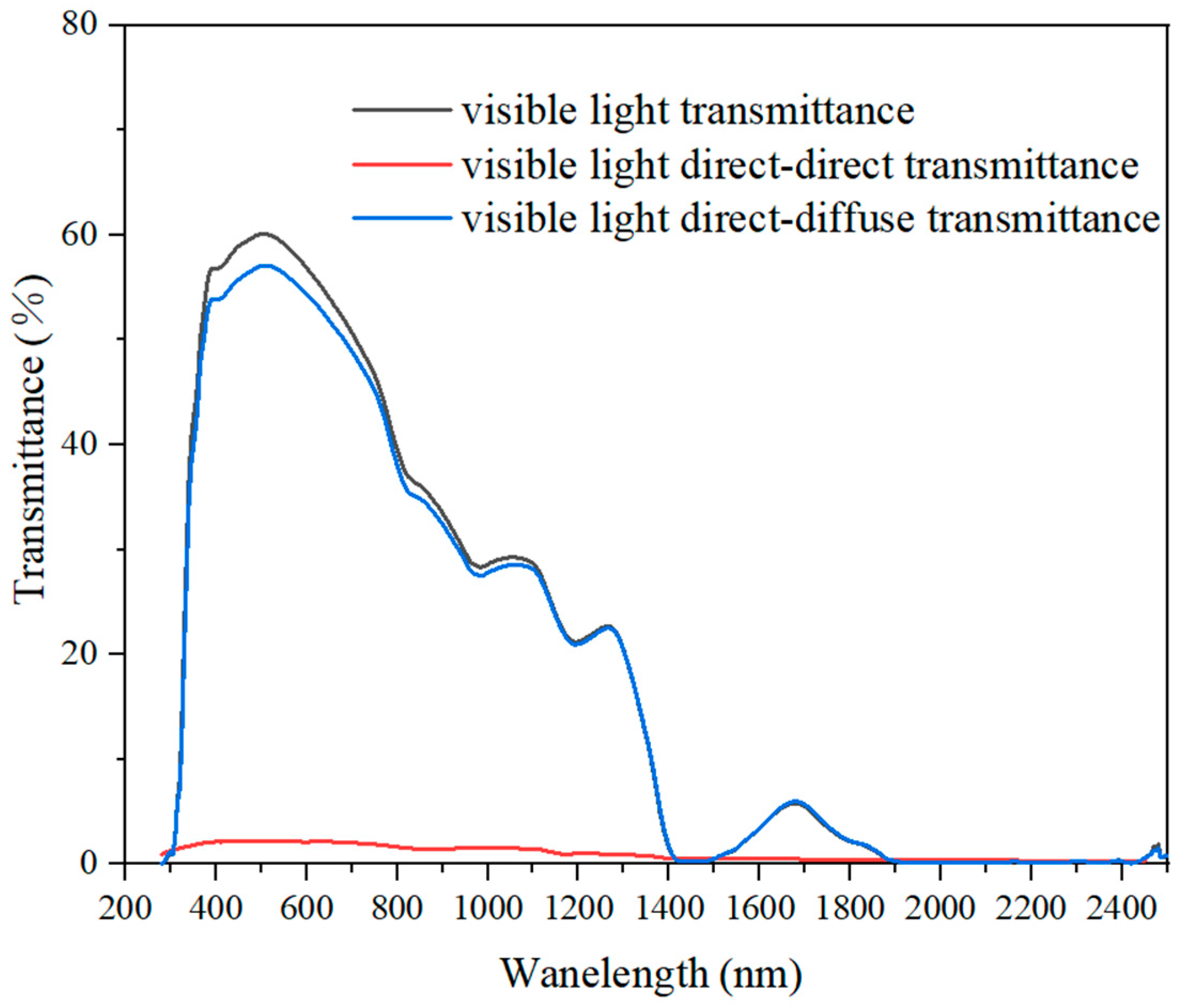

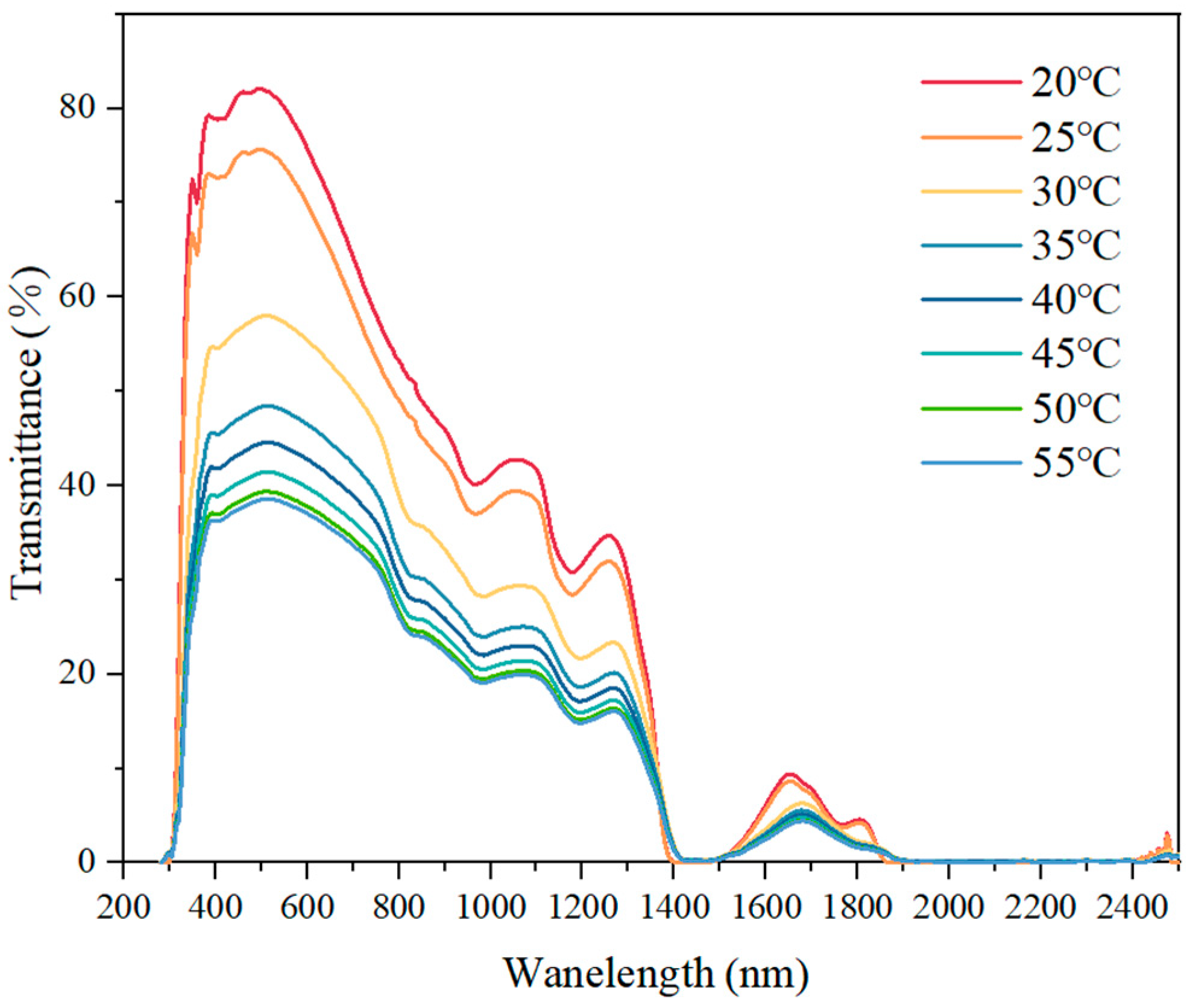

3.1. Optical Properties of TCG 1

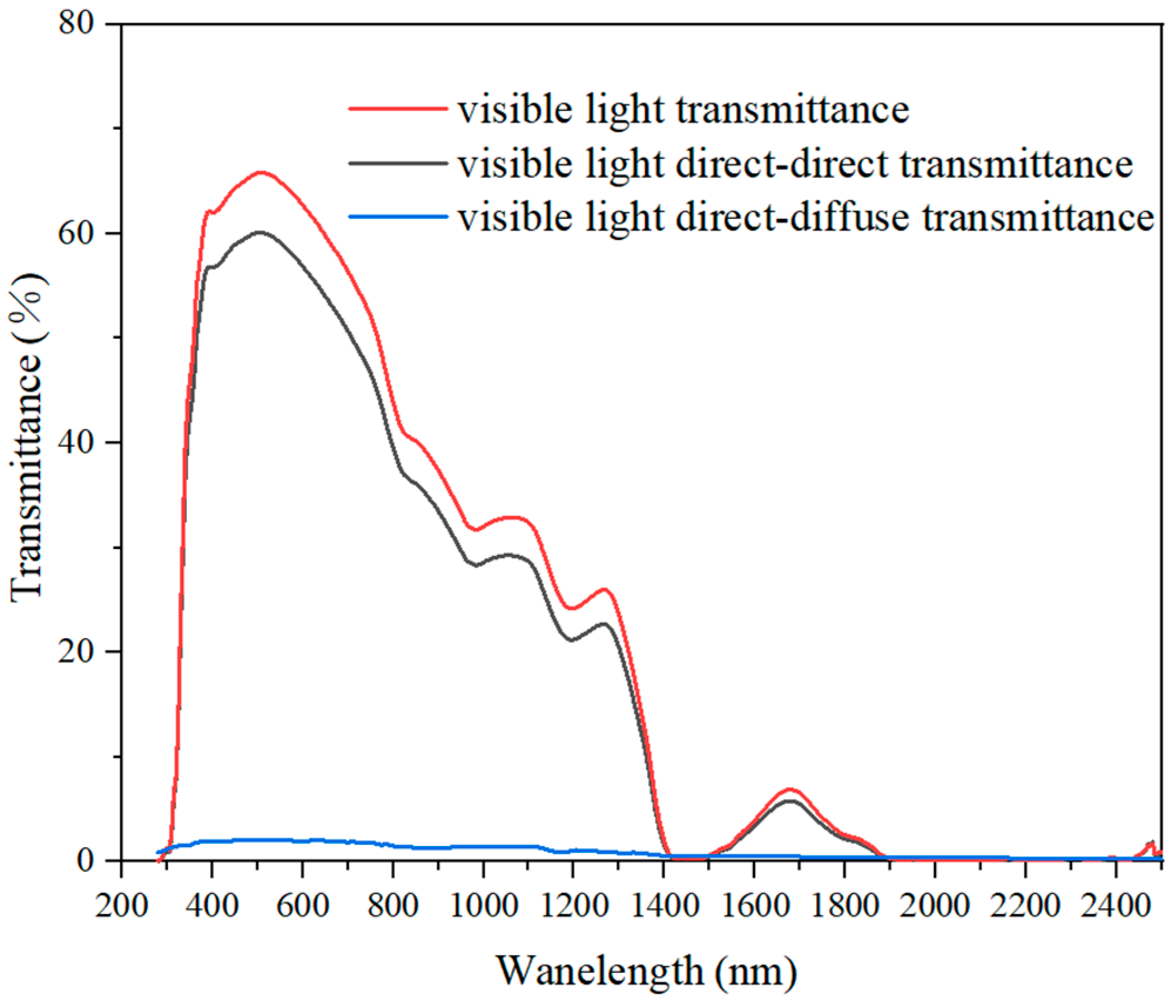

