Creep Deformation Characteristics and Damage Unified Creep Constitutive Model of Undisturbed Structural Loess Under Different Consolidation Conditions

Abstract

:1. Introduction

- (1)

- In loess high-fill excavation and filling construction, the undisturbed loess will produce stress paths of vertical unloading and horizontal loading, and consolidation deformation and subsequent creep deformation will occur under these stress states (isometric consolidation). However, few creep tests and constitutive models consider the influence of isometric consolidation.

- (2)

- Undisturbed loess is a geotechnical engineering material with a cemented structure. When subjected to external loads, local damage will occur in the internal cementation, which creates creepy characteristics of undisturbed loess on the macro scale shared by the internal complete cementation structure and the damaged structure. However, the existing creep models rarely consider this local dynamic damage mechanism.

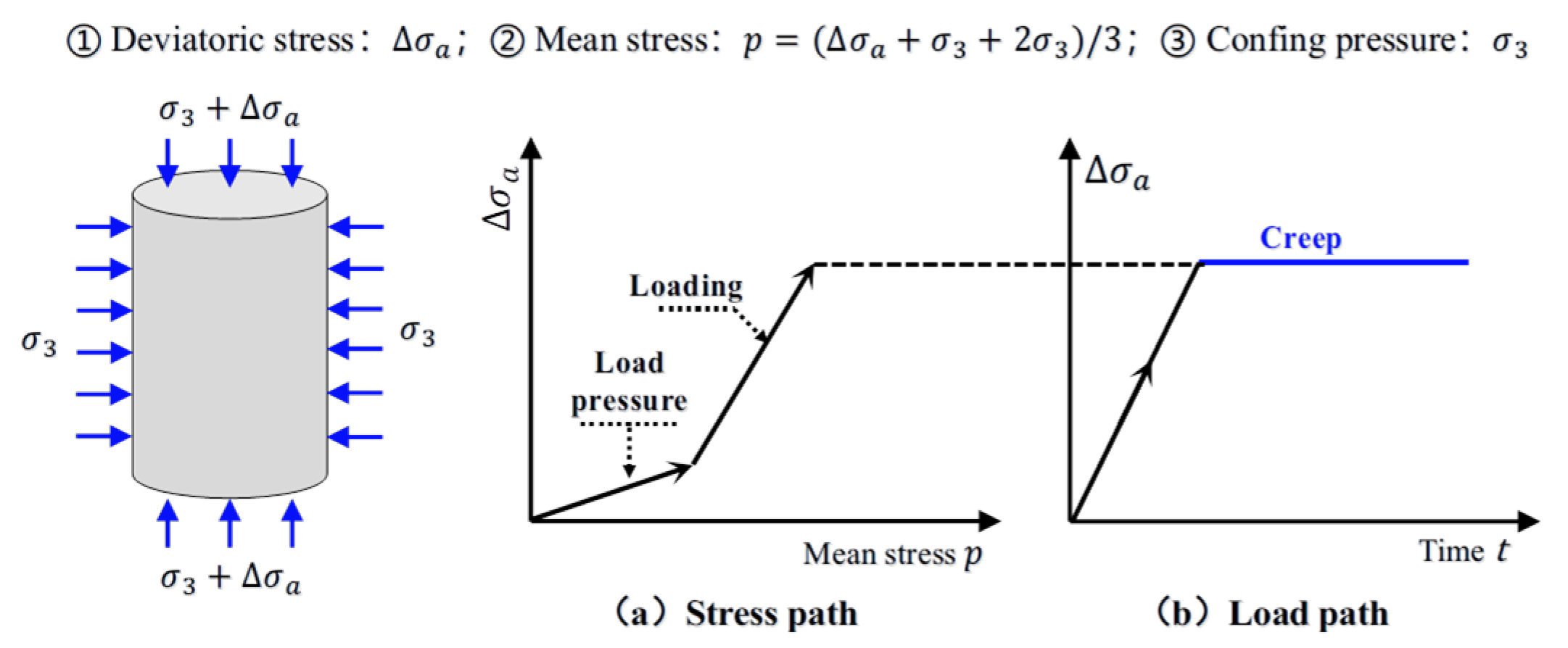

2. Test Scheme

2.1. Test Soil Sample

