Abstract

To apply the cementitious capillary crystalline waterproof materials (CCCWs) in real engineering practice, the mechanical properties and related mechanism of cement after adding CCCW are investigated in this study. By using a combination of techniques including X-ray diffraction, Fourier-transform infrared spectroscopy, thermogravimetric analysis, scanning electron microscopy, and mercury intrusion porosimetry, the effect of Penetron (PNC, a kind of CCCW) content on the microstructure and compressive strength of cement with different water-to-bind (w/b) ratio were studied. The results show that the high-water content definitely decreased the mechanical properties of cement pastes. The addition of PNC appeared to play a detrimental role in the 7 d compressive strength due to the lower reactivity of PNC than cement. As the PNC content increased from 0% to 1.5%, the 28 d compressive strength of cement pastes increased despite the w/b ratio. For cement pastes with a w/b ratio of 0.50, its 28 d compressive strength increased from 24.6 MPa to 32.9 MPa. This can be attributed to the sulfate/carbonate-containing species in PNC to react with cement to form suitable ettringite. Consequently, the microstructure became denser, and porosity decreased. As PNC content increased to a further 2.5%, the compressive strength of cement pastes decreased gradually. The excessive PNC caused the excess ettringite, which destroyed the microstructure and increased the porosity of cement pastes. This study demonstrated that the PNC and its dosage affected the microstructure and the mechanical properties of cement paste. Suitable content, normally 1.5%, is recommended to apply in cement paste considering the mechanical properties despite the w/b ratio.

1. Introduction

As a stable and low-cost cementitious material, ordinary Portland cement (OPC) has become the most commonly used construction material since its invention in 1824 [1,2]. After mixing with aggregates to prepare concrete, it can be applied on bridges, infrastructures, buildings, etc., [3]. Despite that, OPC still faces many challenges, like large environmental footprint and insufficient properties when applying specific fields [4,5,6]. Notably, concrete prepared from hydrated cement is a porous and heterogeneous material, which easily suffers from penetration with water or other chemical species, causing the reduced durability and service life of related structures and finally, threatening our property and life [7,8]. It has been widely reported that water seepage of many concrete-based roads and tunnels caused significant disasters [9,10]. Therefore, alleviating the leakage of concrete is very important to maintain the high quality of structures.

In fact, many measurements have been taken to improve the water-resistance properties of cement or concrete, including coating with a hydrophobic agent, covering with waterproof rolling materials, and sealing with bitumen [11]. Although these methods have been applied in the engineering field, the role played by waterproof materials is largely dependent on the interaction effect between waterproof materials and concrete surfaces by these means. The easy degradation of the adhesive force between materials and concrete caused the failure of waterproofing [12]. Therefore, it is of great interest to find a kind of waterproof material that can interact with concrete inside.

Recently, a kind of rigid waterproof material called cementitious capillary crystalline waterproof material (CCCW) attracted more attention [13,14,15]. The CCCW has been applied to the construction field by coating due to its long-term waterproofing and environmentally friendly [16,17]. The strong interaction between CCCW and concrete provides a longer service life and shorter construction period for CCCW than waterproofing rolling materials. In addition to the water-resistance properties, it is also reported that the gas permeability, carbonation resistance, and reduced chloride diffusion are also improved [18,19,20] after coating with CCCW. However, compared with coating, adding the CCCW directly into fresh cement/concrete pastes appears to be more convenient construction and superior performance. It has been reported that the durability of concrete was improved through the processes of permeation and crystallization after incorporation of CCCW [21,22,23]. It has been widely reported that nanocomposite CCCW can help to improve the healing performance of cement mortar [24]. Fan et al. [25] added CCCW into mortar to compensate for the bad impermeability caused by rice husk, successfully.

Although the aim of the addition of CCCW into concrete is for waterproofing improvement, its mechanical properties are inevitably influenced. For example, Zheng et al. [7] found that the incorporation of CCCW into cement-gravel concrete decreased its setting time and increased its compressive strength, which is in proportion to the increased CCCW content. In contrast, Hodul et al. [26] found that 1.6% of CCCW decreased the compressive strength by 3.5%. Therefore, the addition of CCCW will play both positive and detrimental roles in the mechanical properties of cement, depending on the CCCW types, water content, concrete types, etc., [27].

On the other hand, compared with CCCW, which consists of sodium silicate, sodiumaluminate, and glycine [25], the CCCW prepared using cement, fine quartz sand, and other auxiliary materials appears to be greener and cheaper [28], which is beneficial to the widespread application. Furthermore, it is well-known that the water-binder ratio (w/b) is one of the most important factors influencing the fresh and hardened properties of cement and concrete [29,30]. Normally, higher w/b ratio leads to better flowability, but higher porosity and lower compressive strength. In different application fields, various w/b ratios are used to adjust the fresh and hardened properties of cement or concrete to fit its application. For instance, self-leveling concrete requires high w/b ratio by scarifying the compressive strength [31]. In this situation, it is essential to improve its waterproofing properties. Therefore, there must be different optimal dosages for different w/b ratios of cement paste, and thus the reaction mechanism between CCCW and cement also warrants research. Meanwhile, adjusting suitable content of CCCW in concrete, both for anti-permeability performance and mechanical properties, is necessary.

In this study, a kind of CCCW was added into cement with various w/b. The physical and chemical properties of CCCW was studied and its effect on the mechanical properties and microstructure of cement pastes was also investigated. X-ray diffraction (XRD), Fourier-transform infrared (FTIR) spectroscopy, Scanning Electron Microscopy/Energy Dispersive X-ray Spectroscopy (SEM/EDX), and Mercury Intrusion Porosimetry (MIP) were employed to identify the reaction mechanism between CCCW and cement. The aim of this study is to clarify the role of CCCW in cement paste, which promotes the application of low-cost CCCW in civil engineering. The mechanism study also plays a fundamental role in understanding the water-proofing properties of cement.

2. Experimental

2.1. Materials

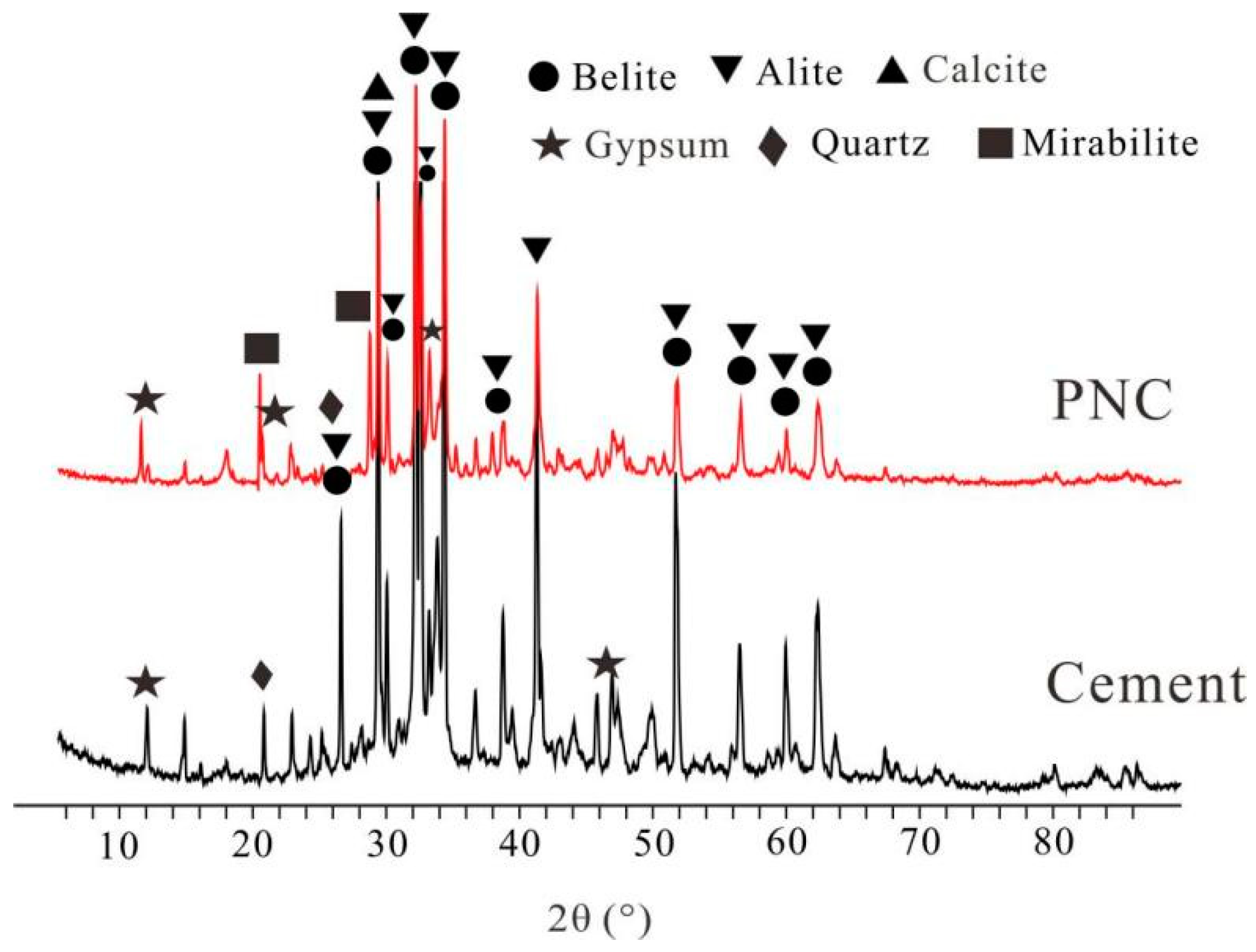

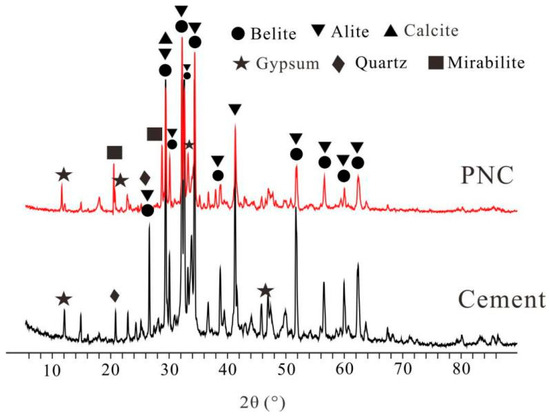

A kind of cementitious capillary crystalline waterproof material, named as PNC, and cement (P.O 42.5) were purchased from suppliers. Table 1 and Figure 1 present the chemical composition and mineralogical composition of cement and PNC. Obviously, cement mainly consisted of CaO and SiO2, accounting for 80.39% of total content because the main mineral composition of cement was tricalcium silicate (C3S), tricalcium aluminate (C3A), and dicalcium silicate (C2S) (Figure 1). These minerals can be hydrated after contact with water.

Table 1.

Chemical composition of CCCWs and cement. Values are percentages.

Figure 1.

XRD patterns of cement and PNC.

Interestingly, PNC also contained high content of CaO (51.43%), followed by the SiO2 (14.92%) and Na2O (8.45%). Notably, the proportion of loss on ignition (L.O.I) for PNC reached 12.62%, indicating that there are many thermal instable species, like water (including OH-), calcite, or/and organic species in PNC (Table 1). Meanwhile, XRD patterns of PNC showed that PNC also contained belite (PDF 53-0890), alite (PDF 50-1653), and gypsum (PDF 41-1451), which were the main component of cement. However, there was no quartz in PNC according to the absence of diffraction of quartz in its XRD pattern. In addition, the diffraction attributed to mirabilite (PDF 11-0647) was also found, indicating the presence of Na2SO4 in PNC.

