Abstract

This paper reviews the potential of Wire Arc Additive Manufacturing (WAAM) for architecture. It uniquely addresses its feasibility by evaluating existing large-scale, real-world prototypes developed to date and compiling critical gaps identified in the literature. Although previous review papers concerning WAAM for architecture exist, they focus on the technical aspects of the technology, such as the mechanical properties, defects, and process parameters. No existing review analyzes which architectural applications are being implemented nor the scale and degree prototyping accomplished for each application. WAAM, a form of metal additive manufacturing using an electric arc to melt and deposit wire, offers unique advantages for the construction industry. It allows for high deposition rates, structural integrity, and cost-efficiency using steel. However, challenges such as producing large-scale components and limited design freedom and lower resolution compared to other additive manufacturing processes remain. This review first contextualizes WAAM within the broader landscape of additive manufacturing technologies for construction and examines its proposed architectural applications, such as steel connections, columns, trusses, and bridge elements. This study emphasizes the need for real-world experimentation through large-scale prototypes to assess the practicality and scalability of WAAM in architecture. The results of this study reveal that 36 architectural projects using WAAM exist in the literature, whose application range from structural (such as beams, columns, and nodes) to nonstructural components (such as facades and ornamental elements). Based on these, a classification for WAAM in architecture is proposed: (1) stand-alone WAAM structures, (2) printed connector pieces to join standard steel parts, and (3) reinforcement for conventional steel elements using WAAM. The size of typical functional prototypes to date averages 200 × 200 × 200 mm, with exceptional cases such as the diagrid column of 2000 mm height and the MX3D Bridge, which spans over 12 m. A detailed analysis of seven projects documents the scale and development of the prototypes, functional lab configuration, and process parameters. Through this review, the current technical feasibility of WAAM in architecture is established.

1. Introduction

Architecture is undergoing a significant transformation, driven by advancements in additive manufacturing (AM) technologies. Among these, Wire Arc Additive Manufacturing (WAAM) stands out for its potential to transform how we design, fabricate, and assemble architectural components [1]. WAAM leverages a controlled electric arc to melt and deposit metallic wire layer by layer, creating complex 3D structures at a comparatively faster speed and lower cost. This technology offers several compelling advantages for construction applications [2].

Firstly, WAAM can produce structures with mechanical properties comparable to conventional construction materials, in particular steel, making them structurally sound for various construction applications [3]. Second, WAAM offers higher deposition rates compared to most other AM processes, making it suitable for fabricating large-scale building elements in a time-efficient manner [2]. Additionally, it offers significant cost benefits due to low-cost consumables [4]. However, WAAM also presents several limitations. While offering a higher degree of design freedom compared with traditional construction methods, it currently struggles with achieving the same level of freedom and resolution compared to other metal AM techniques [5].

Despite the initial promise in lab experiments [6,7], transitioning WAAM from small printed specimens to widespread architectural use presents significant challenges [5]. Bridging this gap requires a comprehensive understanding of the technology’s capabilities and limitations in real-world construction scenarios. Large-scale prototypes serve as a crucial bridge, enabling researchers and industry professionals to evaluate the feasibility and practical implications of WAAM for construction [8]. Although reviews of the state of the art of WAAM for construction exist [9,10,11,12,13], they are primarily focused on compiling the result of research on the mechanical properties of WAAM specimens, process parameters, and print defects. No review to date thoroughly analyzes the intended architectural applications and the extent of prototyping results. This information, crucial in architectural technology research, is currently scattered in publications for each project.

This paper begins by positioning WAAM in the context of other AM technologies for construction, surveying the characteristics of WAAM technology. Then, it assesses the feasibility of WAAM in architecture by evaluating the available full-scale WAAM prototypes published to date, analyzing the intended architectural applications and the level of prototyping accomplished and compiling critical barriers identified in the literature. The 36 identified projects are classified into three categories, providing an overview of the whole range of architectural applications proposed for WAAM technology.

Finally, an analysis of a selection of seven large-scale prototypes provides more detailed information regarding the specific WAAM implementation and material use, lab setup, scale, and strength and weight of the prototypes, leading to a discussion on the current state of WAAM technology in architecture and highlighting its strengths, weaknesses, and opportunities for further development.

By providing insights gained from large-scale prototypes, this paper aims to contribute to the understanding of the current status and future prospect of WAAM for architecture as a transformative technology.

2. Materials and Methods

This review addresses three key questions: (1) Which architectural applications have been proposed and prototyped using WAAM? (2) How extensively and successfully have these applications been tested through large-scale prototypes? (3) What challenges and opportunities have been identified in WAAM for architecture through such prototypes?

To evaluate WAAM’s potential for widespread use in architecture, the methodology is organized into two main parts:

- Identification of Construction Applications for WAAM: An extensive literature search was conducted using the academic databases Scopus, Web of Science, and Google Scholar. After a thorough search, the review identified a total of 36 relevant projects explicitly developing architectural applications of WAAM. Each project was analyzed to extract information on the proposed architectural application, the experiments conducted, and the scale and characteristics of its prototypes. A classification system for architectural applications was developed to organize the projects. The size of the prototypes associated with each project was also recorded to assess their scale in relation to the intended construction use.

- Detailed Analysis of Large-Scale WAAM Prototypes: From the identified projects, a selection of 8 representative projects, which included salient large-scale prototypes, was analyzed in detail. For this review, a large-scale prototype is defined as a physical artifact produced using WAAM that significantly reflects the intended construction’s scale and functionality. Key information was systematically extracted from each project, including the application, date, prototype dimensions, key process parameters, hardware and software used, and construction setting (laboratory vs. onsite). This analysis highlights the technical feasibility, design implications, and scalability of WAAM in architectural contexts.

3. Positioning WAAM in Architecture

AM and WAAM are active fields of research in the architecture and the construction industry. This section positions WAAM in the context of other additive manufacturing technologies.

Architecture is increasingly benefiting from additive manufacturing (AM) technology as it allows for better component planning, design customization and freedom, and saving resources required for construction [14,15,16,17]. Several printing technologies and materials have been proposed and are actively being developed for architecture, addressing the scale, speed, resolution, and mechanical properties required in construction. AM for architecture ranges from concrete and soil paste extrusion [18,19,20], large-scale polymer extrusion [21,22], large-scale binderjetting [23], and various methods of metal additive manufacturing (MAM). Among these, MAM, the layer-by-layer production of parts from metals and metal alloys, offers promising relevance in architecture and structural applications [24,25]. Using MAM in architectural and construction projects, lightweight and high-strength construction components such as custom shells, reinforcements, and connections are manufactured according to specific designs or load demands [26]. Therefore, MAM in the construction industry can optimize resource efficiency, shorten delivery times, and improve structural performance, bringing promising advancements toward sustainable and resilient infrastructure [25,27].

MAM technologies are classified according to the process design, organized into three categories [5,28,29]. The three main types of MAM are powder bed fusion (PBF), directed energy deposition (DED), and binder blasting (BJ). These processes differ in how metal is melted, joined, and deposited, making them suitable for production lines. Most metal 3D printing technologies utilize powder-form materials, an expensive consumable. The sole solid-based technique is Wire Arc Additive Manufacturing (WAAM), a variant of DED, which involves depositing layers of metallic wires as weld beads through an electric arc for heat to produce components.

In the WAAM literature, architecture and construction are identified as the main potential application for WAAM using steel [30,31,32,33,34]. Speed, scale, and cost are presented as the defining factors. Additionally, WAAM’s potential for enhancing resource efficiency in the construction sector is highlighted [35]: minimizing material usage by optimizing the structure of components, reducing both energy consumption and CO2 emissions, customizability, and digital integration with Building Information Modeling (BIM).

