Experimental Investigation and Analysis of the Influence of Depth and Moisture Content on the Relationship Between Subgrade California Bearing Ratio Tests and Cone Penetration Tests for Pavement Design

Abstract

1. Introduction

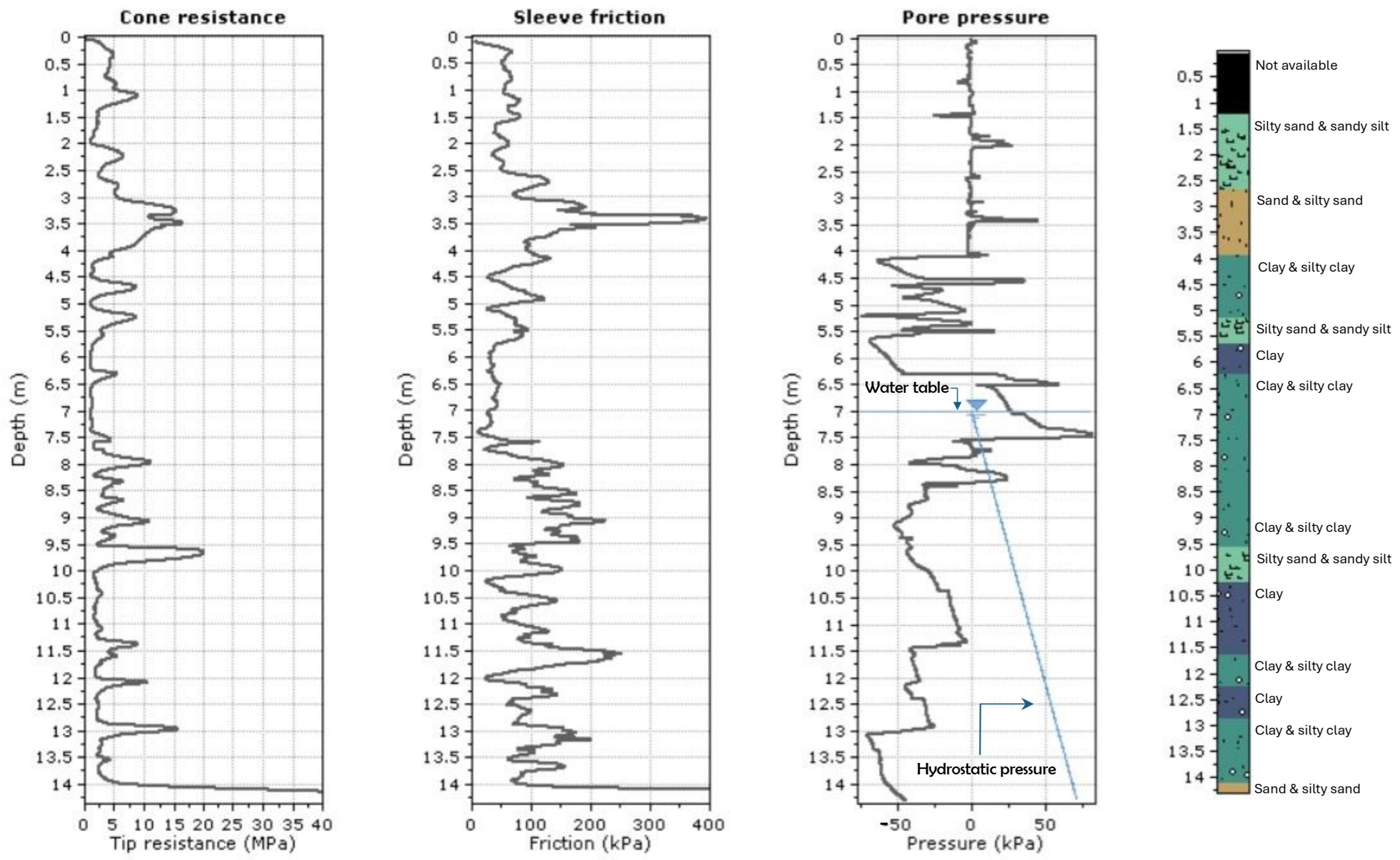

1.1. Cone Penetration Test (CPT)

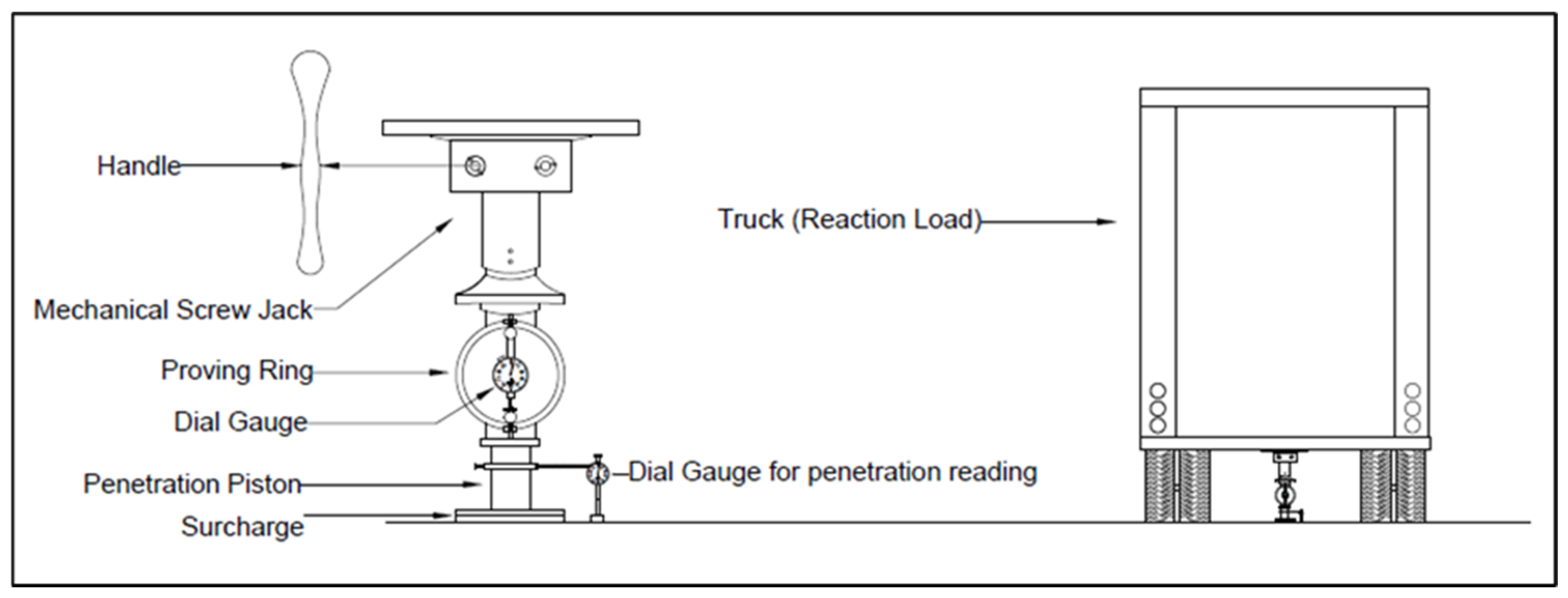

1.2. CBR Testing Details

