Progress and Prospect of Solid Waste Utilization in Construction Industry: A Bibliometric Analysis Based on CiteSpace and VOSviewer

Abstract

1. Introduction

2. Methodology and Data Resource

2.1. Methodology

2.2. Data Resources

3. Results Analysis

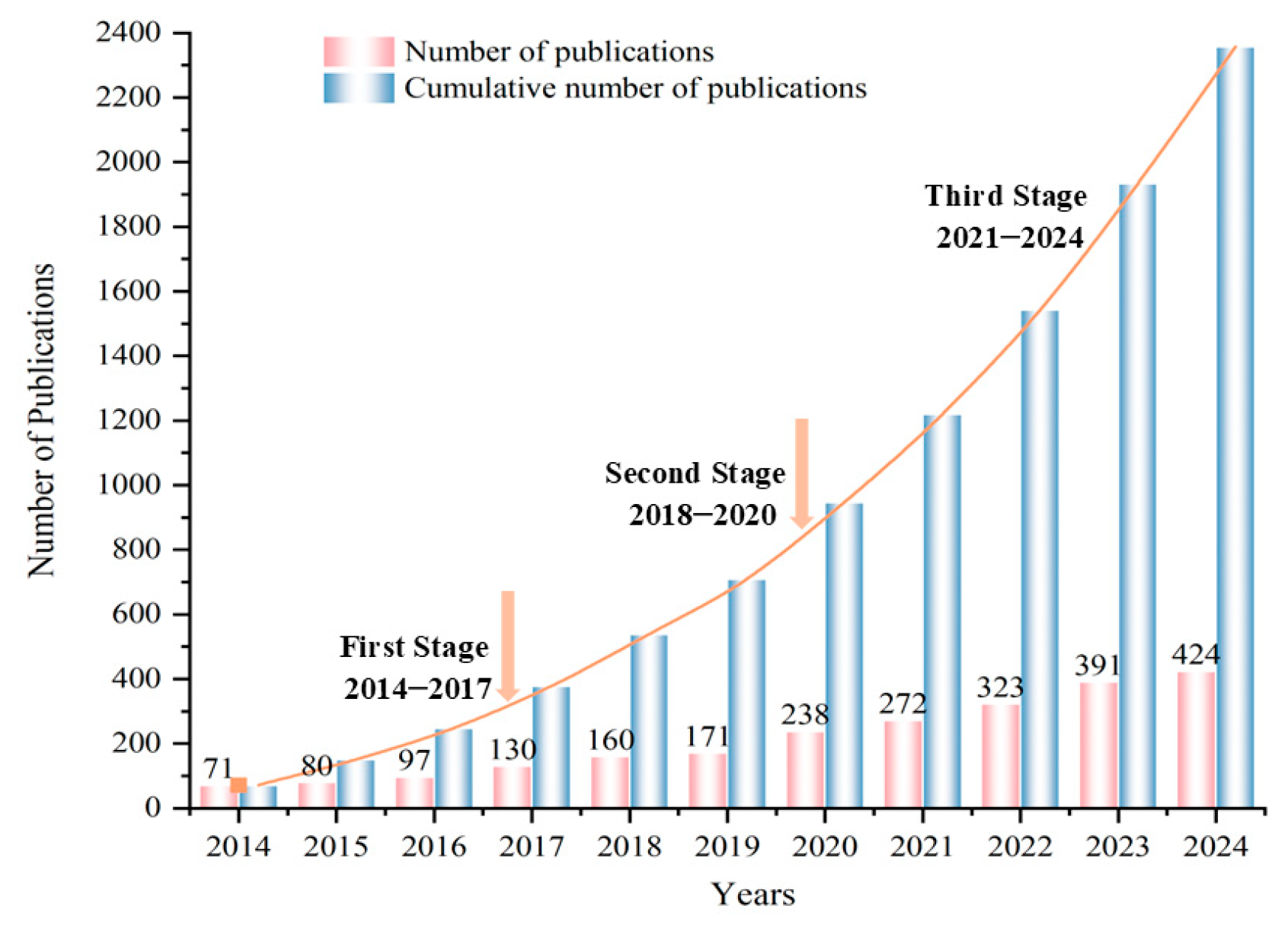

3.1. Annual Publications and Trends

3.2. Types of Solid Wastes Used in Construction

3.3. Global Distribution Collaborations Analysis

3.3.1. Analysis of Author Collaboration Network

3.3.2. Analysis of Institution Collaboration Network

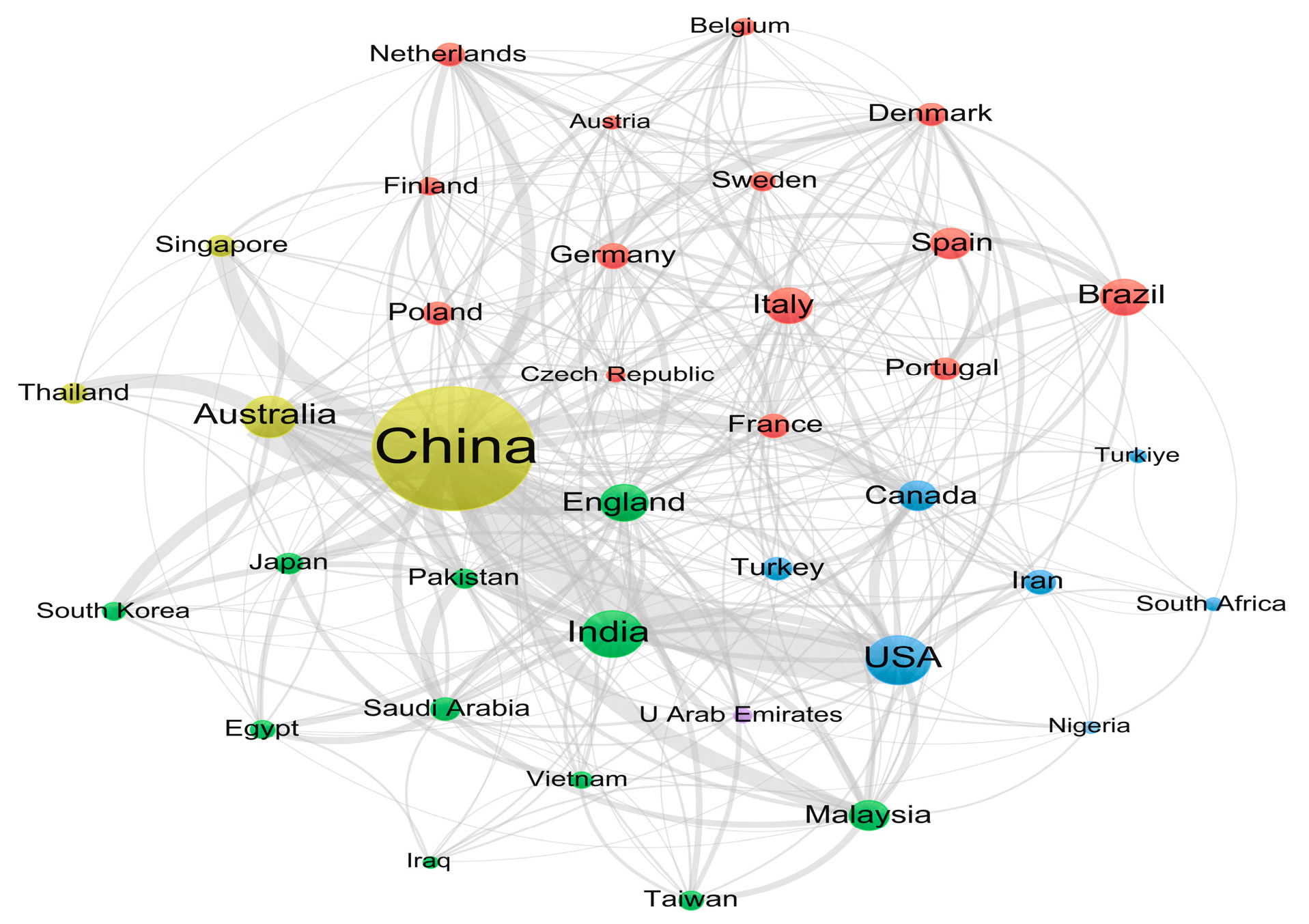

