A New Method for Identifying Kinetic Parameters of Industrial Robots

Abstract

:1. Introduction

2. Robotic arm Dynamics Model

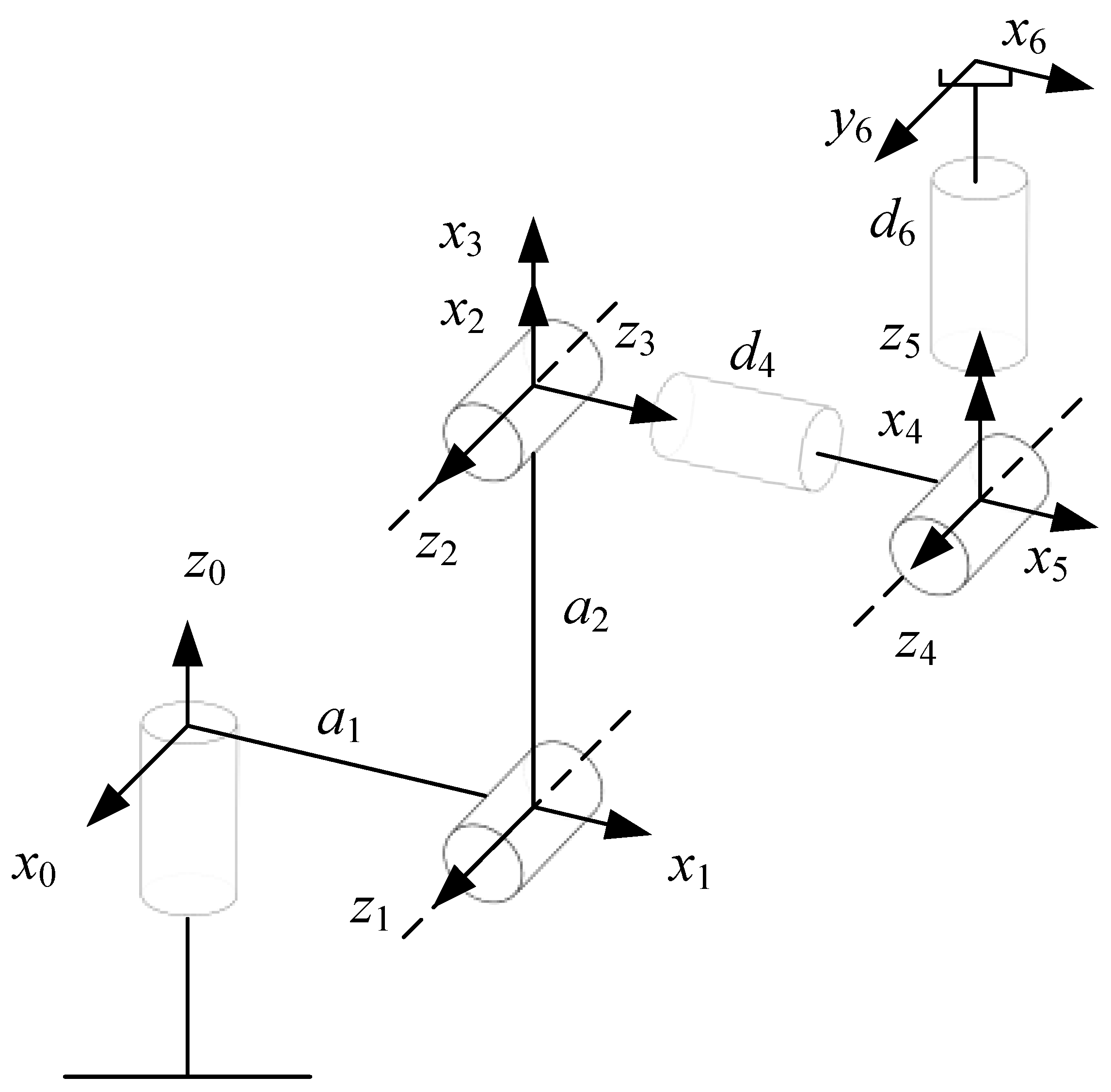

2.1. RS010N Industrial Robots

2.2. Dynamics Modeling

2.3. Minimum Set of Parameters for the Dynamical Model

3. Incentive Track Design

4. SEDSABSO for the Identification of Industrial Robot Dynamics Parameters

4.1. Improving Global Optimal Search

BSO

4.2. Improving BSO

4.2.1. Improved Global Optimal Solution

- (1)

- Simulated annealing algorithm

- The algorithm is initialized, and an initial solution x is randomly generated as the optimal solution.