2. Materials and Methods

3. Analyses and Discussions

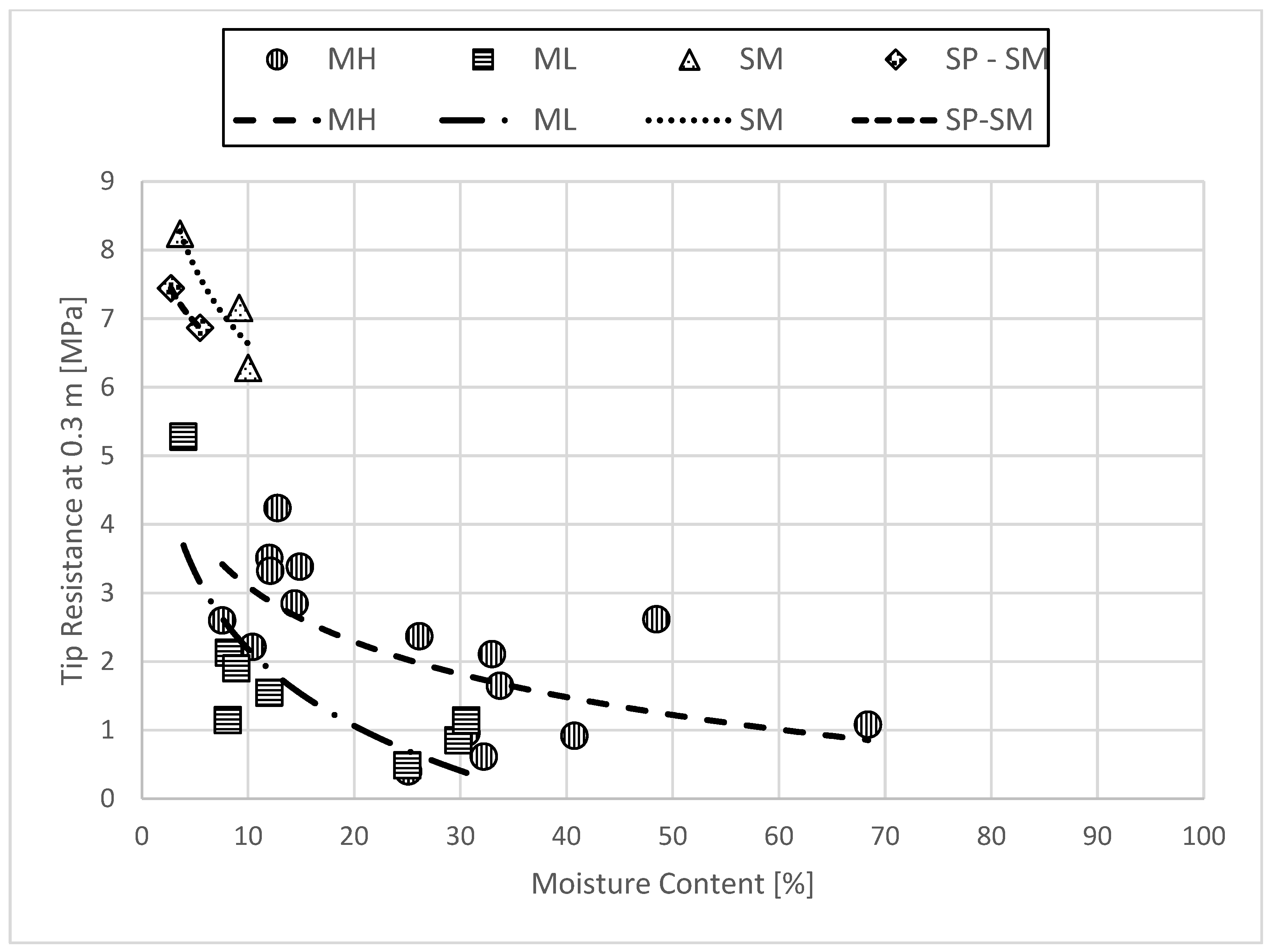

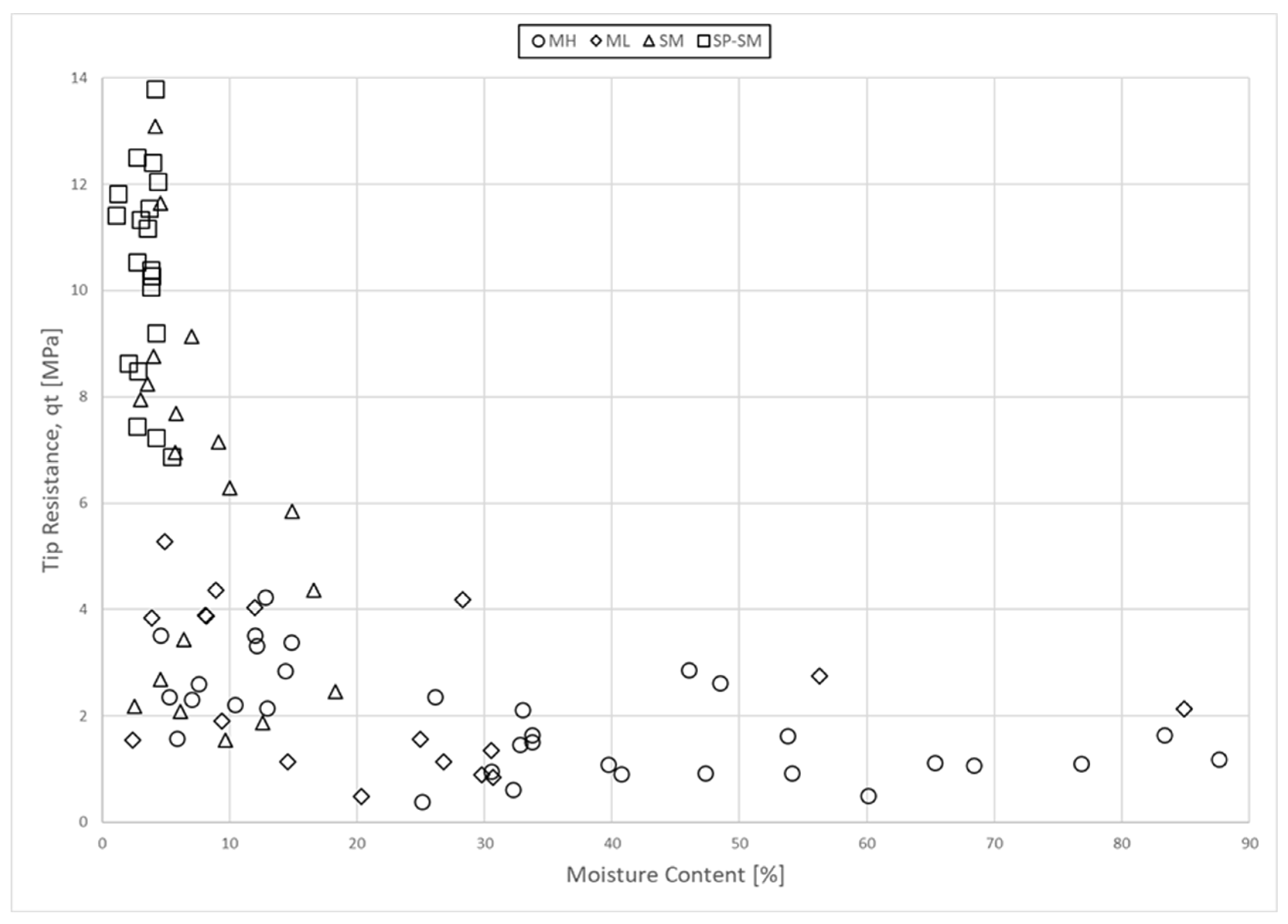

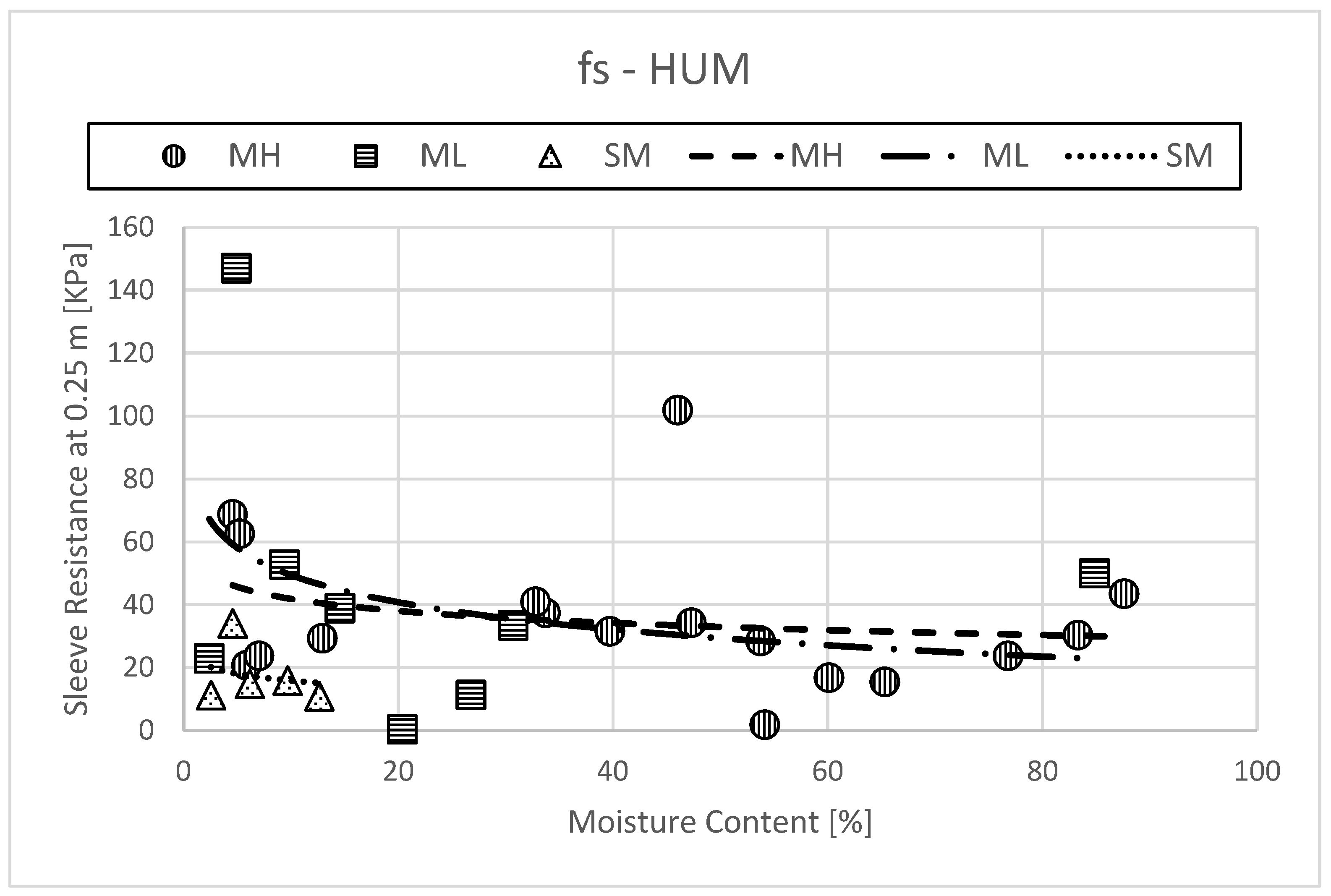

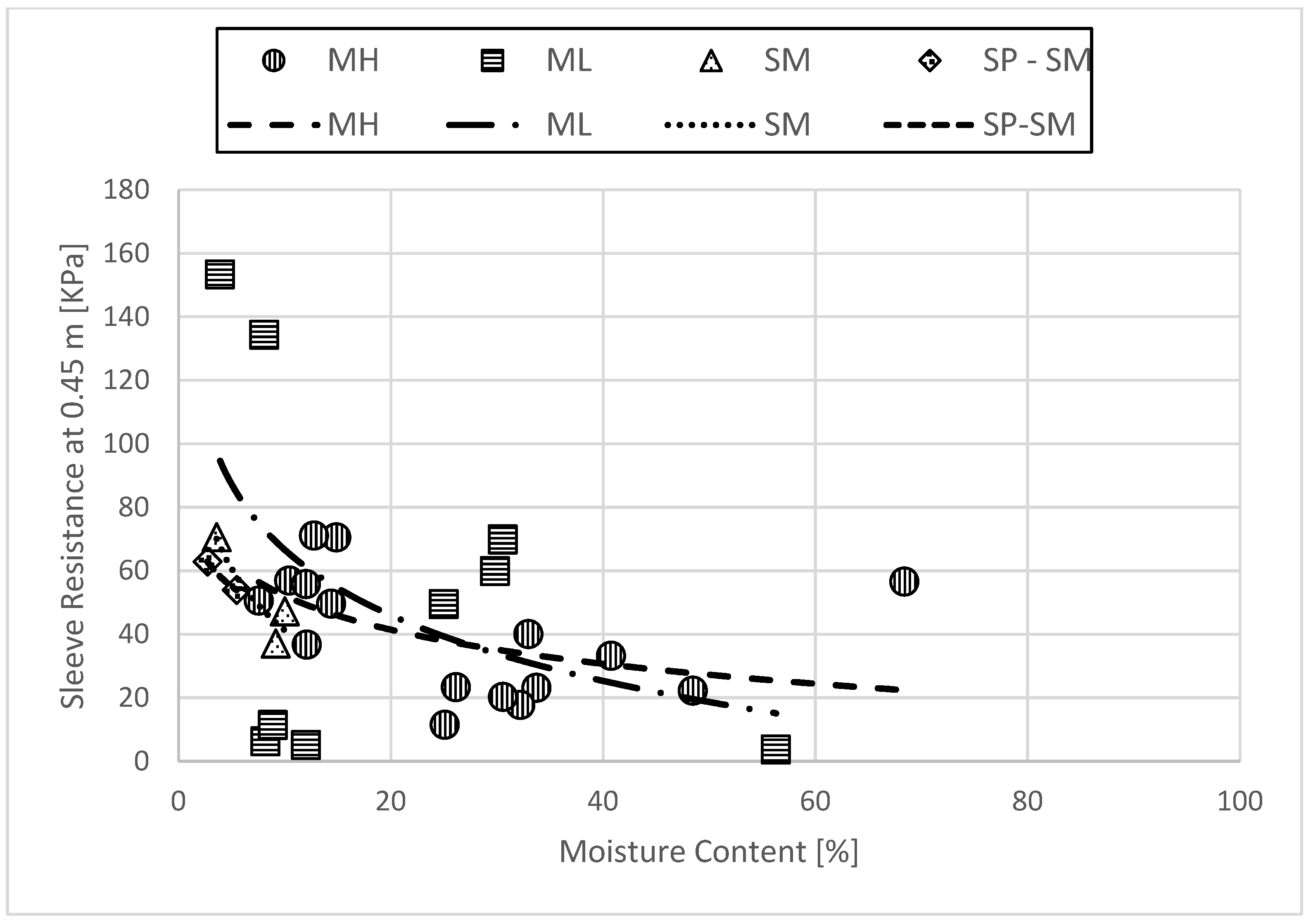

3.1. Influence of Moisture Content

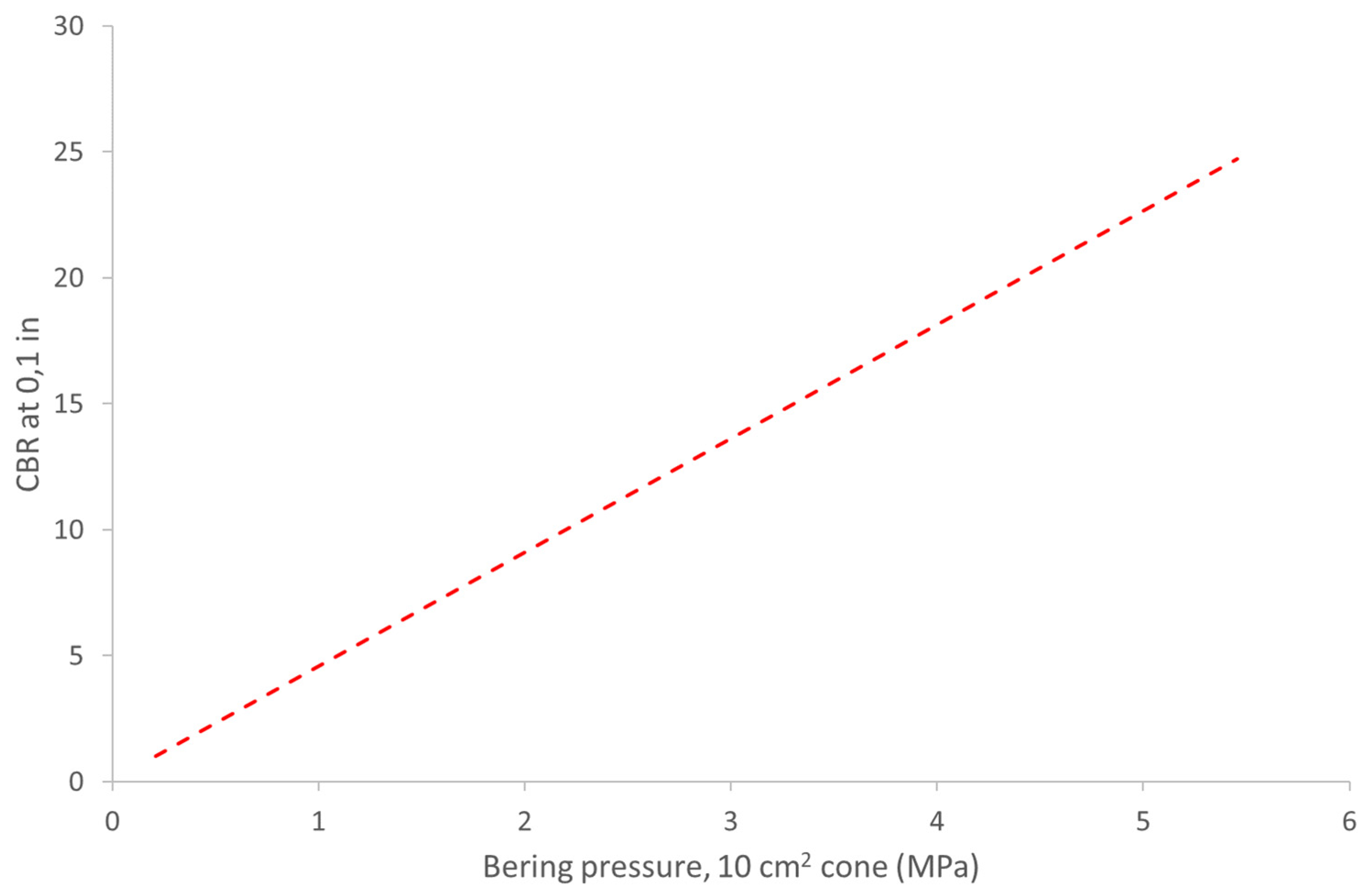

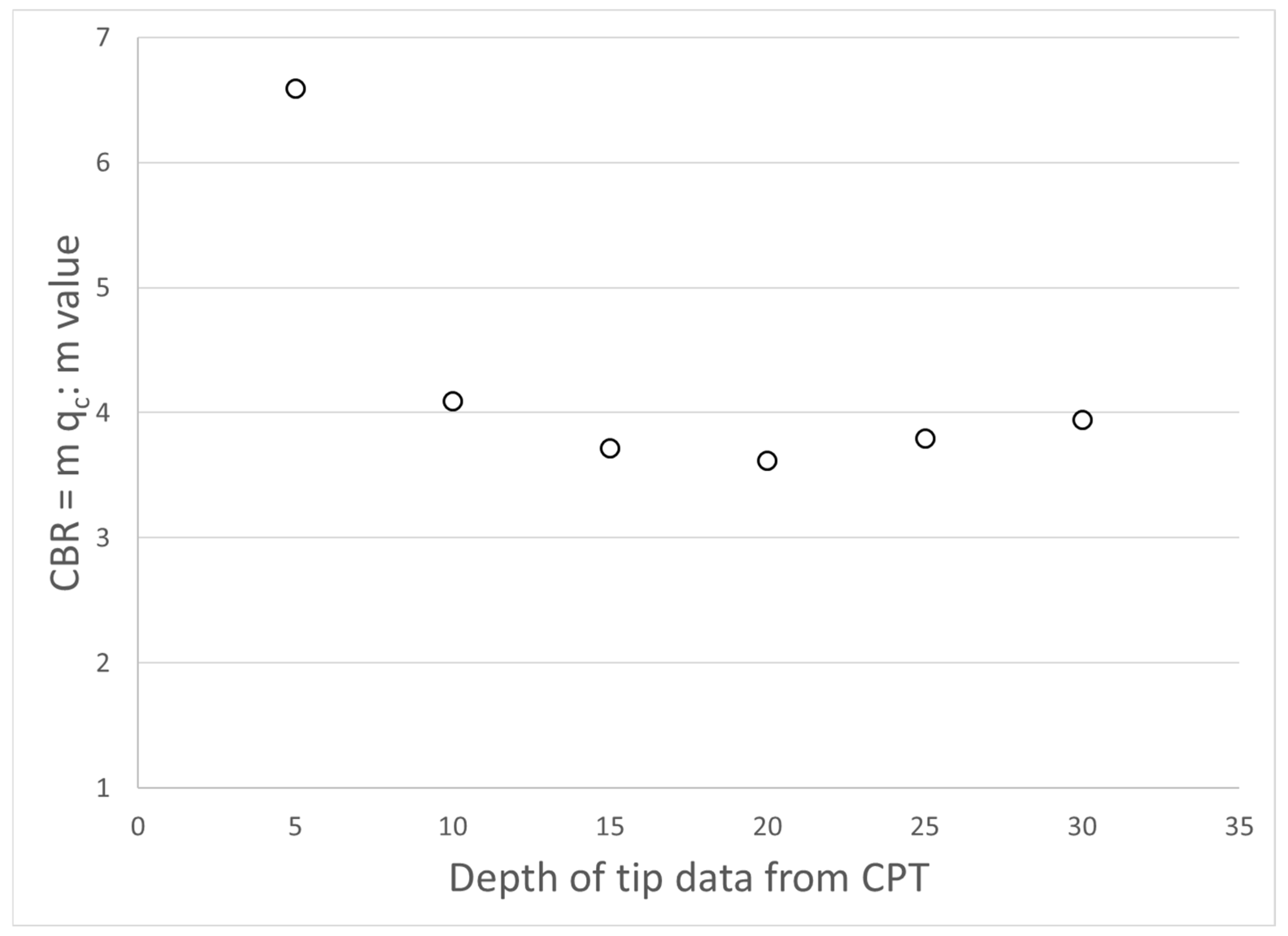

3.2. Correlation Between CPTu and CBR Test Results

4. Summary Remarks and Conclusions

- The efficiency of CPT Testing: CPT testing is significantly faster than CBR testing. The rate of CPT testing is approximately 20 to 30 times faster than in situ CBR tests for subgrade evaluation. Testing every 100 m of highway could allow a CPT truck to test 10 to 15 km of subgrade daily.

- CBR Dependence on Moisture Content: CBR test results show a significant dependence on moisture content up to approximately 30–40%. Beyond this range, the soil’s density or state has a more substantial influence than moisture content.

- CPT Tip Resistance and Moisture Content: CPT tip resistance (qc) also depends on moisture content up to 30–40%. Above this range, changes in moisture content are primarily associated with variations in soil density or consolidation.

- Correlation Between CPT and CBR: Data collected at a depth of 0.2 m showed a stronger correlation between CPT tip resistance (qc) and CBR values. This finding, not previously highlighted, is critical for optimizing correlations between CBR and qc.