3.3.3. Analysis of Country Collaboration Network

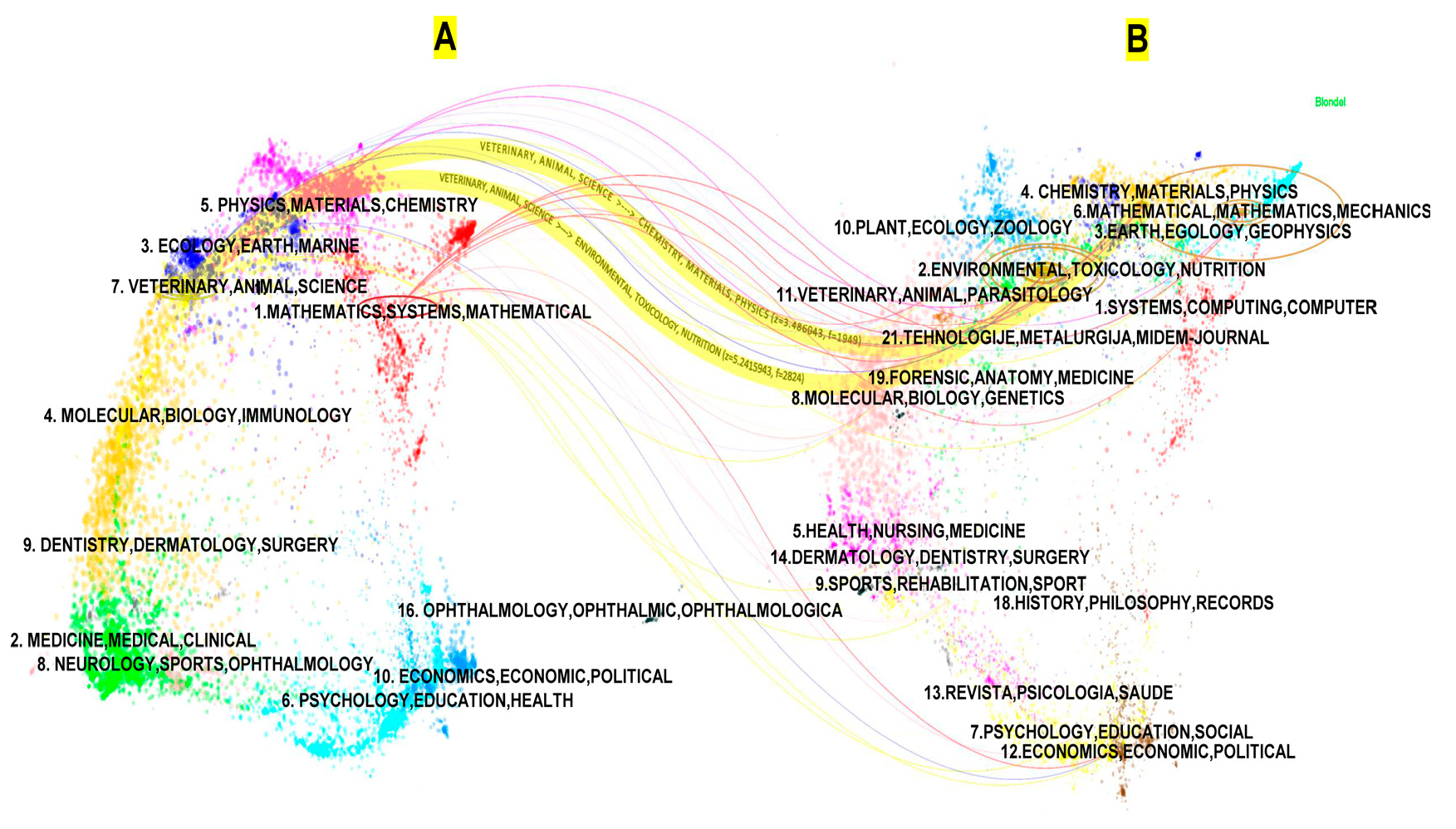

3.4. Subject and Journal Analysis

3.5. Theme Analysis of Research Hotspots

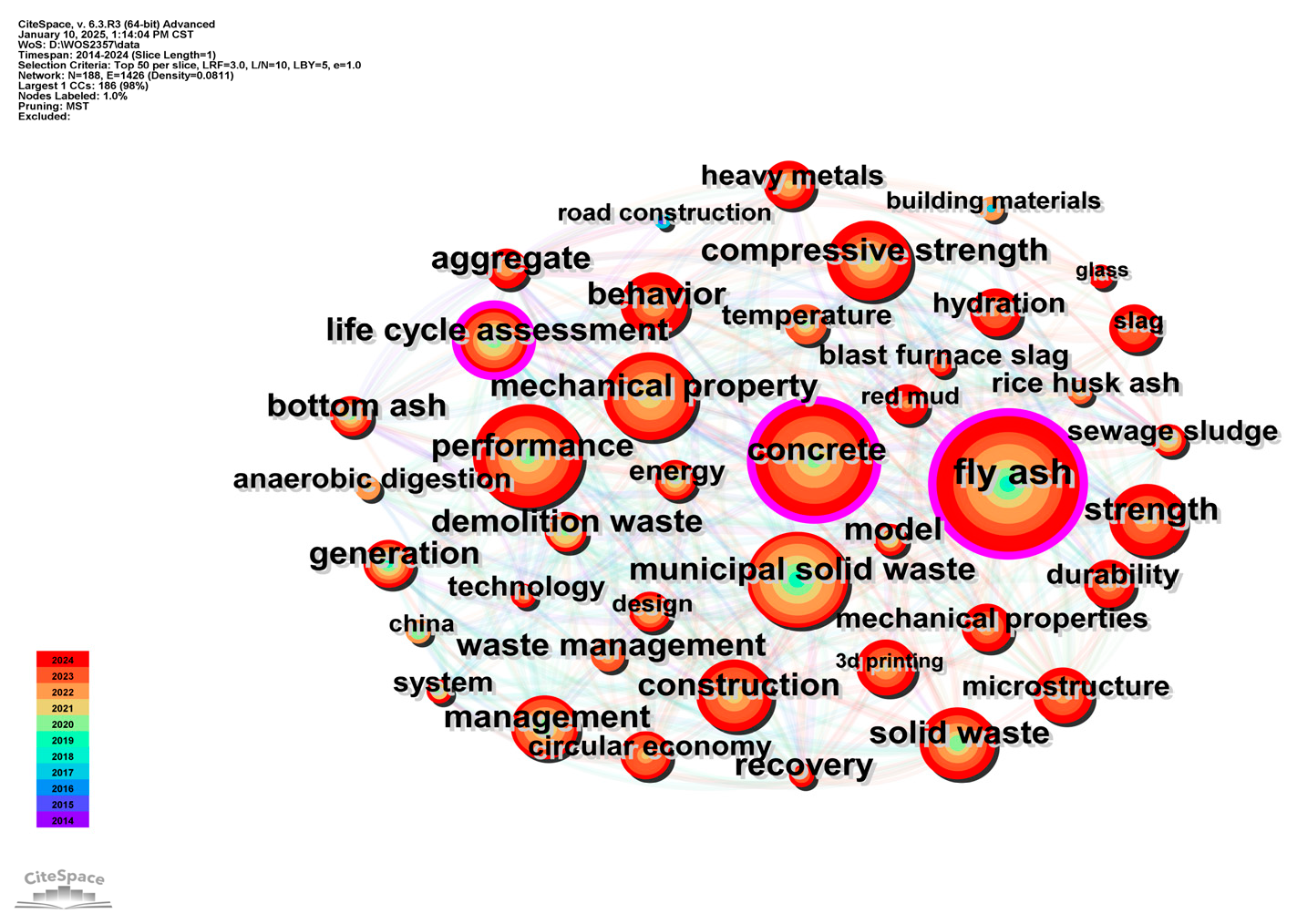

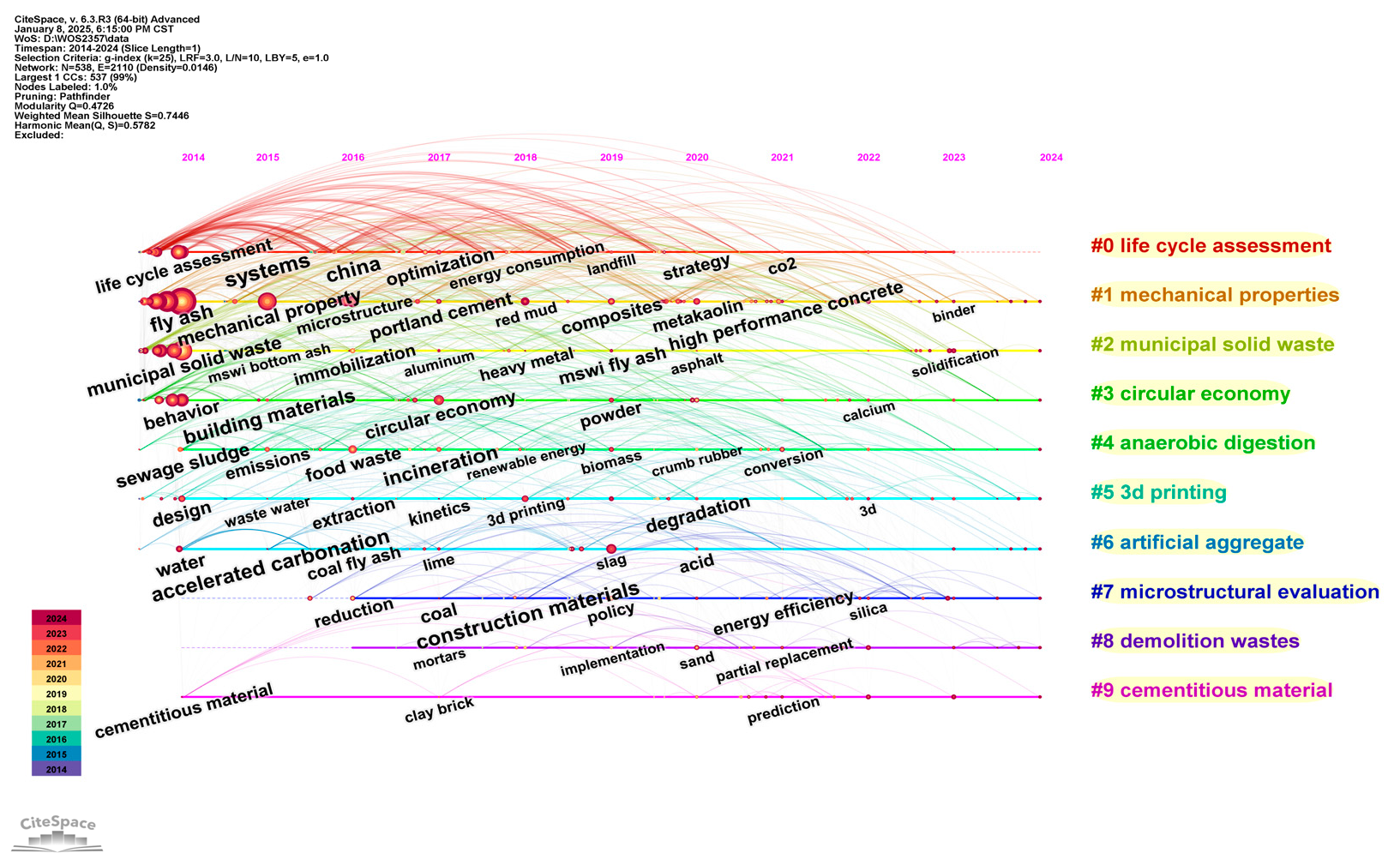

3.5.1. Analysis of Keyword Network

3.5.2. Analysis of Keyword Cluster

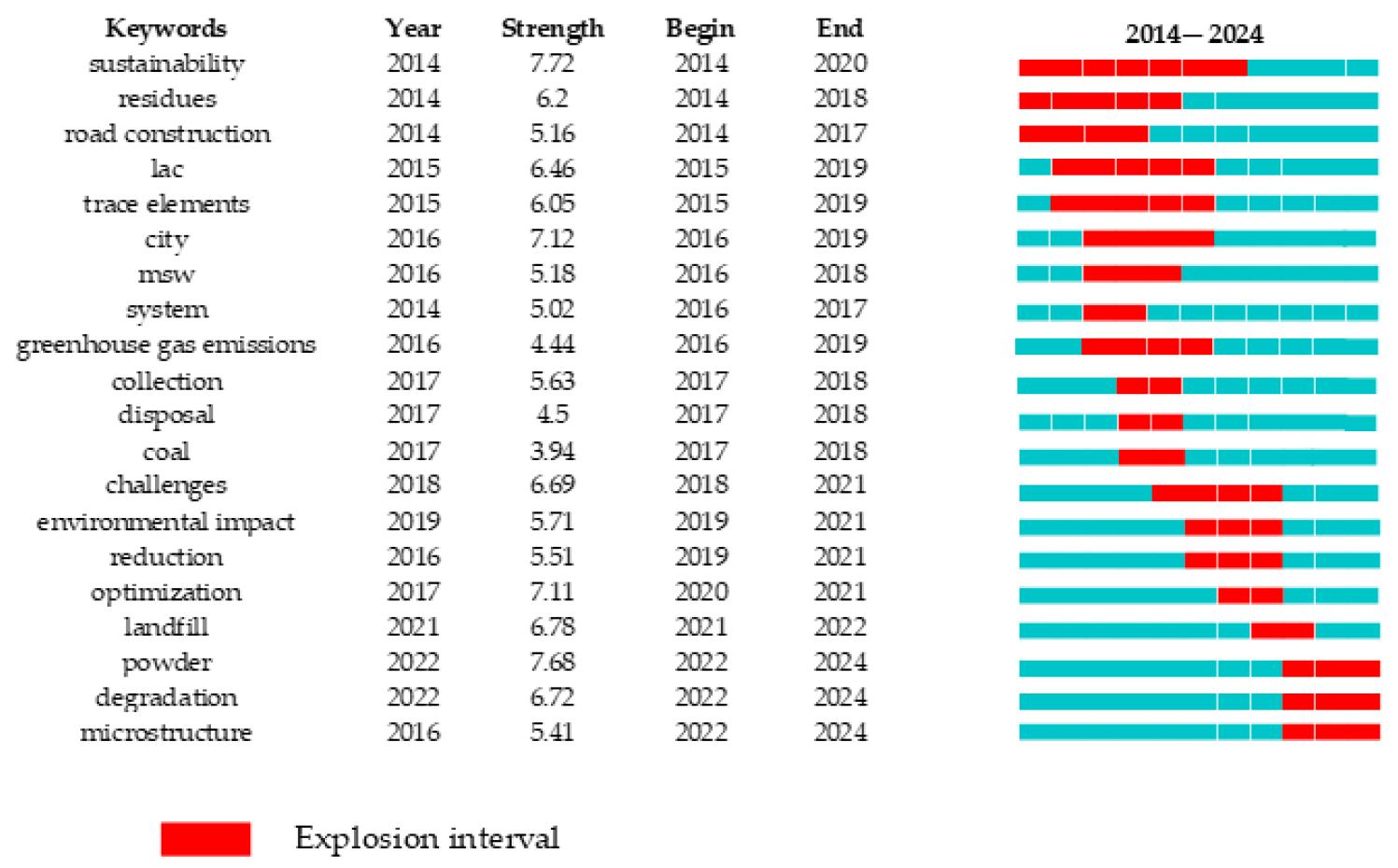

3.5.3. Keywords with Citation Bursts

4. Discussion

5. Research Needs and Future Directions

- (1)

- In-Depth Exploration of the Synergistic Effects of Solid Waste

- (2)

- High-Performance and Diversified Applications of Solid Waste

- (3)

- Emerging Intelligent and Automated Technologies Steering the Future of Solid Waste Reutilization

6. Conclusions

- (1)

- Growth of Research Output

- (2)

- Global Collaboration and Network Analysis

- (3)

- Journal and Thematic Analysis

- (4)

- Research Hotspots and Evolutionary Trends

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- World Bank. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. World Bank. 2018. Available online: https://openknowledge.worldbank.org/handle/10986/30317 (accessed on 22 February 2025).

