Assessing Construction Safety Performance in Urban Underground Space Development Projects from a Resilience Enhancement Perspective

Abstract

:1. Introduction

2. Literature Review

2.1. Framework for Infrastructure Resilience Assessment

2.2. Identification and Measurement of Infrastructure Resilience

2.3. Review of Existing Research

- (1)

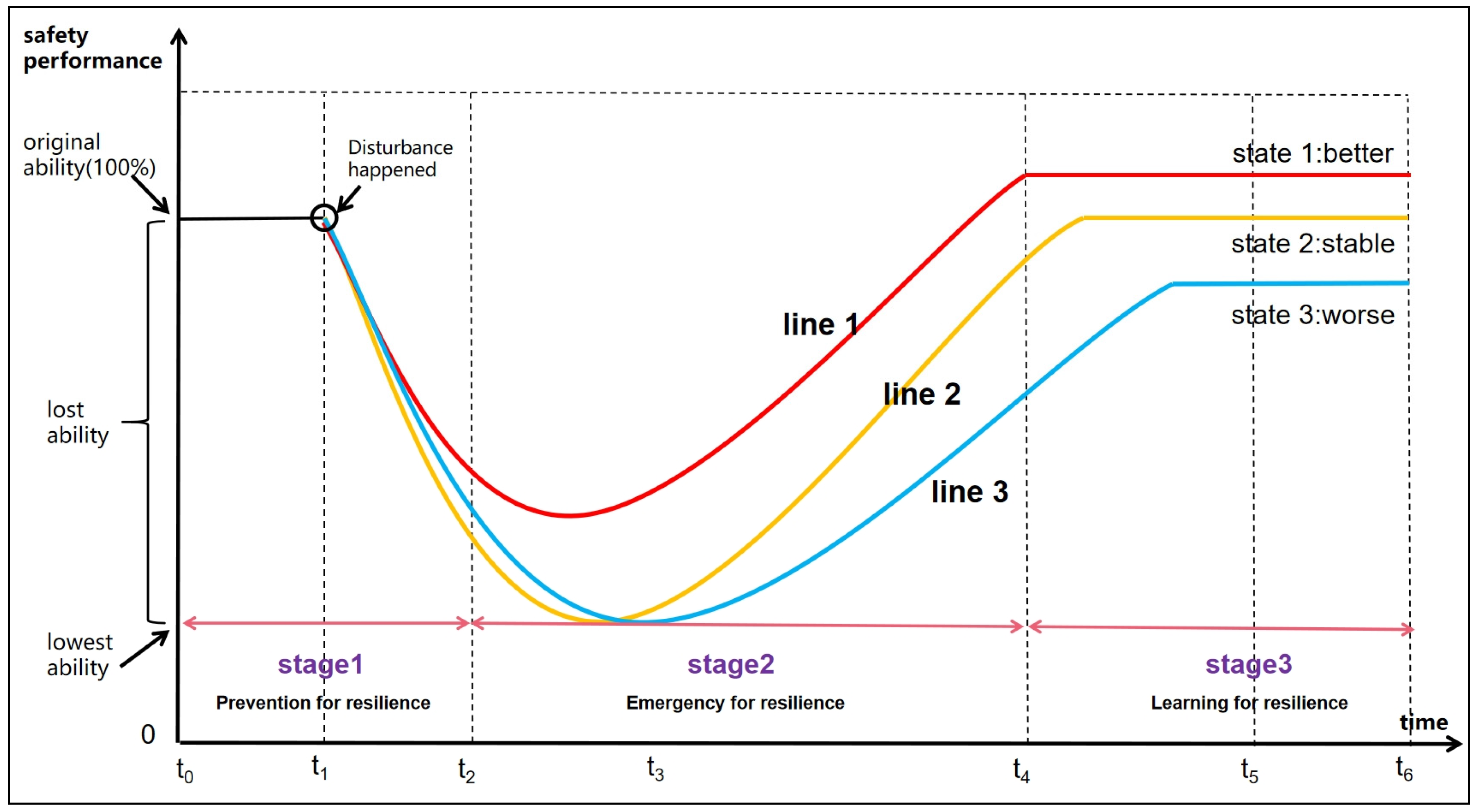

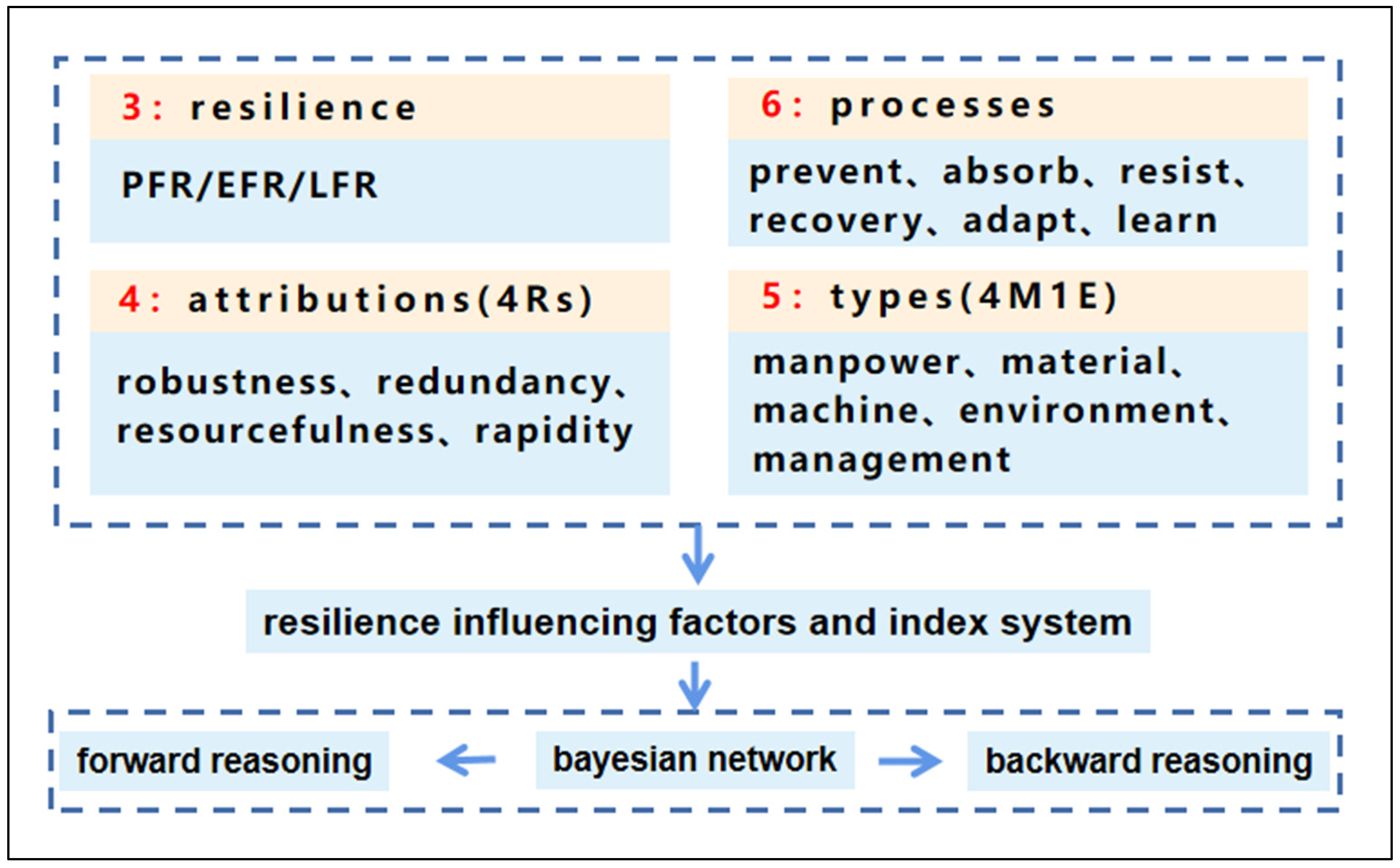

- A three-stage resilience evolution model, encompassing prevention for resilience (PFR), emergency for resilience (EFR), and learning for resilience (LFR), is proposed in order to address the temporal characteristics of infrastructure construction processes. This model integrates the entire disaster process with the response characteristics of the construction organization system to disturbances, representing an effective enhancement and upgrade compared to existing resilience assessment models.

- (2)

- Combining the theories and practices of existing safety resilience, this study couples technical factors with management factors, identifying the components of safety resilience in underground space construction from multiple perspectives of “4M1E”, and constructs a reasonable evaluation index system. The assessment framework optimizes the system safety management model, representing an important improvement in the current stage of infrastructure safety management, which tends to emphasize technical factors over management factors.

- (3)

- Utilizing the Bayesian network reasoning method, the numerical value of construction safety resilience during the construction phase of underground space projects is proactively calculated. This approach effectively assesses the safety status at the early stages of the project. Conversely, backward reasoning uncovers the longest chain of causes for accidents that occur during the construction of underground space development projects, identifying weak links in the management process. It addresses the issues of unclear focus and illogical reasoning in the safety management process.