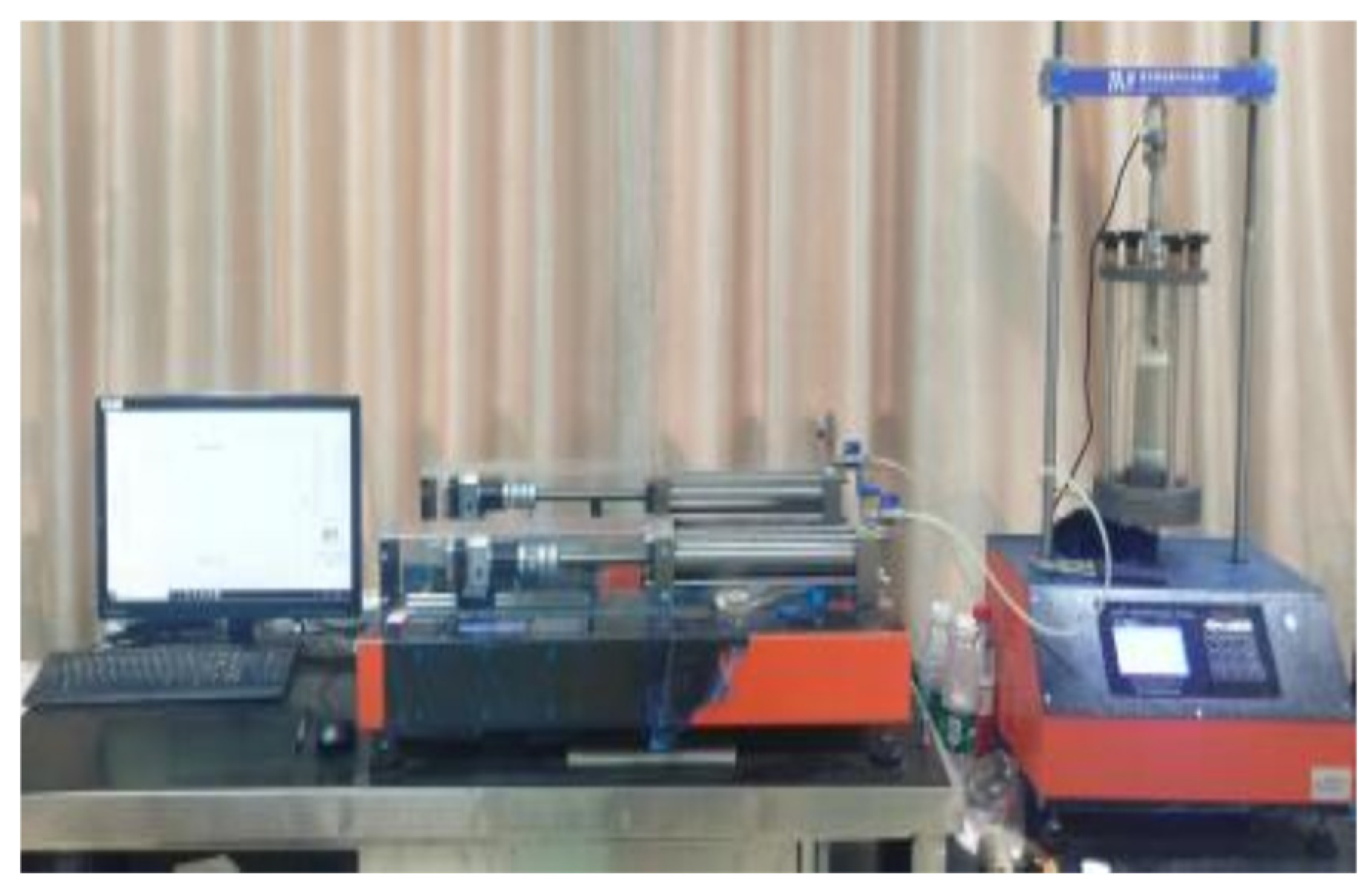

2.2. Test Scheme and Instruments

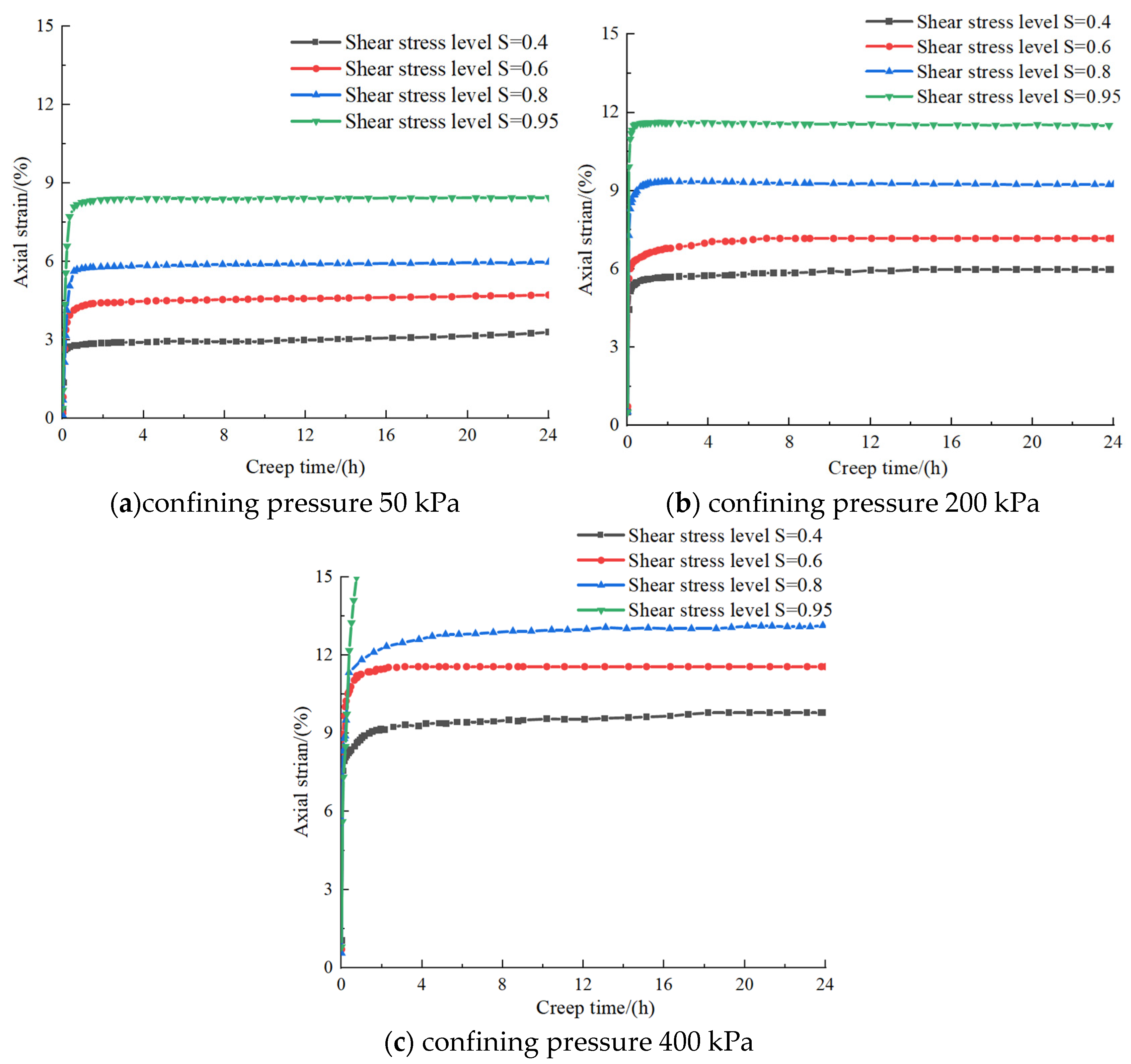

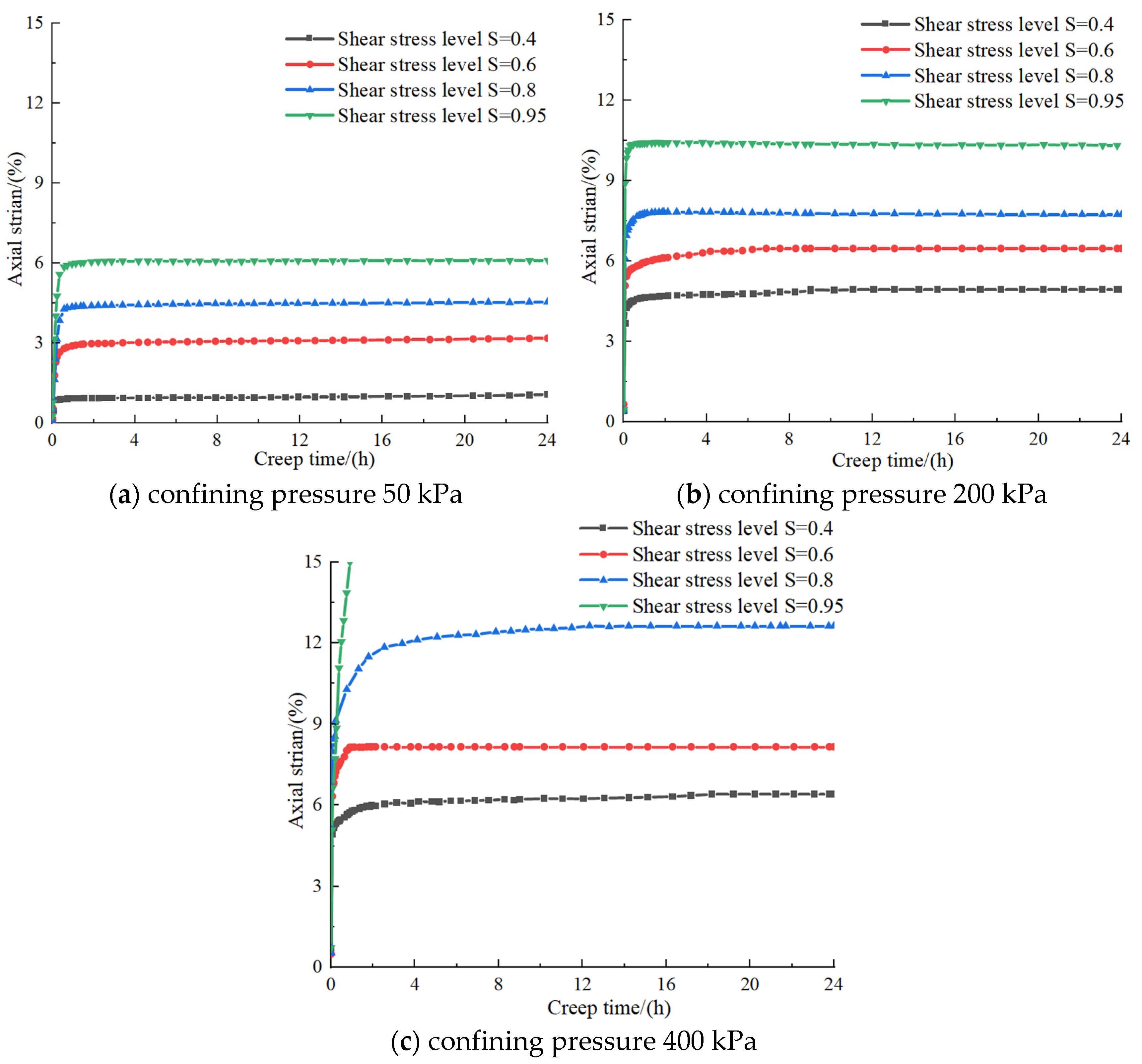

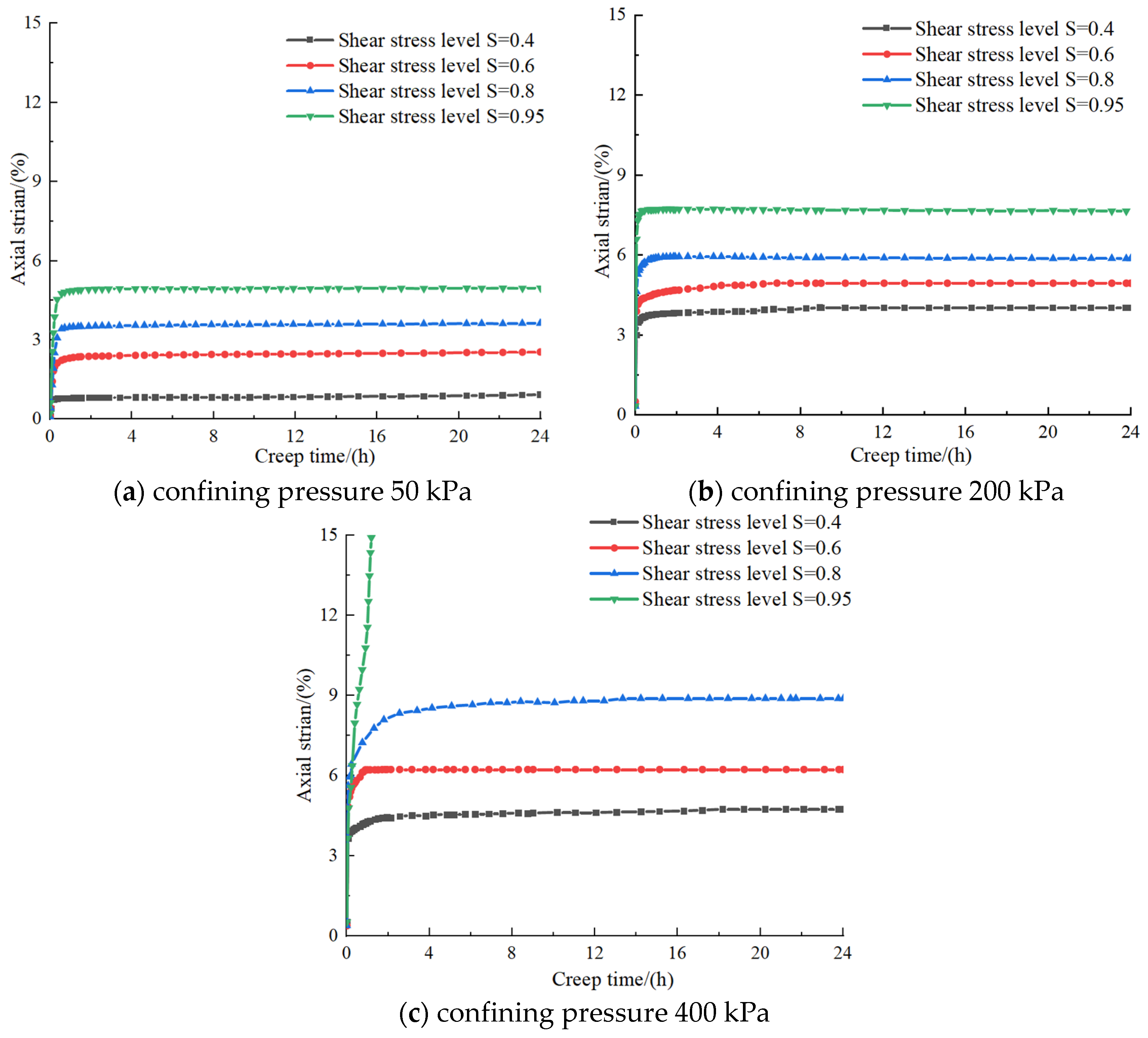

3. Analysis of Triaxial Creep Test Results

4. Creep Constitutive Model for Undisturbed Loess

4.1. Creep Mechanism

4.2. Creep Model Framework

4.3. Creep Constitutive Model for Cemented Element

4.4. Creep Constitutive Model for Frictional Element

4.5. Breakage Ratio

- (1)

- Under the condition of low confining pressure, it shows attenuation creep under the condition of low stress. Under applying high stress, it shows non-attenuation creep, and the time of each stage of the creep curve under different conditions is different. When the load is large, the stable creep stage in the non-attenuation creep curve is not apparent, and it quickly transforms into the acceleration stage, and the damage rate of rock and soil increases.

- (2)

- With the increase in confining pressure, the creep acceleration stage is less obvious, showing a decreasing trend.

- (3)