- United Nations Environment Programme (UNEP). Global Waste Management Outlook. United Nations Environment Programme. 2024. Available online: https://www.unep.org/resources/global-waste-management-outlook-2024 (accessed on 22 February 2025).

- The Business Research Company. Construction and Demolition Waste Management Global Market Report 2024. 2024. Available online: https://cn.gii.tw/report/tbrc1436155-construction-demolition-waste-management-global.html (accessed on 22 February 2025).

- Chen, D.M.C.; Bodirsky, B.L.; Krueger, T.; Mishra, A.; Popp, A. The world’s growing municipal solid waste: Trends and impacts. Environ. Res. Lett. 2020, 15, 074021. [Google Scholar] [CrossRef]

- Harihanandh, M.; Karuppanan, K.; Viswanathan, K.E.; Krishnaraja, A.R. Characterization of nano fly ash and study on durability properties of nano fly ash embedded concrete. Matéria 2023, 28, e20230281. [Google Scholar] [CrossRef]

- Zhuang, S.; Wang, Q.; Luo, T. Modification of ultrafine blast furnace slag with steel slag as a novel high-quality mineral admixture to prepare high-strength concrete. J. Build. Eng. 2023, 71, 106501. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, B.; Zhang, S.; Blom, K.; Luković, M.; Ye, G. Characterization, pre-treatment, and potential applications of fine MSWI bottom ash as a supplementary cementitious material. Constr. Build. Mater. 2024, 421, 135769. [Google Scholar] [CrossRef]

- Narendra, S.; Vasugi, V. Development of red mud based sintered artificial aggregates with various industrial wastes. Mater. Res. Express. 2024, 11, 066401. [Google Scholar] [CrossRef]

- Souza, E.D.F.C.D.; Silva, T.F.D.; Castro, M.A.D.; Ferreira, G.C.D.S. Combined Use of Ladle Furnace Slag and Rice Husk Ash as a Supplementary Cementitious Material. Mater. Res. 2023, 26, e20230069. [Google Scholar] [CrossRef]

- Segui, P.; Safhi, A.E.M.; Amrani, M.; Benzaazoua, M. Mining Wastes as Road Construction Material: A Review. Minerals 2023, 13, 90. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Wu, H.; Xiao, J.; Liang, C.; Ma, Z. Properties of cementitious materials with recycled aggregate and powder both from clay brick waste. Buildings 2021, 11, 119. [Google Scholar] [CrossRef]

- Tamanna, K.; Raman, S.N.; Jamil, M.; Hamid, R. Utilization of wood waste ash in construction technology: A review. Constr. Build. Mater. 2020, 237, 117654. [Google Scholar] [CrossRef]

- Silveira, N.C.; Martins, M.L.; Bezerra, A.C.; Araújo, F.G. Red mud from the aluminium industry: Production, characteristics, and alternative applications in construction materials—A review. Sustainability 2021, 13, 12741. [Google Scholar] [CrossRef]

- Heriyanto; Pahlevani, F.; Sahajwalla, V. From waste glass to building materials–An innovative sustainable solution for waste glass. J. Clean. Prod. 2018, 191, 192–206. [Google Scholar]

- Jiang, Z.Y.; Sun, X.P.; Luo, Y.Q.; Fu, X.L.; Xu, A.; Bi, Y.Z. Recycling, reusing and environmental safety of industrial by-product gypsum in construction and building materials. Constr. Build. Mater. 2024, 432, 136609. [Google Scholar] [CrossRef]

- Hossain, S.S.; Roy, P.K.; Bae, C.J. Utilization of waste rice husk ash for sustainable geopolymer: A review. Constr. Build. Mater. 2021, 310, 125218. [Google Scholar]

- Jun, Z.; Shuzhong, W.; Zhiqiang, W.; Haiyu, M.; Lin, C. Hydrogen-rich syngas produced from the co-pyrolysis of municipal solid waste and wheat straw. Int. J. Hydrog. Energy 2017, 42, 19701–19708. [Google Scholar]

- Kanojia, A.; Jain, S.K. Performance of coconut shell as coarse aggregate in concrete. Constr. Build. Mater. 2017, 140, 150–156. [Google Scholar]

- Yeo, R.J.; Sng, A.; Wang, C.; Tao, L.; Zhu, Q.; Bu, J. Strategies for heavy metals immobilization in municipal solid waste incineration bottom ash: A critical review. Rev. Environ. Sci. Biotechnol. 2024, 23, 503–568. [Google Scholar]

- Liu, Y.; Lu, H.; Liu, M.; Cai, L.; Wei, N.; Liu, Y. Microanalytical characterizations, mechanical strength and water resistance performance of solidified dredged sludge with industrial solid waste and architecture residue soil. Case Stud. Constr. Mater. 2022, 17, e01492. [Google Scholar]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Ahn, Y.H.; et al. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Zhang, Q.; Cao, X.; Ma, R.; Sun, S.; Fang, L.; Lin, J.; Luo, J. Solid waste-based magnesium phosphate cements: Preparation, performance and solidification/stabilization mechanism. Constr. Build. Mater. 2021, 297, 123761. [Google Scholar]

- Liu, X.; Zhang, Z.; Wu, P. Utilization of solid wastes for aerated concrete preparation: Mechanical properties and microstructural analysis. J. Build. Eng. 2024, 82, 108235. [Google Scholar]

- Das, D.; Gołąbiewska, A.; Rout, P.K. Geopolymer bricks: The next generation of construction materials for sustainable environment. Constr. Build. Mater. 2024, 445, 137876. [Google Scholar]

- Sun, Q.; Huang, T.; Tian, R.; Wang, F.; Ba, M. Exploring the binding potential of magnesium oxysulfate cement with multi-source solid wastes. Constr. Build. Mater. 2024, 411, 134649. [Google Scholar] [CrossRef]

- Liu, J.; Shi, X.; Zou, Q.; Zhao, T.; Zheng, J.; Liu, T.; Han, L.; Ke, Y.; Wang, Q. Recycling of water quenched slag and silica sand tailing for the synthesis of an eco-friendly permeable material. Constr. Build. Mater. 2022, 357, 129310. [Google Scholar]

- Sun, Y.; Zhang, X.; Chen, J.; Liao, J.; Shi, C.; Huang, C. Mixing design and performance of porous asphalt mixtures containing solid waste. Case Stud. Constr. Mater. 2024, 21, e03644. [Google Scholar]

- Guo, X.; Zeng, M.; Yu, H.; Lin, F.; Li, J.; Wang, W.; Chen, G. Critical review for the potential analysis of material utilization from inorganic industrial solid waste. J. Clean. Prod. 2024, 459, 142457. [Google Scholar]

- Zupic, I.; Čater, T. Bibliometric methods in management and organization. Organ. Res. Methods. 2015, 18, 429–472. [Google Scholar]

- Mingers, J.; Leydesdorff, L. A review of theory and practice in scientometrics. Eur. J. Oper. Res. 2015, 246, 1–19. [Google Scholar]

- Pan, X.; Yan, E.; Cui, M.; Hua, W. Examining the usage, citation, and diffusion patterns of bibliometric map** software: A comparative study of three tools. J. Informetr. 2018, 12, 481–493. [Google Scholar]