- A new solution xt is obtained in the vicinity of the initial solution, denoted by ∆f = f(xt) − f(x).

- The new solution xt is accepted according to min{1,exp(−∆f/Tk)}>random. Tk denotes the temperature and exp denotes the exponential function, with natural number e as the base.

- (2)

- Random behavior

4.2.2. Improved Iterative Approach to N Particles of the Aspen Swarm

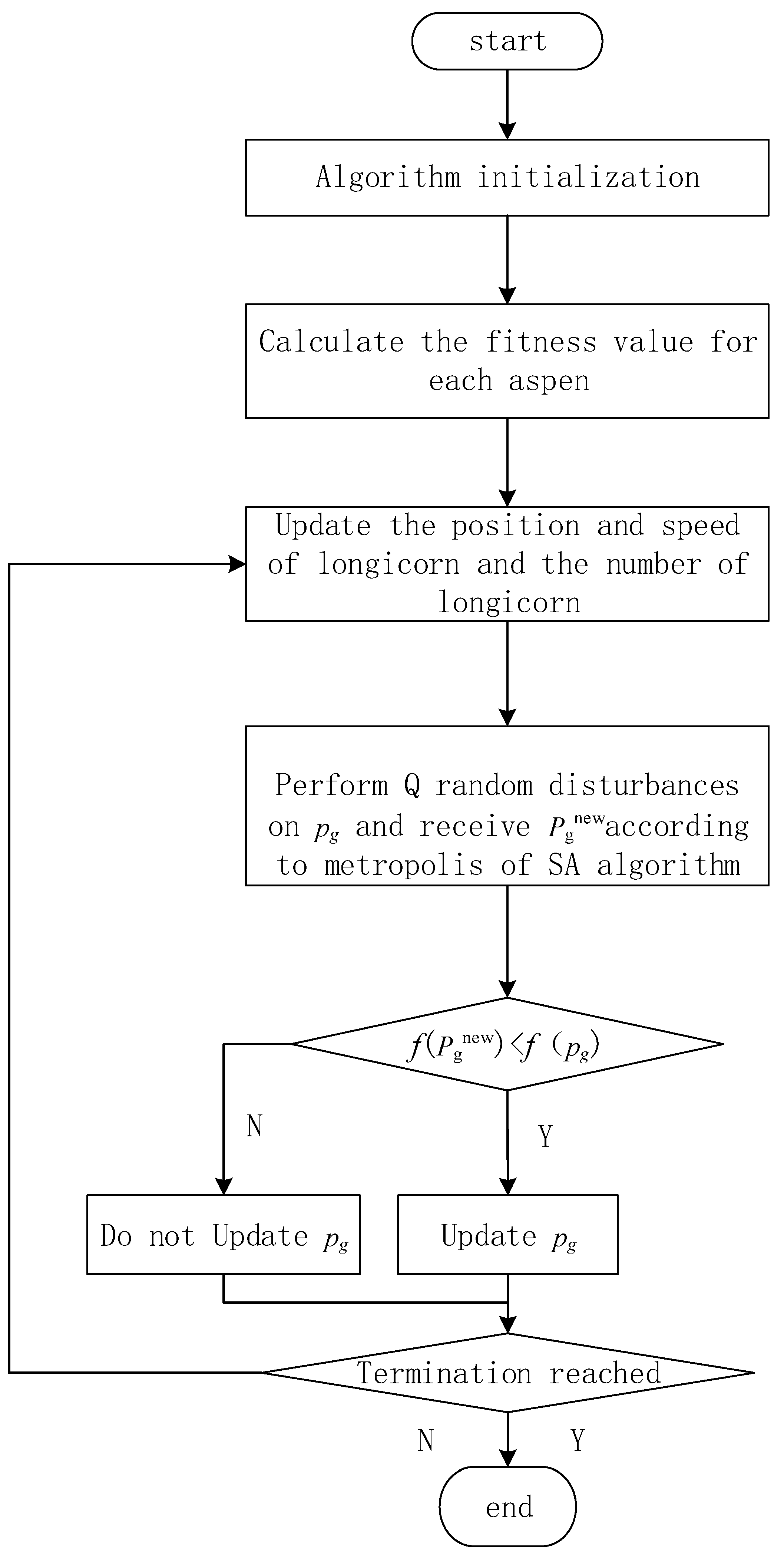

4.3. Robot Dynamic Parameter Identification Based on SEDSABSO

- (1)

- Initialization of the algorithm.

