Management of Carbon Emissions Throughout the Building Life Cycle Based on the Analytic Hierarchy Process

Abstract

:1. Introduction

2. Methods

2.1. Life Cycle Analysis

2.2. Low-Carbon Building

2.3. Analytic Hierarchy Process

2.4. Low-Carbon Evaluation Index System

3. Case Study: Engineering Project

3.1. Project Overview

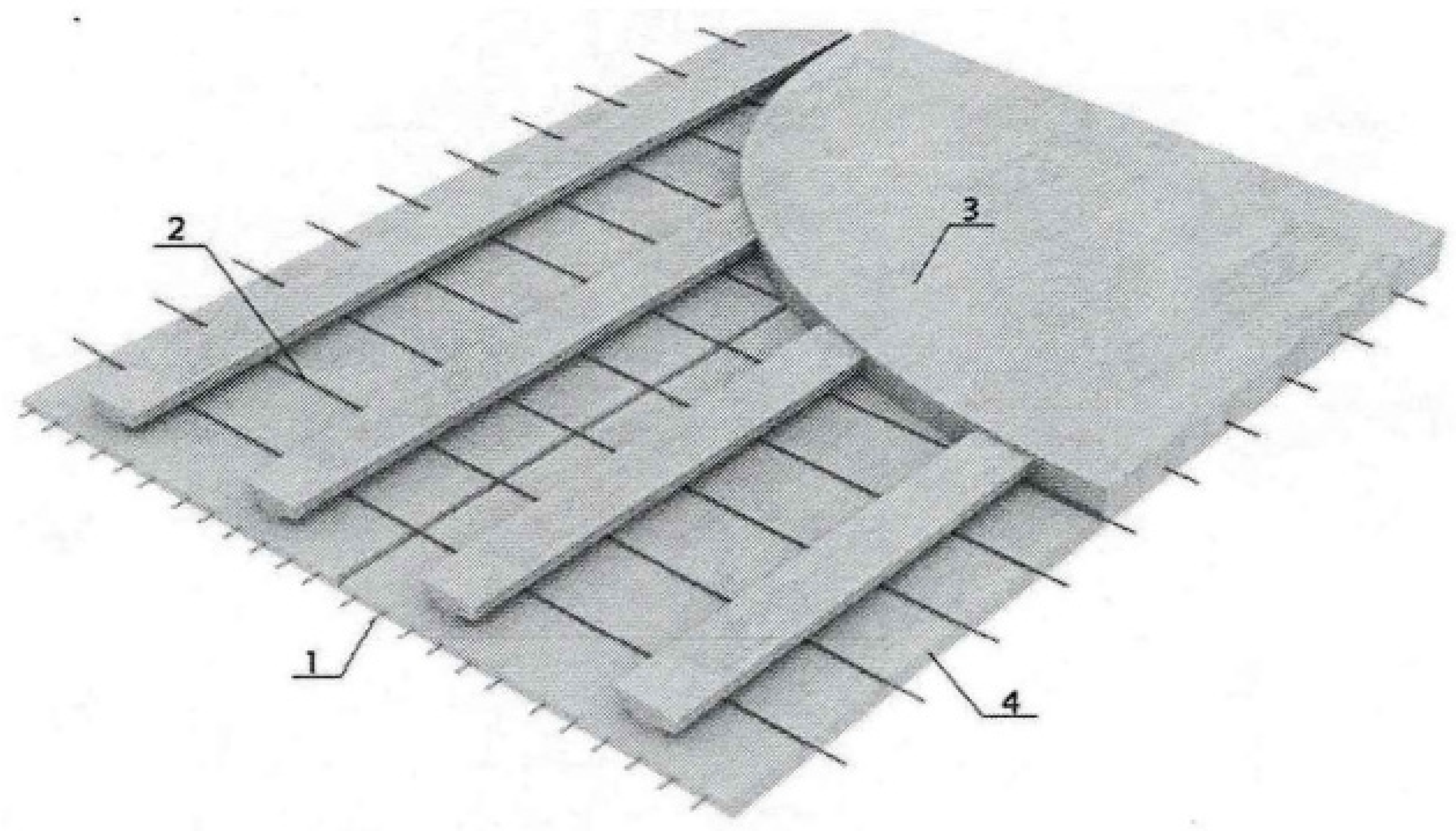

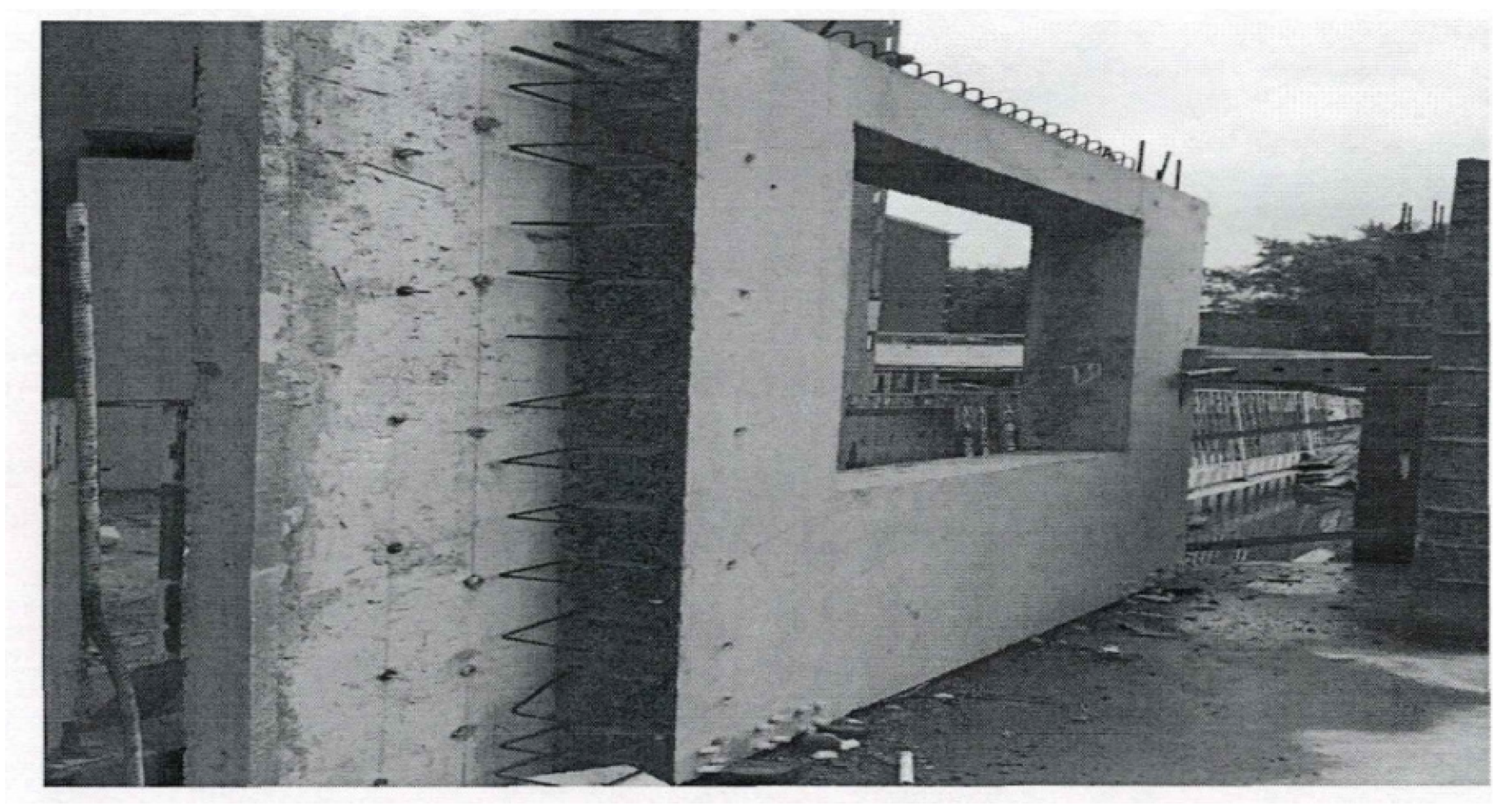

3.2. Application of Prefabricated Structures

3.3. Calculation of Carbon Emissions from Building Materials During Construction

3.4. Application of Low-Carbon Production Management in Construction Period

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, R.; Xu, P.; Chen, L.; Yao, H. Did electrification of the building sector achieve carbon mitigation? A provincial retrospection in China. Build. Environ. 2024, 248, 111084. [Google Scholar] [CrossRef]

- Hu, M.; Ghorbany, S. Building Stock Models for Embodied Carbon Emissions—A Review of a Nascent Field. Sustainability 2024, 16, 2089. [Google Scholar] [CrossRef]

- Huang, R.; Zhang, X.; Liu, K. Assessment of operational carbon emissions for residential buildings comparing different machine learning approaches: A study of 34 cities in China. Build. Environ. 2024, 250, 111176. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, M.; Zhu, H.; Jiang, H.; Liu, J. Impact factors and peaking simulation of carbon emissions in the building sector in Shandong Province. J. Build. Eng. 2024, 87, 109141. [Google Scholar] [CrossRef]

- Ding, Y.; Ye, X.W.; Su, Y.H. Wind-induced fatigue life prediction of bridge hangers considering the effect of wind direction. Eng. Struct. 2025, 327, 119523. [Google Scholar] [CrossRef]