- Liu, H.; Luo, Y.; Geng, J.; Yao, P. Research hotspots and frontiers of product R&D management under the background of the digital intelligence era—Bibliometrics based on citespace and histcite. Appl. Sci. 2021, 11, 6759. [Google Scholar] [CrossRef]

- Sabe, M.; Chen, C.; Perez, N.; Solmi, M.; Mucci, A.; Galderisi, S.; Strauss, G.P.; Kaiser, S. Thirty years of research on negative symptoms of schizophrenia: A scientometric analysis of hotspots, bursts, and research trends. Neurosci. Biobehav. Rev. 2023, 144, 104979. [Google Scholar] [CrossRef]

- Pang, T.; Shen, J. Visualizing the Landscape and Evolution of Capacitive Deionization by Scientometric Analysis. Desalination 2022, 527, 115562. [Google Scholar] [CrossRef]

- Brzezinski, M. Power Laws in Citation Distributions: Evidence from Scopus. Scientometrics 2015, 103, 213–228. [Google Scholar] [CrossRef]

- Harzing, A.W.; Alakangas, S. Google Scholar, Scopus and the Web of Science: A longitudinal and cross-disciplinary comparison. Scientometrics 2016, 106, 787–804. [Google Scholar] [CrossRef]

- Kumpulainen, M.; Seppänen, M. Combining Web of Science and Scopus datasets in citation-based literature study. Scientometrics 2022, 127, 5613–5631. [Google Scholar] [CrossRef]

- Towards a Circular Economy: A Zero Waste Programme for Europe (COM (2014) 398). Brussels: European Commission. 2014. Available online: https://leap.unep.org/en/countries/eu/national-legislation/towards-circular-economy-zero-waste-programme-europe (accessed on 22 February 2025).

- Closing the Loop-An EU Action Plan for the Circular Economy (COM (2015) 614 final). Brussels: European Commission. 2015. Available online: https://www.eea.europa.eu/policy-documents/com-2015-0614-final (accessed on 22 February 2025).

- Wu, Z.; Ann, T.W.; Shen, L.; Liu, G. Quantifying construction and demolition waste: An analytical review. Waste Manag. 2014, 34, 1683–1692. [Google Scholar] [CrossRef]

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The possible use of sewage sludge ash (SSA) in the construction industry as a way towards a circular economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- A New Circular Economy Action Plan For a cleaner and more competitive Europe (COM (2020) 98final). Brussel: Euro-pean Commission. 2020. Available online: https://www.eea.europa.eu/policy-documents/com-2020-98-final-a (accessed on 22 February 2025).

- Hepburn, C.; Qi, Y.; Stern, N.; Ward, B.; Xie, C.; Zenghelis, D. Towards carbon neutrality and China’s 14th Five-Year Plan: Clean energy transition, sustainable urban development, and investment priorities. Environ. Sci. Ecotechnol. 2021, 8, 100130. [Google Scholar] [CrossRef]

- Kapelewska, J.; Kotowska, U.; Karpińska, J.; Astel, A.; Zieliński, P.; Suchta, J.; Algrzym, K. Water pollution indicators and chemometric expertise for the assessment of the impact of municipal solid waste landfills on groundwater located in their area. Chem. Eng. J. 2019, 359, 790–800. [Google Scholar] [CrossRef]

- Kanhai, G.; Fobil, J.N.; Nartey, B.A.; Spadaro, J.V.; Mudu, P. Urban Municipal Solid Waste management: Modeling air pollution scenarios and health impacts in the case of Accra, Ghana. Waste Manag. 2021, 123, 15–22. [Google Scholar] [PubMed]

- Akmalaiuly, K.; Berdikul, N.; Pundienė, I.; Pranckevičienė, J. The effect of mechanical activation of fly ash on cement-based materials hydration and hardened state properties. Materials 2023, 16, 2959. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wu, H.; Jiang, J.; Wang, L.; Kong, D.; Yu, K. Properties of flue gas desulphurization gypsum–activated steel slag fine aggregate red mud–based concrete. J. Mater. Civ. Eng. 2023, 35, 04023025. [Google Scholar]

- Wang, C.; Ji, Y.; Qie, R.; Wang, J.; Wang, D. Mechanical performance investigation on fiber strengthened recycled iron tailings concrete. Case Stud. Constr. Mater. 2024, 20, e02734. [Google Scholar]

- Zhao, H.; Wang, S.; Wang, R.; Shen, L.; Wang, Q. Utilization of raw coal gangue as coarse aggregates in pavement concrete. Constr. Build. Mater. 2023, 378, 131062. [Google Scholar]

- Feng, D.; Wang, J.; Wang, Y.; Xiao, X.; Hou, W.; Liang, S. Alkali-activated geopolymer materials prepared from coal gangue and municipal solid waste incineration byproducts. J. Build. Eng. 2023, 80, 108074. [Google Scholar]

- Maier, D. A review of the environmental benefits of using wood waste and magnesium oxychloride cement as a composite building material. Materials 2023, 16, 1944. [Google Scholar] [CrossRef]

- Mazhoud, B.; Sedran, T.; Cazacliu, B.; Cothenet, A.; Torrenti, J.M. Influence of residual mortar volume on the properties of recycled concrete aggregates. J. Build. Eng. 2022, 57, 104945. [Google Scholar]

- Ho, H.J.; Iizuka, A.; Shibata, E. Chemical recycling and use of various types of concrete waste: A review. J. Clean. Prod. 2021, 284, 124785. [Google Scholar] [CrossRef]

- Wang, C.Q.; Cheng, L.X.; Ying, Y.; Yang, F.H. Utilization of all components of waste concrete: Recycled aggregate strengthening, recycled fine powder activity, composite recycled concrete and life cycle assessment. J. Build. Eng. 2024, 82, 108255. [Google Scholar]

- Nasr, M.S.; Salih, M.A.; Shubbar, A.; Falah, M.W.; Abadel, A.A. Influence of mechanical activation on the behavior of green high-strength mortar including ceramic waste. Mater. Sci.-Pol. 2023, 41, 41–56. [Google Scholar]

- Chiang, K.Y.; Yen, H.R.; Lu, C.H. Recycled gypsum board acted as a mineral swelling agent for improving thermal conductivity characteristics in manufacturing of green lightweight building brick. Environ. Sci. Pollut. Res. 2019, 26, 34205–34219. [Google Scholar]

- Chen, S.; Huang, J.; Xiao, T.; Gao, J.; Bai, J.; Luo, W.; Dong, B. Carbon emissions under different domestic waste treatment modes induced by garbage classification: Case study in pilot communities in Shanghai, China. Sci. Total Environ. 2020, 717, 137193. [Google Scholar] [PubMed]

- Abdel-Shafy, H.I.; Mansour, M.S. Solid waste issue: Sources, composition, disposal, recycling, and valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar]

- Deng, Q.; Zou, S.; Xi, Y.; Singh, A. Development and characteristic of 3D-printable mortar with waste glass powder. Buildings 2023, 13, 1476. [Google Scholar] [CrossRef]

- Thakare, A.A.; Singh, A.; Gupta, T.; Chaudhary, S. Effect of size variation of fibre-shaped waste tyre rubber as fine aggregate on the ductility of self-compacting concrete. Environ. Sci. Pollut. Res. 2023, 30, 20031–20051. [Google Scholar]

- Mareya, M.; Bahurudeen, A.; Varghese, J.; Thomas, B.S.; Sithole, N.T. Transformation of rice husk modified basic oxygen furnace slag into geopolymer composites. J. Mater. Res. Technol. 2023, 24, 6264–6278. [Google Scholar]

- Fernando, S.; Gunasekara, C.; Law, D.W.; Nasvi, M.C.M.; Setunge, S.; Dissanayake, R. Assessment of long term durability properties of blended fly ash-Rice husk ash alkali activated concrete. Constr. Build. Mater. 2023, 369, 130449. [Google Scholar]

- Deng, J.X.; Li, X.; Li, X.J.; Wei, T.B. Research on the performance of recycled-straw insulating concrete and optimization design of matching ratio. Sustainability 2023, 15, 9608. [Google Scholar] [CrossRef]