3.2. Optical Properties of TCG 2

3.3. Summary of Optical Performance Test Results of TCG Samples

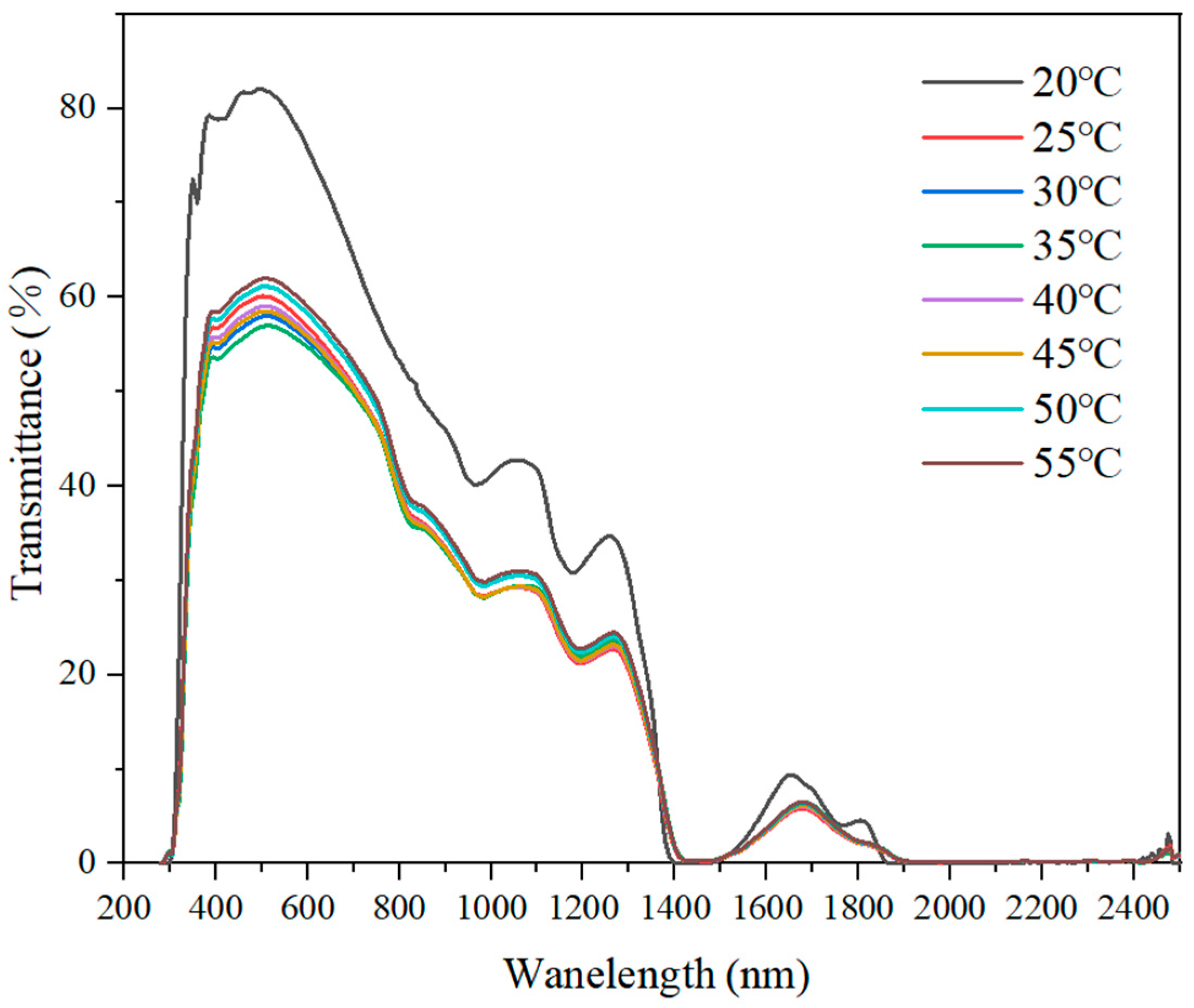

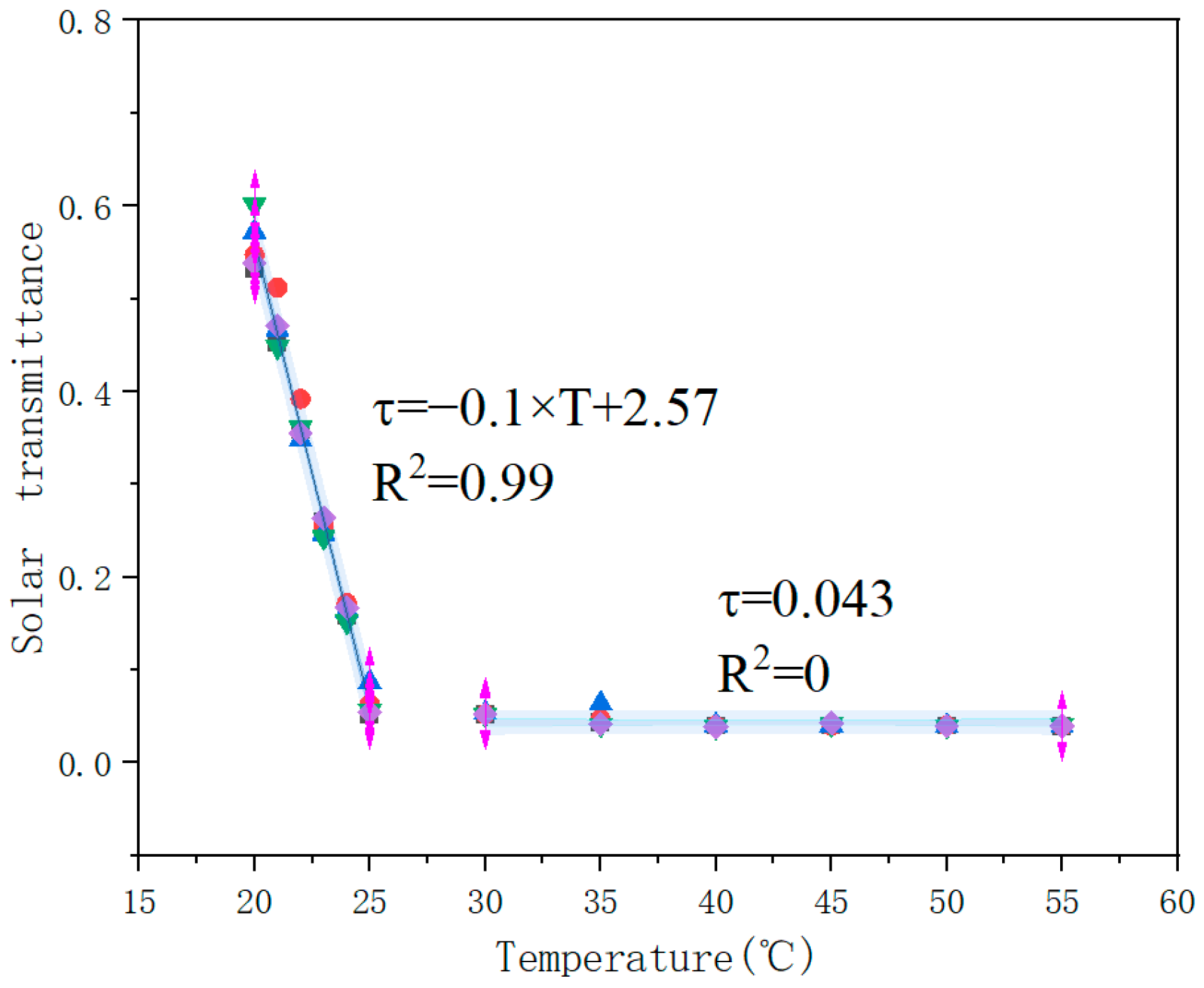