- Ding, Y.; Ye, X.W.; Su, Y.H.; Zheng, X.L. A framework of cable wire failure mode deduction based on Bayesian network. Structures 2023, 57, 104996. [Google Scholar] [CrossRef]

- Ding, Y.; Ye, X.W.; Guo, Y. Copula-based JPDF of wind speed, wind direction, wind angle, and temperature with SHM data. Probabilistic Eng. Mech. 2023, 73, 103483. [Google Scholar] [CrossRef]

- Ding, Y.; Ye, X.W.; Guo, Y.; Zhang, R.; Ma, Z. Probabilistic method for wind speed prediction and statistics distribution inference based on SHM data-driven. Probabilistic Eng. Mech. 2023, 73, 103475. [Google Scholar] [CrossRef]

- Ding, Y.; Hang, D.; Wei, Y.J.; Zhang, X.L.; Ma, S.Y.; Liu, Z.X.; Han, Z. Settlement prediction of existing metro induced by new metro construction with machine learning based on SHM data: A comparative study. J. Civ. Struct. Health Monit. 2023, 13, 1447–1457. [Google Scholar] [CrossRef]

- Ding, Y.; Ye, X.; Ding, Z.; Wei, G.; Cui, Y.; Han, Z.; Jin, T. Short-term tunnel-settlement prediction based on Bayesian wavelet: A probability analysis method. J. Zhejiang Univ.-SCIENCE A 2023, 24, 960–977. [Google Scholar] [CrossRef]

- Su, S.; Zang, Z.; Yuan, J.; Pan, X.; Shan, M. Considering critical building materials for embodied carbon emissions in buildings: A machine learning-based prediction model and tool. Case Stud. Constr. Mater. 2024, 20, e02887. [Google Scholar] [CrossRef]

- Hasan, M.; Chan, C.K. ISO 14000 and its perceived impact on corporate performance. Bus. Manag. Horiz. 2014, 2, 1–14. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Hu, X.; Ran, B.; Wu, T.; Zhou, X.; Xiong, Y. Physical performance, durability, and carbon emissions of recycled cement concrete and fully recycled concrete. Constr. Build. Mater. 2024, 447, 138128. [Google Scholar] [CrossRef]

- Osman, A.I.; Farghali, M.; Dong, Y.; Kong, J.; Yousry, M.; Rashwan, A.K.; Chen, Z.; Al-Fatesh, A.; Rooney, D.W.; Yap, P.S. Reducing the carbon footprint of buildings using biochar-based bricks and insulating materials: A review. Environ. Chem. Lett. 2024, 22, 71–104. [Google Scholar] [CrossRef]

- Zhan, J.; He, W.; Huang, J. Comfort, carbon emissions, and cost of building envelope and photovoltaic arrangement optimization through a two-stage model. Appl. Energy 2024, 356, 122423. [Google Scholar] [CrossRef]

- Chu, X.; Fei, Z.; Chu, Z.; Huang, W.C. Decarbonizing the sludge treatment industry: Assessing the feasibility of achieving carbon reduction from carbon peaking to carbon neutrality. J. Clean. Prod. 2024, 434, 140023. [Google Scholar] [CrossRef]

- Du, Q.; Yang, M.; Wang, Y.; Wang, X.; Dong, Y. Dynamic simulation for carbon emission reduction effects of the prefabricated building supply chain under environmental policies. Sustain. Cities Soc. 2024, 100, 105027. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Wang, H.; Yan, P.; Shan, L.; Hua, S. Properties of RCA stabilized with alkali-activated steel slag based materials in pavement base: Laboratory tests, field application and carbon emissions. Constr. Build. Mater. 2024, 411, 134547. [Google Scholar] [CrossRef]

- Gao, H.; Wang, D.; Du, X.; Zhao, Z. An LCA-BIM integrated model for carbon-emission calculation of prefabricated buildings. Renew. Sustain. Energy Rev. 2024, 203, 114775. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, C.; Chen, L.; Qiu, L.; Wu, W.; Wang, Q. Using BIM and LCA to Calculate the Life Cycle Carbon Emissions of Inpatient Building: A Case Study in China. Sustainability 2024, 16, 5341. [Google Scholar] [CrossRef]

- Ding, Y.; Guo, Z.Z.; Zhou, S.X.; Wei, Y.Q.; She, A.M.; Dong, J.L. Research on carbon emissions during the construction process of prefabricated buildings based on BIM and LCA. J. Asian Archit. Build. Eng. 2024, 1–13. [Google Scholar] [CrossRef]

- Seyedabadi, M.R.; Karrabi, M.; Shariati, M.; Karimi, S.; Maghrebi, M.; Eicker, U. Global building life cycle assessment: Comparative study of steel and concrete frames across European Union, USA, Canada, and Australia building codes. Energy Build. 2024, 304, 113875. [Google Scholar] [CrossRef]