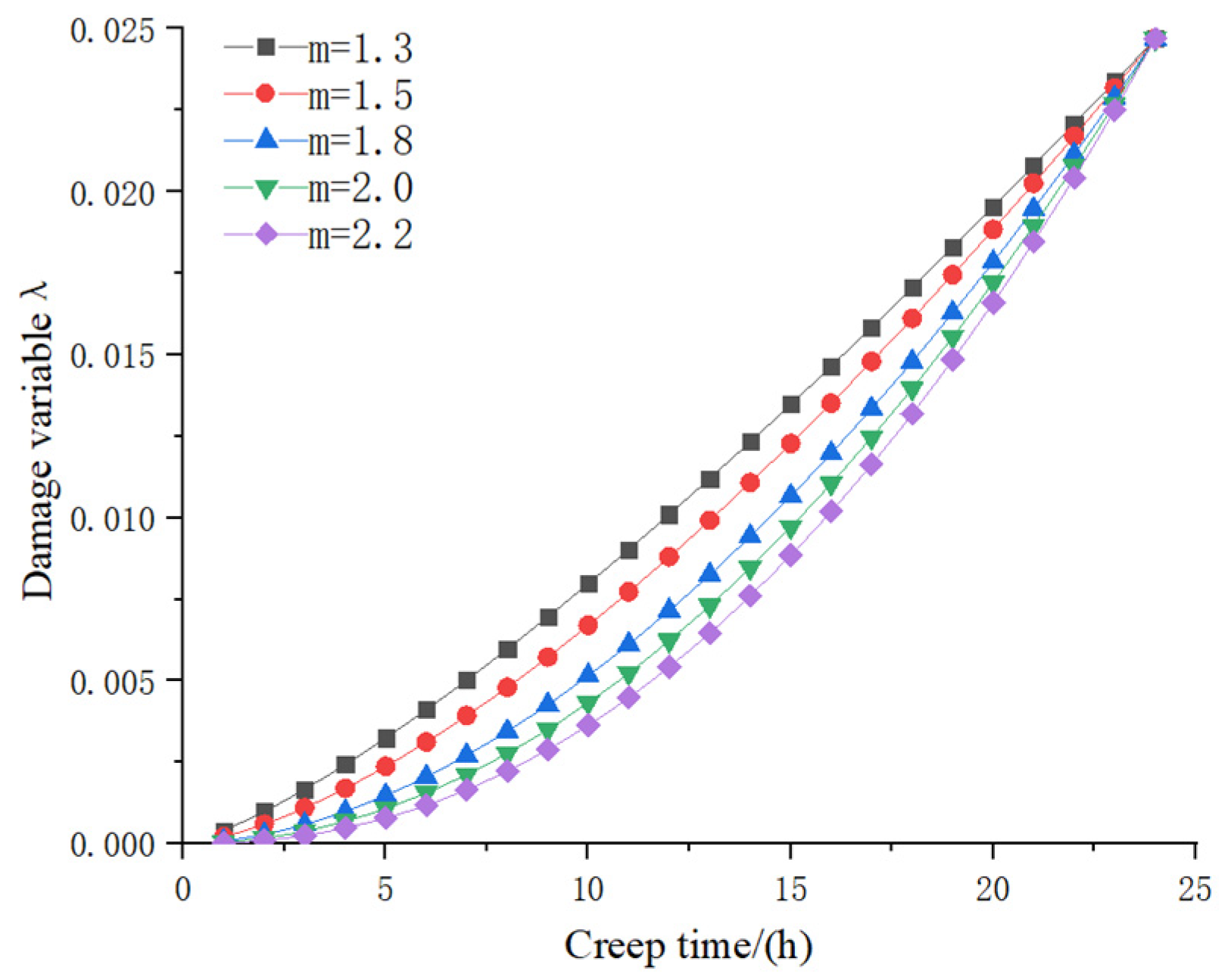

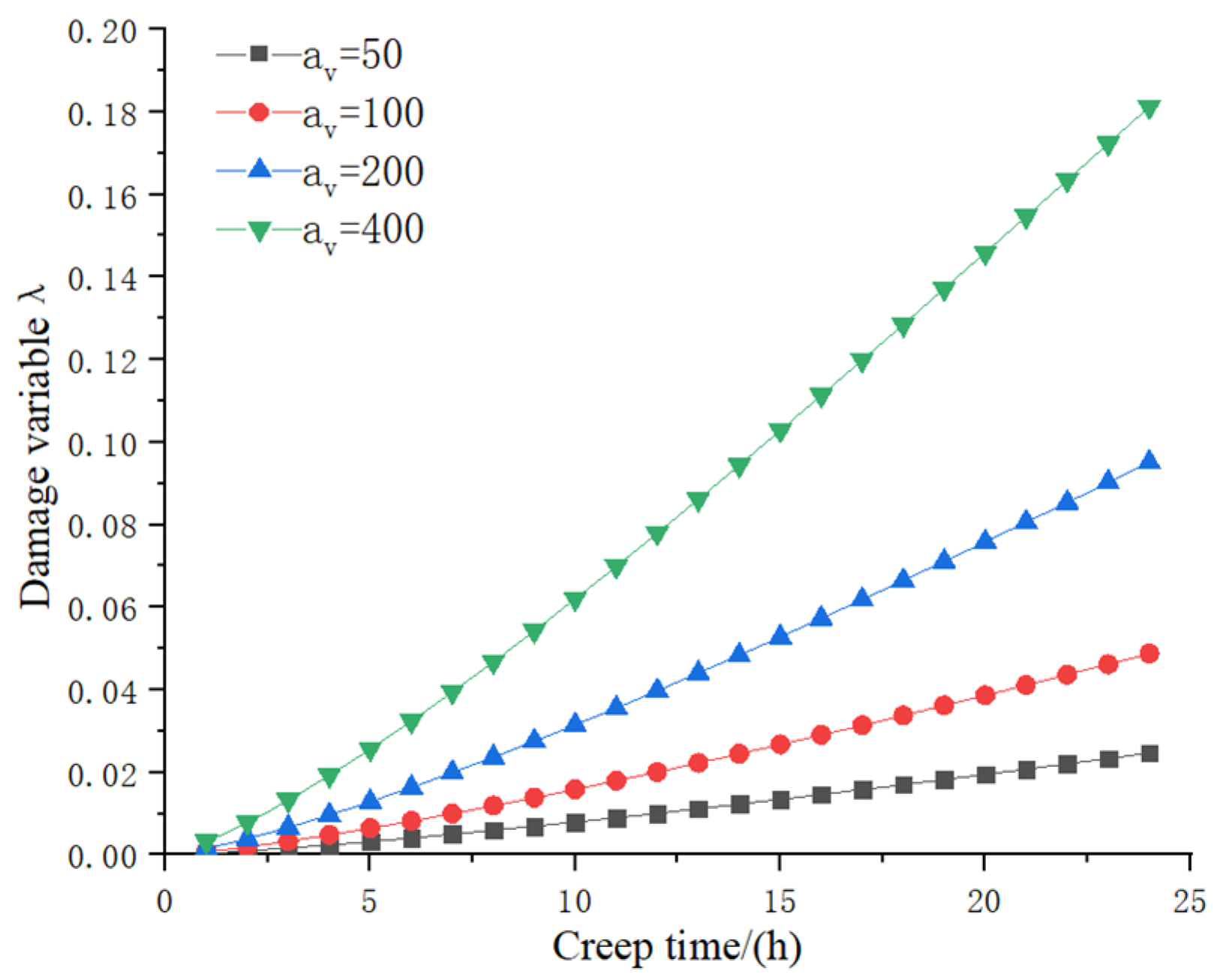

- With the increase in loading time, the damage rate of loess increases first and then tends to be stable. Its value changes from a value slightly greater than 0 to a value less than 1.

4.6. Determination Method of Model Parameters

| Parameter | Implication | Determine Method |

|---|---|---|

| Elastic modulus | Determined by undisturbed loess triaxial compression test | |

| Coefficient of viscosity | The creep deformation curve of undisturbed loess under low-stress levels is simulated without considering the damage rate. | |

| M | Critical stress ratio | Determined by undisturbed loess triaxial compression test |

| K0 | Consolidation coefficient | K0 consolidation test |

| Initial yield stress | Determined by undisturbed loess triaxial compression test | |