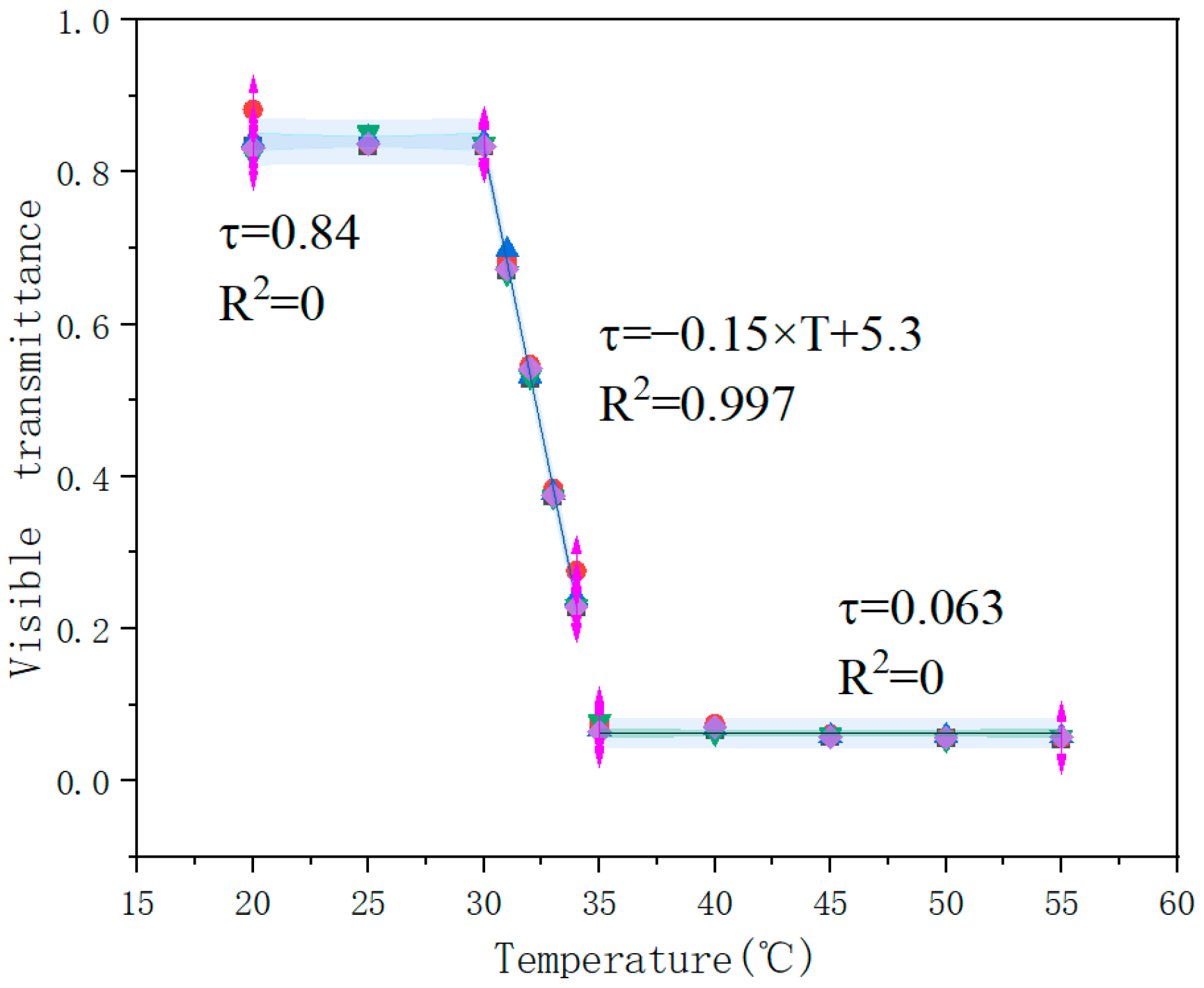

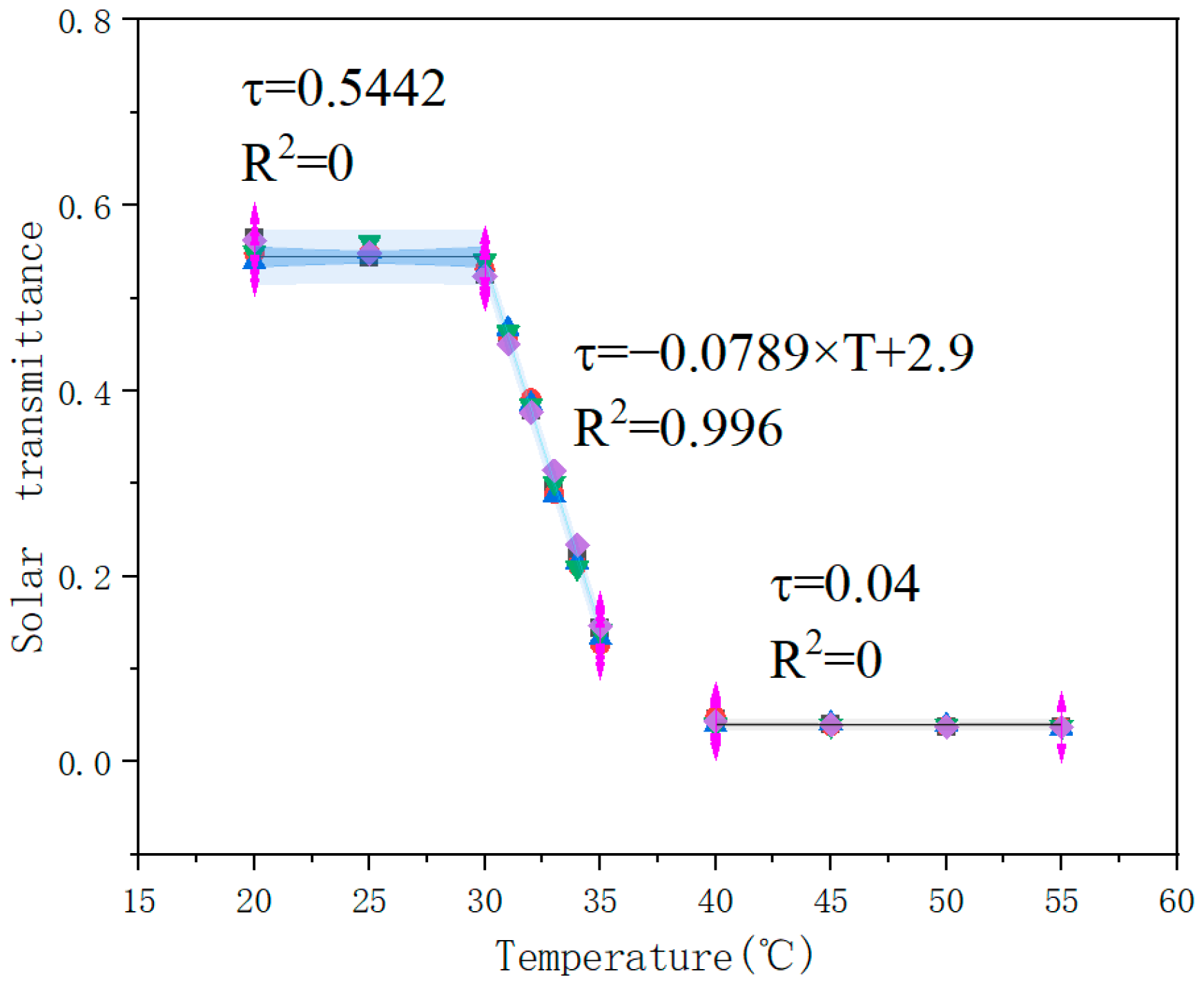

3.4. Spectral Transmittance as a Function of Temperature

4. Discussion

5. Conclusions

- (1)

- The thermochromic glass demonstrates selective light transmission, primarily in the visible (320–1420 nm) and some near-infrared wavelengths, while exhibiting low transmittance in other spectral bands. Its transmittance is high in the transparent state and significantly reduced in the translucent state.