4. Description of WAAM Technology

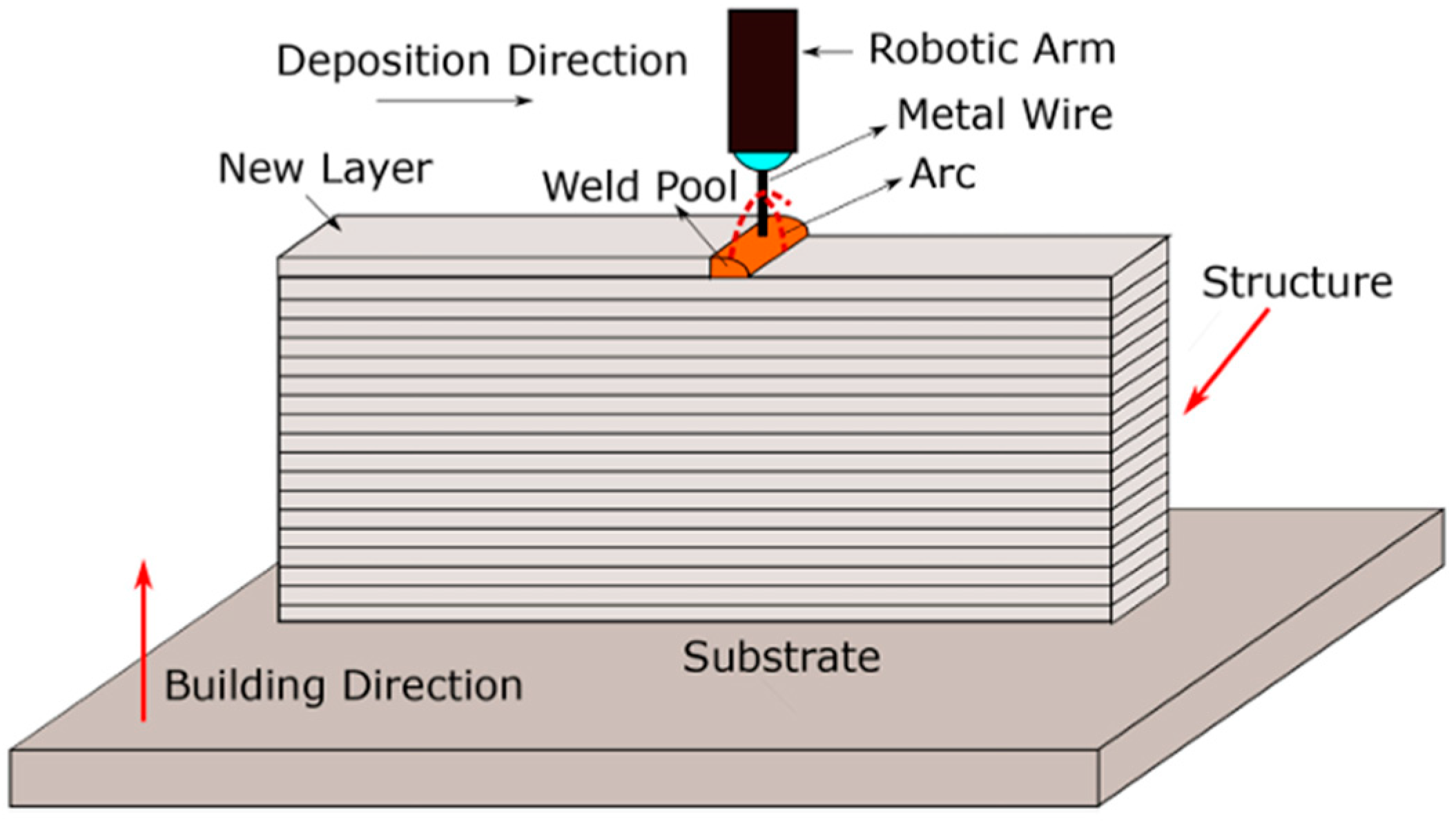

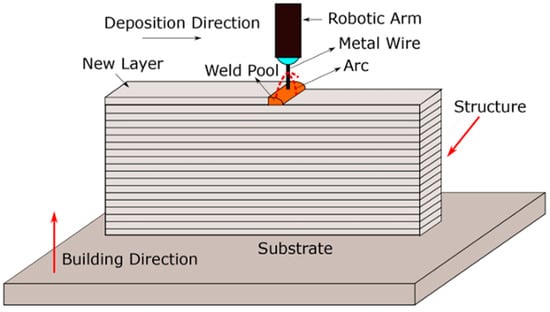

WAAM is a process in additive manufacturing that uses metal wire as a raw material to build metal parts layer by layer. In this process, an electric arc melts the wire, creating a molten pool that is deposited onto a substrate. WAAM utilizes traditional arc welding methods and is recognized for its high deposition rates, making it especially suitable for producing large metal parts. This method minimizes material waste and production costs while ensuring strong mechanical properties [36]. WAAM is employed in aerospace and automotive industries to manufacture custom, durable components [37,38]. A typical WAAM process is illustrated in Figure 1.

Figure 1.

WAAM process. Image credit: [39] (Creative Commons CC-BY).

WAAM processes can be classified according to the heat source, the material feedstock, and the cooling technique [5,6]. The system includes key components like a welding machine, wire feeder, and either robotic or CNC controls, each tailored to specific material requirements [40].

WAAM’s performance is influenced by critical parameters, including the heat input, wire feeding speed, traveling speed, and arc voltage and amperage [41]. These factors directly affect the molten pool dynamics, influencing the mechanical properties and surface finish of the final product [42,43]. CMT technology enhances WAAM by providing low heat input and high arc stability, reducing distortion and improving deposition quality [43,44].

Enhancements to WAAM include hybrid additive–subtractive processes to improve accuracy and reduce defects, such as porosity and residual stresses [45,46]. By integrating traditional machining techniques post-deposition, WAAM can achieve near-net shapes that require minimal finishing [47].

5. Review of WAAM Technology for Architecture

WAAM in architecture offers significant potential alongside several challenges. A review of the literature for WAAM in architecture exists [9,10,11,12,13], summarizing key advantages and challenges, mechanical properties, and weight reduction strategies. However, no review focuses the analysis on thoroughly understanding which architectural applications are being proposed nor the advancements in prototyping accomplished to date. A summary of the existing studies is provided below.

5.1. General Advantages and Limitations of WAAM in Architecture

The following advantages and limitations of WAAM in architecture have been identified in the literature.

General advantages of WAAM for architecture:

- Design Freedom, Customization, and Flexibility: WAAM allows for the mass customization of components, especially for free-form structures and non-standard geometries [4,9,11,48]. It enables the fabrication of components that integrate multiple functions, such as structural and aesthetic roles [4,12,13].

- Structural Optimization: The integration of advanced computational design and optimization enables customized, load-optimized components [11,49]. Optimized structural elements typically present complex geometries for which WAAM is a suitable manufacturing technology [35,36,37].

- Cost and Material Savings: For complex geometries, WAAM offers reduced material waste compared to traditional subtractive manufacturing methods [13,50] and its use of cheaper feedstocks (e.g., wire) compared to powder-based MAM methods [10]. WAAM is suitable for producing large steel components with high deposition rates (4–9 kg/h), which is economically beneficial compared to other AM methods [8].

- Sustainability Goals: Structural optimization, lighter structures, and reduced weight aligns with goals for a circular construction industry [12,13], offering potential material, energy, and cost savings [10,11].

- Onsite Fabrication: The potential for onsite printing of components has been argued and tested in bridges, which could reduce transportation and installation complexity [11].

General limitations of WAAM in architecture:

- Geometric Limitations: The current technology has restrictions on the geometries that can be printed, particularly concerning the angles at which layers can be deposited without requiring support structures. This can limit the complexity of designs that can be feasibly realized [12].

- Post-Processing Requirements: While WAAM allows for complex geometries, it often necessitates significant post-processing to achieve the desired surface finishes and tolerances, which can increase manufacturing time and costs [10,13].

- Geometric Distortion: The effects of thermal distortion during the WAAM process can lead to inaccuracies in large-scale components, which is particularly problematic for structures that require precise alignments and dimensions [51].

- Process Parameters: Authors also identify the need for further research to establish optimal process parameters and ensure that the mechanical properties and structural stability of WAAM-produced components meet the design requirements for civil applications. Process parameters are studied in the literature [34].

- In-Process Monitoring: Implementing effective monitoring and feedback systems during the WAAM process is necessary to adapt to real-time conditions and variations, which could mitigate issues related to inaccuracies and material properties [11,13]. Enhancements in path planning, layer height adjustments, and adaptive slicing techniques for better geometric accuracy are considered [10,11].

- Integration of Design and Manufacturing: The need for a seamless connection between computational design tools and the manufacturing process is crucial. The current methods may not fully capitalize on the flexibility of WAAM due to gaps in this integration [12,13].

5.2. Material and Technical Constraints of WAAM for Large-Format Architectural Elements

WAAM has demonstrated significant potential for creating large-scale architectural components, but its structural limitations stem primarily from the anisotropic nature of WAAM-produced materials, residual stresses, geometric imperfections, and weight considerations. Addressing these technical issues is critical for the effective integration of WAAM into the development of large-format architectural elements.

5.2.1. Mechanical Strength

WAAM-produced components exhibit mechanical properties comparable to traditional welded structures, with some variability based on deposition parameters [9,10,52]. Functionally graded materials and tailored microstructures could be achieved through controlled cooling rates and alloy selection [12,13]. Research by Nguyen et al. [53] has demonstrated that the mechanical properties of WAAM parts can match or even surpass those made with conventional manufacturing. A comparison between mechanical properties of WAAM vs. construction steel (S 235 JR + AR structural-grade steel commonly used in construction) is presented in Table 1.

Table 1.

Comparison of mechanical properties of WAAM vs. conventional manufacturing.

5.2.2. Anisotropy

However, WAAM materials are often limited by anisotropy. Studies by Weber et al. [55] and Kyvelou et al. [56] emphasize that WAAM components tend to have reduced tensile strength and stiffness when loads are applied perpendicular to the layer orientation. Weber et al. [55] reported that optimized deposition methods could reduce this anisotropy, improving tensile properties to approach those of conventionally manufactured steel. Gardner [33] and Xin et al. [57] also highlighted the directional dependency of WAAM materials, noting that anisotropy is more pronounced in high-stress applications, such as columns and load-bearing beams. This variability necessitates careful design consideration and testing for components subjected to multi-directional forces.

