Recycled Concrete in Foundations: Mechanical and Environmental Insights

Abstract

Highlights

- A total of 26 recycled aggregate concrete (RAC) mixtures with different mix proportions are comprehensively evaluated.

- The two-stage recycling process improves aggregate quality, enhancing concrete properties.

- The mechanical performance assessment confirms RAC viability for structural foundation applications.

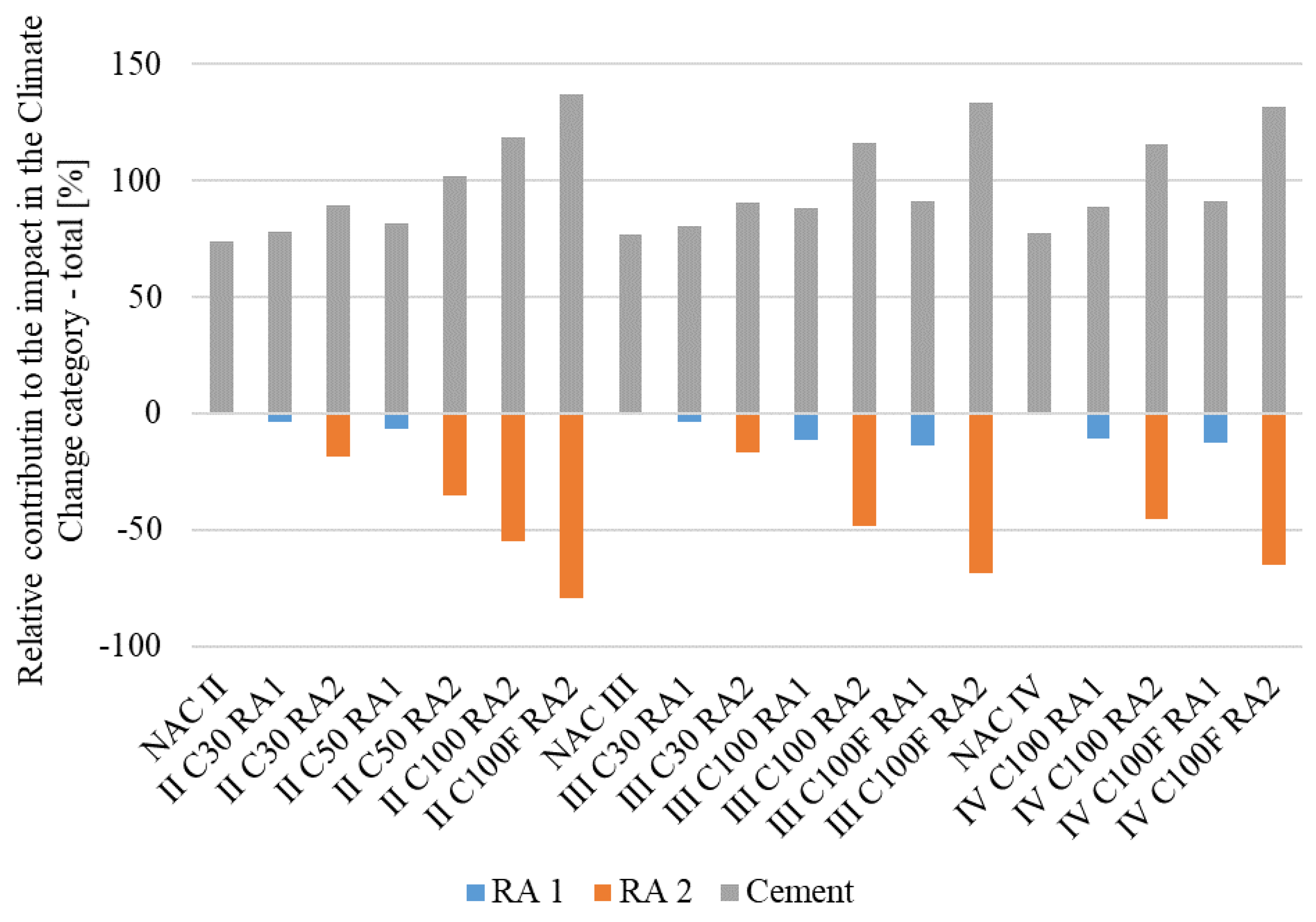

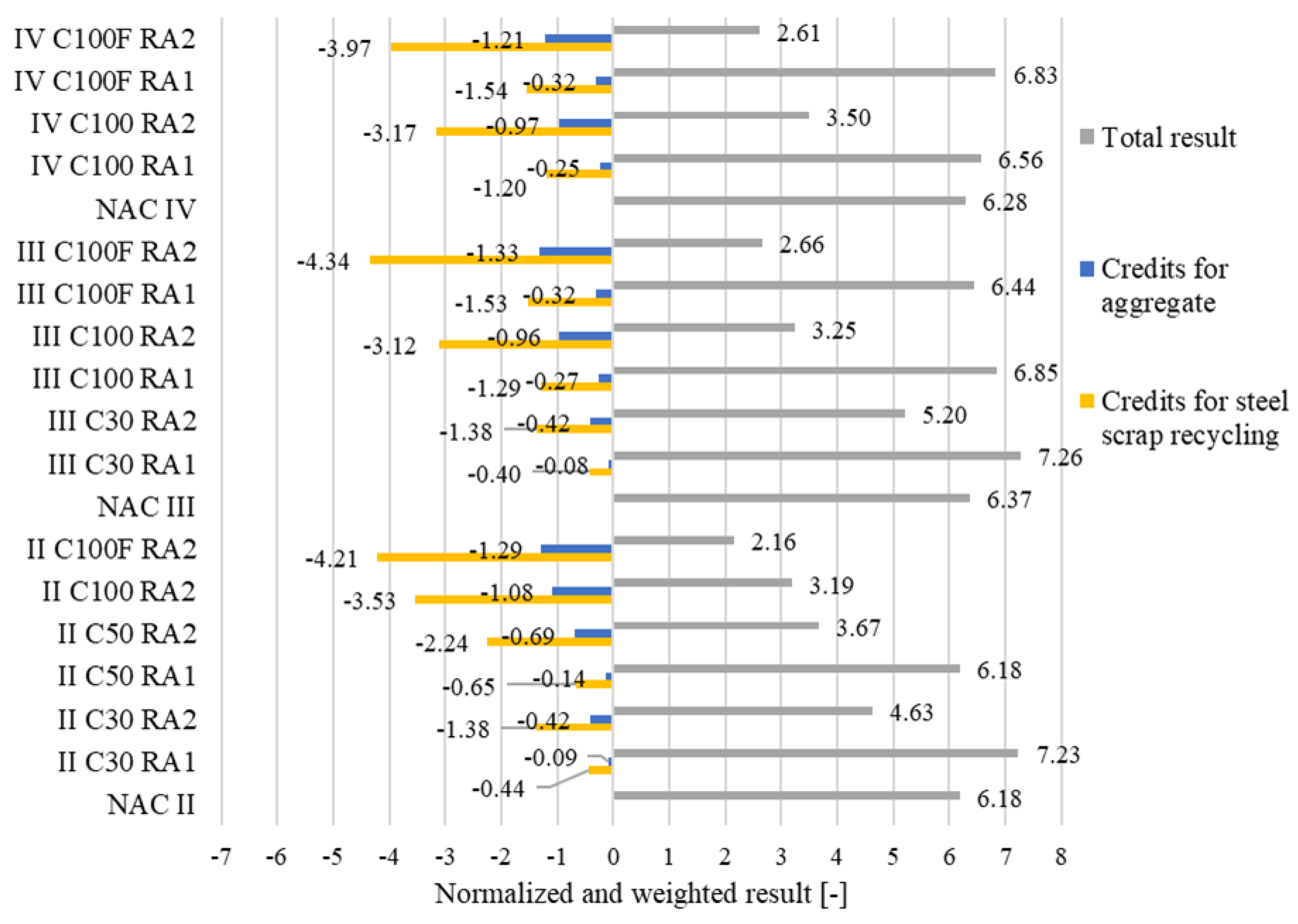

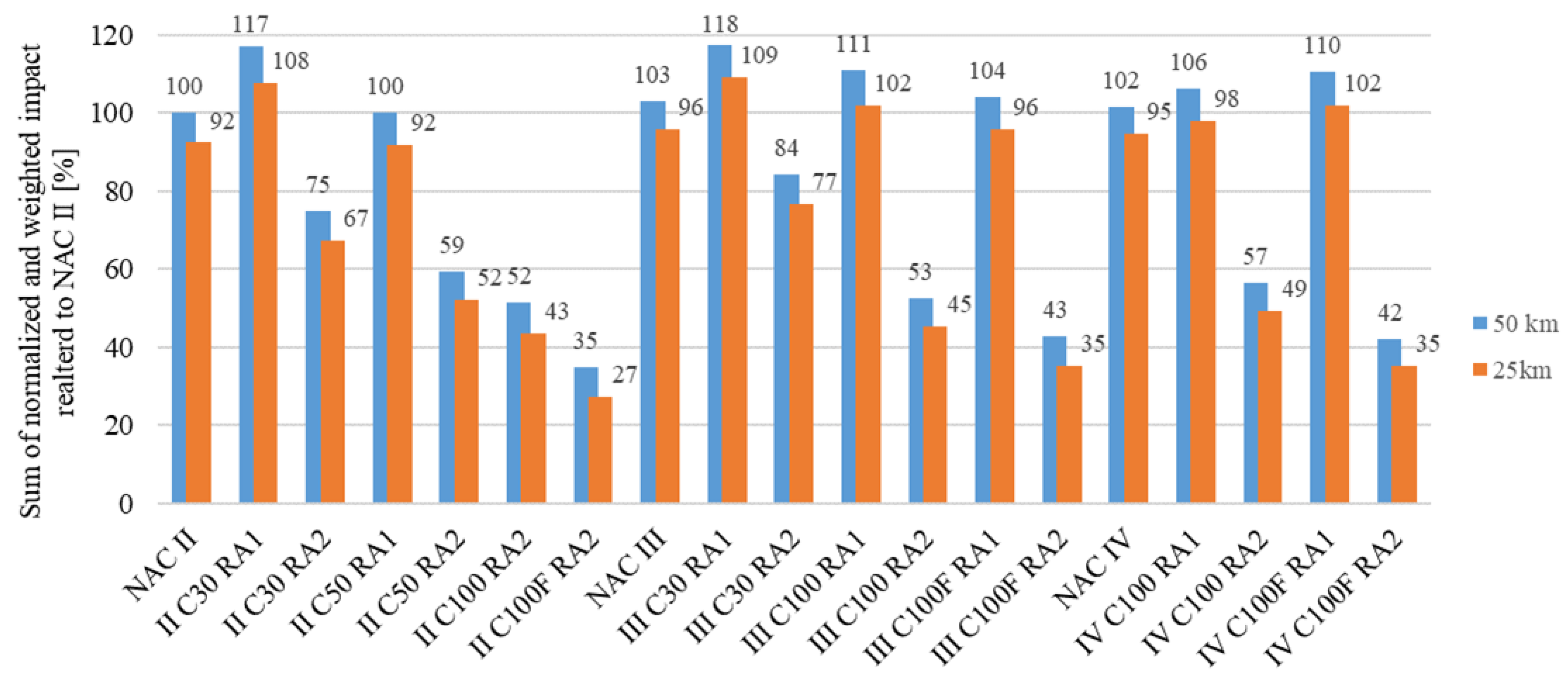

- The Life Cycle Assessment (LCA) shows a nearly 50% reduction in environmental impact with full natural aggregate replacement.

