Influence of Water-to-Binder Ratio on Autogenous Shrinkage and Electrical Resistivity of Cement Mortar

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Raw Materials

2.2. Experimental Design and Methods

2.2.1. Mix Proportions

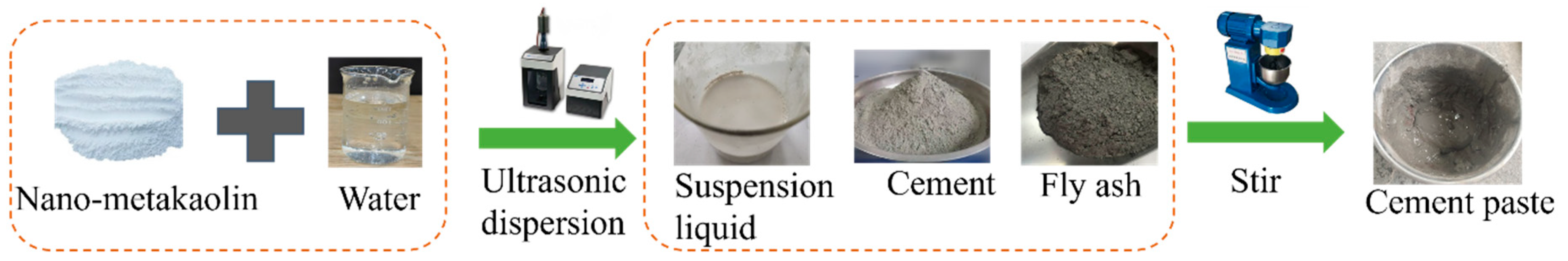

2.2.2. Specimen Preparation

2.3. Test Methods

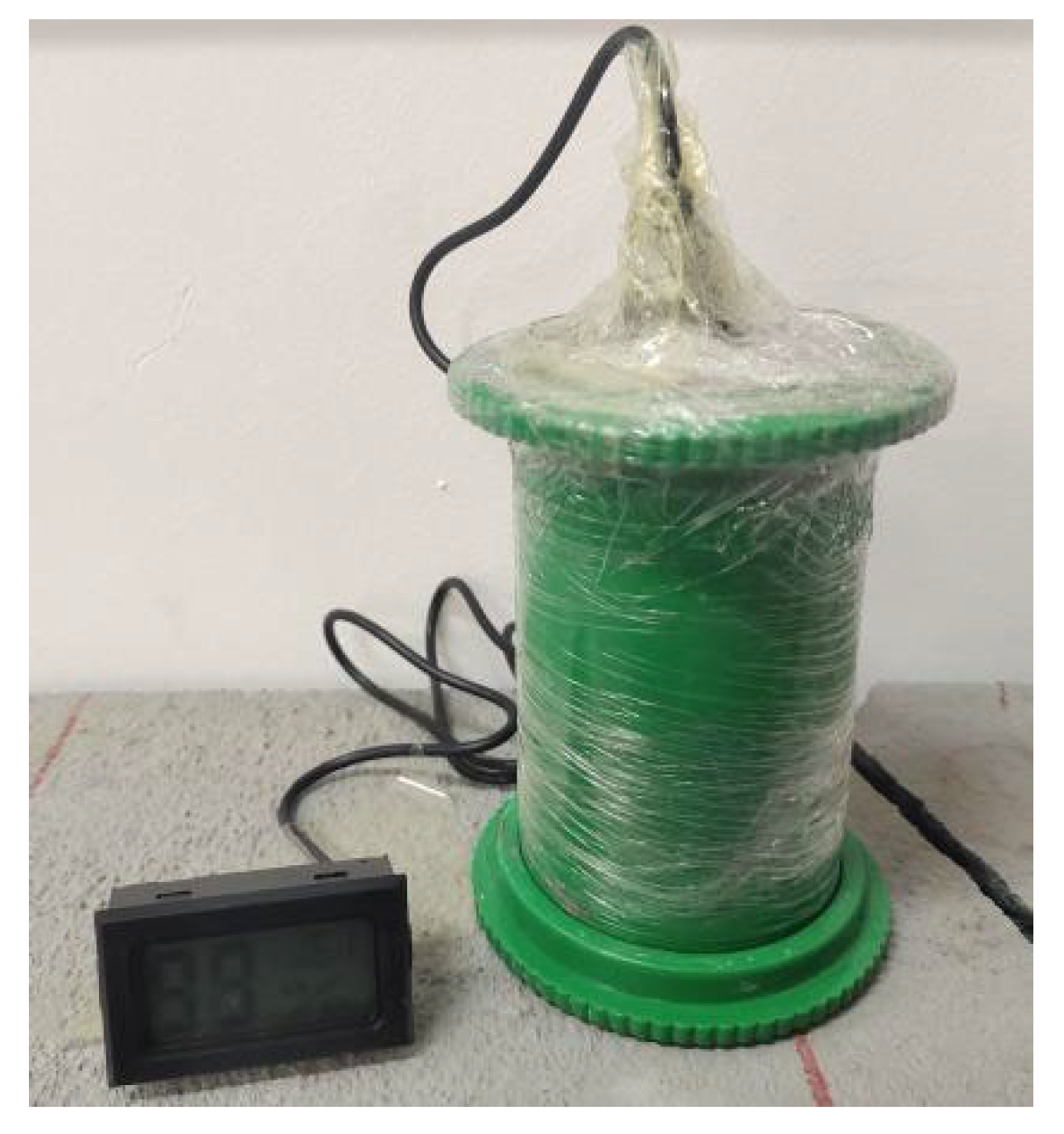

2.3.1. Internal Relative Humidity (IRH)

2.3.2. Autogenous Shrinkage Test

- : Autogenous shrinkage value at time t (με), commencing from the final setting time;

- , : Initial readings of the left and right dial gauges (mm);

- , : Readings of the left and right dial gauges at time t (mm);

- L0: Initial length of the autogenous shrinkage specimen at test start (mm).