- Nilimaa, J.; Zhaka, V. Material and environmental aspects of concrete flooring in cold climate. Constr. Mater. 2023, 3, 180–201. [Google Scholar] [CrossRef]

- Mosquini, L.N.; Delinchant, B.; Jusselme, T. Dynamic LCA methodology to support post-occupancy decision-making for carbon budget compliance. Energy Build. 2024, 309, 114006. [Google Scholar] [CrossRef]

- Sandaruwan IP, T.; Manoharan, K.; Kulatunga, U. Cradle-to-gate embodied carbon assessment of green office building using life cycle analysis: A case study from Sri Lanka. J. Build. Eng. 2024, 88, 109155. [Google Scholar] [CrossRef]

- Hosamo, H.; Coelho, G.B.; Buvik, E.; Drissi, S.; Kraniotis, D. Building sustainability through a novel exploration of dynamic LCA uncertainty: Overview and state of the art. Build. Environ. 2024, 264, 111922. [Google Scholar] [CrossRef]

- Tang, B.; Wu, H.; Wu, Y.F. Evaluation of carbon footprint of compression cast waste rubber concrete based on LCA approach. J. Build. Eng. 2024, 86, 108818. [Google Scholar] [CrossRef]

- Feng, X.; Zhao, Y.; Yan, R. Does carbon emission trading policy has emission reduction effect?—An empirical study based on quasi-natural experiment method. J. Environ. Manag. 2024, 351, 119791. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, X. Does carbon emission trading policy induce financialization of non-financial firms? Evidence from China. Energy Econ. 2024, 131, 107316. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, X.; Liu, Y.; Zhou, T. Carbon emission trading, carbon efficiency, and the Porter hypothesis: Plant-level evidence from China. Energy 2024, 308, 132870. [Google Scholar] [CrossRef]

- Bian, Z.; Liu, J.; Zhang, Y.; Peng, B.; Jiao, J. A green path towards sustainable development: The impact of carbon emissions trading system on urban green transformation development. J. Clean. Prod. 2024, 442, 140943. [Google Scholar] [CrossRef]

- Ren, Y.S.; Derouiche, I.; Hassan, M.; Liu, P.Z. Do creditors price climate transition risks? A natural experiment based on China’s carbon emission trading scheme. Int. Rev. Econ. Financ. 2024, 91, 138–155. [Google Scholar] [CrossRef]

- Warrier, G.A.; Palaniappan, S.; Habert, G. Classification of sources of uncertainties in building LCA. Energy Build. 2024, 305, 113892. [Google Scholar] [CrossRef]

- Decorte, Y.; Van Den Bossche, N.; Steeman, M. Importance of technical installations in whole-building LCA: Single-family case study in Flanders. Build. Environ. 2024, 250, 111209. [Google Scholar] [CrossRef]

- Shinde, R.; Kim, A.; Hellweg, S. Bottom-up LCA building stock model: Tool for future building-management scenarios. J. Clean. Prod. 2024, 434, 140272. [Google Scholar] [CrossRef]

- Kathiravel, R.; Zhu, S.; Feng, H. LCA of net-zero energy residential buildings with different HVAC systems across Canadian climates: A BIM-based fuzzy approach. Energy Build. 2024, 306, 113905. [Google Scholar] [CrossRef]

- Xiong, L.; Wang, M.; Mao, J.; Huang, B. A Review of Building Carbon Emission Accounting Methods under Low-Carbon Building Background. Buildings 2024, 14, 777. [Google Scholar] [CrossRef]

- McCord, K.H.; Dillon, H.E.; Gunderson, P.; Carlson, S.; Phillips, A.R.; Griechen, D.; Antonopoulos, C.A. Strategies for connecting whole-building LCA to the low-carbon design process. Environ. Res. Infrastruct. Sustain. 2024, 4, 015002. [Google Scholar] [CrossRef]

- Nilimaa, J. Smart materials and technologies for sustainable concrete construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Ding, Y.; He, Z.X.; Zhou, S.X. Multi-dimensional models for predicting the chloride diffusion in concrete exposed to marine tidal zone: Methodology, Numerical Simulation and Application. Comput. Concr. 2024, 34, 169–178. [Google Scholar]

- Terán-Cuadrado, G.; Tahir, F.; Nurdiawati, A.; Almarshoud, M.A.; Al-Ghamdi, S.G. Current and potential materials for the low-carbon cement production: Life cycle assessment perspective. J. Build. Eng. 2024, 96, 110528. [Google Scholar] [CrossRef]