3. Resilience Assessment Methods and Framework

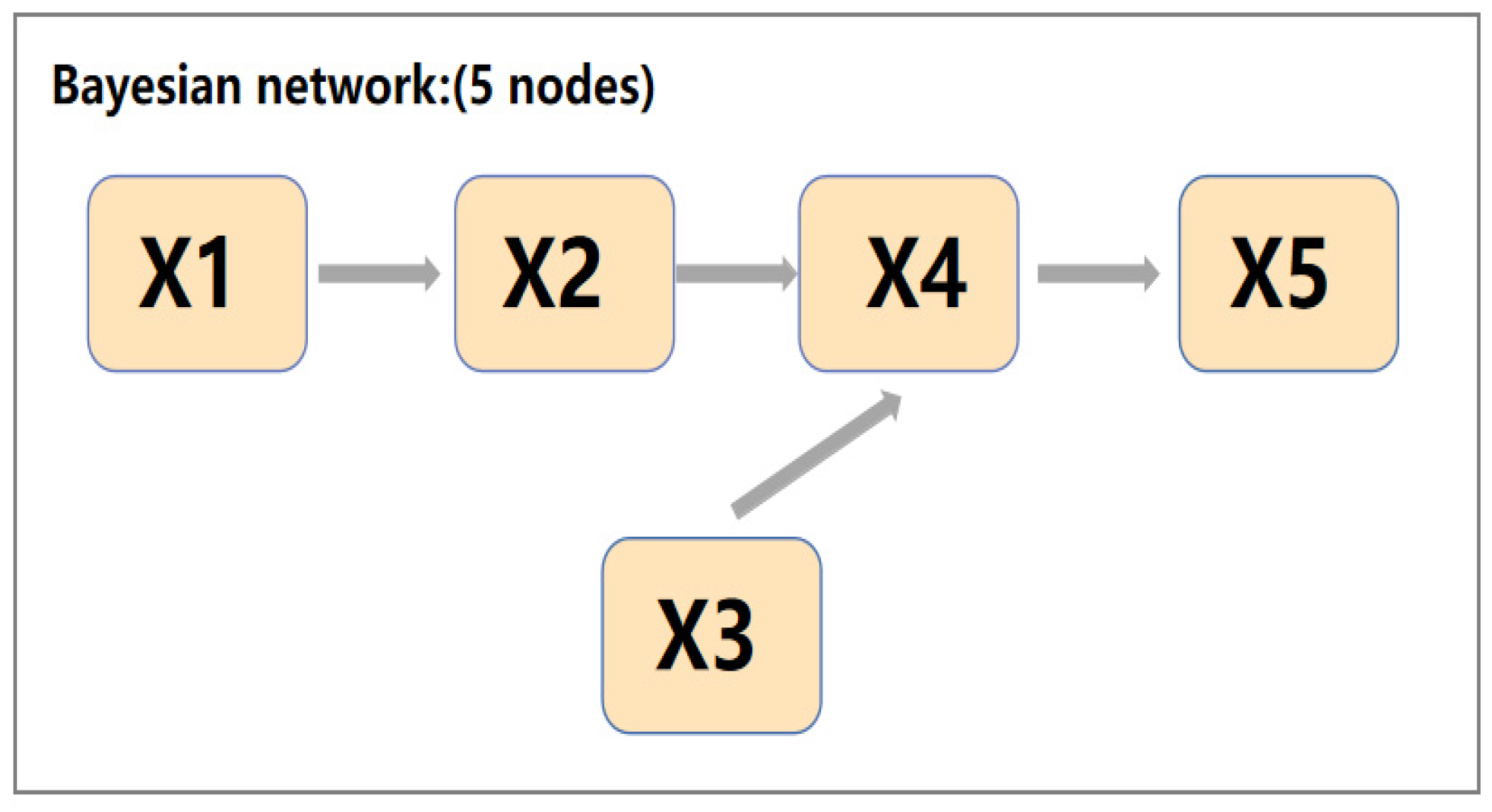

3.1. Bayesian Network Theory

3.2. Assessment Model and Framework

4. Case Study

4.1. Project Overview

4.2. Identification of Influencing Factors

4.3. Construction Safety Resilience Analysis

4.3.1. Forward Reasoning Analysis

4.3.2. Backward Reasoning Analysis

5. Discussion and Conclusions

5.1. Discussion

5.2. Conclusions

- (1)

- The research framework for underground space construction safety resilience proposed in this paper, which encompasses the identification of influencing factors and Bayesian network computation, is both reasonable and effective. It can be utilized for safety assessments in actual projects. The numerical value of resilience indicates the system’s ability to withstand risks and recover from accidents. In the case study, the construction safety resilience value of the system was 0.716, signifying a medium level. This suggests that the overall construction safety risk of the project is manageable, yet risk monitoring should be intensified. During the construction process, the failure probabilities were as follows: absorption capacity was at 51.3%, resistance capacity was at 57.3%, recovery capacity was at 37.3%, and adaptability was at 52.7%. This indicates that, throughout the entire process of accident evolution, resistance capacity is the weakest link, representing the system’s inherent ability to respond to disaster events.

- (2)

- Construction technology is often regarded as a crucial method of enhancing safety performance. Efforts to update and optimize mechanical equipment, along with the implementation of information management platforms, have indeed significantly contributed to the improvement of construction efficiency. However, this article demonstrates, through Bayesian network inference based on questionnaire survey results, that personnel management factors at the construction site continue to be major contributors to accidents. In the outcomes of Bayesian network forward inference, nodes with elevated failure probabilities, such as SV1, AbsR3, etc., are all associated with personnel factors. Unsafe behavior by personnel persists as the primary cause of safety accidents at construction sites. The primary reasons for unsafe behavior are as follows: first, there is a lack of safety awareness, and second, unsafe behaviors are closely linked to the formation of the safety culture and the safety atmosphere at the construction site.

- (3)

- This article proposes a resilience analysis process of “PFR-EFR-LFR” based on the temporal characteristics and evolution rules of system responses following disturbances. In the case study, the failure probability of PFR is 21.1%, the EFR is 36.5%, and the LFR is 21.1%. Among the three resilience sub-modules, EFR has the highest probability of failure, indicating that response capability is the key factor determining the level of construction safety resilience. The response process mainly relies on resistance and recovery capabilities. To improve the construction safety level of underground space projects, it is essential to strengthen personnel safety awareness, safety management inspections, on-site professional rescue capabilities, and the allocation of mechanical equipment resources.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, T.; Liu, D.; Liu, D.; Zhang, L.; Li, M.; Khan, M.I.; Li, T.; Cui, S. A New Method for Flood Disaster Resilience Evaluation: A Hidden Markov Model Based on Bayesian Belief Network Optimization. J. Clean. Prod. 2023, 412, 137372. [Google Scholar] [CrossRef]

- Gulzar, S.M.; Mir, F.U.H.; Rafiqui, M.; Tantray, M.A. Damage Assessment of Residential Constructions in Post-Flood Scenarios: A Case of 2014 Kashmir Floods. Environ. Dev. Sustain. 2021, 23, 4201–4214. [Google Scholar] [CrossRef]

