Shear Strength of Concrete Incorporating Recycled Optimized Concrete and Glass Waste Aggregates as Sustainable Construction Materials

Abstract

:1. Introduction

2. Problem Statement

3. Experimental Work

3.1. Materials Used

3.2. Mixtures Planning

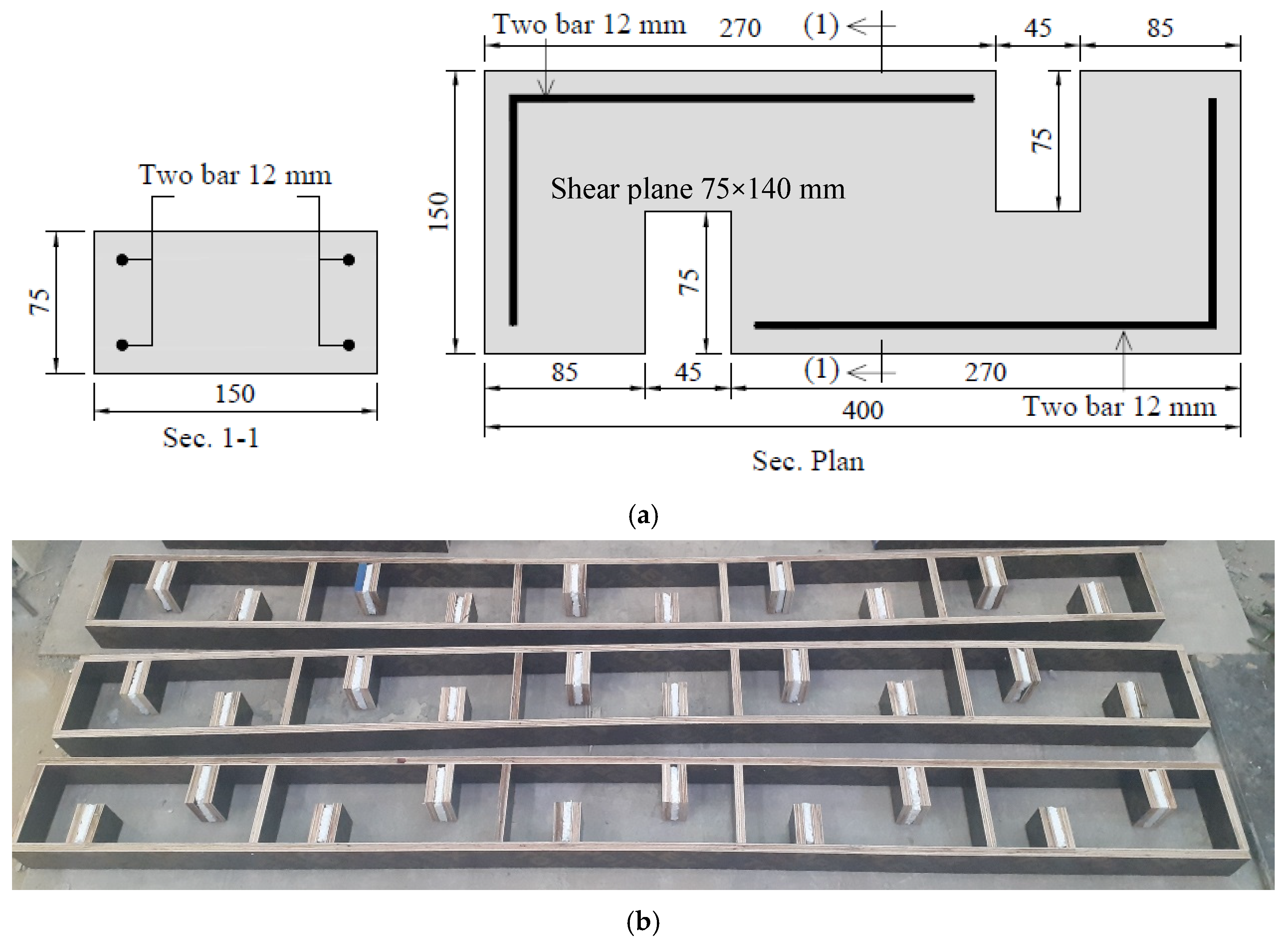

3.3. Shear Specimens

3.4. Shear Test

4. Results and Analysis

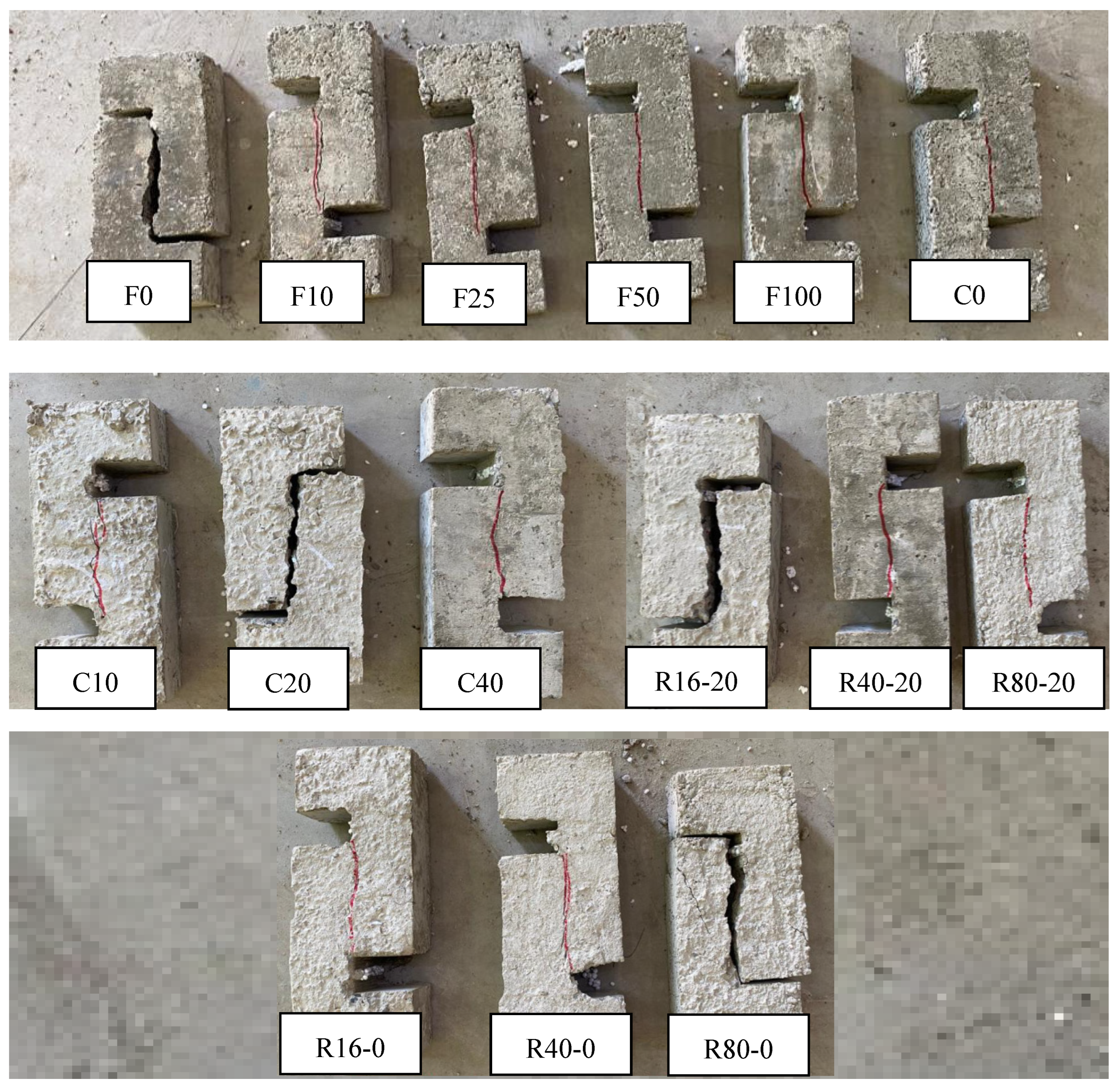

4.1. Modes of Failure

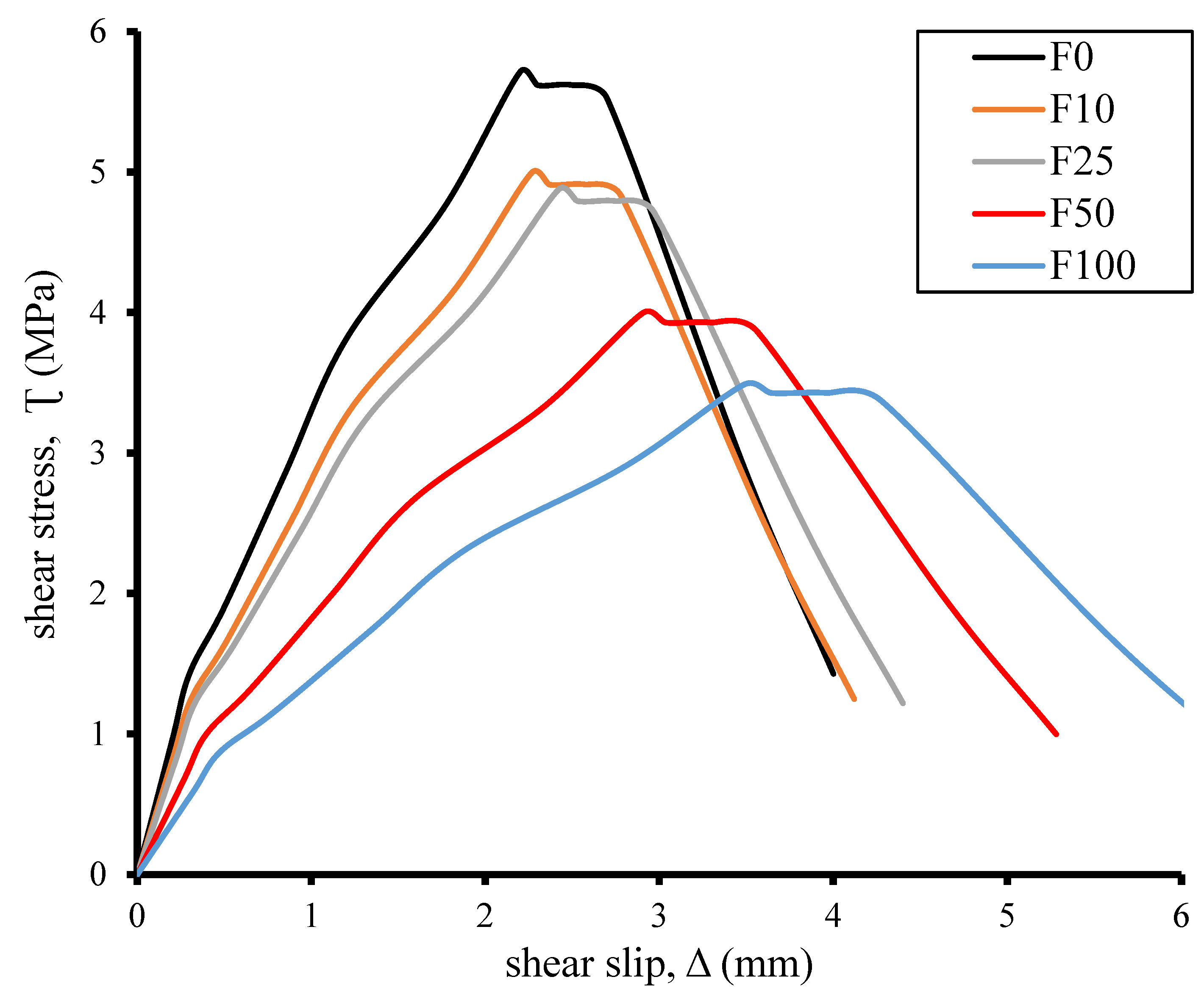

