Abstract

There is an increasing demand to replace traditional construction techniques with more sustainable systems that can reduce environmental impacts. Emissions are typically assessed only in carbon dioxide and embodied energy terms, yet these metrics alone cannot fully capture the overall impact generated. This study provides a comparative Life Cycle Assessment (LCA) of three steel warehouse projects with varying cladding systems: steel walls (SW), steel-clay brick walls (SClaW), and steel-concrete block walls (SConW). Life Cycle Assessment (LCA) methodology was used to assess the environmental impact of materials used during the whole life cycle. The study used the software program SimaPro (System for Integrated Environmental Assessment of Products) version 9.6.0.1, with data extracted from the international Ecoinvent database. ReCiPe Midpoint approach were adopted to assess potential impacts. The results indicate that the SW project under end-of-life Scenario 2—waste recycling—exhibited the lowest impacts across most categories, followed by the SConW and SClaW projects. The findings emphasize the environmental benefits of utilizing steel cladding systems over brick or concrete masonry and considering recycling as the end of life of the materials. Additionally, the study provides insights into the significance of material choices in minimizing environmental impact on human health, resource availability, and ecosystems.

1. Introduction

The built environment provides many benefits to society. It primarily contributes to economic growth and social prosperity due to its substantial potential for job creation and income generation [1]. However, infrastructure and urbanization deteriorate the quality of the environment [2]; they are related to resource consumption [3,4,5], a large quantity of water use [6,7], and waste generation. These impacts are critical drivers of energy consumption [8,9,10] and carbon dioxide emissions in the industrial sector [11,12,13,14,15], and they affect stakeholders throughout the construction life cycle [16,17,18].

There is still no absolute answer to solve all the problems highlighted; however, approaches based on a building’s life cycle provide a framework capable of relating technical aspects to environmental variables. In this context, the design phase has a crucial influence on the impact of construction, as this impact is directly linked to the choice of structural system and to design optimization aimed at resource minimization [19,20]. These facts indicate a growing demand to replace traditional techniques with more sustainable construction systems that quantify and effectively reduce the emissions of buildings and infrastructures based on Life Cycle Assessment (LCA) [16,17,18,21,22].

Life Cycle Assessment (LCA) estimates the possible environmental impacts of a service, process, or product throughout its life cycle. The ISO 14040 [23,24] series offers a framework for comprehensive assessment of a product’s life cycle, from the extraction of raw materials to the disposal of the product at the end of its life. It is an invaluable resource for gauging the environmental impact of construction materials. The primary objectives of LCA are to minimize the product’s resource utilization and emissions and to enhance its socio-economic performance over its entire life cycle [25].

Despite the widespread application of LCA in product manufacturing, its introduction to the building sector is relatively recent [10,13,14,26,27,28,29,30]. Buildings, being complex systems composed of numerous materials with diverse life cycles, present unique challenges in LCA analysis. This complexity is further compounded by the variability in building types, climate conditions, and regional regulations, making comparing case studies difficult. However, by providing valuable information on the energy and resources consumed throughout a building’s life cycle, LCA is becoming an essential tool for assessing the sustainability of construction materials and methods.

Warehouses present distinct characteristics compared to other building typologies, such as residential, commercial, or institutional structures. The warehousing of goods between successive supply chain stages is a fundamental aspect of any supply chain, encompassing the core functions of receiving, warehousing, picking, and shipping [31]. Warehouses are typically designed to store raw materials and agricultural inputs, and harvest results in activities related to natural resources and agriculture. They also serve as facilities for manufacturing, raw material processing, commerce, and various services [32]. This type of construction often features large open spans, minimal internal divisions, and high structural efficiency, resulting in lower operational complexity but elevating the significance of structural and cladding materials in terms of their environmental performance. Steel structures and efficient cladding systems are common, aiming to reduce construction time and allow for future adaptability. However, such design choices also influence embodied energy and emissions throughout the life cycle. Therefore, sustainability assessment of warehouses requires specific considerations that differ from those used for conventional buildings, especially in how structural systems, cladding options, and functional requirements impact the overall environmental footprint.

Recent studies have begun to apply Life Cycle approaches specifically to warehouse construction, offering insight into the environmental impacts of these facilities. Rai et al. (2011) illustrated the relative importance of operational and embodied energy in a flexible-use light distribution warehouse in Europe [33]. Burek and Nutter (2018) studied distribution centers’ environmental impacts [34], the trade-offs and effects on costs and climate change impact related to the increase of renewable energy use [35], and energy, water, and refrigerant use and their implications on the environmental impacts of perishables in the United States [36]. Mutlu Ozturk et al. (2019) applied life cycle costs to refrigerated warehouses to determine optimum insulation thickness in Turkey [37]. Iancu and Moga (2022) conducted a comparative analysis of the life cycles of industrial warehouse-type buildings to compare the embodied emissions and energy in Romania [38]. Kyaw et al. (2023) explored the environmental performance of adaptive reuse of an industrial heritage building compared to new construction using Life Cycle Assessment in Norway [39]. Luo et al. (2024) adopted a process-based whole life cycle to develop a comprehensive carbon footprint accounting model for electric power material warehouses in China [40]. Vitorio Junior and Costa (2024) applied LCA in steel warehouse structural projects in Brazil [41]. These examples demonstrate the growing relevance of LCA in warehouse design and underline the need for comprehensive, multi-indicator assessments to support sustainable decision-making in this sector.

There is still a lack of comprehensive studies focusing specifically on warehouses, particularly those using steel structures and cladding systems. Many existing works analyze isolated stages of the life cycle, prioritize operational energy, or address specific regional contexts without providing a complete cradle-to-grave perspective. Additionally, few studies compare multiple design alternatives for the same functional use, which limits the ability to identify trade-offs and best practices in material selection. The literature also reveals limited integration of multiple environmental indicators beyond carbon emissions, such as resource depletion or ecosystem impacts, which are essential for more robust sustainability assessments. As a result, there remains a knowledge gap regarding how different design configurations—especially cladding systems—influence the environmental performance of steel warehouses across their entire life cycle.

In response to the growing demand for sustainability in warehouse design, this paper uses a cradle-to-grave LCA methodology to explore the sustainability profile of three steel warehouse structures with different cladding systems. The aim is to evaluate the environmental impact of each design, identify the main factors affecting sustainability, and guide future warehouse construction projects. This study focuses on the whole life cycle to demonstrate how design decisions can positively impact sustainability outcomes.

The structure of this paper is as follows: Section 2 introduces the fundamental concepts of Life Cycle Assessment. Section 3 delves into a detailed analysis of the case study. Section 4 and Section 5 present the results along with a discussion. Lastly, Section 6 summarizes the conclusions and offers recommendations for future research.

2. Life Cycle Assessment

Life Cycle Thinking (LCT) tools have been developed for use across both private and public sectors, aiming to encourage and facilitate the shift toward sustainable development. The approaches can be applied across all industries, comprehensively examining a range of critical impact categories and indicators. They facilitate the assessment of environmental, social, and economic impacts and their ultimate effects on the complete triple bottom line [42]. Life Cycle Assessment (LCA) is an environmental impact tool used to evaluate a product’s potential effects on the environment over its entire lifespan [43,44,45,46].