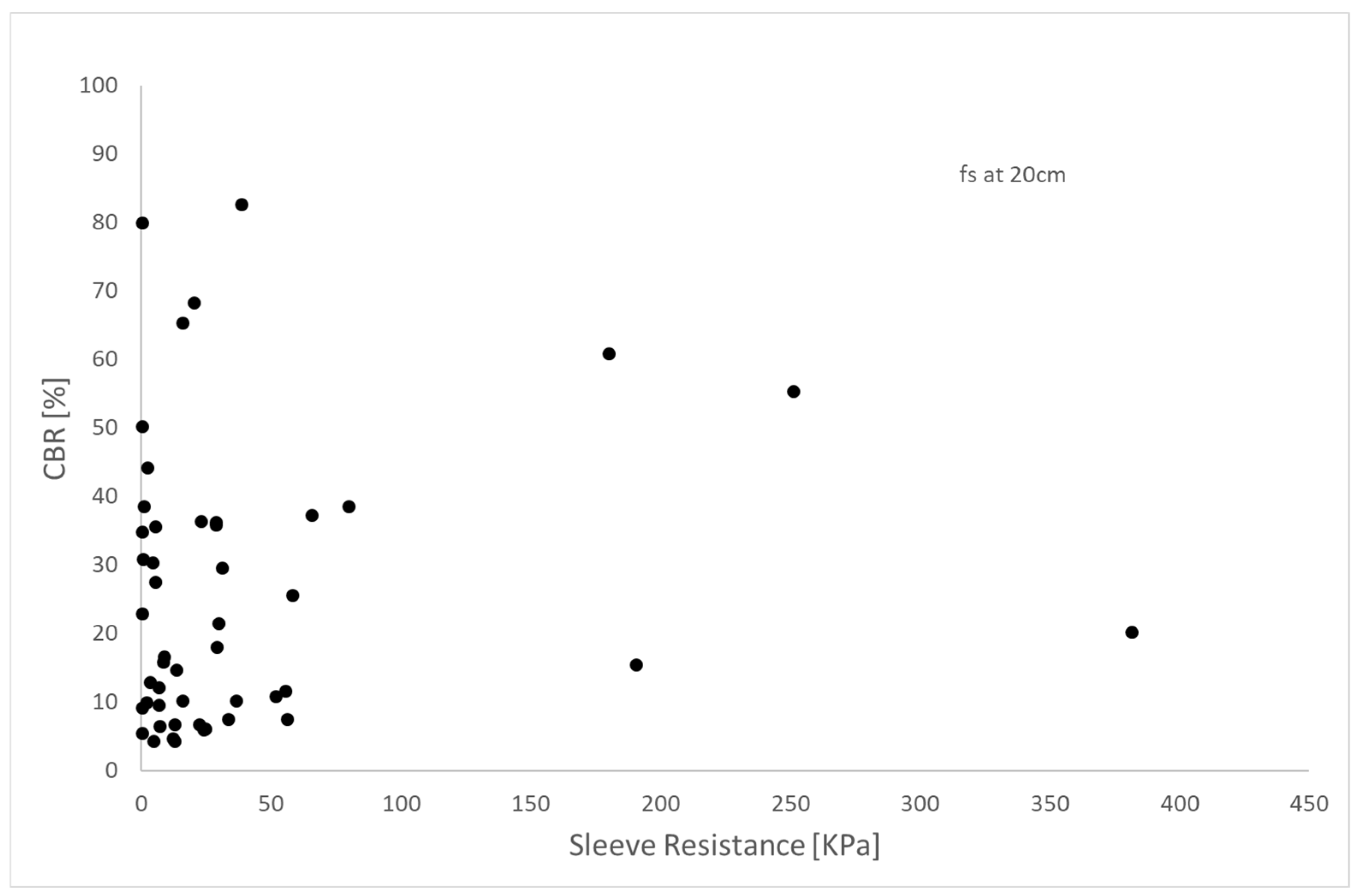

- Sleeve Friction and Correlation: No significant relationship was observed between CPT sleeve friction (fs) and moisture content, nor was there any correlation between sleeve resistance (fs)_and CBR values. This agrees with prior research indicating that sleeve friction is less critical in CPT-derived geotechnical parameters than tip resistance.

- Critical Moisture Content: CPT and CBR testing should be conducted at moisture contents above 30%, as no significant decrease in strength is expected at higher soil saturation levels. Testing this moisture content provides a representative measure of the soil’s critical strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mallick, R.B.; Tahar, E. Pavement Engineering. Principles and Practice, 4th ed.; CRC Press: Abingdon, UK, 2023. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO Guide for Design of Pavement Structures; AASHTO: Washington, DC, USA, 1993. [Google Scholar]

- Putri, E.E.; Rao, N.S.V.; Mannan, M.A. Evaluation of modulus of elasticity and modulus of subgrade reaction of soils using CBR test. J. Civil Eng. Res. 2012, 2, 34–40. [Google Scholar] [CrossRef]

- Witczak, M.W.; Qi, X.; Mirza, M.W. Use of nonlinear subgrade modulus in AASHTO design procedure. J. Transp. Eng. 1995, 121, 273–282. [Google Scholar] [CrossRef]

- Erlingsson, S. On forecasting the resilient modulus from the CBR value of granular bases. Road Mater. Pavement Des. 2007, 8, 783–797. [Google Scholar] [CrossRef]

- ASTM D4429-18; Standard Test Method for CBR (California Bearing Ratio) of Soils in Place. ASTM: West Coshohocken, PA, USA, 2018.

- Scala, A.J. The use of cone penetration in determining the bearing capacity of soils: Simple methods of flexible pavement design using cone penetrometers. In Proceedings of the Australia-New Zealand Conference on Soil Mechanics and Foundation Engineering, Canterbury University, Christchurch, New Zealand, January 1954; pp. 73–84. [Google Scholar]

- Misra, A.; Supadhayaya, S.; Horn, C.; Kondagari, S.; Gustin, F. CBR and DCP correlation for class C Fly Ash-stabilized soil. Geotech. Test. J. 2006, 29, 1–7. [Google Scholar] [CrossRef]

- Neupane, M.; Parsons, R.L.; Han, J. Rapid estimation of fouled railroad ballast mechanical properties. Geotech. Test. J. 2018, 41, 777–786. [Google Scholar] [CrossRef]

- Wesley, L.; Dobie, M. Early development of the Dutch cone penetrometer test (CPT). Proc. Inst. Civ. Eng. Eng. Hist. Herit. 2022, 175, 145–152. [Google Scholar] [CrossRef]

- Sanglerat, G. Developments in Geotechnical Engineering. In The Penetrometer and Soil Exploration; Elsevier Science: Amsterdam, The Netherlands, 1982; Volume 1. [Google Scholar]

- Ampadu, S.I.K.; Fiadjoe, G.J.Y. The influence of water content on the Dynamic Cone Penetration Index of a lateritic soil stabilized with various percentages of a quarry by-product. Transp. Geotech. 2015, 5, 68–85. [Google Scholar] [CrossRef]

- Robertson, P.K.; Cabal, K. Guide to Cone Penetration Testing, 7th ed.; Gregg: Los Angeles, CA, USA, 2022; 164p. [Google Scholar]

- ASTM D5778-20; Standard Test Method for Electronic Friction Cone and Piezocone Penetration Testing of Soils. ASTM: West Coshohocken, PA, USA, 2020.