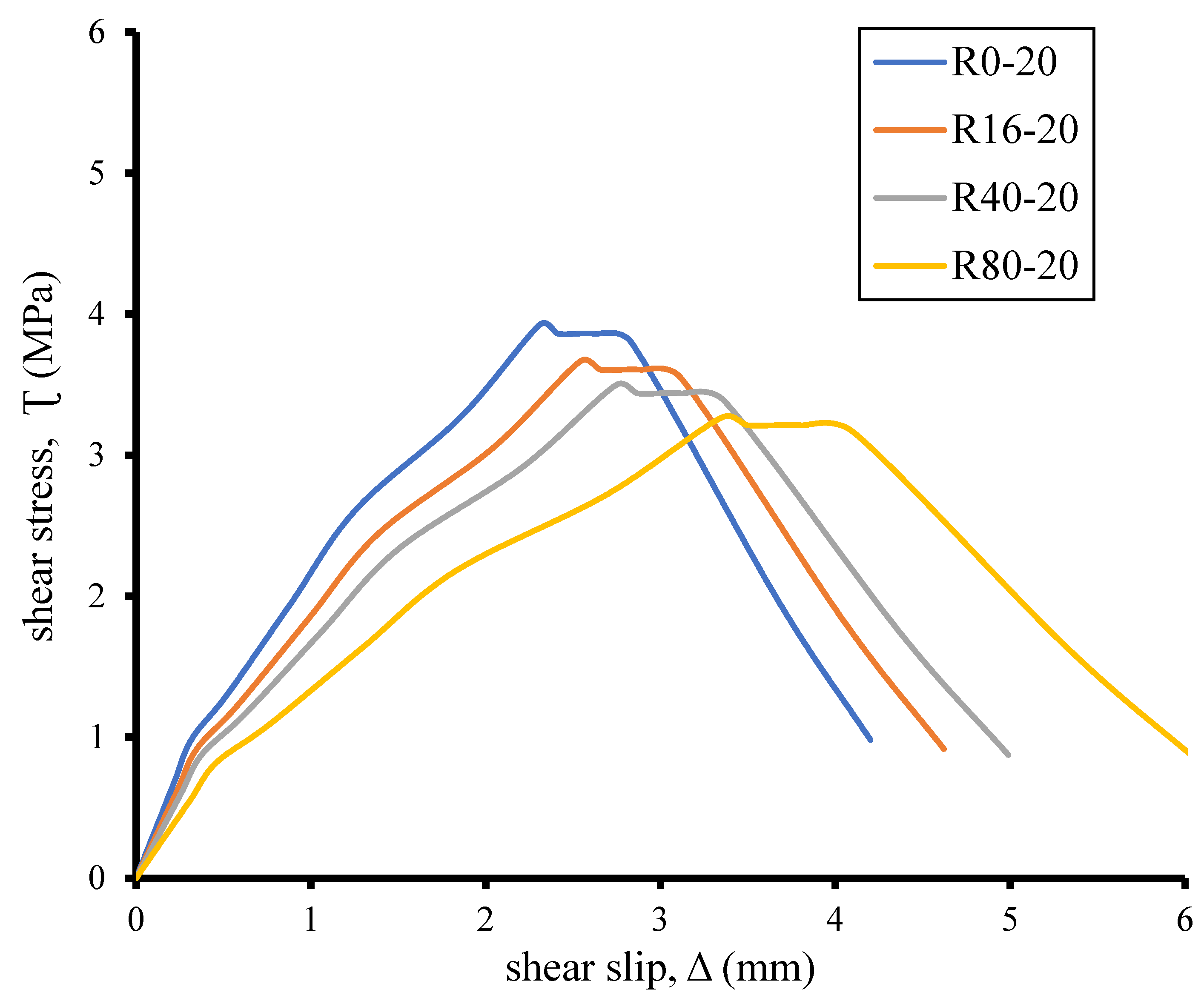

4.2. Shear Stress-Slip Curves

4.3. Shear Strength

4.4. Shear Slip

4.5. Shear Stiffness

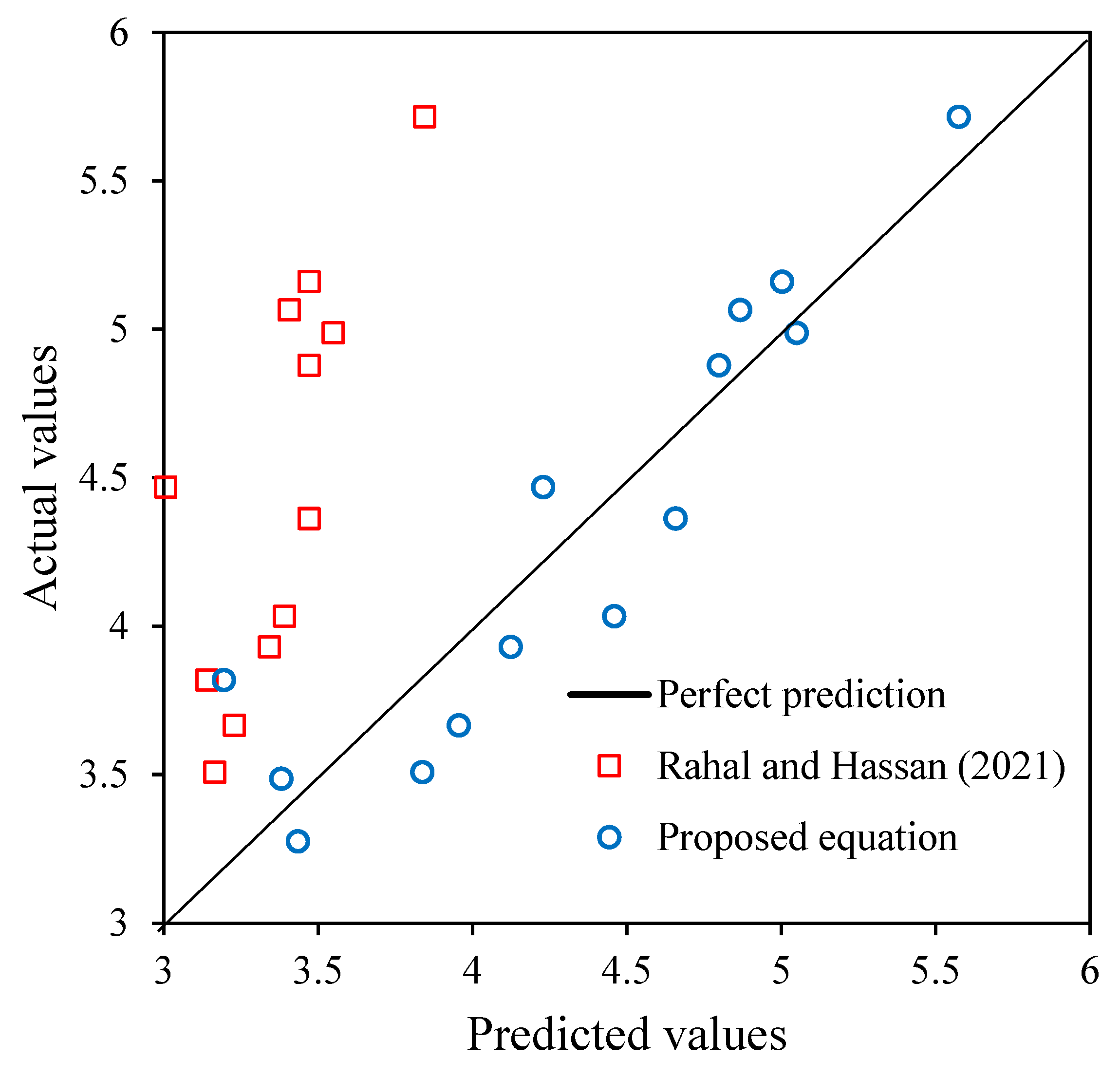

5. Proposed Formula for the Shear Strength Prediction

6. Conclusions

- At the shear-transfer plane, every sample failed. The specimens separated into two halves as a result of the failure, which was the formation of distinct fractures at the critical shear surface. This suggested a brittle failure mechanism.