- (2)

- As the temperature increases, the visible light transmittance, solar light transmittance, and UV transmittance of TCG decrease and the haze gradually increases. This characteristic allows TCG used in building doors, windows, and transparent curtain walls to achieve the purpose of shading and energy efficiency.

- (3)

- The transmission and reflection spectra of two types of thermochromic glass (TCG) were obtained at temperatures ranging from 20 °C to 25 °C, 30 °C to 35 °C, 40 °C to 45 °C, and 50 °C to 55 °C. A piecewise function model was established for the visible light transmittance and solar light transmittance as a function of temperature, with an R2 value of 0.99. This function provides a foundational and effective tool for parameter input in building energy consumption simulations and for the selection of TCG during the design phase.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclatures

| TC | Thermochromic |

| TCG | thermochromic glass |

| LCST | lower critical solution temperature |

| PID | Proportional–Integral–Derivative control |

| Visible light transmittance | |

| UV-transmittance | |

| Visible light direct–diffuse transmittance | |

| Visible light direct–direct transmittance | |

| Diffuse–hemispherical light transmittance | |

| Solar transmittance | |

| Solar direct–hemispherical transmittance | |

| Visible light reflectance | |

| Solar reflectance | |

| Solar direct–hemispherical transmittance | |

| Sunlight absorption ratio | |

| Shading coefficient | |

| Haze | |

| General color rending index | |

| Solar energy transmittance | |

| Thermal transmittance | |

| Shading coefficient | |

| Total solar infrared heat transmittance | |

| Visible light to total solar energy transmittance | |

| Luminous transmittance | |

| CIE damage factor | |

| Skin damage factor |

References

- Wang, X.; Narayan, S. Thermochromic Materials for Smart Windows: A State-of-Art Review. Front. Energy Res. 2021, 9, 382. [Google Scholar] [CrossRef]

- Giovannini, L.; Favoino, F.; Pellegrino, A.; Verso, V.R.M.L.; Serra, V.; Zinzi, M. Thermochromic glazing performance: From component experimental characterisation to whole building performance evaluation. Appl. Energy 2019, 251, 113335. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, Y.; Jiang, T.; Yang, R.; Tan, G.; Long, Y. Thermochromic smart windows with highly regulated radiative cooling and solar transmission. Nano Energy 2021, 89, 106440. [Google Scholar] [CrossRef]

- Mustafa, M.N.; Abdah, M.A.A.M.; Numan, A.; Moreno-Rangel, A.; Radwan, A.; Khalid, M. Smart window technology and its potential for net-zero buildings: A review. Renew. Sustain. Energy Rev. 2023, 181, 113355. [Google Scholar] [CrossRef]

- Ke, Y.; Yin, Y.; Zhang, Q.; Tan, Y.; Hu, P.; Wang, S.; Tang, Y.; Zhou, Y.; Wen, X.; Wu, S.; et al. Adaptive Thermochromic Windows from Active Plasmonic Elastomers. Joule 2019, 3, 858–871. [Google Scholar] [CrossRef]

- Connelly, K.; Wu, Y.; Chen, J.; Lei, Y. Design and development of a reflective membrane for a novel Building Integrated Concentrating Photovoltaic (BICPV) ‘Smart Window’ system. Appl. Energy 2016, 182, 331–339. [Google Scholar] [CrossRef]

- Wang, M.; Gao, Y.; Cao, C.; Chen, K.; Wen, Y.; Fang, D.; Li, L.; Guo, X. Binary Solvent Colloids of Thermosensitive Poly(N-isopropylacrylamide) Microgel for Smart Windows. Ind. Eng. Chem. Res. 2014, 53, 18462–18472. [Google Scholar] [CrossRef]

- Maiorov, V.A. Optical Properties of Thermotropic Hydrogels (a Review). Opt. Spectrosc. 2020, 128, 367–386. [Google Scholar] [CrossRef]

- Chen, F.; Wu, X.; Lu, G.; Nie, J.; Zhu, X. Thermochromic Hydrogels with Adjustable Transition Behavior for Smart Windows. ACS Appl. Mater. Interfaces 2024, 16, 21013–21023. [Google Scholar] [CrossRef]

- Arnesano, M.; Pandarese, G.; Martarelli, M.; Naspi, F.; Gurunatha, K.L.; Sol, C.; Portnoi, M.; Ramirez, F.V.; Parkin, I.P.; Papakonstantinou, I.; et al. Optimization of the thermochromic glazing design for curtain wall buildings based on experimental measurements and dynamic simulation. Sol. Energy 2021, 216, 14–25. [Google Scholar] [CrossRef]

- Warwick, M.E.; Ridley, I.; Binions, R. The effect of variation in the transition hysteresis width and gradient in thermochromic glazing systems. Sol. Energy Mater. Sol. Cells 2015, 140, 253–265. [Google Scholar] [CrossRef]

- Vu, T.D.; Chen, Z.; Zeng, X.; Jiang, M.; Liu, S.; Gao, Y.; Long, Y. Physical vapour deposition of vanadium dioxide for thermochromic smart window applications. J. Mater. Chem. C 2019, 7, 2121–2145. [Google Scholar] [CrossRef]

