Enhancement of Cement-Based Materials: Mechanisms, Impacts, and Applications of Carbon Nanotubes in Microstructural Modification

Abstract

1. Introduction

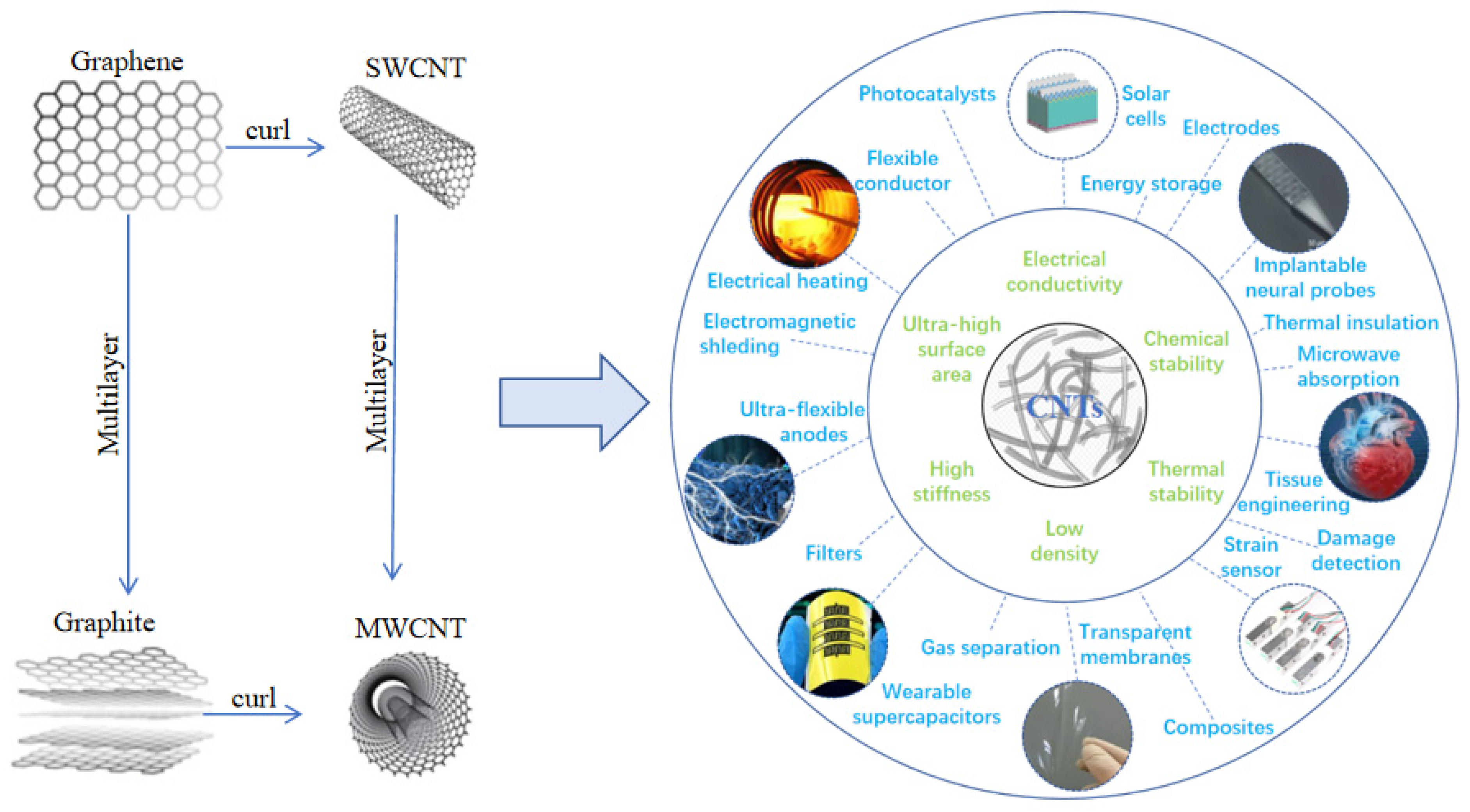

2. The Fundamental Properties and Fabrication Processes of CNTs

2.1. Composition of CNTs

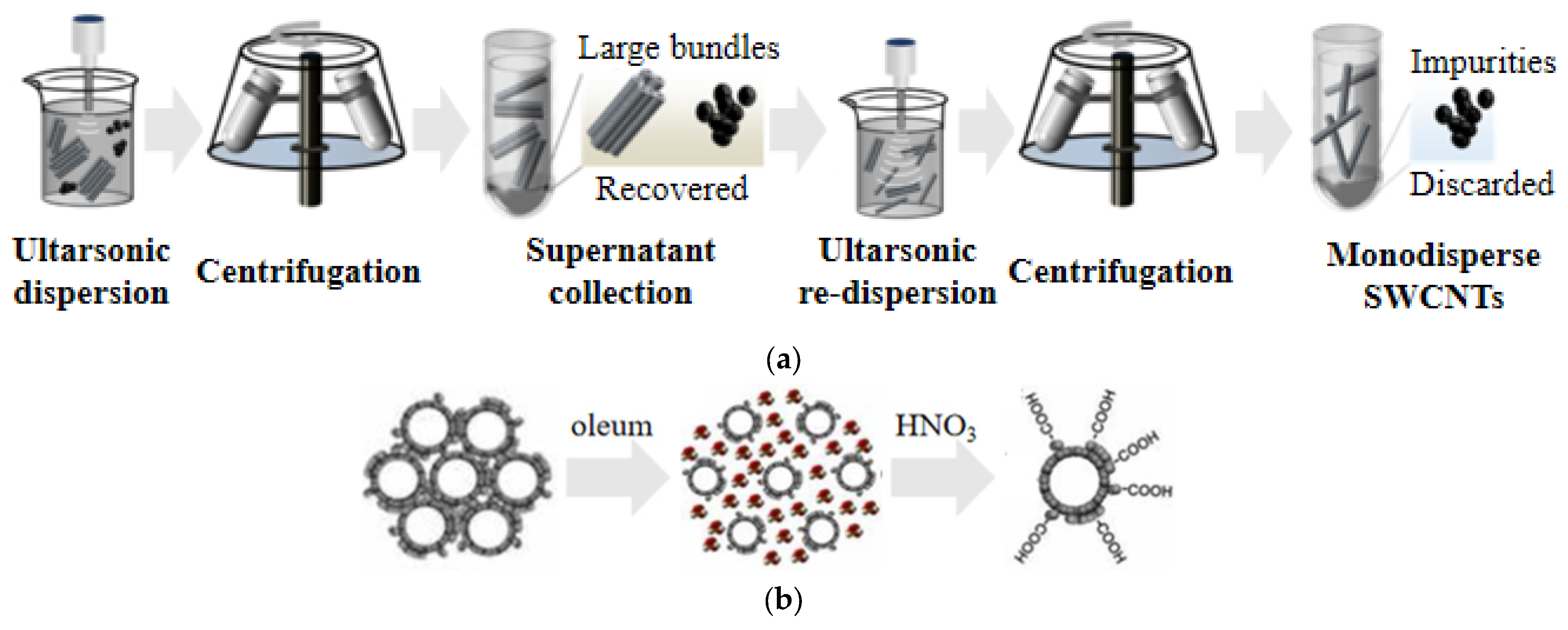

2.2. Process of CNTs

| Method | Craft | Product Type | Advantages | References |

|---|---|---|---|---|

| Arc discharge | Control pressure, adjust make-up rate, catalyst | SWCNTs, MWCNTs | Easy to operate, features simple procedures, is cost-effective, and has a short production cycle | F Y Zhang [16] |