- In comparison to the control combination without fine glass, the shear strengths of mixtures containing 10, 25, 50, and 100% fine glass were, respectively, 12.8%, 14.7%, 29.5%, and 39% lower. In comparison to the control mixture, the shear strengths of mixtures containing 10, 20%, and 40% were, respectively, 23.7%, 31.3%, and 33.25% lower. The shear strength of combinations containing 16, 40, and 80% recycled concrete aggregate decreased by 9.8%, 11.45%, and 21.88%, respectively, as compared to the control mixture.

- Compared to control mixes without glass, the shear slip of mixtures made of fine and coarse glass aggregates was higher. The shear slip at the shear transfer plane rose more as the quantity of recycled concrete aggregates and recycled glass replacement increased.

- Compared to control mixes, the shear stiffness of mixtures composed of fine and coarse glass was lower. In the first, second, third, and fourth groups, stiffness dropped by 61.47%, 42%, 43%, and 41.18%, respectively.

- This study introduced a new formula to predict shear strength of the plain concrete considering the content of fine glass, coarse glass, and recycled concrete aggregates.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baek, C.; Park, S.-H.; Suzuki, M.; Lee, S.-H. Life cycle carbon dioxide assessment tool for buildings in the schematic design phase. Energy Build. 2013, 61, 275–287. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O. Integrating construction supply chains within a circular economy: An ANFIS-based waste analytics system (A-WAS). J. Clean. Prod. 2019, 229, 863–873. [Google Scholar] [CrossRef]

- Tan, K.H.; Du, H. Use of waste glass as sand in mortar: Part I–Fresh, mechanical and durability properties. Cem. Concr. Compos. 2013, 35, 109–117. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Impact of combined use of ground glass powder and crushed glass aggregate on selected properties of Portland cement concrete. Constr. Build. Mater. 2016, 117, 263–272. [Google Scholar] [CrossRef]

- Chesner, W.H.; Collins, R.J.; MacKay, M.H.; Emery, J. User Guidelines for Waste and By-Product Materials in Pavement Construction; Recycled Materials Resource Center: Washington, DC, USA, 2002. [Google Scholar]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Olofinnade, O.M.; Ndambuki, J.M.; Ede, A.N.; Booth, C. Application of waste glass powder as a partial cement substitute towards more sustainable concrete production. Int. J. Eng. Res. Afr. 2017, 31, 77–93. [Google Scholar] [CrossRef]

- Olofinnade, O.; Ede, A.; Ndambuki, J. Sustainable green environment through utilization of waste soda-lime glass for production of concrete. J. Mater. Environ. Sci. 2017, 8, 1139–1152. [Google Scholar]

- Olofinnade, O.M.; Ede, A.N.; Ndambuki, J.M.; Innovation, T. Experimental investigation on the effect of elevated temperature on compressive strength of concrete containing waste glass powder. Int. J. Eng. Technol. Innov. 2017, 7, 280–291. [Google Scholar]

- Shayan, A.; Xu, A. Performance of glass powder as a pozzolanic material in concrete: A field trial on concrete slabs. Cem. Concr. Res. 2006, 36, 457–468. [Google Scholar] [CrossRef]

- Grabiec, A.M.; Zawal, D.; Rasaq, W.A. The Effect of Curing Conditions on Selected Properties of Recycled Aggregate Concrete. Appl. Sci. 2020, 10, 4441. [Google Scholar] [CrossRef]

- Al Ajmani, H.; Suleiman, F.; Abuzayed, I.; Tamimi, A. Evaluation of Concrete Strength Made with Recycled Aggregate. Buildings 2019, 9, 56. [Google Scholar] [CrossRef]

- Vieira, G.L.; Schiavon, J.Z.; Borges, P.M.; da Silva, S.R.; de Oliveira Andrade, J.J. Influence of recycled aggregate replacement and fly ash content in performance of pervious concrete mixtures. J. Clean. Prod. 2020, 271, 122665. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Influence of recycled aggregate on slump and bleeding of fresh concrete. Mater. Struct. 2007, 40, 981–988. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Lehman, D.E.; Geng, Y.; Kuder, K. Time-dependent drying shrinkage model for concrete with coarse and fine recycled aggregate. Cem. Concr. Compos. 2020, 105, 103426. [Google Scholar] [CrossRef]

- Silva, R.; de Brito, J.; Dhir, R. Comparative analysis of existing prediction models on the creep behaviour of recycled aggregate concrete. Eng. Struct. 2015, 100, 31–42. [Google Scholar] [CrossRef]

- Fan, Y.; Xiao, J.; Tam, V.W.Y. Effect of old attached mortar on the creep of recycled aggregate concrete. Struct. Concr. 2014, 15, 169–178. [Google Scholar] [CrossRef]

- Kim, J. The Effect of Residual Mortar in Recycled Aggregate on Behavior of Recycled Aggregate Concrete. Ph.D. Thesis, Korea University of Technology and Education, Cheonan, Republic of Korea, 2016. [Google Scholar]