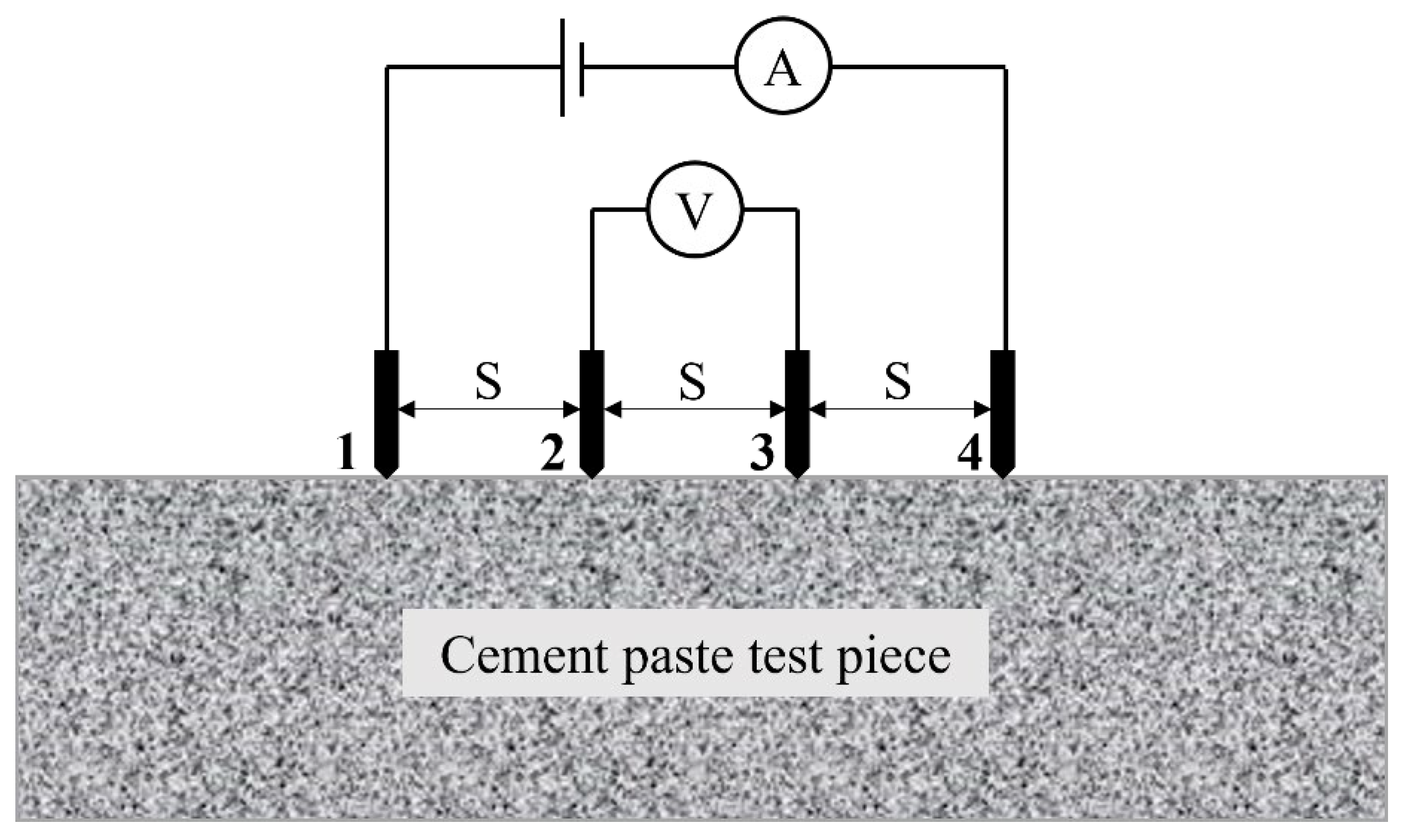

2.3.3. Resistivity Test

- ρ: Resistivity of the cementitious material (Ω · m);

- S: Probe spacing of the resistivity tester, set to 1.2 mm;

- V: Potential difference between Probes 2 and 3 (V);

- I: Measured current (A).

2.3.4. Hydration Heat Test

2.3.5. X-Ray Diffraction Test

2.3.6. Thermal Analyzer Test

2.3.7. Scanning Electron Microscope Test

2.3.8. Mercury Intrusion Porosimetry Test

- and : Calculated from mercury intrusion data;

- n: Number of applied mercury pressure intervals;

- : Average pressure;

- : Mercury intrusion volume at pressure interval n;

- : Total mercury intrusion volume;

- : Pore diameter corresponding to the n-th mercury intrusion.