- Wei, C.-C. Conceptual Weather Environmental Forecasting System for Identifying Potential Failure of Under-Construction Structures During Typhoons. J. Wind. Eng. Ind. Aerodyn. 2017, 168, 48–59. [Google Scholar] [CrossRef]

- Tang, S.; Roberts, D.; Golparvar-Fard, M. Human-Object Interaction Recognition for Automatic Construction Site Safety Inspection. Autom. Constr. 2020, 120, 103356. [Google Scholar] [CrossRef]

- Curt, C.; Tacnet, J. Resilience of Critical Infrastructures: Review and Analysis of Current Approaches. Risk Anal. 2018, 38, 2441–2458. [Google Scholar] [CrossRef]

- Hossain, N.U.I.; Nur, F.; Hosseini, S.; Jaradat, R.; Marufuzzaman, M.; Puryear, S.M. A Bayesian Network Based Approach for Modeling and Assessing Resilience: A Case Study of a Full Service Deep Water Port. Reliab. Eng. Syst. Saf. 2019, 189, 378–396. [Google Scholar] [CrossRef]

- Wang, N.; Wu, M.; Yuen, K.F. Assessment of Port Resilience Using Bayesian Network: A Study of Strategies to Enhance Readiness and Response Capacities. Reliab. Eng. Syst. Saf. 2023, 237, 109394. [Google Scholar] [CrossRef]

- Wadhawan, Y.; AlMajali, A.; Neuman, C. A Comprehensive Analysis of Smart Grid Systems Against Cyber-Physical Attacks. Electronics 2018, 7, 249. [Google Scholar] [CrossRef]

- Hossain, N.U.I.; Jaradat, R.; Hosseini, S.; Marufuzzaman, M.; Buchanan, R.K. A Framework for Modeling and Assessing System Resilience Using a Bayesian Network: A Case Study of an Interdependent Electrical Infrastructure System. Int. J. Crit. Infrastruct. Prot. 2019, 25, 62–83. [Google Scholar] [CrossRef]

- Jin, J.G.; Tang, L.C.; Sun, L.; Lee, D.H. Enhancing Metro Network Resilience Via Localized Integration with Bus Services. Transp. Res. Part E Logist. Transp. Rev. 2014, 63, 17–30. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D. Bayesian Networks for Supply Chain Risk, Resilience and Ripple Effect Analysis: A Literature Review. Expert Syst. Appl. 2020, 161, 113649. [Google Scholar] [CrossRef] [PubMed]

- George, P.G.; Renjith, V. Evolution of Safety and Security Risk Assessment Methodologies Towards the Use of Bayesian Networks in Process Industries. Process Saf. Environ. Prot. 2021, 149, 758–775. [Google Scholar] [CrossRef]

- Liu, J.; Zhai, C.; Yu, P. A Probabilistic Framework to Evaluate Seismic Resilience of Hospital Buildings Using Bayesian Networks. Reliab. Eng. Syst. Saf. 2022, 226, 108644. [Google Scholar] [CrossRef]

- Liu, S.-C.; Peng, F.-L.; Qiao, Y.-K.; Zhang, J.-B. Evaluating Disaster Prevention Benefits of Underground Space from the Perspective of Urban Resilience. Int. J. Disaster Risk Reduct. 2021, 58, 102206. [Google Scholar] [CrossRef]

- Bakhtiari, S.; Najafi, M.R.; Goda, K.; Peerhossaini, H. Integrated Bayesian Network and Strongest Path Method (Bn-Spm) for Effective Multi-Hazard Risk Assessment of Interconnected Infrastructure Systems. Sustain. Cities Soc. 2024, 104, 105294. [Google Scholar] [CrossRef]

- Bao, H.; Guo, Y.; Zhang, H.; Peng, C.; Lu, J. Bayesian Analysis Method on Processing Reliability Data of High Flux Engineering Test Reactor. Reliab. Eng. Syst. Saf. 2020, 199, 106912. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, D.; Huang, Z. Resilience of City Underground Infrastructure Under Multi-Hazards Impact: From Structural Level to Network Level. Resilient Cities Struct. 2022, 1, 76–86. [Google Scholar] [CrossRef]

- Qiu, T.; Chen, X.; Chen, K.; Su, D.; Shen, J.; Wang, L.; Zheng, Z. An Adaptation Resilience Assessment Framework for Key Components of Prefabricated Underground Stations. Tunn. Undergr. Space Technol. 2023, 136, 105037. [Google Scholar] [CrossRef]

- Jiang, L.; Huang, S. Analyzing Connectivity Reliability and Critical Units for Highway Networks in High-Intensity Seismic Region Using Bayesian Network. J. Infrastruct. Intell. Resil. 2022, 1, 100006. [Google Scholar] [CrossRef]

- Penman, T.D.; Cirulis, B.; Marcot, B.G. Bayesian Decision Network Modeling for Environmental Risk Management: A Wildfire Case Study. J. Environ. Manag. 2020, 270, 110735. [Google Scholar] [CrossRef]

- Gondia, A.; Ezzeldin, M.; El-Dakhakhni, W. Dynamic Networks for Resilience-Driven Management of Infrastructure Projects. Autom. Constr. 2022, 136, 104149. [Google Scholar] [CrossRef]