- Jayasuriya, A.; Adams, M.P.; Bandelt, M.J. Understanding variability in recycled aggregate concrete mechanical properties through numerical simulation and statistical evaluation. Constr. Build. Mater. 2018, 178, 301–312. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Abhiram, K.; Manoj, B. Properties of treated recycled aggregates and its influence on concrete strength characteristics. Constr. Build. Mater. 2016, 111, 611–617. [Google Scholar] [CrossRef]

- Fayed, S.; Mansour, W. Behavior of RC columns incorporating with steel and recycled plastic fibers under eccentric load: An experimental work. Struct. Concr. 2023, 24, 3443–3460. [Google Scholar] [CrossRef]

- Fayed, S.; Madenci, E.; Bahrami, A.; Özkiliç, Y.O.; Mansour, W. Experimental study on using recycled polyethylene terephthalate and steel fibers for improving behavior of RC columns. Case Stud. Constr. Mater. 2023, 19, e02344. [Google Scholar] [CrossRef]

- Saleh, A.M. Size effect on shear strength of normal and high strength concrete shallow beams. J. Eng. Appl. Sci. 2007, 54, 91–103. [Google Scholar]

- Mouli, C.C.; Rao, G.V.R. Effect of Specimen Size on Flexural Behavior of Doubly Reinforced Concrete Beams. Int. J. Eng. Trends Technol. 2023, 71, 168–175. [Google Scholar] [CrossRef]

- Liu, Q.; Cheng, A.; Sun, C.; Chen, K.; Wang, Y.; Li, W. Effects of aggregate’s type and orientation on stress concentration and crack propagation of modeled concrete applied a shear force. J. Build. Eng. 2024, 95, 110340. [Google Scholar] [CrossRef]

- Jin, L.; Wan, S.; Li, D.; Miao, L.; Du, X. Influence of concrete strength and aggregate size on the size effect of shear capacity of RC beam-column joints under monotonic loading: Mesoscale numerical tests. Structures 2022, 37, 671–685. [Google Scholar] [CrossRef]

- Albidah, A.S.; Alqarni, A.S.; Wasim, M.; Abadel, A.A. Influence of aggregate source and size on the shear behavior of high strength reinforced concrete deep beams. Case Stud. Constr. Mater. 2023, 19, e02260. [Google Scholar] [CrossRef]

- Barham, W.S.; Obaidat, Y.T.; Qublan, A.W. Effect of maximum coarse aggregate size upon shear strengthening of RC beams using NSM-CFRP strips. Structures 2023, 53, 652–663. [Google Scholar] [CrossRef]

- Yi, W.-J.; Deng, Q.; Tang, F. Effect of Coarse Aggregate Size on the Shear Behavior of Beams without Shear Reinforcement. ACI Struct. J. 2017, 114, 1131. [Google Scholar] [CrossRef]

- Reba, T.C.; Aure, T.W. Influence of aggregate size on shear mechanism of reinforced concrete beam subjected to impact load. SN Appl. Sci. 2022, 4, 224. [Google Scholar] [CrossRef]

- Cho, S.; Kim, M.O. Effect of Aggregate Type on the Shear Behavior of Reinforced Lightweight Concrete Beams. Appl. Sci. 2024, 14, 5992. [Google Scholar] [CrossRef]

- da Cunha, B.F.; de Andrade Pinto, R.C.; Savaris, G. Evaluation of self-consolidating concrete shear strength by means of push-off test. Mag. Concr. Res. 2022, 74, 879–888. [Google Scholar] [CrossRef]

- Ganeshan, M.; Venkataraman, S. Interface shear strength evaluation of self compacting geopolymer concrete using push-off test. J. King Saud Univ. Eng. Sci. 2022, 34, 98–107. [Google Scholar] [CrossRef]

- Jongvivatsakul, P.; Attachaiyawuth, A.; Pansuk, W. A crack-shear slip model of high-strength steel fiber-reinforced concrete based on a push-off test. Constr. Build. Mater. 2016, 126, 924–935. [Google Scholar] [CrossRef]

- Neupane, R.P.; Imjai, T.; Makul, N.; Garcia, R.; Kim, B.; Chaudhary, S. Use of recycled aggregate concrete in structural members: A review focused on Southeast Asia. J. Asian Archit. Build. Eng. 2023, 1–24. [Google Scholar] [CrossRef]

- ECP 203-2018; Egyptian Code for the Design and Construction of Concrete Structures. Egyptian Code Committee: Giza, Egypt, 2018; tests guide, part II.