5.2.3. Residual Stresses and Their Impact

Residual stresses are inherent in WAAM due to the repeated heating and cooling cycles during deposition. Dhinakaran et al. [58] and Wächter et al. [59] emphasized that these stresses reduce yield strength and tensile performance, particularly in high-strength materials. While post-deposition heat treatments can alleviate some residual stresses, they often lead to grain coarsening, which negatively affects material resistance. The presence of residual stresses in structural elements, such as hollow sections and walls, has implications for long-term performance under static and dynamic loads. Kyvelou et al. [56] observed that residual stresses contributed to localized buckling in WAAM square hollow sections (SHSs), limiting their effectiveness in high-stress applications.

5.2.4. Geometric Imperfections and Their Structural Implications

Geometric imperfections are a consistent challenge in WAAM, with surface undulations and dimensional inconsistencies frequently reported. Weber et al. [55] demonstrated that tubular WAAM components, despite optimized deposition strategies, exhibited stress concentrations at surface irregularities, reducing their ultimate tensile strength and ductility. Müller and Hensel [26] and Xin et al. [57] corroborated these findings, showing that even small geometric deviations can significantly affect the load-bearing capacity and stability of WAAM-produced walls and columns. Such imperfections necessitate post-processing, such as machining or cold rolling, to achieve the smooth surfaces required for critical structural applications. However, these processes add complexity and time to the production of large-format architectural elements.

5.2.5. Weight Considerations

WAAM structures have demonstrated acceptable load-bearing capacities when designed and fabricated with precision. WAAM enables the fabrication of non-prismatic, load-optimized shapes that minimize material usage [11,13], and, in theory, computational design and structural optimization allow for the creation of lightweight, material-efficient geometries [9]. WAAM’s ability to produce components customized for specific load paths and conditions could lead to significant material savings [12,13]. For example, Joosten [60] and Wächter et al. [59] evaluated WAAM-manufactured bridge components and medium-strength steel elements, respectively, and found that load distribution and strength could meet or exceed safety standards. However, the weight of WAAM components often exceeds that of equivalent conventionally manufactured parts due to the need for additional material to compensate for geometric imperfections. Kyvelou et al. [56] and Weber et al. [55] noted that WAAM components often require additional reinforcement or thicker cross-sections to ensure structural integrity, which may increase weight. This could limit the feasibility of WAAM for lightweight architectural applications where material efficiency is paramount.

5.2.6. Fatigue Resistance

Fatigue resistance in WAAM materials is a critical consideration for structural components exposed to cyclic loads, such as bridges or high-rise structures. Surface roughness and microstructural inconsistencies in WAAM materials significantly reduced fatigue life [56,59]. This underscores the importance of post-processing and real-time monitoring to ensure consistent quality during fabrication.

6. Applications of WAAM in Construction

Wire Arc Additive Manufacturing (WAAM) is gaining attention in architectural research. Several applications have been proposed and developed into prototypes, but they are currently scattered in the literature. In this section, to present the state of the art, 36 relevant projects identified from a comprehensive search are compiled, analyzed, and organized into a proposed category system: stand-alone structures, reinforcement of existing components, and connection elements. Each category reflects the specific way in which WAAM can contribute to architecture, emphasizing its flexibility and adaptability in addressing diverse needs. Figure 2 shows a selection of examples of each category.

Figure 2.

Applications of WAAM in architecture. Selection of cases for each category. Image credits: [41,61,62,63,64,65]. Reprinting permission for this image has been obtained from the publisher, or under CC-BY and CC-BY-NC-ND.

6.1. Stand-Alone Structures

WAAM is used to construct large, stand-alone metal structures, which take full advantage of WAAM’s geometric freedom (when compared to conventional metal manufacturing). A review of the literature reveals numerous structural applications, such as columns, trusses, and tubes, among others, and nonstructural applications, such as facade elements and stairs. Applications in this category include the following:

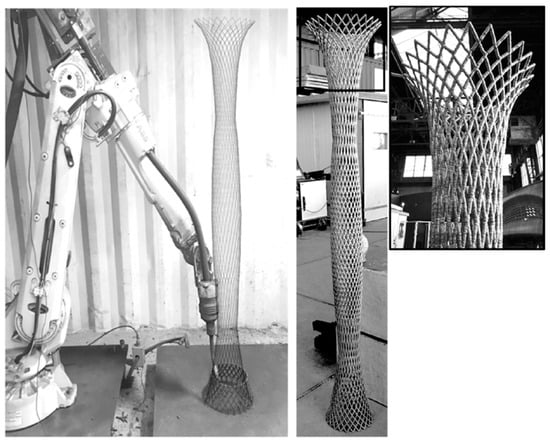

- Columns: WAAM for columns has been proposed [12,61,66] and a diagrid column was prototyped in a 150 × 150 × 2000 mm proof of concept [67]. A Y-shaped column structure, with segments of up to 1020 mm in height, has been prototyped [68].

- Truss: Optimized truss structures have been developed and prototyped up to 400 × 2000 mm [62].

- Structural tubes: Hollow structural elements have been prototyped up to 180 × 180 × 720 mm [56,69].

- Slab Structures: These are sized at 4500 × 4500 × 100 mm [70].

- Lattice structures: In order to achieve larger structures with less material, lattice structures using WAAM have been proposed and tested at a small scale of 200 × 200 × 50 mm (estimated size) [71,72].

- Bridge: Two bridges have been identified in the literature, one executed offsite and transported and the other built onsite [63,73]. The largest construction built using WAAM is the MX3D Bridge (12,500 × 2500 mm).

- Facades: Nonstructural applications such as facade elements and sculptural forms have been developed and tested in large artifacts of up to 1500 × 1000 × 500 mm (estimated size) [64].

- Staircase: The use of WAAM for staircase design was proposed but not yet prototyped [74].

6.2. Reinforcement and Repair

WAAM is often proposed as a custom reinforcement addition to off-the-shelf construction components, improving their structural performance without the need to manufacture whole pieces. This approach takes advantage of the economy and speed of conventional steel manufacturing while providing standard pieces with increased performance and connection details [75]. Additionally, this approach has also been extended to the repair of existing steel structures [76]. Identified applications of reinforcement in the literature include the following:

- Beam reinforcement and repair: Printed structures to reinforce beams have been proposed and prototyped into a 200 × 250 section of an I-beam [76].

- Sheet metal reinforcement: The reinforcement of thin metal materials to increase stiffness has been prototyped in specimens of around 300 × 300 × 100 mm [9,77] and 200 × 70 mm [78].

- Reinforcement bars: Printing of reinforcement steel bars for concrete structures (traditionally casted or 3D printed) using the WAAM dot-by-dot technique has been proposed and prototyped [65,79,80,81]. The potential benefit of printed reinforcement involves variation in densities and trajectories that better accommodate the stresses. Prototypes of up to a length of 250 mm have been manufactured [76,82].

6.3. Connections

WAAM is also proposed for connection elements, which are essential in modular construction and component assembly. Focusing on connectors allows for concentrating on the complexity of a structure in the connection, which is smaller and therefore faster and cheaper to print, while leaving the bulk of the structure to be manufactured with industrialized parts [14]. With WAAM, each connector can be custom-made for its structural needs, leading to more efficient structures and complex architectural designs [83]. Key applications in this area include the following:

- Beam-to-beam connection: Attachments to steel beams such as hooks and head plates have been proposed and prototyped with a size of 150 × 150 mm (estimated) [84]. T-stub connections [85], single-lap shear-bolted connections [86], and optimized connectors [26,87] have been prototyped at 200 × 200 × 200 (estimated), as well as customized connection details, also prototyped at a 100 × 100 × 100 mm scale [88,89]. Optimized spaceframes have been tested [90,91], with the largest optimized node prototyped at 375 mm in height [92].

- Facades: Connection elements for facades have been proposed and prototyped for supporting glass [64] and metal sheets [48] and prototyped into 200 × 200 × 200 mm (estimated).

7. Large-Scale Prototypes Using WAAM Technology

The application of Wire Arc Additive Manufacturing (WAAM) in large-scale construction projects is still in its initial stages, yet several prototypes have demonstrated its potential to meet the real-world needs of the industry. The relevance of large-scale prototypes for the deployment of technology has been argued [8] and constitutes a fundamental dimension of the Technology Readiness Level (TRL) [93]. This section presents a review of seven selected prototypes that have successfully utilized WAAM technology to create structural components at a scale relevant to the architectural application investigated. Each case highlights different aspects of WAAM’s capabilities, including its application, scale, material, laboratory setup, and process parameters, as well as the strength, weight, and production time, when available. The first four projects belong to the stand-alone WAAM pieces, one deals with the reinforcement of conventional material, and the last two are connector pieces. By examining these prototypes, we evaluate WAAM’s readiness for widespread construction use, identifying both its current limitations and the opportunities it presents for future developments in the sector.

