A Comparative Whole-Building Life Cycle Assessment of the Four Framing Systems of the Bakers Place Building Using the Tally LCA Tool

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope of LCA

2.1.1. Functional Unit and System Boundary

2.1.2. Bakers Place Project Overview

2.2. Building Material Inventory

2.3. Building Material Specifications and Assumptions

- The transportation distance for concrete was assumed to be 40 km, while mass timber components (CLT and glulam) were sourced from Austria, requiring transport by truck, boat, and train over distances of 799 km, 6482 km, and 1127 km, respectively. For other materials, including steel, Tally® used default industry-average values.

- All materials were assumed to have the same lifespan as the building, which was set to 60 years.

- Regarding connections, the structural designer specified an assumption of 0.2 pounds per square foot (psf) of A36 steel for the hybrid (baseline) model. For the steel scheme, they assumed 0.15 psf of headed studs for the connections. However, since the Tally® database lacked an EPD for headed studs, it was recommended, in consultation with structural engineers, to use 0.3 psf of A36 steel plate as a substitute. These quantities were added as an accessory material to the floor system of each building scenario.

- The only EPD available for GLT in Tally® was from the EPD published by the American Wood Council for North American glulam products, with a moisture content of 14%. However, the Wiehag GLT used in the project has a lower density of 466 kg/m3 than the GLT EPD available in the Tally® database (534 kg/m3), as well as a lower moisture content of 11%. To ensure accuracy in the analysis, the material take-off in Tally® was adjusted to reflect the Wiehag GLT density, rather than the default North American glulam density.

- Most concrete elements in the project, including columns, foundation, slabs on grade, and mat slabs, were located in the podium and reported as cast-in-place with 30–50% supplementary cementitious material (SCM). The National Ready Mixed Concrete Association’s (NRMCA) industry-wide EPDs for cast-in-place concrete, based on the Great Lakes Midwest regional average for SCM, were used in this analysis. Since Tally® does not offer a specific 30–50% SCM option, the regional average was selected. Reinforcement for concrete was defined using the Concrete Reinforcing Steel Institute’s (CRSI) EPD. In the columns above the podium, concrete strength varied by height: 10,000 psi for floors 4–7, 7000 psi for floors 7–10, and 5000 psi for floors 10–roof, with an assumed reinforcement of 178 kg/m3. The podium columns had similar reinforcement but with a concrete strength of 6000 psi. The foundation and wall elements were designed with 4000 psi concrete, reinforced with 25 kg/m3 and 119 kg/m3 of rebar, respectively. The slab on grade also used 4000 psi concrete with welded wire mesh reinforcement at 20.3 kg/m2, while the mat slab had a concrete strength of 6000 psi, reinforced with 25 kg/m3 of rebar, similar to the foundation elements.

- As there is no North American industry-average EPD available for acoustic underlayment mats within the Tally® database, this material was excluded from the LCA for the CLT floor systems in both the hybrid and mass timber schemes, assuming the quantity of this material would not have significant impacts on the final result [19].

- For the post-tensioned concrete used in the podium and the overall concrete design, structural engineers specified reinforcement with rebars at 1.75 kg per square foot and pre-stressed steel tendons at 0.8 kg per square foot. However, Tally® does not have EPD data for tendons; so, an adjustment was required. The GWP of tendons, based on the Suncoast Post-Tensioning System Manufacturer-Specific EPD [20], is approximately 1.7 times higher per metric tonne than that of rebars, according to the Concrete Reinforcing Steel Institute’s (CRSI) EPD [21]. To account for this difference, the quantity of tendons per cubic meter of concrete was calculated and then multiplied by 1.7 to reflect the higher GWP. This adjusted figure was then used in Tally® instead of the tendon data.

- A Type IV-B building requires that mass timber be protected with non-combustible material, typically Type X Gypsum Wall Board (GWB), except where it is exposed. The structural engineers specified that the exposed area of the CLT floor and attached beams must not exceed 20% of the CLT floor area in any residential unit. In Tally®, GWB was specified as an accessory material to the CLT floor, with the take-off method based on area and only the thickness of the GWB layer being adjustable. To meet the fire rating requirement of covering 80% of the CLT floor area, the required GWB volume was manually calculated by multiplying 80% of the CLT area by two layers of GWB (31.8 mm). Since Tally® does not allow assigning the required thickness to a specific portion of the area, the GWB thickness was adjusted from 31.8 mm (two layers of 5/8″) to 25.4 (80% of 31.8) mm to achieve the same overall volume designed to comply the fire rating requirement. The take-off method for the GWB used the modeled area, an adjusted thickness of 25.4 mm, and a density of 1092 kg/m3 to obtain the total mass (kg) of the GWB required in the designs for the LCA analysis.