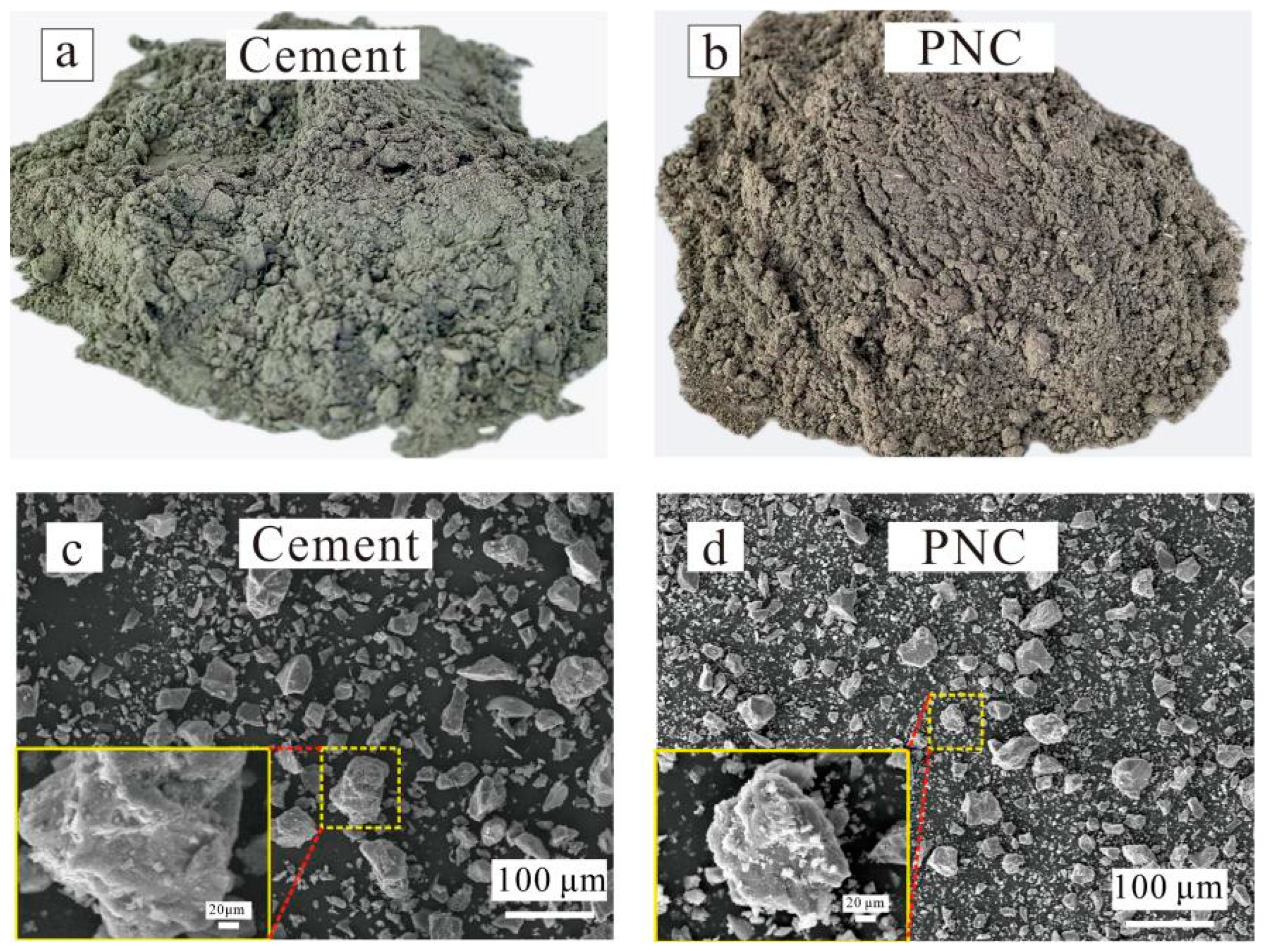

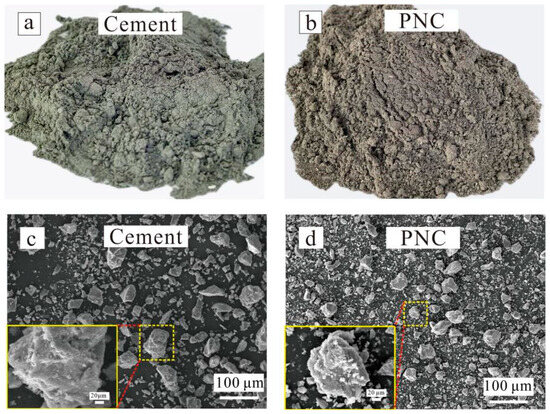

Photography and SEM images of raw materials were shown in Figure 2. It can be observed that the cement showed darker color than PNC (Figure 2a,b), which likely resulted from the organic species. In SEM images, both cement and PNC possesses irregular and angular particles with different sizes.

Figure 2.

Photo of (a) cement, (b) PNC, and SEM images of (c) cement, (d) PNC.

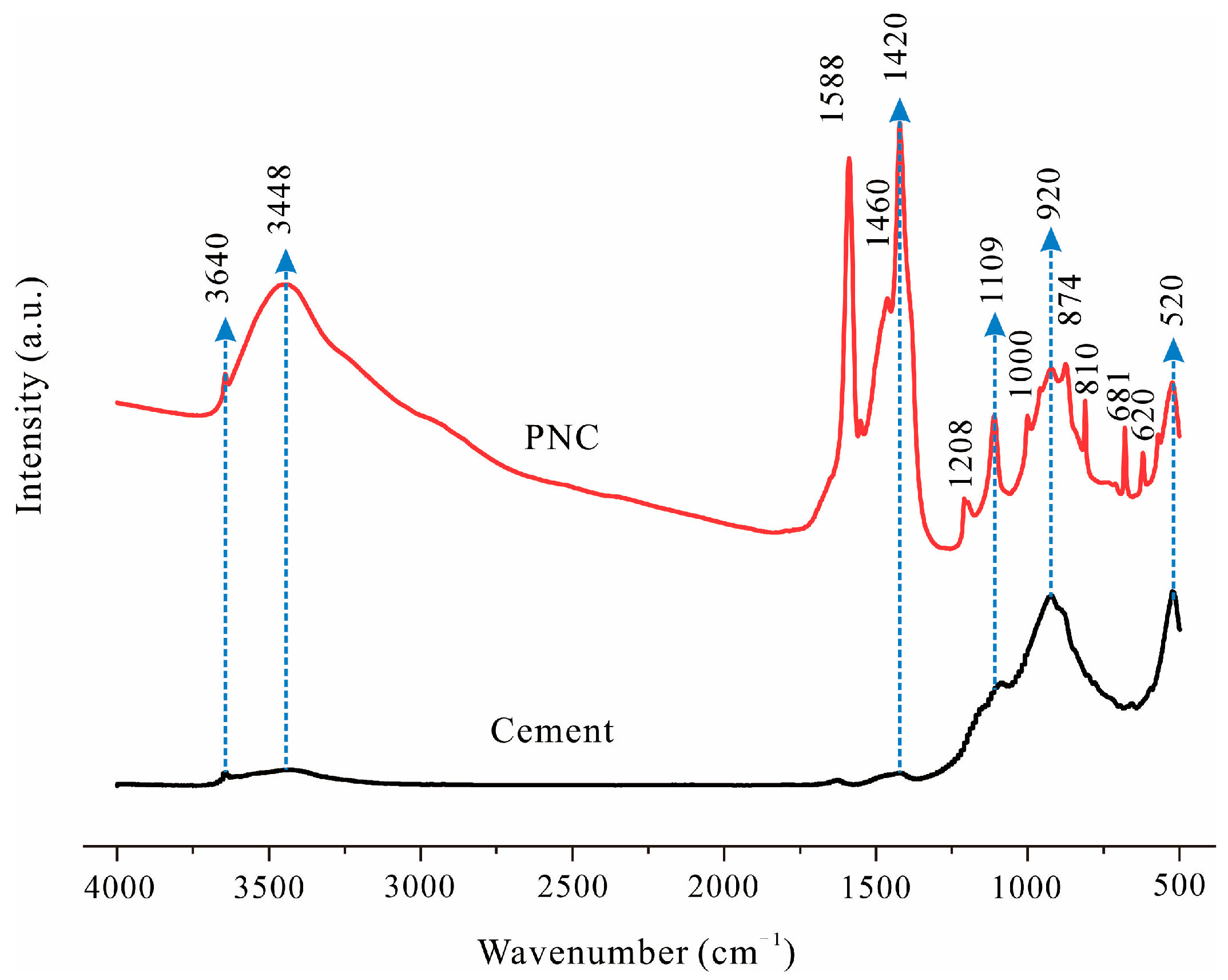

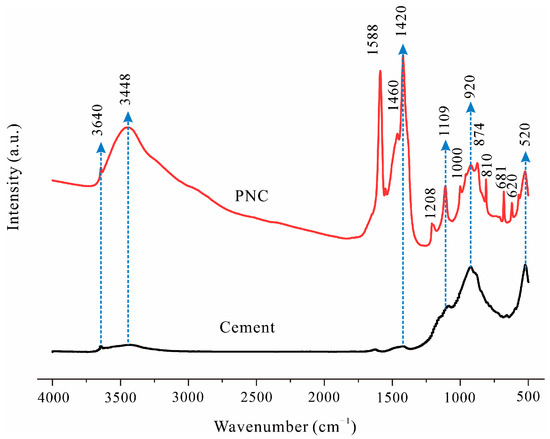

Figure 3 shows the FTIR spectra of cement and PNC. A small absorption band at 3640 cm−1 in the FTIR spectrum of cement was attributed to symmetric stretching vibration of the Ca-OH bond [32], indicating the slight hydration of cement as it was placed in ambient environment. The small band located at 1107 cm−1 was attributed to the stretching vibration S-O (SO42−) from gypsum in cement [33,34]. The absorption band located at approximately 920 cm−1 was attributable to the asymmetric stretching of Si-O in tricalcium silicate (alite, C3S, i.e., 3CaO·SiO2) or dicalcium silicate (belite, C2S, i.e., 2CaO·SiO2). Additionally, the absorption band at 520 cm−1 was attributable to out-of-plane bending of Si-O [35].

Figure 3.

FTIR spectra of cement and PNC.

Notably, although PNC show little diffraction difference from cement, their FTIR spectra shows quite difference. There are many sharp peaks observed in the FTIR spectra of PNC, where 1588 cm−1 should be attributed to stretching vibration of C=N [36]. A sharp peak located at 1420 cm−1 and 874 cm−1 should be attributed to the C-O asymmetric stretching vibration and CO32− deformation vibration of calcite, respectively [37,38]. This result confirmed that there are many CaCO3 in PNC, which can partially explain the high content of LOI. In addition, the absorption at 1208 cm−1 was attributed to Sulfonate group (OSO2) [39]. The bands at 1109 cm−1, 810 cm−1, and 681 cm−1 were assigned to Q3, Q1 type Si-O bonds and bending vibration of SiO4 [40]. The OH and CH out-of-plane bending can be observed in the range of 500–700 cm−1 [41]. The above FTIR spectra demonstrated that some organic species like superplasticizers were the composition of PNC.

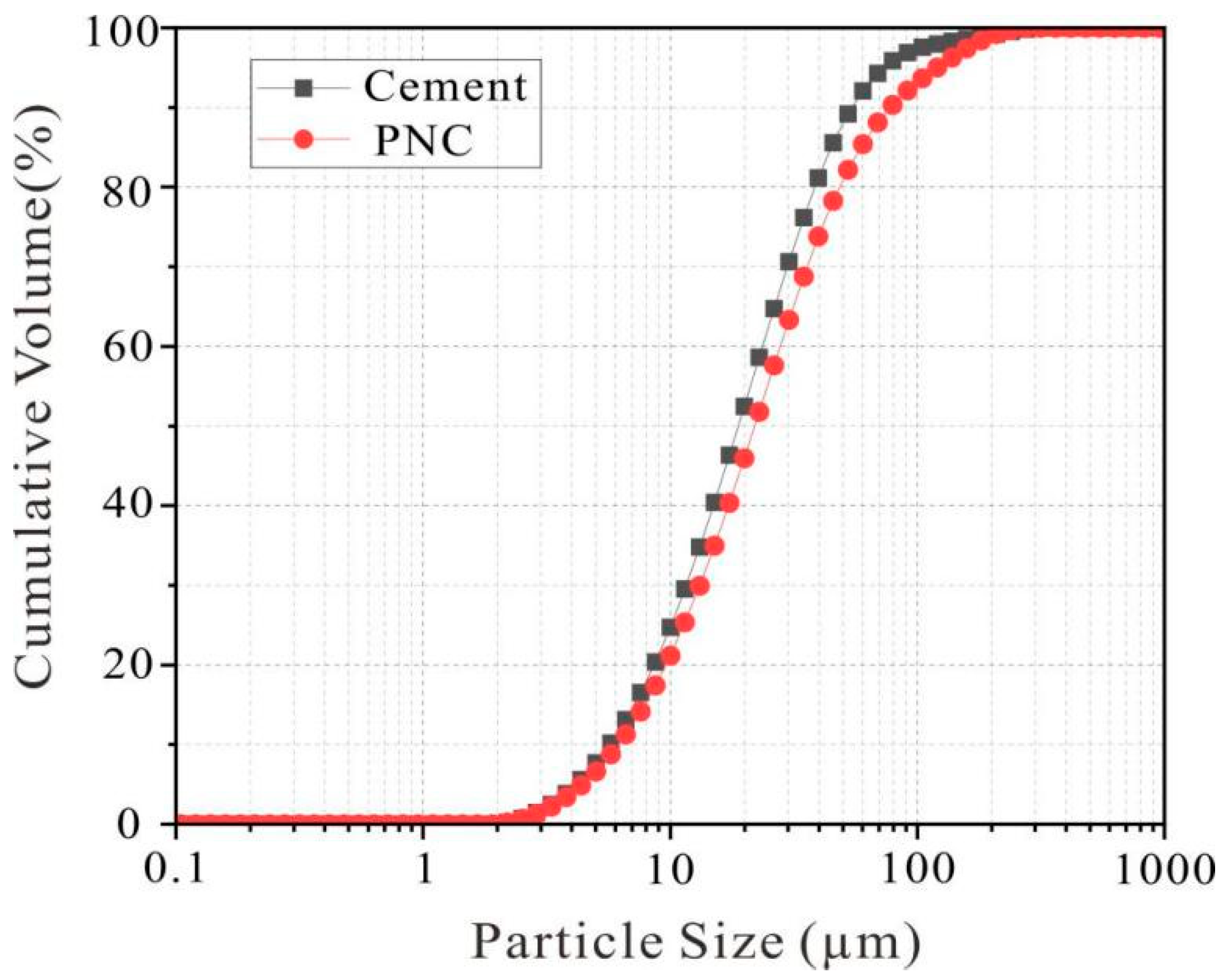

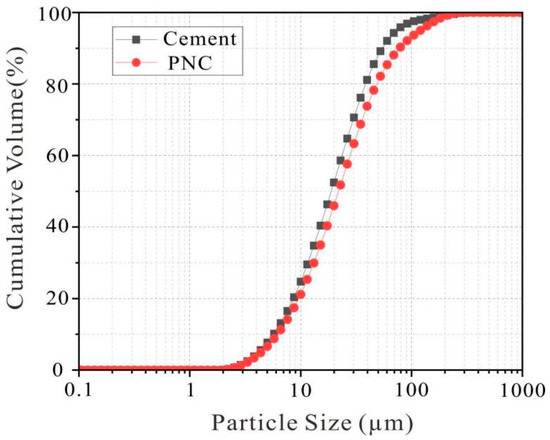

Particle size distribution displayed in Figure 4 shows that the particle size of cement was found to be slightly smaller than that of PNC. For PNC, its d0.1, d0.5, and d0.9 were 6.2 μm, 22.0 μm, and 77.8 μm, respectively, while for cement, its d0.1, d0.5, and d0.9 were only 5.7 μm, 18.9 μm, and 54.3 μm, respectively.

Figure 4.

Particle size distribution of cement and PNC.