- Liu, S.; Du, Y.; Zhang, R.; He, H.; Pan, A.; Ho, T.C.; Zhu, Y.; Li, Y.; Yip, H.; Jen, A.K.; et al. Perovskite Smart Windows: The Light Manipulator in Energy-Efficient Buildings. Adv. Mater. 2024, 36, e2306423. [Google Scholar] [CrossRef]

- Wostoupal, O.S.; Meyer, J.; Griffith, J.; Rasamani, K.D.; Frank, C.E.; Shevchenko, E.; Lin, X.-M.; Arigong, B.; Xu, T.; Li, J. Advanced VO2/Polymer Nanocomposite Smart Window Films Using VO2 Nanoparticles from High-Throughput Flow Synthesis. ACS Appl. Opt. Mater. 2024, 2, 262–275. [Google Scholar] [CrossRef]

- Wang, K.; Chen, G.; Weng, S.; Hou, L.; Ye, D.; Jiang, X. Thermo-Responsive Poly(N-isopropylacrylamide)/Hydroxypropylmethyl Cellulose Hydrogel with High Luminous Transmittance and Solar Modulation for Smart Windows. ACS Appl. Mater. Interfaces 2023, 15, 4385–4397. [Google Scholar] [CrossRef]

- Wu, S.; Sun, H.; Duan, M.; Mao, H.; Wu, Y.; Zhao, H.; Lin, B. Applications of thermochromic and electrochromic smart windows: Materials to buildings. Cell Rep. Phys. Sci. 2023, 4, 101370. [Google Scholar] [CrossRef]

- Lin, C.; Hur, J.; Chao, C.Y.H.; Liu, G.; Yao, S.; Li, W.; Huang, B. All-weather thermochromic windows for synchronous solar and thermal radiation regulation. Sci. Adv. 2022, 8, eabn7359. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wilson, R.; Liu, H.; Wu, Y. Numerical investigation of a smart window system with thermotropic Parallel Slat Transparent Insulation Material for building energy conservation and daylight autonomy. Build. Environ. 2021, 203, 108048. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Y. Experimental characterisation of a smart glazing with tuneable transparency, light scattering ability and electricity generation function. Appl. Energy 2021, 303, 117521. [Google Scholar] [CrossRef]

- ISO 9050-1:2003; Glass in Building Determination of Light Transmittance, Solar Direct Transmittance, Total Solar Energy Transmittance, Ultraviolet Transmittance and Related Glazing Factors. ISO: Geneva, Switzerland, 2003.

- ISO 15099:2003; Thermal Performance of Windows, Doors and Shading Devices—Detailed Calculations. ISO: Geneva, Switzerland, 2003.

- ISO 10292:1994; Glass in Building Calculation of Steady-State U Values (Thermal Transmittance) of Multiple Glazing. ISO: Geneva, Switzerland, 1994.

- ISO 10293:1997; Glass in Building Determination of Steady-State U Values (Thermal Transmittance) of Multiple Glazing Heat Flow Meter Method. ISO: Geneva, Switzerland, 1997.

- NFRC 300; Test Method for Determining the Solar Optical Properties of Glazing Materials and Systems. NFRC: Bethesda, MD, USA, 2023.

- ASTM D1003; Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM E903-12; Standard Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres. ASTM: West Conshohocken, PA, USA, 2020.

- GB/T2680; Chinese Standard. Glass in Building-Determination of Light Transmittance, Solar Direct Transmittance, Total Solar Energy Transmittance, Ultraviolet Transmittance and Related Glazing Factors. National Standardization Administration (SAC): Beijing, China, 2021.

- GB/T 5137.2-2020; Chinese Standard. Test Methods of Safety Glazing Materials Used on Road Vehicles Part 2: Optical Properties Tests. National Standardization Administration (SAC): Beijing, China, 2020.

- GB/T 2410-2008; Chinese Standard. Determination of the Luminous Transmittance and Haze of Transparent Plastics. National Standardization Administration (SAC): Beijing, China, 2020.

- JG/T 356-2012; Chinese Standard. Test Methods of Building Shading Products on Indoor Environment Thermal and Visual Comfort. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2012.

- DBJ50/T-367-2020; Chongqing Standard. Technical Standard for Engineering Application of Thermochromic Glass. Chongqing Housing and Urban-Rural Development Commission: Chongqing, China, 2020.

- JC/T2670-2022; China Industry Standard. Thermochromic Dimming Laminated Glass. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2022.

- Sun, Y.; Wu, Y.; Wilson, R. A review of thermal and optical characterisation of complex window systems and their building performance prediction. Appl. Energy 2018, 222, 729–747. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, X.; Sun, W.; Xiao, Y.; Zhang, H.; Deng, J.; Li, Z.; Yan, D.; Zhao, J.; Li, Y. A dual-responsive smart window based on inorganic all-solid-state electro- and photochromic device. Nano Energy 2024, 123, 109352. [Google Scholar] [CrossRef]

- Giovannini, L.; Favoino, F.; Serra, V.; Zinzi, M. Thermo-chromic glazing in buildings: A novel methodological framework for a multi-objective performance evaluation. Energy Procedia 2019, 158, 4115–4122. [Google Scholar] [CrossRef]

- Chen, J.; Li, G.; Jiang, T.; Wang, S.; Hu, H.; Bai, Z.; Shi, D.; Chen, M.; Guan, J.; Tan, G.; et al. Zwitterionic hydrogel smart windows: Radiative cooling, privacy protection and energy savings. Nano Energy 2024, 123, 109386. [Google Scholar] [CrossRef]

