Optimizing Rebar Process and Supply Chain Management for Minimized Cutting Waste: A Building Information Modeling-Based Data-Driven Approach

Abstract

:1. Introduction

2. Literature Review

2.1. Conventional Rebar Workflow

2.2. BIM-Based Rebar Workflow

2.3. Conventional and Special-Length Priority Optimizations

2.4. Supply Chain Management for Rebar Work

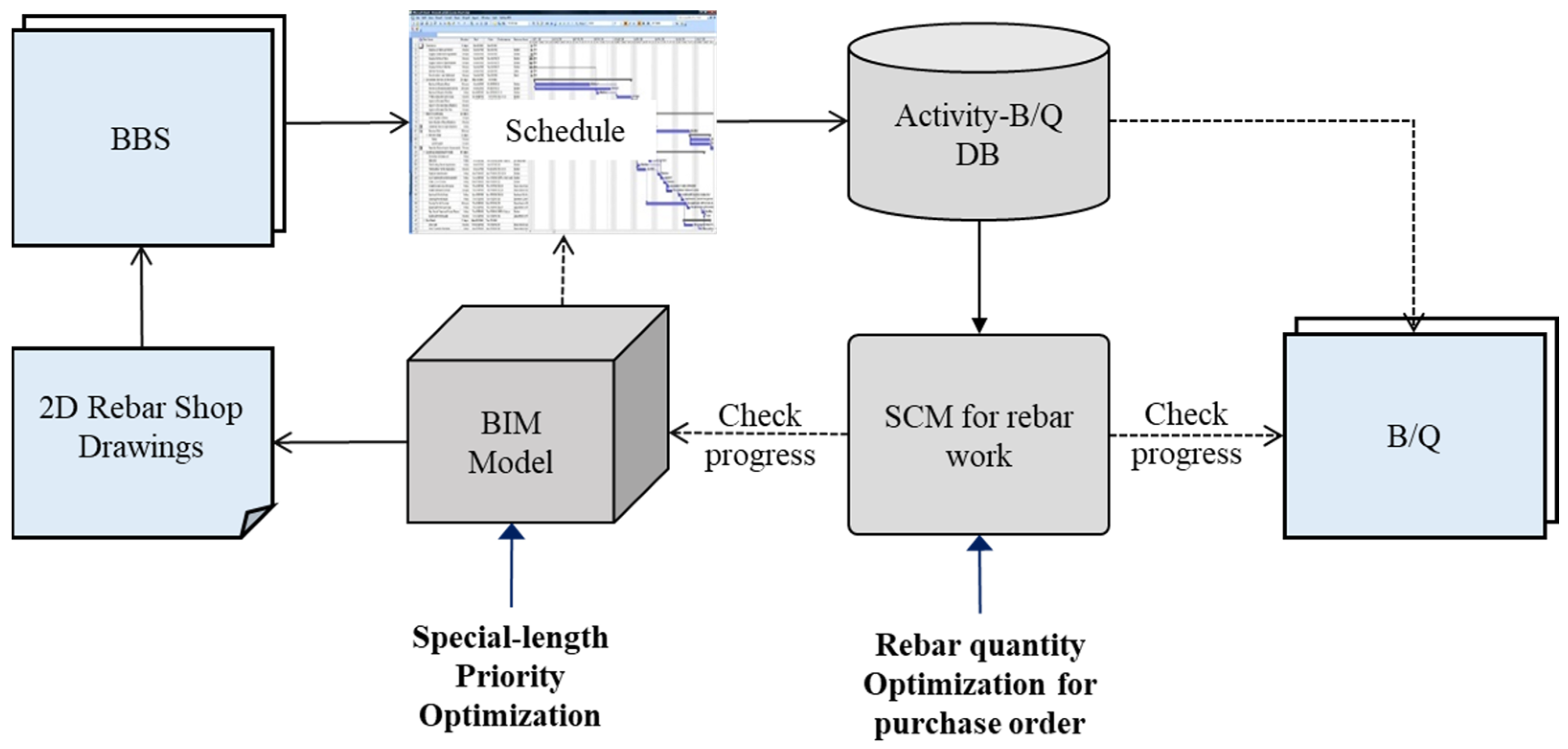

3. Methodology

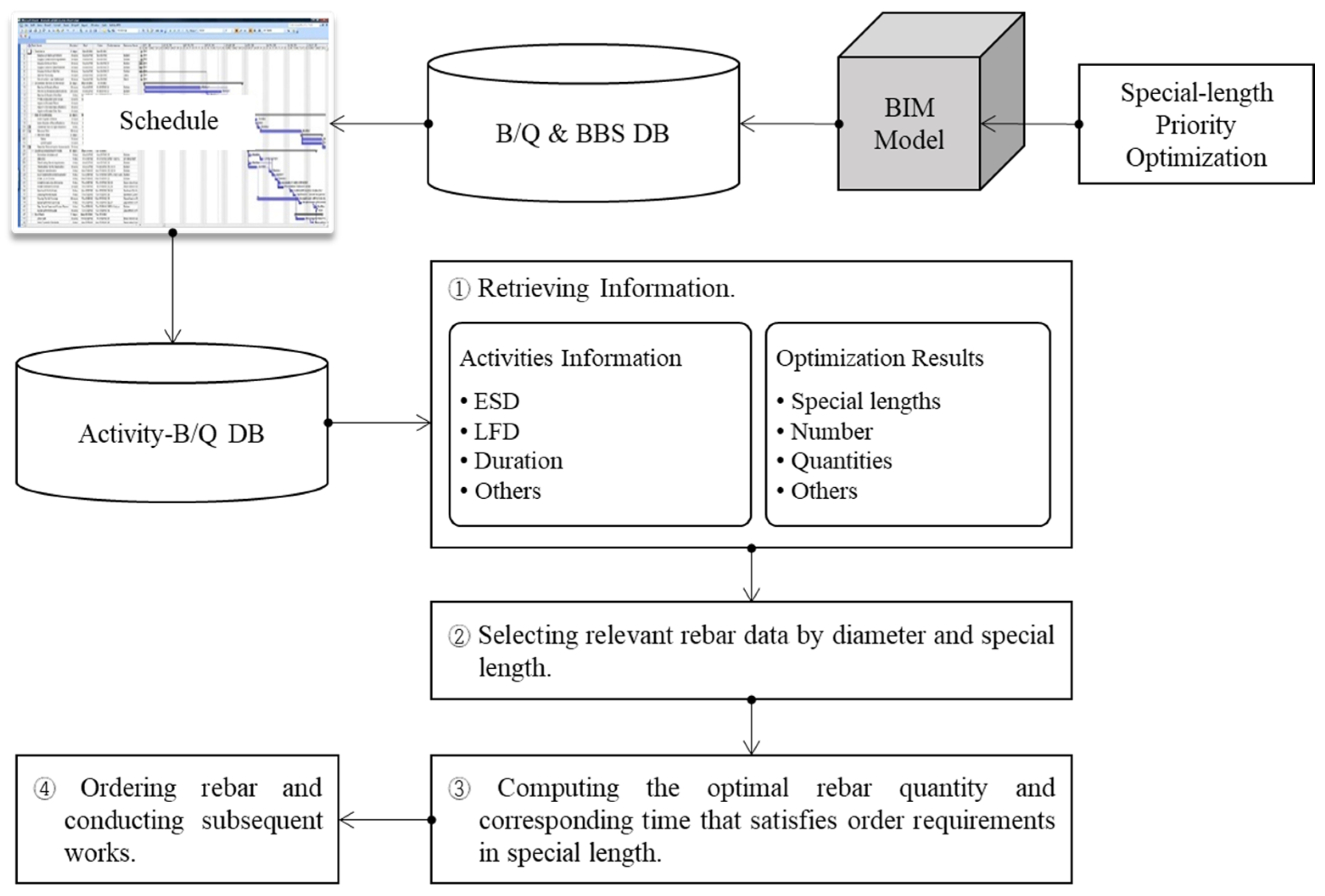

- Retrieving information: The activity database generated from the BIM-based BBS and the construction schedule retrieves information to determine rebar order phases based on optimization results. This information involves the sequence of activities and their earliest start date (ESD), latest finish date (LFD), and duration, as well as optimization results associated with the schedule.

- Selecting relevant rebar data: Rebars in the activity database are sorted by diameters and special lengths, facilitating quick identification of the rebar order phase. The relevant rebars are selected to meet special-length order requirements for each schedule phase.