3. Results and Discussion

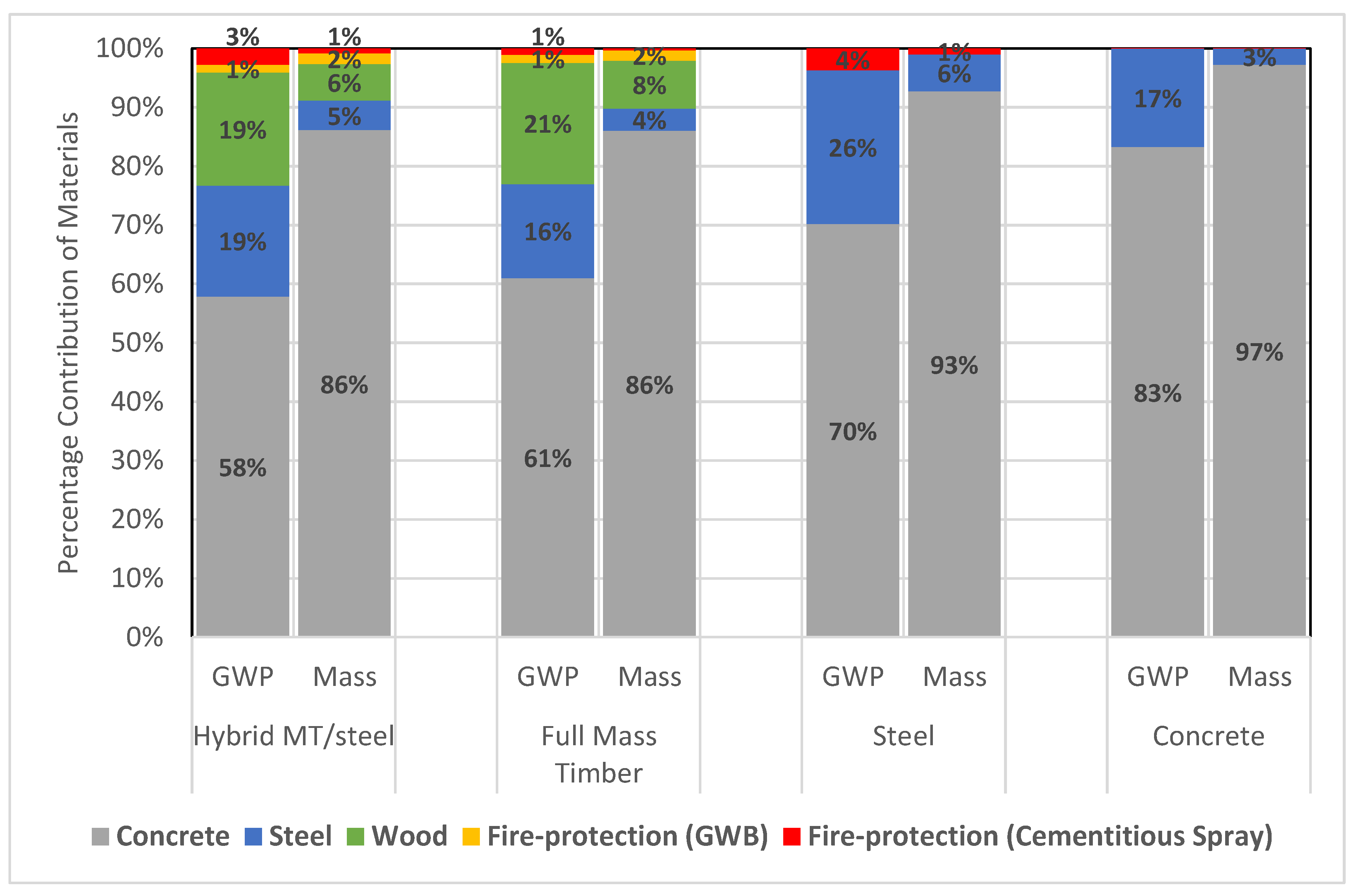

3.1. Comparison of Building Material Mass and Relative GWP

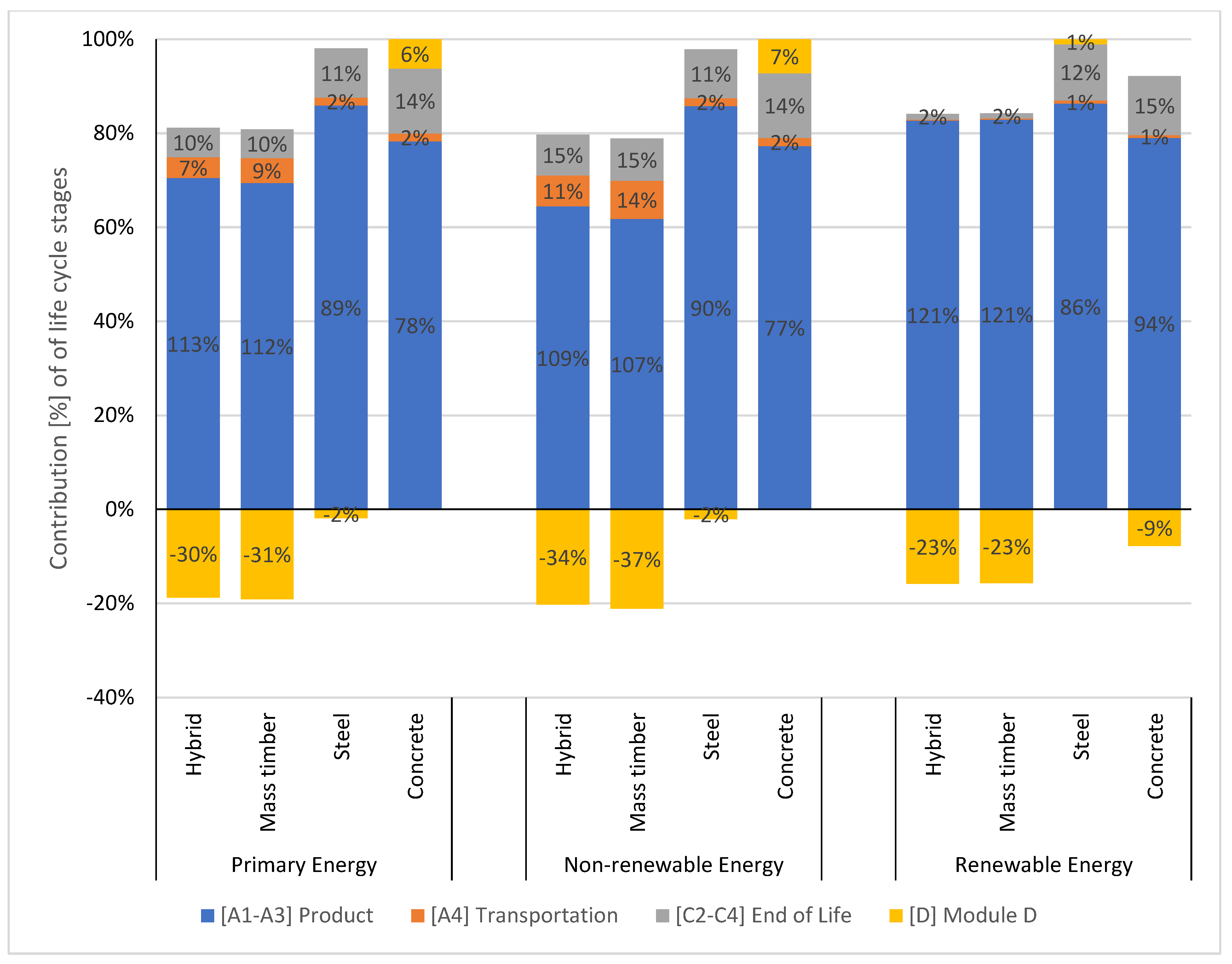

3.2. Life Cycle Assessment Comparison for Environmental Impacts

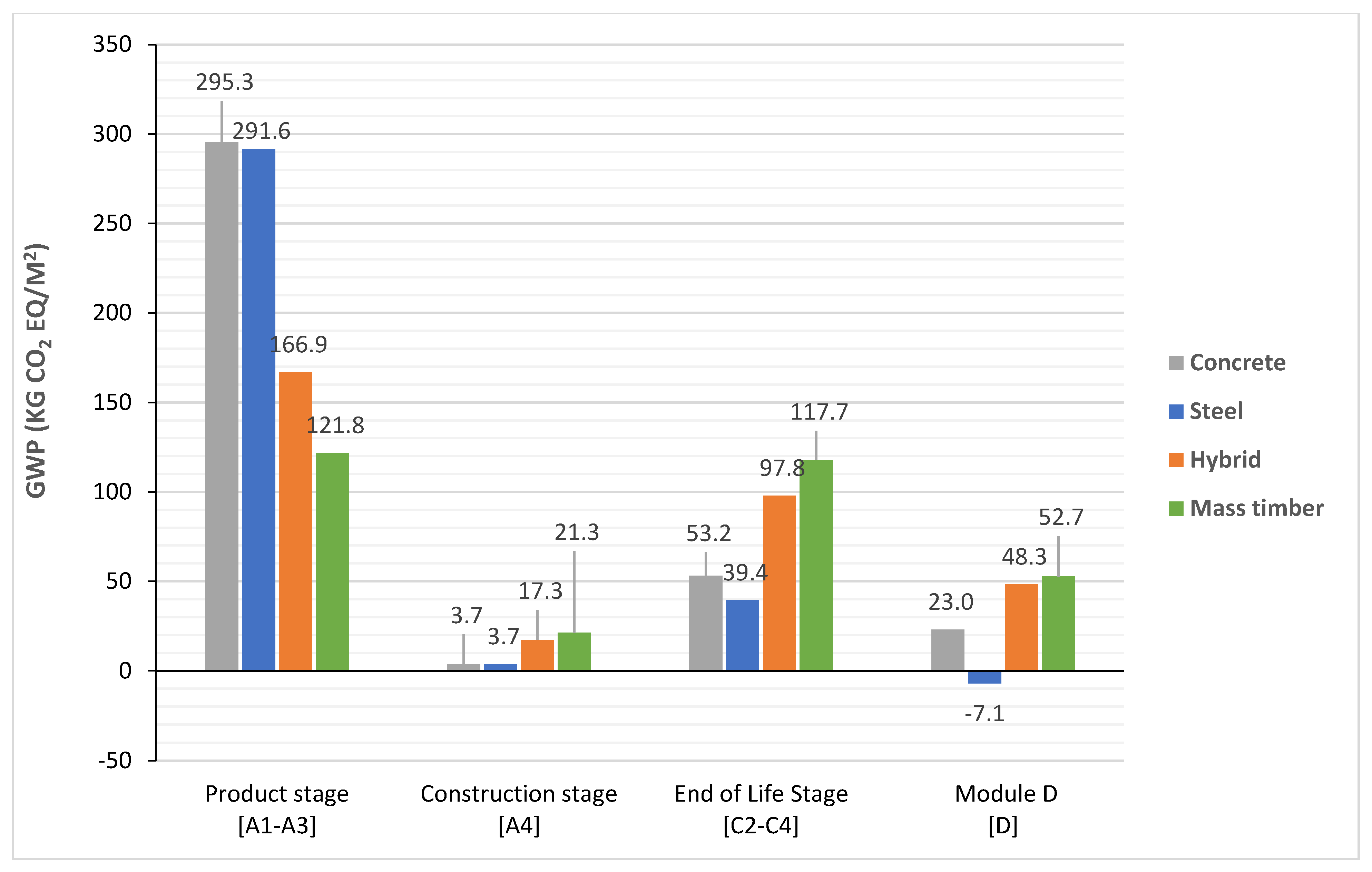

3.3. Comparison of GWP Impact on Different Life Cycle Stages

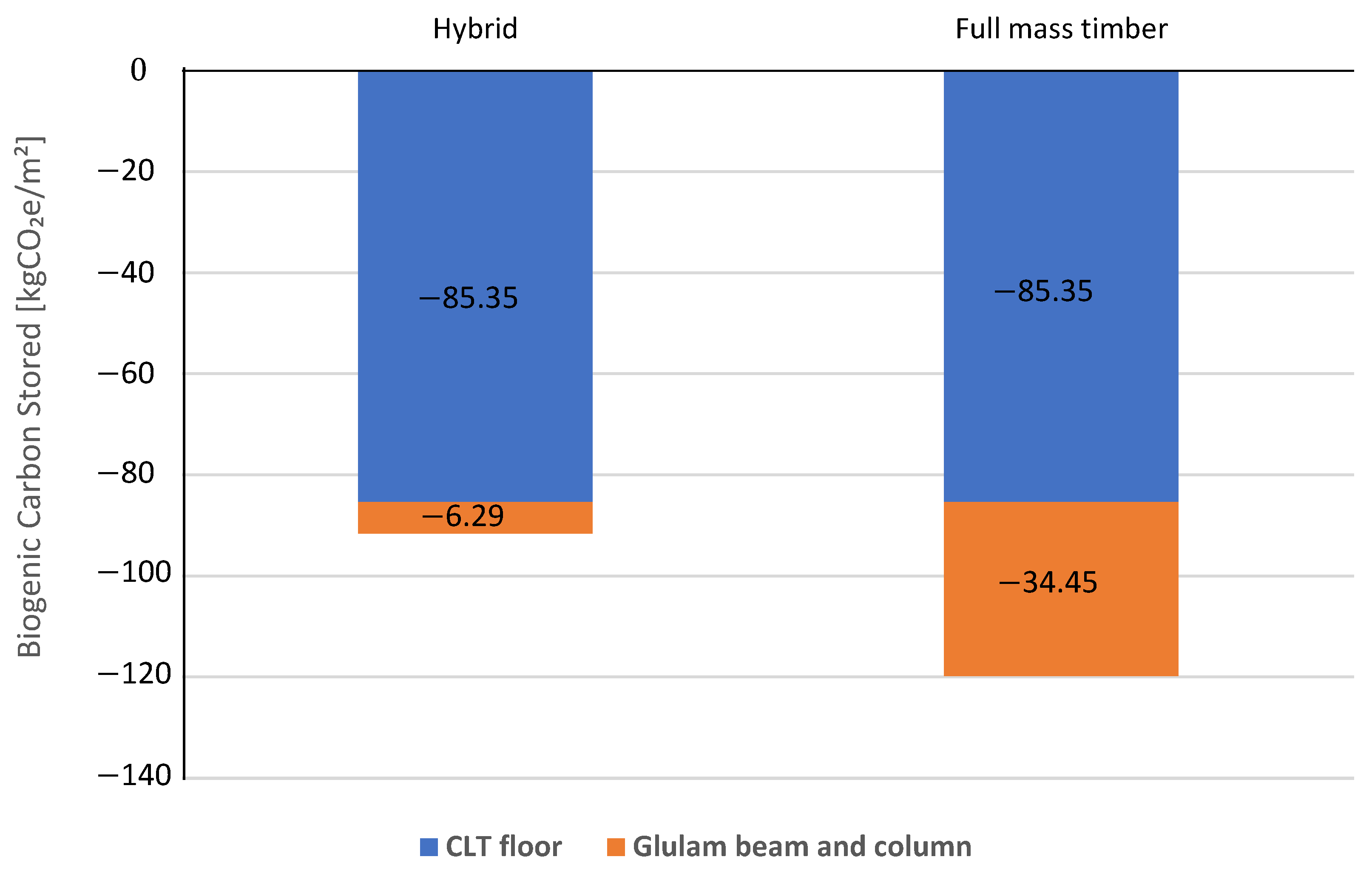

3.4. Biogenic Carbon in the Buildings

4. Conclusions

- Mass timber and hybrid designs weighed 33% and 12% less than the concrete and steel designs, respectively, significantly reducing the reliance on concrete, a major contributor to GWP.