Abstract

1. Introduction

2. Recycling Challenges and Solutions

2.1. Recycling of Concrete Waste and Properties of Recycled Aggregate

2.2. Standards and Structural Use of RAC

2.3. Life Cycle Assessment (LCA) of RAC

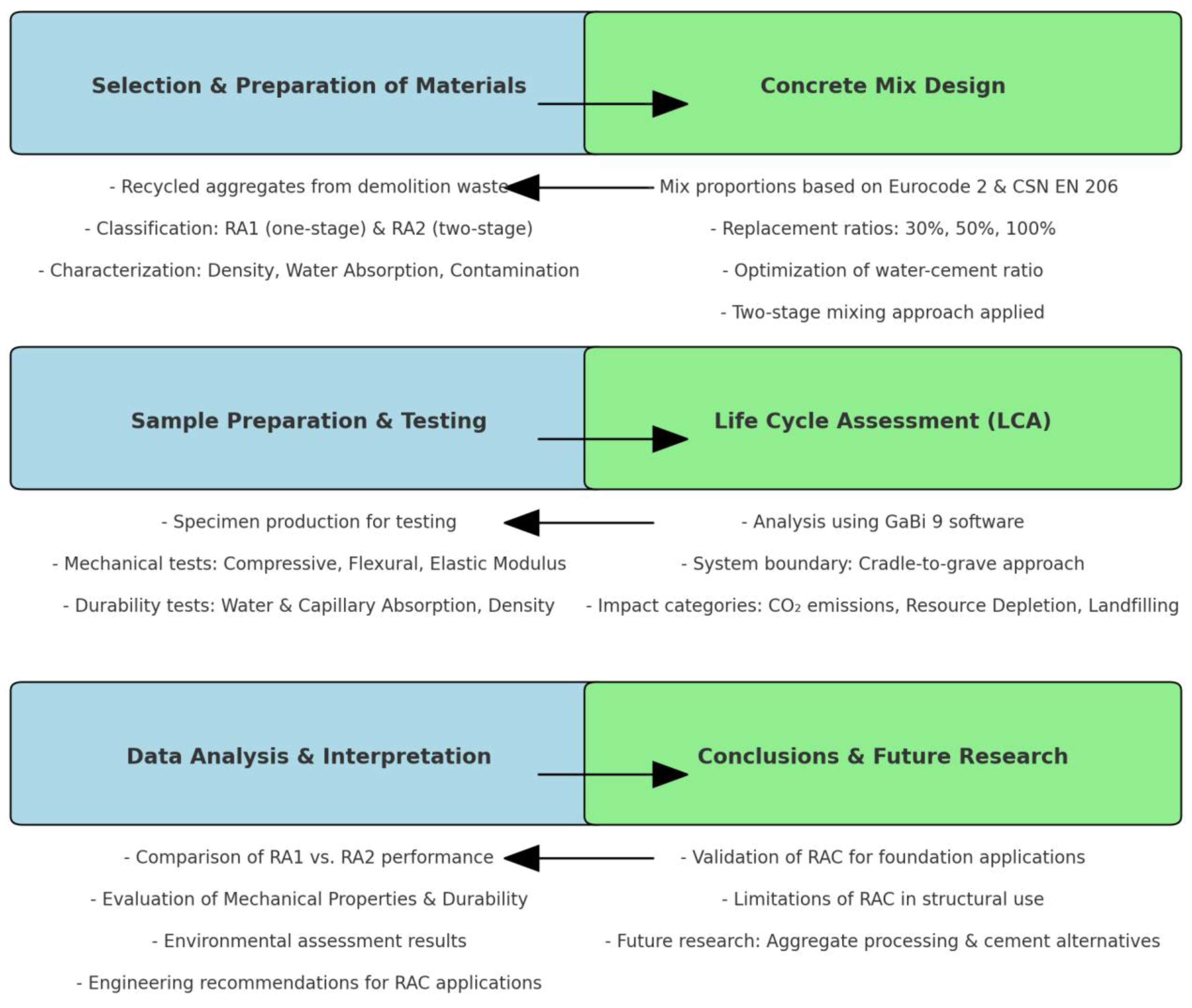

3. Materials and Methods

3.1. Materials

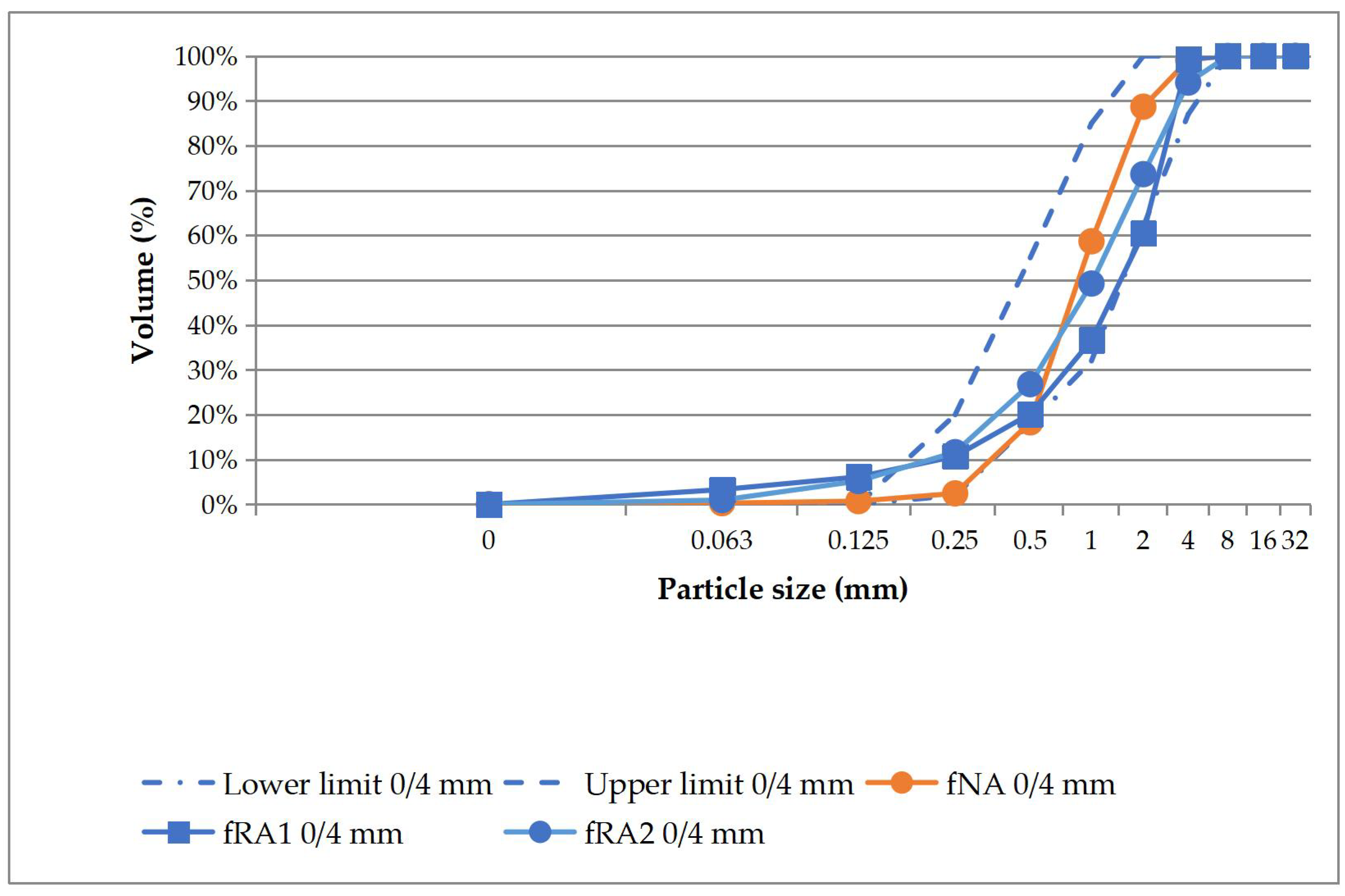

3.1.1. Recycled Concrete Aggregate

3.1.2. Concrete Mixtures

3.2. Methods

3.2.1. Concrete Properties Evaluation Methodology

3.2.2. Foundation Structural Element

3.2.3. Environmental Assessment

Goal and Scope Definition, Functional Unit, and System Boundaries

Life Cycle Inventory (LCI)