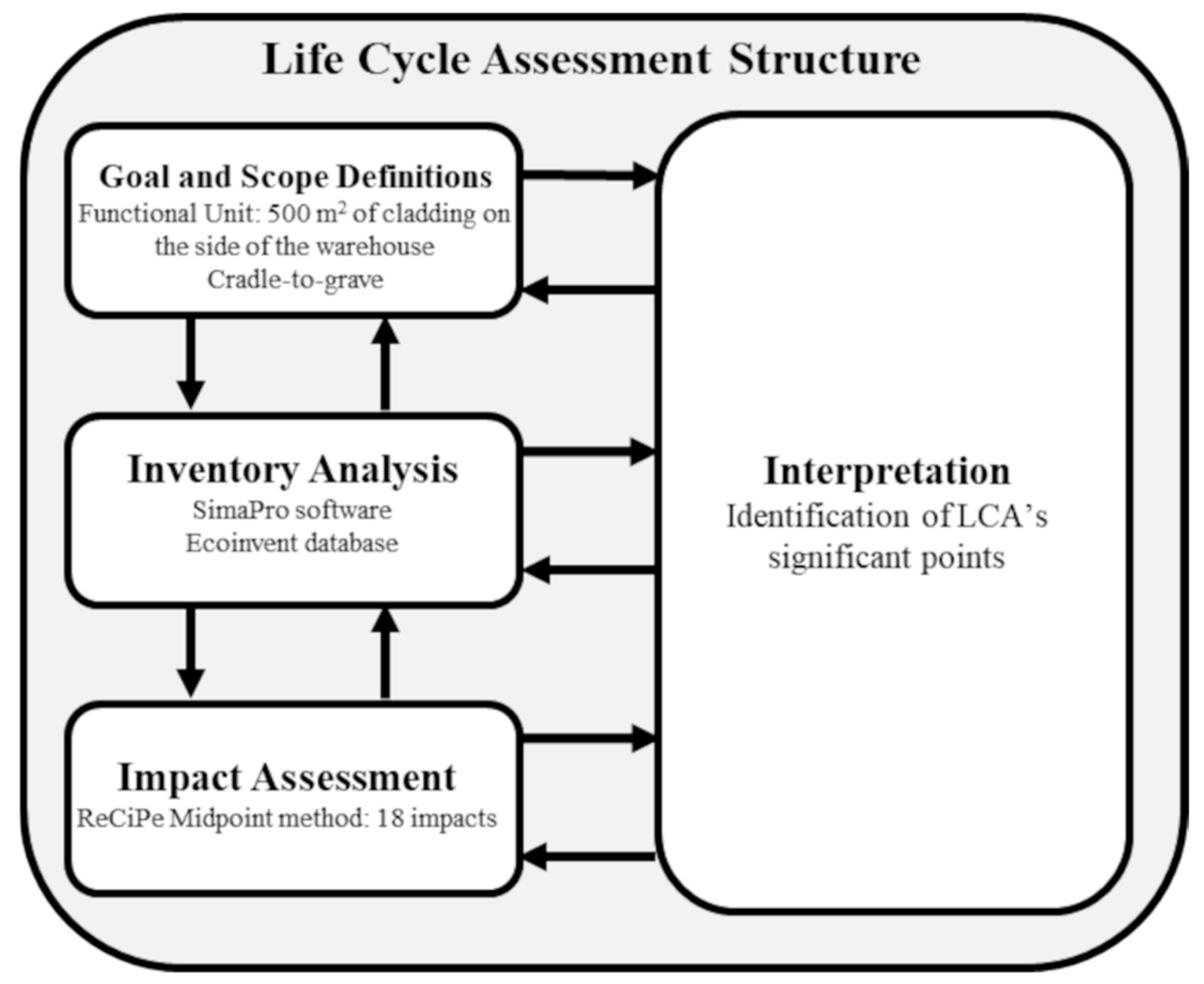

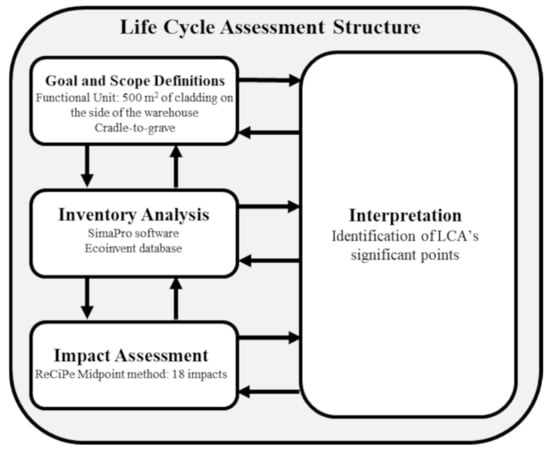

The International Organization for Standardization (ISO) established the principles of LCA in its 14040 series of standards. A four-phase structure was developed to guide the process: (i) definition of the objectives and boundaries, (ii) inventory analysis, (iii) impact assessment, and (iv) interpretation [23,24]. The initial phase comprehensively examines the research context, including the study objective, the target audience, the system boundary, and the functional unit [44,47]. The second stage of the process collects data, establishes the LCA model, and derives Life Cycle Inventory (LCI) results [48]. The third phase determines the overall impact of consuming resources (inputs) and environmental emissions (outputs) during the various life cycle phases of the product. The objective is to gain insight into and quantify the potential environmental impacts. The interpretation phase aims to evaluate the completeness, sensitivity, and consistency of the data, identify any limitations in the conclusions drawn, and make recommendations based on the findings of the previous phases of the LCA [49].

LCA has gained importance with the current push for green building [3,50]. LCA can offer valuable insights into material, water, and energy consumption throughout a building’s predicted lifespan [51]. It should be noted that the introduction of LCA to buildings is a recent development [5]. It has been used in the architectural and construction industries to assess sustainability [46] and has been integrated into assessing the environmental performance of buildings and construction projects [52]. The building LCA literature is relatively dispersed, spread across several publications [3]. Buildings differ from general consumer products [53]. A building can include thousands of products, each with its own life cycle [10]. It is challenging to compare the case studies presented in the literature, as each project has unique characteristics, including the building type, climate, and comfort standards, as well as the regulatory environment in each location [3].

3. Materials and Methods

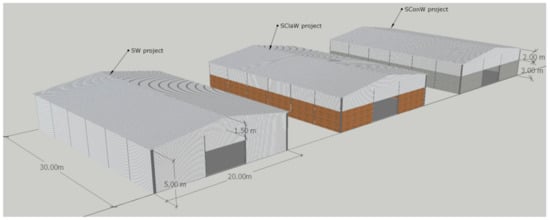

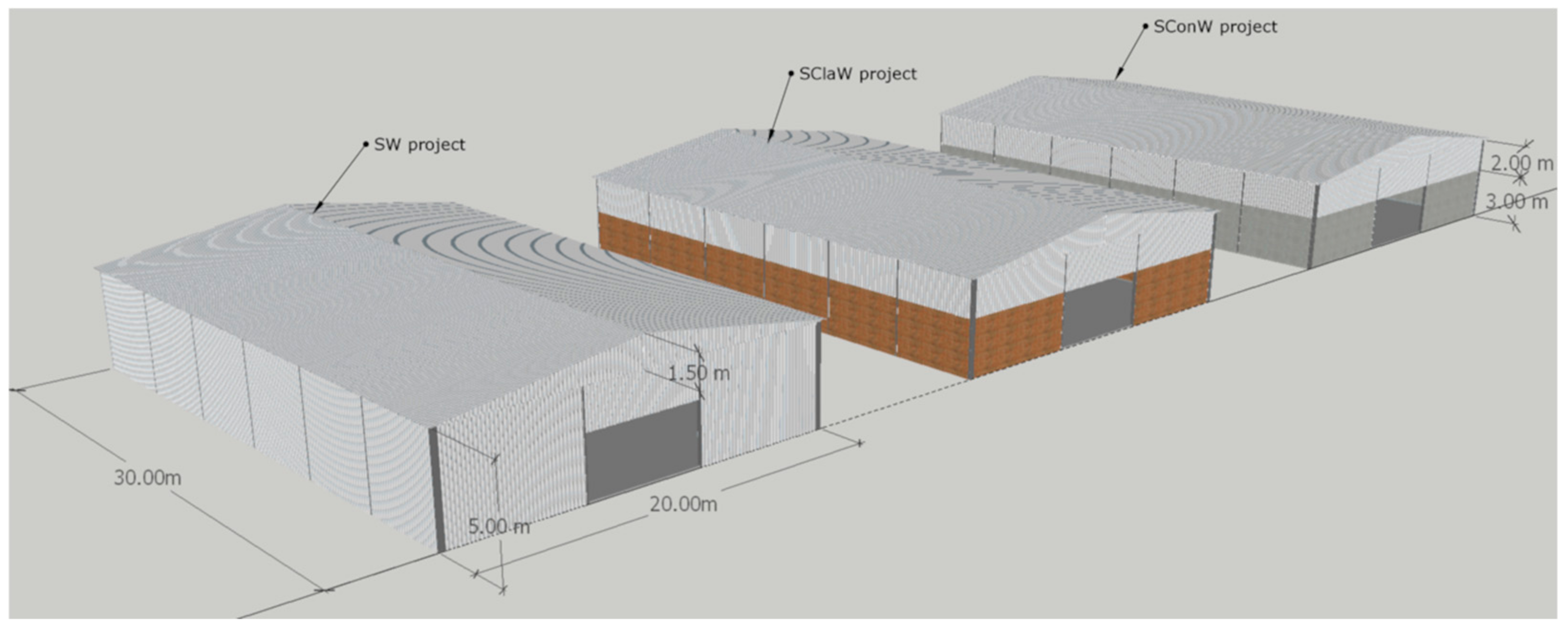

This study involved analysis of three warehouses using LCA. The structures are made of hot-rolled profiles and were modeled to align with the specified boundary conditions, namely the precise dimensions. The plan dimensions of this study comprise an area of 600 m2, with a length of 30 m, a width of 20 m, and a height of 5 m. The steel warehouses were designed in Pato Branco (State of Paraná) in Brazil, where this type of building is typical for storing agricultural, industrial, and commercial materials.

As shown in Figure 1, the difference between the warehouses is in the cladding system of the structures. The three case studies are:

- Steel Walls (SW): galvanized steel walls;

- Steel Clay Brick Walls (SClaW): walls made of clay brick (3 m) and galvanised steel (2 m);

- Steel Concrete Block Walls (SConW): concrete block masonry walls (3 m) and galvanized steel (2 m).

Figure 1.

Warehouse projects: SW, SClaW, and SConW.

Figure 1.

Warehouse projects: SW, SClaW, and SConW.

Comparison among the three cladding systems—Steel Walls (SW), Steel Clay Brick Walls (SClaW), and Steel Concrete Block Walls (SConW)—is important due to their distinct material compositions, construction processes, and environmental profiles. Each system combines materials with varying environmental impacts, durability, and end of life. SWs have functional benefits concerning weather resistance, durability, and non-combustibility. Being lightweight, with good spanning ability, they can be installed quickly and easily with minimal waste [54]; however, their cost is high, so it is advisable to study cladding alternatives such as SClaWs and SConWs, which can offer reduced costs and high availability of labor and materials. By analyzing these three alternatives under the same functional and structural conditions, this study aimed to isolate the influence of the cladding system on the overall environmental performance of steel warehouses, providing valuable insights for material selection and sustainable design strategies.

ASTM A36 [55] and ASTM A572 Gr.50 [56] steels were used to size the structural elements. The roof was closed with AM TP-40 [57] trapezoidal sheet galvanized steel tiles with a thickness of 0.5 mm and a 5% slope. The Brazilian technical standards used were those for “Design of steel structures and mixed steel and concrete building structures” (NBR 8800:2008) [58]; “Cold-formed steel sections—Design” (NBR 14762:2010) [59]; “Loads for Calculating Building Structures” (NBR 6120:2019) [60]; and “Wind forces on buildings” (NBR 6123:2023) [61]. Sizing will not be covered in this article.