- The hybrid design exhibited a slightly higher GWP (1%) than the steel design but showed a 12% lower GWP compared to the concrete design. The full mass timber design performed the best, with 5%, 4%, and 16% lower GWP than the hybrid, steel, and concrete designs, respectively.

- Full mass timber and hybrid designs had higher eutrophication impacts at the end-of-life stage, primarily due to wood decomposition in landfills. In contrast, the steel and concrete designs saw most of their eutrophication impacts occur in the production stage.

- Full mass timber and hybrid designs experienced significantly higher acidification and smog impacts, mainly due to longer transportation distances for imported timber. Conversely, steel and concrete systems benefited from local sourcing of materials.

- Mass timber and hybrid designs relied more on renewable energy sources, while steel and concrete systems heavily depended on non-renewable energy sources.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2021: The Physical Science Basis; Working Group I contribution to the IPCC Sixth Assessment Report; Cambridge University Press: Cambridge, UK, 2021; Available online: https://www.ipcc.ch/assessment-report/ar6 (accessed on 29 December 2024).

- Sartori, I.; Hestnes, A.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energies 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Architecture 2030. (n.d.). Why the Built Environment? Available online: https://www.architecture2030.org/why-the-built-environment/ (accessed on 15 July 2024).

- Gu, H.; Liang, S.; Pierobon, F.; Puettmann, M.; Ganguly, I.; Chen, C.; Pasternack, R.; Wishnie, M.; Jones, S.; Maples, I. Mass Timber Building Life Cycle Assessment Methodology for the U.S. Regional Case Studies. Sustainability 2021, 13, 14034. [Google Scholar] [CrossRef]

- Puettmann, M.; Pierobon, F.; Ganguly, I.; Gu, H.; Chen, C.; Liang, S.; Jones, S.; Maples, I.; Wishnie, M. Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration. Sustainability 2021, 13, 13987. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Gu, H.; Bergman, R. Life Cycle Assessment and Environmental Building Declaration for the Design Building at the University of Massachusetts; U.S. Department of Agriculture, Forest Service: Madison, WI, USA, 2018. [CrossRef]