Life Cycle Impact Assessment, Normalization, and Weighing

4. Results and Discussion

4.1. Potential of Concrete Mixtures for Foundation Structure Element

4.2. Life Cycle Impact Assessment

4.3. Properties of Recycled Aggregate Concrete

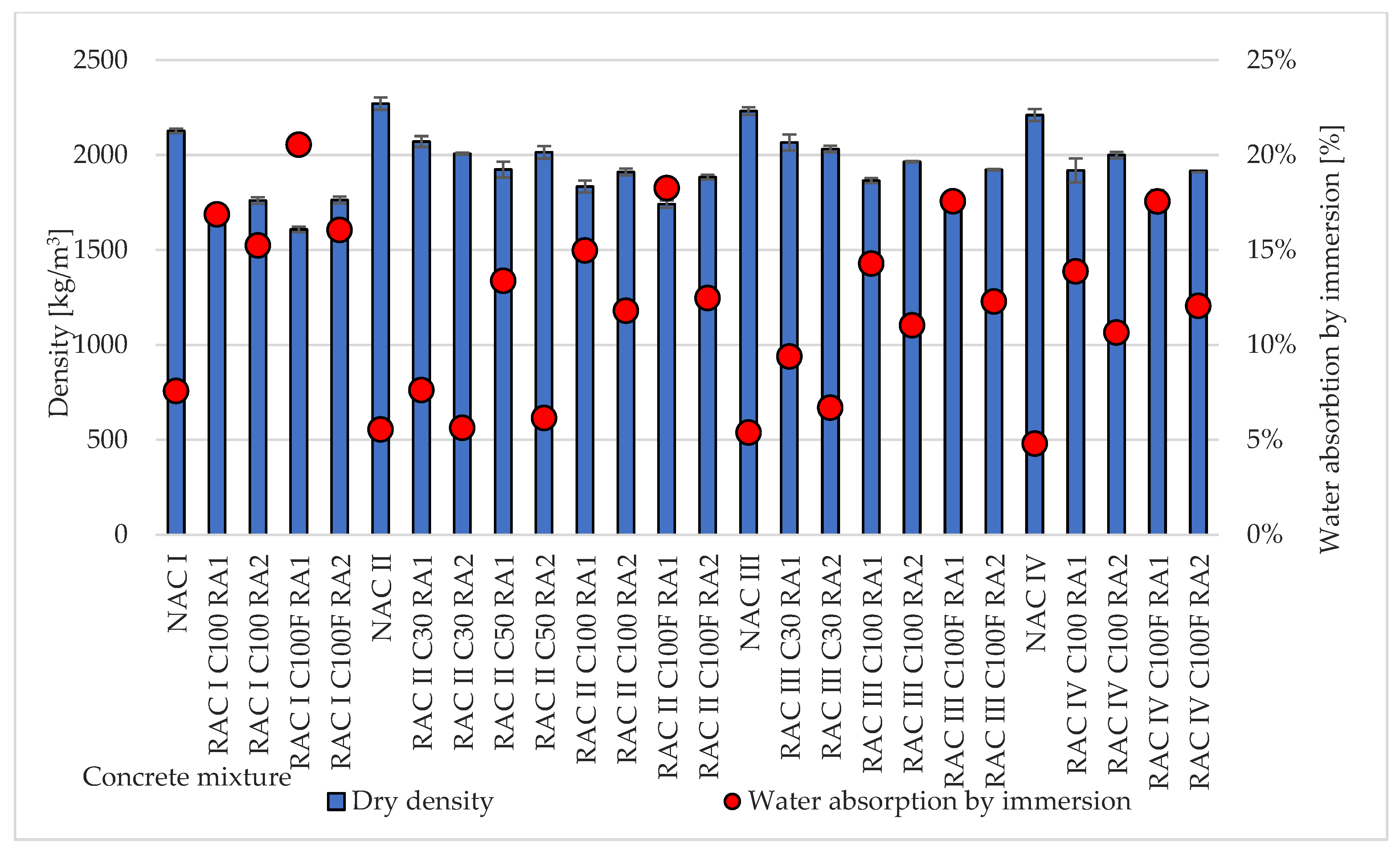

4.3.1. Physical Properties of Concrete

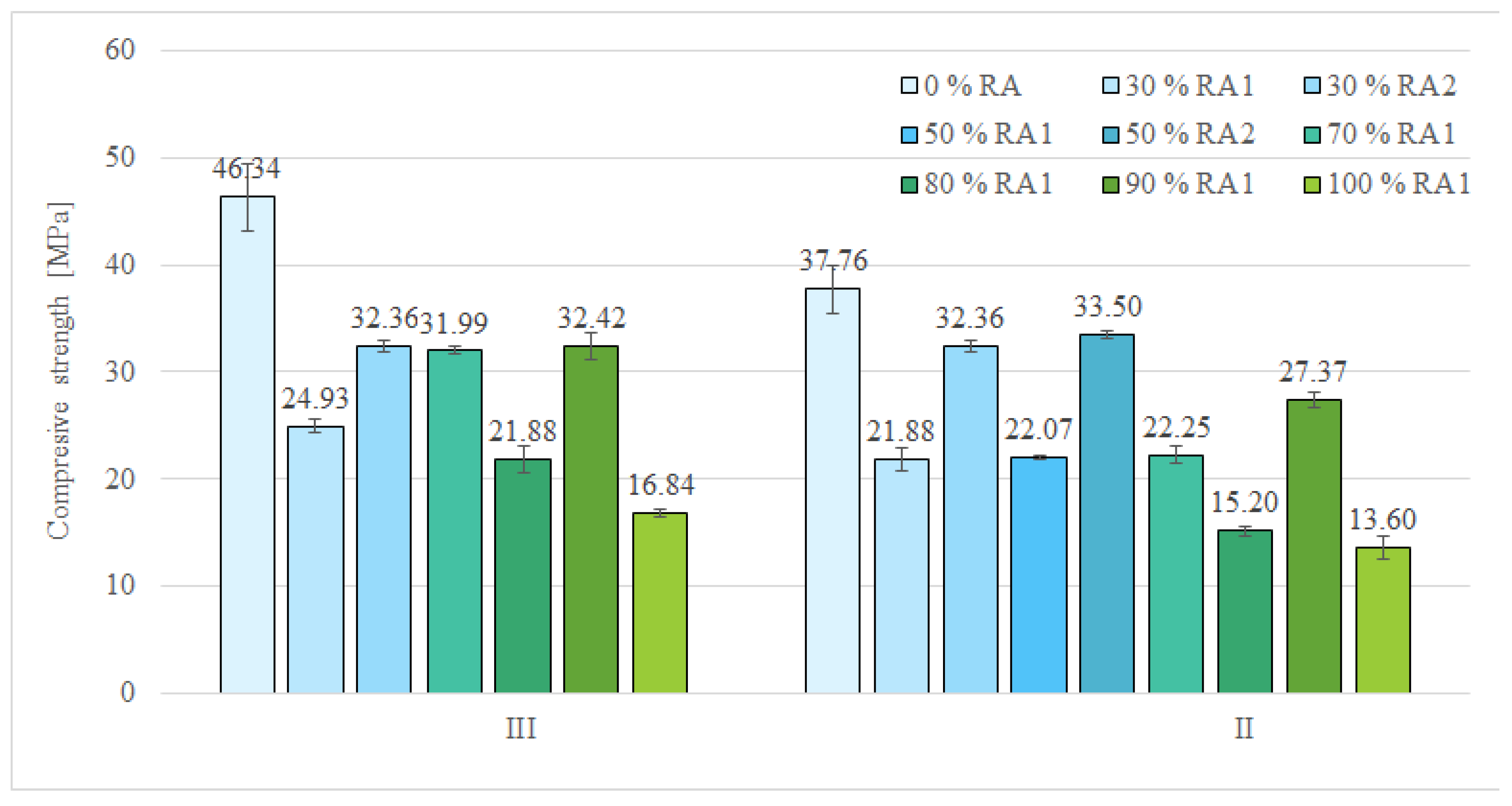

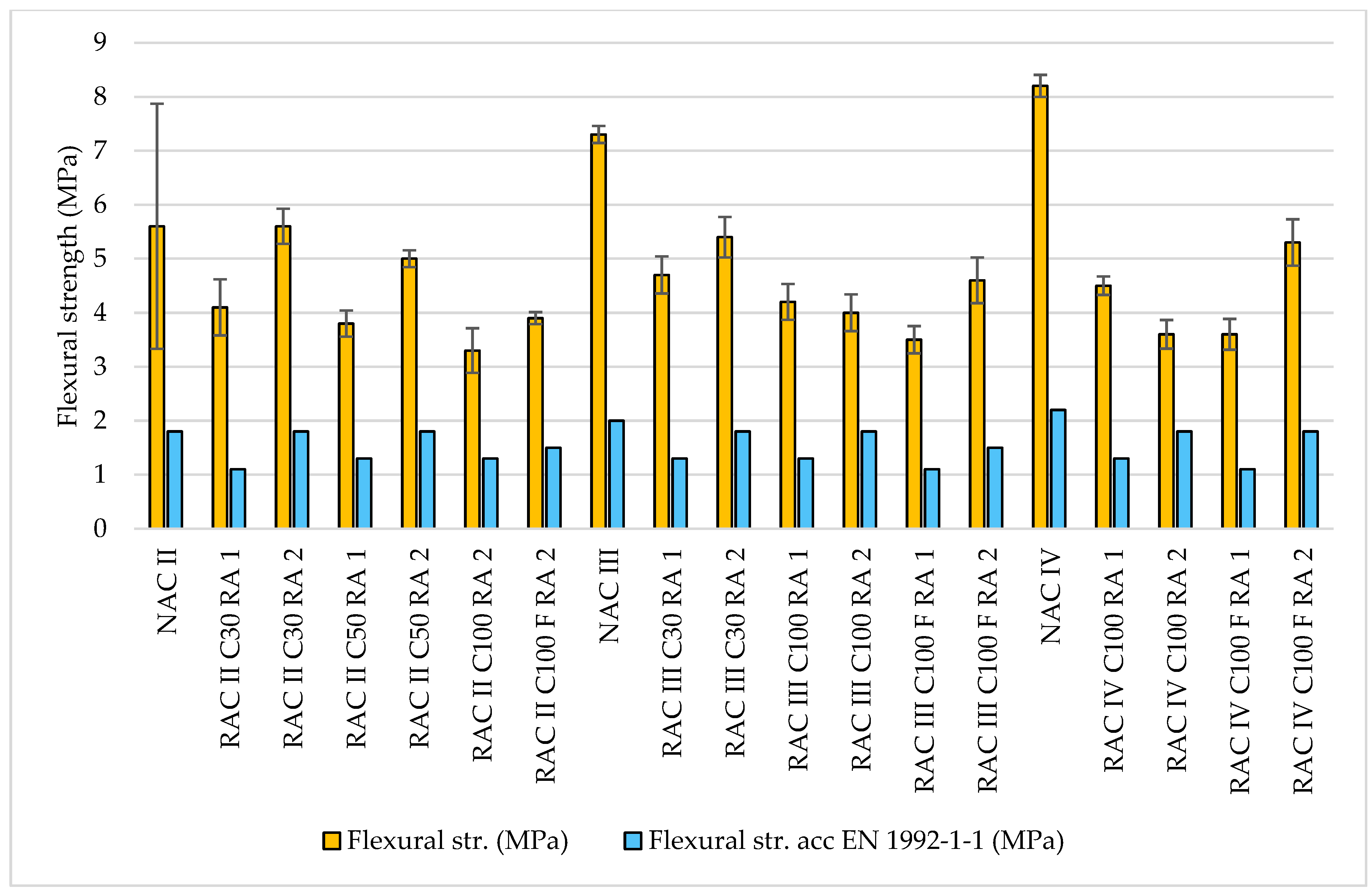

4.3.2. Mechanical Properties of Concrete

4.4. Contribution of Recycled Aggregate to Impact on Climate Change

4.5. Beneficial Impact of Recycling Process

4.6. Contribution of Transport

5. Conclusions

5.1. Key Findings

- Recycling Process Impact—The two-stage crushing procedure produces a higher-quality recycled aggregate (RA) compared to one-stage crushing, leading to improved mechanical properties and reduced contaminants.

- Durability Considerations—RAC exhibits higher water absorption and lower density, which may negatively affect long-term durability and should be considered in structural design.

- Mechanical Performance—While compressive and flexural strengths decline, the verified flexural strength values still meet Eurocode requirements, allowing for safe use in foundation structures.

- Environmental Benefits—Life Cycle Assessment (LCA) confirms that cement production and transportation contribute the most to RAC’s environmental footprint, but replacing the natural aggregate (NA) with a high-quality RA can reduce the environmental impact by nearly 50%.

5.2. Engineering Implications and Future Research

- Optimizing Aggregate Processing—Enhancing RA quality through water-based washing techniques to remove fine contaminants, though this increases processing costs and must be balanced with economic feasibility.

- Reducing Cement Dependency—Replacing CEM I with CEM II and low-carbon supplementary cementitious materials (SCMs) (e.g., fly ash, silica fume, and ground granulated blast-furnace slag) to improve durability while reducing carbon emissions.