Conducting the Life Cycle Assessment

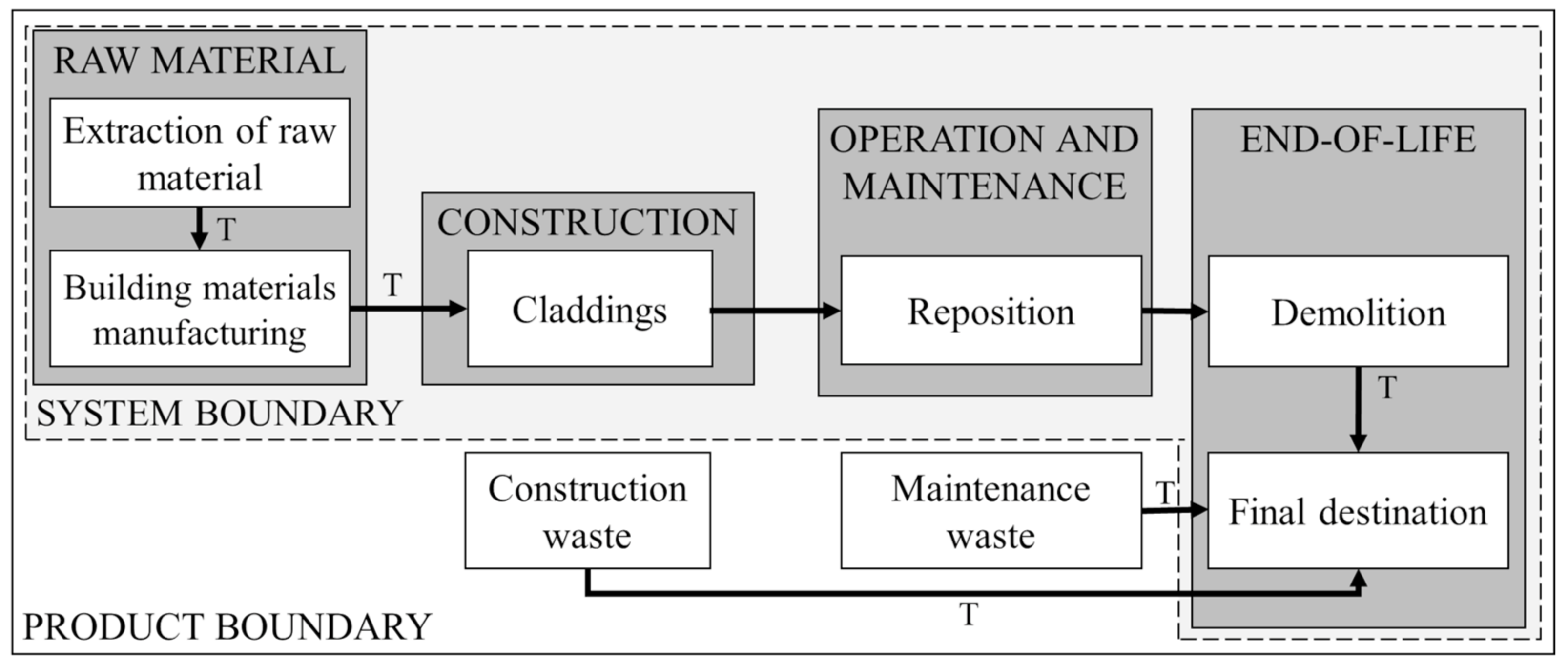

The Life Cycle Assessment was carried out on the warehouse projects, as illustrated in Figure 2. Cradle-to-grave LCA was employed to ascertain environmental impacts and evaluate the projects’ environmental performance throughout their life cycles. These results will inform decisions on more sustainable materials and construction techniques for future environmentally preferable projects. The functional unit used is 500 m2 of cladding on the side of the warehouse.

Figure 2.

Life Cycle Assessment Structure.

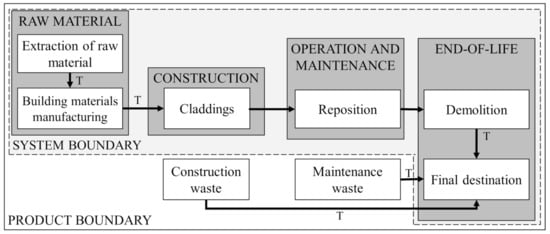

Figure 3 presents the system’s frontier as the whole warehouse life cycle. Construction and maintenance waste were excluded because reliable and site-specific data on waste generation during construction and maintenance activities for warehouse projects are scarce and highly variable, depending on project management practices, workforce behavior, and local regulations.

Figure 3.

Product system and boundaries of the study system.

The life cycle inventory was built from the structural designs of the projects. The reference flow was used as the basis for the inventory, which comprises the materials required to perform the given function. A life cycle inventory analysis includes compiling and measuring the inputs and outputs relating to the materials throughout a project’s life cycle.

The operation and maintenance stage considers the necessary replacement of materials during the use of the building. ABNT NBR 15575 (2024) [62] was used as the criterion for defining durability compatible with the project’s Useful Life (UL). The reposition factor (RF) was calculated by dividing the construction’s useful life by the material’s useful life minus 1, as shown in Equation (1).

A useful life of 50 years was considered for the warehouses. To identify the amount of material that would need to be replaced during the operational phase, the quantity of the item in the system was multiplied by the reposition factor (RF). The minimum expected useful life of the cladding system, according to ABNT NBR 15575 (2024) [62], was considered to be 40 years. Therefore, the replacement factor (RF) used was 0.25.

The end-of-life phase considered the final disposal of waste in accordance with Resolution Number 307 of 2002 of the Brazilian National Environment Council (CONAMA) [63]. Class A waste is clay brick, concrete block, and cement mortar, for which final disposal in an inert landfill is recommended. Steel tiles are considered class B waste and should be sent to a sanitary landfill. In addition to each of these destinations, there is also the possibility of recycling this waste. Based on the construction scenario described by Vilčeková et al. (2023) [64], this article proposes two different end-of-life scenarios. Scenario 1 represents a more conventional disposal route (sanitary or inert landfilling), which still predominates in several regions, as in a study carried out by Evangelista et al. (2018) [26].

In contrast, Scenario 2 considers implementing recycling strategies aligned with circular economy principles for steel, clay bricks, concrete blocks, and cement mortar [65,66,67]. By analyzing these two scenarios side by side, this study tried to capture how material choices combined with waste management strategies can alter the overall environmental performance of warehouse structures. Table 1 shows the cladding system quantities of the warehouse projects. The end-of-life scenarios considered can be seen in Table 2.

Table 1.

Cladding system material quantities of warehouse projects.

Table 2.

Post-operational scenarios.

SimaPro (System for Integrated Environmental Assessment of Products) software was used in this study. SimaPro follows international guidelines such as ISO 14040/14044, allowing product system and process modeling, covering all life cycle stages. SimaPro was adopted in this study because it is a widely used and validated tool for carrying out Life Cycle Assessments (LCA) in various sectors, including the construction industry [68,69,70,71]. SimaPro offers direct integration with widely recognized databases such as Ecoinvent, which was used in this article. Ecoinvent is one of the world’s most representative certified eco-inventory databases [72]. Among the impact assessment methods included in SimaPro is ReCiPe 2016, which translates various environmental impacts into a set of indicators, allowing for evaluation of potential environmental harm associated with products, processes, or activities. The 18 midpoint categories of the ReCiPe 2016 method focus on single environmental problems and provide characterization factors that are representative of the global scale, while maintaining the possibility of using several impact categories to implement characterization factors at country and continental scales [73].

The Faculty license for version 9.6.0.1 of SimaPro was utilized. Data were extracted from Ecoinvent v3.10 international database. The process used can be seen in Table 3.

Table 3.

SimaPro processes.

The ReCiPe 2016 Midpoint, in its hierarchical perspective assessment, was quantified. The interpretation identified the key points of the LCA based on the inventory results and their impacts. The projects were evaluated, and the study’s conclusions and limitations were outlined.

4. Results

4.1. Midpoint Impacts

The midpoint impacts analyzed include: “Global warming potential” (GWP), “Stratospheric ozone depletion” (ODP); “Ionizing radiation” (IRP); “Ozone formation, human health” (HOFP); “Fine particulate matter formation” (PMFP); “Ozone formation, terrestrial ecosystems” (EOFP); “Terrestrial acidification” (TAP); “Freshwater eutrophication” (FEP); “Marine eutrophication” (MEP); “Terrestrial ecotoxicity” (TETP); “Freshwater ecotoxicity” (FETP); “Marine ecotoxicity” (METP); “Human carcinogenic toxicity” (HTPc); “Human non-carcinogenic toxicity” (HTPnc); “Land use” (LOP); “Mineral resource scarcity” (SOP); “Fossil resource scarcity” (FFP); and “Water consumption” (WCP).