3. Results and Discussion

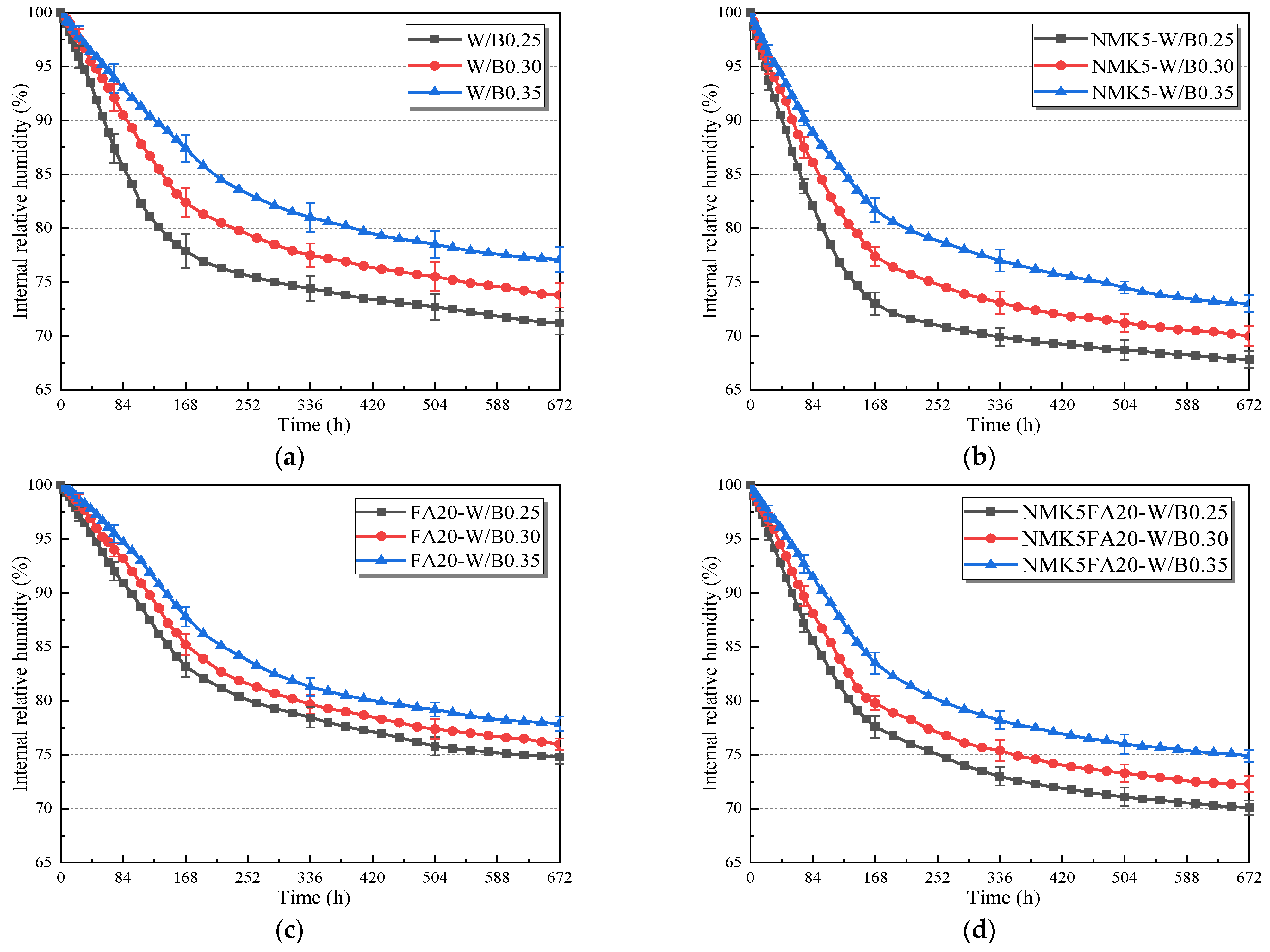

3.1. Internal Relative Humidity Changes in Cement Paste

3.2. Autogenous Shrinkage Changes in Cement Paste

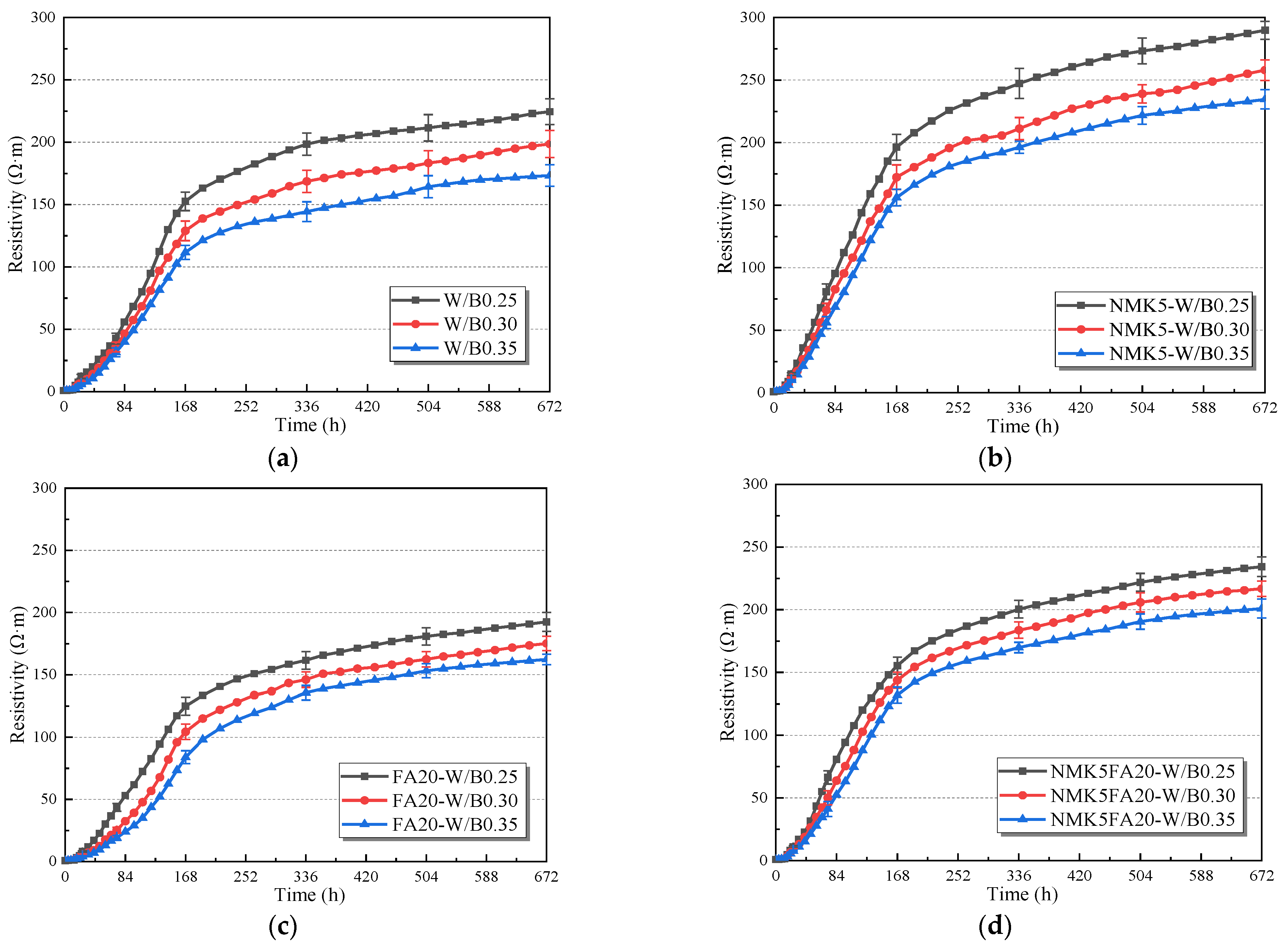

3.3. Resistivity Changes in Cement Paste

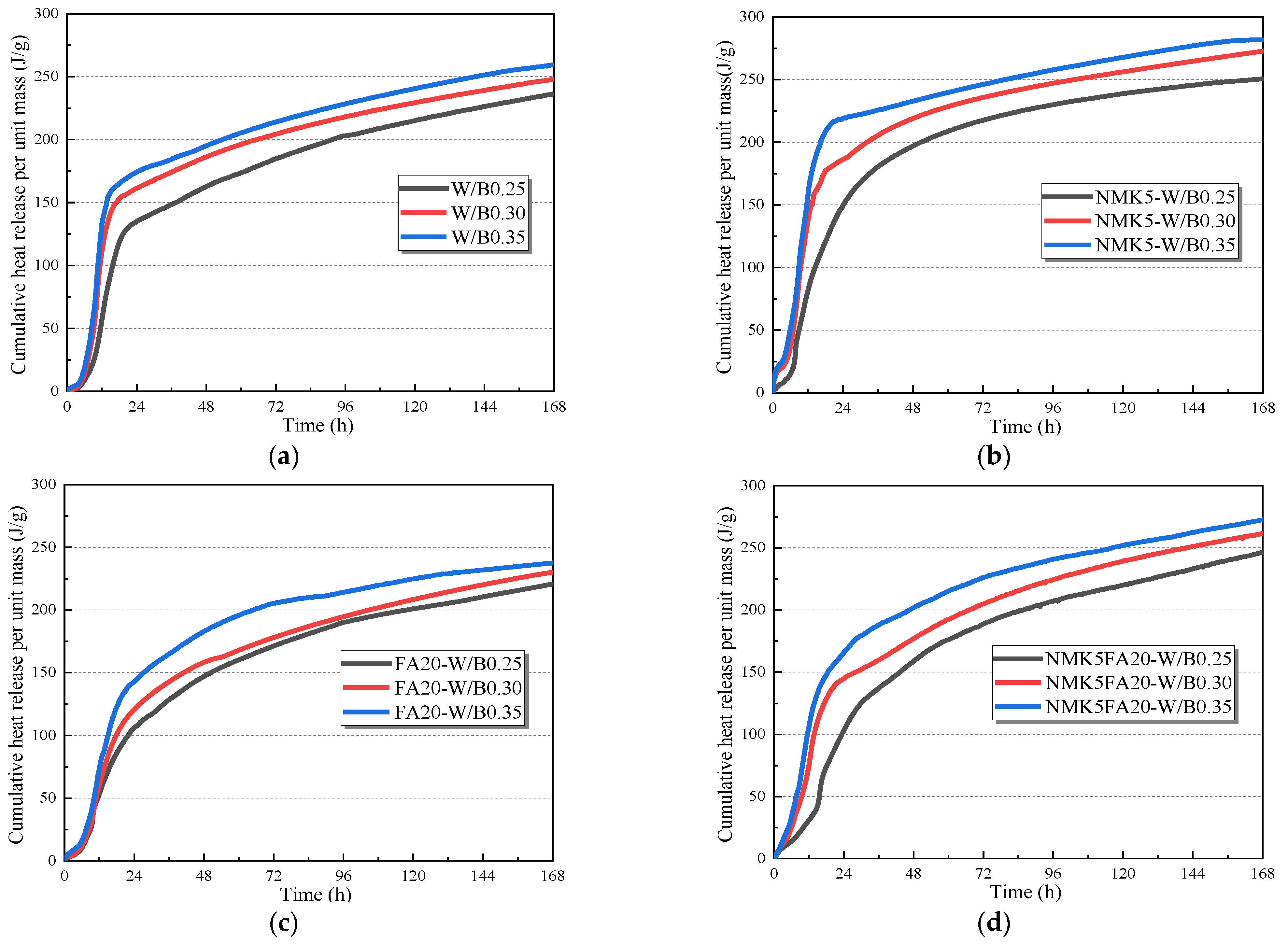

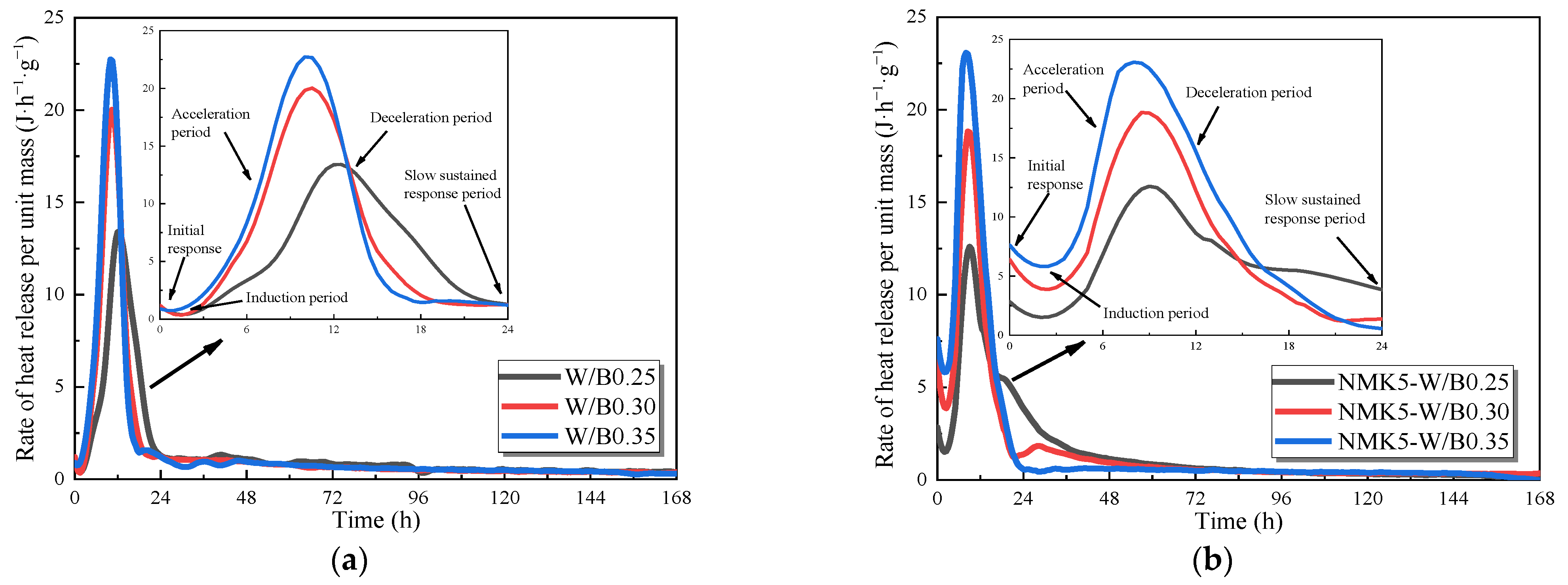

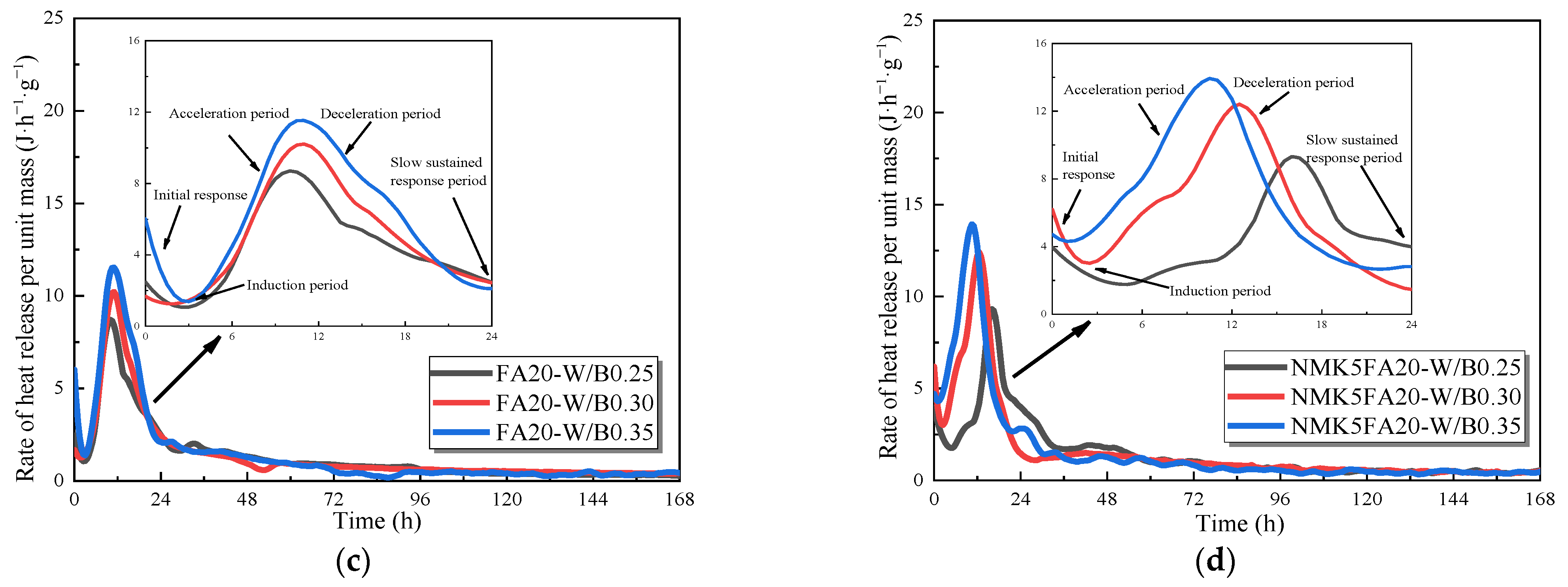

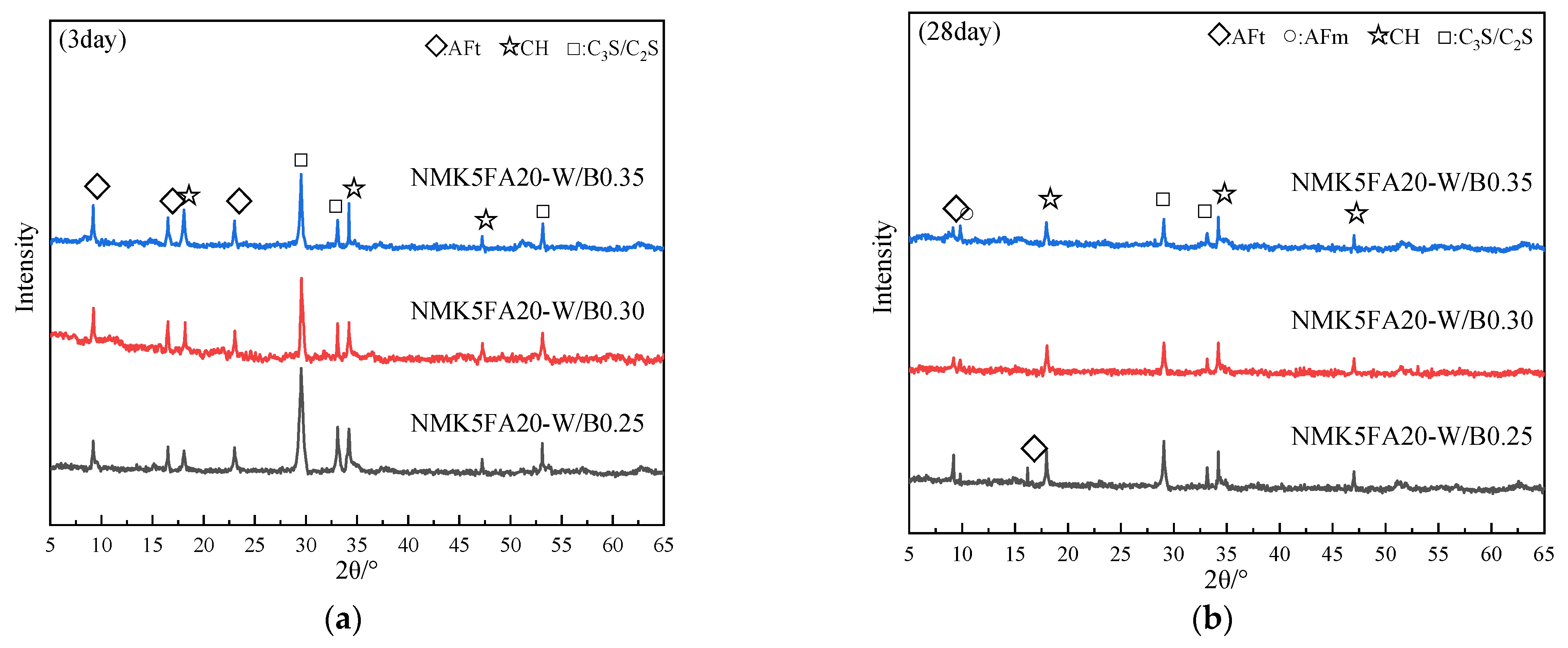

3.4. Influence of Water-to-Binder Ratio on Hydration Processes of Nano-Metakaolin and Fly Ash Cement

3.5. Influence of Water-to-Binder Ratio on Phase Composition of Nano-Metakaolin and Fly Ash Cement

3.6. Influence of Water-to-Binder Ratio on Pore Structure of Nano-Metakaolin and Fly Ash Cement

4. Conclusions

- (1)