- This study contributes to shifting the perception of RAC from a low-value material to a structurally viable and environmentally sustainable alternative, paving the way for broader adoption in construction.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life Cycle Assessment of Recycled Aggregate Concrete on Its Environmental Impacts: A Critical Review. Constr. Build. Mater. 2022, 317, 125950. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Mechanical Performance of Concrete Made with Aggregates from Construction and Demolition Waste Recycling Plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Bai, W.; Shen, J.; Guan, J.; Wang, J.; Yuan, C. Study on Compressive Mechanical Properties of Recycled Aggregate Concrete with Silica Fume at Different Strain Rates. Mater. Today Commun. 2022, 31, 103444. [Google Scholar] [CrossRef]

- Český Statistický Úřad. Available online: https://www.czso.cz/csu/czso/domov (accessed on 11 June 2022).

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. Quality Improvement of Recycled Concrete Aggregate by Removal of Residual Mortar: A Comprehensive Review of Approaches Adopted. Constr. Build. Mater. 2021, 288, 123066. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G. 10—Separation Processes to Improve the Quality of Recycled Concrete Aggregates (RCA). In Handbook of Recycled Concrete and Demolition Waste; Pacheco-Torgal, F., Tam, V.W.Y., Labrincha, J.A., Ding, Y., de Brito, J., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2013; pp. 246–269. ISBN 978-0-85709-682-1. [Google Scholar]

- Fan, C.-C.; Huang, R.; Hwang, H.; Chao, S.-J. The Effects of Different Fine Recycled Concrete Aggregates on the Properties of Mortar. Materials 2015, 8, 2658–2672. [Google Scholar] [CrossRef]

- Florea, M.V.A.; Brouwers, H.J.H. Properties of Various Size Fractions of Crushed Concrete Related to Process Conditions and Re-Use. Cem. Concr. Res. 2013, 52, 11–21. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Qian, X.; Chen, P.; Xu, Y.; Guo, J. An Environmentally Friendly Method to Improve the Quality of Recycled Concrete Aggregates. Constr. Build. Mater. 2017, 144, 432–441. [Google Scholar] [CrossRef]

- Bru, K.; Touzé, S.; Bourgeois, F.; Lippiatt, N.; Ménard, Y. Assessment of a Microwave-Assisted Recycling Process for the Recovery of High-Quality Aggregates from Concrete Waste. Int. J. Miner. Process. 2014, 126, 90–98. [Google Scholar] [CrossRef]

- Pradhan, S.; Tiwari, B.R.; Kumar, S.; Barai, S.V. Comparative LCA of Recycled and Natural Aggregate Concrete Using Particle Packing Method and Conventional Method of Design Mix. J. Clean. Prod. 2019, 228, 679–691. [Google Scholar] [CrossRef]