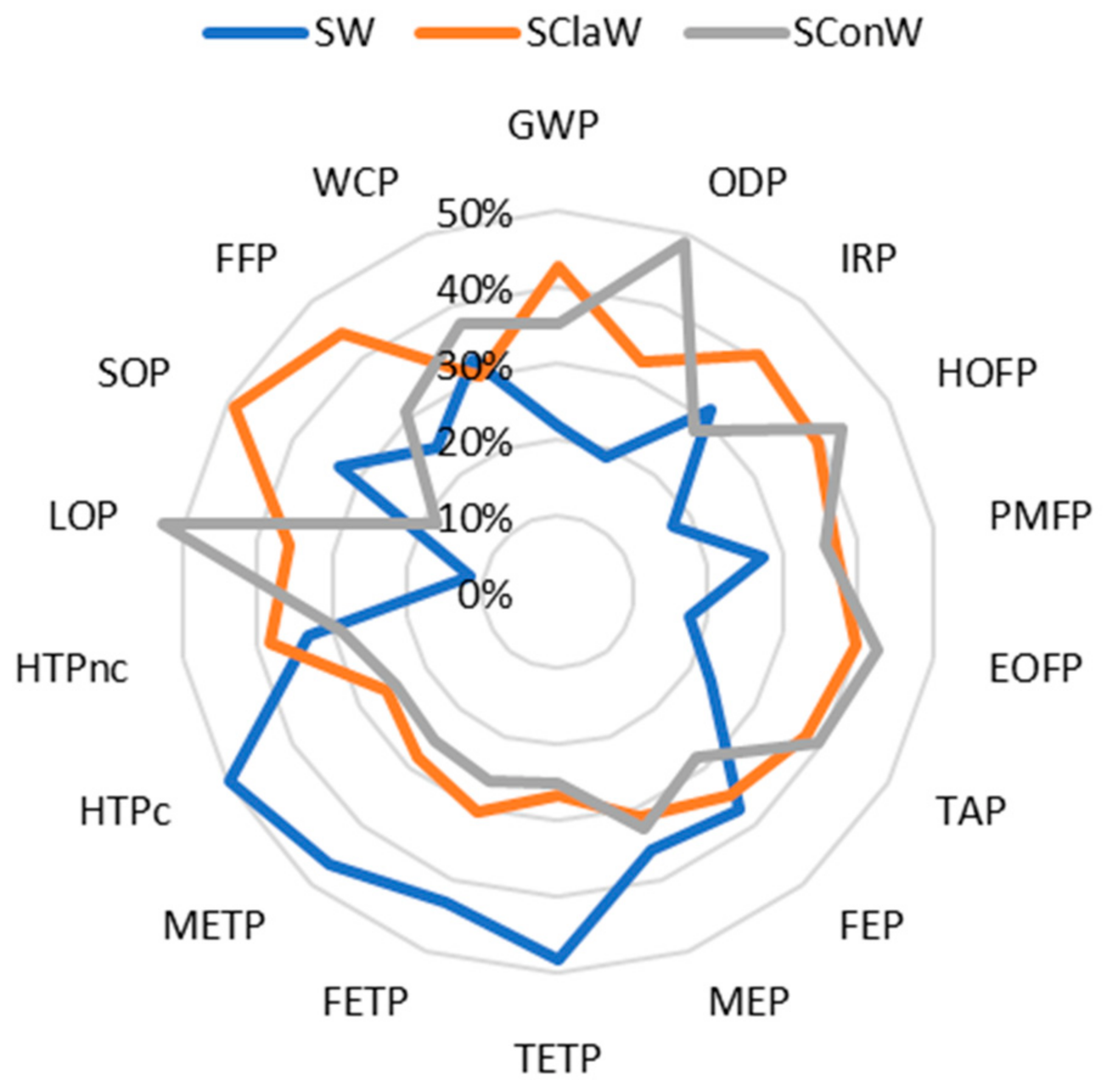

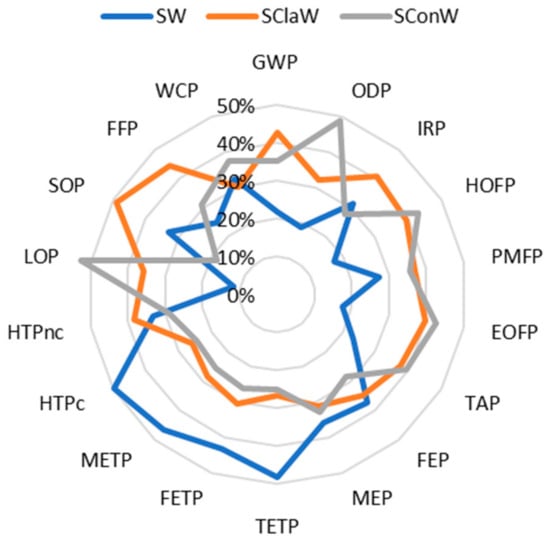

4.1.1. Pre-Operational and Operational Stage

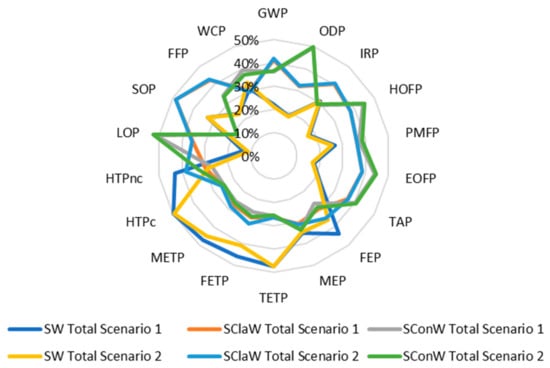

All materials used generated potential environmental impacts in all categories during the production and construction processes. However, each project analyzed which processes contribute most to generating potential impacts. In the operational stage, environmental impact is similar to that identified in the pre-operational stage, as the RF, equal to 0.25, was the same for all three projects. Hence, the absolute value of the environmental impacts shown in the operational stage represents 25% of the environmental impacts of the pre-operational stage. In this way, the impacts were added together for joint analysis of the pre-operational and operational phases. Figure 4 shows the comparison of midpoint impacts.

Figure 4.

Pre-operational and operational stage midpoint impacts.

As shown in Figure 4, there are variations in the effects depending on the category analyzed.

The SW project generated higher impacts in six categories. Steel production involves mining iron ore and metallurgical coal, as well as industrial processes that release nutrients and compounds such as phosphorus and nitrogen into bodies of water, which contribute to categories “Freshwater eutrophication” and “Marine eutrophication”. The tailings generated in the production process are rich in heavy metals (such as cadmium, lead, mercury, and zinc), as well as toxic chemical compounds such as cyanides and polycyclic aromatic hydrocarbons (PAHs), which increase the impacts of the categories “Terrestrial ecotoxicity”, “Freshwater ecotoxicity”, and “Marine ecotoxicity”. Human exposure to compounds released during the production and use of steel contributes to the “Human carcinogenic toxicity” category.

The SClaW project had the most significant environmental impacts in six categories. The production of clay bricks consumes large volumes of mineral raw materials and is dependent on burning coal, oil, and natural gas, which contributes to “Mineral resource scarcity” and “Fossil resource scarcity”. Burning fossil fuels releases large quantities of CO2, which increase the values of “Global warming potential”, and also releases fine particles (PM2.5 and PM10). “Fine particulate matter formation” is also related to the dust generated during the extraction and transportation of clay. The clay used to make the blocks may contain naturally occurring radioactive elements that emit “Ionizing radiation” that contribute to increasing “Human non-carcinogenic toxicity”.

The SConW project generated more environmental impacts in six categories. Cement production, the main component of concrete blocks, can involve the use of substances that contribute to “Stratospheric ozone depletion”, such as certain nitrogen oxides and compounds released in manufacturing chemical additives. The fuels used during the production of concrete can release ozone precursors, which, when reacting in the atmosphere under sunlight, form tropospheric ozone, can interfere with human health and biodiversity (“Ozone formation, Human health”, “Ozone formation Terrestrial ecosystems”). Also, during the manufacturing process, sulfur dioxide (SO2) and nitrogen oxides are released, and these compounds can dissolve in rainwater and generate “Terrestrial acidification”. The production of concrete involves the use of sand, gravel, and water, which have a direct impact on “Land use” and “Water consumption”.