2.2. Sample Preparation

According to GB 18445-2012 Cementitious capillary crystalline waterproofing material [42] and GB/T 17671-2021 Test method of cement mortar strength (ISO method) [43], the cement and different content (0%, 0.5%, 0.75%, 1.0%, 1.25%, 1.5%, 1.75%, 2.0%, 2.5%) of PNC were blended in a mixing vessel for mixing 30 s with a speed of 100 rpm. Then, the water (w/b of 0.45, 0.50, 0.55) was added for mixing another 60 s at the same speed, followed by a high speed of 200 rpm for 180s. The resulting paste was cast into silicon molds of 20 × 20 × 20 mm3 and allowed to vibrate for 30 s to remove bubbles. The molded samples were cured at a curing chamber with a temperature of 20 °C and a relative humidity of 95% for 24 h before being demolding. Finally, all samples were placed in ambient environment until test. All of the samples after the compressive strength test, were immersed in ethanol for 4 days to stop the hydration. The as-obtained samples were denoted as CXPY, where X indicates the w/b and Y indicates the addition content of PNC. For example, C0.45P0.5 represents the cement paste adding 0.5% PNC with a w/b of 0.45.

2.3. Characterization Methods

A cone mold was used to test the fluidity of cement pastes according to GB/T 8077-2012 [44]. A Vicat apparatus was used to record the initial and final setting times of cement pastes according to the ASTM C191 [45] standard test method. A compression resistance tester (STS100K, Lugong Intelligent Manufacturing Instrument Co., Ltd., Xiamen, China) was used to test the compressive strength of cement pastes at a loading rate of 100 N/s. Six sample of each specimen were tested and the results for each were averaged to give the value of strength.

A Bruker D8 Advance diffractometer (Mannheim, Germany) was used to collect XRD patterns of raw materials and selected cement pastes with a copper α radiation (λ = 0.154) generated at 40 kV and 40 mA. A Thermo Nicolet iS5 spectrometer (Thermofisher, Waltham, MA, USA) was used to obtain the FTIR spectra of raw materials and cement pastes in the range of 4000 cm−1–400 cm−1. A Netzsch STA 209F1 instrument (Selb, Germany) was applied to analyze the thermogravimetric (TG) in the temperature ranging 30–1000 °C. An Apreo 2s field-emission scanning electron microscope (Thermofisher, Waltham, MA, USA) was used to record SEM images and EDX spectroscopy of cement pastes at accelerating voltages of 3 and 15 kV, respectively. An Autopore 9600 (Micromeritics, Norcross, GA, USA) instrument was utilized to determine the total porosities and the pore size distributions of cement pastes. The pressure range was from 0.10 to 61,000.00 psi.

3. Results and Discussion

3.1. Physical Properties of Cement with and Without PNC

3.1.1. Flowability

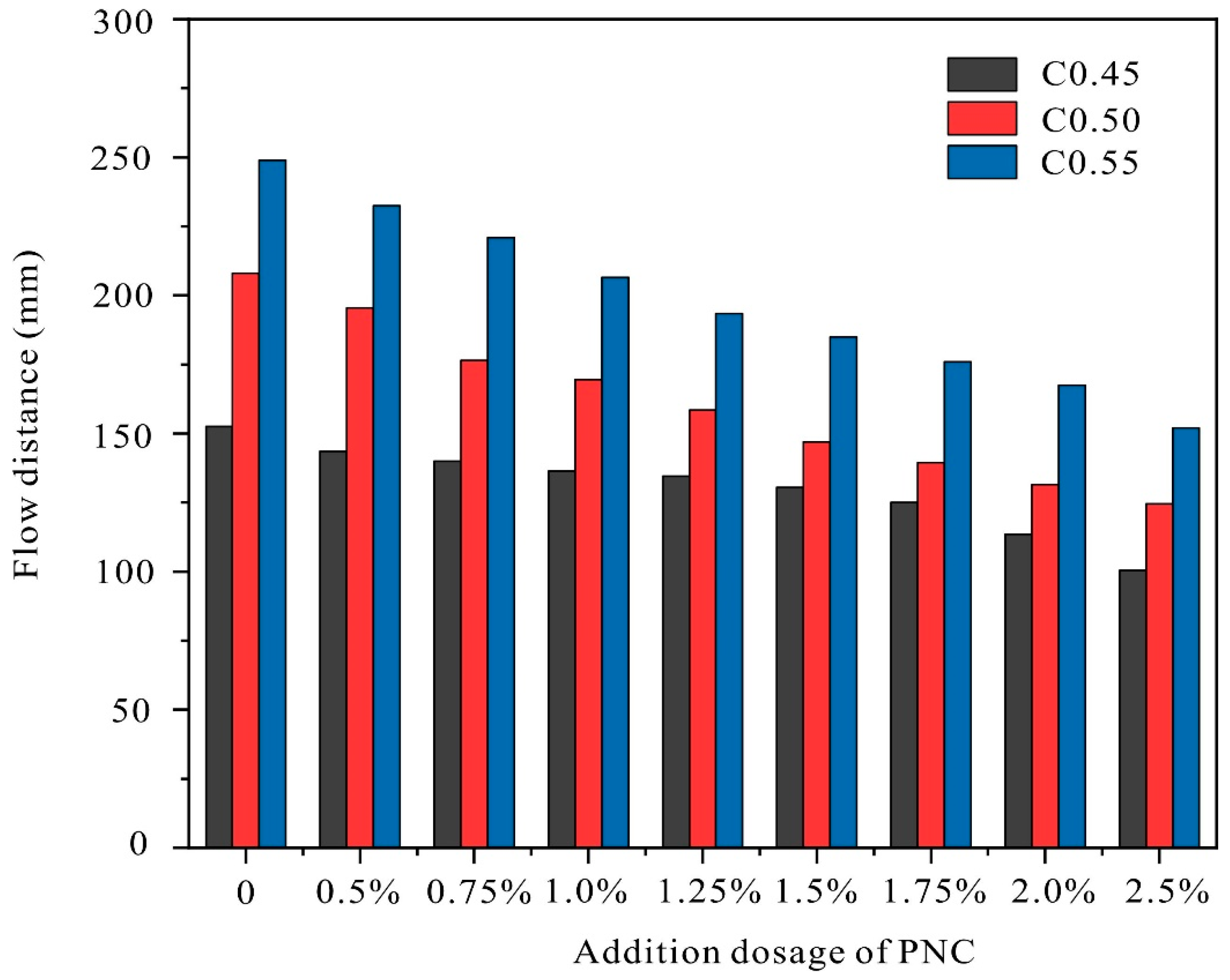

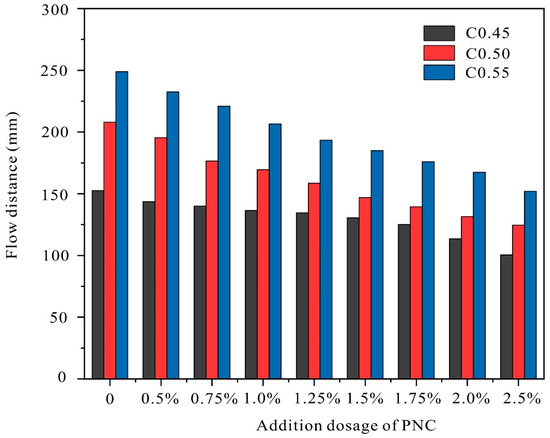

The flowability of cement pastes with and without various content of PNC are shown in Figure 5. The increase in w/b ratio increased the flowability for all samples. It is normal that the increase in water content is favorable to the flowability of the cementitious materials [46,47]. However, the addition of PNC decreased the flowability gradually. For example, the flow distance of C0.45P0 decreased from 153 mm to 101 mm as the PNC dosages increased to 2.5% while that of C0.55P0 decreased from 249 to 152 mm. It appeared to show that the PNC content posed greater negative effect on cement pastes with higher w/b ratio.

Figure 5.

Slump of cement paste with different w/b ratios.

The above results indicated that PNC tended to inhibit the flow behavior of cement paste. This can be attributed to the sulfate/carbonate-containing species and organic matters. As reported by Mbasha et al. [48], the formation of ettringite can increased the yield stress and the plastic viscosity of cement pastes, which will decrease the flowability. In addition, the superplasticizers in PNC also decreased the flowability of cement pastes.

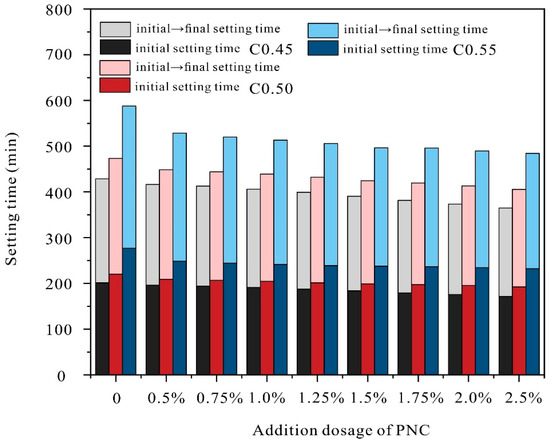

3.1.2. Setting Time

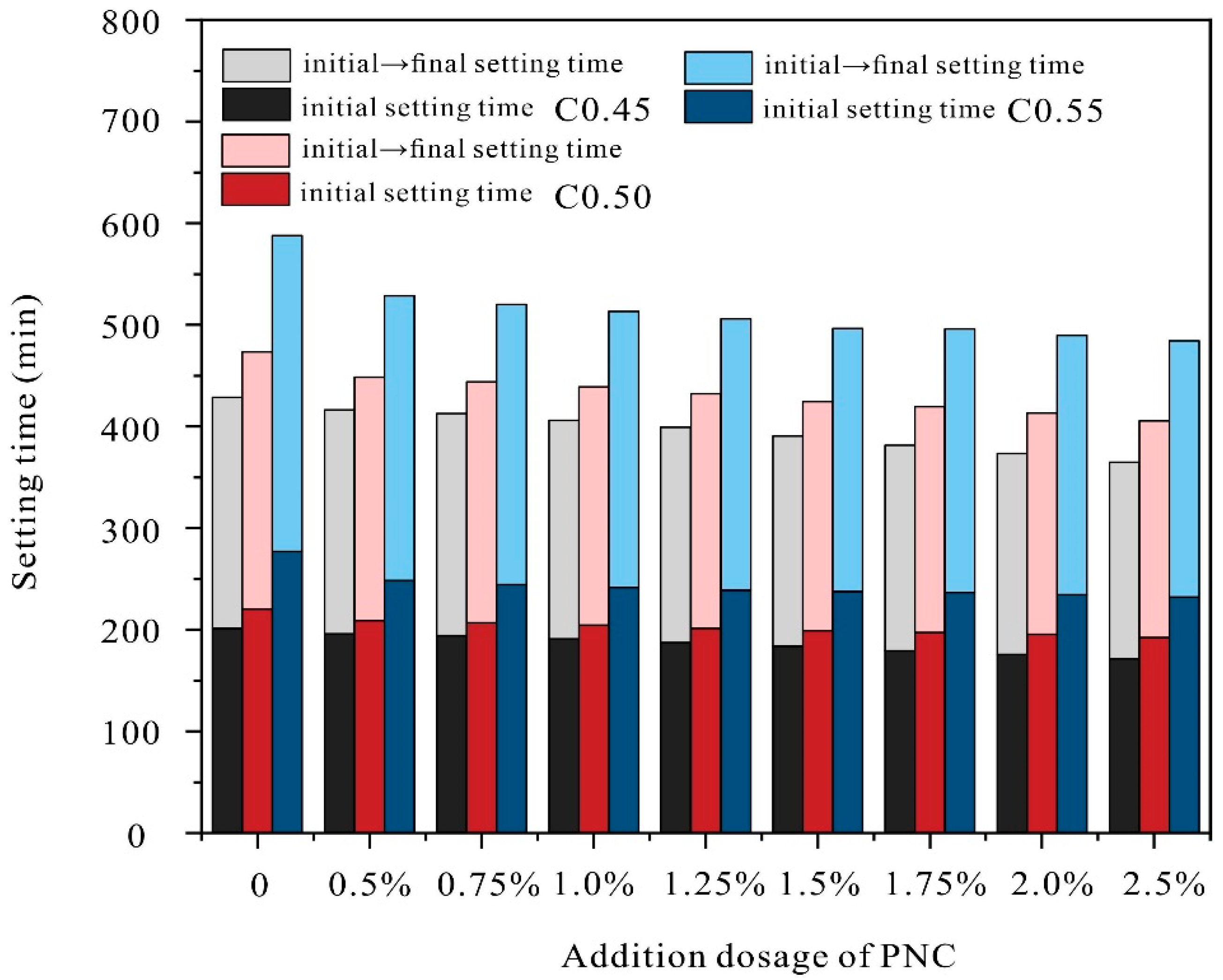

The initial and final setting times of all samples are shown in Figure 6. Similarly to the case of flowability, the increase in w/b ratio increased the setting time because the high-water content inhibited the interaction between cement particles, prolonging the hydration time and thus setting times.

Figure 6.

Setting times of cement paste with different w/b.

Meanwhile, the addition of PNC also decreased the setting time of cement pastes, especially at high w/b ratio. The final setting time of C0.45P0 decreased by 15% after the addition of 2.5% PNC while that of C0.55P0 was decreased by 19%. Therefore, the addition of little amount of PNC can accelerate the hydration process of cement. This result is also consistent with previous studies [49,50,51,52], who reported that the presence of sulfate favored the reaction between water and cement. However, too much sulfate may cause the erosion of cement, which warrants to further study [53].