- Jean, B.; Liu, H.; Zhu, X.; Wang, X.; Yan, X.; Ma, T. Enhancing the Mechanical and Durability Properties of Fully Recycled Aggregate Concrete Using Carbonated Recycled Fine Aggregates. Materials 2024, 17, 1715. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Kamchoom, V.; Hanandeh, S.; Anandha Kumar, S.; Zabala Vizuete, R.F.; Santillán Murillo, R.O.; Zurita Polo, S.M.; Torres Castillo, R.M.; Ebid, A.M.; Awoyera, P.; et al. Physics-Informed Modeling of Splitting Tensile Strength of Recycled Aggregate Concrete Using Advanced Machine Learning. Sci. Rep. 2025, 15, 7135. [Google Scholar] [CrossRef] [PubMed]

- Prasittisopin, L.; Tuvayanond, W.; Kang, T.H.-K.; Kaewunruen, S. Concrete Mix Design of Recycled Concrete Aggregate (RCA): Analysis of Review Papers, Characteristics, Research Trends, and Underexplored Topics. Resources 2025, 14, 21. [Google Scholar] [CrossRef]

- Pereira, P.; Evangelista, L.; de Brito, J. The Effect of Superplasticisers on the Workability and Compressive Strength of Concrete Made with Fine Recycled Concrete Aggregates. Constr. Build. Mater. 2012, 28, 722–729. [Google Scholar] [CrossRef]

- Leite, M.B.; Figueire do Filho, J.G.L.; Lima, P.R.L. Workability Study of Concretes Made with Recycled Mortar Aggregate. Mater. Struct. 2013, 46, 1765–1778. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, Chemical and Mineralogical Properties of Fine Recycled Aggregates Made from Concrete Waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- de Brito, J.; Saikia, N. Recycled Aggregate in Concrete; Green Energy and Technology; Springer: London, UK, 2013; ISBN 978-1-4471-4539-4. [Google Scholar]

- Tošić, N.; Marinković, S.; Dašić, T.; Stanić, M. Multicriteria Optimization of Natural and Recycled Aggregate Concrete for Structural Use. J. Clean. Prod. 2015, 87, 766–776. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative Environmental Evaluation of Aggregate Production from Recycled Waste Materials and Virgin Sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Pacheco Torgal, F.; Jalali, S. Eco-Efficient Construction and Building Materials; Springer: London, UK, 2011; ISBN 978-0-85729-891-1. [Google Scholar]

- Zhang, Y.; Zhang, J.; Luo, W.; Wang, J.; Shi, J.; Zhuang, H.; Wang, Y. Effect of Compressive Strength and Chloride Diffusion on Life Cycle CO2 Assessment of Concrete Containing Supplementary Cementitious Materials. J. Clean. Prod. 2019, 218, 450–458. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life Cycle Assessment of Concrete Made with High Volume of Recycled Concrete Aggregates and Fly Ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Tam, V.W.Y. A Closed-Loop Life Cycle Assessment of Recycled Aggregate Concrete Utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life Cycle Greenhouse Gas Emissions of Blended Cement Concrete Including Carbonation and Durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of Recycled Concrete Aggregate and Their Influence in New Concrete Production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Sri Ravindrarajah, R.; Tam, C.T. Recycling Concrete as Fine Aggregate in Concrete. Int. J. Cem. Compos. Lightweight Concr. 1987, 9, 235–241. [Google Scholar] [CrossRef]

- Evangelista, L.; Brito, J. Criteria for the Use of Fine Recycled Concrete Aggregates in Concrete Production. 2004. Available online: https://www.researchgate.net/profile/Luis-Evangelista/publication/266298542_Criteria_for_the_Use_of_Fine_Recycled_Concrete_Aggregates_in_Concrete_Production/links/543f7c6f0cf2eaec07e81e39/Criteria-for-the-Use-of-Fine-Recycled-Concrete-Aggregates-in-Concrete-Production.pdf (accessed on 2 April 2025).

- Zega, C.J.; Di Maio, Á.A. Use of Recycled Fine Aggregate in Concretes with Durable Requirements. Waste Manag. 2011, 31, 2336–2340. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Properties of Concrete Prepared with Crushed Fine Stone, Furnace Bottom Ash and Fine Recycled Aggregate as Fine Aggregates. Constr. Build. Mater. 2009, 23, 2877–2886. [Google Scholar] [CrossRef]

- Delobel, F.; Bulteel, D.; Mechling, J.M.; Lecomte, A.; Cyr, M.; Rémond, S. Application of ASR Tests to Recycled Concrete Aggregates: Influence of Water Absorption. Constr. Build. Mater. 2016, 124, 714–721. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.; Tian, Q. Method for Controlling the Absorbed Water Content of Recycled Fine Aggregates by Centrifugation. Constr. Build. Mater. 2018, 160, 316–325. [Google Scholar] [CrossRef]

- Sosa, M.E.; Villagrán Zaccardi, Y.A.; Zega, C.J. A Critical Review of the Resulting Effective Water-to-Cement Ratio of Fine Recycled Aggregate Concrete. Constr. Build. Mater. 2021, 313, 125536. [Google Scholar] [CrossRef]

- CSN EN 206+A1; Concrete: Specification, Performance, Production and Conformity. CEN: Prague, Czech Republic, 2018. (In Czech)

- Tam, V.W.Y.; Tam, C.M. Diversifying Two-Stage Mixing Approach (TSMA) for Recycled Aggregate Concrete: TSMAs and TSMAsc. Constr. Build. Mater. 2008, 22, 2068–2077. [Google Scholar] [CrossRef]

- Guardigli, L.; Monari, F.; Bragadin, M.A. Assessing Environmental Impact of Green Buildings through LCA Methods: Acomparison between Reinforced Concrete and Wood Structures in the European Context. Procedia Eng. 2011, 21, 1199–1206. [Google Scholar] [CrossRef]

- Hoxha, E.; Habert, G.; Lasvaux, S.; Chevalier, J.; Le Roy, R. Influence of Construction Material Uncertainties on Residential Building LCA Reliability. J. Clean. Prod. 2017, 144, 33–47. [Google Scholar] [CrossRef]

- Thiel, C.L.; Campion, N.; Landis, A.E.; Jones, A.K.; Schaefer, L.A.; Bilec, M.M. A Materials Life Cycle Assessment of a Net-Zero Energy Building. Energies 2013, 6, 1125–1141. [Google Scholar] [CrossRef]

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. CEN: Brussels, Belgium, 2019.

- EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. CEN: Brussels, Belgium, 2019.

- EN 12390-13:2021; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. CEN: Brussels, Belgium, 2021.

- EN 12504-4:2021; Testing Concrete in Structures—Part 4: Determination of Ultrasonic Pulse Velocity. CEN: Brussels, Belgium, 2021.