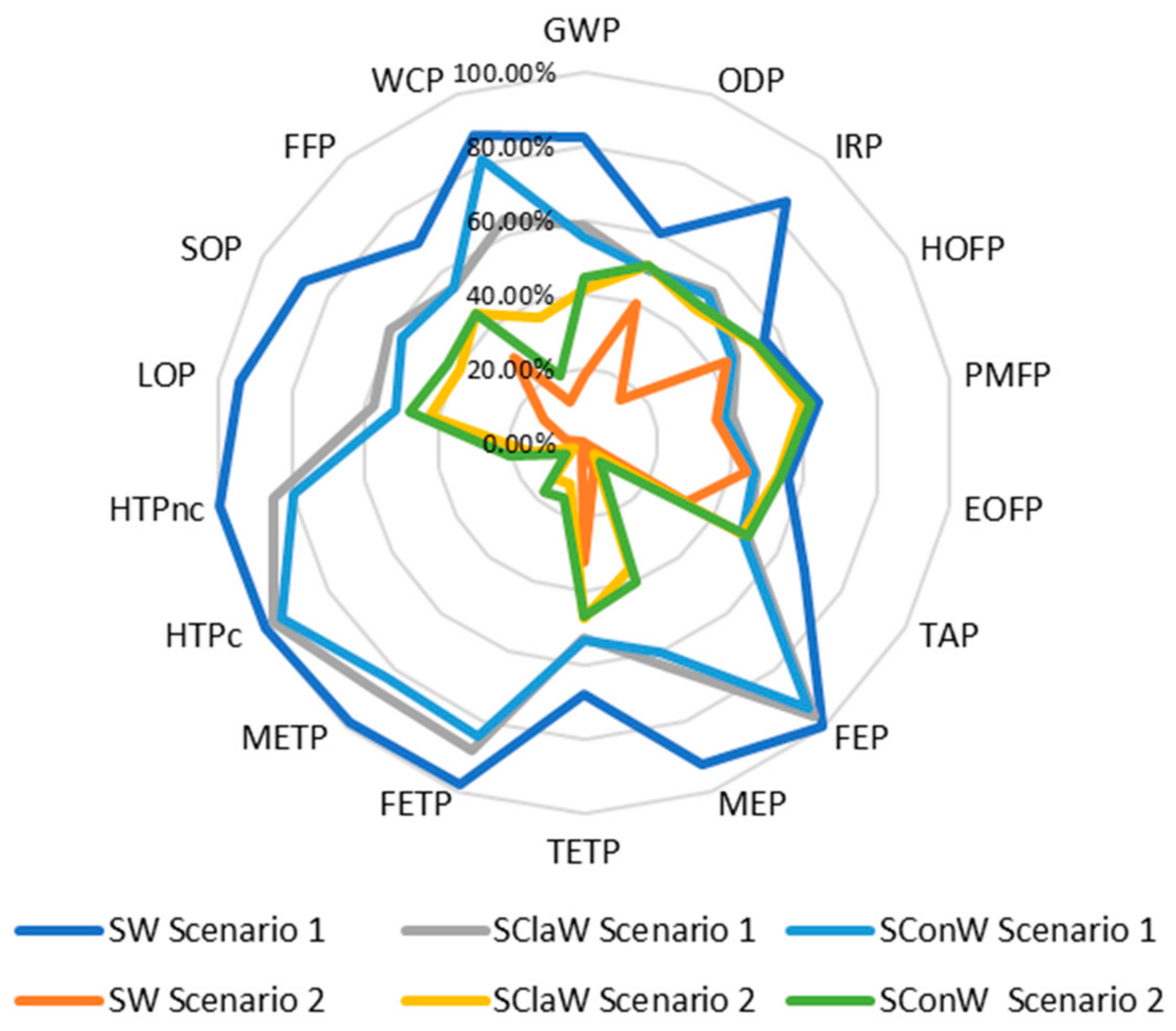

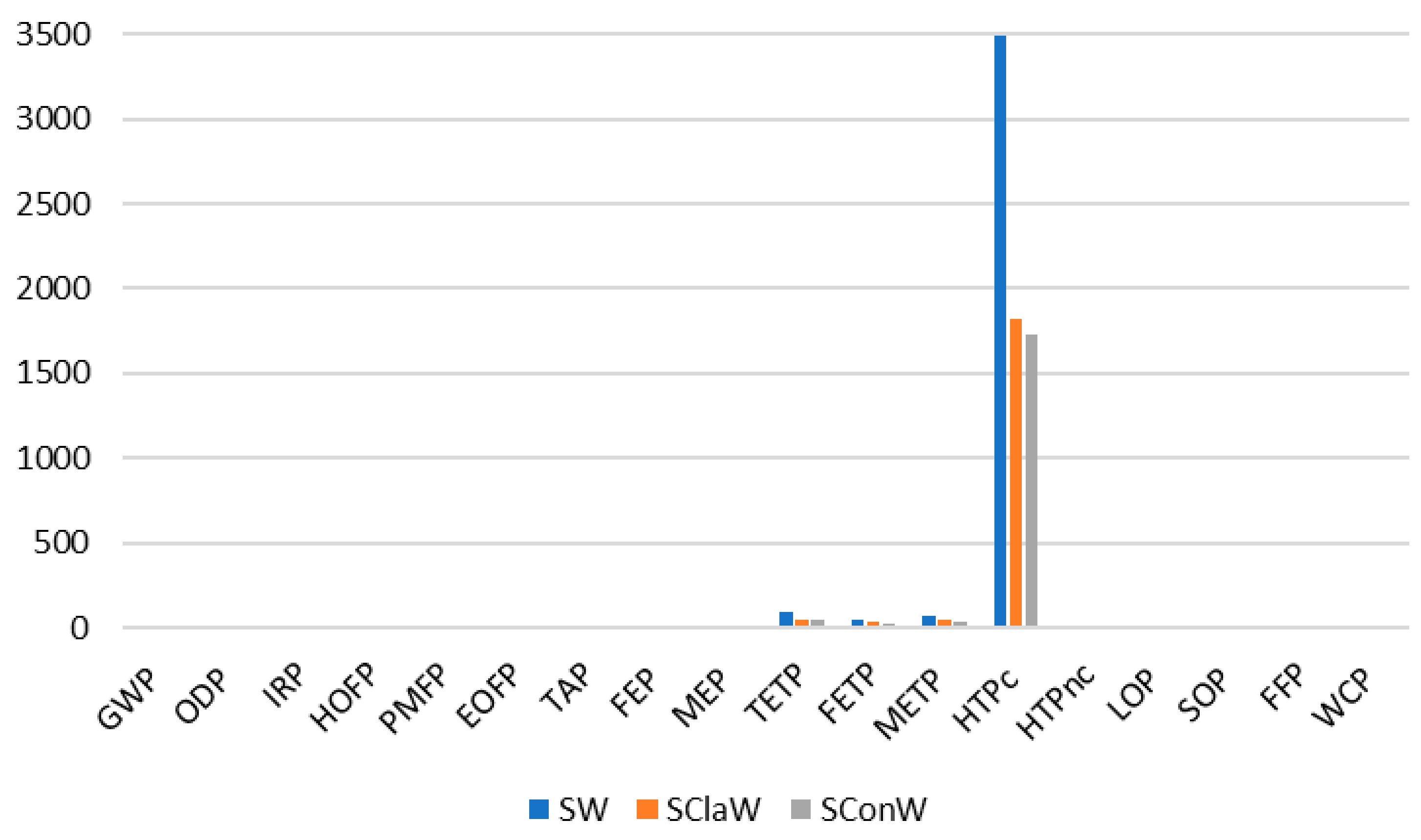

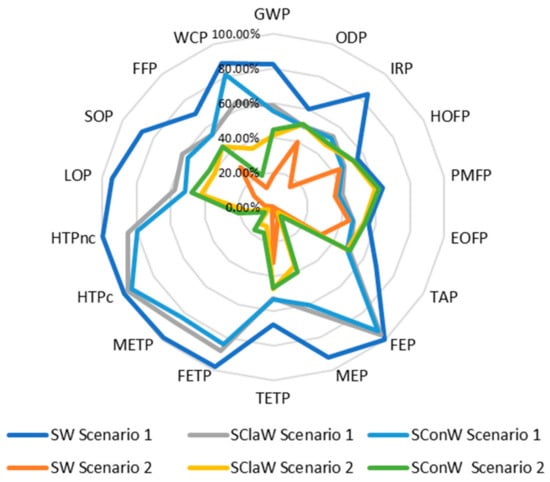

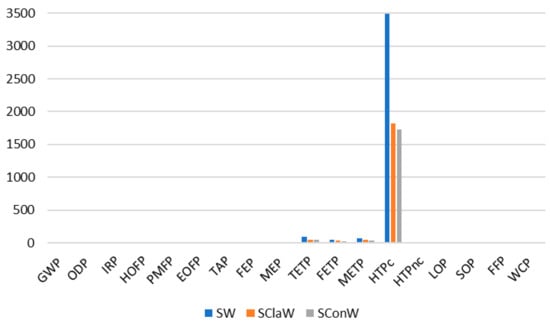

4.1.2. Post-Operational Stage

The post-operational stage considered two end-of-life scenarios for the warehouses, aiming to identify the most appropriate disposal alternative for the SW, SClaW, and SConW projects. Scenario 1 involved sending the waste to landfills: Class B waste (steel) to a sanitary landfill and Class A waste (clay brick, cement mortar, and concrete block) to an inert waste landfill. Scenario 2 involved sending both Class B and Class A waste for recycling. The results can be seen in Figure 5.

Figure 5.

Post-operational stage midpoint impacts.

According to Figure 5, Scenario 2—waste recycling—proved to be environmentally more advantageous for all three projects, as it resulted in significantly lower environmental impacts compared to Scenario 1. The SW Project achieved the best environmental performance under Scenario 2. Under Scenario 1—landfill—the SW Project also exhibited the highest impacts, particularly in the categories of “Global warming potential”, “Fossil resource scarcity”, “Human carcinogenic toxicity”, “Human non-carcinogenic toxicity”, and “Water consumption”. Disposing of steel in sanitary landfills represents a loss of a 100% recyclable material, which consequently increases the demand for iron ore extraction, water and energy consumption, and emissions associated with the extraction and production of virgin materials. In landfills, the oxidation of steel may lead to the release of metallic oxides, which can pose risks to human health through soil contamination. The SClaW and SConW projects also exhibited higher impacts in Scenario 1 compared to Scenario 2; however, the difference between the scenarios was less pronounced than for the SW Project.