- Płoszaj-Mazurek, M.; Ryńska, E. Artificial Intelligence and Digital Tools for Assisting Low-Carbon Architectural Design: Merging the Use of Machine Learning, Large Language Models, and Building Information Modeling for Life Cycle Assessment Tool Development. Energies 2024, 17, 2997. [Google Scholar] [CrossRef]

- Kertsmik, K.A.; Arumägi, E.; Hallik, J.; Kalamees, T. Low carbon emission renovation of historical residential buildings. Energy Rep. 2024, 11, 3836–3847. [Google Scholar] [CrossRef]

- Moslem, S. A novel parsimonious spherical fuzzy analytic hierarchy process for sustainable urban transport solutions. Eng. Appl. Artif. Intell. 2024, 128, 107447. [Google Scholar] [CrossRef]

- Ransikarbum, K.; Pitakaso, R. Multi-objective optimization design of sustainable biofuel network with integrated fuzzy analytic hierarchy process. Expert Syst. Appl. 2024, 240, 122586. [Google Scholar] [CrossRef]

- Islam, M.R.; Aziz, M.T.; Alauddin, M.; Kader, Z.; Islam, M.R. Site suitability assessment for solar power plants in Bangladesh: A GIS-based analytical hierarchy process (AHP) and multi-criteria decision analysis (MCDA) approach. Renew. Energy 2024, 220, 119595. [Google Scholar] [CrossRef]

- Banti, N.; Krawczyk, D.A. Integrating energy simulations and analytical hierarchy process procedure in multi-criteria evaluation of heating systems for industrial buildings. J. Build. Eng. 2024, 95, 110203. [Google Scholar] [CrossRef]

- Algafri, M.; Alghazi, A.; Almoghathawi, Y.; Saleh, H.; Al-Shareef, K. Smart City Charging Station allocation for electric vehicles using analytic hierarchy process and multiobjective goal-programming. Appl. Energy 2024, 372, 123775. [Google Scholar] [CrossRef]

- Tapia JF, D.; Promentilla MA, B.; Tseng, M.L.; Tan, R.R. Screening of carbon dioxide utilization options using hybrid Analytic Hierarchy Process-Data Envelopment Analysis method. J. Clean. Prod. 2017, 165, 1361–1370. [Google Scholar] [CrossRef]

- Ligus, M. Evaluation of economic, social and environmental effects of low-emission energy technologies development in Poland: A multi-criteria analysis with application of a fuzzy analytic hierarchy process (FAHP). Energies 2017, 10, 1550. [Google Scholar] [CrossRef]

- Muryani, M.; Nisa’, K.; Esquivias, M.A.; Zulkarnain, S.H. Strategies to control industrial emissions: An analytical network process approach in East Java, Indonesia. Sustainability 2023, 15, 7761. [Google Scholar] [CrossRef]

- Wen, C.; Li, Y.; Zhang, W.; Wang, G.; Li, B.; Meng, S. Research on Evaluation Index System of Low-carbon Existing Communities. Int. J. Nat. Resour. Environ. Stud. 2024, 2, 248–257. [Google Scholar] [CrossRef]

- Li, Q.; Zeng, Y.; Meng, Y.; Kong, W.; Pei, Z. A Comparative Analysis of Low-Carbon Design Strategies for China’s Higher Education Parks Based on Building and Urban Scale in Sustainability Rating Systems. Buildings 2024, 14, 1846. [Google Scholar] [CrossRef]

- Wang, Y.; Fang, X.; Yin, S.; Chen, W. Low-carbon development quality of cities in China: Evaluation and obstacle analysis. Sustain. Cities Soc. 2021, 64, 102553. [Google Scholar] [CrossRef]

- Zhang, N.; Luo, Z.; Liu, Y.; Feng, W.; Zhou, N.; Yang, L. Towards low-carbon cities through building-stock-level carbon emission analysis: A calculating and maping method. Sustain. Cities Soc. 2022, 78, 103633. [Google Scholar] [CrossRef]

- Na, W.; Zhao, Z.C. The comprehensive evaluation method of low-carbon campus based on analytic hierarchy process and weights of entropy. Environ. Dev. Sustain. 2021, 23, 9308–9319. [Google Scholar] [CrossRef]

- Wang, X.; Du, Q.; Lu, C.; Li, J. Exploration in carbon emission reduction effect of low-carbon practices in prefabricated building supply chain. J. Clean. Prod. 2022, 368, 133153. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, Y.; Feng, W.; Fang, Y.; Feng, A. Factors that influence the quantification of the embodied carbon emission of prefabricated buildings: A systematic review, meta-analysis and the way forward. Buildings 2022, 12, 1265. [Google Scholar] [CrossRef]

- Han, Q.; Chang, J.; Liu, G.; Zhang, H. The carbon emission assessment of a building with different prefabrication rates in the construction stage. Int. J. Environ. Res. Public Health 2022, 19, 2366. [Google Scholar] [CrossRef] [PubMed]