- ASTM C1585-20; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Marinković, S.B.; Malešev, M.; Ignjatović, I. 11—Life Cycle Assessment (LCA) of Concrete Made Using Recycled Concrete or Natural Aggregates. In Eco-Efficient Construction and Building Materials; Woodhead Publishing: Philadelphia, PA, USA, 2014; pp. 239–266. ISBN 978-0-85709-767-5. [Google Scholar]

- Marinković, S.B. Life Cycle Assessment (LCA) Aspects of Concrete. In Eco-Efficient Concrete; Elsevier: Amsterdam, The Netherlands, 2013; pp. 45–80. ISBN 978-0-85709-424-7. [Google Scholar]

- Braunschweig, A.; Kytzia, S.; Bischof, S. Recycled Concrete: Environmentally Beneficial over Virgin Concrete? Available online: https://www.lcm2011.org/6_Braunschweig-Recycled_concrete-669_b1be4.pdf?file=tl_files/pdf/paper/3_Session_LCM_Tools%20for_Green_and_Sustainable_Buildings/6_Braunschweig-Recycled_concrete-669_b.pdf (accessed on 2 April 2025).

- Serres, N.; Braymand, S.; Feugeas, F. Environmental Evaluation of Concrete Made from Recycled Concrete Aggregate Implementing Life Cycle Assessment. J. Build. Eng. 2016, 5, 24–33. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A Review of Recycled Aggregate in Concrete Applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Fiala, C. Optimalizace Betonových Konstrukcí v Environmentálních Souvislostech, 1st ed.; Faculty of Civil Engineering, CTU in Prague: Prague, Czech Republic, 2011; ISBN 978-80-01-04663-0. [Google Scholar]

- Life Cycle Assessment LCA Software: Gabi Software. Available online: http://www.gabisoftware.com/ (accessed on 30 October 2020).

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative Environmental Assessment of Natural and Recycled Aggregate Concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- ČSN EN 1992 – 1-1; Eurocode 2: Design of Concrete Structures—Part 1–1: General Reles and Rules for Buildings. CEN: Prague, Czech Republic, 2006. (In Czech)

- ISO 12491; Statistical Methods for Quality Control of Building Materials and Components. Beuth: Berlin, Germany, 1997.

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled Aggregates from Construction and Demolition Waste towards an Application on Structural Concrete: A Review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Butler, L.; West, J.S.; Tighe, S.L. The Effect of Recycled Concrete Aggregate Properties on the Bond Strength between RCA Concrete and Steel Reinforcement. Cem. Concr. Res. 2011, 41, 1037–1049. [Google Scholar] [CrossRef]

- Jiménez, C.; Barra, M.; Josa, A.; Valls, S. LCA of Recycled and Conventional Concretes Designed Using the Equivalent Mortar Volume and Classic Methods. Constr. Build. Mater. 2015, 84, 245–252. [Google Scholar] [CrossRef]

- Marinković, S.B.; Ignjatović, I.; Radonjanin, V. 23—Life-Cycle Assessment (LCA) of Concrete with Recycled Aggregates (RAs). In Handbook of Recycled Concrete and Demolition Waste; Pacheco-Torgal, F., Tam, V.W.Y., Labrincha, J.A., Ding, Y., de Brito, J., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2013; pp. 569–604. ISBN 978-0-85709-682-1. [Google Scholar]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of Fine Recycled Concrete Aggregates in Concrete: A Critical Review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Pešta, J.; Pavlů, T.; Fořtová, K.; Kočí, V. Sustainable Masonry Made from Recycled Aggregates: LCA Case Study. Sustainability 2020, 12, 1581. [Google Scholar] [CrossRef]

- Kleijer, A.L.; Lasvaux, S.; Citherlet, S.; Viviani, M. Product-Specific Life Cycle Assessment of Ready Mix Concrete: Comparison between a Recycled and an Ordinary Concrete. Resour. Conserv. Recycl. 2017, 122, 210–218. [Google Scholar] [CrossRef]

| Types of Recycled Aggregate | Grading (mm) | Content of the Finest Particles | Oven-Dried Particle Density | Water Absorption Capacity | Saturation Level | ||

|---|---|---|---|---|---|---|---|

| f (%) | ρRD (kg/m3) | σ | WA24 (%) | σ | (%) | ||

| Natural aggregate (NA) | 0/4 | 0.3 | 2570 | 81 | 1.0 | 0.0 | 0.0 |

| 4/8 | 0.3 | 2530 | 12 | 1.7 | 0.3 | 0.0 | |

| 8/16 | 0.4 | 2540 | 12 | 1.9 | 0.2 | 0.0 | |

| Recycled concrete aggregate (RA1) | 0/4 | 3.6 | 2220 | 80 | 6.9 | 0.5 | 2.5 |

| 4/8 | 0.3 | 2380 | 320 | 7.0 | 0.2 | 4.5 | |

| 8/16 | 0.0 | 2420 | 150 | 9.0 | 0.4 | 4.5 | |

| Recycled concrete aggregate (RA2) | 0/4 | 1.0 | 2430 | 60 | 3.6 | 0.8 | 1.6 |

| 4/8 | 0.3 | 2420 | 150 | 7.0 | 0.3 | 2.5 | |

| 8/16 | 0.1 | 2420 | 320 | 6.0 | 0.3 | 3.7 | |

| CEM | WATER | NA (0/4) | NA (4/8) | NA (8/16) | RCA (0/4) | RCA (4/8) | RCA (8/16) | W/C | EFF W/C | RR | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (-) | (-) | (%) | |