- Zuo, P.; Liu, Z.; Zhang, H.; Sivanathan, A.; Dai, D.; Fan, M. Thermal transformation of bamboo sawdust for its advanced cementitious composites. Constr. Build. Mater. 2023, 383, 131395. [Google Scholar]

- Hernández-Olivares, F.; Medina-Alvarado, R.E.; Burneo-Valdivieso, X.E.; Zúñiga-Suárez, A.R. Short sugarcane bagasse fibers cementitious composites for building construction. Constr. Build. Mater. 2020, 247, 118451. [Google Scholar] [CrossRef]

- Wu, H.; Kang, S.; Zhang, H.; Sun, Q.; Shen, R.; Shu, Z. Research of the workability, mechanical and hydration mechanism of coal gangue-construction solid waste backfilling materials. Constr. Build. Mater. 2023, 408, 133833. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Y.; Liu, X.; Wang, X.; Chen, Z.; Lei, Z.; Zhou, Y.; Singh, A. Review on solid wastes incorporated cementitious material using 3D concrete printing technology. Case Stud. Constr. Mater. 2024, e03676. [Google Scholar] [CrossRef]

- Khalil, M.S.; Arab, M.A.E.S.; Etman, A.E.; Abdelwahab, N.R.; Moustafa, W.M.; Hamouda, A.S. Experimental and theoretical investigation for shielding efficiency of self-compacted concrete containing lead smelting waste for gamma ray. Case Stud. Constr. Mater. 2023, 19, e02401. [Google Scholar]

- Wang, X.; Ding, C.; Long, H.; Wu, Y.; Jiang, F.; Chang, R.; Xue, S.; Wu, J.; Cheng, K. A novel approach to treating nickel-containing electroplating sludge by solidification with basic metallurgical solid waste. J. Mater. Res. Technol. 2023, 27, 3644–3654. [Google Scholar] [CrossRef]

- Kubiliute, R.; Kaminskas, R.; Kazlauskaite, A. Mineral wool production waste as an additive for Portland cement. Cem. Concr. Comp. 2018, 88, 130–138. [Google Scholar] [CrossRef]

- Wang, J.N.; Chen, F.X.; Yu, R.; Fan, D.Q.; Zhang, T.S. Effect of heavy metal (Mn, Pb and Cr) on the properties and hydration in low water/binder cement-based composites (LW/B-CC). Constr. Build. Mater. 2023, 386, 131567. [Google Scholar] [CrossRef]

- Peng, G.; Zhang, P.; Zeng, L.; Yu, L.; Li, D. Immobilization of chromium ore processing residue by alkali-activated composite binders and leaching characteristics. Environ. Sci. Pollut. Res. 2023, 30, 71154–71170. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, T.; Li, H.; Tu, S.; Zhang, L.; Hao, T.; Yan, B. Mineral phase transition characteristics and its effects on the stabilization of heavy metals in industrial hazardous wastes incineration (IHWI) fly ash via microwave-assisted hydrothermal treatment. Sci. Total Environ. 2023, 877, 162842. [Google Scholar] [CrossRef]

- Poon, C.S.; Shen, P.; Jiang, Y.; Ma, Z.; Xuan, D. Total recycling of concrete waste using accelerated carbonation: A review. Cem. Concr. Res. 2023, 173, 107284. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete–A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Zhan, B.J.; Xuan, D.X.; Poon, C.S.; Scrivener, K.L. Multi-scale investigation on mechanical behavior and microstructural alteration of CSH in carbonated Alite paste. Cem. Concr. Res. 2021, 144, 106448. [Google Scholar]

- Kua, T.A.; Arulrajah, A.; Horpibulsuk, S.; Du, Y.J.; Shen, S.L. Strength assessment of spent coffee grounds-geopolymer cement utilizing slag and fly ash precursors. Constr. Build. Mater. 2016, 115, 565–575. [Google Scholar]

- Arulrajah, A.; Mohammadinia, A.; Phummiphan, I.; Horpibulsuk, S.; Samingthong, W. Stabilization of recycled demolition aggregates by geopolymers comprising calcium carbide residue, fly ash and slag precursors. Constr. Build. Mater. 2016, 114, 864–873. [Google Scholar] [CrossRef]

- Xue, Y.; Arulrajah, A.; Horpibulsuk, S.; Chu, J. Strength and stiffness performance of geopolymer stabilized washed recycled sands derived from demolition wastes in pavement subgrades. Constr. Build. Mater. 2023, 369, 130618. [Google Scholar]

- Magnuson, J.K.; Weiksnar, K.D.; Patel, A.D.; Clavier, K.A.; Ferraro, C.C.; Townsend, T.G. Processing municipal solid waste incineration bottom ash for integration into cement product manufacture. Resour. Conserv. Recycl. 2023, 198, 107139. [Google Scholar] [CrossRef]

- Yu, S.; Chen, J.; Wang, H.; Xie, Q. Multi-scale characterization and modeling of concrete permeability containing recycled steel slag aggregate. Constr. Build. Mater. 2024, 436, 137018. [Google Scholar]

- Xiao, C.; Wang, X.; Chen, Q.; Bin, F.; Wang, Y.; Wei, W. Strength Investigation of the Silt-Based Cemented Paste Backfill Using Lab Experiments and Deep Neural Network. Adv. Mater. Sci. Eng. 2020, 1, 6695539. [Google Scholar]

- Zhao, Z.; Xiao, F.; Amirkhanian, S. Recent applications of waste solid materials in pavement engineering. Waste Manag. 2020, 108, 78–105. [Google Scholar]

- Zhao, W.; Yang, Q. Design and performance evaluation of a new green pavement: 100% recycled asphalt pavement and 100% industrial solid waste. J. Clean. Prod. 2023, 421, 138483. [Google Scholar]

- Ding, T.; Xiao, J.; Qin, F.; Duan, Z. Mechanical behavior of 3D printed mortar with recycled sand at early ages. Constr. Build. Mater. 2020, 248, 118654. [Google Scholar]

- Guo, X.; Yang, J.; Xiong, G. Influence of supplementary cementitious materials on rheological properties of 3D printed fly ash based geopolymer. Cem. Concr. Compos. 2020, 114, 103820. [Google Scholar]

- Sawadogo, B.; Bao, S.; Otoo, S.L.; Baffoe, E.E.; Leba-Kamanya, C. Preparation of geopolymers from alkaline thermally activated granite waste powder and burnt coal cinder blended with blast furnace slag. Constr. Build. Mater. 2024, 445, 137826. [Google Scholar]

- Alvi, I.H.; Li, Q.; Hu, H.; Onyekwena, C.C.; Hou, Y.; Hakuzweyezu, T.; Iftikhar, S.; Chen, B. A critical review of the advancements in acid-activated metakaolin geopolymers. Constr. Build. Mater. 2024, 421, 135609. [Google Scholar]

- Hossain, M.U.; Xuan, D.; Ng, S.T.; Amor, B. Designing sustainable partition wall blocks using secondary materials: A life cycle assessment approach. J. Build. Eng. 2021, 43, 103035. [Google Scholar]

- Jiao, M.; Rong, Z.; Zhang, L. The preparation and formation mechanism of ferrochrome slag-based high-strength ceramic aggregate and its impact on the performance of concrete. Constr. Build. Mater. 2024, 422, 135842. [Google Scholar]

- World Green Building Council. Zero Carbon and Climate Resilience Readiness Framework. Available online: https://worldgbc.org/zero-carbon-framework/ (accessed on 21 March 2025).