- Zinetullina, A.; Yang, M.; Khakzad, N.; Golman, B.; Li, X. Quantitative Resilience Assessment of Chemical Process Systems Using Functional Resonance Analysis Method and Dynamic Bayesian Network. Reliab. Eng. Syst. Saf. 2021, 205, 107232. [Google Scholar] [CrossRef]

- Omićević, N.; Zaninović, T.; Bojanić Obad Šćitaroci, B. Integrating Underground Space into the Groundscape Resilience Concept. Buildings 2024, 14, 2406. [Google Scholar] [CrossRef]

- Tong, Q.; Gernay, T. Resilience Assessment of Process Industry Facilities Using Dynamic Bayesian Networks. Process Saf. Environ. Prot. 2023, 169, 547–563. [Google Scholar] [CrossRef]

- Tasmen, T.; Sen, M.K.; Hossain, N.U.I.; Kabir, G. Modelling and Assessing Seismic Resilience of Critical Housing Infrastructure System by Using Dynamic Bayesian Approach. J. Clean. Prod. 2023, 428, 139349. [Google Scholar] [CrossRef]

- Sen, M.K.; Dutta, S.; Kabir, G. Modelling and Quantification of Time-Varying Flood Resilience for Housing Infrastructure Using Dynamic Bayesian Network. J. Clean. Prod. 2022, 361, 132266. [Google Scholar] [CrossRef]

- Hossain, N.U.I.; El Amrani, S.; Jaradat, R.; Marufuzzaman, M.; Buchanan, R.; Rinaudo, C.; Hamilton, M. Modeling and Assessing Interdependencies Between Critical Infrastructures Using Bayesian Network: A Case Study of Inland Waterway Port and Surrounding Supply Chain Network. Reliab. Eng. Syst. Saf. 2020, 198, 106898. [Google Scholar] [CrossRef]

- Dixit, V.; Verma, P.; Tiwari, M.K. Assessment of Pre and Post-Disaster Supply Chain Resilience Based On Network Structural Parameters with Cvar as a Risk Measure. Int. J. Prod. Econ. 2020, 227, 107655. [Google Scholar] [CrossRef]

- Lu, Q.-C. Modeling Network Resilience of Rail Transit Under Operational Incidents. Transp. Res. Part A Policy Pract. 2018, 117, 227–237. [Google Scholar] [CrossRef]

- Shi, Y.; Zhai, G.; Xu, L.; Zhou, S.; Lu, Y.; Liu, H.; Huang, W. Assessment Methods of Urban System Resilience: From the Perspective of Complex Adaptive System Theory. Cities 2021, 112, 103141. [Google Scholar] [CrossRef]

- An, X.; Yin, Z.; Tong, Q.; Fang, Y.; Yang, M.; Yang, Q.; Meng, H. An Integrated Resilience Assessment Methodology for Emergency Response Systems Based On Multi-Stage Stamp and Dynamic Bayesian Networks. Reliab. Eng. Syst. Saf. 2023, 238, 109445. [Google Scholar] [CrossRef]

- Han, K.; Zhang, D.; Chen, X.; Su, D.; Ju, J.W.W.; Lin, X.T.; Cui, H. A Resilience Assessment Framework for Existing Underground Structures Under Adjacent Construction Disturbance. Tunn. Undergr. Space Technol. 2023, 141, 105339. [Google Scholar] [CrossRef]

- He, R.; Tiong, R.L.; Yuan, Y.; Zhang, L. Enhancing Resilience of Urban Underground Space Under Floods: Current Status and Future Directions. Tunn. Undergr. Space Technol. 2024, 147, 105674. [Google Scholar] [CrossRef]

- Toroghi, S.S.H.; Thomas, V.M. A Framework for the Resilience Analysis of Electric Infrastructure Systems Including Temporary Generation Systems. Reliab. Eng. Syst. Saf. 2020, 202, 107013. [Google Scholar] [CrossRef]

- Zeng, Z.; Fang, Y.-P.; Zhai, Q.; Du, S. A Markov Reward Process-Based Framework for Resilience Analysis of Multistate Energy Systems Under the Threat of Extreme Events. Reliab. Eng. Syst. Saf. 2021, 209, 107443. [Google Scholar] [CrossRef]

- Specking, E.; Cottam, B.; Parnell, G.; Pohl, E.; Cilli, M.; Buchanan, R.; Wade, Z.; Small, C. Assessing Engineering Resilience for Systems with Multiple Performance Measures. Risk Anal. 2019, 39, 1899–1912. [Google Scholar] [CrossRef] [PubMed]

- Ahmadian, N.; Lim, G.J.; Cho, J.; Bora, S. A Quantitative Approach for Assessment and Improvement of Network Resilience. Reliab. Eng. Syst. Saf. 2020, 200, 106977. [Google Scholar] [CrossRef]

- Chen, Y.; Bakker, M.M.; Ligtenberg, A.; Bregt, A.K. External Shocks, Agent Interactions, and Endogenous Feedbacks—Investigating System Resilience with a Stylized Land Use Model. Ecol. Complex. 2019, 40, 100765. [Google Scholar] [CrossRef]

- Bao, M.; Ding, Y.; Sang, M.; Li, D.; Shao, C.; Yan, J. Modeling and Evaluating Nodal Resilience of Multi-Energy Systems Under Windstorms. Appl. Energy 2020, 270, 115136. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, M.; Ding, Y.; Nie, R. Resilience of China’s Oil Import System Under External Shocks: A System Dynamics Simulation Analysis. Energy Policy 2020, 146, 111795. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Papadonikolaki, E.; Palliyaguru, R.; Arashpour, M. Collaboration in Bim-Based Construction Networks: A Bibliometric-Qualitative Literature Review. Int. J. Proj. Manag. 2017, 35, 1288–1301. [Google Scholar] [CrossRef]