| Coal-based composite carbon rod was used as anode material | SWCNTs, MWCNTs | Higher yields | J S Qiu [17] | |

| A method for mass production of SWCNT by temperature-controlled electric arc furnace | SWCNTs | High purity | Y N Liu [18] | |

| CVD | Method for fabricating carbon nanotube arrays by wire-assisted CVD | CNTs arrays | High crystallinity, intact structure and low impurity content | N Q Zhao [19] |

| Preparation of CNT by hydrogen-free CVD | SWCNTs, MWCNTs | High purity, good structural integrity, thin, long pipe diameter | M Y Liu [20] | |

| Bulk preparation of bamboo CNT by CVD | Bamboo CNTs | Continuous batch preparation | F Y Kang [21] | |

| Electrolytic process | High-temperature electrolysis of CO2 to CNTs | CNTs | Increase speed and reduce production costs | H J Wu [22] |

| Electrolysis of CO2 to prepare graphene or CNTs | CNTs | Recyclable, environmentally friendly, easy to operate | S Q Jiao [23] | |

| Preparation of CNT-coated metal materials by molten salt electrochemical method | CNT-coated metal material | Simplify processes, save costs | W Xiao [24] |

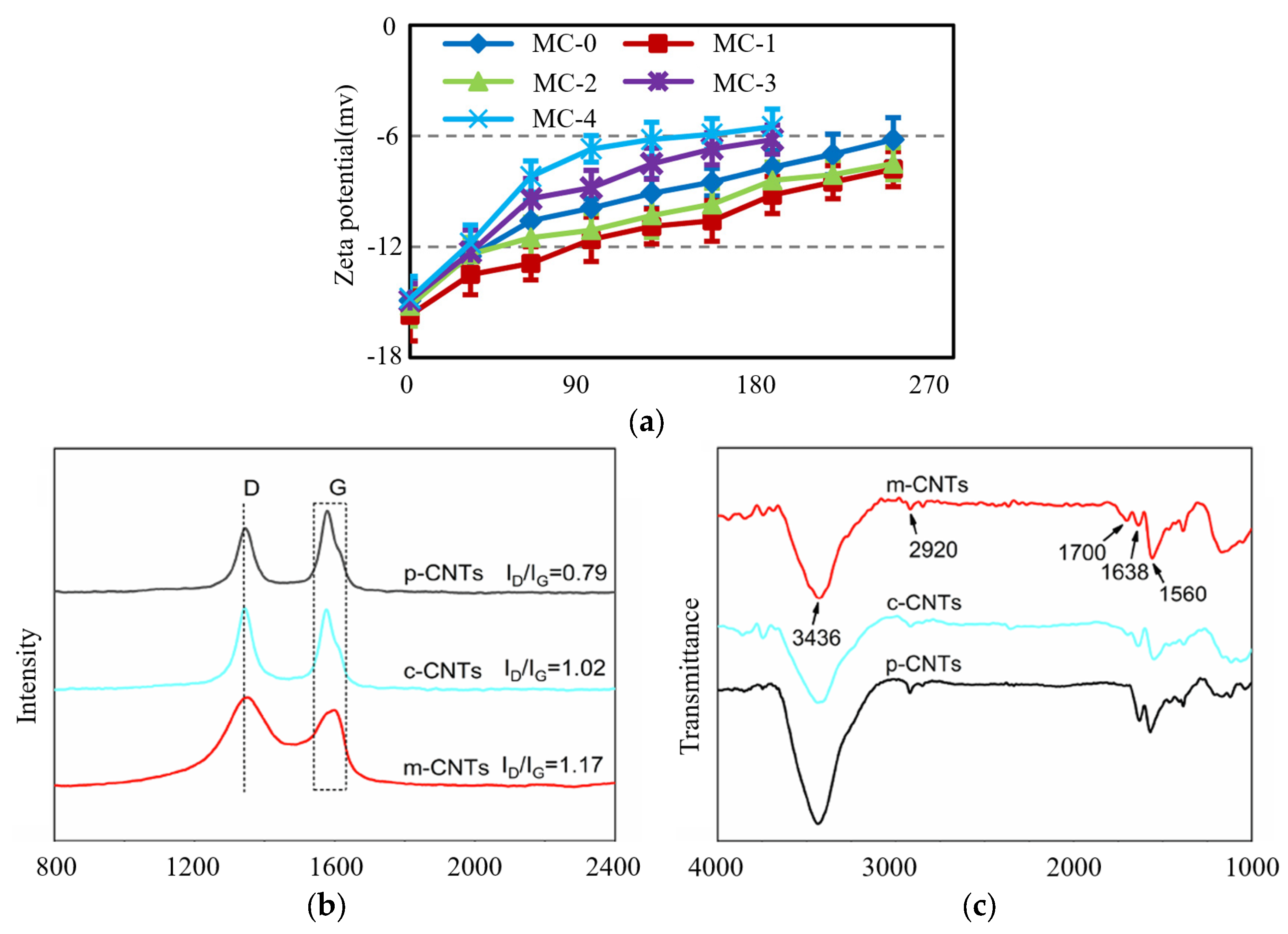

2.3. Characteristics of CNTs

2.3.1. Physical Characteristics

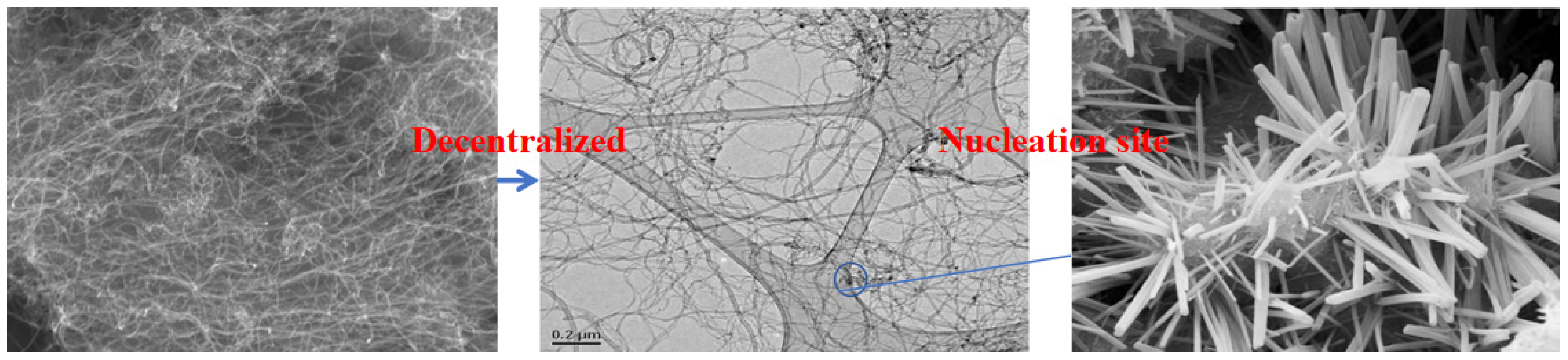

2.3.2. Microscopic Characteristics

3. Effect Mechanism of Carbon Nanotubes on Cement-Based Materials

3.1. Physical Characteristics

3.1.1. Effects of Mechanical Properties

- Static Strength

- 2.

- Bending Strength

- 3.

- Dynamic Strength

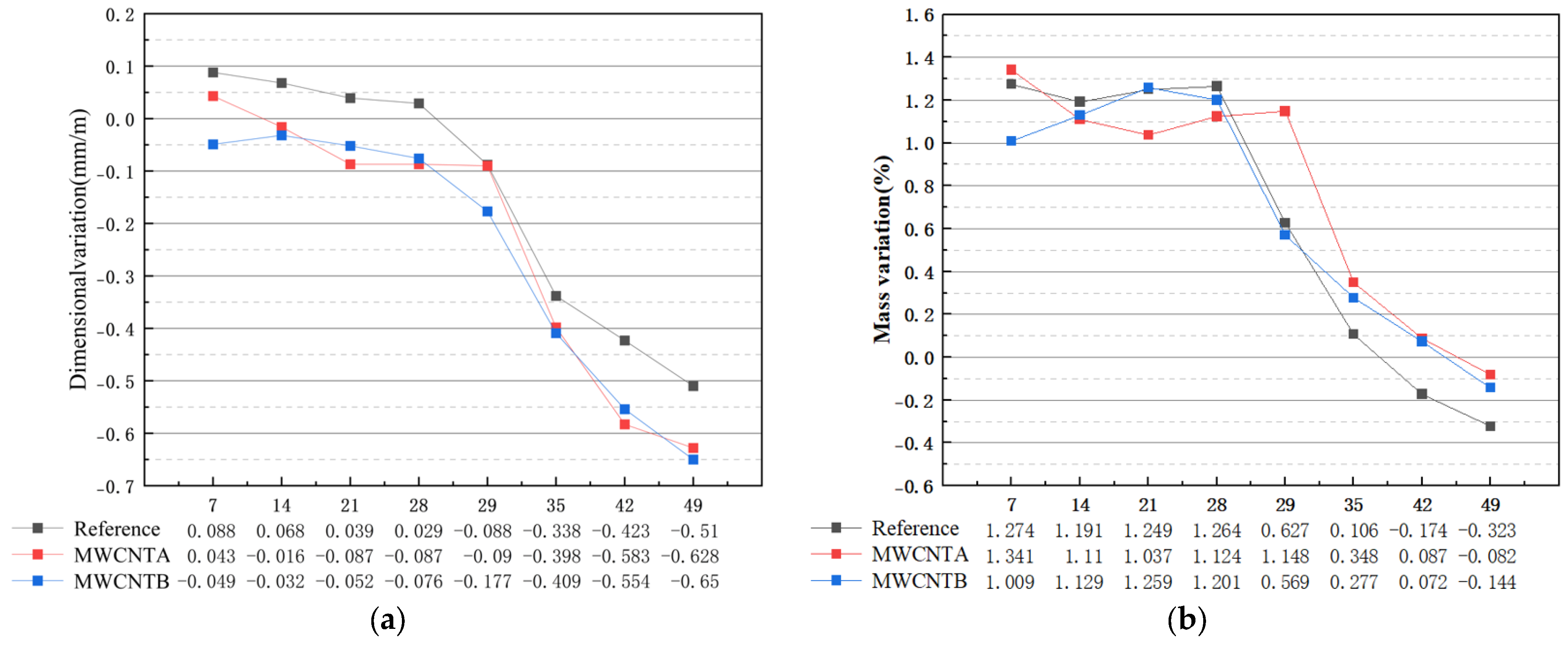

3.1.2. Effect of Contractility

- Different types

- 2.

- Different dosage

- 3.