| Coefficient of viscosity | The non-attenuation creep curve of the simulated original loess is determined. | |

| Breakage parameter | According to the model’s prediction of the experimental data, the inversion is determined. | |

5. Model Verification

5.1. Parameter Analysis of Cementation Elements

5.2. Parameter Analysis of Friction Elements

5.3. Breakage Parameter Analysis

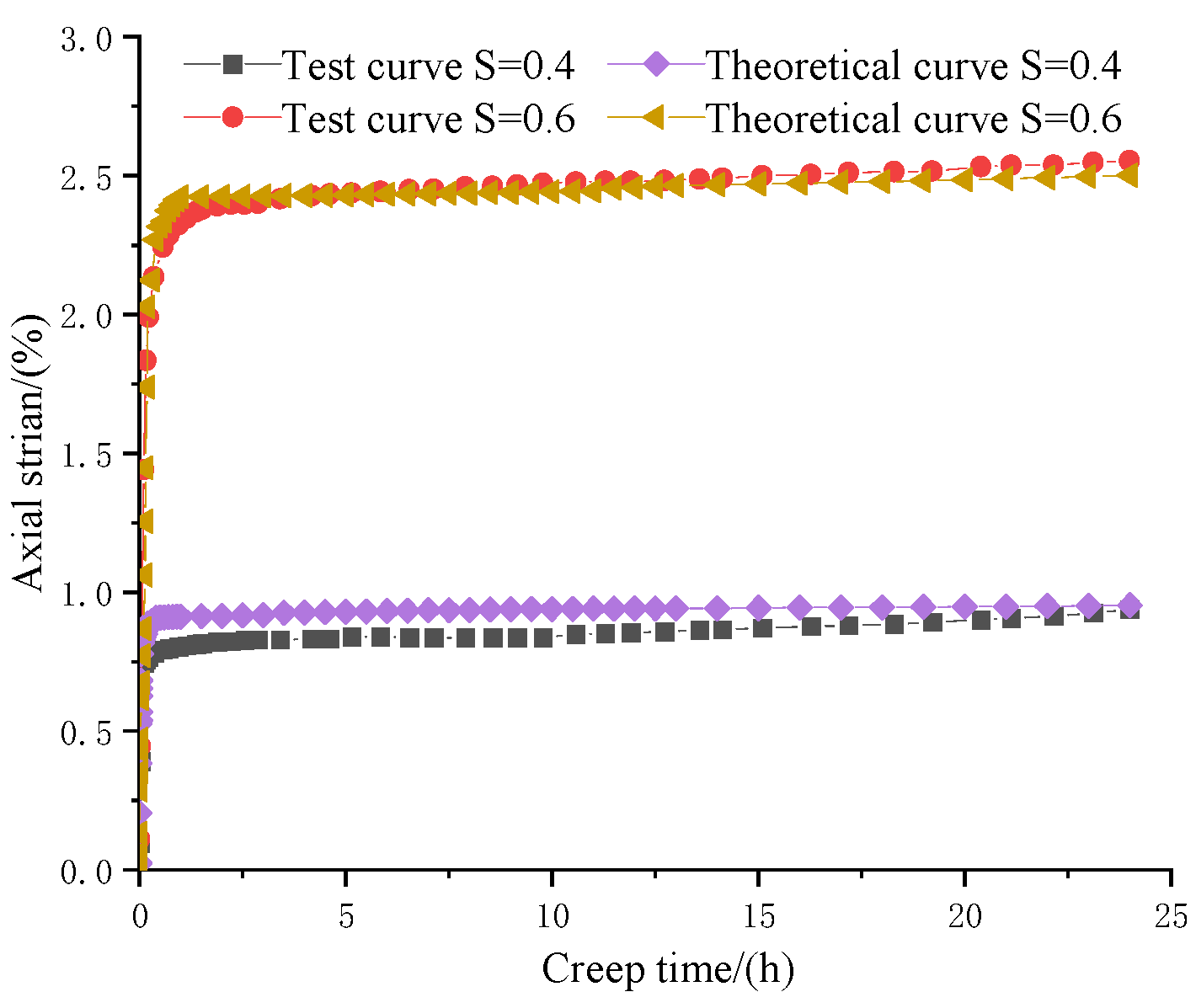

5.4. Theoretical Model Verification

6. Conclusions

- (1)

- Based on the Nishihara model, the relationship between the strain of the cementation element and the creep time is proposed. And the isometric consolidation coefficient is introduced into the overstress model in the friction element, and the relationship between the strain of the friction element and the creep time is proposed. The expression of the volume damage rate can quickly and effectively determine the mechanical parameters of the soil.