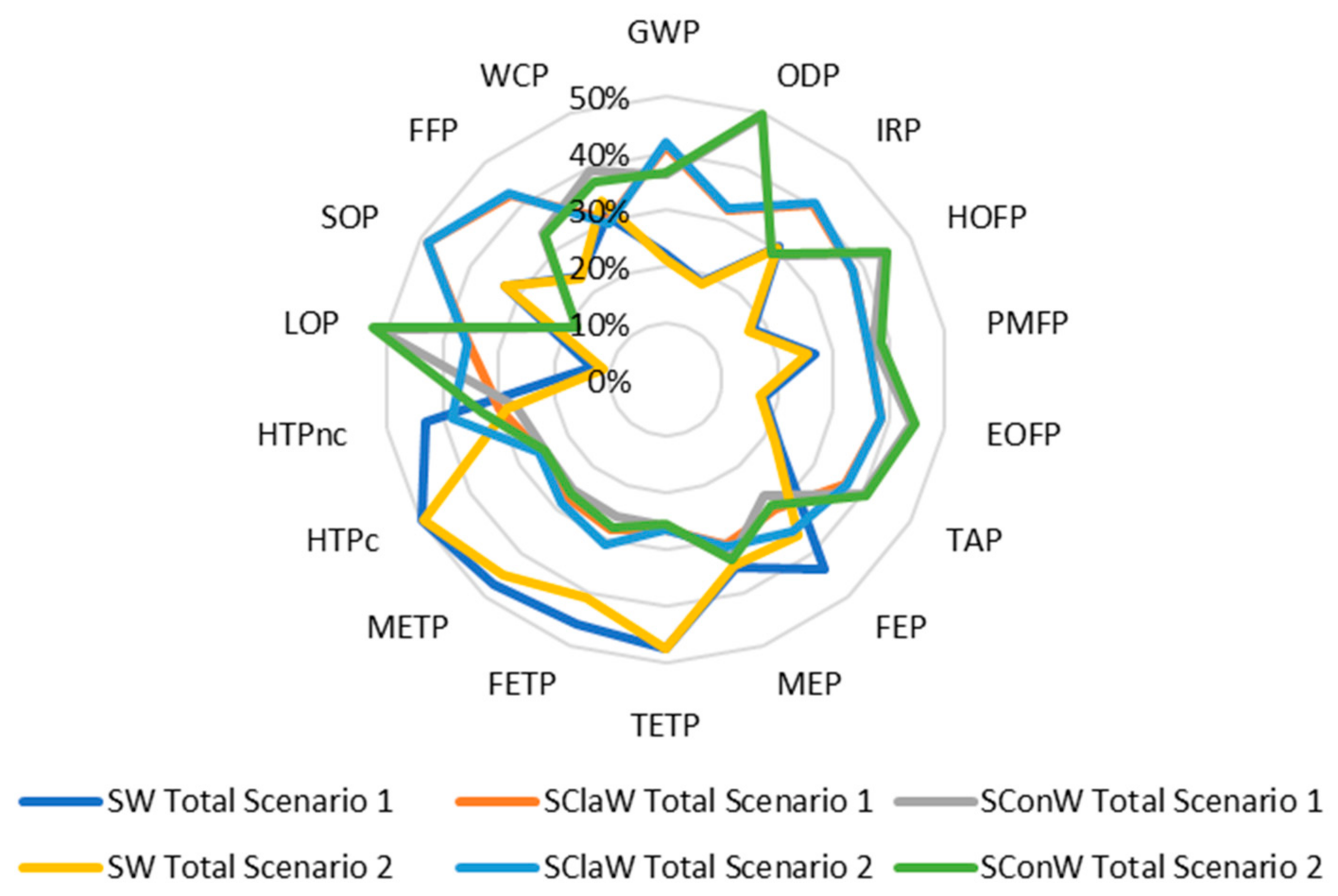

4.1.3. Whole Life Cycle

As shown in Figure 6, the SW Project under end-of-life Scenario 2 demonstrated the best environmental performance, with notably lower impacts in nine categories related to atmospheric emissions (“Global warming potential”, “Stratospheric ozone depletion”, “Ozone formation—human health”, “Fine particulate matter formation”, “Ozone formation—terrestrial ecosystems”), human health (“Human non-carcinogenic toxicity”), and land use and natural resources (“Terrestrial acidification”, “Land use”, “Fossil resource scarcity”). The SConW Project under Scenario 2 showed lower environmental impacts in seven categories associated with toxicity (“Terrestrial ecotoxicity”, “Freshwater ecotoxicity”, “Marine ecotoxicity”, “Human carcinogenic toxicity”, “Freshwater eutrophication”), radioactivity (“Ionizing radiation”), and mineral resource use (“Mineral resource scarcity”).

Figure 6.

Whole life cycle midpoint impacts.

The worst environmental performance was observed in the SW Project under end-of-life Scenario 1, with higher impacts in seven categories compared to the other analyses. These categories are primarily related to toxicity (“Terrestrial ecotoxicity”, “Freshwater ecotoxicity”, “Marine ecotoxicity”, “Human carcinogenic toxicity”, “Human non-carcinogenic toxicity”) and aquatic ecosystem pollution (“Freshwater eutrophication”, “Marine eutrophication”). This outcome is likely associated with releasing toxic contaminants during material decomposition or final disposal. These findings underscore the importance of incorporating recycling and material reuse practices into the production chain, particularly in construction systems with high material input, such as steel.

Table 4 summarizes the LCA results for each cladding system under both end-of-life scenarios, showcasing specific numerical data such as percentage reductions and increases according to the SW Project under end-of-life Scenario 2 as a reference.

Table 4.

Whole life cycle midpoint impact comparison.

Despite the environmental performance verified for the SW Project under end-of-life Scenario 2, the relative significance among the impact categories is worth highlighting. In the normalized results, shown in Figure 7, the most critical impact categories were related to toxicity, whose contributions were considerably higher than that of the “Global warming potential” category—traditionally used as a reference in environmental impact discussions. This indicates that the analyzed warehouse project generated more significant environmental impacts near its production and application sites. The “Human carcinogenic toxicity” category suggested that occupational or environmental exposure from handling hazardous substances may adversely affect human health and ecosystems, particularly water resources.

Figure 7.

Normalized midpoint impacts.

5. Discussion

Life Cycle Assessment (LCA) is an invaluable tool, not only because it enables comparison of construction solutions but also because it facilitates identification of the factors and systems that contribute most to environmental impact. Once the main impact sources are identified, targeted efforts can be made to mitigate these effects through material improvements and substitution.

Each project, through its unique material composition and production processes, reveals a distinct environmental footprint, offering insights into the areas where improvements can be made to reduce overall environmental impacts. The results from the analyzed structures indicate that the midpoint impact assessments pointed to the SW project under end-of-life Scenario 2 as having the best environmental advantages compared to the SClaW and SConW projects. This indicates the importance of recycling and material reuse practices, particularly in construction systems that rely heavily on material input, such as steel. The results compile the impacts of extracting raw materials and processing steel, clay brick, concrete blocks, and cement mortar. The raw materials include recycled steel scrap, iron ore, limestone, coal, renewable energy sources, and various other materials in different amounts, such as air, oil, refractories, chemicals, alloys, refining materials, and water. These materials are supplied by road, rail, sea, or river and usually require handling and transport within the plant, and eventually storage and blending [74,75] (UNEP, 1997; UNEP; Industry and Environment Office, 1984). The combustion of fossil fuels utilized in the production and transportation phases leads to the emission of greenhouse gases (GHGs), including methane (CH4), carbon dioxide (CO2), sulfur hexafluoride (SF6), and nitrous oxide (N2O), as well as two groups of gases: perfluorocarbons (PFCs) and hydrofluorocarbons (HFCs). They cause “Global warming potential”, i.e., the indicator that measures increases in average global temperatures. This directly impacts ecosystems, such as heat waves and deaths caused by other extreme events like hurricanes and floods. However, these effects are often indirect, through changes in the environment, such as changes in biogeochemical cycles, which can affect human health by increasing the incidence of infectious and non-communicable diseases like malnutrition and mental illness [76].

Raw material extraction interferes with the number of resources available on the planet, and “Fossil resource scarcity” may lead to non-availability of fossil fuels for future generations. Many construction companies also own and operate large underground or surface mines. Dust is generated during surface operations such as quarrying, transporting, crushing, grinding, and sizing. Sintering, smelting, and melting produce very fine fumes. Cokemaking produces fine coal, coke, and tar emissions, while the heating of limestone in a kiln can generate a fine white emission. Particulate matter formation alters air quality and is harmful to human health. The cumulative effects of particulate matter in the form of smoke particles and other elements on the breathing tract can affect those vulnerable to respiratory and heart disease [66,67].

In addition to human health, particulate matter deposition on plant leaves’ surfaces can decrease the exchange of gases and photosynthesis. Combining these with other pollutants can cause the plant to stop growing or to be damaged. Particulate matter can also be lightly dispersed and cause atmospheric smog, reducing visibility and sunlight transmission, causing contamination and erosion of buildings, materials, and paintwork, increasing the cost of cleaning and maintenance, and reducing property values [66].

In the context of the materials steel, clay brick, concrete block, and cement mortar, the environmental impacts can vary significantly depending on the end-of-life (EOL) scenarios considered, such as landfills (Scenario 1) and recycling (Scenario 2). Life Cycle Assessment of these materials (LCA) sheds light on how their disposal or recycling influences overall sustainability and environmental impact.

6. Conclusions

This article presented LCA of steel warehouse projects. The study evaluated three steel warehouse projects, considering the environmental sustainability dimension. The results showed that the steel wall project (SW) under the end-of-life Scenario 2—waste recycling—had the shortest environmental consequence in 9 of the 18 midpoint impact categories assessed, even though the steel material comes from a production supplier chain that generates high impacts and consumes many natural resources. Within the context analyzed, the SW project generated the least environmental impact and damage compared to incorporating clay bricks, cement blocks, and cement mortar.

Despite the large quantity and versatility of steel warehouses, studies are lacking to help designers make sustainable choices in this type of construction. In addition, most studies investigating applying LCA tools to warehouse evaluation consider only carbon dioxide or embodied energy to evaluate the impacts. Furthermore, when normalizing the impacts across all categories, it was observed that toxicity-related categories—such as “Human carcinogenic toxicity” and various forms of ecotoxicity—present significantly higher impacts than “Global warming potential”. This suggests that the environmental impacts of the analyzed warehouse projects are particularly concerning in the vicinity of production and application sites. These categories point to potential risks to human health and ecosystems, especially concerning occupational and environmental exposure.

According to the proposed approach, decision makers can check potential points for improvement in the life cycle of the steel warehouse considered. In this context, LCA results can help develop new steel warehouse projects that use smaller quantities of materials and natural resources or even use a combination of different construction typologies.

This study highlights and encourages the development of methodologies to minimize problems related to climate change adaptation, mitigation, and human health issues caused by steel warehouses. These approaches can contribute directly to the 2030 Agenda through SDG 3—“Good Health and Well-Being”, SDG 9—“Industry, Innovation and Infrastructure”, SDG 11—“Sustainable Cities and Communities”, and SDG 13—“Climate Action”.

Despite providing relevant insights into the environmental impacts associated with the analyzed construction materials—steel, clay bricks, concrete blocks, and cement mortar—this study presents some limitations that must be acknowledged. Although a cradle-to-grave Life Cycle Assessment (LCA) approach was adopted, the system boundaries excluded waste generated during the construction and maintenance phases. This decision was based on the lack of reliable, project-specific data for warehouse projects and aimed to ensure consistency in comparison among structural alternatives. The scope was also restricted to a limited number of cladding systems without exploring all possible construction alternatives. Moreover, the analysis focused exclusively on environmental sustainability indicators, leaving out economic and social dimensions that are equally relevant for integrated decision-making. Another important constraint is the scarcity of Brazilian Life Cycle Inventory (LCI) data, which may affect the regional representativeness of the results. Although internationally recognized databases such as Ecoinvent were used, the dependence on secondary sources and the absence of updated or empirically validated primary data may have introduced uncertainty into the estimates.