- Li, J.F.; Gu, A.L.; Ma, Z.Y.; Zhang, C.L.; Sun, Z.Q. Economic development, energy demand, and carbon emission prospects of China’s provinces during the 14th Five-Year Plan period: Application of CMRCGE model. Adv. Clim. Change Res. 2019, 10, 165–173. [Google Scholar]

- Chen, C.; Dubin, R.; Kim, M.C. Emerging trends and new developments in regenerative medicine: A scientometric update (2000–2014). Expert. Opin. Biol. Ther. 2014, 14, 1295–1317. [Google Scholar]

- Yu, C.; La, W. The methodology function of CiteSpace map knowledge domains. Stud. Sci. Sci. 2015, 33, 242–253. [Google Scholar]

- Yusuf, M.O.; Johari, M.A.M.; Ahmad, Z.A.; Maslehuddin, M. Strength and microstructure of alkali-activated binary blended binder containing palm oil fuel ash and ground blast-furnace slag. Constr. Build. Mater. 2014, 52, 504–510. [Google Scholar]

- Hu, S.; Zhong, L.; Yang, X.; Bai, H.; Ren, B.; Zhao, Y.; Zhang, W.; Ju, X.; Wen, H.; Mao, S.; et al. Synthesis of rare earth tailing-based geopolymer for efficiently immobilizing heavy metals. Constr. Build. Mater. 2020, 254, 119273. [Google Scholar] [CrossRef]

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Feng, H.; Su, Y.; Guo, A.; Yu, Z.; Guo, Z. Mechanical properties of cellulose nanocrystal modified cement/fly ash pastes under various water/binder ratios. Constr. Build. Mater. 2024, 447, 138213. [Google Scholar] [CrossRef]

- Teerawattanasuk, C.; Voottipruex, P.; Horpibulsuk, S. Improved heavy metal immobilization of compacted clay by cement treatment. Heliyon 2021, 7, e06917. [Google Scholar] [CrossRef]

- Sun, S.; Lin, J.; Zhang, P.; Fang, L.; Ma, R.; Quan, Z.; Song, X. Geopolymer synthetized from sludge residue pretreated by the wet alkalinizing method: Compressive strength and immobilization efficiency of heavy metal. Constr. Build. Mater. 2018, 170, 619–626. [Google Scholar] [CrossRef]

- Tang, Q.; Liu, Y.; Gu, F.; Zhou, T. Solidification/stabilization of fly ash from a municipal solid waste incineration facility using Portland cement. Adv. Mater. Sci. Eng. 2016, 2016, 7101243. [Google Scholar] [CrossRef]

- Yu, H.; Guo, M.Z.; Ling, T.C. Carbon sequestration via CO2 curing of cement compacts: Optimizing flue gas inherent heat and water vapor. J. Ind. Eng. Chem. 2024, 137, 252–259. [Google Scholar] [CrossRef]

- Hou, J.; Liu, Z.; Ni, X. Unlocking the potential: Transforming hazardous waste into solid cementitious materials. J. Clean. Prod. 2024, 472, 143483. [Google Scholar] [CrossRef]

- Hassani, A.; Kazemian, F. Investigating geopolymer mortar incorporating industrial waste using response surface methodology: A sustainable approach for construction materials. Case Stud. Constr. Mater. 2024, 21, e03609. [Google Scholar] [CrossRef]

- Bai, Y.; Arulrajah, A.; Horpibulsuk, S.; Zhou, A. Geopolymer stabilization of carbon-negative gasified olive stone biochar as a subgrade construction material. Constr. Build. Mater. 2024, 442, 137617. [Google Scholar] [CrossRef]

- Wang, J.; Ding, Y.; Zhou, Y.; Wei, W.; Wang, Y. Municipal solid waste incineration bottom ash recycling assessment: Carbon emission analysis of bottom ash applied to pavement materials. Constr. Build. Mater. 2024, 421, 135774. [Google Scholar]

- Bansal, D.; Ramana, G.V.; Datta, M. Sustainable utilization of incineration bottom ash in pavement construction: Environmental impacts and life cycle assessment. Sci. Total Environ. 2024, 931, 172890. [Google Scholar] [PubMed]

- Chen, C. CiteSpace: A Practical Guide for Mapping Scientific Literature; Nova Science Publishers: Hauppauge, NY, USA, 2016; pp. 41–44. [Google Scholar]

- Kul, A.; Ozel, B.F.; Ozcelikci, E.; Gunal, M.F.; Ulugol, H.; Yildirim, G.; Sahmaran, M. Characterization and life cycle assessment of geopolymer mortars with masonry units and recycled concrete aggregates assorted from construction and demolition waste. J. Build. Eng. 2023, 78, 107546. [Google Scholar]

- Zhang, F.; Wang, D.; Falchetto, A.C.; Cao, Y. Microwave deicing properties and carbon emissions assessment of asphalt mixtures containing steel slag towards resource conservation and waste reuse. Sci. Total Environ. 2024, 912, 169189. [Google Scholar] [CrossRef]

- Shi, Y.; Guo, W.; Jia, Y.; Xue, C.; Qiu, Y.; Zhao, Q.; Wang, D. Preparation of non-sintered lightweight aggregate ceramsite based on red mud-carbide slag-fly ash: Strength and curing method optimization. J. Clean. Prod. 2022, 372, 133788. [Google Scholar]

- Ho, L.S.; Huynh, T.P. Recycled waste medical glass as a fine aggregate replacement in low environmental impact concrete: Effects on long-term strength and durability performance. J. Clean. Prod. 2022, 368, 133144. [Google Scholar]

- Liang, Y.; Wang, Q.; Zhang, C.; Ho, J. Impact of limestone powder on the mechanical and microstructure properties of magnesium oxychloride cement pastes. J. Mater. Civ. Eng. 2022, 34, 04022211. [Google Scholar]

- Wiranata, D.Y.; Yang, S.H.; Akgul, C.M.; Hsien, H.Y.; Nugraha, M.Z.P. Use of coal ash cement stabilized material as pavement base material: Laboratory characterization and field evaluation. Constr. Build. Mater. 2022, 344, 128055. [Google Scholar]

- Sikder, R.; Chakravarty, S.; Sau, D.; Haldar, P.; Mandal, S.; Nandi, T.; Sutradhar, G. Study of durability and mechanical properties for utilization of cupola slag as a coarse aggregate in M20 grade green concrete. J. Build. Eng. 2024, 87, 109101. [Google Scholar]

- Chen, B.; Perumal, P.; Illikainen, M.; Ye, G. A review on the utilization of municipal solid waste incineration (MSWI) bottom ash as a mineral resource for construction materials. J. Build. Eng. 2023, 71, 106386. [Google Scholar]

- Sharma, H.B.; Vanapalli, K.R.; Samal, B.; Cheela, V.S.; Dubey, B.K.; Bhattacharya, J. Circular economy approach in solid waste management system to achieve UN-SDGs: Solutions for post-COVID recovery. Sci. Total Environ. 2021, 800, 149605. [Google Scholar] [CrossRef] [PubMed]

- Wainaina, S.; Awasthi, M.K.; Sarsaiya, S.; Chen, H.; Singh, E.; Kumar, A.; Ravindran, B.; Awasthi, S.K.; Duan, Y.; Kumar, S.; et al. Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresour. Technol. 2020, 301, 122778. [Google Scholar] [CrossRef]

- Zhu, L.; Yao, J.; Zhao, Y.; Ruan, W.; Ge, Y.; Guan, X. Printability and early mechanical properties of material composition modified 3D printing engineered cementitious composites based on the response surface methodology. J. Build. Eng. 2023, 79, 107837. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, C.; Ma, J.; Jiao, H.; Kim, M. Utilization of solid mine waste in the building materials for 3D printing. PLoS ONE 2023, 18, e0292951. [Google Scholar] [CrossRef] [PubMed]

- Colyn, M.; van Zijl, G.; Babafemi, A.J. Fresh and strength properties of 3D printable concrete mixtures utilising a high volume of sustainable alternative binders. Constr. Build. Mater. 2024, 419, 135474. [Google Scholar] [CrossRef]

- Qin, L.; Gao, X. Properties of coal gangue-Portland cement mixture with carbonation. Fuel 2019, 245, 1–12. [Google Scholar] [CrossRef]

- Zhu, L.; Zhu, Z. Reuse of clay brick waste in mortar and concrete. Adv. Mater. Sci. Eng. 2020, 1, 6326178. [Google Scholar] [CrossRef]