- Different Length–Diameter Ratio

3.1.3. Effect of Crack Resistance

3.1.4. Effect of Electrical Conductivity

3.2. Chemical Characteristic

3.3. Environmental Adaptation Characteristics

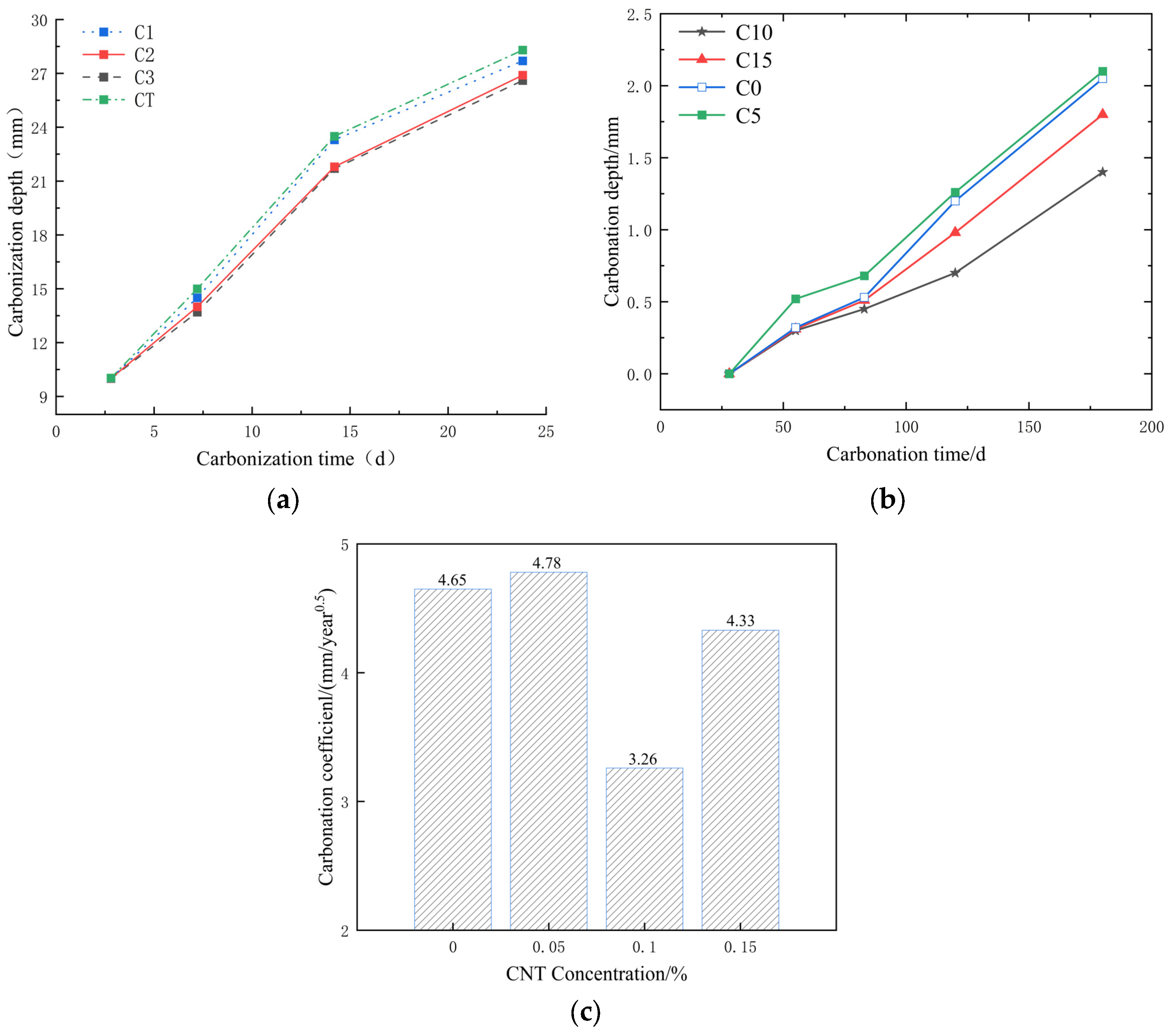

3.3.1. Effects of Resists Carbonization

- Different Dosage

- 2.

- Different Dispersion Methods

- 3.

- Different Length–Diameter Ratio

3.3.2. Effect of Durability

- Freeze–Thaw Resistance

- 2.

- Resistance to Chloride Ion Penetration

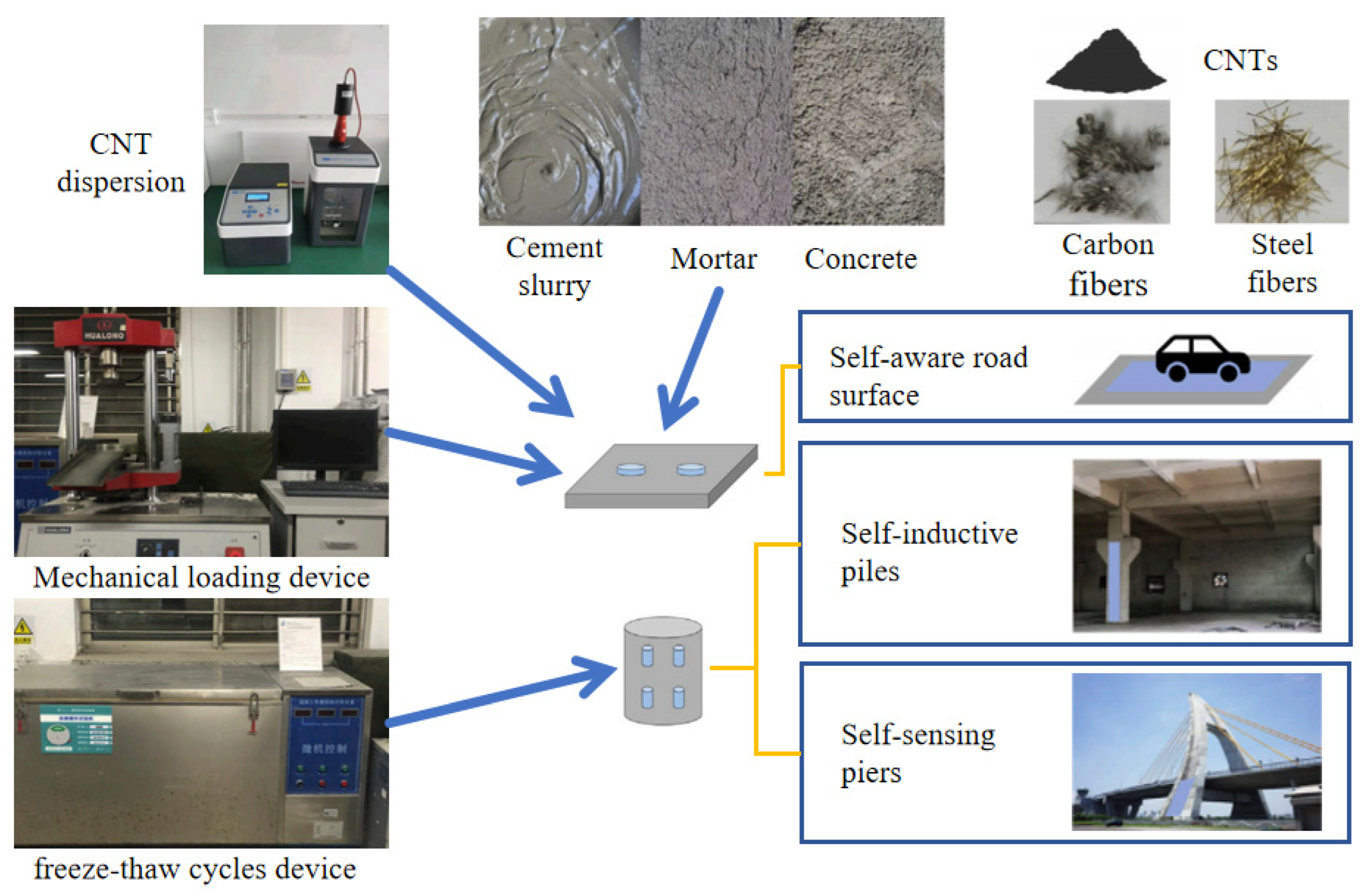

4. Prospects for the Application of CNTs in Cement-Based Materials

- Traditional architecture

- 2.

- Cement-Based CNT Sensor

- 3.

- Three-Dimensional Printed Concrete

- 4.

- Future Research Directions

5. Conclusions

5.1. Effects After the Addition of CNTs

- Mechanical properties: Compressive and flexographic strength increased by 10–50%, toughness increased (fracture energy increased by 3–5 times), and CNTs bridge cracks and disperse stress.

- Contractility: Carboxylated CNTs inhibited early contraction by 46.7%, and excessive dosage (>0.5 wt%) may reverse the contraction.

- Carbonization resistance: Porosity is reduced by 20–30%, CO2 diffusion is blocked, and the carbonization depth is minimum when 0.1–0.5 wt% is added.

- Electrical conductivity: A seepage network is formed, the resistivity decreases, and the electrical conductivity increases with the increase in the dosage when the dispersion is uniform.