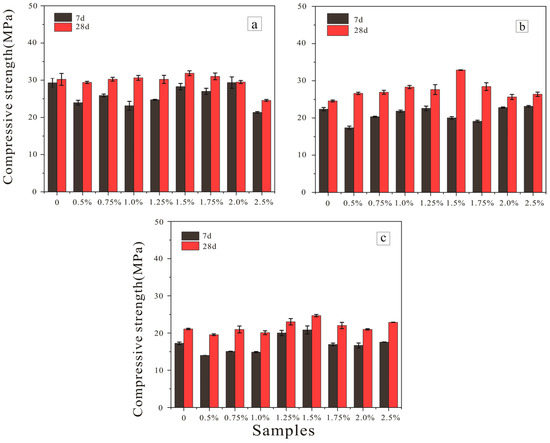

3.1.3. Compressive Strength

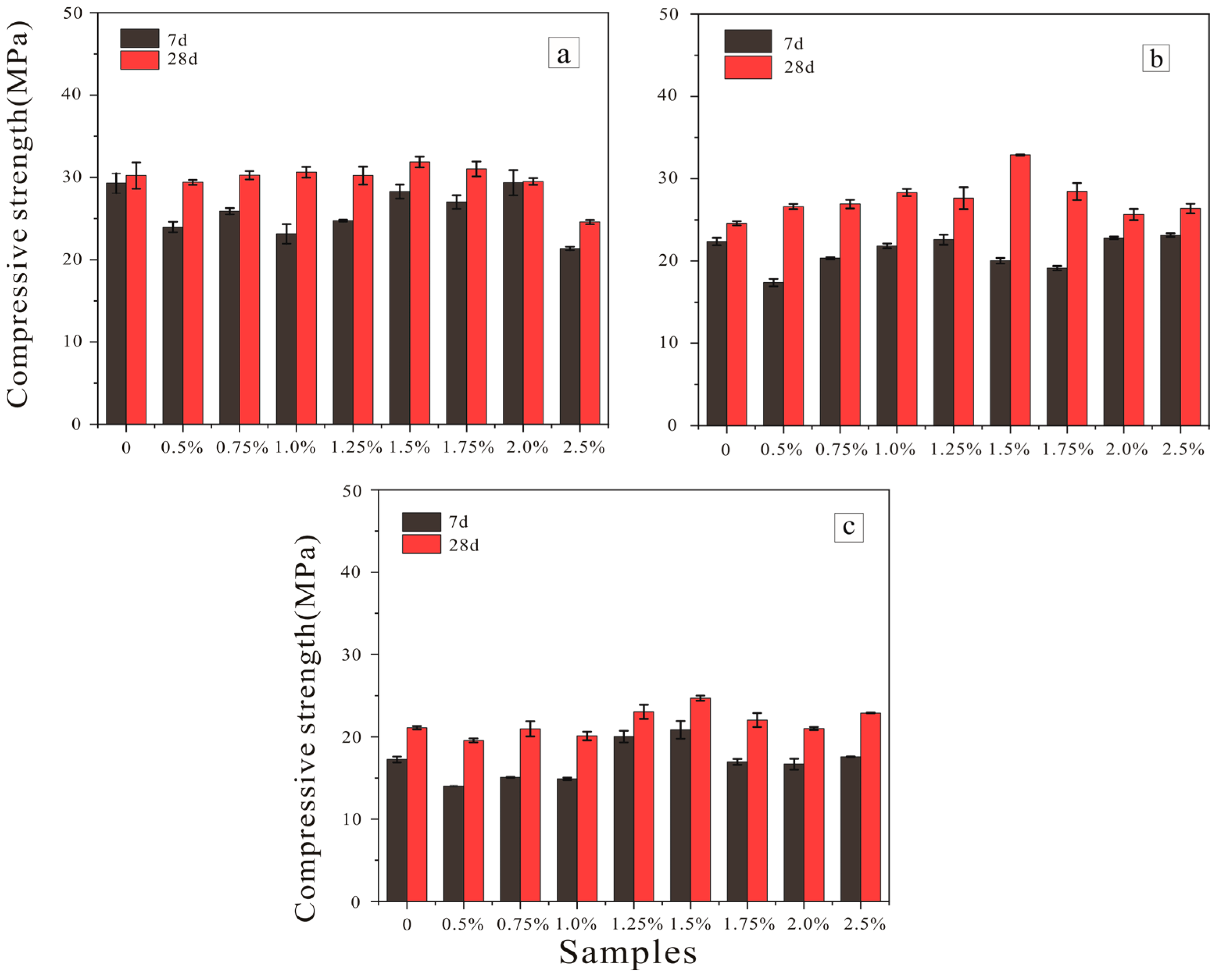

The 7 and 28 d compressive strengths of all cement pastes with and without PNC are shown in Figure 7. The continuous hydration of cement caused the higher 28 d compressive strength than 7 d compressive strength for all samples. In addition, the increasing w/b ratio decreased the compressive strength due to the dilute effect [54]. Moreover, from the compressive strength perspective, the PNC posed different impacts on the mechanical properties of cement pastes, depending on various w/b ratio and PNC dosage. As can be observed, the PNC played slight detrimental and positive roles in the late compressive strength of cement pastes at high and medium content, respectively. While low content of PNC barely affected the late compressive strength of cement paste.

Figure 7.

Compressive strength of cement pastes with different w/b ratio (a) 0.45, (b) 0.50, (c) 0.55.

At low w/b ratio of 0.45, the addition of PNC did not significantly alter the 28 d compressive strength (~29.5 MPa) of cement paste even at the addition dosage of 2.0%. However, the 7 d compressive strength slightly decreased. For instance, the 7 d compressive strength of C0.45P0 decreased from 29.3 MPa to 23.14 MPa after addition of 1.0% PNC. Notably, adding high content (2.5%) of PNC decreased the mechanical properties of cement pastes. This is likely attributed to the low flowability of cement after adding such high content of PNC. The insufficient flowability will inhibit the spread and hydration of cement, which decreased the compressive strength. In addition, the changes in chemical composition and pores also pose great impact on the compressive strength of cement pastes, which will be discussed in following section.

At medium w/b ratio of 0.50, the addition of PNC increased the 28 d compressive strength of cement pastes gradually although the 7 d compressive strength was still decreased. As the addition dosage increased from 0% to 1.5%, the 28 d compressive strength increased from 24.6 MPa to 32.9 MPa. This phenomenon reflected that the PNC could promote the hydration of cement with a slow speed. However, further increasing the PNC content decreased the compressive strength possibly due to the low flowability. In addition, the excessive PNC powder likely destroyed the microstructure of cement. Consequently, the compressive strength decreased but was still higher than C0.50P0.

The cement pastes with high w/b ratio of 0.55 had very low compressive strengths, where 7 d and 28 d compressive strengths of C0.55P0 were only 17.2 MPa and 21.1 MPa. Notably, the addition of 1.5% PNC improved both the 7 day and 28 d compressive strengths most, but to a slight extent. Further increasing PNC content did not significantly alter the compressive strength of cement pastes.

3.2. Composition Changes in Cement Pastes

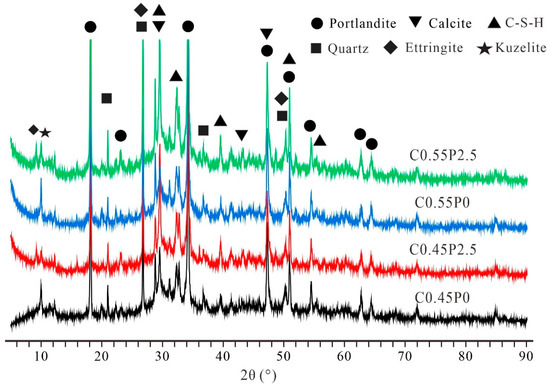

3.2.1. XRD Patterns

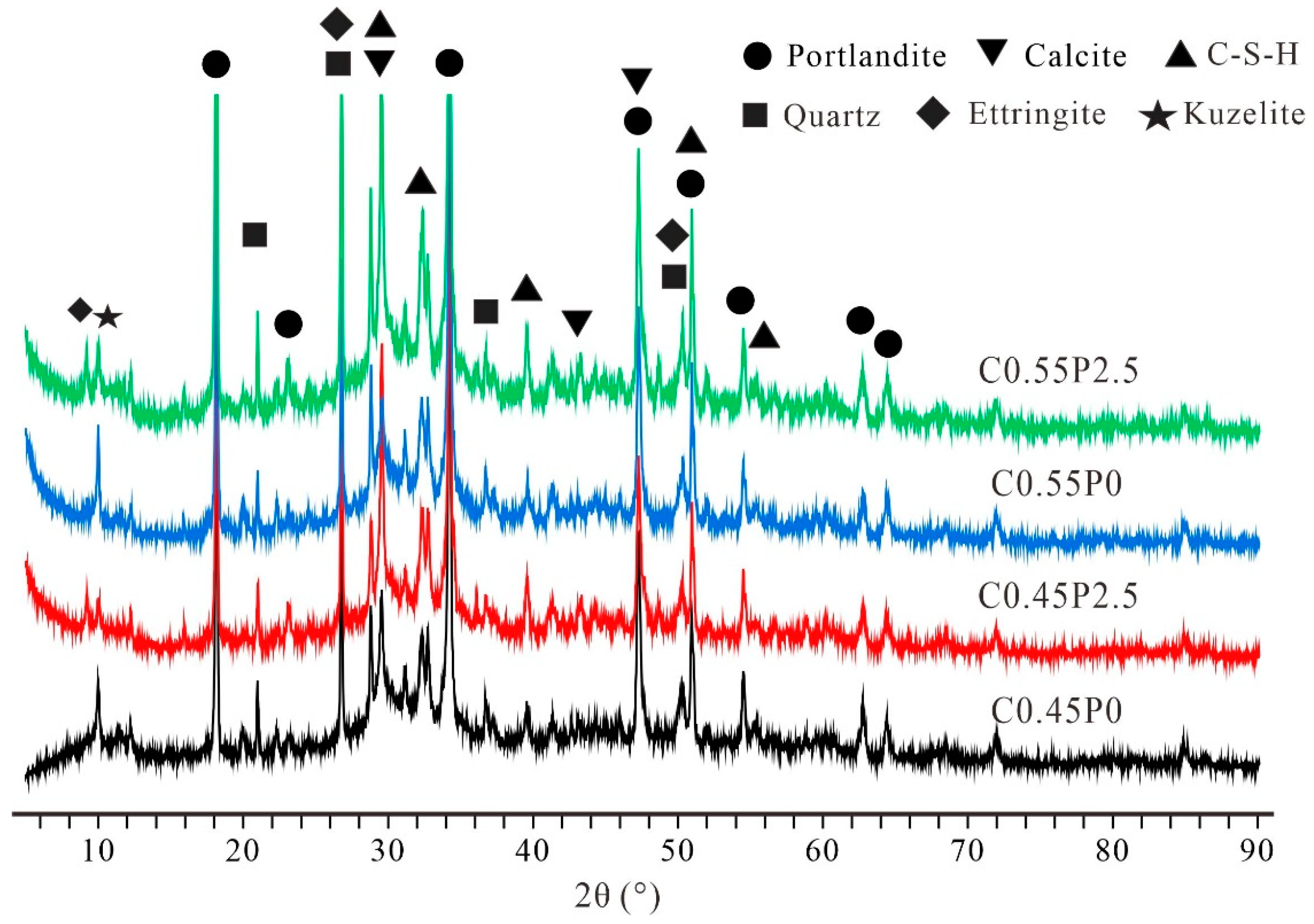

Figure 8 displays the changes in the phase assemblage of selected cement pastes. As can be seen in the XRD pattern of C0.45P0, the hydration of cement produced portlandite (PDF 44-1481), kuzelite (Ca4Al2(SO4)(OH)12·H2O; PDF 50-1607), and amorphous and crystal calcium-silicate-hydration (C-S-H) gels. The formation of C-S-H gels corresponded to the strength development of cement pastes [55]. The increased w/b ratio appeared to show no significant effect on the mineralogical phase of cement pastes according to the similar XRD patterns between C0.45P0 and C0.55P0. In fact, the water content will not alter the hydration mechanism of cement.

Figure 8.

XRD patterns of cement pastes with and without PNC.

After addition of PNC, an obvious change lied in the presence of ettringite compared with cement paste. This can be attributed to the presence of SO42⁻ ions in PNC, such as gypsum, mirabilite, which promoted the formation of ettringite (Ca6Al2(SO4)3(OH)12·26H2O; PDF 41-1451), a phase with higher water content compared to C-S-H [56]. Normally, the suitable content of ettringite favored the development of strength; however, too many ettringite will delay the hydration and destroy the microstructure of cement due to expansion. This is one reason the compressive strength of cement pastes decreased slightly as the PNC content increased to 2.5%.