- Computing the optimal rebar quantity for the order phase: After selecting relevant rebar data, the order phases can be investigated to conform to the minimum quantity and lead time for the rebar order. Rebar quantities of each activity and each phase are calculated and optimized, satisfying the quantity and lead-time constraints.

- Ordering rebar and conducting subsequent works: Rebars are ordered based on a phase-wise schedule, ensuring alignment with planned construction activities.

4. Case Study Application

5. Discussion

6. Conclusions

- Employing special-length priority optimization effectively reduced cutting waste to 1.49% by reducing lap splices and combining rebars into efficient cutting patterns. The initial rebar optimization resulted in ordered quantities of 496.44 tons for D29 diameter column rebars and 523.79 tons for D22 beam rebars, totaling 1020.23 tons. These quantities were optimized by employing special lengths for main continuous rebars and special-length cutting patterns for discontinuous rebars. It is important to note that these ordered rebar quantities should be supplied for on-site usage.

- Integrating BIM with SCM processes automated key documentation, such as BBS/BOQ and the activity tracking database. This alignment addressed typical challenges regarding procurement errors and delivery delays, facilitating accurate forecasting and timely rebar delivery.

- This systematic approach enabled real-time updates and effective rebar tracking, ensuring smooth application on-site.

- The proposed method was validated in a simplified project that included 24 floors—17 floors above the ground and 7 underground floors. The case study demonstrated that optimizing column rebars led to 12 procurement batches. Each batch aligned the minimum order requirement of 15 tons of the same rebar diameter and met the two-month lead-time requirement.

- After implementing the proposed method of SCM optimization, the column rebar quantity was calculated as 496.482 tons and the beam rebar quantity as 523.817 tons, summing up to 1020.299 tons. Therefore, the proposed method increased an insignificant amount of 0.06 ton (0.0059%) in the total ordered quantity compared to the special-length rebar optimization while facilitating phase-wise optimized rebar usage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BIM | Building Information Modeling |

| BBS | Bar Bending Schedule |

| BOQ | Bill of quantity |

| SCM | Supply chain management |

Appendix A

| Order Batch | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | Total | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Columns (D29 rebars) | (ton) | 7.403 | 7.403 | 7.403 | 7.403 | 12.338 | 12.338 | 9.102 | 6.169 | 6.169 | 6.169 | 6.169 | 4.935 | |

| 17.273 | 17.273 | 17.273 | 17.273 | 43.183 | 43.183 | 39.590 | 14.806 | 12.338 | 12.338 | 12.338 | 9.870 | |||

| 8.637 | 8.637 | 8.637 | 8.637 | 24.676 | 24.676 | 23.938 | 12.995 | 8.637 | 6.169 | 6.169 | 4.935 | |||

(ton) | 33.313 | 33.313 | 33.313 | 33.313 | 80.197 | 80.197 | 72.630 | 33.970 | 27.144 | 24.676 | 24.676 | 19.740 | 496.482 | |

| Beams (D22 rebars) | (ton) | 2.656 | 2.656 | 2.656 | 2.656 | 2.656 | 2.656 | 2.656 | 2.681 | 2.681 | 2.681 | 2.681 | 2.681 | |

| 7.082 | 7.082 | 7.082 | 7.082 | 7.082 | 7.082 | 7.082 | 7.150 | 7.150 | 5.363 | 5.363 | 5.363 | |||

| 2.568 | 2.568 | 2.568 | 2.568 | 2.568 | 2.568 | 2.568 | 2.568 | 1.948 | 1.948 | 1.970 | 1.970 | |||

| 4.045 | 4.045 | 4.045 | 4.045 | 4.045 | 4.045 | 3.543 | 4.035 | 7.511 | 7.511 | 7.496 | 7.496 | |||

| 4.482 | 4.482 | 4.482 | 4.482 | 4.482 | 4.482 | 3.967 | 4.651 | 8.638 | 8.638 | 8.799 | 8.799 | |||

| 2.656 | 2.656 | 2.656 | 2.656 | 2.656 | 2.681 | 2.681 | 2.681 | 2.681 | 2.681 | |||||

| 7.082 | 7.082 | 7.082 | 7.082 | 7.082 | 7.150 | 7.150 | 5.363 | 5.363 | 5.363 | |||||

| 2.568 | 2.568 | 2.568 | 2.568 | 2.568 | 2.568 | 2.568 | 1.970 | 1.970 | 1.970 | |||||