- Caetano, H.O.; Desuó, L.; Fogliatto, M.S.; Maciel, C.D. Resilience Assessment of Critical Infrastructures Using Dynamic Bayesian Networks and Evidence Propagation. Reliab. Eng. Syst. Saf. 2024, 241, 109691. [Google Scholar] [CrossRef]

- Folke, C. Resilience: The Emergence of a Perspective for Social–Ecological Systems Analyses. Glob. Environ. Change 2006, 16, 253–267. [Google Scholar] [CrossRef]

- Davoudi, S.; Brooks, E.; Mehmood, A. Evolutionary Resilience and Strategies for Climate Adaptation. Plan. Pract. Res. 2013, 28, 307–322. [Google Scholar] [CrossRef]

- Li, K.; Xiahou, X.; Wu, Z.; Shi, P.; Tang, L.; Li, Q. Influencing Factor Identification and Simulation for Urban Metro System Operation Processes—A Resilience Enhancement Perspective. Systems 2024, 12, 43. [Google Scholar] [CrossRef]

- Bruneau, M.; Chang, S.E.; Eguchi, R.T.; Lee, G.C.; O’Rourke, T.D.; Reinhorn, A.M.; Shinozuka, M.; Tierney, K.; Wallace, W.A.; Von Winterfeldt, D. A Framework to Quantitatively Assess and Enhance the Seismic Resilience of Communities. Earthq. Spectra 2003, 19, 733–752. [Google Scholar] [CrossRef]

- Zhang, F.; Ju, Y.; Gonzalez, E.D.S.; Wang, A.; Dong, P.; Giannakis, M. Evaluation of Construction and Demolition Waste Utilization Schemes Under Uncertain Environment: A Fuzzy Heterogeneous Multi-Criteria Decision-Making Approach. J. Clean. Prod. 2021, 313, 127907. [Google Scholar] [CrossRef]

- Tan, R.; Zhang, W. Multiple Attribute Decision Making Method Based on Dematel and Fuzzy Distance of Trapezoidal Fuzzy Neutrosophic Numbers and its Application in Typhoon Disaster Evaluation. J. Intell. Fuzzy Syst. 2020, 39, 3413–3439. [Google Scholar] [CrossRef]

- Crispim, J.; Fernandes, J.; Rego, N. Customized Risk Assessment in Military Shipbuilding. Reliab. Eng. Syst. Saf. 2020, 197, 106809. [Google Scholar] [CrossRef]

- Babaleye, A.O.; Kurt, R.; Khan, F. Safety Analysis of Plugging and Abandonment of Oil and Gas Wells in Uncertain Conditions with Limited Data. Reliab. Eng. Syst. Saf. 2019, 188, 133–141. [Google Scholar] [CrossRef]

- Huang, Z.; Fu, H.; Chen, W.; Zhang, J.; Huang, H. Damage Detection and Quantitative Analysis of Shield Tunnel Structure. Autom. Constr. 2018, 94, 303–316. [Google Scholar] [CrossRef]

- Xie, X.; Wang, Q.; Shahrour, I.; Li, J.; Zhou, B. A Real-Time Interaction Platform for Settlement Control During Shield Tunnelling Construction. Autom. Constr. 2018, 94, 154–167. [Google Scholar] [CrossRef]

- Li, X.; Zhu, H. Development of a Web-Based Information System for Shield Tunnel Construction Projects. Tunn. Undergr. Space Technol. 2013, 37, 146–156. [Google Scholar] [CrossRef]

- Sun, J.; Bathgate, K.; Zhang, Z. Bayesian Network-Based Resilience Assessment of Interdependent Infrastructure Systems Under Optimal Resource Allocation Strategies. Resilient Cities Struct. 2024, 3, 46–56. [Google Scholar] [CrossRef]

- Eldosouky, A.; Saad, W.; Mandayam, N. Resilient Critical Infrastructure: Bayesian Network Analysis and Contract-Based Optimization. Reliab. Eng. Syst. Saf. 2021, 205, 107243. [Google Scholar] [CrossRef]

| Classification of Influencing Factors | Restricted Content | Key Points of the Content |

|---|---|---|

| Environmental constraints | The construction of deep foundation pits by the river involves significant dewatering challenges. | The project is near the Yangtze River, 0.7 to 1 km away, with a shallow water table. It features a 20 m thick silt layer prone to water and mud gushing. The design uses a fully sealed barrier with 10 m deep diaphragm walls and relies on drainage wells extending into the gravel layer. |

| Poor geological conditions make it difficult to control deformation and water leakage in the foundation pit. | BinJiang Station Line 13 is part of an ultra-deep foundation pit project with a maximum excavation depth of 51 m. The stratum at a 10 m depth consists mainly of silty clay, which is highly compressible and presents poor engineering geological conditions, posing challenges and risks for deep foundation pit construction. | |

| Pipeline protection. | The project involves municipal pipelines and underground space design with multiple facilities. Construction requires high protection standards for pipelines, posing challenges. | |

| The construction site is narrow, with limited work space. | BinJiang Station Line 13 lacks an auxiliary construction site, with various pieces of construction equipment present during the construction phase. Adjacent plots 22# and 23# are used to construct retaining structures, involving significant work with large amounts of special equipment. Simultaneous multiple processes make on-site construction organization challenging. | |