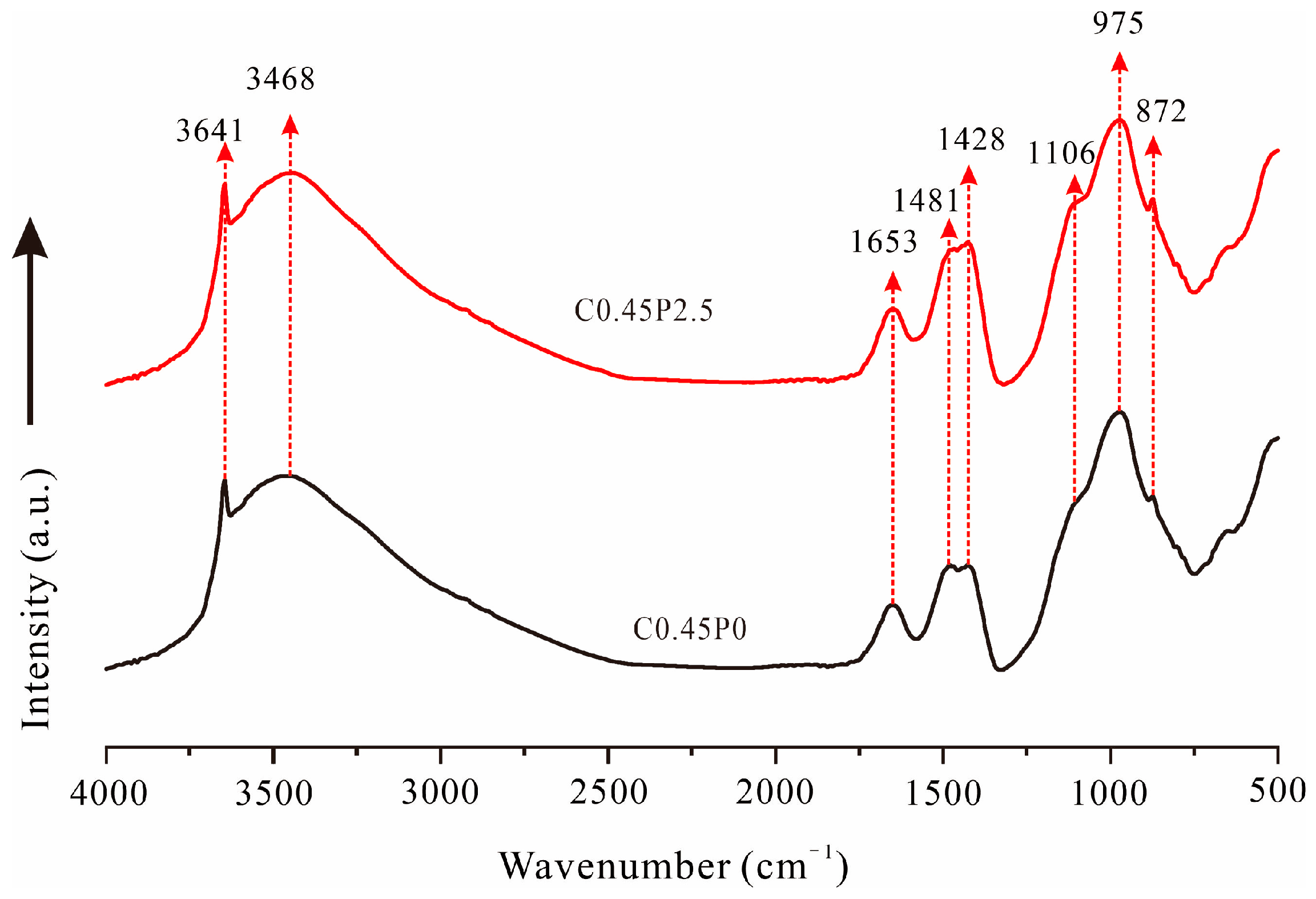

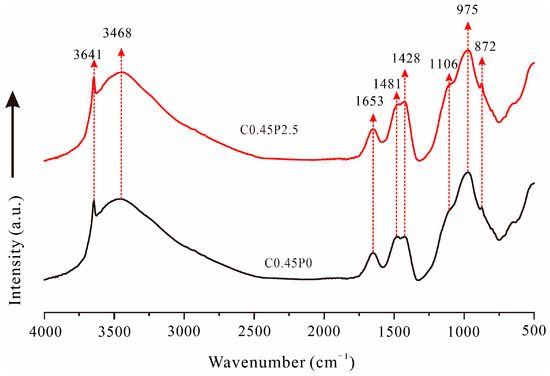

3.2.2. FTIR Spectroscopy

Since the change in w/b ratio barely altered the microstructure of cement pastes at molecular scale, we just analyzed the FTIR spectra (Figure 9) of C0.45P0 and C0.45P2.5 in this study. The absorption band at 3641 cm−1 after hydration of cement (C0.45P0) were assigned to the symmetric stretching vibration of the Ca-OH bond from Ca(OH)2 [32]. While bands located at 3468 cm−1 and 1653 cm−1 were attributed to the stretching and bending vibration of the H-O-H in the absorption water [32]. In addition, bands attributed to carbonate were found in 1428 cm−1 and 872 cm−1, which were characterized as asymmetric stretching vibration of O-C-O from CO2 and symmetric out-of-plane bending vibration of CO32− from calcite [57]. The peak located at 975 cm−1 was attributed to the symmetric stretching vibration of Si-O from C-S-H gels [58], which was also evidenced by XRD patterns. A shoulder band at 1106 cm−1 should be attributed to the Si-O asymmetric stretching of the polymerized silica [59].

Figure 9.

FTIR spectra of cement pastes with PNC.

Notably, the FTIR spectra of C0.45P2.5 was similar to that of C0.45P0, indicating that even the addition of 2.5% PNC did not alter the molecular structure of cement pastes. Indeed, it is hard to detect changes in molecular structure of cement pastes just adding so low content of PNC.

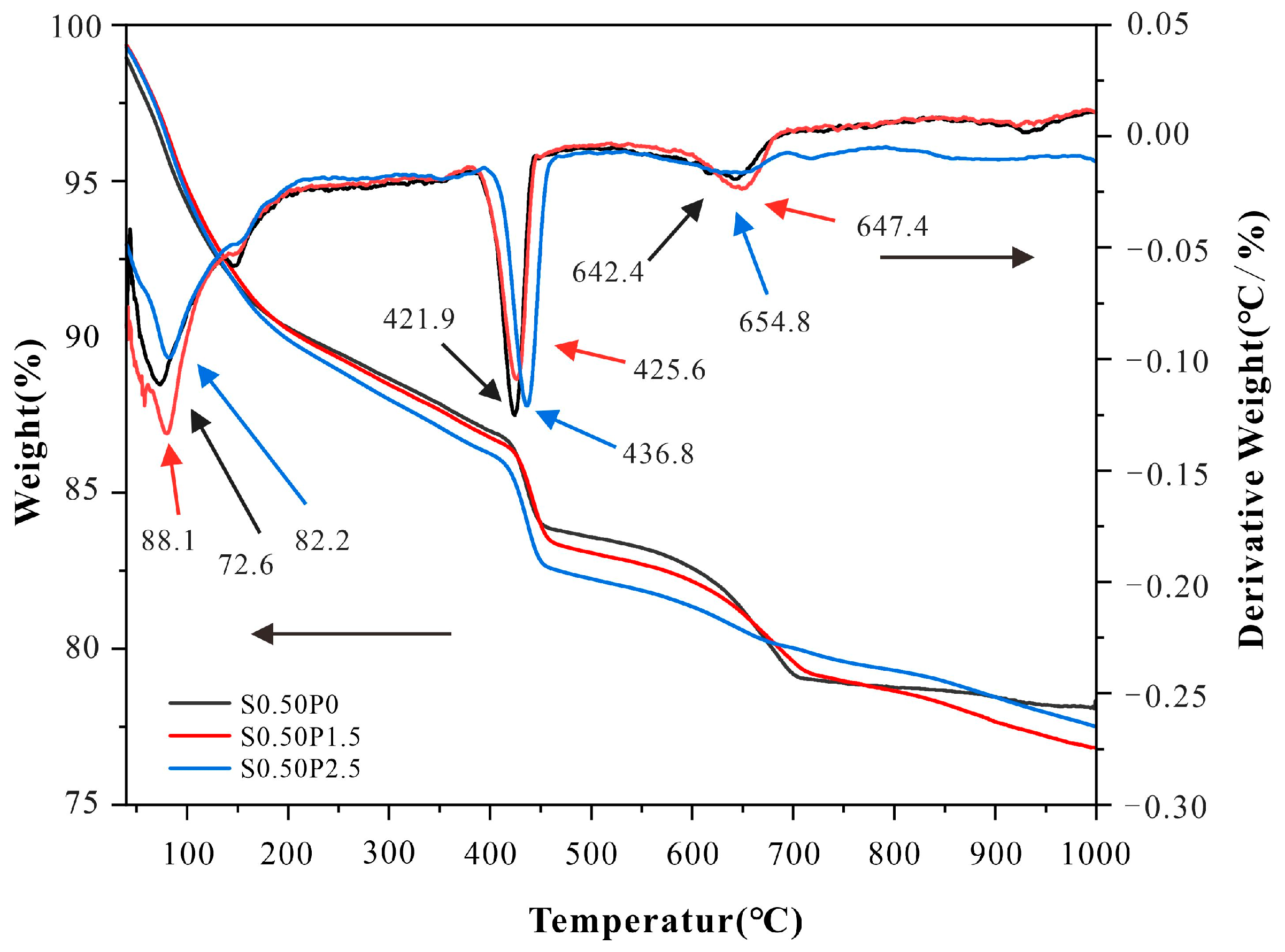

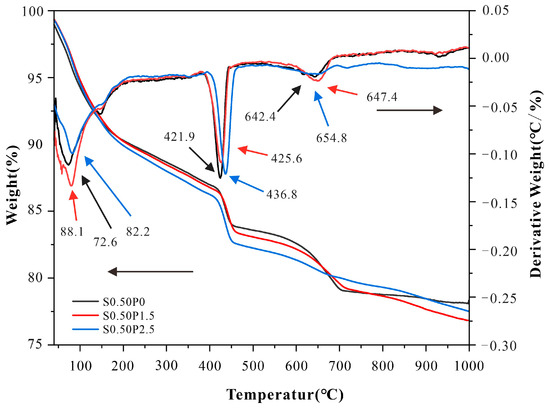

3.2.3. TG Analysis

To investigate the effect of PNC dosage on thermal and composition of cement pastes, the TG/DTG curves of cement pastes with addition of 0, 1.5%, and 2.5% PNC at a w/b ratio of 0.5 were tested (Figure 10). There are three significant mass-loss regions lied on 30–150 °C, 400–500 °C, and 600–700 °C. Correspondingly, three peaks centered at ~75 °C, ~430 °C, and ~645 °C were observed in DTG curves. The first peak was attributed to the evaporation of absorbed water and decomposition of C-S-H and ettringite for cement pastes [60]. The second peak was attributed to the decomposition of Ca(OH)2 and the third one was assigned to the decomposition of CaCO3 [61]. As can be seen from Figure 10 that these three peaks slightly shifted to the right direction as the increase in PNC, reflecting the cement pastes became stable after addition of PNC.

Figure 10.

TG curve of cement pastes with PNC.

The Ca(OH)2 content was calculated using the weight loss between 400 °C and 500 °C with following formula [56]:

where W400 and W500 are weight percentages of the dry pastes at 400 °C and 500 °C. MCa(OH)2 and MH2O are the molar masses of Ca(OH)2 and H2O, respectively. The Ca(OH)2 content decreased from 17.3% to 17.1% after the addition of 1.5% PNC. The consumption of Ca(OH)2 caused by PNC resulted in an increase in compressive strength (Figure 7). However, further increasing PNC dosage increased the Ca(OH)2 content to 20.0%, and thus the compressive strength decreased. Therefore, the excessive PNC appeared to pose detrimental role in the chemical composition and properties of cement pastes.