| NAC I | 240 | 240 | 755 | 530 | 554 | 0 | 0 | 0 | 1.00 | 1.00 | 0 |

| RAC I C100 RA1 | 240 | 250 | 440 | 0 | 0 | 0 | 247 | 1102 | 1.04 | 1.00 | 75 |

| RAC I C100 RA2 | 240 | 248 | 0 | 0 | 0 | 0 | 133 | 1060 | 1.03 | 1.00 | 100 |

| RAC I C100F RA1 | 240 | 282 | 608 | 0 | 0 | 471 | 522 | 526 | 1.18 | 1.00 | 63 |

| RAC I C100F RA2 | 240 | 271 | 248 | 0 | 0 | 411 | 346 | 553 | 1.13 | 1.00 | 84 |

| NAC II | 260 | 169 | 736 | 533 | 570 | 0 | 0 | 0 | 0.65 | 0.65 | 0 |

| RAC II C30 RA1 | 260 | 201 | 632 | 0 | 656 | 0 | 485 | 0 | 0.77 | 0.65 | 27 |

| RAC II C30 RA2 | 260 | 184 | 632 | 0 | 656 | 0 | 485 | 0 | 0.71 | 0.65 | 27 |

| RAC II C50 RA1 | 260 | 206 | 611 | 0 | 311 | 0 | 506 | 283 | 0.79 | 0.65 | 46 |

| RAC II C50 RA2 | 260 | 206 | 611 | 0 | 311 | 0 | 506 | 283 | 0.79 | 0.65 | 46 |

| RAC II C100 RA1 | 260 | 179 | 415 | 0 | 0 | 0 | 239 | 1134 | 0.69 | 0.65 | 77 |

| RAC II C100 RA2 | 260 | 211 | 588 | 0 | 0 | 0 | 526 | 538 | 0.81 | 0.65 | 64 |

| RAC II C100F RA1 | 260 | 177 | 0 | 0 | 0 | 444 | 132 | 1094 | 0.68 | 0.65 | 100 |

| RAC II C100F RA2 | 260 | 200 | 221 | 0 | 0 | 418 | 346 | 567 | 0.77 | 0.65 | 86 |

| NAC III | 300 | 165 | 700 | 538 | 601 | 0 | 0 | 0 | 0.55 | 0.55 | 0 |

| RAC III C30 RA1 | 300 | 200 | 615 | 0 | 674 | 0 | 485 | 615 | 0.67 | 0.55 | 55 |

| RAC III C30 RA2 | 300 | 183 | 615 | 0 | 674 | 0 | 485 | 615 | 0.65 | 0.55 | 55 |

| RAC III C100 RA1 | 300 | 175 | 364 | 0 | 0 | 0 | 225 | 1198 | 0.58 | 0.55 | 82 |

| RAC III C100 RA2 | 300 | 208 | 549 | 0 | 0 | 0 | 533 | 564 | 0.69 | 0.55 | 75 |

| RAC III C100F RA1 | 300 | 174 | 0 | 0 | 0 | 390 | 131 | 1163 | 0.69 | 0.55 | 100 |

| RAC III C100F RA2 | 300 | 196 | 169 | 0 | 0 | 433 | 347 | 593 | 0.69 | 0.55 | 89 |

| NAC IV | 320 | 160 | 681 | 541 | 616 | 0 | 0 | 0 | 0.50 | 0.50 | 0 |

| RAC IV C100 RA1 | 320 | 170 | 339 | 0 | 0 | 0 | 217 | 1230 | 0.53 | 0.50 | 81 |

| RAC IV C100 RA2 | 320 | 204 | 529 | 0 | 0 | 0 | 537 | 577 | 0.64 | 0.50 | 68 |

| RAC IV C100F RA1 | 320 | 169 | 0 | 0 | 0 | 363 | 130 | 1198 | 0.53 | 0.50 | 100 |

| RAC IV C100F RA2 | 320 | 191 | 143 | 0 | 0 | 440 | 348 | 606 | 0.60 | 0.50 | 91 |

| Type of Concrete | Density | Water abs. by Immersion | Capillary Water abs. | Compress. str. | Flexural str. | Static Elastic Modulus | Strength Class acc. Standard | Flexural str. acc. Standard | The Volume of the Element |

|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (%) | (kg/m2) | (MPa) | (MPa) | (GPa) | (-) | (MPa) | (m3) | |

| NAC I | 2199 | 7.6 | 14.440 | 15.0 | 4.5 | 22.7 | C8/10 | - | - |

| RAC I C100 RA 1 | 1864 | 16.9 | 26.267 | 8.6 | 2.3 | 9.8 | - | - | - |

| RAC I C100 RA 2 | 1949 | 15.2 | 19.393 | 11.0 | 2.5 | 12.2 | C8/10 | - | - |

| RAC I C100 F RA 1 | 1777 | 20.5 | 30.657 | 6.7 | 2.1 | 8.1 | - | - | - |

| RAC I C100 F RA 2 | 1983 | 16.1 | 13.133 | 11.8 | 3 | 13.6 | C8/10 | - | - |

| NAC II | 2284 | 5.5 | 5.967 | 37.8 | 5.6 | 30.1 | C25/30 | 1.8 | 3.96 |

| RAC II C30 RA 1 | 2143 | 7.6 | 5.760 | 21.9 | 4.1 | 23.6 | C12/15 | 1.1 | 5.06 |

| RAC II C30 RA 2 | 2199 | 5.6 | 5.433 | 32.4 | 5.6 | 28.9 | C25/30 | 1.8 | 3.96 |

| RAC II C50 RA 1 | 2023 | 13.4 | 5.763 | 22.1 | 3.8 | 18 | C16/20 | 1.3 | 4.62 |

| RAC II C50 RA 2 | 2168 | 6.1 | 6.500 | 33.5 | 5 | 25.4 | C25/30 | 1.8 | 3.96 |

| RAC II C100 RA 1 | 1977 | 15 | 15.593 | 15.2 | 3.6 | 14.2 | C8/10 | - | - |

| RAC II C100 RA 2 | 2054 | 11.8 | 8.413 | 22.3 | 3.3 | - | C16/20 | 1.3 | 4.62 |

| RAC II C100 F RA 1 | 1881 | 18.3 | 20.947 | 13.6 | 3.2 | 11.9 | C8/10 | - | - |

| RAC II C100 F RA 2 | 2100 | 12.5 | 3.733 | 27.4 | 3.9 | 21.6 | C20/25 | 1.5 | 4.4 |

| NAC III | 2277 | 5.4 | 4.653 | 46.3 | 7.3 | 33.2 | C30/37 | 2.0 | 3.74 |

| RAC III C30 RA 1 | 2141 | 9.4 | - | 24.9 | 4.7 | 22.7 | C16/20 | 1.3 | 4.62 |

| RAC III C30 RA 2 | 2200 | 6.7 | 5.067 | 32.4 | 5.4 | 28.5 | C25/30 | 1.8 | 3.96 |

| RAC III C100 RA 1 | 2006 | 14.3 | 12.533 | 21.9 | 4.2 | 13.8 | C12/15 | 1.3 | 5.06 |

| RAC III C100 RA 2 | 2109 | 11 | 4.867 | 32.0 | 4.0 | 21.1 | C25/30 | 1.8 | 3.96 |

| RAC III C100 F RA 1 | 1903 | 17.6 | 18.427 | 16.8 | 3.5 | - | C12/15 | 1.1 | 5.06 |

| RAC III C100 F RA 2 | 2104 | 12.3 | 3.167 | 32.4 | 4.6 | 22.6 | C20/25 | 1.5 | 4.4 |

| NAC IV | 2317 | 4.8 | 3.320 | 56.5 | 8.2 | 35.7 | C35/45 | 2.2 | 3.52 |

| RAC IV C100 RA 1 | 2005 | 13.9 | 7.533 | 23.6 | 4.5 | 14.5 | C16/20 | 1.3 | 4.62 |

| RAC IV C100 RA 2 | 2127 | 10.6 | 3.627 | 30.5 | 3.6 | 23.5 | C25/30 | 1.8 | 3.96 |

| RAC IV C100 F RA 1 | 1933 | 17.6 | 9.567 | 18.7 | 3.6 | 12.9 | C12/15 | 1.1 | 5.06 |

| RAC IV C100 F RA 2 | 2106 | 12.1 | 3.267 | 35.4 | 5.3 | 23.5 | C25/30 | 1.8 | 3.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlů, T.; Pešta, J.; Fořtová, K.; Řepka, J. Recycled Concrete in Foundations: Mechanical and Environmental Insights. Buildings 2025, 15, 1237. https://doi.org/10.3390/buildings15081237

Pavlů T, Pešta J, Fořtová K, Řepka J. Recycled Concrete in Foundations: Mechanical and Environmental Insights. Buildings. 2025; 15(8):1237. https://doi.org/10.3390/buildings15081237

Chicago/Turabian StylePavlů, Tereza, Jan Pešta, Kristina Fořtová, and Jakub Řepka. 2025. "Recycled Concrete in Foundations: Mechanical and Environmental Insights" Buildings 15, no. 8: 1237. https://doi.org/10.3390/buildings15081237

APA StylePavlů, T., Pešta, J., Fořtová, K., & Řepka, J. (2025). Recycled Concrete in Foundations: Mechanical and Environmental Insights. Buildings, 15(8), 1237. https://doi.org/10.3390/buildings15081237