| Organizational Management | Completely enclosed construction. | To protect the surrounding environment, the construction phase of the foundation pit earthwork excavation and structural construction adopts fully enclosed construction. |

| The excavation of earthwork from the foundation pit is difficult, requiring secondary transfer. | At BinJiang Station, daily soil excavation is significant. Continuous excavation is not possible due to site conditions, and there is limited space for soil stockpiling, which hinders comprehensive construction. The proper management of soil secondary transportation is necessary. | |

| Many process overlaps. | The project involves large-scale construction, including subway stations, road ramps, rail lines, tunnel structures, and ancillary works. Multi-profession and multi-trade collaboration is challenging. | |

| Construction technology | The construction schedule handover is complex, and there is mutual influence between the foundation pits. | BinJiang Station Line 13 has an excavation depth of about 44.79 m, with the large shield construction well at 51 m. The Central Business District Station’s excavation depths are approximately 29 m as a standard, 30 m at the end, and 31 m for local deep pits. The project construction sequence is complex, with excavations having a sequential relationship and mutual influence. |

| The coexistence of the open-cut excavation method and top-down construction method. | Binjiang Station’s A area uses open-cut construction for the upper three layers and reverse construction for the lower three layers. The B area uses only reverse construction. The Central Business District Station employs full top-down construction. Combining open-cut and top-down methods is complex and requires high technical and management standards. | |

| The demolition of diaphragm walls causes significant disturbance to adjacent excavation pits. | In the project’s first and second phases, shared diaphragm walls exist. Demolishing these walls causes disturbances between adjacent excavation pits. The removal of steel and concrete supports leads to stress release in the pit, making soil displacement and deformation control challenging. | |

| Removal of wall surfaces and straightening of wall ties. | Binjiang Station on Line 13 has a six-level underground structure with 1500 mm diaphragm walls. During excavation, walls are chiseled for texture and reinforcement steel is exposed and straightened, which extends the construction period. |

| Resilience Classification | Resilience Characterization | Identify Dimensions | Specific Manifestations | Summary of Influencing Factors | Encoding |

|---|---|---|---|---|---|

| PFR | Absorptive capacity | manpower | All personnel entering the construction site should have the qualifications. | Personnel entry Security check system | AbsR1 |

| Workers operating specialized machinery on-site should possess the corresponding operating qualifications. | Specialized machinery Operator qualification Review | AbsR2 | |||

| Construction personnel and management possess adequate safety awareness, adhere to the construction plan correctly, and refrain from operating in violation of regulations. | Personal safety awareness | AbsR3 | |||

| material | All materials utilized for deep foundation pit construction must undergo safety inspections for quality upon entry, and strict acceptance procedures should be applied to materials processed on-site to prevent safety hazards. | Material entry and acceptance during the process | AbsC1 | ||

| Site managers should conduct routine inspections of material storage on construction sites to reduce safety hazards. | Safety inspection of material stacking conditions | AbsC2 | |||

| machinery | The dewatering equipment at the construction site should be maintained and its safety should be checked to reduce equipment hazards and ensure normal equipment conditions. | Rainfall equipment maintenance and safety inspection | AbsJ1 | ||

| Large-scale mechanical equipment at the construction site must undergo maintenance and safety inspections to ensure its normal condition. The parking location of the equipment should adhere to regulations. | Maintenance and safety inspection of machinery equipment | AbsJ2 | |||

| environment | The surveying company should provide a comprehensive survey report, allowing the construction unit to accurately understand the geological and hydrological conditions at the construction site. | Inspection report improvement | AbsH1 | ||

| Managers should anticipate extreme weather conditions that may arise at the construction site in the future and have corresponding countermeasures. | Extreme weather forecasting and emergency plans | AbsH2 | |||

| management | The construction department should conduct effective technical handover for deep foundation pit engineering. | Technical disclosure improvement | AbsG1 | ||

| Construction department regularly conduct safety training and assessments for construction workers, and regularly carry out emergency drills and accident simulations. | Emergency safety training | AbsG2 | |||

| The management personnel inspect the construction site, find the dangerous points in time, and correct the illegal operations. | Inspections ensure safe and standardized construction operations | AbsG3 |

| Node Type | Encoding | Node Name | Consequences of Node Failure |

|---|---|---|---|

| Leaf node | R | Construction safety Resilience of underground spaces | It failed to effectively prevent construction safety accidents; when such accidents occurred, it failed to effectively minimize production and construction efficiency losses and mitigate the destructive consequences; it failed to effectively reduce recovery time; and it failed to effectively improve accident adaptability. |

| Phase resilience nodes | PFR | Preventive resilience | It failed to effectively prevent the occurrence of construction safety accidents. |

| EFR | Response resilience | At the time of the accident, there was an inability to effectively mitigate production and construction losses, to reduce the destructive consequences of the accident, and to effectively shorten the recovery time. | |

| LFR | Learning resilience | Following the accident, there was an inability to effectively enhance adaptability to the incident. | |

| Resilience measurement node | Abs | Absorptive capacity | It failed to effectively prevent unsafe personnel behaviors and unsafe conditions in terms of materials and equipment, leading to the occurrence of construction safety accidents. |

| Res | Resistance capability | The construction safety accident was not controlled in time, resulting in severe damage to the construction site and serious consequences such as casualties. | |