3.3. Microstructures of Cement Paste with CCCW

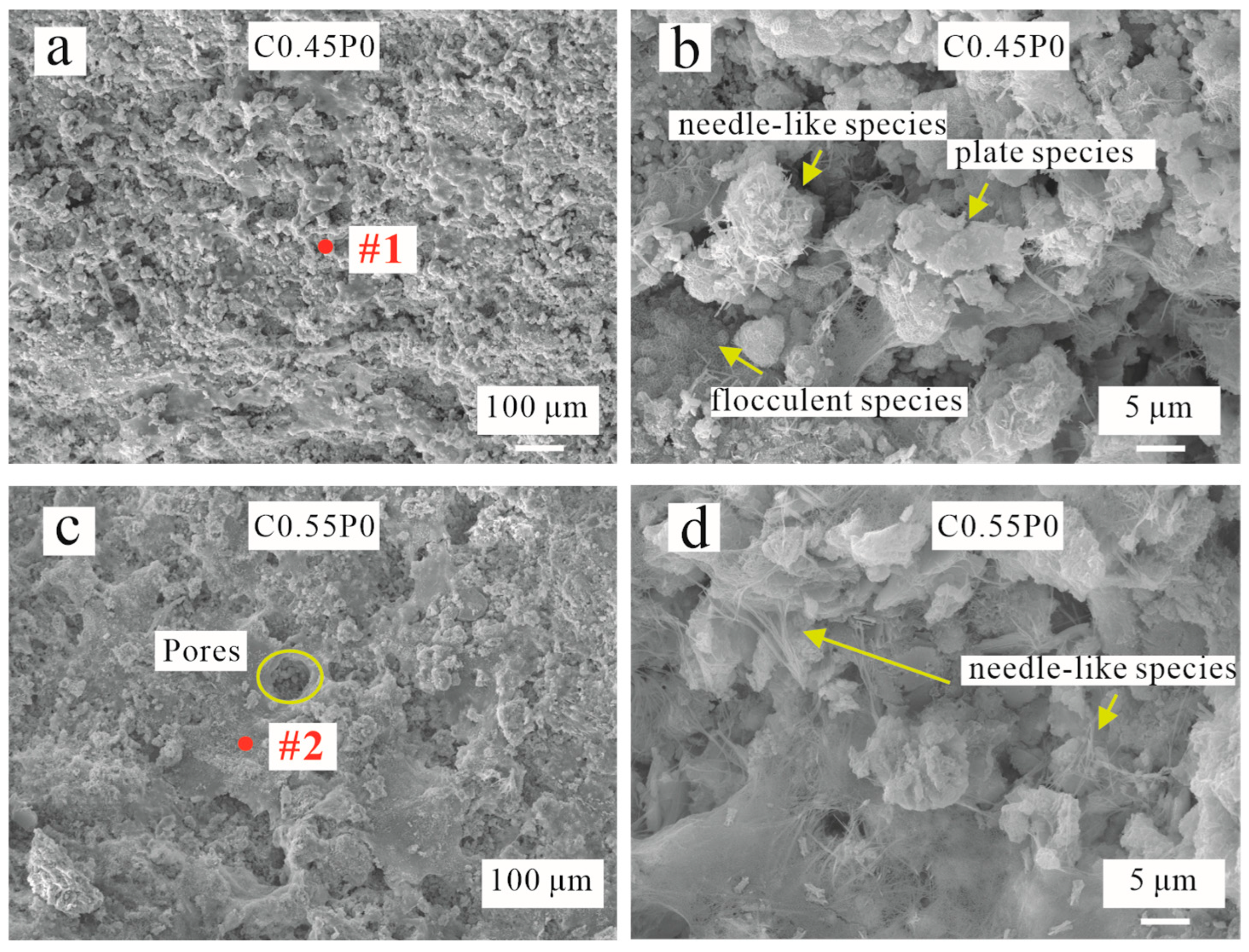

3.3.1. SEM Results

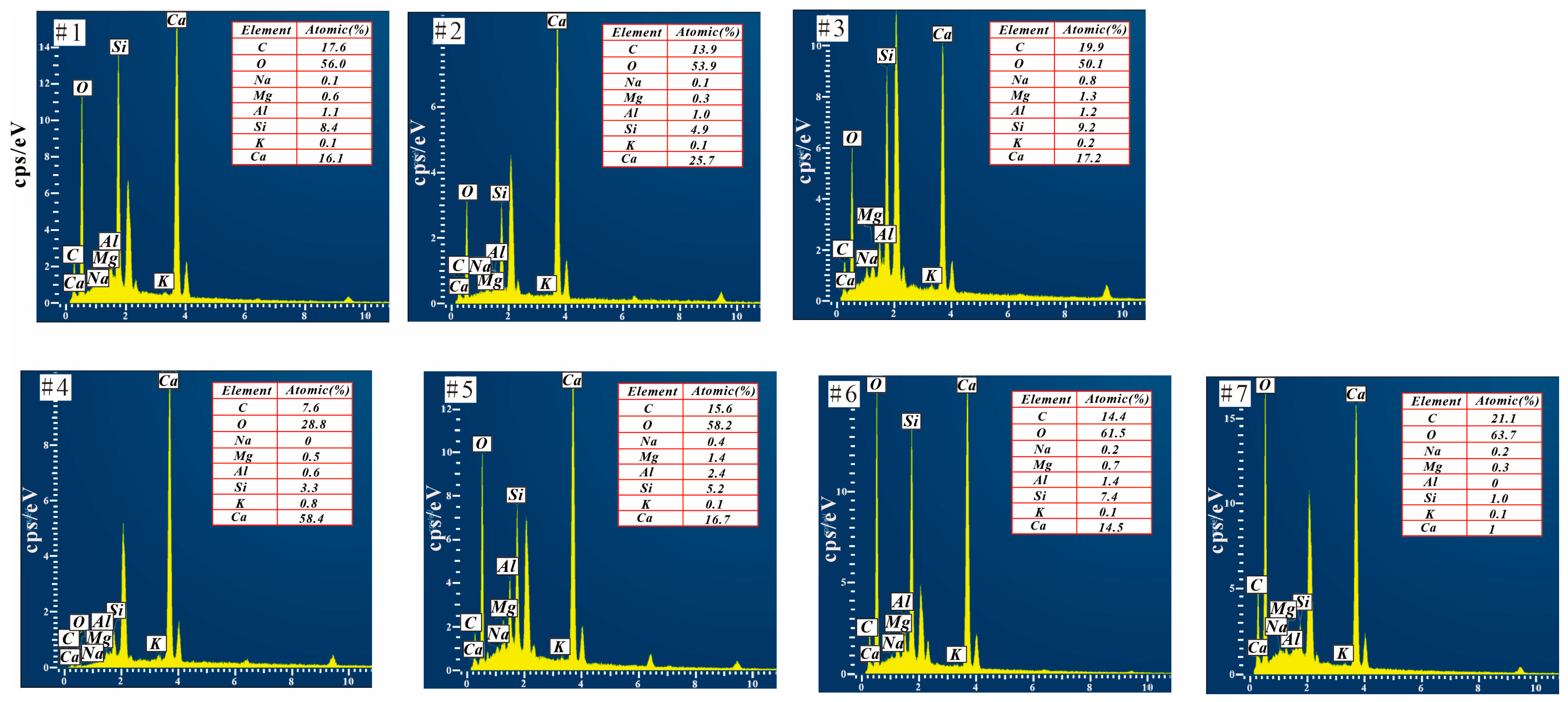

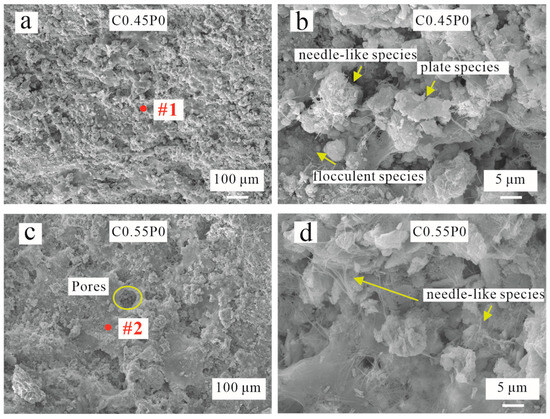

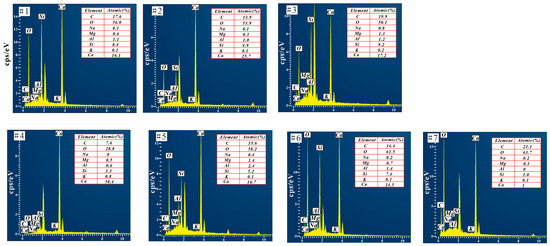

The SEM micrographs of cement pastes without addition of PNC were shown in Figure 11. C0.45P0 showed a more compacted microstructure than C0.55P0 at low magnification SEM image (Figure 11a,c). C0.55P0 contained large pores and inhomogeneous texture, corresponding to its low compressive strength. The EDX results (Spots 1 and 2 in Figure 14) displays the matrix of cement mainly contained Ca, C, Si, Al, O, which were C-(A)-S-H gels and calcite. At higher magnification, their morphology shows little difference. Both samples contained plate species and needle-like species, which were Ca(OH)2 and ettringite, respectively.

Figure 11.

SEM images of cement pastes without PNC: (a) C0.45P0 at low magnification, (b) C0.45P0 at high magnification, (c) C0.55P0 at low magnification, and (d) C0.55P0 at high magnification.

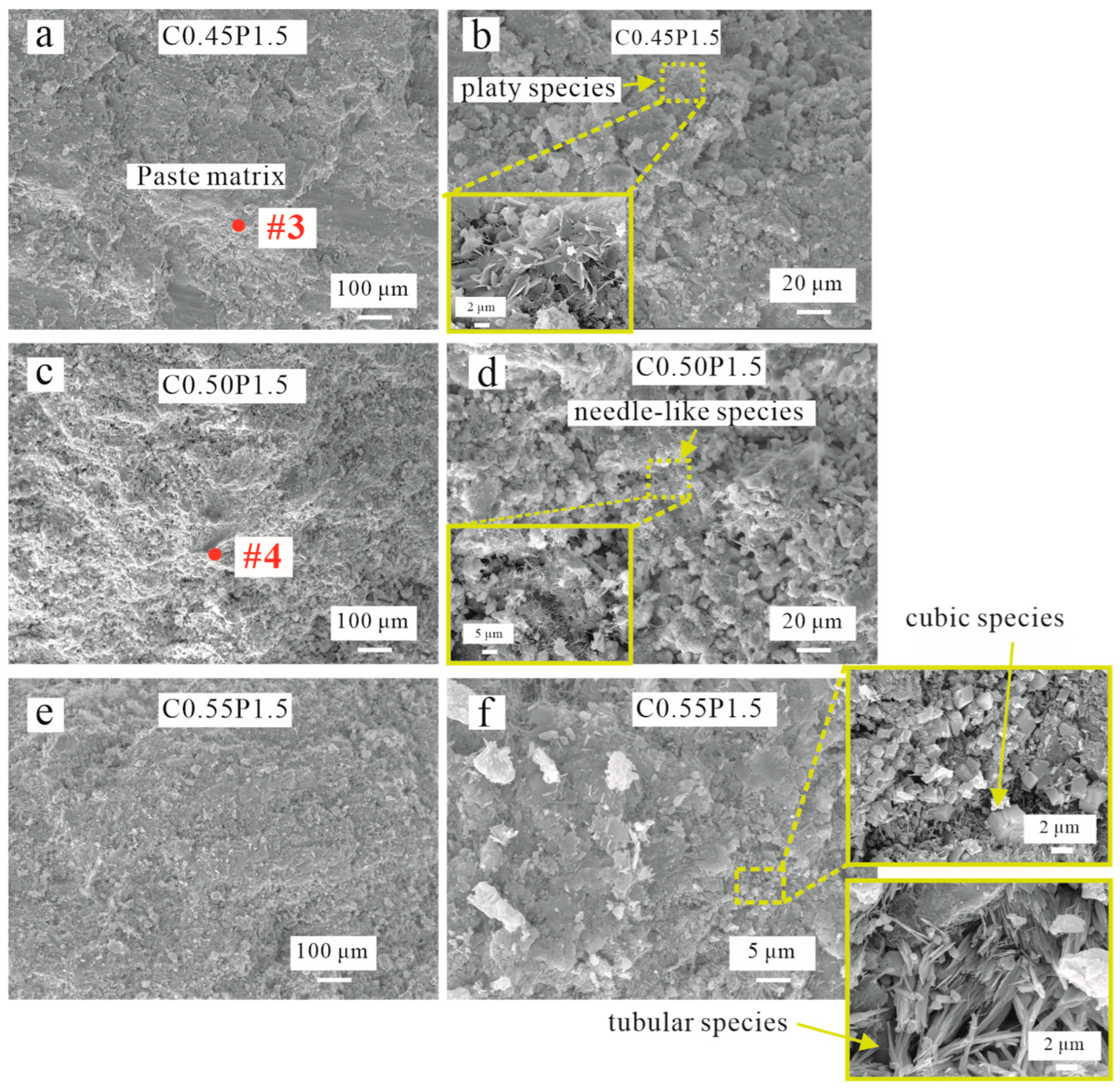

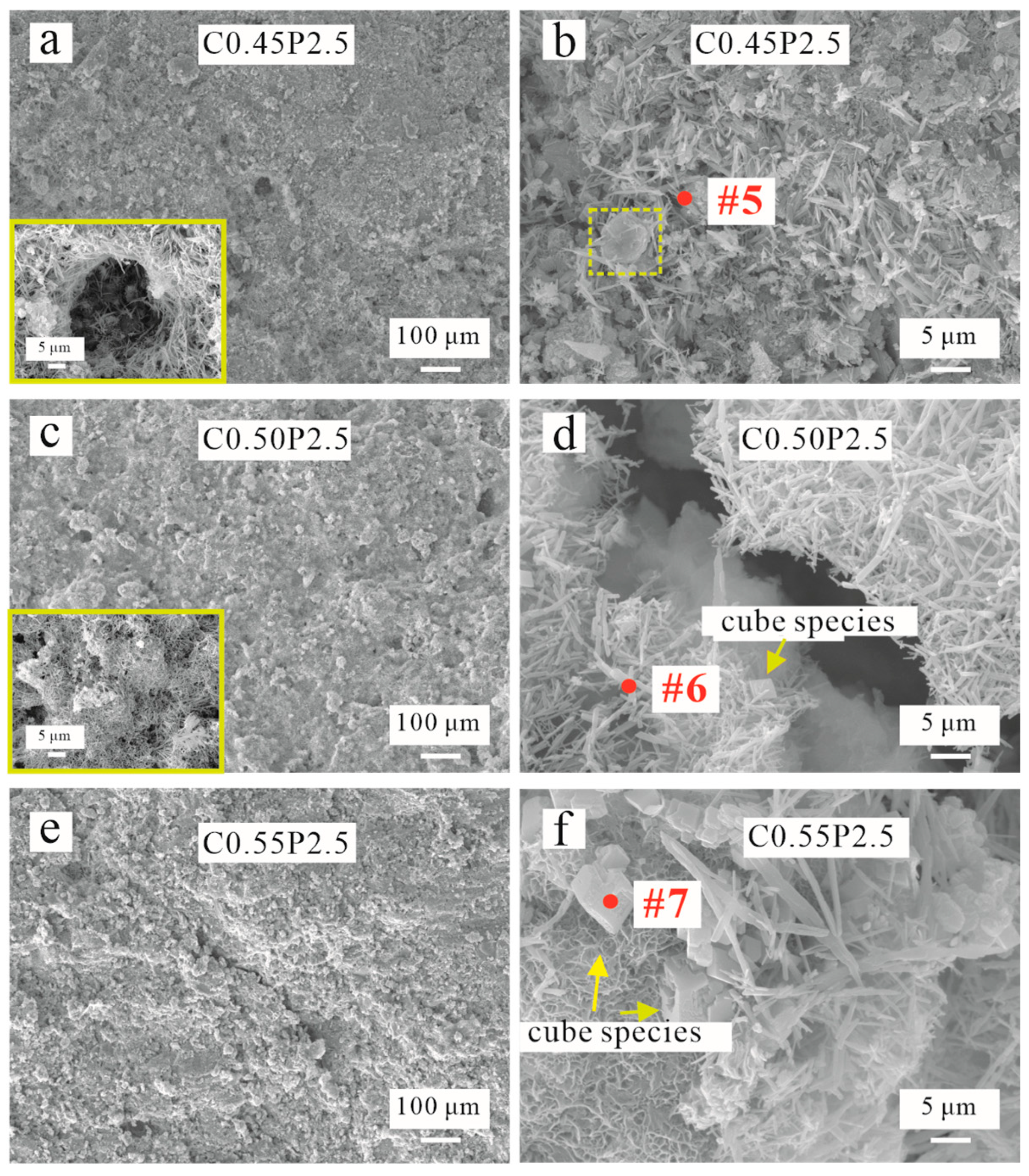

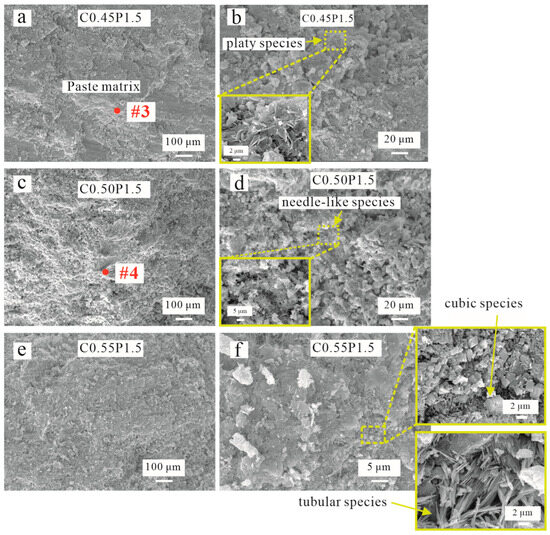

After adding 1.5% PNC, there was no obvious morphological difference for all cement pastes. They all show a very dense microstructure. The cement matrix of C0.50P1.5 demonstrates high content of Ca, C, and O (Spot 4 in Figure 14), indicating the formation of C-S-H and CaCO3. Combined with Figure 11c, it can be concluded that the PNC was beneficial to the pore-refining and compacted structure, especially at high w/b ratio. However, at higher magnification, there are different morphologies being found. In the SEM image of C0.45P1.5 (Figure 12b), a cluster of plate-like species was observed in its matrix. This species should be the neoformed C-S-H. Comparatively, the SEM image of C0.50P1.5 (Figure 12d) show a great number of needle-like species, ettringites, in the matrix of C0.50P1.5. This can be attributed to the incorporated of S [62]. Interestingly, for C0.55P1.5, we can find two species with different morphology in their SEM image (Figure 12f), cubic species and stacked tubular species. According to previous studies, the cubic species should be the calcite, which resulted from the reaction between Ca(OH)2 and CO2. The high w/b ratio provide a moist environment to improve this reaction [62]. This can also be confirmed by the EDX result (Spot 7 in Figure 14). In addition, the stacked tubular species were also C-S-H gels [63].