| 4.045 | 4.045 | 4.045 | 4.045 | 3.978 | 4.035 | 7.511 | 7.496 | 7.496 | 7.496 | |||||

| 4.482 | 4.482 | 4.482 | 4.482 | 4.560 | 4.651 | 8.638 | 8.799 | 8.799 | 8.799 | |||||

| 2.681 | 2.681 | |||||||||||||

| 5.363 | 5.363 | |||||||||||||

| 1.948 | 1.970 | |||||||||||||

| 4.925 | 4.925 | |||||||||||||

| 7.511 | 7.496 | |||||||||||||

(ton) | 21.166 | 42.332 | 42.332 | 21.166 | 42.332 | 42.332 | 41.763 | 42.498 | 71.878 | 44.863 | 44.870 | 67.305 | 523.817 | |

(ton)/batch | 54.479 | 75.645 | 75.645 | 54.479 | 122.529 | 122.529 | 114.393 | 76.468 | 99.022 | 69.539 | 69.546 | 87.045 | 1020.299 | |

References

- Nigussie, T.; Chandrasekar, M.K. Influence of rebar practice in the total cost of building construction projects: The case of Hawassa City, Ethiopia. Int. J. Eng. Sci. Technol. 2020, 12, 54–65. [Google Scholar] [CrossRef]

- Navon, R.; Berkovich, O. Development and on-site evaluation of an automated materials management and Control Model. J. Constr. Eng. Manag. 2005, 131, 1328–1336. [Google Scholar] [CrossRef]

- Patel, K.V.; Vyas, C.M. Construction Material Management on Project Site. In Proceedings of the National Conference on Recent Trends in Engineering & Technology, Gujarat, India, 13–14 May 2011; pp. 1–5. Available online: https://www.bvmengineering.ac.in/misc/docs/published-20papers/civilstruct/Civil/101002.pdf (accessed on 4 March 2025).

- Lien, L.-C.; Dolgorsuren, U. BIM-based steel reinforcing bar detail construction design and picking optimization. Structures 2023, 49, 520–536. [Google Scholar] [CrossRef]

- Rahimi, Z.; Maghrebi, M. Minimizing rebar cost using design and construction integration. Autom. Constr. 2023, 147, 104701. [Google Scholar] [CrossRef]

- Widjaja, D.D.; Kim, S. Reducing rebar cutting waste and rebar usage of beams: A two-stage optimization algorithm. Buildings 2023, 13, 2279. [Google Scholar] [CrossRef]

- Widjaja, D.D.; Rachmawati, T.S.; Kim, S.; Lee, S. An algorithm to minimize near-zero rebar-cutting waste and rebar usage of columns. Sustainability 2023, 16, 308. [Google Scholar] [CrossRef]

- Khant, L.P.; Widjaja, D.D.; Kwon, K.-H.; Kim, S. A BIM-Based Bar Bending Schedule Generation Algorithm with Enhanced Accuracy. Buildings 2024, 14, 1207. [Google Scholar] [CrossRef]

- Pagare, P.G.; Sonawane, A.R. Literature Review on Inventory and Material Management in Construction Industries. Int. J. Res. Trends Innov. 2022, 7, 622–625. [Google Scholar]

- Tresnandhini Kusumaningroem, T.; Gondokusumo, O. Comparison of building information modeling and conventional methods for concrete and rebar quantity take-off. Int. J. Appl. Sci. Technol. Eng. 2023, 1, 674–684. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Park, C.; Ballard, G. A Case Study on Rebar Supply Chain Management by GS E&C. In Proceedings of the IGLC-15, East Lansing, MI, USA, 18–20 July 2007. [Google Scholar]

- Vrihoefi, R.; Koskela, L. Roles of Supply Chain Management in Construction. In Proceedings of the IGLC-7, Berkeley, CA, USA, 26–28 August 1999. [Google Scholar]

- Gegana, G. BIM Consultant Jakarta. (n.d.). Autodesk Revit Collection. Available online: https://bimconsultantjakarta.wordpress.com/author/greggegana/ (accessed on 4 March 2025).