7.1. Optimized Truss (Imperial College London, Zhejiang University, MX3D, and University of Sheffield)

In 2021, Ye et al. [62] developed an automated framework for the design and additive manufacture of optimized tubular trusses using Wire Arc Additive Manufacturing (WAAM). The study integrated layout and geometry optimization techniques to generate structurally efficient designs tailored for WAAM fabrication. The optimized trusses demonstrated significantly improved performance compared to conventional designs, with at least a twofold increase in the capacity-to-mass ratio. The trusses were manufactured using a multi-axis robotic WAAM system by MX3D, and their mechanical properties were assessed through finite-element modeling and physical testing. The research highlights the feasibility of WAAM for creating high-performance, large-scale construction components, with applications including roof trusses and bridge elements. Figure 3 shows the manufacturing process and Table 2 summarizes the project’s salient aspects.

Figure 3.

Fabrication process of optimized truss fabrication process. Image credit: [62] (Creative Commons CC-BY).

Table 2.

Summary of key aspects of optimized truss.

7.2. AM Bridge 2019 (TU Dormstadt)

In 2022, Feucht et al. [63] explored the use of Wire Arc Additive Manufacturing (WAAM) to construct a small steel bridge directly onsite at the Technical University of Darmstadt. The project, known as “AM Bridge 2019,” demonstrated the feasibility of manufacturing complex steel structures using a robot-guided gas-shielded metal arc welding (GMAW) system. The key innovation was the in situ fabrication process, where the bridge was constructed over a stream without the need for prefabricated parts or support structures. The study involved slicing the bridge design into layers and employing parametric robot programming (PRP) to handle variations in geometry during the build process. The authors also addressed challenges such as thermally induced residual stresses and the need for optimized shielding gases to improve the deposition rates. The successful construction of the bridge showcases WAAM’s potential for onsite construction of large-scale steel components. Figure 4 shows the manufacturing process and Table 3 summarizes the project’s salient aspects.

Figure 4.

Result of in situ printing of the AM Bridge. Image credit: [63] (Creative Commons CC-BY-NC-ND).

Table 3.

Summary of key aspects of AM Bridge.

7.3. MX3D Bridge

The MX3D Bridge is the first full-size 3D-printed metal pedestrian bridge, developed by the Dutch company MX3D in collaboration with partners, including Autodesk, Imperial College London, and the University of Bologna [73,94,95]. The bridge spans 12.5 m and was designed to be printed with WAAM. The structure is made of 308LSi stainless steel and was printed in sections, which were later assembled and installed over the Oudezijds Achterburgwal canal in Amsterdam.

This project demonstrates the feasibility of using WAAM for large-scale, free-form structures in construction, pushing the boundaries of design freedom and efficiency in material use. Figure 5 shows the manufacturing process and Table 4 summarizes the project’s salient aspects.

Figure 5.

Printed bridge in its final position. Reprinting permission for this image has been ob-tained from the publisher [10].

Table 4.

Summary of key aspects of the MX3D Bridge.