- Xu, A.; Zhu, Y.; Wang, Z.; Zhao, Y. Carbon emission calculation of prefabricated concrete composite slabs during the production and construction stages. J. Build. Eng. 2023, 80, 107936. [Google Scholar] [CrossRef]

- Li, X.J.; Xie, W.J.; Xu, L.; Li, L.L.; Jim, C.Y.; Wei, T.B. Holistic life-cycle accounting of carbon emissions of prefabricated buildings using LCA and BIM. Energy Build. 2022, 266, 112136. [Google Scholar] [CrossRef]

- Xiao, Q.M.; Zheng, C.J. Research on evaluation of green construction of municipal road considering carbon emissions. J. Chang. Univ. Sci. Technol. (Nat. Sci.) 2024, 21, 113–121. (In Chinese) [Google Scholar]

- Wang, G.; Cai, J. Experimental study on nano-material modified Portland cement-based grouting material. J. Henan Polytech. Univ. (Nat. Sci.) 2024, 1–12. (In Chinese) [Google Scholar] [CrossRef]

- Yu, Y.J.; Liu, X.M. A two-stage optimization decision making model of virtual power plantgroup considering multi-time scale. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2024, 43, 120–130. (In Chinese) [Google Scholar]

- Wang, Q. Strategies and practices of green travel for building a sustainable urban transportation system. J. Munic. Technol. 2025, 43, 26–32+40. (In Chinese) [Google Scholar]

| Comparison Between Risk Factor i and Risk Factor j | aij | |

|---|---|---|

| Risk factor i is equally important as risk factor j | 1 | ai = aj |

| Risk factor i and risk factor j are slightly more important | 3 | ai = 3aj |

| Risk factor i is more important than risk factor j | 5 | ai = 5aj |

| Risk factor i and risk factor j are much more and more important | 7 | ai = 7aj |

| Risk factor i and risk factor j are much more important | 9 | ai = 9aj |

| The importance of risk factor i and risk factor j lies between the above judgments | 2, 4, 6, 8 | / |

| The important results of risk factor i and risk factor j are reciprocal to each other | aij = 1/aji | / |

| Water/m3 | C-W | BQ | C-CO2/kg | A-CO2/kg | T-CO2/kg | DR/% |

| 133,386.75 | 138,544.69 | 0.194 | 25,877.03 | 26,877.67 | −3.7% | |

| T-W | BQ | C-CO2/kg | A-CO2/kg | T-CO2/kg | DR/% | |

| 6473.28 | 6951.43 | 0.194 | 1255.82 | 1348.58 | −6.9% | |

| Electricity/KWh | C-E | BQ | C-CO2/kg | A-CO2/kg | T-CO2/kg | DR/% |

| 853,675.2 | 919,908.62 | 0.7802 | 666,037.39 | 717,712.71 | −7.2% | |

| T-E | BQ | C-CO2/kg | A-CO2/kg | T-CO2/kg | DR/% | |

| 94,852.8 | 97,988.43 | 0.7802 | 74,004.15 | 76,450.57 | −3.2% | |

| C-C | BQ | C-CO2/kg | A-CO2/kg | T-CO2/kg | DR/% | |

| Rebar/t | 8181.05 | 8365.09 | 982 | 8,033,795.03 | 8,214,514.34 | −2.2% |

| Concrete/m3 | 106,709.4 | 108,665.38 | 250 | 26,677,350.00 | 27,166,345.00 | −1.8% |

| Cement/t | 42,769.42 | 47,324.08 | 700 | 29,938,594.00 | 331,268,556.00 | −9.6% |

| Dijk | Pijk |

|---|---|

| Equip professional technical personnel—D111 | 65 |

| Low-carbon construction organization structure—D112 | 68 |

| Responsibilities of low-carbon construction positions—D113 | 64 |

| Development of low-carbon construction management plan—D121 | 76 |

| Layout of project construction plan—D122 | 78 |

| Develop energy-saving and consumption reduction management plans—D123 | 64 |

| Refine and improve the design drawings before construction—D131 | 65 |

| Develop overall and specialized construction plans—D132 | 76 |

| Establish a construction quality management team—D133 | 70 |

| Protection of completed processes—D134 | 72 |

| Evaluate the effectiveness of low-carbon technologies and processes adopted during the construction process—D141 | 60 |

| Assess the natural environmental impact caused by construction—D142 | 49 |

| Use wall materials with good insulation and thermal insulation performance, as well as lightweight aggregates—D211 | 78 |

| Use building materials with good corrosion resistance and waterproof performance—D212 | 72 |

| Replace traditional high energy consuming materials with green and environmentally friendly materials—D213 | 70 |