5.2. Current Technological Challenges

- Challenges with CNTs

- 2.

- Challenges with CNT Cement-Based Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CNTs | Carbon nanotubes |

| SWCNTs | Single-walled carbon nanotubes |

| MWCNTs | Multiwalled carbon nanotubes |

| RPC | Reactive powder concrete |

References

- Chen, Y.; Liu, P.; Yin, J.; Wang, D.; He, S.S.; Zhang, X.Q.; Yu, Z.W. Progress of chemical thermodynamics and multi-scale research on sulfate erosion of concrete. Concrete 2024, 3, 35–41. [Google Scholar]

- Zhang, X.F.; Sheng, Y.; Shi, R.; Li, S.Y. Experimental study on mechanical properties of RCC with different porosity. Chin. J. Appl. Mech. 2023, 40, 840–847. [Google Scholar]

- Reiterman, P.; Holčapek, O.; Zobal, O.; Keppert, M. Freeze-Thaw Resistance of Cement Screed with Various Supplementary Cementitious Materials. Rev. Adv. Mater. Sci. 2019, 58, 66–74. [Google Scholar] [CrossRef]

- Long, W.J.; Wang, W.L.; Xian, X.P.; Chen, S.; Fan, Y.F. High-strength self-compacting concrete and its application. Concrete 2014, 1, 90–92. [Google Scholar]

- He, B.; Yang, Z.D.; Yang, F.; Tang, Y.Q.; Zhang, H.E.; Zhu, X.P.; Jiang, Z.W. Review on Mechanical Properties and Evolution Mechanism of Concretes under Extreme Cryogenic Environment. J. Chin. Ceram. Soc. 2024, 52, 1698–1709. [Google Scholar]

- Zhao, X.L.; Zheng, X.H.; Zhong, W.; Hu, D.Y. Study on strength and frost resistance of lightweight aggregate concrete for prefabricated Bridges. Highway 2024, 69, 382–387. [Google Scholar]

- Qiu, X. Research on Abrasion Resistance of Ultra-High-Performance Concrete. Master’s Thesis, Zhong Yuan University of Technology, Zhengzhou, China, 2023. [Google Scholar]

- Norhasri, M.M.; Hamidah, M.S.; Fadzil, A.M. Applications of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Das, B.B.; Mitra, A. Nanomaterials for Construction Engineering—A Review. Int. J. Mater. Mech. Manuf. 2014, 2, 96. [Google Scholar] [CrossRef]

- Sarkar, S.G.; Acharya, S.; Alexender, R.; Kaushal, A.; Bahadur, J.; Mondal, J.; Dasgupta, K. Exceptional field emission characteristics of self-assembled carbon nanotube sheets with ultra-low turn-on field and outstanding stability. Chem. Eng. J. 2025, 503, 158622. [Google Scholar] [CrossRef]

- Tafesse, M.; Kim, H.K. The role of carbon nanotube on hydration kinetics and shrinkage of cement composite. Composites 2019, 169, 55–64. [Google Scholar] [CrossRef]

- Zhuang, W. Study on Detection Performance of Modified Carbon Nanotube Smart. Master’s Thesis, Suzhou University of Science and Technology, Suzhou, China, 2022. [Google Scholar] [CrossRef]

- Chaitra, M.N. A Review on Application of Carbon Nanotubes in Cement Concrete. J. Comput. Al Theor. Nanosci. 2018, 15, 3210–3213. [Google Scholar] [CrossRef]

- Liu, Q.L.; Li, H.C.; Peng, Y.J.; Dong, X.B. Nanomechanical properties of multi-wall carbon nanotubes/cementitious composites. Acta Mater. Compos. Sin. 2020, 37, 952–961. (In Chinese) [Google Scholar]

- Hu, G.F.; Zhang, X.H.; Liu, X.Y.; Yu, J.Y.; Ding, B. Strategies in Precursors and Post Treatments to Strengthen Carbon Nanofibers. Adv. Fiber Mater. 2020, 2, 18. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhou, P.; Su, Y.; Wei, H. A Method of Producing Carbon Nanotubes by Direct DC Arc Discharge. CN201110339551.7[P]/102502583B, 3 September 2024. [Google Scholar]

- Qiu, J.; Li, Y.; Wang, Y. A Method of Producing Carbon Nanotubes by Arc Discharge Technology Under Vacuum Conditions. CN200310105220.2, 3 September 2024. [Google Scholar]

- Liu, Y.N.; Zhao, T.K.; Zhu, J.W.; Song, X.L.; Yu, G. A Method for Mass-Producing Single-Walled Carbon Nanotubes Using a Temperature-Controlled Arc Furnace. CN200410026135.1[P]/CN1579931, 3 September 2024. [Google Scholar]

- Zhao, N.; Li, L.; Sha, J.; Ma, L.; Shi, C.; Li, Q.; He, C.; He, F. A Metal Wire-Assisted Chemical Vapor Deposition Method for Preparing Carbon Nanotube Arrays. CN202010865305.4[P]/CN111943172A, 3 September 2024. [Google Scholar]

- Li, M.Y.; Du, H.W.; Hong, L.; Zhang, J.J.; Zong, Q.; Wang, J.Y. The Invention Relates to a Method for Preparing Carbon Nanotubes by Hydrogen Free Chemical Vapor Deposition. CN202210962506.5[P]/202210962506.5, 3 September 2024. [Google Scholar]

- Kang, F.; Lu, R.; Zou, L.; Gui, X.; Gu, J.; Wei, J.; Wang, K.; Wu, D. The Invention Relates to a Batch Preparation Method of bamboo Carbon Nanotubes by Chemical Vapor Deposition. CN 200710302013[P]/CN 101195483 A, 3 September 2024. [Google Scholar]

- Wu, H.; Liu, Y.; Mao, Q.; Wang, B.; Li, L.; Lin, H. An Improved Method for Making Carbon Nanotubes from CO2 by High Temperature Electrolysis. CN201510891230.6[P], 3 September 2024. [Google Scholar]

- Jiao, S.; Hu, L.; Tu, J.; Wang, J. A Method for Preparing Graphene or Carbon Nanotubes by Electrolysis of Carbon Dioxide. CN201610007071.3[P]/CN105624722B, 3 September 2024. [Google Scholar]

- Xiao, W.; Weng, W.; Jiang, B. The Invention Relates to a Method for Preparing Carbon Nanotubes Coated Metal Materials Based on Molten Salt Electrochemical Method. CN201910725591.1[P]/CN110359068A, 3 September 2024. [Google Scholar]

- Zhang, C.S.; Zhang, N.; Zhang, J. Controlled Synthesis of Carbon Nanotubes: Past, Present and Future. Acta Phys.-Chim. Sin. 2020, 36, 54–69. [Google Scholar] [CrossRef]