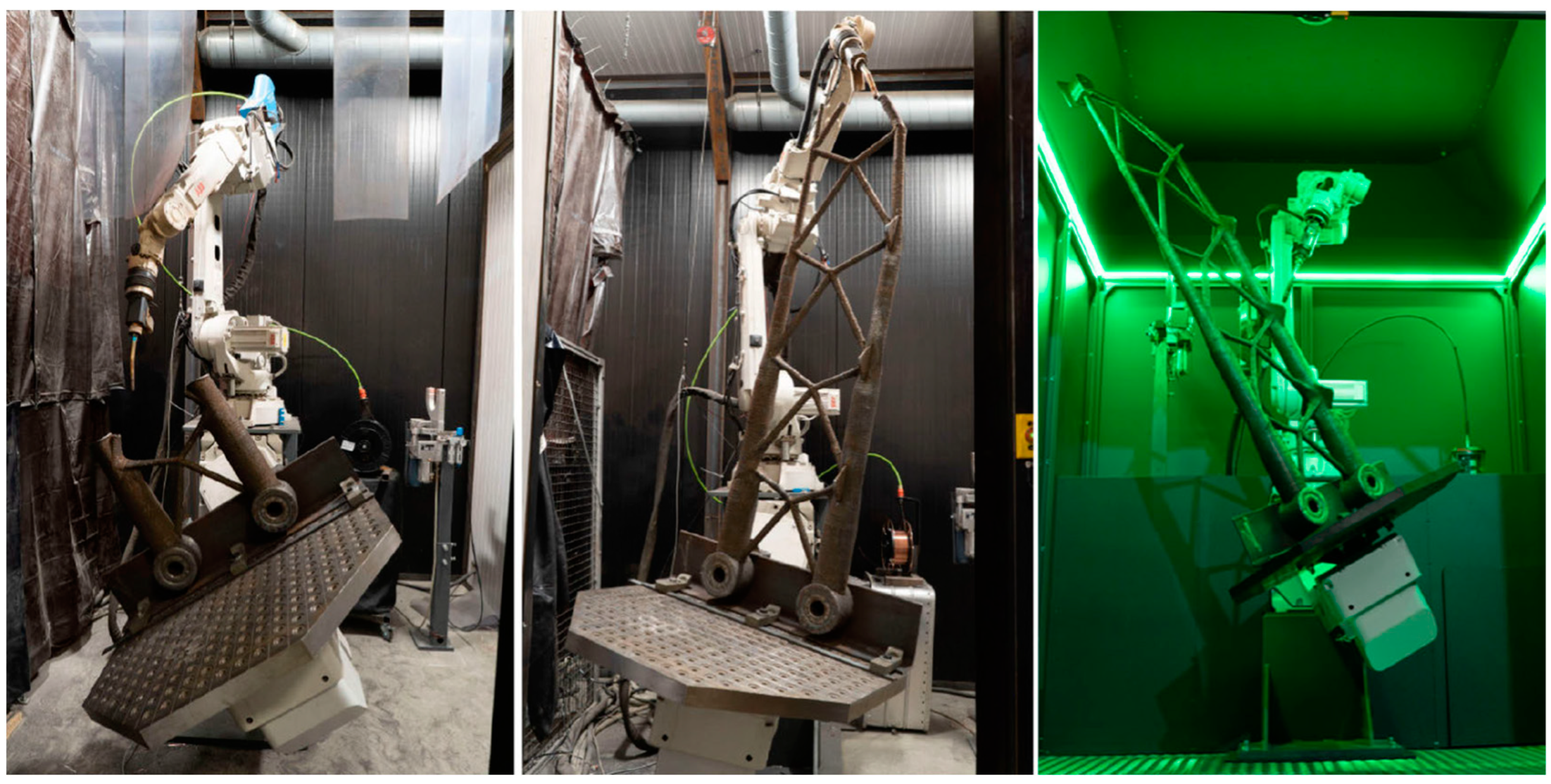

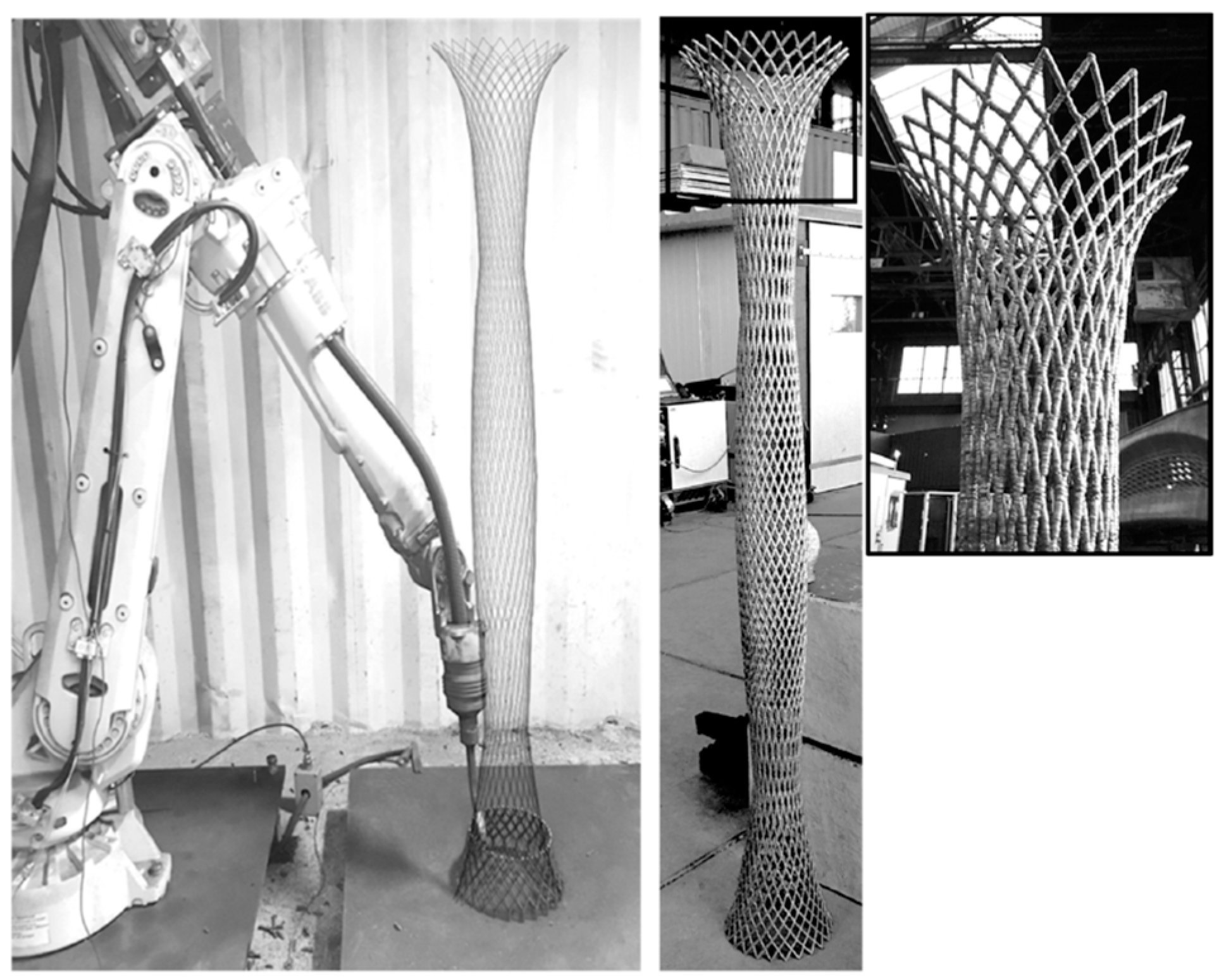

7.4. WAAMGRID (Universitá di Bologna and TU Braunschweig, MX3D)

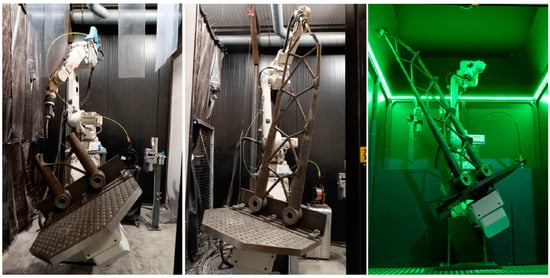

In 2022, Laghi et al. [61,67] developed the WAAMGRID, a digital design and fabrication framework for diagrid lattice structures. This approach combines computational design with WAAM to create optimized lattice structures for architectural applications, specifically focusing on free-form, lightweight diagrids. The lattice structure, manufactured using a robotic arm-based WAAM system, served as a proof of concept for the feasibility of constructing larger, more complex architectural elements using this method. Figure 6 shows the manufacturing process and Table 5 summarizes the project’s salient aspects.

Figure 6.

Column WAAMGRID lattice. Reprinting permission for this image has been obtained from the publisher [61].

Table 5.

Summary of key aspects of the WAAMGRID.

7.5. Reinforced I-Beam (Technische Universität Braunschweig, University of Bologna, Massachusetts Institute of Technology)

The study investigates the use of Wire-and-Arc Additive Manufacturing (WAAM) to strengthen I-beam profiles by adding ribs to areas of increased bending or load introduction. IPE 200 profiles (S 235 JR+AR steel) with a length of 200 mm served as substrates. Reinforcement strategies focused on both full and partial ribs, designed to minimize material usage while optimizing structural performance. The manufacturing process utilized a UR16e robot and a Fronius TPS 600i CMT welding system, producing layer heights of approximately 1.6 mm with copper-coated manganese steel wire and Sagox 18 shielding gas. Path planning was handled via Grasshopper3D, emphasizing flange bonding and heat management. Results demonstrated effective deformation control and flange integration, although residual stresses and minor inaccuracies in dimensional tolerances were noted (Figure 7 and Table 6).

Figure 7.

Final prototype of reinforced metal sheet. Image credit: [41] (Creative Commons CC-BY).

Table 6.

Summary of key aspects of the reinforced sheet metal project.

7.6. Adaptive Detailing (ETH Zürich)

Ariza’s doctoral research explores the use of in-place Wire Arc Additive Manufacturing for fabricating adaptive connection details in spatial structures, focusing on creating adaptable, load-bearing connections without the need for prefabrication [88,89]. The developed adaptive detailing pipeline integrates robotic fabrication, spatial awareness, and material processing techniques to dynamically adapt connection details based on real-time data, providing an innovative solution for connecting non-planar steel elements within complex geometries. The process incorporates sensing, path planning, and adaptive adjustments, enabling high customization and ensuring structural stability through precise material placement in situ. Figure 8 shows the manufacturing process and Table 7 summarizes the project’s salient aspects.

Figure 8.

Adaptative connection WAAM welding. Image credit: [65] (Creative Commons CC-BY).

Table 7.

Summary of key aspects of adaptive detailing.

7.7. Wire-Arc Facade (RMIT University)

The Wire-Arc Facade, developed by Roland Snooks and the Tectonic Formation Lab at RMIT University, illustrates an innovative use of Wire Arc Additive Manufacturing (WAAM) to produce complex facade components for architectural applications [64]. This 2021 prototype combines WAAM with prefabricated sheet metal, allowing the facade’s intricate geometries to be built efficiently by depositing molten metal directly onto fabricated steel parts. This hybrid approach leverages WAAM’s strengths in creating complex geometries while incorporating cost-effective, planar metal components. The Wire-Arc Facade represents a significant step in integrating WAAM for architectural facades, showcasing the potential for customization and reducing reliance on traditional molds. The process also required technical adaptations, such as using cold metal transfer technology, to ensure precision and minimize material waste. Figure 9 shows the manufacturing process and Table 8 summarizes the project’s salient aspects.

Figure 9.

Wire-Arc Facade connection made with WAAM, joining flat material pieces. Image credit: [64].

Table 8.

Summary of key aspects of the Wire-Arc Facade.

8. Conclusions

This review provides a detailed analysis of Wire Arc Additive Manufacturing (WAAM) as a transformative technology for architecture, emphasizing the scale and level of prototyping accomplished and the breadth of applications explored. These advancements demonstrate WAAM’s readiness for large-scale architectural use while also identifying key technical challenges that must be addressed for its broader adoption.

8.1. Advances in Prototyping Scale and Complexity

The research highlights significant progress in the scale of WAAM prototypes, with projects like the MX3D Bridge (12.5 m) showcasing its capability to produce large, free-form structures. Other notable examples include the WAAMGRID diagrid column (2 m tall), optimized trusses (2 m long), and reinforced sheet metal components, all fabricated with varying levels of complexity and precision. The diversity in prototype scales—ranging from 200 × 200 × 200 mm connection nodes to full-scale bridge elements—illustrates WAAM’s versatility across architectural applications.

These advancements in prototyping provide critical insights into WAAM’s potential for structural and nonstructural uses. Stand-alone structures like columns and trusses demonstrate its suitability for creating highly customized, structurally optimized components, while reinforcements and connectors highlight its ability to enhance existing construction systems with minimal material waste.

8.2. Architectural Applications and Categorization

This review categorizes WAAM applications into three key areas: stand-alone structures, reinforcements, and connectors. Stand-alone structures, including bridges, facade elements, and trusses, leverage WAAM’s geometric freedom and high deposition rates to deliver bespoke architectural components. Nonstructural applications, such as ornamental facade panels, further expand WAAM’s utility in realizing unique design visions.

Reinforcements, such as printed stiffening elements for metal sheets and custom steel reinforcement bars for concrete, illustrate WAAM’s capacity to improve the structural performance of standard materials. These applications combine WAAM’s customization capabilities with cost-efficiency, offering solutions tailored to specific load conditions and performance requirements.

Connection elements, such as optimized spaceframe nodes and beam-to-beam adapters, showcase WAAM’s adaptability in modular construction. By concentrating complexity in smaller, high-precision components, these applications streamline workflows and enable the integration of diverse materials and geometries in architectural design.

8.3. Technical Challenges and Limitations

Despite these advances, WAAM faces several technical challenges that constrain its scalability and reliability for architectural applications. Key issues include the following:

- Geometric Precision and Surface Quality: Achieving consistent dimensional accuracy in large-scale prototypes remains difficult due to layer-by-layer deposition errors, thermal distortion, and material shrinkage. Post-processing, such as machining or grinding, often becomes necessary, increasing costs and production times.

- Material Anisotropy: WAAM-fabricated components often exhibit anisotropic properties, with mechanical performance varying based on load direction. Advanced deposition strategies, such as tailored layer orientations and material modeling, are needed to minimize these effects and ensure uniform strength.

- Residual Stresses: The repeated heating and cooling cycles during WAAM can introduce residual stresses, leading to warping and reduced structural integrity. Improved thermal control systems and post-deposition treatments are essential to mitigate these effects without compromising material properties.