- ASTM D1883-21; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM: West Coshohocken, PA, USA, 2021.

- Rahman, M.M.; Gassman, S.L.; Islam, K.M. Effect of moisture content on subgrade soils resilient modulus for predicting pavement rutting. Geosciences 2023, 13, 103. [Google Scholar] [CrossRef]

- Lim, S.; Indraratna, B.; Heitor, A.; Yao, K.I.; Jin, D.; Albadro, W.M.; Liu, X. Influence of matric suction on resilient modulus and CBR of compacted Ballina clay. Constr. Build. Mater. 2022, 359, 129482. [Google Scholar] [CrossRef]

- Wu, X.R.; Shen, J.M. Research on the Impact of Moisture Content on the CBR Value of Shanxi Loess. Adv. Mater. Res. 2013, 838–841, 80–83. [Google Scholar] [CrossRef]

- Purwana, Y.M.; Nikraz, H.; Jitsangiam, P. Experimental study of suction-monitored CBR test on sand-Kaolin clay mixture. Int. J. Geomate 2012, 3, 419–422. [Google Scholar]

- Krahn, J.; Fredlund, D.G. On total, matric and osmotic suction. Soil Sci. 1972, 114, 339–348. [Google Scholar] [CrossRef]

- Tang, G.X.; Graham, J.; Blatz, J.; Gray, M.; Rajapakse, R.K.N.D. Suctions, stresses and strengths in unsaturated sand-betonite. Eng. Geol. 2002, 64, 147–156. [Google Scholar] [CrossRef]

- Robertson, P.K.; da Fonseca, A.V.; Ulrich, B.; Coffin, J. Characterization of unsaturated mine waste: A case history. Can. Geotech. J. 2017, 54, 1752–1761. [Google Scholar] [CrossRef]

- Russell, A.R.; Vo, T.; Ayala, J.; Wang, Y.; Reid, D.; Fourie, A.B. Cone penetration tests in saturated and unsaturated silty tailings. Geotechnique 2024, 74, 281–295. [Google Scholar] [CrossRef]

- Heraldo Luiz Giacheti, H.L.; Cravera, R.; Padovezi, B.; Rodrigues, R. Seasonal influence on cone penetration test: An unsaturated soil site example. J. Rock Mech. Geotech. Eng. 2019, 11, 361–368. [Google Scholar] [CrossRef]

- Fioravante, V.; Giretti, D.; Dodaro, E.; Gragnano, C.G.; Gottardi, G. CPT Calibration in Centrifuge: Effect of Partial Saturation on Cone Resistance; Cone Penetration Testing: Bologna, Italy, 2022. [Google Scholar]

- Scala, A.J. Simple methods of flexible pavement design using cone penetrometers. In Golden Jubilee of the International Society for Soil Mechanics and Foundation Engineering: Commemorative Volume; Institution of Engineers: Barton, Australia, 1956. [Google Scholar]

- Arbianto, R.; Yuono, T.; Gunarso, G. Comparison of California Bearing Ratio (CBR) value based on Cone Penetration Test (CPT) and Dynamic Cone Penetrometer (DCP). J. Adv. Civ. Environ. Eng. 2021, 4, 70–78. [Google Scholar] [CrossRef]