- Teshnizi, Z.; Pilon, A.; Storey, S.; Lopez, D.; Froese, T.M. Lessons Learned from Life Cycle Assessment and Life Cycle Costing of Two Residential Towers at the University of British Columbia. Procedia CIRP 2018, 69, 172–177. [Google Scholar] [CrossRef]

- Huang, M.; Chen, C.; Pierobon, F.; Ganguly, I.; Simonen, K. Life Cycle Assessment of Katerra’s Cross-Laminated Timber (CLT) and Catalyst Building: Final Report; Carbon Leadership Forum, University of Washington: Seattle, WA, USA, 2019. [Google Scholar]

- Jensen, A.S. Mass Timber Solutions for Eight-Story Mixed-Use Buildings: A Comparative Study of GHG Emissions. Preprints 2020. Available online: https://www.preprints.org/manuscript/202007.0175/v2 (accessed on 12 October 2023).

- Chen, Z.; Gu, H.; Bergman, R.D.; Liang, S. Comparative Life Cycle Assessment of a High-Rise Mass Timber Building with an Equivalent Reinforced Concrete Alternative Using the Athena Impact Estimator for Buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Gu, H.; Nepal, P.; Arvanitis, M.; Alderman, D. Carbon Impacts of Engineered Wood Products in Construction; IntechOpen: Rijeka, Croatia, 2022. [Google Scholar] [CrossRef]

- Pasternack, R.; Wishnie, M.; Clarke, C.; Wang, Y.; Belair, E.; Marshall, S.; Gu, H.; Nepal, P.; Dolezal, F.; Lomax, G.; et al. What Is the Impact of Mass Timber Utilization on Climate and Forests? Sustainability 2022, 14, 758. [Google Scholar] [CrossRef]

- National Research Council Canada. National Whole-Building Life Cycle Assessment Practitioner’s Guide: Guidance for Compliance Reporting of Embodied Carbon in Canadian Building Construction; National Research Council Canada: Ottawa, ON, Canada, 2024. Available online: https://nrc-publications.canada.ca/eng/view/ft/?id=533906ca-65eb-4118-865d-855030d91ef2&dsl=en (accessed on 15 April 2024).

- ISO 21930:2017; Sustainability in Buildings and Civil Engineering Works—Core Rules for Environmental Product Declarations of Construction Products and Services. ISO: Geneva, Switzerland, 2017.

- ISO 21931-1:2010; Sustainability in Building Construction—Framework for Methods of Assessment of the Environmental Performance of Construction Works. ISO: Geneva, Switzerland, 2010.

- The Neutral Project LLC. Bakers Place Case Study: A Comparative Exploration into Mass Timber and Conventional Construction Methods. USDA Wood Innovations Grant Program, 2024. Available online: https://www.theneutralproject.com (accessed on 20 December 2024).

- Feitel, A.; Redwine, B.; Kingsley, G. Think Wood, WoodWorks—Wood Products Council. Nordic Structures, 2021. Available online: https://www.nordic.ca/data/files/publication/multilang_file/Platte15LCACaseStudy_July2021_KLA.pdf (accessed on 17 May 2024).

- Suncoast Post-Tension. Environmental Product Declaration (EPD): Post-Tensioning Strand; Suncoast Post-Tension: Houston, TX, USA, 2021; Available online: https://cdn.scscertified.com/products/cert_pdfs/SCS-EPD-06741_Suncoast-PT_PT-Strand_030121.pdf (accessed on 12 May 2024).

- Concrete Reinforcing Steel Institute (CRSI). Industry-Wide Environmental Product Declaration (EPD); CRSI: Schaumburg, IL, USA, 2022; Available online: https://www.crsi.org/wp-content/uploads/CRSI_Industry-Wide_EPD_Sep2022.pdf (accessed on 12 May 2024).

- Chen, C.X. Environmental Assessment of the Production and End-of-Life of Cross-Laminated Timber in Western Washington. Ph.D. Thesis, University of Washington, Seattle, WA, USA, 2019. [Google Scholar]

- Gu, C.; Gu, H.; Gong, M.; Blackadar, J. A Case Study on the Impact of Transportation of Mass Timber Products on the Cradle-to-Gate LCA Results for an Institutional Building. Recent Prog. Mater. 2022, 4, 014. [Google Scholar] [CrossRef]

- Kwok, A.G.; Zalusky, H.; Rasmussen, L.; Rivera, I.; McKay, H. Cross-Laminated Timber Buildings: A Whole Building Life Cycle Assessment Case Study Series; TallWood Design Institute: Corvallis, OR, USA, 2019; Available online: https://tallwoodinstitute.org (accessed on 23 November 2024).