- Process Monitoring and Control: Real-time feedback mechanisms for monitoring deposition quality, thermal conditions, and layer alignment are still underdeveloped. Enhancements in process automation and adaptive control will be critical for ensuring consistent quality at scale.

- Economic Viability: While WAAM can potentially excel in producing bespoke, high-performance components, its cost-effectiveness is unclear and cost information in the literature is scarce. Reducing energy consumption, material waste, and production time will be necessary to improve its market viability.

8.4. A Path Forward for WAAM in Architecture

The demonstrated ability of WAAM to fabricate components at construction-relevant scales positions it as a promising technology for both bespoke and standardized architectural applications. Projects like the MX3D Bridge and WAAMGRID column confirm its potential for producing functional, large-scale structures, while smaller prototypes, such as connection nodes and reinforcements, showcase its precision and adaptability.

Future research should focus on overcoming the outlined technical challenges through multidisciplinary collaboration. Integrating advanced computational design tools with WAAM processes will enhance workflow efficiency, while real-world testing will provide the performance data needed for regulatory acceptance. Additionally, sustainable practices, such as energy-efficient production and recycling of feedstock materials, should be prioritized to align WAAM with global construction sustainability goals.

WAAM has proven itself as a versatile and scalable technology for architecture, capable of addressing a wide range of structural and nonstructural needs. However, its full integration into construction practices will depend on resolving key technical challenges and demonstrating its cost-effectiveness across diverse applications. By advancing the scale and complexity of prototypes while addressing material and process limitations, WAAM can establish itself as a cornerstone of innovative and sustainable construction.

Author Contributions

Conceptualization, F.R., E.V. and M.P.; methodology, F.R.; investigation, F.R., E.V., P.B., M.P. and M.C.; data curation, F.R. and M.C.; writing—original draft preparation, F.R.; writing—review and editing, F.R., E.V., P.B., M.P. and M.C.; supervision, F.R.; project administration, F.R. and S.A.; funding acquisition, F.R. All authors have read and agreed to the published version of the manuscript.

Funding

This Project was funded by the ANID Chile, through the grant Fondecyt 1230737. Additional funding comes from Aldolfo Ibáñez University’s Fondo Puente.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- The British Standards Institution. Additive Manufacturing. Wire Arc Guide-PAS 6012:2020. 2020. Available online: https://www.bsigroup.com/en-GB/insights-and-media/insights/brochures/pas-6012-additive-manufacturing/ (accessed on 30 November 2024).

- Saleh, B.; Fathi, R.; Tian, Y.; Radhika, N.; Jiang, J.; Ma, A. Fundamentals and advances of wire arc additive manufacturing: Materials, process parameters, potential applicatsions, and future trends. Arch. Civ. Mech. Eng. 2023, 23, 96. [Google Scholar] [CrossRef]

- Müller, J.; Hensel, J.; Dilger, K. Mechanical properties of wire and arc additively manufactured high-strength steel structures. Weld. World 2022, 66, 395–407. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Y.; Ge, Y.; Hou, Z.; Chen, S. Wire and arc additive manufacturing of metal components: A review of recent research developments. Int. J. Adv. Manuf. Technol. 2020, 111, 149–198. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A Review of the Recent Developments and Challenges in Wire Arc Additive Manufacturing (WAAM) Process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Huang, L.; Chen, X.; Konovalov, S.; Su, C.; Fan, P.; Wang, Y.; Xiaoming, P.; Panchenko, I. A Review of Challenges for Wire and Arc Additive Manufacturing (WAAM). Trans. Indian Inst. Met. 2023, 76, 1123–1139. [Google Scholar] [CrossRef]

- Raut, L.P.; Taiwade, R.V. Wire Arc Additive Manufacturing: A Comprehensive Review and Research Directions. J. Mater. Eng. Perform. 2021, 30, 4768–4791. [Google Scholar] [CrossRef]

- Wiltgen, F. Prototypes Are Important. |Transformations/Transformacje|EBSCOhost. Available online: https://openurl.ebsco.com/contentitem/gcd:162314538?sid=ebsco:plink:crawler&id=ebsco:gcd:162314538 (accessed on 23 September 2024).

- Costanzi, C.B.; Waldschmitt, B.; Knaack, U.; Lange, J. Transforming the Construction Industry Through Wire Arc Additive Manufacturing. In Coding Architecture: Designing Toolkits, Workflows, Industry; Ruttico, P., Ed.; Springer Nature: Cham, Switzerland, 2024; pp. 213–238. ISBN 978-3-031-47913-7. [Google Scholar]

- Evans, S.I.; Wang, J.; Qin, J.; He, Y.; Shepherd, P.; Ding, J. A review of WAAM for steel construction—Manufacturing, material and geometric properties, design, and future directions. Structures 2022, 44, 1506–1522. [Google Scholar] [CrossRef]

- Kühne, R.; Feldmann, M.; Citarelli, S.; Reisgen, U.; Sharma, R.; Oster, L. 3D printing in steel construction with the automated Wire Arc Additive Manufacturing. ce/papers 2019, 3, 577–583. [Google Scholar] [CrossRef]

- Laghi, V.; Gasparini, G. Explorations of efficient design solutions for Wire-and-Arc Additive manufacturing in construction. Structures 2023, 56, 104883. [Google Scholar] [CrossRef]

- Pan, A.; Lai, W.; Bernal, S.; Chaudhary, K.; Zhou, H.; Ridings, A.; Yin, H. A Literature Review of WAAM and Future Application in Buildings. Available online: https://www.researchgate.net/profile/Hongxi-Yin/publication/371289398_A_Literature_Review_of_WAAM_and_Future_Application_in_Buildings/links/64e52c8e40289f7a0fad2d72/A-Literature-Review-of-WAAM-and-Future-Application-in-Buildings.pdf (accessed on 24 September 2024).

- Bañón, C.; Raspall, F. 3D Printing Architecture: Workflows, Applications, and Trends, SpringerLink. Available online: https://link.springer.com/book/10.1007/978-981-15-8388-9 (accessed on 3 September 2023).

- Rael, R.; Fratello, V.S. Printing Architecture: Innovative Recipes for 3D Printing; Chronicle Books: San Francisco, CA, USA, 2018; ISBN 978-1-61689-747-5. [Google Scholar]

- van Woensel, R.N.P.; van Oirschot, T.; Burgmans, M.J.H.; Mohammadi, M.; Hermans, K. Printing Architecture: An overview of existing and promising additive manufacturing methods and their application in the building industry. Int. J. Constr. Environ. 2018, 9, 57–81. [Google Scholar] [CrossRef]

- Wu, Z.; Memari, A.M.; Duarte, J.P. State of the Art Review of Reinforcement Strategies and Technologies for 3D Printing of Concrete. Energies 2022, 15, 360. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A review of the current progress and application of 3D printed concrete. Compos. Part. Appl. Sci. Manuf. 2019, 125, 105533. [Google Scholar] [CrossRef]

- Asaf, O.; Bentur, A.; Larianovsky, P.; Sprecher, A. From soil to printed structures: A systematic approach to designing clay-based materials for 3D printing in construction and architecture. Constr. Build. Mater. 2023, 408, 133783. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Mohamed, H.; Bao, D.W.; Snooks, R. Super Composite: Carbon Fibre Infused 3D Printed Tectonics. In Proceedings of the Proceedings of the 2020 DigitalFUTURES; Yuan, P.F., Yao, J., Yan, C., Wang, X., Leach, N., Eds.; Springer: Singapore, 2021; pp. 297–308. [Google Scholar]

- Raspall, F.; Bañón, C. Large-Scale 3D Printing Using Recycled PET. The Case of Upcycle Lab @ DB Schenker Singapore. In Hybrid Intelligence; Yuan, P.F., Chai, H., Yan, C., Li, K., Sun, T., Eds.; Springer Nature: Singapore, 2023; pp. 432–442. [Google Scholar]

- Shakor, P.; Chu, S.H.; Puzatova, A.; Dini, E. Review of binder jetting 3D printing in the construction industry. Prog. Addit. Manuf. 2022, 7, 643–669. [Google Scholar] [CrossRef]

- Singh, L.I.; Sachidananda, K. Metal Additive Manufacturing Technique in Construction Industry: A Review Paper. In Recent Advances in Materials; Swain, B.P., Ed.; Springer Nature: Singapore, 2023; pp. 31–42. [Google Scholar]

- Capasso, I.; Andreacola, F.R.; Brando, G. Additive Manufacturing of Metal Materials for Construction Engineering: An Overview on Technologies and Applications. Metals 2024, 14, 1033. [Google Scholar] [CrossRef]

- Müller, J.; Hensel, J. WAAM of structural components-Building strategies for varying wall thicknesses. Weld. World 2023, 67, 833–844. [Google Scholar] [CrossRef]

- The Innovation in wire arc additive manufacturing (WAAM): A review. Available online: https://mrforum.com/product/9781644902592-54/ (accessed on 31 October 2024).