- (2)

- The parameters proposed in the model are calculated reasonably, and the damage law of undisturbed loess is analyzed: with the increase in loading time, the damage rate of loess increases first and then gradually tends to be stable, and the value of volume damage rate is a value between 0–1.

- (3)

- This paper proposes a creep damage constitutive model of undisturbed loess based on a binary medium model considering the isometric consolidation, which can better reflect the creep characteristics. By the test curve and theoretical curve, it can be obtained that the model has a good prediction effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, G. Experimental Study on Triaxial Creep Properties of Loess; Northwest University of Agriculture and Forestry: Xianyang, China, 2011. [Google Scholar]

- Xie, N.; Yao, H. A review of soil rheology. J. Yunnan Univ. Technol. 1999, 54–58. [Google Scholar]

- Smalley, I. Making the material:the formation of silt sized primary mineral particles for loess deposits. Quat. Sci. Rev. 1995, 14, 645–651. [Google Scholar] [CrossRef]

- Zhang, Z. Chinese Loess; Hebei Education Press: Shijiazhuang, China, 2003. [Google Scholar]

- Smalley, J.I.; Marković, B.S. Loessification and hydroconsolidation: There is a connection. Catena 2014, 117, 94–99. [Google Scholar]

- Liu, Z. Mechanics and Engineering of Loess; Shaanxi Science and Technology Press: Xi’an, China, 1997. [Google Scholar]

- Gao, Y.; Ma, Y.; Zhang, W.; Guo, J. Analysis of wetting deformation characteristics and microstructure of loess in Xining area. J. Eng. Geol. 2019, 27, 803–810. [Google Scholar]

- Chen, C.; Hu, Z.; Gao, P. Research on the structure of undisturbed loess and its relationship with deformation characteristics. Geotech. Mech. 2006, 11, 1891–1896. [Google Scholar]

- Zhi, B.; Wang, S.; Wei, P.; Liu, E.; Han, W. Experimental Study on Creep Characteristics of Loess with Different Compactness. KSCE J. Civ. Eng. 2024, 28, 1702–1714. [Google Scholar] [CrossRef]

- Wei, P. Creep Test of High Fill Soil in Loess Area; Xi’an University of Science and Technology: Xi’an, China, 2022. [Google Scholar]

- Chen, L. Study on Creep Characteristics and Microstructure Evolution of Loess; Chang’an University: Xi’an, China, 2023. [Google Scholar]

- Yuan, Y.-L.; Hu, C.-M.; Mei, Y.; Wang, F.-F.; Wang, G. Uncertainty Analysis of Creep Behavior of Compacted Loess and a Non-Deterministic Predication Method for Post-Construction Settlement of a High-Fill Embankment. Buildings 2023, 13, 1118. [Google Scholar] [CrossRef]

- Pang, X. Research on rheological constitutive model of subgrade compacted loess based on creep test. J. Railw. Sci. Eng. 2017, 14, 1206–1216. [Google Scholar]

- Le, T.; Airey, D.; Standing, J. Creep behaviour of undisturbed London Clay in triaxial stress space. E3S Web Conf. 2019, 92, 05006. [Google Scholar]

- Leng, Y.; Peng, J.; Wang, S.; Lu, F. Development of water sensitivity index of loess from its mechanical properties. Eng. Geol. 2021, 280, 105918. [Google Scholar] [CrossRef]

- Nan, J.; Peng, J.; Zhu, F.; Ma, P.; Liu, R.; Leng, Y.; Meng, Z. Shear behavior and microstructural variation in loess from the Yan’an area, China. Eng. Geol. 2020, 280, 105964. [Google Scholar] [CrossRef]

- Li, J.; Fang, H.; Wu, S. Test on Creep Characteristics of Remolded Loess Under High Stress. J. Henan Univ. Sci. Technol. (Nat. Sci.) 2018, 39, 56–60. [Google Scholar]

- Huang, C.; Wang, H.; Wang, Y.; Cao, J. Effect of sand content on one-dimensional creep behavior of sand-fine grained mixed soil. Geomech. Mech. 2023, 44, 3370–3382+3511. [Google Scholar]

- Hu, C.; Tian, M.; Yuan, Y.; Wang, F.; Hu, T.; Hou, X. Creep Model of Compacted Loess Considering Parameter Randomness and Engineering Application; Water Conservancy and Civil Construction Volume 1; CRC Press: Boca Raton, FL, USA, 2023; pp. 341–348. [Google Scholar]

- Li, X.; Liu, E.; Song, B.; Liu, X. An improved Nishihara model for frozen loess considering the influence of temperature. Adv. Mater. Sci. Eng. 2018, 2018, 9073435. [Google Scholar] [CrossRef]

- Tang, H.; Luo, J.; Duan, Z.; Wang, D.; Qi, S. Experimental investigation of the creep behaviour of remoulded loess under different levels of compactness. PLoS ONE 2022, 17, e0262456. [Google Scholar] [CrossRef]