- Zhao, H.; Zhou, A.; Zhang, L.; Arulrajah, A. A novel three-dimensional DEM model for recycled aggregate concrete considering material heterogeneity and microcrack evolution. Compos. Struct. 2025, 352, 118677. [Google Scholar] [CrossRef]

- Zhao, H.; Zhou, A. Effects of recycled aggregates on mechanical and fractural properties of concrete: Insights from DEM modelling. Compos. Part A Appl. Sci. Manuf. 2024, 186, 108395. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Z.; Liu, A.; Zhang, L. Numerical insights into the effect of ITZ and aggregate strength on concrete properties. Theor. Appl. Fract. Mech. 2022, 120, 103415. [Google Scholar] [CrossRef]

- Badawi, M.; Bahrami, A.; Ghalla, M.; Emara, M.; Mlybari, E.A.; Elsamak, G. Flexural strengthening of reinforced concrete cantilever beams having insufficient splice length. Results Eng. 2024, 24, 102869. [Google Scholar] [CrossRef]

- Ghalla, M.; Bahrami, A.; Badawi, M.; Elsamak, G.; Emara, M.; Abdallah, A.M. Sustainable shear strengthening of defected RC beams using aluminum boxes and high-performance concretes. Ain Shams Eng. J. 2025, 16, 103354. [Google Scholar] [CrossRef]

- Ghalla, M.; Bahrami, A.; Badawi, M.; Mlybari, E.A. Novel sustainable techniques for enhancing shear strength of RC beams mitigating construction failure risk. Ain Shams Eng. J. 2024, 15, 103017. [Google Scholar] [CrossRef]

- Hamoda, A.; Basha, A.; Fayed, S.; Sennah, K. Experimental and numerical assessment of reinforced concrete beams with disturbed depth. Int. J. Concr. Struct. Mater. 2019, 13, 55. [Google Scholar] [CrossRef]

- Fayed, S.; Basha, A.; Elsamak, G. Behavior of RC stepped beams with different configurations: An experimental and numerical study. Struct. Concr. 2020, 21, 2601–2627. [Google Scholar] [CrossRef]

- Shaheen, Y.B.; Eltaly, B.A.; Yousef, S.G.; Fayed, S. Structural performance of ferrocement beams incorporating longitudinal hole filled with lightweight concrete. Int. J. Concr. Struct. Mater. 2023, 17, 21. [Google Scholar] [CrossRef]

- Rahal, K.N.; Hassan, W. Shear strength of plain concrete made of recycled low-strength concrete aggregates and natural aggregates. Constr. Build. Mater. 2021, 311, 125317. [Google Scholar] [CrossRef]

- Imjai, T.; Kefyalew, F.; Aosai, P.; Garcia, R.; Kim, B.; Abdalla, H.M.; Raman, S.N. A new equation to predict the shear strength of recycled aggregate concrete Z push-off specimens. Cem. Concr. Res. 2023, 169, 107181. [Google Scholar] [CrossRef]

- Setkit, M.; Leelatanon, S.; Imjai, T.; Garcia, R.; Limkatanyu, S. Prediction of Shear Strength of Reinforced Recycled Aggregate Concrete Beams without Stirrups. Buildings 2021, 11, 402. [Google Scholar] [CrossRef]

| Size (mm) | Passing of C (%) | Passing of R (%) | Passing of Sand (%) | Passing of F (%) | Passing of CN (%) |

|---|---|---|---|---|---|

| 12 mm | 100 | 100 | -- | -- | 100 |

| 9.75 mm | 53 | 82 | -- | -- | 78 |

| 4.75 mm | 12 | 40 | 100 | 100 | 15 |

| 2.3 mm | 0 | 0 | 91 | 60 | 0 |

| 1.20 mm | 0 | 0 | 81 | 39 | 0 |

| 0.9 mm | 0 | 0 | 63 | 32 | 0 |

| 0.42 mm | 0 | 0 | 9 | 22 | 0 |

| 0.22 mm | 0 | 0 | 1 | 14 | 0 |

| 0.07 mm | 0 | 0 | -- | -- | 0 |

| Material | Item | Weight kg/m3 | S.G | Particles Size mm/mm | Absorption Ability to Water wt. (%) |

|---|---|---|---|---|---|

| Fine aggregate | Riversand | 1229.5 | 2.5 | 2.36/0.075 | 1.65 |

| Fine recycled glass (F) | 1397.3 | 2.87 | 2.36/0.075 | 0.13 | |

| Coarse aggregate | Coarse naturally aggregate (CN) | 1456 | 2.73 | 10/2 | 1.5 |

| R | 1150 | 2.74 | 10/2 | 6 | |

| C | 1511 | 2.8 | 10/2 | 0.08 |

| Group | Sample | fcu (MPa) | Ʈm (MPa) | Decline in Ʈm (%) | Δm (mm) | Gain in Δm (%) | Stiffness (MPa/mm) | Decline in Stiffness (%) |