- Qiu, J.L.; Cui, G.H.; Lai, J.X.; Zhao, K.; Tang, K.J.; Qiang, L.; Jia, D. Influence of Fissure-Induced Linear Infiltration on the Evolution Characteristics of the Loess Tunnel Seepage Field. Tunn. Undergr. Space Technol. 2025, 157, 105216. [Google Scholar]

- Tang, Y.; Li, X.; Lin, L.; Xu, H.; Huang, B. Method for Synthesizing Metal-Free Catalyst Self-Growing Carbon Nanotubes by Chemical Vapor Deposition. CN200810031235.1[P]/CN101270470A, 3 September 2024. [Google Scholar]

- Yang, D.H.; Li, L.H.; Li, X.; Xi, W.; Zhang, Y.J.; Liu, Y.M.; Wei, X.J.; Zhou, W.Y.; Wei, F.; Xie, S.S.; et al. Preparing high-concentration individualized carbon nanotubes for industrial separation of multiple single-chirality species. Nat. Commun. 2023, 14, 2491. [Google Scholar] [CrossRef]

- Du, M.R.; Gao, Y.; Han, G.S.; Li, L.; Jing, H.W. Stabilizing effect of methylcellulose on the dispersion of multi-walled carbon nanotubes in cementitious composites. Nanotechnol. Rev. 2020, 9, 93–104. [Google Scholar] [CrossRef]

- Li, S.J.; Zhang, Y.L.; Cheng, C.; Wei, H.; Du, S.G.; Yan, J. Surface-treated carbon nanotubes in cement composites: Dispersion, mechanical properties and microstructure. Constr. Build. Mater. 2021, 310, 125262. [Google Scholar] [CrossRef]

- Habib, A.; Houri, A.A.; Habib, M.; Elzokra, A.; Yildirim, U. Structural Performance and Finite Element Modeling of Roller Compacted Concrete Dams: A Review. Lat. Am. J. Solids Struct. 2021, 18, e376. [Google Scholar] [CrossRef]

- Habib, A.; Yildirim, U.; Zgür, E. Seismic Behavior and Damping Efficiency of Reinforced Rubberized Concrete Jacketing. Arab. J. Sci. Eng. 2021, 46, 4825–4839. [Google Scholar] [CrossRef]

- Habib, A.; Junaid, M.T.; Dirar, S.; Barakat, S.; Al-Sadoon, Z.A. Machine Learning-Based Estimation of Reinforced Concrete Columns Stiffness Modifiers for Improved Accuracy in Linear Response History Analysis. J. Earthq. Eng. 2024, 29, 130–155. [Google Scholar] [CrossRef]

- Habib, A.; Barakat, S.; Al-Toubat, S.; Junaid, M.T.; Maalej, M. Developing Machine Learning Models for Identifying the Failure Potential of Fire-Exposed FRP-Strengthened Concrete Beams. Arab. J. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- Zhang, Z.K.; Lai, J.X.; Song, Z.P.; Xie, Y.L.; Qiu, J.L.; Cheng, Y. Investigating fracture response characteristics and fractal evolution laws of pre-holed hard rock using infrared radiation: Implications for construction of underground works. Tunn. Undergr. Space Technol. 2025, 161, 106594. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Chaipanich, A.; Nochaiya, T.; Wongkeo, W.; Torkittikul, P. Compressive strength and microstructure of carbon nanotubes–fly ash cement composites. Mater. Sci. Eng. A 2010, 527, 1063–1067. [Google Scholar] [CrossRef]

- Li, H.G.; Wang, Y.L.; Lin, D.P.; Su, Q.W.; Lin, S.Y.; Pan, Z.Y.; Yang, J.L.; Ghimire, P.; Zhu, D.L. Research on the effects of dispersing treatment of multi-walled carbon nanotubes on the electrical and mechanical properties of cement paste. Ind. Constr. 2019, 49, 146–150. [Google Scholar] [CrossRef]

- Tian, W.; Gao, F.F.; He, L. Variation of mechanical property and meso structure of MWCNTs concrete exposed to high temperature. J. Zhejiang Univ. (Eng. Sci.) 2022, 56, 2280–2289. [Google Scholar]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube/cement nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Wang, M.B. Research on Mechanism and Impervious Behavious of Cement Based Composites with Carbon Nanotube. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

- Li, L.S.; Liu, D.S.; Yang, J.; Chen, B.; Song, Y.H. Study on Dynamic Mechanical Properties of CFRP Wrapped Concrete. J. Highw. Transp. Res. Dev. 2010, 27, 22–27. [Google Scholar]

- Wang, C.; Yu, L.Y.; Du, R.M.; Su, H.J.; Wu, J.Y.; Ge, Y. Dynamic Mechanical Properties of Carbon Nanotubes Enhanced Cement Paste. J. Chin. Ceram. Soc. 2021, 49, 2486–2493. [Google Scholar] [CrossRef]

- Wu, J.W.; Xu, K.; Liu, X.L.; Zeng, C.; Wang, J.Y. Damping properties of CNT-reinforced cementitious composites. Concrete 2023, 6, 75–80. [Google Scholar]

- Ruan, Y.F. Investigation on Static and Dynamic Mechanical Properties of Cementitious Composites with Carbon Nanotubes. Master’s Thesis, Dalian University of Technology, Dalian, China, 2019. [Google Scholar] [CrossRef]

- Wei, F.C.; Lai, J.X.; Su, X.L. Investigation of power-law fluid infiltration grout characteristics on the basis of fractal theory. Buildings 2025, 15, 987. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. [Google Scholar] [CrossRef]

- Blandine, F.; Habermehi-Cwirzen, K.; Cwirzen, A. Contribution of CNTs/CNFs morphology to reduction of autogenous shrinkage of Portland cement paste. Front. Struct. Civ. Eng. 2016, 10, 224–235. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.; Dias, A. On the mechanical and shrinkage behavior of cement mortars reinforced with carbon nanotubes. Constr. Build. Mater. 2018, 168, 459–470. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A. Creep, shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr. Build. Mater. 2019, 198, 70–81. [Google Scholar] [CrossRef]

- Qian, X.Y.; Qiu, J.L.; Lai, J.X.; Liu, Y.H. Guarantee rate statistics and product-moment correlation analysis of the optimal deformation allowance for loess tunnel in China. Appl. Sci. 2025, 15, 2451. [Google Scholar] [CrossRef]

- Shi, T.; Yang, Z.P.; Zheng, L.W. FTIR spectra for early age hydration of cement-based composites incorporated with CNTs. Acta Mater. Compos. Sin. 2017, 34, 653–660. [Google Scholar] [CrossRef]

- Xiao, H. Study on Autogenous Shrinkage Properties of Carbon Nanomaterials Cement-Based Composites. Master’s Thesis, Dalian University of Technology, Dalian, China, 2018. [Google Scholar]