| Choose local building materials—D221 | 60 |

| Adopting energy-efficient and effective transportation methods—D222 | 58 |

| Developing technology for separating recyclable construction waste—D231 | 71 |

| Adopting an industrialized construction model—D232 | 78 |

| Significantly reduce the application of brick materials—D233 | 80 |

| Temporary facilities use detachable structures—D241 | 78 |

| The auxiliary tools are rented out—D242 | 67 |

| Reasonably divide the construction flow section—D243 | 74 |

| Establish a strict water management system—D311 | 76 |

| Adopting water-saving construction techniques—D312 | 75 |

| The construction water pipe network should be arranged according to the water consumption, and the installation and maintenance of pipelines should be supervised—D313 | 63 |

| The domestic water supply at the construction site adopts intelligent water-saving devices—D314 | 74 |

| Measure domestic water and engineering water separately—D315 | 75 |

| On-site production of reservoirs and circulating water tanks, and installation of treatment devices—D321 | 59 |

| On-site equipment and vehicle washing should be equipped with a circulating water device—D322 | 61 |

| Establish a management system for construction machinery and equipment—D411 | 82 |

| Configure construction machinery and equipment with power matching the load—D412 | 68 |

| Reasonably divide processes to improve equipment utilization and full load rate—D413 | 70 |

| Adopting energy-saving construction equipment and tools-D414 | 70 |

| The lighting layout is based on the principle of meeting the minimum illuminance required for room functionality—D421 | 62 |

| Adopting energy-saving lighting system—D422 | 72 |

| Develop reasonable construction and living electricity consumption quotas, and measure and assess construction and living electricity separately—D423 | 58 |

| Temporary board houses use energy-saving materials with good thermal insulation performance–D431 | 60 |

| Utilize the existing natural conditions of the site—D432 | 56 |

| Utilization of solar energy—D441 | 57 |

| Utilization of wind energy—D442 | 40 |

| Utilization of geothermal energy—D443 | 0 |

| Material transport vehicles should be cleaned before leaving the site—D511 | 61 |

| Control measures for materials that are prone to dust formation—D512 | 76 |

| The main road at the exit should be hardened—D513 | 82 |

| Reasonably dispose of construction wastewater—D521 | 50 |

| Reasonably dispose of domestic sewage on construction sites—D522 | 55 |

| Conduct water quality testing on treated wastewater and sewage—D523 | 0 |

| Reasonably stack and cover the backfill soil excavated during construction—D524 | 59 |

| Cover the exposed soil with gravel and planted vegetation in a timely manner—D525 | 58 |

| Select low-noise construction equipment and set up noise reduction enclosures—D531 | 74 |

| Reasonably arrange homework time—D532 | 76 |

| Classification and treatment of construction waste for convenient recycling and reuse—D541 | 63 |