- Pak, A. Biogenic Carbon Storage Accounting in WBLCA. YouTube, 2020. Available online: https://www.youtube.com/watch?v=7XTzKESNGEU (accessed on 22 December 2024).

- Ximenes, F.; Gardner, W.; Cowie, A. The Decomposition of Wood Products in Landfills in Sydney, Australia. Waste Manag. 2008, 28, 2344–2354. [Google Scholar] [CrossRef] [PubMed]

- Jolly, R.; Fairweather, H.; Rayburg, S.; Rodwell, J. Life Cycle Assessment and Cost Analysis of Mid-Rise Mass Timber vs. Concrete Buildings in Australia. Sustainability 2024, 16, 6465. [Google Scholar] [CrossRef]

- Hemmati, M.; Messadi, T.; Gu, H.; Seddelmeyer, J.; Hemmati, M. Comparison of Embodied Carbon Footprint of a Mass Timber Building Structure with a Steel Equivalent. Buildings 2024, 14, 1276. [Google Scholar] [CrossRef]

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S.S. Comparative Life-Cycle Assessment of a Mass Timber Building and Concrete Alternative. Wood Fiber Sci. 2020, 52, 217–229. [Google Scholar] [CrossRef]

- Bergman, R.; Puettmann, M.; Taylor, A.; Skog, K.E. The Carbon Impacts of Wood Products. For. Prod. J. 2014, 64, 220–231. [Google Scholar] [CrossRef]

| Hybrid (Baseline) | Full Mass Timber | Full Steel | Full Concrete | |

|---|---|---|---|---|

| Floor-to-Floor Height | 10′–9″ | 10′–9″ | 9′–7 ½″ | 12′–4″ |

| Slab | CLT floors (KLH 180mm), 5/16″ sound mat, and 2″ gypcrete | Same as the baseline | 3½″ lightweight concrete on top of 3″ 20 ga. steel deck | 7.5″ post-tensioned concrete |

| Framing | Steel framing and column with 1″ spray fireproofing + glulam beams | Steel framing with 1″ spray fireproofing + glulam columns and beams | Steel beams, columns, and braced frames with 1″ spray fireproofing | Reinforced concrete columns and shear walls |

| Fireproofing | 2 layers of 5/8″ Type X GWB over CLT and 1″ spray fireproofing for steel elements | 2 layers of 5/8″ Type X GWB over CLT | 1″ spray fireproofing | N/A |

| Impact to Podium | Foundation as per the podium model in Revit (No impact relative to the baseline) | Foundation as per the podium model in Revit (No impact relative to the baseline) | 30% increase in column cross-sectional area and 50% increase in foundation volume | 55% increase in column cross-sectional area and 100% increase in foundation volume |

| Materials Used in Different Assemblies | Unit | Hybrid Building (Baseline) | Mass Timber | Steel | Concrete | |

|---|---|---|---|---|---|---|

| Floor and Roof | Concrete | m3 | 4648.11 | 4648.11 | 5188.65 | 8283.98 |

| Lightweight Concrete | m3 | 605.82 | 605.82 | 1209.57 | ||

| Steel Reinforcement Rebar | kg | 196,951.11 | 196,951.11 | 210,313.54 | 426,484.33 | |

| Steel Welded Wire Mesh Reinforcement | kg | 44,105.29 | 44,105.29 | 84,355.89 | 43,128.89 | |

| Steel Deck | kg | 3222.00 | 3222.00 | 136,064.00 | ||

| Cross-Laminated Timber (CLT) | m3 | 2,335.23 | 2335.23 | |||

| Steel Plate Connection | kg | 12,653.00 | 12,653.00 | 19,930.00 | ||

| Gypsum Wall Board (GWB) | kg | 347,796.00 | 347,796.00 | |||

| Foundation | Concrete | m3 | 758.82 | 758.82 | 1138.23 | 1517.64 |

| Steel Reinforcement Rebar | kg | 18,972.56 | 18,972.56 | 28,457.92 | 37,944.01 | |

| Column and Beam | Concrete | m3 | 219.28 | 219.28 | 285.05 | 492.80 |

| Steel Reinforcement Rebar | kg | 39,030.10 | 39,030.10 | 50,859.37 | 87,730.05 | |

| Cold-Formed Hollow Structural Steel | kg | 236,946.70 | 155,195.90 | 160,134.90 | 1043.00 | |

| Hot-Rolled Structural Steel | kg | 291,561.23 | 111,535.38 | 541,687.58 | 65.69 | |