- Souza, D.J.; Yamashita, L.Y.; Dranka, F. Repair mortars incorporating multiwalled carbon nanotubes: Shrinkage and sodiumsulfate attack. J. Mater. Civ. Eng. 2017, 29, 1–10. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Liu, Q.L.; Sun, W.; Ma, Z.X.; Jia, L.Q.; Feng, L.F. Effect of Carbon Nanotube on Mechanical and 2D-3D Microstructure Properties Cement Mortars with Silica Fume. J. Chin. Ceram. Soc. 2014, 42, 1266–1273. [Google Scholar]

- Xie, J.C. Research on the Influence Law of Doped Carbon Nanotubes on the Mechanical Properties, Deformation Properties and Durabilities of Concretes. Master’s Thesis, Guangxi University, Nanning, China, 2020. [Google Scholar] [CrossRef]

- Li, S.S. Research on Early Shrinkage and Crack Resistance of Carbon Nanotubes Reinforced Cement Composites. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 2018. [Google Scholar]

- Zheng, B.M.; Chen, J.Q.; Shi, T.; Liu, Y.M.; Xu, J.H.; Ge, N.; Zhao, Q.F.; Shao, X.J. Fracture Properties of Multi-Walled Carbon Nanotubes Reinforced Concrete. J. Chin. Ceram. Soc. 2021, 49, 2502–2508. [Google Scholar] [CrossRef]

- Wang, Z.K.; Fan, J.; Li, G.Y. Influences of Carbon Nanotubes and Polyvinyl Alcohol Nano-Composites on Mechanical Properties and Dry Shrinkage of Concrete. J. Chin. Ceram. Soc. 2020, 48, 1653–1658. [Google Scholar] [CrossRef]

- Fakhim, B.; Hassani, A.; Rashidi, A.; Ghodoushi, P. Preparation and microstructural properties study on cement composites reinforced with multi-walled carbon nanotubes. J. Compos. Mater. 2015, 49, 85–98. [Google Scholar] [CrossRef]

- Niu, F.Y.; Liu, Y.H.; Xue, F.C.; Sun, H.; Liu, T.; He, H.J.; Kong, X.G.; Chen, Y.T.; Liao, H.J. Ultra-high performance concrete: A review of its material properties and usage in shield tunnel segment. Case Stud. Constr. Mater. 2025, 22, e04194. [Google Scholar] [CrossRef]

- Wansom, S.; Kidner, N.J.; Woo, L.Y.; Mason, T.O. AC-impedance response of multi-walled carbon nanotube/cement composites. Cem. Concr. Compos. 2006, 28, 509–519. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Multifunctional and Smart Carbon Nanotube Reinforced Cement-Based Materials; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Lu, J.G. Study on the Electro-Mechanical Effect of Carbon Fiber Smart Concrete Beam. Master’s Thesis, Nanjing University of Science and Technology, Nanjing, China, 2007. [Google Scholar]

- Li, H.G.; Wang, Y.L.; Luo, H.; Ghimire, P.; Lin, S.Y.; Pan, Z.Y.; Yang, J.L.; Su, Q.W. Effect of Dispersion of Multi-Walled Carbon Nanotubes on Electrical and Electrothermal Properties of Cement-Based Materials. J. Chin. Ceram. Soc. 2020, 39, 3438–3443. [Google Scholar] [CrossRef]

- Cui, H.; Yang, S.; Memon, S. Development of Carbon Nanotube Modified Cement Paste with Microencapsulated Phase-Change Material for Structural–Functional Integrated Application. Int. J. Mol. Sci. 2015, 16, 8027–8039. [Google Scholar] [CrossRef]

- Zhao, J.J.; Ren, S.X.; Du, Y.L.; Zhu, W.H.; Wang, W.N.; Kong, L.J.; Lu, X. Study on the Influence of Carbon Nanotubes on the Mechanical Properties of Portland Cement. Int. J. Mol. Sci. 2013, 32, 1361–1366+1370. [Google Scholar] [CrossRef]

- Makar, J.M.; Beaudoin, J.J. Carbon Nanotubes and their Application in the Construction Industry. Spec. Publ. R. Soc. Chem. 2004, 292, 331–342. [Google Scholar] [CrossRef]

- Li, H.G.; Lin, X.Q.; Chen, F.; Zhen, Q.; Yang, Y.; Wang, Y.L. Effect of adding multi-wall carbon nanotubes on hydration of cement paste. J. Xinxiang Univ. 2022, 39, 57–62. [Google Scholar]

- Liu, Y. Experimental Study on Resistance of Carbon Nanotubes to Carbonization and Chlorine Salt Attack of Cement Mortar. Master’s Thesis, Shenzhen University, Shenzhen, China, 2016. [Google Scholar]

- Tang, G.C.; Shang, C.K.; Qin, Y.W.; Lai, J.X. Current Advances in Flame-Retardant Performance of Tunnel Intumescent Fireproof Coatings: A Review. Coatings 2025, 15, 99. [Google Scholar] [CrossRef]

- Zhuang, W.J. Dispersion of Multi Walled Carbon Nanotubes and Its Modification of Cement Based Materials. Master’s Thesis, China University of Mining and Technology, Beijing, China, 2021. [Google Scholar] [CrossRef]

- Camacho, M.D.; Galao, O.; Baeza, F.J.; Zornoza, E.; Garces, P. Mechanical Properties and Durability of CNT Cement Composites. Materials 2014, 7, 1640. [Google Scholar] [CrossRef]

- Zhang, S.W.; Zhang, J.; Wang, G.C. Preparation of carbon nanotube cement-based materials and study on their thermal expansion coefficient. New Build. Mater. 2019, 46, 41–45. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M. Microstructure and mechanical properties of carbon nanotubes cement matrix composites. J. Chin. Ceram. Soc. 2005, 33, 105–108. [Google Scholar]

- Han, B.G.; Yang, Z.X.; Shi, X.M.; Yu, X. Transport Properties of Carbon-Nanotube/Cement Composites. J. Mater. Eng. Perform. 2013, 22, 184–189. [Google Scholar] [CrossRef]

- Wang, B.; Han, Y.; Liu, S. Effect of highly dispersed carbon nanotubes on the flexural toughness of cement-based composites. Constr. Build. Mater. 2013, 46, 8–12. [Google Scholar] [CrossRef]

- Su, X.L.; Lai, J.X.; Ma, E.L.; Xu, J.W.; Qiu, J.L.; Wang, W.F. Failure mechanism analysis and treatment of tunnels built in karst fissure strata: A case study. Eng. Fail. Anal. 2024, in press. [CrossRef]

- Carrico, A.; Bogas, J.A.; Hawreen, A.; Guedes, M. Durability of multi-walled carbon nanotube reinforced concrete. Constr. Build. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Al-Rub, R.K.A.; Ashour, A.I.; Tyson, B.M. On the aspect ratio effect of multi-walled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N.; Emon, M.A.B. Effect of Carbon Nanotube Size on Compressive Strengths of Nanotube Reinforced Cementitious Composites. J. Mater. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Su, X.; Zhang, C.; Zou, Z.; Wang, Y.; Lai, J.; Liu, T. Influence of Water Rock Interaction on Stability of Tunnel Engineering. Pol. J. Environ. Stud. 2025, 34, 535–548. [Google Scholar] [CrossRef]