| The disposal of waste must be legal and traceable—D542 | 50 |

| Construction water consumption—D611 | 73 |

| Non construction water consumption—D612 | 75 |

| Construction electricity consumption—D621 | 58 |

| Non construction electricity consumption—D622 | 65 |

| Steel consumption—D631 | 65 |

| Concrete consumption—D632 | 67 |

| Cement consumption—D633 | 64 |

| Dijk | Wijk | Pijk | Tijk | Tij | Cij | Wij | Ti | Bi | Wi | T |

|---|---|---|---|---|---|---|---|---|---|---|

| D111 | 0.54 | 65 | 35.10 | 65.18 | C11 | 0.06 | 66.36 | B1 | 0.44 | 65.88 |

| D112 | 0.16 | 68 | 10.88 | |||||||

| D113 | 0.30 | 64 | 19.20 | |||||||

| D121 | 0.53 | 76 | 40.28 | 72.32 | C12 | 0.16 | ||||

| D122 | 0.14 | 78 | 10.92 | |||||||

| D123 | 0.33 | 64 | 21.12 | |||||||

| D131 | 0.12 | 65 | 7.80 | 71.22 | C13 | 0.54 | ||||

| D132 | 0.28 | 76 | 21.28 | |||||||

| D133 | 0.53 | 70 | 37.10 | |||||||

| D134 | 0.07 | 72 | 5.04 | |||||||

| D141 | 0.25 | 60 | 15.00 | 51.75 | C14 | 0.24 | ||||

| D142 | 0.75 | 49 | 36.75 | |||||||

| D211 | 0.12 | 78 | 9.36 | 71.5 | C21 | 0.24 | 72.62 | B2 | 0.09 | |

| D212 | 0.27 | 72 | 19.44 | |||||||

| D213 | 0.61 | 70 | 42.70 | |||||||

| D221 | 0.67 | 60 | 40.20 | 59.34 | C22 | 0.10 | ||||

| D222 | 0.33 | 58 | 19.14 | |||||||

| D231 | 0.10 | 71 | 7.10 | 78.58 | C23 | 0.14 | ||||

| D232 | 0.26 | 78 | 20.28 | |||||||

| D233 | 0.64 | 80 | 51.20 | |||||||

| D241 | 0.23 | 78 | 17.94 | 74.08 | C24 | 0.52 | ||||

| D242 | 0.12 | 67 | 8.04 | |||||||

| D243 | 0.65 | 74 | 48.10 | |||||||

| D311 | 0.47 | 76 | 35.72 | 74.37 | C31 | 0.67 | 69.52 | B3 | 0.06 | |

| D312 | 0.25 | 75 | 18.75 | |||||||

| D313 | 0.08 | 63 | 5.04 | |||||||

| D314 | 0.14 | 74 | 10.36 | |||||||

| D315 | 0.06 | 75 | 4.50 | |||||||

| D321 | 0.67 | 59 | 39.53 | 59.66 | C32 | 0.33 | ||||

| D322 | 0.33 | 61 | 20.13 | |||||||

| D411 | 0.11 | 82 | 9.02 | 71.16 | C41 | 0.46 | 61.62 | B4 | 0.05 | |

| D412 | 0.08 | 68 | 5.44 | |||||||

| D413 | 0.26 | 70 | 18.20 | |||||||

| D414 | 0.55 | 70 | 38.50 | |||||||

| D421 | 0.12 | 62 | 7.44 | 62.26 | C42 | 0.12 | ||||

| D422 | 0.27 | 72 | 19.44 | |||||||

| D423 | 0.61 | 58 | 35.38 | |||||||

| D431 | 0.33 | 60 | 19.80 | 57.32 | C43 | 0.18 | ||||

| D432 | 0.67 | 56 | 37.52 | |||||||

| D441 | 0.65 | 57 | 37.05 | 46.25 | C44 | 0.24 | ||||

| D442 | 0.23 | 40 | 9.20 | |||||||

| D443 | 0.12 | 0 | 0.00 | |||||||

| D511 | 0.12 | 61 | 7.32 | 75.82 | C51 | 0.30 | 59.33 | B5 | 0.14 | |

| D512 | 0.61 | 76 | 46.36 | |||||||

| D513 | 0.27 | 82 | 22.14 | |||||||

| D521 | 0.15 | 50 | 7.50 | 27.48 | C52 | 0.19 | ||||

| D522 | 0.15 | 55 | 8.25 | |||||||

| D523 | 0.50 | 0 | 0.00 | |||||||

| D524 | 0.13 | 59 | 7.67 | |||||||

| D525 | 0.07 | 58 | 4.06 | |||||||

| D531 | 0.67 | 74 | 49.58 | 74.66 | C53 | 0.06 | ||||

| D532 | 0.33 | 76 | 25.08 | |||||||

| D541 | 0.75 | 63 | 47.25 | 59.75 | C54 | 0.45 | ||||

| D542 | 0.25 | 50 | 12.50 | |||||||

| D611 | 0.83 | 73 | 60.59 | 73.34 | C61 | 0.23 | 66.29 | B6 | 0.22 | |

| D612 | 0.17 | 73 | 12.75 | |||||||

| D621 | 0.83 | 58 | 48.14 | 59.19 | C62 | 0.22 | ||||

| D622 | 0.17 | 65 | 11.05 | |||||||

| D631 | 0.12 | 65 | 7.80 | 64.93 | C63 | 0.67 | ||||

| D632 | 0.27 | 67 | 18.09 | |||||||

| D633 | 0.61 | 64 | 39.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.-F.; Lu, Z.-P.; Ding, Y.; Guo, Z.-Z.; Zhou, S.-X. Management of Carbon Emissions Throughout the Building Life Cycle Based on the Analytic Hierarchy Process. Buildings 2025, 15, 592. https://doi.org/10.3390/buildings15040592

Zheng J-F, Lu Z-P, Ding Y, Guo Z-Z, Zhou S-X. Management of Carbon Emissions Throughout the Building Life Cycle Based on the Analytic Hierarchy Process. Buildings. 2025; 15(4):592. https://doi.org/10.3390/buildings15040592

Chicago/Turabian StyleZheng, Jie-Fu, Zhi-Peng Lu, Yang Ding, Zhen-Zhen Guo, and Shuang-Xi Zhou. 2025. "Management of Carbon Emissions Throughout the Building Life Cycle Based on the Analytic Hierarchy Process" Buildings 15, no. 4: 592. https://doi.org/10.3390/buildings15040592

APA StyleZheng, J.-F., Lu, Z.-P., Ding, Y., Guo, Z.-Z., & Zhou, S.-X. (2025). Management of Carbon Emissions Throughout the Building Life Cycle Based on the Analytic Hierarchy Process. Buildings, 15(4), 592. https://doi.org/10.3390/buildings15040592