|---|---|---|---|---|---|---|---|---|

| A | F0 | 27 | 5.72 | 0.00 | 2.20 | 0.00 | 4.76 | 0.00 |

| F10 | 23 | 4.99 | 12.80 | 2.27 | 3.00 | 4.04 | 15.10 | |

| F25 | 22 | 4.88 | 14.72 | 2.42 | 10.00 | 3.69 | 22.41 | |

| F50 | 21 | 4.03 | 29.50 | 2.90 | 32.00 | 2.52 | 47.00 | |

| F100 | 15 | 3.49 | 39.06 | 3.48 | 58.40 | 1.83 | 61.47 | |

| B | C0 | 27 | 5.72 | 0.00 | 2.2 | 0.00 | 4.76 | 0.00 |

| C10 | 22 | 4.36 | 23.74 | 2.4 | 9.09 | 3.49 | 26.58 | |

| C20 | 20.4 | 3.93 | 31.30 | 2.31 | 5.00 | 3.12 | 34.54 | |

| C40 | 18 | 3.82 | 33.25 | 2.54 | 15.45 | 2.76 | 42.02 | |

| C | R0-20 | 20.4 | 3.93 | 0.00 | 2.31 | 0.00 | 3.12 | 0.00 |

| R16-20 | 19.04 | 3.67 | 6.73 | 2.54 | 9.96 | 2.64 | 15.38 | |

| R40-20 | 18.3 | 3.51 | 10.74 | 2.7 | 16.88 | 2.33 | 25.32 | |

| R80-20 | 15.2 | 3.27 | 16.67 | 3.3 | 42.86 | 1.78 | 42.95 | |

| D | R0-0 | 27 | 5.72 | 0.00 | 2.2 | 0.00 | 4.76 | 0.00 |

| R16-0 | 22 | 5.16 | 9.80 | 2.38 | 8.18 | 3.95 | 17.02 | |

| R40-0 | 21.2 | 5.06 | 11.45 | 2.64 | 20.00 | 3.50 | 26.47 | |

| R80-0 | 16.5 | 4.47 | 21.88 | 2.9 | 31.82 | 2.80 | 41.18 |

| Mix ID | fcu (MPa) | Ʈm (exp) (MPa) | F (%) | C (%) | R (%) | Ʈm (theo) (MPa) | Ʈm (theo)/Ʈm (exp) |

|---|---|---|---|---|---|---|---|

| F0 | 27 | 5.72 | 0 | 0 | 0 | 5.58 | 0.98 |

| F10 | 23 | 4.99 | 10 | 0 | 0 | 5.05 | 1.01 |

| F25 | 22 | 4.88 | 25 | 0 | 0 | 4.80 | 0.98 |

| F50 | 21 | 4.03 | 50 | 0 | 0 | 4.46 | 1.11 |

| F100 | 15 | 3.49 | 100 | 0 | 0 | 3.38 | 0.97 |

| C0 | 27 | 5.72 | 0 | 0 | 0 | 5.58 | 0.98 |

| C10 | 22 | 4.36 | 0 | 10 | 0 | 4.66 | 1.07 |

| C20 | 20.4 | 3.93 | 0 | 20 | 0 | 4.12 | 1.05 |

| C40 | 18 | 3.82 | 0 | 40 | 0 | 3.19 | 0.84 |

| R0-20 | 20.4 | 3.93 | 0 | 20 | 0 | 4.12 | 1.05 |

| R16-20 | 19.04 | 3.67 | 0 | 20 | 16 | 3.96 | 1.08 |

| R40-20 | 18.3 | 3.51 | 0 | 20 | 40 | 3.84 | 1.09 |

| R80-20 | 15.2 | 3.27 | 0 | 20 | 80 | 3.43 | 1.05 |

| R0-0 | 27 | 5.72 | 0 | 0 | 0 | 5.58 | 0.98 |

| R16-0 | 22 | 5.16 | 0 | 0 | 16 | 5.00 | 0.97 |

| R40-0 | 21.2 | 5.06 | 0 | 0 | 40 | 4.87 | 0.96 |

| R80-0 | 16.5 | 4.47 | 0 | 0 | 80 | 4.23 | 0.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fayed, S.; El-Zohairy, A.; Salim, H.; Mlybari, E.A.; Bazuhair, R.W.; Ghalla, M. Shear Strength of Concrete Incorporating Recycled Optimized Concrete and Glass Waste Aggregates as Sustainable Construction Materials. Buildings 2025, 15, 1420. https://doi.org/10.3390/buildings15091420

Fayed S, El-Zohairy A, Salim H, Mlybari EA, Bazuhair RW, Ghalla M. Shear Strength of Concrete Incorporating Recycled Optimized Concrete and Glass Waste Aggregates as Sustainable Construction Materials. Buildings. 2025; 15(9):1420. https://doi.org/10.3390/buildings15091420

Chicago/Turabian StyleFayed, Sabry, Ayman El-Zohairy, Hani Salim, Ehab A. Mlybari, Rabeea W. Bazuhair, and Mohamed Ghalla. 2025. "Shear Strength of Concrete Incorporating Recycled Optimized Concrete and Glass Waste Aggregates as Sustainable Construction Materials" Buildings 15, no. 9: 1420. https://doi.org/10.3390/buildings15091420

APA StyleFayed, S., El-Zohairy, A., Salim, H., Mlybari, E. A., Bazuhair, R. W., & Ghalla, M. (2025). Shear Strength of Concrete Incorporating Recycled Optimized Concrete and Glass Waste Aggregates as Sustainable Construction Materials. Buildings, 15(9), 1420. https://doi.org/10.3390/buildings15091420