- Sherafat, B.; Taghaddos, H.; Shafaghat, E. Enhanced automated quantity take-off in building information modeling. Eng. Sci. Iran. 2021, 29, 1024–1037. [Google Scholar]

- Taghaddos, H.; Mashayekhi, A.; Sherafat, B. Automation of construction quantity take-off: Using building information modeling (BIM). Constr. Res. Congr. 2016, 2016, 2218–2227. [Google Scholar] [CrossRef]

- Khosakitchalert, C.; Yabuki, N.; Fukuda, T. Improving the accuracy of BIM-based quantity takeoff for compound elements. Autom. Constr. 2019, 106, 102891. [Google Scholar] [CrossRef]

- Khalifa, Y.; Salem, O.; Shahin, A. Cutting stock waste reduction using genetic algorithms. In Proceedings of the 8th Annual Conference on Genetic and Evolutionary Computation, Seattle, WA, USA, 8 July 2006; pp. 1675–1680. [Google Scholar]

- Khondoker, M.T.H. Automated reinforcement trim waste optimization in RC frame structures using building information modeling and mixed-integer linear programming. Autom. Constr. 2021, 124, 103599. [Google Scholar] [CrossRef]

- Zheng, C.; Lu, M. Optimized reinforcement detailing design for sustainable construction: Slab case study. Procedia Eng. 2016, 145, 1478–1485. [Google Scholar] [CrossRef]

- Nadoushani, Z.S.M.; Hammad, A.W.; Xiao, J.; Akbarnezhad, A. Minimizing cutting wastes of reinforcing steel bars through optimizing lap splicing within reinforced concrete elements. Constr. Build. Mater. 2018, 185, 600–608. [Google Scholar] [CrossRef]

- Chen, Y.H.; Yang, T.K. Lapping pattern, stock length, and shop drawing of beam reinforcements of an RC building. J. Comput. Civ. Eng. 2015, 29, 04014028. [Google Scholar] [CrossRef]

- BS 8666; Scheduling, Dimensioning, Cutting and Bending of Steel Reinforcement for Concrete; Specification. British Standards Institution: London, UK, 2020.

- Charette, R.P.; Marshall, H.E. Uniformat II Elemental Classification for Building Specifications, Cost Estimating and Cost Analysis. NIST. 12 October 2021. Available online: https://www.nist.gov/publications/uniformat-ii-elemental-classification-building-specifications-cost-estimating-and-cost (accessed on 4 March 2025).

| Members | Rebar Diameter (mm) | Dimension (mm × mm) | ||||

|---|---|---|---|---|---|---|

| Column, C1 | D29 | C1-1(B7F-F5) | C1-2(F5-F7) | C1-3(F7-F9) | C1-4(F9-F13) | C1-5(F13-RF) |