- Yu, H.S.; He, J.B. Fracture Toughness and Durability Performance of Highly Dispersed Multi-Walled Carbon Nanotubes Reinforced Cement-Based Composites. J. Adv. Microsc. Res. 2015, 10, 14–19. [Google Scholar] [CrossRef]

- Qi, R. Study on Mechanical Properties and Freezing Resistance of Cement-Based Materials with Different Diameters of Carbon Nanotubes. Master’s Thesis, Chang’an University, Xi’an, China, 2019. [Google Scholar]

- Lu, L.; Ouyang, D.; Xu, W. Mechanical properties and durability of ultra high strength concrete incorporating multi-walled carbon nanotubes. Materials 2016, 9, 419. [Google Scholar] [CrossRef]

- Wang, B.M.; Liu, S.; Han, Y.; Leng, P. Preparation and Durability of Cement-Based Composites Doped with Multi-Walled Carbon Nanotubes. Nanosci. Nanotechnol. Lett. 2015, 7, 411–416. [Google Scholar] [CrossRef]

- Sun, G.L. Morphological, Mechanical and Durability Properties of Cement Mortar Reinforced with Multi-Walled Carbon Nanotubes. J. Adv. Microsc. Res. 2015, 10, 60–64. [Google Scholar] [CrossRef]

- Chen, Z.; He, S.J.; Wei, J.L.; Yu, J.M.; Zhang, L.X. Study on chlorine- sulfate coupling erosion in cement- based materials with carbon nanotubes. Concrete 2023, 10, 138–142. [Google Scholar]

- Dulaj, A.; Peeters, S.; Poorsolhjouy, P.; Salet, T.; Lucas, S.S. Combined analytical and numerical modelling of the electrical conductivity of 3D printed carbon nanotube-cementitious nanocomposites. Mater. Des. 2024, 246, 113324. [Google Scholar] [CrossRef]

- Jiang, H.F. Self-Sensing Carbon Nanotube Cement-Based Composites and Their Application in Traffic Detection. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2012. [Google Scholar]

- Cui, K.; Chang, J.; Feo, L.; Chow, C.L.; Lau, D. Developments and applications of carbon nanotube reinforced cement-based composites as functional building materials. Front. Mater. 2022, 9, 861646. [Google Scholar] [CrossRef]

| CNTs Dominance | Specific Reason | |

|---|---|---|

| Graphene | Dispersion | CNTs have a high length–diameter ratio |

| mechanics | CNTs fibrous structure can effectively bridge cracks | |

| Electrical conductivity | CNTs conductive network is easier to form | |

| Cost and process | CNTs are mature in industrial production and relatively low in cost | |

| Nanosilica | Versatility | CNTs have both mechanical tensile and cracking resistance and electrical and thermal conductivity |

| Toughness | CNTs bridging effect of inhibition of crack propagation and significantly increased toughness | |

| Long-term stability | CNTs had little effect on the hydration process |

| Water Cement Ratio | The Dosage Shrinks the Cement Mortar/(μm/m) | |||

|---|---|---|---|---|

| 0 | 0.05% | 0.1% | 0.15% | |

| 0.30 | −1397 | −1178 | −1119 | −1318 |

| 0.35 | −1178 | −884 | −780 | −990 |

| 0.40 | −1132 | −728 | −638 | −981 |

| CNT content | 0.05% | 0.1% | 0.15% | 0.3% | 0.6% |

| Shrinkage value decreased by percentage | 15% | 20% | 5% | −5% | −18% |

| CNTs Mass Fraction | Closed Experiment | |

|---|---|---|

| Cracking Time/h | Cracking Strain/10−6 | |

| 0 | 212.2 | −142 |

| 0.05 | 223.2 | −133 |

| 0.10 | 310.2 | −138 |

| 0.15 | 248.5 | −121 |

| CNTs Are Lifted by Adding Cement Base | ||

|---|---|---|

| Mechanical | Static strength | Within 60 days of water age, the content was less than 1% of CNTs, and the compressive strength increased with the increase in CNTs |

| Bending strength | The bending strength increased with the increase in CNT content and increased with the extension of age | |

| Dynamic mechanics | When the dosage is 0.1%, it reaches the highest, and the dynamic compressive strength is increased by about 30% | |

| Contractility | Type | The effect of carboxyl carbon nanotubes is the most significant |

| Dosage | The optimal dosage is 0.05–0.1%, and the increase in water–cement ratio will shorten the shrinkage effect | |

| Slenderness ratio | Medium aspect ratio (300–500) | |

| Crack resistance | The optimal dosage is 0.05%, and >0.15% will reduce the effect due to caking | |

| Electrical conductivity | The optimal dosage is 0.1% and tends to be stable at 80 °C with the increase in temperature | |

| Hydrability | CNTs are hydrophilic and promote hydration | |

| Carbonization resistance | Dosage | The optimal content is 0.05–0.1%, the pore ratio is reduced by 30%, and the carbonization depth is minimum |

| Slenderness ratio | The length–diameter ratio of short pipe is easier to fill | |

| Dispersion method | The reasonable dispersion method can reduce the porosity by about 30% | |

| Durability | Freeze–thaw property | When the number of cycles increases and the content is 0.1%, the loss of bending and compressive strength is minimal |

| Chloride ion resistance | The optimal dosage is 0.1%, which is attributed to the bridging effect | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, E.; Zhang, W.; Lai, J.; Hu, H.; Xue, F.; Su, X. Enhancement of Cement-Based Materials: Mechanisms, Impacts, and Applications of Carbon Nanotubes in Microstructural Modification. Buildings 2025, 15, 1234. https://doi.org/10.3390/buildings15081234

Guo E, Zhang W, Lai J, Hu H, Xue F, Su X. Enhancement of Cement-Based Materials: Mechanisms, Impacts, and Applications of Carbon Nanotubes in Microstructural Modification. Buildings. 2025; 15(8):1234. https://doi.org/10.3390/buildings15081234

Chicago/Turabian StyleGuo, Erdong, Wenhao Zhang, Jinxing Lai, Haoran Hu, Fangchen Xue, and Xulin Su. 2025. "Enhancement of Cement-Based Materials: Mechanisms, Impacts, and Applications of Carbon Nanotubes in Microstructural Modification" Buildings 15, no. 8: 1234. https://doi.org/10.3390/buildings15081234

APA StyleGuo, E., Zhang, W., Lai, J., Hu, H., Xue, F., & Su, X. (2025). Enhancement of Cement-Based Materials: Mechanisms, Impacts, and Applications of Carbon Nanotubes in Microstructural Modification. Buildings, 15(8), 1234. https://doi.org/10.3390/buildings15081234