- Zhang, Y.; Tso, C.; Iñigo, J.; Liu, S.; Miyazaki, H.; Chao, C.Y.; Yu, K. Perovskite thermochromic smart window: Advanced optical properties and low transition temperature. Appl. Energy 2019, 254, 113690. [Google Scholar] [CrossRef]

- Liang, R.; Sun, Y.; Aburas, M.; Wilson, R.; Wu, Y. An exploration of the combined effects of NIR and VIS spectrally selective thermochromic materials on building performance. Energy Build. 2019, 201, 149–162. [Google Scholar] [CrossRef]

| Standard | Test/Calculation Parameters | Test Instruments/Calculation Tools | Scope |

|---|---|---|---|

| ISO9050-2003 [20] | Spectrophotometer |

| |

| ISO15099 [21] | A procedure for calculating |

| |

| ISO10292 [22] | A procedure for calculating |

| |

| ISO10293 [23] | Heat flow meter |

| |

| NFRC300 [24] | , | Double-beam ratio-recording spectrophotometer equipped with a multiple-port comparison-type integrating sphere |

|

| ASTM D1003 [25] | Haze meter and spectrophotometer |

| |

| ASTM E903-12 [26] | Spectrophotometer |

| |

| GB/2680-2021 [27] | Spectrophotometer |

| |

| GB/T 5137.2-2020 [28] | Target light source, collimating telescope, and spectrophotometer |

| |

| GB/T 2410-2008 [29] | Haze meter and spectrophotometer |

| |

| JG/T 356-2012 [30] | Radiometer Double-beam spectrophotometer |

| |

| DBJ50/T-367-2020 [31] | Initial thermochromic temperature and complete thermochromic temperature | Haze meter |

|

| JC/T2670-2022 [32] | , | Haze meter and spectrophotometer |

|

| Temperature | τv (%) | τv,dir-dif (%) | ρv (%) | τe (%) | ρe (%) | αe (%) | τuv (%) | H (%) | Sc |

|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 78.9 | 64.4 | 7.49 | 53.2 | 6.19 | 40.5 | 67.1 | 81.60 | 0.76 |

| 25 °C | 7.36 | 6.78 | 9.18 | 5.19 | 7.19 | 87.6 | 5.50 | 92.10 | 0.39 |

| 30 °C | 7.35 | 7.00 | 11.7 | 5.18 | 8.69 | 86.1 | 5.49 | 95.30 | 0.39 |

| 35 °C | 6.37 | 6.11 | 14.0 | 4.4 | 10.09 | 86.1 | 4.82 | 95.90 | 0.38 |

| 40 °C | 5.89 | 5.71 | 15.7 | 3.99 | 11.14 | 85.5 | 4.47 | 97.10 | 0.37 |

| 45 °C | 5.84 | 5.67 | 16.1 | 3.98 | 11.7 | 84.8 | 4.44 | 97.90 | 0.37 |

| 50 °C | 5.81 | 5.68 | 16.2 | 3.98 | 11.8 | 84.2 | 4.42 | 97.10 | 0.37 |

| 55 °C | 5.80 | 5.73 | 17.0 | 3.98 | 11.8 | 84.2 | 4.41 | 98.80 | 0.37 |

| Temperature | τv (%) | τv,dir-dif (%) | ρv (%) | τe (%) | ρe (%) | αe (%) | τuv (%) | H (%) | Sc |

|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 81.5 | 7.82 | 8.69 | 56.5 | 6.9 | 36.6 | 70.5 | 9.6 | 0.79 |

| 25 °C | 79.8 | 8.13 | 8.7 | 54.36 | 6.87 | 38.8 | 69.2 | 10.2 | 0.77 |

| 30 °C | 70.2 | 12.92 | 8.71 | 52.46 | 6.59 | 40.9 | 65.1 | 18.4 | 0.76 |

| 35 °C | 6.93 | 5.84 | 8.74 | 14.48 | 6.38 | 79.1 | 10.0 | 84.3 | 0.39 |

| 40 °C | 6.58 | 5.63 | 11.96 | 4.65 | 9.07 | 86.3 | 4.9 | 85.6 | 0.37 |

| 45 °C | 5.83 | 5.35 | 15.07 | 4.01 | 10.88 | 85.1 | 4.4 | 91.7 | 0.37 |

| 50 °C | 5.62 | 5.20 | 18.04 | 3.83 | 12.67 | 83.5 | 4.2 | 92.6 | 0.37 |

| 55 °C | 5.62 | 5.18 | 19.55 | 3.83 | 13.46 | 82.7 | 4.0 | 93.9 | 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, M.; Qian, D.; Zhao, L.; Jin, R. Experimental Study on the Photothermal Properties of Thermochromic Glass. Buildings 2025, 15, 233. https://doi.org/10.3390/buildings15020233

Gao M, Qian D, Zhao L, Jin R. Experimental Study on the Photothermal Properties of Thermochromic Glass. Buildings. 2025; 15(2):233. https://doi.org/10.3390/buildings15020233

Chicago/Turabian StyleGao, Mingyi, Dewei Qian, Lihua Zhao, and Rong Jin. 2025. "Experimental Study on the Photothermal Properties of Thermochromic Glass" Buildings 15, no. 2: 233. https://doi.org/10.3390/buildings15020233

APA StyleGao, M., Qian, D., Zhao, L., & Jin, R. (2025). Experimental Study on the Photothermal Properties of Thermochromic Glass. Buildings, 15(2), 233. https://doi.org/10.3390/buildings15020233