- Zhou, Z.; Ma, W.; Zhang, S.; Mu, Y.; Li, G. Effect of freeze-thaw cycles in mechanical behaviors of frozen loess. Cold Reg. Sci. Technol. 2018, 146, 9–18. [Google Scholar] [CrossRef]

- Ding, R.; Tang, H.; Duan, Z.; Zhang, Y.; Jing, H. Analysis on Creep Properties of Aquiferous Loess under a High Confining Pressure. J. Eng. Sci. Technol. Rev. 2021, 14, 59–68. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Zhang, D. Creep behavior of intact loess followed unloading paths. Front. Earth Sci. 2021, 9, 744864. [Google Scholar] [CrossRef]

- Chowdhury, A.; Sahu, R.B. Creep potential of soft clays of Normal Kolkata Deposit. Arab. J. Geosci. 2021, 14, 1354. [Google Scholar] [CrossRef]

- Arqub, O.A.; Al-Smadi, M.; Gdairi, R.A.; Alhodaly, M.; Hayat, T. Implementation of reproducing kernel Hilbert algorithm for pointwise numerical solvability of fractional Burgers’ model in time-dependent variable domain regarding constraint boundary condition of Robin. Results Phys. 2021, 24, 104210. [Google Scholar] [CrossRef]

- Lian, B.; Wang, X.; Zhan, H.; Wang, J.; Peng, J.; Gu, T.; Zhu, R. Creep mechanical and microstructural insights into the failure mechanism of loess landslides induced by dry-wet cycles in the Heifangtai platform, China. Eng. Geol. 2022, 300, 106589. [Google Scholar] [CrossRef]

- Ohta, H.; Nishihara, A. Anisotropy of undrained shear strength of clays under axi-symmetric loading conditions. Soils Found. 1985, 25, 78–86. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.Z.; Shen, K.L.; Ye, S.H. Undrained shear strength of K0 consolidated soft soil. J. Geomech. Eng. 2006, 8, 970–977. [Google Scholar] [CrossRef]

- Hou, L.; Weng, X.; Cui, Y.; Han, W.; Chen, Y. Anisotropic constitutive model of K0 consolidated structural loess. J. Rock Mech. Eng. 2022, 41, 2124–2134. [Google Scholar]

- GB/T 50123-2019; Standard for Geotechnical Test Methods. Water Resources Department of Henan Province: Henan, China, 2019. (In Chinese)

| Water Content w | Void Ratio e | Liquid Limit WL | Plastic Limit WP | Density | Dry Density |

|---|---|---|---|---|---|

| 12.56% | 0.983 | 28.8% | 18.6% | 1.82 g/cm3 | 1.62 g/cm3 |

| Consolidation Coefficient | Confining Pressure (kPa) | Shear Stress Level |

|---|---|---|

| 0.5 | 50, 200, 400 | 0.4, 0.6, 0.8, 0.95 |

| 0.8 | 50, 200, 400 | 0.4, 0.6, 0.8, 0.95 |

| 1.0 | 50, 200, 400 | 0.4, 0.6, 0.8, 0.95 |

| Confining Pressure/kPa | /kPa | /kPa | /105 kPa·h |

|---|---|---|---|

| 50 | 175.42 | 223.65 | 2.33 |

| 200 | 184.72 | 311.34 | 1.95 |

| 400 | 191.72 | 423.37 | 1.87 |

| Confining Pressure/kPa | M | /105 kPa·h |

|---|---|---|

| 50 | 1.04 | 1.02 |

| 200 | 1.04 | 1.79 |

| 400 | 1.04 | 2.69 |

| Consolidation Coefficient | Confining Pressure/kPa | Shear Stress Level | Axial Strain for Test (%) | Axial Strain for Theoretical (%) | Relative Error (%) |

|---|---|---|---|---|---|

| 0.8 | 50 | 0.4 | 1.07818 | 0.9768 | 9.40 |

| 0.6 | 3.19184 | 2.96148 | 7.21 | ||

| 0.8 | 200 | 0.4 | 4.94257 | 4.88834 | 1.09 |

| 0.6 | 6.4799 | 6.23682 | 3.758 | ||

| 1.0 | 200 | 0.4 | 0.93755 | 0.95218 | −1.56 |

| 0.6 | 2.55347 | 2.5006 | 2.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Zhang, H.-M.; Gou, Z.-Y.; Wang, P. Creep Deformation Characteristics and Damage Unified Creep Constitutive Model of Undisturbed Structural Loess Under Different Consolidation Conditions. Buildings 2025, 15, 1199. https://doi.org/10.3390/buildings15071199

Yuan Y, Zhang H-M, Gou Z-Y, Wang P. Creep Deformation Characteristics and Damage Unified Creep Constitutive Model of Undisturbed Structural Loess Under Different Consolidation Conditions. Buildings. 2025; 15(7):1199. https://doi.org/10.3390/buildings15071199

Chicago/Turabian StyleYuan, Yuan, Hui-Mei Zhang, Zhao-Yuan Gou, and Pan Wang. 2025. "Creep Deformation Characteristics and Damage Unified Creep Constitutive Model of Undisturbed Structural Loess Under Different Consolidation Conditions" Buildings 15, no. 7: 1199. https://doi.org/10.3390/buildings15071199

APA StyleYuan, Y., Zhang, H.-M., Gou, Z.-Y., & Wang, P. (2025). Creep Deformation Characteristics and Damage Unified Creep Constitutive Model of Undisturbed Structural Loess Under Different Consolidation Conditions. Buildings, 15(7), 1199. https://doi.org/10.3390/buildings15071199