- Amjad, T.; Shahid, N.; Daud, A.; Khatoon, A. Citation burst prediction in a bibliometric network. Scientometrics 2022, 127, 2773–2790. [Google Scholar] [CrossRef]

- Guo, W.; Xi, B.; Huang, C.; Li, J.; Tang, Z.; Li, W.; Ma, C.; Wu, W. Solid waste management in China: Policy and driving factors in 2004–2019. Resour. Conserv. Recy. 2021, 173, 105727. [Google Scholar] [CrossRef]

- Yousuf, A.; Manzoor, S.O.; Youssouf, M.; Malik, Z.A.; Khawaja, K.S. Fly ash: Production and utilization in India-an overview. J. Mater. Environ. Sci. 2020, 11, 911–921. [Google Scholar]

- Guo, X.; Zhang, W.; Yu, H.; Jin, D. Reduction, stabilization, and solidification of Cr (VI) in contaminated soils with a sustainable by-product-based binder. Chemosphere 2022, 307, 135902. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Xu, X.; Wang, Q.; Park, J.; Lei, H.; Zhou, L.; Wang, X. Machine learning-based prediction of heavy metal immobilization rate in the solidification/stabilization of municipal solid waste incineration fly ash (MSWIFA) by geopolymers. J. Hazard. Mater. 2024, 467, 133682. [Google Scholar] [CrossRef]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of life cycle assessment in municipal solid waste management: A worldwide critical review. J. Clean. Prod. 2019, 209, 630–654. [Google Scholar]

- Das, S.; Lee, S.H.; Kumar, P.; Kim, K.H.; Lee, S.S.; Bhattacharya, S.S. Solid waste management: Scope and the challenge of sustainability. J. Clean. Prod. 2019, 228, 658–678. [Google Scholar]

- Ceraso, A.; Cesaro, A. Life Cycle Sustainability Assessment of municipal solid waste management systems: A review. J. Environ. Manag. 2024, 368, 122143. [Google Scholar]

- Schamne, A.N.; Nagalli, A.; Soeiro, A.A.V.; Martins, J.P.D.S.P. BIM in construction waste management: A conceptual model based on the industry foundation classes standard. Autom. Constr. 2024, 159, 105283. [Google Scholar]

- Ali, T.; El Ouni, M.H.; Qureshi, M.Z.; Islam, A.S.; Mahmood, M.S.; Ahmed, H.; Ajwad, A. A systematic literature review of AI-based prediction methods for self-compacting, geopolymer, and other eco-friendly concrete types: Advancing sustainable concrete. Constr. Build. Mater. 2024, 440, 137370. [Google Scholar]

- Curth, A.; Pearl, N.; Wissemann, E.; Cousin, T.; Alkhayat, L.; Jackow, V.; Lee, K.; Moldow, O.; Ismail, M.; Mueller, C.; et al. EarthWorks: Zero waste 3D printed earthen formwork for shape-optimized, reinforced concrete construction. Constr. Build. Mater. 2024, 449, 138387. [Google Scholar]

| Rank | Author | Count | H-index |

|---|---|---|---|

| 1 | Poon, ChiSun | 42 | 116 |

| 2 | Arulrajah, Arul | 35 | 66 |

| 3 | Horpibulsuk, Suksun | 31 | 74 |

| 4 | Xuan, Dongxing | 24 | 42 |

| 5 | Liu,Jun | 19 | 42 |

| 6 | Ling, Tung-Chai | 18 | 58 |

| 7 | Wang,Wenlong | 16 | 39 |

| 8 | Lu,Weisheng | 14 | 47 |

| 9 | Townsend, Timothy G. | 14 | 52 |

| 10 | Lisak,Grzegorz | 12 | 50 |

| Rank | Institution | Count | Citations |

|---|---|---|---|

| 1 | Tongji University | 57 | 1761 |

| 2 | Chinese Acad Sci | 55 | 1598 |

| 3 | Hong Kong Polytech University | 46 | 2389 |

| 4 | Southeast University | 43 | 536 |

| 5 | Wuhan University of Technology | 43 | 1550 |

| 6 | Zhejiang University | 35 | 840 |

| 7 | Shanghai Jiao Tong Univ | 30 | 1178 |

| 8 | Univ sci & technol Beijing | 29 | 745 |

| 9 | Harbin Inst Technol | 28 | 1033 |

| 10 | Cent south Univ | 28 | 938 |

| Rank | Country | Count | Citations |

|---|---|---|---|

| 1 | China | 872 | 26,527 |

| 2 | USA | 273 | 7251 |

| 3 | India | 182 | 4512 |

| 4 | Australia | 146 | 6364 |

| 5 | Brazil | 102 | 4096 |

| 6 | England | 98 | 4395 |

| 7 | Italy | 96 | 2794 |

| 8 | Spain | 74 | 2220 |

| 9 | Malaysia | 73 | 4358 |

| 10 | Canada | 68 | 3361 |

| Rank | Journal | Citations |

|---|---|---|

| 1 | Construction and Building Materials | 13,326 |

| 2 | Journal of Cleaner Production | 8088 |

| 3 | Waste Management | 6978 |

| 4 | Cement and Concrete Research | 3593 |

| 5 | Resources, Conservation and Recycling | 2996 |

| 6 | Journal of Hazardous Materials | 2614 |

| 7 | Cement and Concrete Composites | 2599 |

| 8 | Bioresource Technology | 1615 |

| 9 | Journal of Environmental Management | 1516 |

| 10 | Science of The Total Environment | 1498 |

| Rank | Keyword | Count |

|---|---|---|

| 1 | fly ash | 442 |

| 2 | concrete | 378 |

| 3 | municipal solid waste | 362 |

| 4 | performance | 308 |

| 5 | mechanical property | 282 |

| 6 | construction | 265 |

| 7 | strength | 220 |

| 8 | life cycle assessment | 206 |

| 9 | compressive strength | 186 |

| 10 | behavior | 157 |

| 11 | heavy metals | 133 |

| 12 | durability | 109 |

| 13 | hydration | 104 |

| 14 | circular economy | 98 |

| 15 | aggregate | 80 |

| Rank | Keyword | Centrality |

|---|---|---|

| 1 | concrete | 0.20 |

| 2 | fly ash | 0.15 |

| 3 | life cycle assessment | 0.15 |

| 4 | mechanical property | 0.12 |

| 5 | behavior | 0.10 |

| 6 | municipal solid waste | 0.08 |

| 7 | aggregate | 0.08 |

| 8 | construction | 0.08 |

| 9 | heavy metals | 0.07 |

| 10 | waste management | 0.06 |

| 11 | bottom ash | 0.06 |

| 12 | demolition waste | 0.05 |

| 13 | sewage sludge | 0.05 |

| 14 | anaerobic digestion | 0.04 |

| 15 | 3d printing | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, R.; Yu, H.; Lu, J. Progress and Prospect of Solid Waste Utilization in Construction Industry: A Bibliometric Analysis Based on CiteSpace and VOSviewer. Buildings 2025, 15, 1044. https://doi.org/10.3390/buildings15071044

Dong R, Yu H, Lu J. Progress and Prospect of Solid Waste Utilization in Construction Industry: A Bibliometric Analysis Based on CiteSpace and VOSviewer. Buildings. 2025; 15(7):1044. https://doi.org/10.3390/buildings15071044

Chicago/Turabian StyleDong, Runrun, Huixian Yu, and Jing Lu. 2025. "Progress and Prospect of Solid Waste Utilization in Construction Industry: A Bibliometric Analysis Based on CiteSpace and VOSviewer" Buildings 15, no. 7: 1044. https://doi.org/10.3390/buildings15071044

APA StyleDong, R., Yu, H., & Lu, J. (2025). Progress and Prospect of Solid Waste Utilization in Construction Industry: A Bibliometric Analysis Based on CiteSpace and VOSviewer. Buildings, 15(7), 1044. https://doi.org/10.3390/buildings15071044