Future studies are encouraged to expand the range of construction systems analyzed, incorporate more regionally representative LCI data, and include economic and social indicators to provide a more holistic sustainability assessment. Additionally, operational performance aspects such as thermal comfort should be explored to broaden the applicability of the findings to real-world projects.

Author Contributions

Conceptualization, P.C.V.J.; methodology, P.C.V.J., M.K. and V.Y.; formal analysis, P.C.V.J.; data curation, P.C.V.J.; writing—original draft preparation, P.C.V.J., M.K., V.Y. and F.O.; writing—review and editing, P.C.V.J., F.O., M.K. and V.Y.; supervision, M.K. and V.Y.; project administration, M.K. and V.Y.; funding acquisition, M.K. and V.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financed in part by the Brazilian National Council for Scientific and Technological Development (Grant CNPq305484/2023-0), Grant PID2023-150003OB-I00 funded by MCIN/AEI/10.13039/501100011033, and the European Regional Development Fund (ERDF), a program of the European Union (EU).

Data Availability Statement

All data generated or analyzed during this study are included in this published article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Silva, E.N.D.; De Brito Mello, L.C.B.; Pinto, G.O. Challenges for Lean Construction Adoption in the Brazilian Industry: A Study in Construction Companies, Universities and Class Organizations. Constr. Innov. 2022, 23, 1130–1150. [Google Scholar] [CrossRef]

- Habiba, U.; Xinbang, C. The Impact of Financial Development on CO2 Emissions: New Evidence from Developed and Emerging Countries. Environ. Sci. Pollut. Res. 2022, 29, 31453–31466. [Google Scholar] [CrossRef] [PubMed]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life Cycle Assessment (LCA) and Life Cycle Energy Analysis (LCEA) of Buildings and the Building Sector: A Review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Asif, M.; Muneer, T.; Kelley, R. Life Cycle Assessment: A Case Study of a Dwelling Home in Scotland. Build. Environ. 2007, 42, 1391–1394. [Google Scholar] [CrossRef]

- Abd Rashid, A.; Idris, J.; Yusoff, S. Environmental Impact Analysis on Residential Building in Malaysia Using Life Cycle Assessment. Sustainability 2017, 9, 329. [Google Scholar] [CrossRef]

- Peuportier, B. Life Cycle Assessment Applications in the Building Sector. Int. J. Environ. Technol. Manag. 2008, 9, 334. [Google Scholar] [CrossRef]

- Gervasio, H.; Dimova, S.; Pinto, A. Benchmarking the Life-Cycle Environmental Performance of Buildings. Sustainability 2018, 10, 1454. [Google Scholar] [CrossRef]

- Cuéllar-Franca, R.M.; Azapagic, A. Environmental Impacts of the UK Residential Sector: Life Cycle Assessment of Houses. Build. Environ. 2012, 54, 86–99. [Google Scholar] [CrossRef]

- Gong, Y.; Tae, S.; Suk, S.; Chae, C.; Ford, G.; Smith, M.E.; Steffen, R. Life Cycle Assessment Applied to Green Building Certification in South Korea. Procedia Eng. 2015, 118, 1309–1313. [Google Scholar] [CrossRef]

- Vieira Neto, J.; Farias Filho, J.R.D. Sustainability in the Civil Construction Industry: An Exploratory Study of Life Cycle Analysis Methods. Int. J. Environ. Technol. Manag. 2013, 16, 420. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Bai, Q.; Bertoldi, P.; Kihila, J.M.; Lucena, A.F.P.; Mata, É.; Mirasgedis, S.; Novikova, A.; Saheb, Y. Buildings. In Climate Change 2022—Mitigation of Climate Change; Intergovernmental Panel on Climate Change (IPCC), Ed.; Cambridge University Press: Cambridge, UK, 2023; pp. 953–1048. ISBN 978-1-00-915792-6. [Google Scholar]

- Bilec, M.M.; Ries, R.J.; Matthews, H.S. Life-Cycle Assessment Modeling of Construction Processes for Buildings. J. Infrastruct. Syst. 2010, 16, 199–205. [Google Scholar] [CrossRef]

- de Lassio, J.; França, J.; Espirito Santo, K.; Haddad, A. Case Study: LCA Methodology Applied to Materials Management in a Brazilian Residential Construction Site. J. Eng. 2016, 2016, 8513293. [Google Scholar] [CrossRef]

- Gonçalves de Lassio, J.G.; Naked Haddad, A. Life Cycle Assessment of Building Construction Materials: Case Study for a Housing Complex. Rev. Constr. 2016, 15, 69–77. [Google Scholar] [CrossRef]

- Singh, A.; Berghorn, G.; Joshi, S.; Syal, M. Review of Life-Cycle Assessment Applications in Building Construction. J. Archit. Eng. 2011, 17, 15–23. [Google Scholar] [CrossRef]

- Al-Ghamdi, S.G.; Bilec, M.M. Green Building Rating Systems and Whole-Building Life Cycle Assessment: Comparative Study of the Existing Assessment Tools. J. Archit. Eng. 2017, 23, 04016015. [Google Scholar] [CrossRef]

- de Barba, D.J.; Gomes, J.d.O.; de Lacerda, J.F.S.B. Sustainability Assessment in Conventional and Industrialized Systems Built in Brazil. Procedia CIRP 2015, 29, 144–149. [Google Scholar] [CrossRef]

- du Plessis, C. Agenda 21 for Sustainable Construction in Developing Countries: A Discussion Document; CIB&UNEP-IETC, CSIR Building and Construction Technology: Pretoria, South Africa, 2002; ISBN 0-7988-5540-1. [Google Scholar]

- Martínez, F.J.; González-Vidosa, F.; Hospitaler, A.; Yepes, V. Heuristic Optimization of RC Bridge Piers with Rectangular Hollow Sections. Comput. Struct. 2010, 88, 375–386. [Google Scholar] [CrossRef]

- Yepes, V.; Torres-Machí, C.; Chamorro, A.; Pellicer, E. Optimal Pavement Maintenance Programs Based on a Hybrid Greedy Randomized Adaptive Search Procedure Algorithm. J. Civ. Eng. Manag. 2016, 22, 540–550. [Google Scholar] [CrossRef]

- Salas, J.; Yepes, V. Urban Vulnerability Assessment: Advances from the Strategic Planning Outlook. J. Clean. Prod. 2018, 179, 544–558. [Google Scholar] [CrossRef]

- Navarro, I.J.; Yepes, V.; Martí, J.V. A Review of Multicriteria Assessment Techniques Applied to Sustainable Infrastructure Design. Adv. Civ. Eng. 2019, 2019, 6134803. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Andrews, E.S.; Barthel, L.-P.; Tabea, B.; Benoît, C.; Ciroth, A.; Cucuzzella, C.; Gensch, C.-O.; Hébert, J.; Lesage, P.; Manhart, A.; et al. Guidelines for Social Life Cycle Assessment of Products; Benoît, C., Mazijn, B., Eds.; UNEP/SETAC Life Cycle Initiative: Paris, France, 2009; ISBN 978-92-807-3021-0. [Google Scholar]

- Evangelista, P.P.A.; Kiperstok, A.; Torres, E.A.; Goncalves, J.P. Environmental Performance Analysis of Residential Buildings in Brazil Using Life Cycle Assessment (LCA). Constr. Build. Mater. 2018, 169, 748–761. [Google Scholar] [CrossRef]

- Morales, M.; Moraga, G.; Kirchheim, A.P.; Passuello, A. Regionalized Inventory Data in LCA of Public Housing: A Comparison between Two Conventional Typologies in Southern Brazil. J. Clean. Prod. 2019, 238, 117869. [Google Scholar] [CrossRef]

- Muneron, L.M.; Hammad, A.W.; Najjar, M.K.; Haddad, A.; Vazquez, E.G. Comparison of the Environmental Performance of Ceramic Brick and Concrete Blocks in the Vertical Seals’ Subsystem in Residential Buildings Using Life Cycle Assessment. Clean. Eng. Technol. 2021, 5, 100243. [Google Scholar] [CrossRef]

- Paulsen, J.S.; Sposto, R.M. A Life Cycle Energy Analysis of Social Housing in Brazil: Case Study for the Program “MY HOUSE MY LIFE”. Energy Build. 2013, 57, 95–102. [Google Scholar] [CrossRef]

- Vitorio Junior, P.C.; Yepes, V.; Kripka, M. Comparison of Brazilian Social Interest Housing Projects Considering Sustainability. Int. J. Environ. Res. Public Health 2022, 19, 6213. [Google Scholar] [CrossRef] [PubMed]

- Boysen, N.; De Koster, R.; Weidinger, F. Warehousing in the E-Commerce Era: A Survey. Eur. J. Oper. Res. 2019, 277, 396–411. [Google Scholar] [CrossRef]

- Dubey, S.; Singh, A.; Kushwah, S.S. Utilization of Iron and Steel Slag in Building Construction. AIP Conf. Proc. 2019, 2158, 020032. [Google Scholar]

- Rai, D.; Sodagar, B.; Fieldson, R.; Hu, X. Assessment of CO2 Emissions Reduction in a Distribution Warehouse. Energy 2011, 36, 2271–2277. [Google Scholar] [CrossRef]

- Burek, J.; Nutter, D. Life Cycle Assessment of Grocery, Perishable, and General Merchandise Multi-Facility Distribution Center Networks. Energy Build. 2018, 174, 388–401. [Google Scholar] [CrossRef]