Figure 12.

SEM images of cement pastes with addition of 1.5% PNC: (a) C0.45P1.5 at low magnification, (b) C0.45P1.5 at high magnification, (c) C0.50P1.5 at low magnification, (d) C0.50P1.5 at high magnification, (e) C0.55P1.5 at low magnification, and (f) C0.55P1.5 at high magnification.

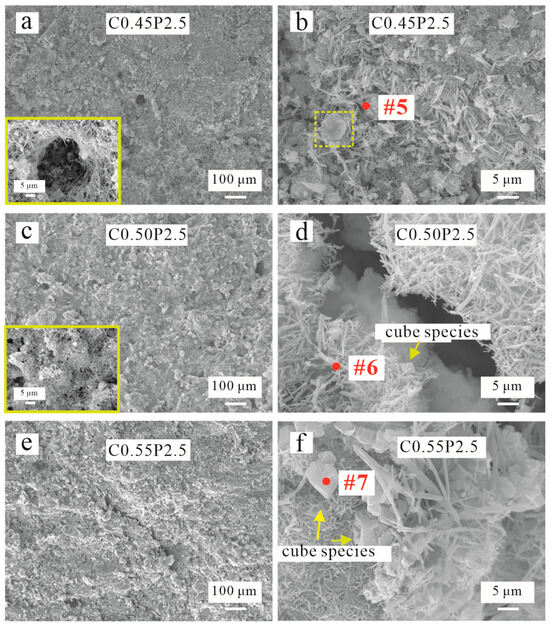

Figure 13 shows the SEM images of cement pastes with addition of 2.5% PNC. Interestingly, it can be observed that the surface of these cement was covered with a layer of needle-like species. The EDX results (Spots 5 and 6 in Figure 14) indicate that these species consisted of Ca, Si, Al, O atoms, which confirm it is ettringite. As stated before, too many ettringite played a detrimental role in the mechanical properties. On the other hand, we can also conclude that the formation of ettringite in cement is one of the most important function mechanisms for PNC.

Figure 13.

SEM images of cement pastes with addition of 2.5% PNC: (a) C0.45P2.5 at low magnification, (b) C0.45P2.5 at high magnification, (c) C0.50P2.5 at low magnification, (d) C0.50P2.5 at high magnification, (e) C0.55P2.5 at low magnification, and (f) C0.55P2.5 at high magnification.

Figure 14.

EDX result of cement pastes.

3.3.2. Pore Structure

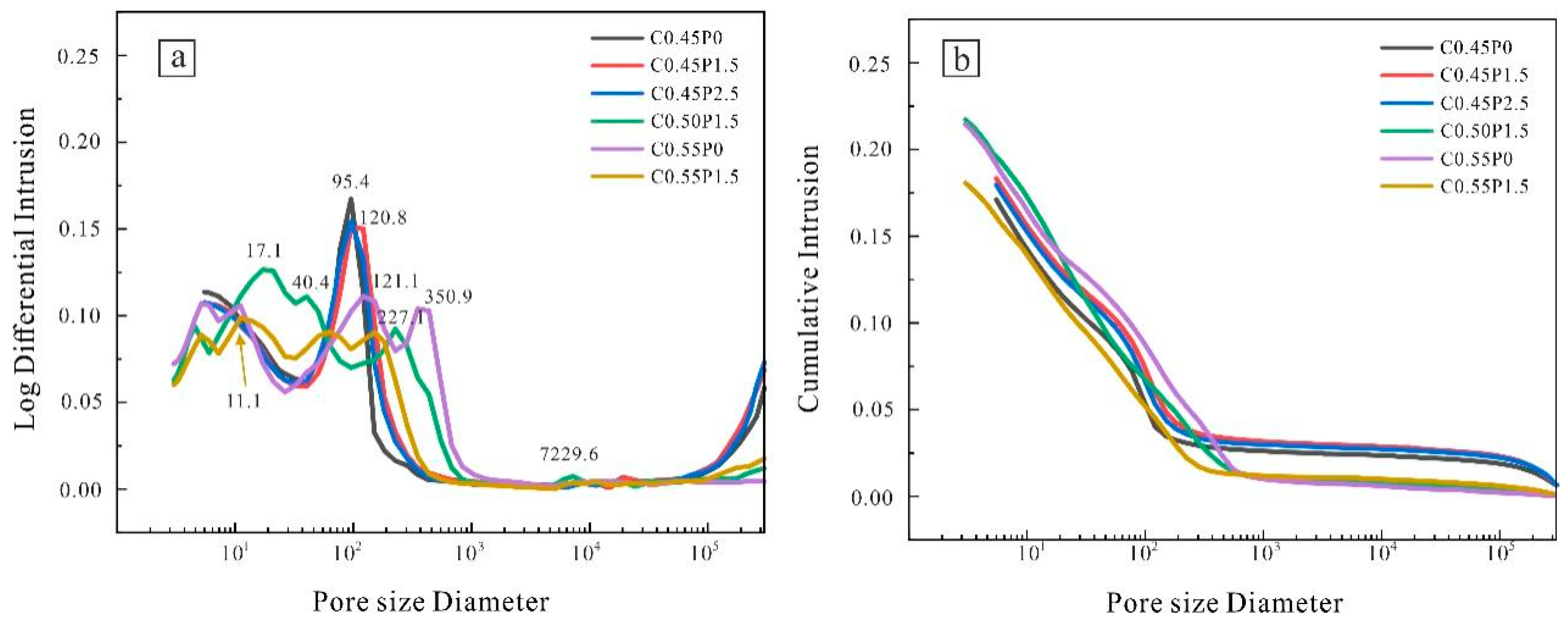

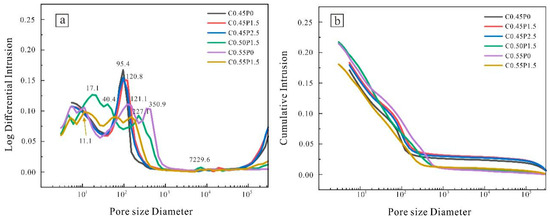

Figure 15 shows the pore structures of C0.45P0, C0.45P1.5, C0.45P2.5, C0.50P1.5, C0.55P0, C0.55P1.5. Table 2 displays the pore parameters (total pore area, average pore diameter, and porosity) of above selected cement pastes.

Figure 15.

Pore structure of cement pastes: (a) cumulative intrusion and (b) log differential intrusion.

Table 2.

Pore parameters of RGP based on MIP results.

For cement paste with a low w/b ratio, it can be observed from Figure 15a that there was only one sharp peak. The critical pore size of cement pastes shifted from ~95 nm to ~121 nm after the addition of 1.5% PNC. Meanwhile, the average pore diameter and porosity, as shown in Table 2, were also increased. However, the compressive strength barely changed (Figure 7), which was contradict to the pore distribution results. This phenomenon reflects that although the PNC will deteriorate the pore structure of cement, the formation of new species can compensate the structure degrade. Furthering increase PNC dosage decreased the critical pore size to ~95 nm, but the compressive strength was decreased. Combined with the TG analysis (Figure 9), the formation of Ca(OH)2 may be benefit to the pore-refining but not the strength improvement [64,65].

As the w/b ratio increased to 0.55, critical pore size of cement pastes became much bigger, accompanied by the increase in pore volume (Figure 15b). In addition, the obvious increase in cumulative intrusion reflected the significantly increase in pore volume and porosity (Table 2). The increased w/b improved the pore formation, as also evidenced by SEM images (Figure 11) and compressive strength (Figure 7). This phenomenon was also found in the cement pastes C0.45P1.5, C0.50P1.5, C0.55P1.5, which porosity and pore volume increased with increasing w/b ratio.

It is interesting that the addition of 1.5% PNC into C0.55P0 did not significantly alter the pore volume and porosity (Figure 15b) despite that the compressive strength increased. In fact, the critical pore size of C0.55P0 at 227 nm and 351 nm shifted to 40.4 nm and 17.1 nm, indicating the optimization of pore size after addition of PNC. This is one reason the compressive strength increased. The above results also reflected that compared to cement pastes with low w/b ratio (0.45), those with higher w/b ratios were prone to be affected by CCCW in properties. This is likely related to the flowability of cement pastes and the characterization of CCCW. Normally, CCCW tends to function at the moist environment and thus the higher w/b ratio provide higher-water content and better flowability, which can react with PNC [16,66].

4. Conclusions

In this study, the effects of PNC content on the microstructure and mechanical properties of cement pastes with various w/b ratios were investigated. The increasing w/b ratio increased the flowability and decreased the compressive strength of cement pastes. The addition of PNC decreased the flowability and setting time slightly due to the superplasticizer and sulfate species. Normally, the PNC play a more negative effect on the early strength than late strength. In addition to having similar mineralogical composition to cement, PNC still contained sulfate/carbonate-containing and organic species. These species could slowly retard hydration of cement but consumed more Ca(OH)2 and improved the formation of ettringite dosage. The suitable content of ettringite strengthened the cement matrix, reduced pores, and thus increased compressive strength. However, too many ettringites caused by the excessive PNC will lead to the less compact cement matrix. Finally, the mechanical properties were weakened.

Further study on the properties of CCCW-adding cement (water-proofing properties, durability, etc.) and role of each composition in PNC (organic species, Ca-containing species) should be conducted to give a fully using PNC in modern construction and buildings.

Author Contributions

Conceptualization, Z.L.; software, H.G.; validation, H.G.; formal analysis, B.Z. and H.G.; investigation, H.G.; resources, Z.L.; data curation, H.G.; writing—original draft preparation, Z.L.; writing—review and editing, Z.L.; visualization, B.Z. and H.G.; supervision, L.L.; project administration, Z.L.; funding acquisition, Z.L. and Z.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data will be available if required.

Acknowledgments

The authors would gratefully like to acknowledge the support provided by the National Natural Science Foundation of China (No. 12032009 and 12072080); the Natural Science Foundation of Guangdong Province under Grant No. 2023A1515012180; the Cooperation project between Guangdong University of Technology and Huateng Green Building Materials Technology (Guangdong) Co., Ltd. (No. 23HK0564).

Conflicts of Interest

Author Zhu Yang was employed by the company China Construction Fifth Engineering Bureau Third Construction (Shenzhen) Co., Ltd. Zhonglin Li was employed by the company Huateng Green Building Materials Technology (Guangdong) Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Wang, J.; Xie, J.; Wang, Y.; Liu, Y.; Ding, Y. Rheological properties, compressive strength, hydration products and microstructure of seawater-mixed cement pastes. Cem. Concr. Compos. 2020, 114, 103770. [Google Scholar] [CrossRef]

- Luo, J.; Wu, G.; Zhao, G.; Ma, Y.; Fang, Z.; Fang, S. Experimental and numerical analysis on shear performance of single embedded nut bolted shear connectors in prefabricated steel-UHPC composite structures under cyclic loading. Structures 2025, 73, 108446. [Google Scholar] [CrossRef]

- Lv, H.; Xiong, Z.; Li, H.; Liu, J.; Xu, G.; Chen, H. Investigating the Mechanical Properties and Water Permeability of Recycled Pervious Concrete Using Three Typical Gradation Schemes. Buildings 2025, 15, 358. [Google Scholar] [CrossRef]

- Kim, G.M.; Adem, J.K.; Park, S. Reaction and microstructural characteristics of OPC pastes with low-lime calcium silicate cements under carbonation curing. Constr. Build. Mater. 2024, 415, 134993. [Google Scholar] [CrossRef]

- Anil Kumar Reddy, N.; Ramujee, K. Comparative study on mechanical properties of fly ash & GGBFS based geopolymer concrete and OPC concrete using nano-alumina. Mater. Today Proc. 2022, 60, 399–404. [Google Scholar]

- Li, P.; Wang, Q.; Li, J.; Pei, Y.; He, P. Mechanism and impact of water seepage during shield tunnelling in sandy cobble strata: A case study. Tunn. Undergr. Space Technol. 2024, 149, 105784. [Google Scholar] [CrossRef]

- Zheng, K.; Yang, X.; Chen, R.; Xu, L. Application of a capillary crystalline material to enhance cement grout for sealing tunnel leakage. Constr. Build. Mater. 2019, 214, 497–505. [Google Scholar] [CrossRef]

- Mai, G.; Xiong, Z.; Zhu, H.; Zhou, L.; Zhou, H.; Li, L. Durability of GFRP bars embedded in seawater sea sand concrete in marine environments. Constr. Build. Mater. 2025, 458, 139488. [Google Scholar] [CrossRef]

- Rebiai, F.; Guettala, A. Analysis of building failure associated with water seepage into gypsiferous soils in an arid area located in the northwestern town of Ouled Djellal (Algeria). Eng. Fail. Anal. 2023, 154, 107730. [Google Scholar] [CrossRef]

- Li, C.; Bai, J.; Jiang, Y.; Xiao, H.; Wang, W.; Xu, F. Investigating the seepage control and plugging capabilities of polyurethane-cement composites: A comprehensive study on material properties. Constr. Build. Mater. 2024, 416, 135191. [Google Scholar] [CrossRef]

- Muhammad, N.Z.; Keyvanfar, A.; Majid, M.Z.A.; Shafaghat, A.; Mirza, J. Waterproof performance of concrete: A critical review on implemented approaches. Constr. Build. Mater. 2015, 101, 80–90. [Google Scholar] [CrossRef]