| ZONE | Sample | Depth [m] | Atterberg Limits | USCS Class. | |||||

|---|---|---|---|---|---|---|---|---|---|

| Fines % | Cu | Cc | LL | PL | PI | ||||

| 01 | 01-CBR-01 | 0.0 | 99.0 | - | - | NP | ML | ||

| 01-CBR-02 | 0.0 | 99.0 | - | - | 35.9 | 26.1 | 9.9 | ML | |

| 01-CBR-03 | 0.0 | 98.4 | - | - | 32.6 | 27.3 | 5.4 | ML | |

| 01-CBR-04 | 0.0 | 98.5 | - | - | 37.2 | 29.1 | 8.1 | ML | |

| 01-CBR-05 | 0.0 | 98.4 | - | - | 37.8 | 29.2 | 8.5 | ML | |

| 01-CPT-01 | 0.0 | 96.5 | - | - | 36.7 | 29.5 | 7.1 | ML | |

| 01-CPT-01 | 0.3 | 84.6 | - | - | 42.4 | 28.6 | 13.8 | ML | |

| 01-CPT-01 | 1.1 | 9.2 | 4.7 | 0.8 | NP | SP-SM | |||

| 01-CPT-02 | 0.0 | 98.8 | - | - | 37.8 | 31.0 | 6.9 | ML | |

| 01-CPT-02 | 0.3 | 86.0 | - | - | 43.7 | 28.5 | 15.3 | ML | |

| 01-CPT-02 | 1.1 | 6.6 | 5.3 | 0.8 | NP | SP-SM | |||

| 01-CPT-03 | 0.0 | 98.2 | - | - | 37.0 | 27.5 | 9.5 | ML | |

| 01-CPT-03 | 0.3 | 71.9 | - | - | 33.9 | 23.7 | 10.1 | ML | |

| 01-CPT-03 | 1.1 | 6.6 | 4.2 | 0.8 | NP | SP-SM | |||

| 01-CPT-04 | 0.0 | 94.3 | - | - | 37.3 | 33.5 | 3.8 | ML | |

| 01-CPT-04 | 0.3 | 89.0 | - | - | 45.1 | 31.7 | 13.5 | ML | |

| 01-CPT-04 | 1.1 | 7.9 | 4.6 | 0.8 | NP | SP-SM | |||

| 01-CPT-05 | 0.0 | 94.5 | - | - | 34.4 | 26.1 | 8.4 | ML | |

| 01-CPT-05 | 0.3 | 91.7 | - | - | 46.8 | 30.6 | 16.3 | ML | |

| 01-CPT-05 | 1.1 | 7.0 | 6.3 | 0.8 | NP | SP-SM | |||

| 02 | 02-CBR-01 | 0.0 | 89.4 | - | - | 71.3 | 57.0 | 14.3 | MH |

| 02-CBR-02 | 0.0 | 89.5 | - | - | 74.0 | 51.0 | 23.0 | MH | |

| 02-CBR-03 | 0.0 | 81.1 | - | - | 73.3 | 63.7 | 9.6 | MH | |

| 02-CBR-04 | 0.0 | 83.7 | - | - | 78.3 | 63.7 | 14.6 | MH | |

| 02-CBR-05 | 0.0 | 88.5 | - | - | 86.2 | 70.7 | 15.5 | MH | |

| 02-CPT-01 | 0.0 | 96.1 | - | - | 69.3 | 52.2 | 17.1 | MH | |

| 02-CPT-01 | 0.3 | 98.8 | - | - | 42.6 | 28.0 | 14.6 | ML | |

| 02-CPT-01 | 1.1 | 61.2 | - | - | 30.4 | 24.8 | 5.6 | ML | |

| 02-CPT-02 | 0.0 | 93.7 | - | - | 76.8 | 65.9 | 10.9 | MH | |

| 02-CPT-02 | 0.3 | 97.4 | - | - | 48.3 | 31.0 | 17.3 | ML | |

| 02-CPT-02 | 1.1 | 24.0 | - | - | NP | SM | |||

| 02-CPT-03 | 0.0 | 96.0 | - | - | 62.4 | 46.5 | 15.9 | MH | |

| 02-CPT-03 | 0.3 | 98.0 | - | - | 44.1 | 29.2 | 14.9 | ML | |

| 02-CPT-03 | 1.1 | 45.9 | - | - | NP | SM | |||

| 02-CPT-04 | 0.0 | 97.7 | - | - | 77.3 | 55.7 | 21.6 | MH | |

| 02-CPT-04 | 0.3 | 98.1 | - | - | 51.9 | 35.8 | 16.1 | MH | |

| 02-CPT-04 | 1.1 | 21.6 | - | - | NP | SM | |||

| 02-CPT-05 | 0.0 | 98.1 | - | - | 86.4 | 64.0 | 22.4 | MH | |

| 02-CPT-05 | 0.3 | 98.6 | - | - | 48.9 | 32.3 | 16.6 | ML | |

| 02-CPT-05 | 1.1 | 12.2 | - | - | NP | SM | |||

| 03 | 03-CBR-01 | 0.0 | 96.5 | - | - | 77.2 | 66.3 | 10.9 | MH |

| 03-CBR-02 | 0.0 | 98.0 | - | - | 80.7 | 62.2 | 18.5 | MH | |

| 03-CBR-03 | 0.0 | 99.2 | - | - | 60.7 | 38.8 | 21.9 | MH | |

| 03-CBR-04 | 0.0 | 98.7 | - | - | 72.1 | 59.3 | 12.8 | MH | |

| 03-CBR-05 | 0.0 | 98.8 | - | - | 79.9 | 57.3 | 22.6 | MH | |

| 03-CPT-01 | 0.0 | 97.6 | - | - | 79.6 | 75.2 | 4.4 | MH | |

| 03-CPT-01 | 0.3 | 99.0 | - | - | 78.4 | 56.7 | 21.7 | MH | |

| 03-CPT-01 | 1.1 | 7.8 | 5.1 | 0.8 | NP | SP-SM | |||

| 03-CPT-02 | 0.0 | 98.6 | - | - | 95.5 | 77.4 | 18.1 | MH | |

| 03-CPT-02 | 0.3 | 99.6 | - | - | 86.1 | 54.6 | 31.5 | MH | |

| 03-CPT-02 | 1.1 | 7.5 | 5.8 | 0.8 | NP | SP-SM | |||

| 03-CPT-03 | 0.0 | 98.5 | - | - | NP | ML | |||

| 03-CPT-03 | 0.3 | 99.2 | - | - | 71.1 | 44.1 | 27.1 | MH | |

| 03-CPT-03 | 1.1 | 6.3 | 7.2 | 0.8 | NP | SP-SM | |||

| 03-CPT-04 | 0.0 | 97.8 | - | - | NP | ML | |||

| 03-CPT-04 | 0.3 | 99.4 | - | - | 82.7 | 61.2 | 21.5 | MH | |

| 03-CPT-04 | 1.1 | 8.0 | 3.9 | 0.8 | NP | SP-SM | |||

| 03-CPT-05 | 0.0 | 99.1 | - | - | 77.5 | 58.8 | 18.6 | MH | |

| 03-CPT-05 | 0.3 | 98.7 | - | - | 98.0 | 66.4 | 31.6 | MH | |

| 03-CPT-05 | 1.1 | 9.5 | 3.6 | 0.9 | NP | SP-SM | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moffat, R.; Faundez, F.; Villalobos, F.A. Experimental Investigation and Analysis of the Influence of Depth and Moisture Content on the Relationship Between Subgrade California Bearing Ratio Tests and Cone Penetration Tests for Pavement Design. Buildings 2025, 15, 345. https://doi.org/10.3390/buildings15030345

Moffat R, Faundez F, Villalobos FA. Experimental Investigation and Analysis of the Influence of Depth and Moisture Content on the Relationship Between Subgrade California Bearing Ratio Tests and Cone Penetration Tests for Pavement Design. Buildings. 2025; 15(3):345. https://doi.org/10.3390/buildings15030345

Chicago/Turabian StyleMoffat, Ricardo, Felipe Faundez, and Felipe A. Villalobos. 2025. "Experimental Investigation and Analysis of the Influence of Depth and Moisture Content on the Relationship Between Subgrade California Bearing Ratio Tests and Cone Penetration Tests for Pavement Design" Buildings 15, no. 3: 345. https://doi.org/10.3390/buildings15030345

APA StyleMoffat, R., Faundez, F., & Villalobos, F. A. (2025). Experimental Investigation and Analysis of the Influence of Depth and Moisture Content on the Relationship Between Subgrade California Bearing Ratio Tests and Cone Penetration Tests for Pavement Design. Buildings, 15(3), 345. https://doi.org/10.3390/buildings15030345