- (2)

- Obtain SEDSABSO individual and group best-fit values.

- (3)

- Update the position, velocity, and number of skinks N

- (4)

- Perform a random perturbation search for the global optimal solution and then accept the searched solution with SA’s Metropolis criterion and cycle through q searches.

- (5)

- Compare with the global optimal solution obtained in step 3 after passing q times of search and proceed to the next step of the search by merit.

- (6)

- Determine whether the algorithm ends, and if the termination condition is not satisfied, return to step 3. If it is satisfied, the global optimal solution is output. In turn, the parameters related to industrial robot dynamics are obtained.

5. Simulation Experiments and Results Analysis

5.1. Adaptation Function

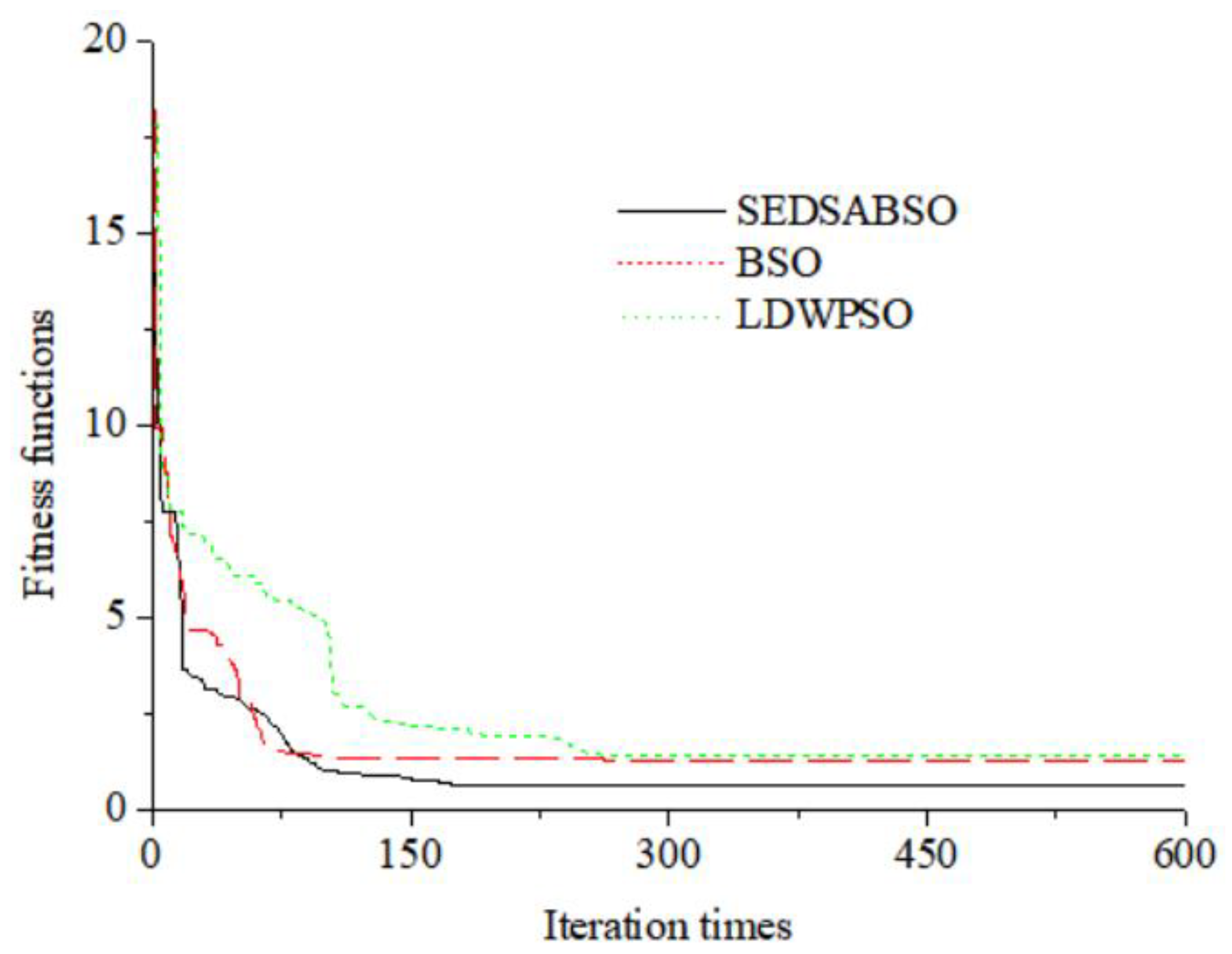

5.2. Analysis of Experimental Results

Experimental Parameter Setting

6. Conclusions

- (1)

- In this paper, a new improved Beetle Antennae Search-QEDSABSO is proposed, which makes a class exponential change to the number of skinks in the iterative process of Beetle Antennae Search and effectively improved the utilization rate of Beetle Antennae Search skinks while the total number of skinks was basically unchanged. Simulation experiments showed that the proposed algorithm is more accurate and faster than the common particle swarm and Beetle Antennae Search in identifying the dynamics parameters of robots. The simulations showed that the proposed algorithm can identify the dynamical parameters of the robot with higher accuracy and faster speed than the common particle swarm and Beetle Antennae Search.

- (2)

- The difficulty in identifying the kinetic parameters of industrial robots lies in the sheer number of variables that need to be determined and the selection of reasonable excitation trajectories. This paper designed the relevant excitation trajectories by using the genetic algorithm and linearized the kinetic parameters of the industrial robot to improve the accuracy of their recognition.

- (3)