- Zhang, M.; Hao, P.; Men, G.; Liu, N.; Yuan, G. Research on the compatibility of waterproof layer materials and asphalt mixture for steel bridge deck. Constr. Build. Mater. 2021, 269, 121346. [Google Scholar] [CrossRef]

- Zhang, C.; Guan, X.; Li, J.; Li, Y.; Lu, R. Coupling effect of cementitious capillary crystalline waterproof material and exposure environments on self-healing properties of engineered cementitious composites (ECC). J. Build. Eng. 2023, 63, 105471. [Google Scholar] [CrossRef]

- Fu, B.; Zhou, H.; Ye, F.; Wang, B.; Liu, S.; Qian, W. Experimental investigation on calcium dissolution performance of shotcrete with different waterproofing agents. Case Stud. Constr. Mater. 2024, 20, e03009. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Dai, Y.; Xu, C.; Yang, R.; Lu, J.; Peng, Y.; Wang, J.; Lv, Q.; Zeng, Q. Upcycling waste plastics to fabricate lightweight, waterproof, and carbonation resistant cementitious materials with polymer-nano silica hybrids. Mater. Today Sustain. 2023, 21, 100325. [Google Scholar] [CrossRef]

- Hu, X.; Xiao, J.; Zhang, Z.; Wang, C.; Long, C.; Dai, L. Effects of CCCW on properties of cement-based materials: A review. J. Build. Eng. 2022, 50, 104184. [Google Scholar] [CrossRef]

- Liu, M.; Liu, P.; Wu, J.; Yu, Z.; Chen, Y.; Cheng, X. Study on improvement of waterproofing performance of CCCW with silicone waterproof material and waterbased capillary inorganic waterproofer. Constr. Build. Mater. 2023, 400, 132842. [Google Scholar]

- Zhang, Y.; Zuo, L.; Yang, J.; Cai, X.; Zhao, Y.; Zeng, X. Effect of cementitious capillary crystalline waterproofing coating on the gas permeability of mortar. Struct. Concr. 2019, 20, 1763–1770. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Chen, J.; Tang, J.; Zhou, H.; Zhou, W.; Chang, X.; Cheng, Y. Preparation and performance study of active chemicals in cementitious capillary crystalline waterproofing materials. Case Stud. Constr. Mater. 2024, 20, e02874. [Google Scholar] [CrossRef]

- Liu, J.B.; Qin, H.; Geng, F.; Guo, W.; Pang, C. Effect of Cement-Based Permeable Crystallization Material on the Performance of Deterioration Concrete. Appl. Mech. Mater. 2013, 368–370, 905–910. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Effect of exposure conditions on self healing behavior of strain hardening cementitious composites incorporating various cementitious materials. Constr. Build. Mater. 2013, 42, 217–224. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar]

- Elsalamawy, M.; Mohamed, A.R.; Abosen, A.-l.E. Performance of crystalline forming additive materials in concrete. Constr. Build. Mater. 2020, 230, 117056. [Google Scholar]

- Li, F.; Yan, D.; Xiao, S.; Li, Z.; Chen, Z.; Leng, B.; Li, J. Effect of nanocomposite cementitious capillary crystalline waterproofing material on self-healing properties of cementitious composites. Case Stud. Constr. Mater. 2024, 21, e03579. [Google Scholar]

- Ding, F.; Fan, X.; Xie, Y.; Jiang, S.; Qiu, C.; Sun, D.; Wu, R. Combined effect of rice husk ash and cementitious capillary crystalline waterproofing materials on the performance of mortar. J. Build. Eng. 2024, 84, 108479. [Google Scholar]

- Hodul, J.; Žižková, N.; Drochytka, R.; Borg, R.P. Influence of Crystallization Admixture on Mechanical Parameters and Microstructure of Polymer-Cement Mortars with Waste Limestone. Solid State Phenom. 2019, 296, 27–34. [Google Scholar]

- Zhang, C.; Guan, X.; Lu, R.; Li, J.; Li, Y. Effect of cementitious capillary crystalline waterproof material on the various transport properties of cracked cementitious composites. Constr. Build. Mater. 2023, 365, 130138. [Google Scholar] [CrossRef]

- Zhang, L.V.; Suleiman, A.R.; Nehdi, M.L. Self-healing in fiber-reinforced alkali-activated slag composites incorporating different additives. Constr. Build. Mater. 2020, 262, 120059. [Google Scholar] [CrossRef]

- Feng, H.; Su, Y.; Guo, A.; Zhou, Z.; Yu, Z.; Guo, Z.; Sun, Z. Capillary water transport performance of cellulose nanocrystal modified cement/fly ash pastes with various water/binder ratios. Constr. Build. Mater. 2024, 450, 138694. [Google Scholar]

- Feng, H.; Su, Y.; Guo, A.; Yu, Z.; Guo, Z. Mechanical properties of cellulose nanocrystal modified cement/fly ash pastes under various water/binder ratios. Constr. Build. Mater. 2024, 447, 138213. [Google Scholar]

- Oliveira, T.V.; Cordeiro, L.d.N.P.; Bessa, S.A.L. Experimental study of self-leveling mortars produced with recycled concrete aggregates. Case Stud. Constr. Mater. 2022, 17, e01294. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, B.; Yuan, P.; Guo, H.; Liu, D.; Chen, J.; Liu, H.; Belaroui, L.S. Optimization of mechanical performance of limestone calcined clay cement: Effects of calcination temperature of nanosized tubular halloysite, gypsum content, and water/binder ratio. Constr. Build. Mater. 2023, 389, 131709. [Google Scholar] [CrossRef]

- Jose, A.; Nivitha, M.; Krishnan, J.M.; Robinson, R. Characterization of cement stabilized pond ash using FTIR spectroscopy. Constr. Build. Mater. 2020, 263, 120136. [Google Scholar] [CrossRef]

- Jain, B.; Sancheti, G.; Jain, V. FTIR analysis of silica fume and iron dust added concrete. Mater. Today Proc. 2022, 60, 777–781. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, B.; Guo, H.; Wang, Q.; Liu, D.; Chen, J.; Yuan, P. Calcined nanosized tubular halloysite for the preparation of limestone calcined clay cement (LC3). Appl. Clay Sci. 2023, 232, 106795. [Google Scholar] [CrossRef]

- Li, H.; Wang, Z.; Zhang, Y.; Zhang, G.; Zhu, H. Composite application of naphthalene and melamine-based superplasticizers in alkali activated fly ash (AAFA). Constr. Build. Mater. 2021, 297, 123651. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, B.; Deng, L.; Yuan, P.; Li, M.; Wang, Q. Preparation of high-performance silico-aluminophosphate geopolymers using fly ash and metakaolin as raw materials. Appl. Clay Sci. 2021, 204, 106019. [Google Scholar] [CrossRef]

- Cong, P.; Mei, L. Using silica fume for improvement of fly ash/slag based geopolymer activated with calcium carbide residue and gypsum. Constr. Build. Mater. 2021, 275, 122171. [Google Scholar] [CrossRef]

- Mahmoud, A.A.M.; Shehab, M.S.H.; El-Dieb, A.S. Concrete mixtures incorporating synthesized sulfonated acetophenone–formaldehyde resin as superplasticizer. Cem. Concr. Compos. 2010, 32, 392–397. [Google Scholar] [CrossRef]

- Zhan, P.; Wang, J.; Yu, W.; Deng, Z.; She, A.; Zuo, J.; Li, W.; Xu, J. Insights into the hydration kinetics, microstructure and early strength of Portland cement containing synthetic C-S-H/PCE nanocomposites. Cem. Concr. Compos. 2025, 157, 105886. [Google Scholar] [CrossRef]

- Kaya, Y.; Kobya, V.; Kaya, Y.; Mardani, A. Impact of PCE-based grinding aids on hydration kinetics in fly ash substituted systems: Influence of pH and dosage. Constr. Build. Mater. 2025, 458, 139531. [Google Scholar] [CrossRef]

- GB 18445-2012; Cementitious Capillary Crystalline Waterproofing Material. Standardization Administration of China: Beijing, China; China Standards Press: Beijing, China, 2012.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standardization Administration of China: Beijing, China; China Standards Press: Beijing, China, 2021.

- GB/T 8077-2012; Test Method for Fluidity of Cement Paste. Standardization Administration of China: Beijing, China; China Standards Press: Beijing, China, 2012.

- ASTM C191-19; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2019.

- Zhao, M.; Zhang, X.; Zhang, Y. Effect of free water on the flowability of cement paste with chemical or mineral admixtures. Constr. Build. Mater. 2016, 111, 571–579. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Jiang, H.; Xing, J.; Sun, X.; Ma, Z. Flowability of ultrafine-tailings cemented paste backfill incorporating superplasticizer: Insight from water film thickness theory. Powder Technol. 2021, 381, 509–517. [Google Scholar] [CrossRef]

- Mbasha, W.; Haldenwang, R.; Masalova, I. The influence of sulfate availability on rheology of fresh cement paste. Appl. Rheol. 2020, 30, 54–63. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, C.; Wei, X. Influence of lithium sulfate addition on the properties of Portland cement paste. Constr. Build. Mater. 2014, 50, 457–462. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Y.; Zhou, P.; Song, Z.; Jia, Y.; Ouyang, W.; Luque, R.; Sun, Y. Effects of Using Aluminum Sulfate as an Accelerator and Acrylic Acid, Aluminum Fluoride, or Alkanolamine as a Regulator in Early Cement Setting. Materials 2023, 16, 1620. [Google Scholar] [CrossRef]

- O’Beirne, J.; Shelton, R.; Lumley, P.; Hofmann, M. Accelerating the setting of Portland cement based dental materials using calcium sulphates. In Proceedings of the 20th International Symposium on Ceramics in Medicine, Nantes, France, 24–26 October 2007. [Google Scholar]

- Wang, C.; Wang, L.; Yao, X.; Du, J.; Zhou, A. The promoting effect of quercetin on oil well cement setting. Constr. Build. Mater. 2022, 317, 125689. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, J.; Long, C.; Zhang, Q.; Shi, J.; Zhang, Z. Influences of the joint action of sulfate erosion and cementitious capillary crystalline waterproofing materials on the hydration products and properties of cement-based materials: A review. J. Build. Eng. 2023, 68, 106061. [Google Scholar] [CrossRef]

- Zheng, Y.; Yuan, B.; Li, Z.; Zhang, B.; Liu, F.; Li, L. Effect of cementitious capillary crystalline waterproof material on the mechanical behavior of concrete. J. Build. Eng. 2024, 98, 111287. [Google Scholar] [CrossRef]

- Zhang, B.; Feng, Y.; Xie, J.; He, J.; Yu, T.; Cai, C.; Huang, D. Compressive behaviours, splitting properties, and workability of lightweight cement concrete: The role of fibres. Constr. Build. Mater. 2022, 320, 126237. [Google Scholar] [CrossRef]

- Zhang, B.; Muhammad, F.; Yu, T.; Fahimizadeh, M.; Hassan, M.A.S.; Liang, J.; Ning, X.; Yuan, P. Harnessing iron tailings as supplementary cementitious materials in Limestone Calcined Clay Cement (LC3): An innovative approach towards sustainable construction. Constr. Build. Mater. 2024, 453, 139111. [Google Scholar] [CrossRef]

- Vagenas, N.V.; Gatsouli, A.; Kontoyannis, C.G. Quantitative analysis of synthetic calcium carbonate polymorphs using FT-IR spectroscopy. Talanta 2003, 59, 831–836. [Google Scholar] [CrossRef]

- Lin, R.-S.; Han, Y.; Wang, X.-Y. Macro–meso–micro experimental studies of calcined clay limestone cement (LC3) paste subjected to elevated temperature. Cem. Concr. Compos. 2021, 116, 103871. [Google Scholar] [CrossRef]

- Santos, V.H.J.M.d.; Pontin, D.; Ponzi, G.G.D.; e Stepanha, A.S.D.G.; Martel, R.B.; Schütz, M.K.; Einloft, S.M.O.; Dalla Vecchia, F. Application of Fourier Transform infrared spectroscopy (FTIR) coupled with multivariate regression for calcium carbonate (CaCO3) quantification in cement. Constr. Build. Mater. 2021, 313, 125413. [Google Scholar] [CrossRef]

- de Oliveira, A.M.; Oliveira, A.P.; Vieira, J.D.; Junior, A.N.; Cascudo, O. Study of the development of hydration of ternary cement pastes using X-ray computed microtomography, XRD-Rietveld method, TG/DTG, DSC, calorimetry and FTIR techniques. J. Build. Eng. 2023, 64, 105616. [Google Scholar] [CrossRef]

- Soin, A.V.; Catalan, L.J.J.; Kinrade, S.D. A combined QXRD/TG method to quantify the phase composition of hydrated Portland cements. Cem. Concr. Res. 2013, 48, 17–24. [Google Scholar] [CrossRef]

- Li, P.; Li, W.; Wang, K.; Zhao, H.; Shah, S.P. Hydration and microstructure of cement paste mixed with seawater—An advanced investigation by SEM-EDS method. Constr. Build. Mater. 2023, 392, 131925. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, G.; Qi, Y.; Zeng, Q. In-situ assessment of the water-penetration resistance of polymer modified cement mortars by μ-XCT, SEM and EDS. Cem. Concr. Compos. 2020, 114, 103821. [Google Scholar] [CrossRef]

- Wang, C.; Wang, L.; Yao, X.; Du, J.; Zhai, W.; Guo, S.; Zhou, A. The effect of rutin on the early-age hydration of oil well cement at varying temperatures. Cem. Concr. Compos. 2022, 128, 104438. [Google Scholar] [CrossRef]

- Wang, C.; Xiang, W.; Du, J.; Yao, X. Heat flow inhibitor suitable for oil well cement at low temperature. Constr. Build. Mater. 2022, 329, 127105. [Google Scholar] [CrossRef]

- Zhong, J.; Zhang, H.; Mao, J.; Zhang, Y.; Lian, S.; Wang, J.; Zhou, H.; Song, Y.; Hu, J.; Wu, H.; et al. Influences of cementitious capillary crystalline waterproofing on the hydration products and properties of cement-based materials. J. Build. Eng. 2024, 98, 111451. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).