- Lower water-to-binder ratios (w/b) accelerated the rate and magnitude of internal relative humidity (RH) decline in cement pastes. Autogenous shrinkage increased with decreasing w/b, with the 28-day shrinkage of NMK-FA composite pastes increasing by 20.56% and 34.39% when w/b decreased from 0.40 to 0.35 and 0.30, respectively. Reduced w/b ratios had a more pronounced effect on autogenous shrinkage in NMK-blended pastes compared to FA-blended pastes. When combined, FA mitigated the excessive autogenous shrinkage caused by NMK under low w/b ratios.

- (2)

- Cement paste resistivity increased more rapidly at lower w/b ratios. When w/b decreased from 0.35 to 0.30 and 0.25, the 28-day resistivity of NMK-FA pastes increased by 8.08% and 7.33%, respectively. The w/b ratio had minimal impact on autogenous shrinkage and resistivity in FA-blended pastes.

- (3)

- Higher w/b ratios accelerated hydration rates and increased porosity. Pore structure coarsened with increasing w/b, with the 28-day porosity increasing by 50.31% when w/b increased from 0.25 to 0.35.

- (4)

- In low w/b hydration systems, rapid internal RH decline and pore refinement increased capillary stress, exacerbating autogenous shrinkage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, R.; Zhang, J.; Liu, K.; Liao, M.; Shui, Z.; Zeng, M.; Hu, F.; Hou, D.; Wang, X. Evaluation and regulation of ultra-high performance concrete (UHPC) crack resistance based on physicochemical multi-factor coupling approach. Constr. Build. Mater. 2021, 301, 124100. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Kang, J.; Yang, Q.; Li, M.; Li, C.; Zeng, X. Early-age autogenous shrinkage and tensile creep of hooked-end steel fiber reinforced concrete with different thermal treatment temperatures. Cem. Concr. Compos. 2022, 131, 104550. [Google Scholar] [CrossRef]

- Klausen, A.E.; Kanstad, T.; Bjøntegaard, Ø. The cracking risk of hardening concrete exposed to realistic curing temperature regimes and restraint conditions experimental investigations of important parameters. Constr. Build. Mater. 2022, 338, 127662. [Google Scholar] [CrossRef]

- Wu, L.; Farzadnia, N.; Shi, C.; Zhang, Z.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Wu, Y.; Yi, G.; Liu, Q.; Li, F.; Zhao, L.; Ma, M. Current Status of Comprehensive Utilization of Fly Ash. Clean Coal Technol. 2013, 6, 107–111. [Google Scholar]