- Burek, J.; Nutter, D.W. A Life Cycle Assessment-Based Multi-Objective Optimization of the Purchased, Solar, and Wind Energy for the Grocery, Perishables, and General Merchandise Multi-Facility Distribution Center Network. Appl. Energy 2019, 235, 1427–1446. [Google Scholar] [CrossRef]

- Burek, J.; Nutter, D.W. Environmental Implications of Perishables Storage and Retailing☆. Renew. Sustain. Energy Rev. 2020, 133, 110070. [Google Scholar] [CrossRef]

- Mutlu Ozturk, H.; Dombayci, O.A.; Caliskan, H. Life-Cycle Cost, Cooling Degree Day, and Carbon Dioxide Emission Assessments of Insulation of Refrigerated Warehouses Industry in Turkey. J. Environ. Eng. 2019, 145, 04019062. [Google Scholar] [CrossRef]

- Iancu, I.E.; Moga, L.M. Life Cycle Analysis of Warehouse-Type Constructions. In Proceedings of the 2022: CLIMA 2022 The 14th REHVA HVAC World Congress, Rotterdam, The Netherlands, 22–25 May 2022. [Google Scholar]

- Kyaw, K.S.; Fufa, S.M.; Kraniotis, D. Adaptive Reuse of Industrial Heritage Building—Comparative Life Cycle Assessment Using a Case Study in Norway. IOP Conf. Ser. Earth Environ. Sci. 2023, 1196, 012107. [Google Scholar] [CrossRef]

- Luo, Y.; Tang, X.; Geng, L.; Yao, X.; Li, F.; Li, X.; Wang, Q. A Comprehensive Life Cycle Carbon Footprint Assessment Model for Electric Power Material Warehouses. Energies 2024, 17, 6352. [Google Scholar] [CrossRef]

- Vitorio Junior, P.C.; Costa, M.S. Environmental Assessment of Steel Warehouse: A Case Study in Pato Branco, Brazil. CLCS 2024, 17, e13990. [Google Scholar] [CrossRef]

- Remmen, A.; Jensen, A.A.; Frydendal, J. Life Cycle Management—A Business Guide to Sustainability; UNEP DTIE: Paris, France, 2007; ISBN 978-92-807-2772-2. [Google Scholar]

- Hossain, M.U.; Poon, C.S.; Dong, Y.H.; Lo, I.M.C.; Cheng, J.C.P. Development of Social Sustainability Assessment Method and a Comparative Case Study on Assessing Recycled Construction Materials. Int. J. Life Cycle Assess. 2018, 23, 1654–1674. [Google Scholar] [CrossRef]

- Allacker, K.; de Souza, D.M.; Sala, S. Land Use Impact Assessment in the Construction Sector: An Analysis of LCIA Models and Case Study Application. Int. J. Life Cycle Assess. 2014, 19, 1799–1809. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life Cycle Analysis in the Construction Sector: Guiding the Optimisation of Conventional Italian Buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Dossche, C.; Boel, V.; De Corte, W. Use of Life Cycle Assessments in the Construction Sector: Critical Review. Procedia Eng. 2017, 171, 302–311. [Google Scholar] [CrossRef]

- Vasishta, T.; Hashem Mehany, M.; Killingsworth, J. Comparative Life Cycle Assesment (LCA) and Life Cycle Cost Analysis (LCCA) of Precast and Cast-in-Place Buildings in United States. J. Build. Eng. 2023, 67, 105921. [Google Scholar] [CrossRef]

- Dong, Y.H.; Ng, S.T. A Social Life Cycle Assessment Model for Building Construction in Hong Kong. Int. J. Life Cycle Assess. 2015, 20, 1166–1180. [Google Scholar] [CrossRef]

- Zampori, L.; Saouter, E.; Castellani, V.; Schau, E.; Cristobal, J.; Sala, S. Guide for Interpreting Life Cycle Assessment Result. Available online: https://op.europa.eu/en/publication-detail/-/publication/6447e6c6-c8dd-11e6-a6db-01aa75ed71a1/language-en (accessed on 19 February 2020).

- Russell-Smith, S.V.; Lepech, M.D. Cradle-to-Gate Sustainable Target Value Design: Integrating Life Cycle Assessment and Construction Management for Buildings. J. Clean. Prod. 2015, 100, 107–115. [Google Scholar] [CrossRef]

- Olinzock, M.A.; Landis, A.E.; Saunders, C.L.; Collinge, W.O.; Jones, A.K.; Schaefer, L.A.; Bilec, M.M. Life Cycle Assessment Use in the North American Building Community: Summary of Findings from a 2011/2012 Survey. Int. J. Life Cycle Assess. 2015, 20, 318–331. [Google Scholar] [CrossRef]

- Dong, Y.H.; Ng, S.T. Comparing the Midpoint and Endpoint Approaches Based on ReCiPe—A Study of Commercial Buildings in Hong Kong. Int. J. Life Cycle Assess. 2014, 19, 1409–1423. [Google Scholar] [CrossRef]

- Lee, K.; Tae, S.; Shin, S. Development of a Life Cycle Assessment Program for Building (SUSB-LCA) in South Korea. Renew. Sustain. Energy Rev. 2009, 13, 1994–2002. [Google Scholar] [CrossRef]

- Brookes, A.; Meijs, M. Cladding of Buildings, 4th ed.; Taylor & Francis: London, UK, 2008; ISBN 978-0-203-09978-0. [Google Scholar]

- ASTM A36/A36-19; Specification for Carbon Structural Steel. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM A572/A572-21e1; Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel. ASTM International: West Conshohocken, PA, USA, 2017.

- ABNT NBR 14513; Corrugated and Trapezoidal Steel Roof Tiles—Requirements. Brazilian Association of Technical Standards: Rio de Janeiro, RJ, Brazil, 2022.

- ABNT NBR 8800; Design of Steel Structures and Mixed Steel and Concrete Building Struct. Brazilian Association of Technical Standards: Rio de Janeiro, RJ, Brazil, 2008.

- ABNT NBR 14762; Cold-Formed Steel Sections—Design. Brazilian Association of Technical Standards: Rio de Janeiro, RJ, Brazil, 2010.

- ABNT NBR 6120; Loads for Calculating Building Structures. Brazilian Association of Technical Standards: Rio de Janeiro, RJ, Brazil, 2019.

- ABNT NBR 6123; Wind Forces on Buildings. Brazilian Association of Technical Standards: Rio de Janeiro, RJ, Brazil, 2023.

- ABNT NBR 15575-1; Residential Buildings—Performance. Brazilian Association of Technical Standards: Rio de Janeiro, RJ, Brazil, 2024.

- CONAMA Number 307; Establishes Directives. Criteria and Procedures of Wastes from Building Construction. Brazilian National Environment Council: Federal District, DF, Brazil, 2002.

- Vilčeková, S.; Mésároš, P.; Burdová, E.K.; Budajová, J. End-of-Life Stage Analysis of Building Materials in Relation to Circular Construction. Eng. Proc. 2023, 57, 43. [Google Scholar] [CrossRef]

- Broadbent, C. Steel’s Recyclability: Demonstrating the Benefits of Recycling Steel to Achieve a Circular Economy. Int. J. Life Cycle Assess. 2016, 21, 1658–1665. [Google Scholar] [CrossRef]

- Zanelli, C.; Marrocchino, E.; Guarini, G.; Toffano, A.; Vaccaro, C.; Dondi, M. Recycling Construction and Demolition Residues in Clay Bricks. Appl. Sci. 2021, 11, 8918. [Google Scholar] [CrossRef]

- Marsh, A.T.M.; Velenturf, A.P.M.; Bernal, S.A. Circular Economy Strategies for Concrete: Implementation and Integration. J. Clean. Prod. 2022, 362, 132486. [Google Scholar] [CrossRef]

- Bahramian, M.; Yetilmezsoy, K. Life Cycle Assessment of the Building Industry: An Overview of Two Decades of Research (1995–2018). Energy Build. 2020, 219, 109917. [Google Scholar] [CrossRef]

- Duan, Z.; Huang, Q.; Zhang, Q. Life Cycle Assessment of Mass Timber Construction: A Review. Build. Environ. 2022, 221, 109320. [Google Scholar] [CrossRef]

- Scolaro, T.P.; Ghisi, E. Life Cycle Assessment of Green Roofs: A Literature Review of Layers Materials and Purposes. Sci. Total Environ. 2022, 829, 154650. [Google Scholar] [CrossRef] [PubMed]

- Aryan, Y.; Dikshit, A.K.; Shinde, A.M. A Critical Review of the Life Cycle Assessment Studies on Road Pavements and Road Infrastructures. J. Environ. Manag. 2023, 336, 117697. [Google Scholar] [CrossRef] [PubMed]

- Milić, I.; Bleiziffer, J. Life Cycle Assessment of the Sustainability of Bridges: Methodology, Literature Review and Knowledge Gaps. Front. Built Environ. 2024, 10, 1410798. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Industry and Environment Office; United Nations Environment Programme. Environmental Aspects of Iron and Steel Production: An Overview, 1st ed.; UNEP Industry and Environment Overview Series; UNEP Industry and Environment Office, Ed.; United Nations Environment Programme: Paris, France, 1984; ISBN 978-92-807-1078-6. [Google Scholar]

- International Iron and Steel Institute; United Nations Environment Programme. Steel Industry and the Environment: Technical and Management Issues; Technical Report Series/United Nations Environment Programme; UNEP, Ed.; IISI: Brussels, Belgium, 1997; ISBN 978-92-807-1651-1. [Google Scholar]

- McMichael, A.J.; Woodruff, R.E.; Hales, S. Climate Change and Human Health: Present and Future Risks. Lancet 2006, 367, 859–869. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).