- The work provided the foundation for experiments compensating for the kinetic moments of the industrial robot. The minimum set of parameters of the kinetics could first be obtained by SymPyBotics. Then, the excitation trajectory of the industrial robot was designed by using the genetic algorithm, the data on its kinetic moments were collected, and the moments were identified by the SEDSABSO algorithm. Following this, the theoretical kinetic moments of the robot were calculated and compared with empirically sampled moments to obtain the error. Finally, this error was used to compensate for the kinetic moment of the robot.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Zhao, B.; Zhu, H. Sorting Experimental Platform Research on Six-DOF Manipulator. Mach. Des.Manuf. 2013, 27, 210–213. [Google Scholar]

- Wu, J.; Wang, J.; You, Z. An overview of dynamic parameter identification of robots. Robot. Comput. Integr. Manuf. 2010, 26, 414–419. [Google Scholar] [CrossRef]

- Gautier, M.; Janot, A.; Vandanjon, P.O. A new closed-loop output error method for parameter identification of robot dynamics. IEEE Trans. Control Syst. Technol. 2013, 21, 428–444. [Google Scholar] [CrossRef] [Green Version]

- Memar, A.H.; Esfahani, E.T. Modeling and Dynamic Parameter Identification of the SCHUNK Powerball Robotic Arm. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; p. VOSCT08A024. [Google Scholar]

- Fu, X.; Yuan, J.; Wang, S.; Wang, N.; Zhang, W. Nonlinear Dynamic Identification of Robotic Manipulators Based on Particle Swarm Optimization Method. Mech.-Electr. Integr. 2017, 023, 3–8. [Google Scholar]

- Ding, L.; Wu, H.; Yao, Y.; Li, Y.; Xie, B.H.; Chen, B. Parameters Identification of Industrial Robots Based on WLS-ABC Algorithm. J. South China Unive. Technol. (Natl. Sci. Ed.) 2016, 44, 90–95. [Google Scholar]

- Jiang, X.; Li, S. BAS: Beetle antennae search algorithm for optimization problems. arXiv 2017, arXiv:1710.10724. [Google Scholar] [CrossRef]

- Chen, T.; Yin, H.; Jiang, H. Particle Swarm Optimization Algorithm Based on Beetle Antennae Search for Solving Portfolio Problem. Comput. Syst. Appl. 2019, 28, 171–176. [Google Scholar]

- Wang, T.; Long, Y.; Qiang, L. Beetle Swarm Optimization Algorithm: Theory and Application. arXiv 2018, arXiv:1808.00206. [Google Scholar] [CrossRef]

- Zhou, T.; Qian, Q.; Fu, Y. Fusion Simulated Annealing and Adaptive Beetle Antennae Search Algorithm. Commun. Technol. 2019, 52, 1626–1631. [Google Scholar]