| Rec | Recovery capacity | The on-site recovery time is too long; the restoration of normal production and construction processes is slow, affecting the normal schedule. | |

| Ada | Adaptive capacity | Failure to learn from historical events and implement corrective and optimization measures may lead to similar incidents happening again. | |

| Status node | SV1 | Prevention of unsafe personnel behavior | Construction accidents in deep foundation pits caused by the unsafe behavior of construction personnel or management staff. |

| SV2 | Prevention of unsafe conditions in materials and equipment | Accidents caused by unsafe conditions such as material stacking and mechanical equipment in deep foundation pits. | |

| SV3 | Prevention of unsafe environmental factors | Occurs due to hydrogeological factors or extreme weather conditions causing safety accidents during deep foundation pit construction. | |

| … | |||

| Root node | AbsR1 | Personnel entry security check system | Failed to detect non-project personnel entering the site, increasing safety hazards. |

| AbsR2 | Specialized machinery personnel qualification review | Unqualified personnel operating specialized machinery, with illegal operation causing foundation pit construction safety accidents. | |

| AbsR3 | Personal safety awareness | Construction site personnel lack a sense of crisis about potential danger points and cannot respond in time when an actual accident occurs. | |

| … | |||

| Primary Intermediate Node | Failure Probability | Secondary Intermediate Node | Failure Probability | Influencing Factors (Third-Level Intermediate Nodes) | Failure Probability | Influencing Factors (Root Node) | Failure Probability |

|---|---|---|---|---|---|---|---|

| PFR | 21.1 | Abs | 51.3 | SV1 | 76.1 | AbsG3 | 35.8 |

| AbsG2 | 34.1 | ||||||

| AbsG1 | 32.8 | ||||||

| AbsR1 | 32.3 | ||||||

| AbsR2 | 36.0 | ||||||

| AbsR3 | 42.9 | ||||||

| SV2 | 50.7 | AbsC2 | 34.0 | ||||

| AbsJ1 | 38.6 | ||||||

| AbsJ2 | 38.6 | ||||||

| SV3 | 39.5 | AbsH1 | 35.5 | ||||

| AbsH2 | 40.1 | ||||||

| AbsC1 | 38.3 | ||||||

| EFR | 42.9 | Res | 57.3 | ResG5 | 59.4 | SV4 | 38.3 |

| ResJ2 | 37.0 | ||||||

| ResG1 | 40.5 | ||||||

| ResG2 | 36.2 | ||||||

| ResG3 | 34.6 | ||||||

| ResG4 | 35.6 | ||||||

| SV5 | 42.0 | ResC1 | 34.0 | ||||

| ResJ1 | 38.4 | ||||||

| SV6 | 51.8 | ResR1 | 42.5 | ||||

| ResR2 | 43.9 | ||||||

| ResH1 | 40.5 | ||||||

| ResH2 | 35.3 | ||||||

| Rec | 37.3 | SV7 | 55.9 | RecC1 | 36.3 | ||

| RecJ1 | 36.8 | ||||||

| RecH1 | 37.0 | ||||||

| SV8 | 25.6 | RecG1 | 34.5 | ||||

| LFR | 21.1 | Ada | 52.7 | AdaR1 | 34.4 | ||

| SV9 | 40.6 | AdaC1 | 37.7 | ||||

| AdaJ1 | 40.0 | ||||||

| SV10 | 27.4 | AdaG3 | 20.1 | ||||

| AdaG4 | 26.0 | ||||||

| AdaG2 | 24.5 | ||||||

| AdaG1 | 34.0 |

| PFR | EFR | LFR | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 40–50% | >50% | 40–50% | >50% | 40–50% | >50% | ||||||

| Node Name | Failure Probability | Node Name | Failure Probability | Node Name | Failure Probability | Node Name | Failure Probability | Node Name | Failure Probability | Node Name | Failure Probability |

| AbsR3 | 42.9% | Abs | 51.3% | ResR1 | 42.5% | Res | 57.3% | AdaJ1 | 40.0% | Ada | 52.7% |

| AbsH2 | 40.1% | SV1 | 76.1% | ResR2 | 43.9% | ResG5 | 59.4% | SV9 | 40.6% | ||

| SV2 | 50.7% | ResH1 | 40.5% | SV6 | 51.8% | ||||||

| ResG1 | 40.5% | SV7 | 55.9% | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Xiahou, X.; Li, K.; Li, Q. Assessing Construction Safety Performance in Urban Underground Space Development Projects from a Resilience Enhancement Perspective. Buildings 2025, 15, 726. https://doi.org/10.3390/buildings15050726

Yang X, Xiahou X, Li K, Li Q. Assessing Construction Safety Performance in Urban Underground Space Development Projects from a Resilience Enhancement Perspective. Buildings. 2025; 15(5):726. https://doi.org/10.3390/buildings15050726

Chicago/Turabian StyleYang, Xiaohua, Xiaer Xiahou, Kang Li, and Qiming Li. 2025. "Assessing Construction Safety Performance in Urban Underground Space Development Projects from a Resilience Enhancement Perspective" Buildings 15, no. 5: 726. https://doi.org/10.3390/buildings15050726

APA StyleYang, X., Xiahou, X., Li, K., & Li, Q. (2025). Assessing Construction Safety Performance in Urban Underground Space Development Projects from a Resilience Enhancement Perspective. Buildings, 15(5), 726. https://doi.org/10.3390/buildings15050726