| 1000 × 1400 | 1000 × 1200 | 900 × 1200 | 900 × 900 | 700 × 700 | ||

| Column, C1A | D29 | C1A-1(B7F-F5) | C1A-2(F5-F9) | C1A-3(F9-F11) | C1A(F11-RF) | |

| 900 × 1400 | 900 × 1200 | 800 × 800 | 700 × 700 | |||

| Column, C2A | D29 | C2A-1(B7F-F5) | C2A-2(F5-RF) | |||

| 900 × 900 | 700 × 700 | |||||

| Beam, G1 | D22 | G1(B7F-RF) | ||||

| 600 × 600 | ||||||

| Beam, G2 | D22 | G2-1(B7F-F8) | G2-2(F9-RF) | |||

| 1400 × 600 | 600 × 600 | |||||

| Beam, G3 | D22 | G3-1(B7F-F8) | G3-2(F9-RF) | |||

| 1400 × 600 | 600 × 600 | |||||

| Beam, B1 | D22 | B1(B7F-RF) | ||||

| 600 × 600 | ||||||

| Description | Rebar Diameter (mm) | (mm) | (mm) | (m) | (m) | |||

|---|---|---|---|---|---|---|---|---|

| C1 | Foundation-RF | D29 | 140,472 | 12 | 12 | 122,112 | 10.2 | - |

| Foundation-F17 | D29 | 134,361 | 12 | 11 | 117,531 | 10.2 | 5.34 | |

| Foundation-F11 | D29 | 101,781 | 9 | 8 | 89,541 | 10.2 | 7.95 | |

| F1-F11 | D29 | 58,870 | 5 | 5 | 51,220 | 10.2 | 0.22 | |

| F1-F9 | D29 | 48,010 | 5 | 3 | 43,420 | 10.2 | 2.62 | |

| F1-F7 | D29 | 37,150 | 4 | 2 | 34,090 | 10.2 | 3.49 | |

| F1-F5 | D29 | 26,290 | 3 | 1 | 24,760 | 10.2 | 4.36 | |

| C1A | Foundation-RF | D29 | 140,472 | 12 | 12 | 122,112 | 10.2 | - |

| Foundation-F17 | D29 | 134,361 | 12 | 11 | 117,531 | 10.2 | 5.34 | |

| Foundation-F9 | D29 | 90,921 | 8 | 7 | 80,211 | 10.2 | 8.82 | |

| F1-F9 | D29 | 48,010 | 5 | 3 | 43,420 | 10.2 | 2.62 | |

| F1-F7 | D29 | 37,150 | 4 | 2 | 34,090 | 10.2 | 3.49 | |

| F1-F5 | D29 | 26,290 | 3 | 1 | 24,760 | 10.2 | 4.36 | |

| C2A | Foundation-RF | D29 | 140,472 | 12 | 12 | 122,112 | 10.2 | - |

| Foundation-F17 | D29 | 134,361 | 12 | 11 | 117,531 | 10.2 | 5.34 | |

| Foundation-F5 | D29 | 69,201 | 6 | 5 | 61,551 | 10.2 | 0.36 | |

| F1-F5 | D29 | 26,290 | 3 | 1 | 24,760 | 10.2 | 4.36 | |

| Activity Code | Activity Name | Duration (days) | Early Start Date | Late Finish Date | Predecessors | Quantity (ton) | BOQ Code |

|---|---|---|---|---|---|---|---|

| B1010-B7-C1A-R | Column C1A main rebar | 14 | 12/17/24 | 1/3/25 | 5, 7 | 17.273 | B1010-B7-C1A-R-01A0 |

| B1010-B5-C1A-R | Column C1A main rebar | 14 | 4/29/25 | 5/16/25 | 19, 21 | 17.273 | B1010-B5-C1A-R-01A0 |

| B1010-B3-C1A-R | Column C1A main rebar | 14 | 8/7/25 | 8/26/25 | 33, 35 | 17.273 | B1010-B3-C1A-R-01A0 |

| B1010-B1-C1A-R | Column C1A main rebar | 14 | 11/13/25 | 12/1/25 | 47, 49 | 17.273 | B1010-B1-C1A-R-01A0 |

| B1010-01-C1A-R | Column C1A main rebar | 14 | 1/1/26 | 1/20/26 | 54, 56 | 43.183 | B1010-01-C1A-R-01A0 |

| B1010-03-C1A-R | Column C1A main rebar | 14 | 4/9/26 | 4/27/26 | 68, 70 | 43.183 | B1010-03-C1A-R-01A0 |

| B1010-05-C1A-R | Column C1A main rebar | 14 | 7/16/26 | 8/4/26 | 82, 84 | 23.442 | B1010-05-C1A-R-01A0 |

| B1010-07-C1A-R | Column C1A main rebar | 14 | 10/22/26 | 11/9/26 | 96, 98 | 14.806 | B1010-07-C1A-R-01A0 |

| B1010-09-C1A-R | Column C1A main rebar | 14 | 1/27/27 | 2/15/27 | 110, 112 | 12.338 | B1010-09-C1A-R-01A0 |

| B1010-12-C1A-R | Column C1A main rebar | 14 | 6/24/27 | 7/13/27 | 131, 133 | 12.338 | B1010-12-C1A-R-01A0 |

| B1010-14-C1A-R | Column C1A main rebar | 14 | 9/30/27 | 10/19/27 | 145, 147 | 9.870 | B1010-14-C1A-R-01A0 |

| B1010-16-C1A-R | Column C1A main rebar | 14 | 1/5/28 | 1/24/28 | 159, 161 | 16.148 | B1010-16-C1A-R-01A0 |

| Building name: 000 Structure: Column Floor: B7 Member: C1A BOQ code: B1010-B7-C1A-R-01A0 Sheet title: C1A rebar | ||||||||||||

| No | BBS Code | Diameter (mm) | No of Rebars | No of Members | Shape | Length (mm) | Bar Length (m) | Total Length (m) | Weight (ton) | |||