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.-G.; Lee, J.-H.; Zhang, J. Additive Manufacturing of Metallic Materials: A Review. J. Mater. Eng. Perform. 2018, 27, 1–13. [Google Scholar] [CrossRef]

- Joshi, S.; Martukanitz, R.P.; Nassar, A.R.; Michaleris, P. Metal Additive Manufacturing Processes—Directed Energy Deposition Processes. In Additive Manufacturing with Metals: Design, Processes, Materials, Quality Assurance, and Applications; Joshi, S., Martukanitz, R.P., Nassar, A.R., Michaleris, P., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 111–150. ISBN 978-3-031-37069-4. [Google Scholar]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Hassan, H.; Rodriguez-Ubinas, E.; Al Tamimi, A.; Trepci, E.; Mansouri, A.; Almehairbi, K. Towards innovative and sustainable buildings: A comprehensive review of 3D printing in construction. Autom. Constr. 2024, 163, 105417. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Gardner, L. Metal additive manufacturing in structural engineering-Review, advances, opportunities and outlook. Structures 2023, 47, 2178–2193. [Google Scholar] [CrossRef]

- Paul, C.; Nath, D.; Tobber, L.; Benoit, M. Review of Opportunities and Challenges for Additive Manufacturing of Steels in the Construction Industry. Adv. Civ. Eng. Mater. 2024, 13, 232–247. [Google Scholar] [CrossRef]

- Kanyilmaz, A.; Demir, A.G.; Chierici, M.; Berto, F.; Gardner, L.; Kandukuri, S.Y.; Kassabian, P.; Kinoshita, T.; Laurenti, A.; Paoletti, I.; et al. Role of metal 3D printing to increase quality and resource-efficiency in the construction sector. Addit. Manuf. 2022, 50, 102541. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Pant, H.; Arora, A.; Gopakumar, G.S.; Chadha, U.; Saeidi, A.; Patterson, A.E. Applications of wire arc additive manufacturing (WAAM) for aerospace component manufacturing. Int. J. Adv. Manuf. Technol. 2023, 127, 4995–5011. [Google Scholar] [CrossRef]

- Mishra, V.; Babu, A.; Schreurs, R.; Wu, K.; Hermans, M.J.M.; Ayas, C. Microstructure estimation and validation of ER110S-G. steel structures produced by wire and arc additive manufacturing. J. Mater. Res. Technol. 2023, 23, 3579–3601. [Google Scholar] [CrossRef]

- Dai, P.; Li, A.; Zhang, J.; Chen, R.; Luo, X.; Wen, L.; Wang, C.; Lv, X. Research Status and Development Trend of Wire Arc Additive Manufacturing Technology for Aluminum Alloys. Coatings 2024, 14, 1094. [Google Scholar] [CrossRef]

- Borg Costanzi, C. Reinforcing and Detailing of Thin Sheet Metal Using Wire Arc Additive Manufacturing as an Application in Facades; Mechanik, Werkstoffe und Konstruktion im Bauwesen; Springer Fachmedien: Wiesbaden, Germany, 2023; Volume 68, ISBN 978-3-658-41539-6. [Google Scholar]

- Ayed, A.; Valencia, A.; Bras, G.; Bernard, H.; Michaud, P.; Balcaen, Y.; Alexis, J. Effects of WAAM Process Parameters on Metallurgical and Mechanical Properties of Ti-6Al-4V Deposits. In Advances in Materials, Mechanics and Manufacturing; Chaari, F., Barkallah, M., Bouguecha, A., Zouari, B., Khabou, M.T., Kchaou, M., Haddar, M., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 26–35. [Google Scholar]

- Manjhi, S.K.; Sekar, P.; Bontha, S.; Balan, A.S.S. Effect of CMT-WAAM Process Parameters on Bead Geometry, Microstructure and Mechanical Properties of AZ31 Mg Alloy. J. Mater. Eng. Perform. 2024, 33, 8567–8581. [Google Scholar] [CrossRef]

- Mirabi, H.; Mirakhorli, F.; Béland, J.-F.; Nadeau, F.; Demers, V.; Bocher, P. On selecting proper process parameters for cold metal transfer (CMT)–based wire arc additive manufacturing (WAAM) process. Int. J. Adv. Manuf. Technol. 2024, 133, 6083–6093. [Google Scholar] [CrossRef]

- Gurmesa, F.D.; Lemu, H.G.; Adugna, Y.W.; Harsibo, M.D. Residual Stresses in Wire Arc Additive Manufacturing Products and Their Measurement Techniques: A Systematic Review. Appl. Mech. 2024, 5, 420–449. [Google Scholar] [CrossRef]

- Li, B.; Nagaraja, K.M.; Zhang, R.; Malik, A.; Lu, H.; Li, W. Integrating robotic wire arc additive manufacturing and machining: Hybrid WAAM machining. Int. J. Adv. Manuf. Technol. 2023, 129, 3247–3259. [Google Scholar] [CrossRef]

- Li, Y.; Su, C.; Zhu, J. Comprehensive review of wire arc additive manufacturing: Hardware system, physical process, monitoring, property characterization, application and future prospects. Results Eng. 2022, 13, 100330. [Google Scholar] [CrossRef]

- Leschok, M.; Cheibas, I.; Piccioni, V.; Seshadri, B.; Schlüter, A.; Gramazio, F.; Kohler, M.; Dillenburger, B. 3D printing facades: Design, fabrication, and assessment methods. Autom. Constr. 2023, 152, 104918. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Campatelli, G.; Montevecchi, F.; Venturini, G.; Ingarao, G.; Priarone, P.C. Integrated WAAM-Subtractive Versus Pure Subtractive Manufacturing Approaches: An Energy Efficiency Comparison. Int. J. Precis. Eng. Manuf. Green. Technol. 2020, 7, 1–11. [Google Scholar] [CrossRef]

- Barath Kumar, M.D.; Manikandan, M. Assessment of Process, Parameters, Residual Stress Mitigation, Post Treatments and Finite Element Analysis Simulations of Wire Arc Additive Manufacturing Technique. Met. Mater. Int. 2022, 28, 54–111. [Google Scholar] [CrossRef]

- Pasco, J.; Lei, Z.; Aranas, C. Additive Manufacturing in Off-Site Construction: Review and Future Directions. Buildings 2022, 12, 53. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.-T.; Minh, P.S.; Uyen, T.M.T.; Do, T.T.; Ngoc, H.V.T.; Le, M.-T.; Tien Nguyen, V.T. WAAM Technique: Process Parameters Affecting the Mechanical Properties and Microstructures of Low-Carbon Steel. Metals 2023, 13, 873. [Google Scholar] [CrossRef]

- Ovako S235JR EN10025-2 (ref) Steel, +AR. Available online: https://www.matweb.com/search/datasheet.aspx?matguid=ffc482278e2e4dc780572160dcada3d1 (accessed on 27 December 2024).

- Weber, B.; Meng, X.; Zhang, R.; Nitawaki, M.; Sagawa, T.; Gardner, L. Tensile behaviour of WAAM high strength steel material and members. Mater. Des. 2024, 237, 112517. [Google Scholar] [CrossRef]

- Kyvelou, P.; Huang, C.; Gardner, L.; Buchanan, C. Structural Testing and Design of Wire Arc Additively Manufactured Square Hollow Sections. J. Struct. Eng. 2021, 147, 04021218. [Google Scholar] [CrossRef]

- Xin, H.; Tarus, I.; Cheng, L.; Veljkovic, M.; Persem, N.; Lorich, L. Experiments and numerical simulation of wire and arc additive manufactured steel materials. Structures 2021, 34, 1393–1402. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Ajith, J.; Fathima Yasin Fahmidha, A.; Jagadeesha, T.; Sathish, T.; Stalin, B. Wire Arc Additive Manufacturing (WAAM) process of nickel based superalloys—A review. Mater. Today Proc. 2020, 21, 920–925. [Google Scholar] [CrossRef]

- Wächter, M.; Leicher, M.; Hupka, M.; Leistner, C.; Masendorf, L.; Treutler, K.; Kamper, S.; Esderts, A.; Wesling, V.; Hartmann, S. Monotonic and Fatigue Properties of Steel Material Manufactured by Wire Arc Additive Manufacturing. Appl. Sci. 2020, 10, 5238. [Google Scholar] [CrossRef]

- Joosten, S.K. Printing a Stainless Steel Bridge: An Exploration of Structural Properties of Stainless Steel Additive Manufactures for Civil Engineering Purposes. 2015. Available online: https://repository.tudelft.nl/islandora/object/uuid%3Ab4286867-9c1c-40c1-a738-cf28dd7b6de5 (accessed on 9 June 2022).