- Khan, A.H.; Cao, X.; Li, S.; Katsikis, V.N.; Liao, L. BAS-ADAM:an ADAM based approach to improve the performance of beetle antennae search optimizer. IEEE/CAA J. Autom. Sin. 2020, 7, 461–471. [Google Scholar] [CrossRef]

- Xu, C. Research on Dynamic Parameter Identification And Feedforward Control of Articulated Robots; Southeast University: Nanjing, China, 2017. [Google Scholar]

- Zhang, J.; Duan, J. Robot Dynamic Parameter Identification Based on Improved Differential Evolution Algorithm. J. Beijing Union Univ. 2020, 1, 49–55. [Google Scholar]

- Craig, J.J. Introduction to Robotics Mechanics and Control; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2005. [Google Scholar]

- Sun, Y.; Zhou, B.; Meng, Z. Dynamic Parameter Identification of Industrial Robot Based on Genetic Algorithm. Ind. Control Comput. 2017, 9, 4–6. [Google Scholar]

- Swevers, J.; Ganseman, C.; De Schutter, J.; Van Brussel, H. Experimental robot identification using optimised periodic trajectories. Mech. Syst. Signal Process. 1996, 10, 561–577. [Google Scholar] [CrossRef]

- Jiang, M.; Yuan, D. Wavelet Threshold Optimization with Artificial Fish Swarm Algorithm. In Proceedings of the 2005 International Conference on Neural Networks, Beijing, China, 13–15 October 2005; IEEE Press: Piscataway, NJ, USA, 2005; pp. 569–572. [Google Scholar]

- Liu, C.; Yan, X.; Liu, C.; Wu, H. The wolf colony algorithm and applications. Chin. J. Electron. 2011, 20, 212–216. [Google Scholar]

- Wang, Q.; Li, L.; Lu, C.; Sun, F. Average Computational Time Complexity Optimized Dynamic Particle Swarm Optimization Algorithm. Comput. Sci. 2010, 37, 191. [Google Scholar]

- Kou, B.; Guo, S.; Ren, D. Geometric parameter calibration of industrial robot based on improved particle swarm optimization. J. Harbin Inst. Technol. 2021, 49, 61–64. [Google Scholar]

- Wang, Y.G.; Qu, T.T.; Li, S. Disruption particle swarm optimization algorithm based on exponential decay weight. Appl. Res. Comput. 2020, 37, 1020–1024. [Google Scholar]

- Liu, Y.; Li, G.X.; Xia, D.; Xu, W.F. Identifying Dynamic parameters of a space robot based on improved genetic algorithm. J. Harbin Inst. Technol. 2010, 42, 1734–1739. [Google Scholar]

| i | αi−1/rad | ai−1/mm | di/mm | θi/rad |

|---|---|---|---|---|

| 1 | pi/2 | a0 | 0 | θ1 |

| 2 | −pi/2 | a1 | 0 | θ2 |

| 3 | 0 | 0 | 0 | θ3 |

| Member Number | 1 | 2 | 3 |

|---|---|---|---|

| Ixx/(kg·m2) | 36.33 | −10.02 | 7.74 |

| Iyy/(kg·m2) | 40.61 | 7.05 | 1.02 |

| Izz/(kg·m2) | 36.33 | 11.61 | 9.81 |

| Ixy/(kg·m2) | 0.00 | 6.14 | 3.34 |

| Ixz/(kg·m2) | 0.00 | 5.93 | −3.42 |

| Iyz/(kg·m2) | 0.00 | −7.82 | −0.29 |

| m/(kg) | 18.33 | 25.18 | 20.47 |

| x/(mm) | 0.00 | 122.41 | 152.34 |

| y/(mm) | 110.11 | 163.81 | 90.24 |

| z/(mm) | 0.00 | 73.36 | −34.21 |

| Fc (N·m) | 0.00 | 0.00 | 0.00 |

| Fv (N·m) | 0.00 | 0.00 | 0.00 |

| Parameter | Joint i | Min | Max |

|---|---|---|---|

| 1 | −180 | 180 | |

| Angle | 2 | −60 | 140 |

| 3 | −180 | 80 | |

| 1 | −125 | 125 | |

| Angle velocity | 2 | −100 | 100 |

| 3 | −165 | 165 | |

| 1 | −45 | 45 | |

| Angle acceleration | 2 | −40 | 40 |

| 3 | −75 | 75 |

| Algorithm | Average Fitness | Average Time/s |

|---|---|---|

| SDESABSO | 0.95 | 16.93 |

| BSO | 1.12 | 17.31 |

| LDWPSO | 1.18 | 12.73 |

| Dynamic Minimum Parameters | Theoretica Value | SEDSABSO Identification Value | BSO Identification Value | LDWPSO Identification Value | SEDSABSO Absolute Error | BSO Absolute Error | LDWPSO Absolute Error |