| A | B | C | D | |||||||||

| 1 | M01 | D29 | 16 | 12 | 12 | 350 | 9850 | 10.2 | 163.2 | 10.575 | ||

| 2 | M02 | D29 | 4 | 12 | 12 | 350 | 9850 | 10.2 | 40.8 | 2.644 | ||

| 3 | M03 | D29 | 8 | 12 | 12 | 350 | 9850 | 10.2 | 81.6 | 5.288 | ||

| 18.507 | ||||||||||||

| Order Batch | Floors | Activities | |

|---|---|---|---|

| Columns (D29 Rebars) | Beams (D22 Rebars) | ||

| 1 | BF7, BF6 | B1010-B7-C2A-R, B1010-B7-C1A-R, B1010-B7-C1-R | B1010-B6-G1-R, B1010-B6-G2-R, B1010-B6-G3-R, B1010-B6-B1-R, B1010-20-B6-DR |

| 2 | BF5, BF4 | B1010-B5-C2A-R, B1010-B5-C1A-R, B1010-B5-C1-R | B1010-B5-G1-R, B1010-B5-G2-R, B1010-B5-G3-R, B1010-B5-B1-R, B1010-B5-DR, B1010-B4-G1-R, B1010-B4-G2-R, B1010-B4-G3-R, B1010-B4-B1-R, B1010-B4-DR |

| 3 | BF3, BF2 | B1010-B3-C2A-R, B1010-B3-C1A-R, B1010-B3-C1-R | B1010-B3-G1-R, B1010-B3-G2-R, B1010-B3-G3-R, B1010-B3-B1-R, B1010-B3F-DR, B1010-B2-G1-R, B1010-B2-G2-R, B1010-B2-G3-R, B1010-B2-B1-R, B1010-B2-DR |

| 4 | BF1 | B1010-B1-C2A-R, B1010-B1-C1A-R, B1010-B1-C1-R | B1010-B1-G1-R, B1010-B1-G2-R, B1010-B1-G3-R, B1010-B1-B1-R, B1010-B1-DR |

| 5 | F1, F2 | B1010-01-C2A-R, B1010-01-C1A-R, B1010-01-C1-R | B1010-01-G1-R, B1010-01-G2-R, B1010-01-G3-R, B1010-01-B1-R, B1010-01-DR, B1010-02-G1-R, B1010-02-G2-R, B1010-02-G3-R, B1010-02-B1-R, B1010-02-DR |

| 6 | F3, F4 | B1010-03-C2A-R, B1010-03-C1A-R, B1010-03-C1-R | B1010-03-G1-R, B1010-03-G2-R, B1010-03-G3-R, B1010-03-B1-R, B1010-03-DR, B1010-04-G1-R, B1010-04-G2-R, B1010-04-G3-R, B1010-04-B1-R, B1010-03-DR |

| 7 | F5, F6 | B1010-05-C2A-R, B1010-05-C1A-R, B1010-05-C1-R | B1010-05-G1-R, B1010-05-G2-R, B1010-05-G3-R, B1010-05-B1-R, B1010-05-DR, B1010-06-G1-R, B1010-06-G2-R, B1010-06-G3-R, B1010-06-B1-R, B1010-06-DR |

| 8 | F7, F8 | B1010-07-C2A-R, B1010-07-C1A-R, B1010-07-C1-R | B1010-07-G1-R, B1010-07-G2-R, B1010-07-G3-R, B1010-07-B1-R, B1010-07-DR, B1010-08-G1-R, B1010-08-G2-R, B1010-08-G3-R, B1010-08-B1-R, B1010-08-DR |

| 9 | F9, F10, F11 | B1010-09-C2A-R, B1010-09-C1A-R, B1010-09-C1-R | B1010-09-G1-R, B1010-09-G2-R, B1010-09-G3-R, B1010-09-B1-R, B1010-09-DR, B1010-10-G1-R, B1010-10-G2-R, B1010-10-G3-R, B1010-10-B1-R, B1010-10F-DR, B1010-11-G1-R, B1010-11-G2-R, B1010-11-G3-R, B1010-11-B1-R, B1010-11-DR |

| 10 | F12, F13 | B1010-12-C2A-R, B1010-12-C1A-R, B1010-12-C1-R | B1010-12-G1-R, B1010-12-G2-R, B1010-12-G3-R, B1010-12-B1-R, B1010-12-DR, B1010-13-G1-R, B1010-13-G2-R, B1010-13-G3-R, B1010-13-B1-R, B1010-13-DR |