| Spray Fireproofing | kg | 162,485.00 | 58,853.84 | 214,223.74 | 322.60 | |

| Glue-Laminated Timber (GLT) | m3 | 171.75 | 941.29 | |||

| Steel Plate Connection | kg | 30,296.00 | ||||

| Wall | Concrete | m3 | 997.31 | 997.31 | 997.31 | 1458.16 |

| Steel Reinforcement Rebar | kg | 118,671.80 | 118,671.80 | 118,671.80 | 173,493.80 | |

| Category | Material Specifications | Tally® Database Equivalent |

|---|---|---|

| Steel | Hollow structural steel (HSS) section | Cold-formed HSS section + Spray fireproofing (cementitious) |

| Hot-rolled steel: W and L sections | Hot-rolled structural steel (AISC-EPD) + Spray fireproofing (cementitious) | |

| Wood | Wiehag GLT | GLT(AWC-EPD), no finish, 534 kg/m3 density |

| Concrete | Type | Cast-in-place (NRMCA-EPD) |

| SCM 30-50% | Great Lakes Midwest regional average | |

| Strength | 5000–10,000 psi | |

| Reinforcement | Concrete reinforcement varies in quantity per volume in different structural concrete elements | |

| Floor Materials | Steel floor assembly 3 1/2″ Concrete over 3VLI floor deck | Lightweight, cast-in-place concrete, 3000 psi, Great Lakes Midwest regional-average SCM (NRMCA-EPD) |

| Welded wire mesh reinforcement, pre-defined value (4 × 4, 6 ga), 3.03 kg/m2 | ||

| Steel roof and floor deck, Steel Deck Institute (SDI- EPD), 10 kg/m2 | ||

| Mass timber floor assembly 5-PLY CLT (7 1/16″) | CLT: generic LCI data set by Tally® LCA | |

| 2″ Gypcrete | 3000 psi, lightweight concrete, 0% SCM (NRMCA- EPD), with no reinforcement | |

| 5/16″ Acoustic mat | No acoustic mat in the Tally® database | |

| Post-tensioned concrete slab | Cast-in-place concrete, 5000 psi, 0% SCM (NRMCA-EPD) | |

| Reinforcement: 1.75 psf (rebar) and 0.8 psf (tendon) | Rebar (CRSI- EPD) |

| Impact Category | Unit | Hybrid | Mass Timber | Steel | Concrete |

|---|---|---|---|---|---|

| Global Warming | kgCO2 eq/m2 | 330.27 | 313.43 | 327.52 | 375.19 |

| Acidification | kg SO₂eq/m2 | 1.53 | 1.64 | 1.12 | 0.99 |

| Eutrophication | kgNeq/m2 | 0.13 | 0.16 | 0.05 | 0.063 |

| Smog Formation | kgO3eq/m2 | 25.54 | 27.63 | 17.60 | 20.12 |

| Ozone Depletion | CFC-11eq/m2 | 1.48 × 10−6 | 2.37 × 10−6 | 7.49 × 10−7 | −1.74 × 10−7 |

| Primary Energy Demand | MJ/m2 | 3290.80 | 3376.50 | 3102.37 | 3265.98 |

| Non-Renewable Energy Demand | MJ/m2 | 2110.10 | 2028.60 | 2915.78 | 3064.89 |

| Renewable Energy Demand | MJ/m2 | 1173.94 | 1340.95 | 186.36 | 200.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahabi, N.; Gu, H.; Gong, M.; Blackadar, J. A Comparative Whole-Building Life Cycle Assessment of the Four Framing Systems of the Bakers Place Building Using the Tally LCA Tool. Buildings 2025, 15, 1192. https://doi.org/10.3390/buildings15071192

Zahabi N, Gu H, Gong M, Blackadar J. A Comparative Whole-Building Life Cycle Assessment of the Four Framing Systems of the Bakers Place Building Using the Tally LCA Tool. Buildings. 2025; 15(7):1192. https://doi.org/10.3390/buildings15071192

Chicago/Turabian StyleZahabi, Nadia, Hongmei Gu, Meng Gong, and Janet Blackadar. 2025. "A Comparative Whole-Building Life Cycle Assessment of the Four Framing Systems of the Bakers Place Building Using the Tally LCA Tool" Buildings 15, no. 7: 1192. https://doi.org/10.3390/buildings15071192

APA StyleZahabi, N., Gu, H., Gong, M., & Blackadar, J. (2025). A Comparative Whole-Building Life Cycle Assessment of the Four Framing Systems of the Bakers Place Building Using the Tally LCA Tool. Buildings, 15(7), 1192. https://doi.org/10.3390/buildings15071192