|---|---|---|---|---|---|---|---|

| I1yy + I2yy + I3zz + 2 ∗ a1 ∗ I1x + m1 ∗ a12 − (m2 + m3) ∗ a22 | 16.41 | 16.80 | 16.89 | 16.82 | −0.39 | −0.48 | −0.41 |

| F1c | 0 | 0.01 | 0.35 | −0.20 | −0.01 | −0.35 | 0.2 |

| F1v | 0 | −0.07 | −0.21 | 0.22 | 0.07 | 0.21 | −0.22 |

| I2xx − I2yy + (m2 + m3) ∗ a22 | 31.83 | 31.77 | 31.92 | 32.21 | 0.06 | −0.09 | −0.38 |

| I2xy | 6.14 | 5.78 | 5.12 | 6.12 | 0.36 | 1.02 | 0.02 |

| I2x − a2 ∗ (I2z − I3y) | 5.76 | 5.54 | 6.22 | 5.83 | 0.22 | −0.46 | −0.07 |

| I2yz | −7.82 | −7.84 | −7.72 | −8.10 | 0.02 | −0.1 | 0.28 |

| I2zz − (m2 + m3) ∗ a22 | −37.29 | −37.11 | −37.30 | −37.94 | −0.18 | 0.01 | 0.65 |

| I2x + (m2 + m3) ∗ a22 | 47.37 | 47.29 | 47.52 | 47.27 | 0.08 | −0.15 | 0.1 |

| I2y | 0.16 | 0.13 | 0.09 | 0.27 | 0.03 | 0.07 | −0.11 |

| F2c | 0 | 0.14 | −0.02 | −0.08 | −0.14 | 0.02 | 0.08 |

| F2v | 0 | −0.21 | −0.23 | −0.03 | 0.21 | 0.23 | 0.03 |

| I3xx − I3zz | −2.07 | −2.20 | −2.40 | −1.51 | 0.13 | 0.33 | −0.56 |

| I3xy | 3.34 | 3.24 | 3.25 | 4.57 | 0.10 | 0.09 | −1.23 |

| I3xz | −3.42 | −3.34 | −2.95 | −4.10 | −0.08 | −0.47 | 0.68 |

| I3yy | 1.02 | 0.77 | 1.12 | −0.85 | 0.25 | −0.1 | 1.87 |

| I3yz | −0.29 | 0.10 | −0.34 | −1.42 | −0.39 | 0.05 | 1.13 |

| I3x | 0.15 | 0.11 | 0.12 | −0.04 | 0.04 | 0.03 | 0.19 |

| I3z | −0.034 | 0.00 | −0.16 | 0.04 | −0.034 | 0.126 | −0.074 |

| F3c | 0 | 0.18 | −0.13 | −1.20 | −0.18 | 0.13 | 1.2 |

| F3v | 0 | 0.06 | −0.34 | −0.1 | −0.06 | 0.34 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kou, B.; Guo, S.; Ren, D. A New Method for Identifying Kinetic Parameters of Industrial Robots. Actuators 2022, 11, 2. https://doi.org/10.3390/act11010002

Kou B, Guo S, Ren D. A New Method for Identifying Kinetic Parameters of Industrial Robots. Actuators. 2022; 11(1):2. https://doi.org/10.3390/act11010002

Chicago/Turabian StyleKou, Bin, Shijie Guo, and Dongcheng Ren. 2022. "A New Method for Identifying Kinetic Parameters of Industrial Robots" Actuators 11, no. 1: 2. https://doi.org/10.3390/act11010002

APA StyleKou, B., Guo, S., & Ren, D. (2022). A New Method for Identifying Kinetic Parameters of Industrial Robots. Actuators, 11(1), 2. https://doi.org/10.3390/act11010002