| 11 | F14, F15 | B1010-14-C2A-R, B1010-14-C1A-R, B1010-14-C1-R | B1010-14-G1-R, B1010-14-G2-R, B1010-14-G3-R, B1010-14-B1-R, B1010-14-DR, B1010-15-G1-R, B1010-15-G2-R, B1010-15-G3-R, B1010-15-B1-R, B1010-15-DR |

| 12 | F16, F17, RF | B1010-16-C2A-R, B1010-16-C1A-R, B1010-16-C1-R | B1010-16-G1-R, B1010-16-G2-R, B1010-16-G3-R, B1010-16-B1-R, B1010-16-DR, B1010-17-G1-R, B1010-17-G2-R, B1010-17-G3-R, B1010-17-B1-R, B1010-17-DR, B1010-RF-G1-R, B1010-RF-G2-R, B1010-RF-G3-R, B1010-RF-B1-R, B1010-RF-DR |

| Description | Rebar Order Quantity After Optimization (ton) | Rebar Order Quantity After SCM Optimization (ton) | Difference | |

|---|---|---|---|---|

| ton | % | |||

| Column | 496.440 | 496.482 | 0.042 | 0.0085 |

| Beam | 523.799 | 523.817 | 0.018 | 0.0034 |

| Total | 1020.239 | 1020.299 | 0.060 | 0.0059 |

| Order Batch | Floors | Early Start Date | Late Finish Date | ||

|---|---|---|---|---|---|

| 1 | BF7, BF6 | 12/17/24 | 1/3/25 | 2 months | 10/17/24 |

| 2 | BF5, BF4 | 4/29/25 | 5/16/25 | 2 months | 2/29/25 |

| 3 | BF3, BF2 | 8/7/25 | 8/26/25 | 2 months | 6/7/25 |

| 4 | BF1 | 11/13/25 | 12/1/25 | 2 months | 9/13/25 |

| 5 | F1, F2 | 1/1/26 | 1/20/26 | 2 months | 11/1/25 |

| 6 | F3, F4 | 4/9/26 | 4/27/26 | 2 months | 2/9/26 |

| 7 | F5, F6 | 7/16/26 | 8/4/26 | 2 months | 5/16/26 |

| 8 | F7, F8 | 10/22/26 | 11/9/26 | 2 months | 8/22/26 |

| 9 | F9, F10, F11 | 1/27/27 | 2/15/27 | 2 months | 11/27/26 |

| 10 | F12, F13 | 6/24/27 | 7/13/27 | 2 months | 4/24/27 |

| 11 | F14, F15 | 9/11/27 | 9/29/27 | 2 months | 7/11/27 |

| 12 | F16, F17, RF | 1/5/2028 | 1/24/2028 | 2 months | 11/5/2027 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khant, L.P.; Widjaja, D.D.; Kim, D.; Rachmawati, T.S.N.; Kim, S. Optimizing Rebar Process and Supply Chain Management for Minimized Cutting Waste: A Building Information Modeling-Based Data-Driven Approach. Buildings 2025, 15, 844. https://doi.org/10.3390/buildings15060844

Khant LP, Widjaja DD, Kim D, Rachmawati TSN, Kim S. Optimizing Rebar Process and Supply Chain Management for Minimized Cutting Waste: A Building Information Modeling-Based Data-Driven Approach. Buildings. 2025; 15(6):844. https://doi.org/10.3390/buildings15060844

Chicago/Turabian StyleKhant, Lwun Poe, Daniel Darma Widjaja, Dongjin Kim, Titi Sari Nurul Rachmawati, and Sunkuk Kim. 2025. "Optimizing Rebar Process and Supply Chain Management for Minimized Cutting Waste: A Building Information Modeling-Based Data-Driven Approach" Buildings 15, no. 6: 844. https://doi.org/10.3390/buildings15060844

APA StyleKhant, L. P., Widjaja, D. D., Kim, D., Rachmawati, T. S. N., & Kim, S. (2025). Optimizing Rebar Process and Supply Chain Management for Minimized Cutting Waste: A Building Information Modeling-Based Data-Driven Approach. Buildings, 15(6), 844. https://doi.org/10.3390/buildings15060844