- Shaikhf, U.A.; Dobson, J. Effect of fly ash on compressive strength and chloride binding of seawater-mixed mortars. J. Sustain. Cem.-Based Mater. 2019, 8, 275–289. [Google Scholar]

- Rukzon, S.; Chindaprasirt, P. Strength, porosity, and chloride resistance of mortar using the combination of two kinds of pozzolanic materials. Int. J. Miner. Metall. Mater. 2013, 20, 808–814. [Google Scholar] [CrossRef]

- Liao, Y.; Wei, X.; Zuo, Y. Effect of Fly Ash Content on Resistivity and Autogenous Shrinkage of Cement Paste. J. Build. Mater. 2014, 17, 517–520. [Google Scholar]

- Hao, C.; Deng, M.; Mo, L.; Liu, K. Influence of Fly Ash on Autogenous Shrinkage and Compressive Strength of Cement Paste. J. Build. Mater. 2011, 14, 746–751. [Google Scholar]

- Klemczak, B.; Golaszewski, J.; Smolana, A. Shrinkage behaviour of self-compacting concrete with a high volume of fly ash and slag experimental tests and analytical assessment. Constr. Build. Mater. 2023, 400, 132608. [Google Scholar] [CrossRef]

- Jiao, D.; Lesage, K.; Yardimci, M.Y.; Shi, C.; De Schutter, G. Possibilities of fly ash as responsive additive in magneto-rheology control of cementitious materials. Constr. Build. Mater. 2021, 296, 123656. [Google Scholar] [CrossRef]

- Fang, Z.; Luo, Y.; Chen, H.; Gao, Y.; Yang, W.; Wang, C. Research on mechanical properties and hydration characteristics of ultra-high performance concrete with high-volume fly ash microsphere. J. Build. Eng. 2023, 78, 107738. [Google Scholar] [CrossRef]

- Meng, J.; Zhong, J.; Xiao, H.; Ou, J. Interfacial design of nano-TiO2 modified fly ash-cement based low carbon composites. Constr. Build. Mater. 2021, 270, 121470. [Google Scholar] [CrossRef]

- Park, B.; Choi, Y.C. Hydration and pore-structure characteristics of high-volume fly ash cement pastes. Constr. Build. Mater. 2021, 278, 122390. [Google Scholar] [CrossRef]

- Garg, R.; Garg, R.; Eddy, N.O.; Khan, M.A.; Khan, A.H.; Alomayri, T.; Berwal, P. Mechanical strength and durability analysis of mortars prepared with fly ash and nano-metakaolin. Case Stud. Constr. Mater. 2023, 18, e01796. [Google Scholar] [CrossRef]

- Weng, J.; Liao, W. Microstructure and shrinkage behavior of high-performance concrete containing supplementary cementitious materials. Constr. Build. Mater. 2021, 308, 125045. [Google Scholar] [CrossRef]

- Gao, X.; Kawashima, S.; Liu, X.; Shah, S.P. Influence of clays on the shrinkage and cracking tendency of SCC. Cem. Concr. Compos. 2012, 34, 478–485. [Google Scholar] [CrossRef]

- Bentz, D.P. A review of early-age properties of cement-based materials. Cem. Concr. Res. 2008, 38, 196–204. [Google Scholar] [CrossRef]

- Luo, Y. Study on Autogenous Shrinkage Properties of Cement-Based Materials. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2020. [Google Scholar]

- Li, Z.; Liang, X.; Chen, Y.; Ye, G. Effect of metakaolin on the autogenous shrinkage of alkali-activated slag-fly ash paste. Constr. Build. Mater. 2021, 278, 122397. [Google Scholar] [CrossRef]

- Luo, D.; Wei, J. Early-age shrinkage behavior of cement mixtures regulated with metakaolin-based internal conditioning. Appl. Clay Sci. 2024, 261, 107583. [Google Scholar] [CrossRef]

- Qian, T. Study on Shrinkage and Mechanism of Cement-Based Materials with Low Water-Binder Ratio and High Volume Mineral Admixtures. Ph.D. Thesis, Southeast University, Nanjing, China, 2006. [Google Scholar]

- Wyrzykowski, M.; Assmann, A.; Hesse, C.; Lura, P. Microstructure development and autogenous shrinkage of mortars with C-S-H seeding and internal curing. Cem. Concr. Res. 2020, 129, 105967. [Google Scholar] [CrossRef]

- He, J.; Long, G.; Ma, K.; Xie, Y. Comprehensive study on the hydration kinetics, mechanical properties and autogenous shrinkage of cement pastes during steam curing. Cem. Concr. Res. 2023, 174, 107310. [Google Scholar] [CrossRef]

- Dong, E.; Chen, Z.; Wu, C. New insights into determining the “time zero” of autogenous shrinkage in low water/binder cement-based composites (LW/B-CC) system based on relaxation theory. J. Build. Eng. 2023, 66, 105852. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Hu, Z.; Ghourchian, S.; Scrivener, K.; Lura, P. Corrugated tube protocol for autogenous shrinkage measurements: Review and statistical assessment. Mater. Struct. 2017, 50, 57. [Google Scholar] [CrossRef]

- GB/T 12959-2008; Test Methods for Heat of Hydration of Cement. China Standards Press: Beijing, China, 2008; pp. 4–6.