- Laghi, V.; Palermo, M.; Gasparini, G.; Trombetti, T. Computational design and manufacturing of a half-scaled 3D-printed stainless steel diagrid column. Addit. Manuf. 2020, 36, 101505. [Google Scholar] [CrossRef]

- Ye, J.; Kyvelou, P.; Gilardi, F.; Lu, H.; Gilbert, M.; Gardner, L. An End-to-End Framework for the Additive Manufacture of Optimized Tubular Structures. IEEE Access 2021, 9, 165476–165489. [Google Scholar] [CrossRef]

- Feucht, T.; Waldschmitt, B.; Lange, J.; Erven, M. Additive manufacturing of a bridge in situ. Steel Constr. 2022, 15, 100–110. [Google Scholar] [CrossRef]

- Snooks, R. Behavioral tectonics: AgentBody prototypes and the compression of tectonics. Archit. Intell. 2022, 1, 9. [Google Scholar] [CrossRef]

- Silvestru, V.-A.; Ariza, I.; Taras, A. Structural behaviour of point-by-point wire arc additively manufactured steel bars under compressive loading. J. Constr. Steel Res. 2023, 207, 107982. [Google Scholar] [CrossRef]

- Waldschmitt, B.; Costanzi, C.B.; Knaack, U.; Lange, J. 3d printing of column structures for architectural applications. Archit. Struct. Constr. 2022, 2, 565–574. [Google Scholar] [CrossRef]

- LAGHI, V. WAAMGRID: Digital design and fabrication framework for wire-and-arc additive manufactured diagrid lattice structures. Built Environ. Addit. Manuf. 2022, 202, 61–67. [Google Scholar]

- Waldschmitt, B.; Lange, J. Robot supported Wire Arc Additive Manufacturing of Steel Columns. ce/papers 2023, 6, 696–701. [Google Scholar] [CrossRef]

- Evans, S.; Xu, F.; Wang, J. Experimental Study on the Local Buckling Response of WAAM Stainless Steel Square Hollow Sections. ce/papers 2023, 6, 684–689. [Google Scholar] [CrossRef]

- MX3D. Lunar Floor for ESA. Available online: https://mx3d.com/industries/construction/lunar-floor-for-esa/ (accessed on 4 December 2024).

- Zhang, H.; Huang, J.; Liu, C.; Ma, Y.; Han, Y.; Xu, T.; Lu, J.; Fang, H. Fabricating Pyramidal Lattice Structures of 304 L Stainless Steel by Wire Arc Additive Manufacturing. Materials 2020, 13, 3482. [Google Scholar] [CrossRef]

- Baglivo, L.; Avallone, G.; Caso, M.; D’Arcangelo, S.; Benni, A.A.; Laghi, V.; Arrè, L.; Gasparini, G.; Palermo, M.; Petrò, S.; et al. Design and prototyping wire arc additively manufactured aluminum alloy lattice structures. Int. J. Adv. Manuf. Technol. 2024, 135, 3747–3764. [Google Scholar] [CrossRef]

- Laghi, V. <1992> Study of Innovative Steel 3D-Printing Process for Structural Engineering Applications. Ph.D. Thesis, Alma Mater Studiorum-Università di Bologna, Bologna, Italy, 2021. [Google Scholar]

- Elhamy, A.A.; Elselmy, R. Computational Design and Fabrication Strategy for Topology Optimization of Spiral Staircase Using Metal Wire Arc Additive Manufacturing. Nexus Netw. J. 2024, 26, 397–408. [Google Scholar] [CrossRef]

- Baqershahi, M.H.; Ayas, C.; Ghafoori, E. Design optimisation for hybrid metal additive manufacturing for sustainable construction. Eng. Struct. 2024, 301, 117355. [Google Scholar] [CrossRef]

- Kloft, H.; Schmitz, L.P.; Müller, C.; Laghi, V.; Babovic, N.; Baghdadi, A. Experimental Application of Robotic Wire-and-Arc Additive Manufacturing Technique for Strengthening the I-Beam Profiles. Buildings 2023, 13, 366. [Google Scholar] [CrossRef]

- Borg Costanzi, C. Proposed Hybrid WAAM and Thin Sheet Metal Welding. In Reinforcing and Detailing of Thin Sheet Metal Using Wire Arc Additive Manufacturing as an Application in Facades; Borg Costanzi, C., Ed.; Springer Fachmedien: Wiesbaden, Germany, 2023; pp. 99–172. ISBN 978-3-658-41540-2. [Google Scholar]

- Grebner, P.; Lange, J. 3D-printing with steel on thin sheets for application in free form façade construction: Welding process development and material properties. ce/papers 2023, 6, 666–671. [Google Scholar] [CrossRef]

- Müller, J.; Grabowski, M.; Müller, C.; Hensel, J.; Unglaub, J.; Thiele, K.; Kloft, H.; Dilger, K. Design and Parameter Identification of Wire and Arc Additively Manufactured (WAAM) Steel Bars for Use in Construction. Metals 2019, 9, 725. [Google Scholar] [CrossRef]

- Dörrie, R.; Freund, N.; Herrmann, E.; Baghdadi, A.; Mai, I.; Galli, F.; David, M.; Dröder, K.; Lowke, D.; Kloft, H. Automated force-flow-oriented reinforcement integration for Shotcrete 3D Printing. Autom. Constr. 2023, 155, 105075. [Google Scholar] [CrossRef]

- Hack, N.; Bahar, M.; Hühne, C.; Lopez, W.; Gantner, S.; Khader, N.; Rothe, T. Development of a Robot-Based Multi-Directional Dynamic Fiber Winding Process for Additive Manufacturing Using Shotcrete 3D Printing. Fibers 2021, 9, 39. [Google Scholar] [CrossRef]

- Straßer, A.; Riegger, F.; Hamilton, L.D.; Kränkel, T.; Gehlen, C.; Zaeh, M.F.; Kwade, A. Selective Paste Intrusion: Integration of reinforcement by WAAM-Concept and current research with special attention to cooling strategies. Constr. Build. Mater. 2023, 406, 133236. [Google Scholar] [CrossRef]

- Binder, J.; Pazdon, J.; Fetuga, R.; De Oliveira, C.; Villamarin, B. Achieving Elegant and Efficient Geometry in Architectural Frames with Casting Technology and Advanced Manufacturing: Day’s End Project Case Study. Proc. IASS Annu. Symp. 2020, 2020, 1–11. [Google Scholar]

- Feucht, T.; Lange, J. 3-D-printing with steel: Additive manufacturing of connection elements. In Advances in Engineering Materials, Structures and Systems: Innovations, Mechanics and Applications; CRC Press: Boca Raton, FL, USA, 2019; ISBN 978-0-429-42650-6. [Google Scholar]

- Guo, X.; Kyvelou, P.; Ye, J.; Gardner, L. Experimental investigation of wire arc additively manufactured steel T-stub connections. J. Constr. Steel Res. 2023, 211, 108106. [Google Scholar] [CrossRef]

- Guo, X.; Kyvelou, P.; Ye, J.; Teh, L.H.; Gardner, L. Experimental investigation of wire arc additively manufactured steel single-lap shear bolted connections. Thin Walled Struct. 2022, 181, 110029. [Google Scholar] [CrossRef]

- MX3D. Connector for Takenaka. Available online: https://mx3d.com/industries/construction/connector-for-takenaka/ (accessed on 24 September 2024).

- Ariza, I. Adaptive Detailing: Design and Fabrication Methods for In Place Wire and Arc Additive Manufacturing Connection Details. Ph.D. Thesis, ETH Zurich, Zürich, Switzerland, 2022. [Google Scholar]

- Ariza, I.M. In Place Detailing. Combining 3D printing and robotic assembly. In ACADIA//2018: Recalibration. On imprecisionand infidelity. In Proceedings of the 38th Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA), Mexico City, Mexico, 18–20 October 2018; pp. 312–321. [Google Scholar]

- Erven, M. 3D-Printed Steel Nodes. Architecture; AADR-Art Architecture Design Research. 2023. Available online: https://aadr.info/product/print-architecture/ (accessed on 30 October 2024).

- Erven, M.; Lange, J. Design of optimized 3D-printed steel nodes. In Structures and Architecture A Viable Urban Perspective? CRC Press: Boca Raton, FL, USA, 2022; pp. 229–236. [Google Scholar]

- Reimann, J.; Henckell, P.; Ali, Y.; Hammer, S.; Rauch, A.; Hildebrand, J.; Bergmann, J.P. Production of Topology-optimised Structural Nodes Using Arc-based, Additive Manufacturing with GMAW Welding Process. J. Civ. Eng. Constr. 2021, 10, 101–107. [Google Scholar] [CrossRef]

- Petrescu, T.-C.; Voordijk, J.T.; Mihai, P. Developing a TRL-oriented roadmap for the adoption of biocomposite materials in the construction industry. Front. Eng. Manag. 2023, 10, 223–236. [Google Scholar] [CrossRef]

- MX3D Smart Bridge. Available online: https://mx3d.com/ (accessed on 12 May 2022).

- Gardner, L.; Kyvelou, P.; Herbert, G.; Buchanan, C. Testing and initial verification of the world’s first metal 3D printed bridge. J. Constr. Steel Res. 2020, 172, 106233. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).