- Shukla, B.K.; Gupta, A.; Gowda, S.; Srivastav, Y. Constructing a greener future: A comprehensive review on the sustainable use of fly ash in the construction industry and beyond. Mater. Today Proc. 2023, 93, 257–264. [Google Scholar] [CrossRef]

- Zhang, B.; Li, S. Determination of the surface fractal dimension for porous media by mercury porosimetry. Ind. Eng. Chem. Res. 1995, 34, 1383–1386. [Google Scholar] [CrossRef]

- Kassai, Y.; Vokoyama, K.; Matsui, I. Tensile properties of early-age concrete. Conf. Mech. Behav. Mater. 1972, 4, 288–299. [Google Scholar]

- Kong, X.; Lu, Z.; Zhang, Z. Research Progress on Cement Hydration Mechanism and Effects of Polymer Admixtures on Cement Hydration. J. Chin. Ceram. Soc. 2017, 45, 274–281. [Google Scholar]

- Nalet, C.; Nonat, A. Effects of functionality and stereochemistry of small organic molecules on the hydration of tricalcium silicate. Cem. Concr. Res. 2016, 87, 97–104. [Google Scholar] [CrossRef]

- Luo, D.; Niu, D. Effects of Different Water-Binder Ratios and Curing Conditions on Water Absorption Properties of Internal Curing Concrete. J. Build. Struct. 2019, 40, 165–173. [Google Scholar]

- Li, Q.; Fan, Y.; Li, X. Effects of Environmental Temperature and Hydration Time on Rheological Properties of Nano-Metakaolin Cement Paste. J. Basic Sci. Eng. 2023, 31, 509–521. [Google Scholar]

- Jin, S.; Zheng, G.; Yu, J. A micro freeze-thaw damage model of concrete with fractal dimension. Constr. Build. Mater. 2020, 257, 119434. [Google Scholar] [CrossRef]

| Chemical Makeup | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | SO3 | Other |

|---|---|---|---|---|---|---|---|---|

| cement | 59.31 | 21.90 | 6.26 | 3.79 | 1.63 | 0.94 | 2.41 | 3.76 |

| nano-metakaolin | 0.10 | 46.82 | 50.46 | 0.44 | 0.13 | 0.58 | — | 1.47 |

| fly ash | 3.16 | 53.80 | 24.60 | 9.32 | 1.52 | 0.82 | 1.96 | 5.64 |

| Specimen Number | Cement (%) | Nano Metakaolin (%) | Coal Fly Ash (%) | W/B Ratio |

|---|---|---|---|---|

| W/B0.25 | 100 | — | — | 0.25 |

| NMK5-W/B0.25 | 95 | 5 | — | 0.25 |

| FA20-W/B0.25 | 80 | — | 20 | 0.25 |

| NMK5FA20-W/B0.25 | 75 | 5 | 20 | 0.25 |

| W/B0.25 | 100 | — | — | 0.30 |

| NMK5-W/B0.30 | 95 | 5 | — | 0.30 |

| FA20-W/B0.30 | 80 | — | 20 | 0.30 |

| NMK5FA20-W/B0.30 | 75 | 5 | 20 | 0.30 |

| W/B0.35 | 100 | — | — | 0.35 |

| NMK5-W/B0.35 | 95 | 5 | — | 0.35 |

| FA20-W/B0.35 | 80 | — | 20 | 0.35 |

| NMK5FA20-W/B0.35 | 75 | 5 | 20 | 0.35 |

| Number | Age | Porosity/% | Average Pore Size/nm | Median Pore Size/nm |

|---|---|---|---|---|

| NMK5FA20-W/B0.25 | 3d | 26.29 | 20.02 | 31.81 |

| 28d | 14.43 | 14.92 | 15.59 | |

| NMK5FA20-W/B0.30 | 3d | 27.07 | 21.63 | 39.97 |

| 28d | 19.77 | 16.97 | 22.35 | |

| NMK5FA20-W/B0.35 | 3d | 28.03 | 23.05 | 41.51 |

| 28d | 21.69 | 18.55 | 24.17 |

| Number | Age | Gel Pore | Capillary Pore | Macropore | |||

|---|---|---|---|---|---|---|---|

| Fractal Dimension | Correlation | Fractal Dimension | Correlation | Fractal Dimension | Correlation | ||

| NMK5FA20-W/B0.25 | 3d | 2.66 | 0.984 | 2.77 | 0.994 | 2.80 | 0.978 |

| 28d | 2.70 | 0.962 | 2.96 | 0.981 | 2.85 | 0.985 | |

| NMK5FA20-W/B0.30 | 3d | 2.63 | 0.965 | 2.74 | 0.987 | 2.79 | 0.996 |

| 28d | 2.67 | 0.996 | 2.91 | 0.985 | 2.83 | 0.993 | |

| NMK5FA20-W/B0.35 | 3d | 2.61 | 0.965 | 2.71 | 0.978 | 2.79 | 0.969 |

| 28d | 2.65 | 0.986 | 2.86 | 0.986 | 2.82 | 0.992 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhang, S.; Fang, Z.; Sun, M.; Fan, Y.; Shah, S.P. Influence of Water-to-Binder Ratio on Autogenous Shrinkage and Electrical Resistivity of Cement Mortar. Buildings 2025, 15, 1444. https://doi.org/10.3390/buildings15091444

Liu Y, Zhang S, Fang Z, Sun M, Fan Y, Shah SP. Influence of Water-to-Binder Ratio on Autogenous Shrinkage and Electrical Resistivity of Cement Mortar. Buildings. 2025; 15(9):1444. https://doi.org/10.3390/buildings15091444

Chicago/Turabian StyleLiu, Yujiang, Shiyi Zhang, Zhisheng Fang, Mingkai Sun, Yingfang Fan, and Surendra P. Shah. 2025. "Influence of Water-to-Binder Ratio on Autogenous Shrinkage and Electrical Resistivity of Cement Mortar" Buildings 15, no. 9: 1444. https://doi.org/10.3390/buildings15091444

APA StyleLiu, Y., Zhang, S., Fang, Z., Sun, M., Fan, Y., & Shah, S. P. (2025). Influence of Water-to-Binder Ratio on Autogenous Shrinkage and Electrical Resistivity of Cement Mortar. Buildings, 15(9), 1444. https://doi.org/10.3390/buildings15091444