The Research on Soft Pneumatic Actuators in Italy: Design Solutions and Applications

Abstract

:1. Introduction

2. Design Features and Functionality of Pneumatic Deformable (Soft) Actuators

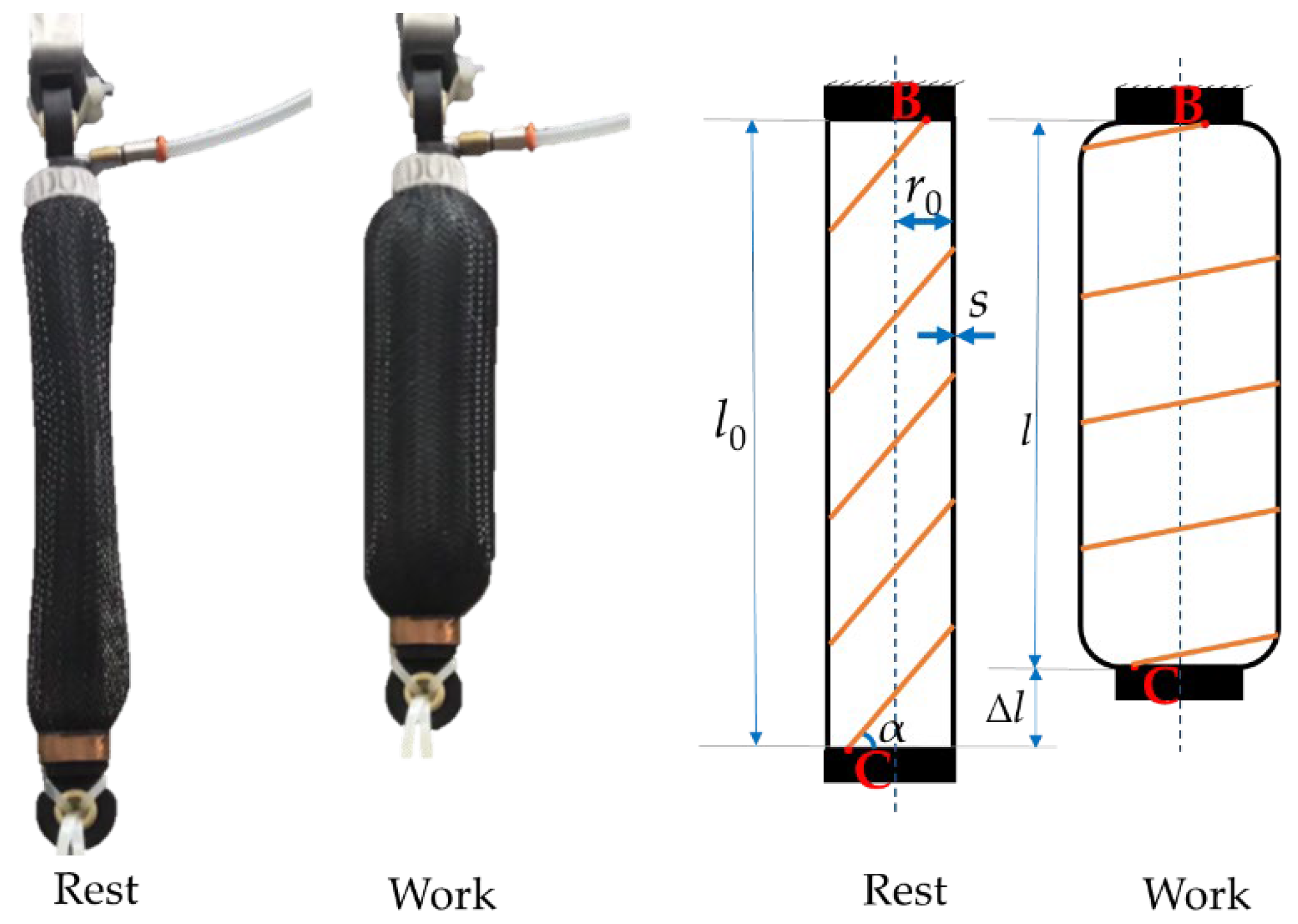

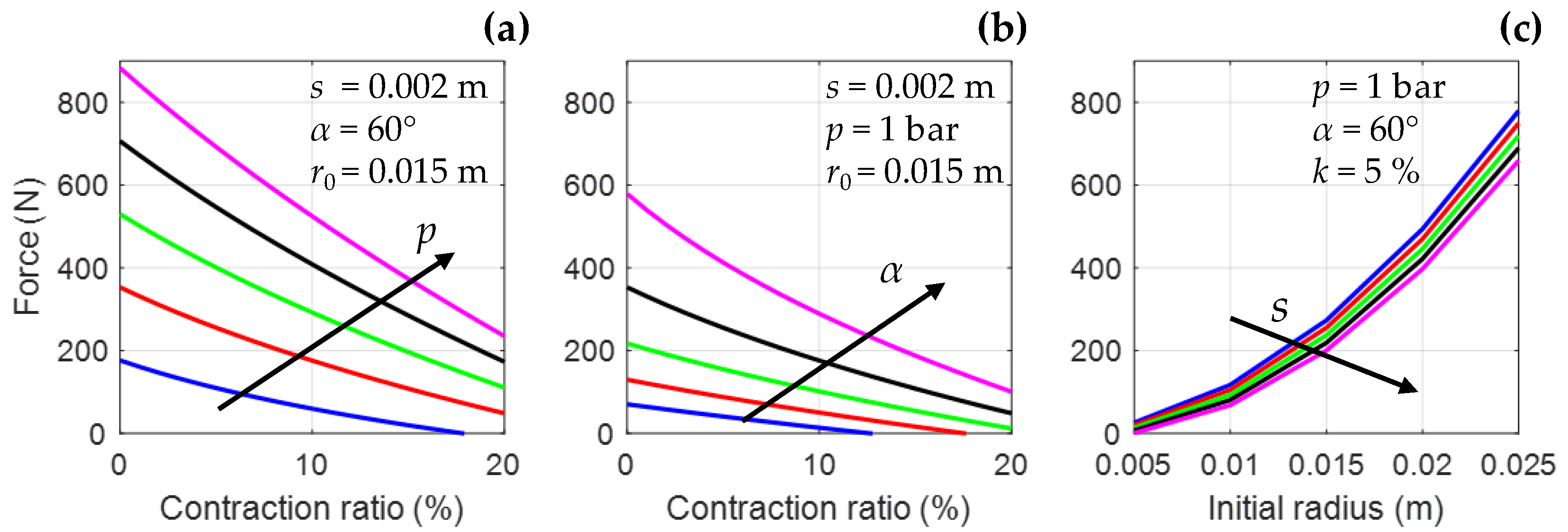

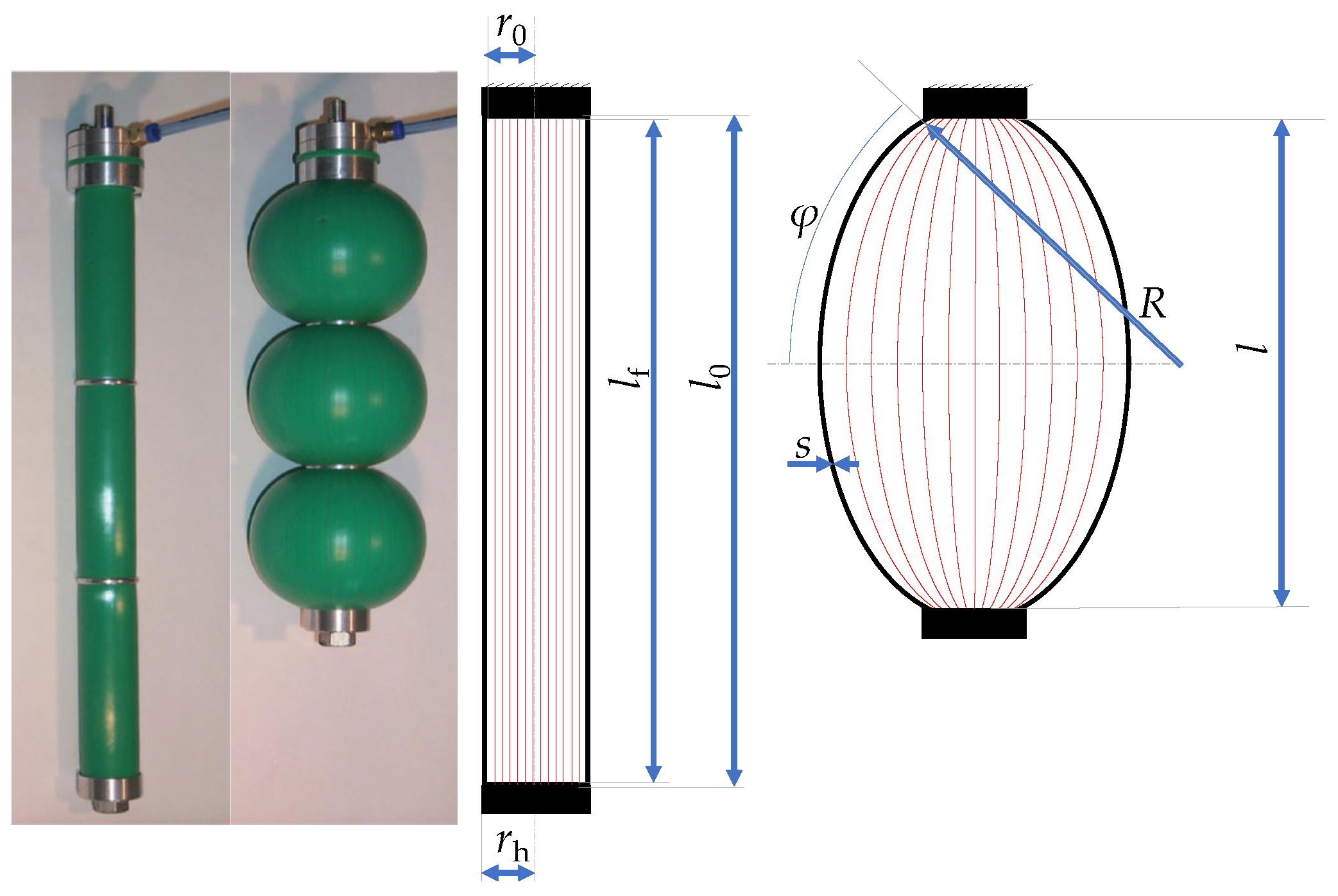

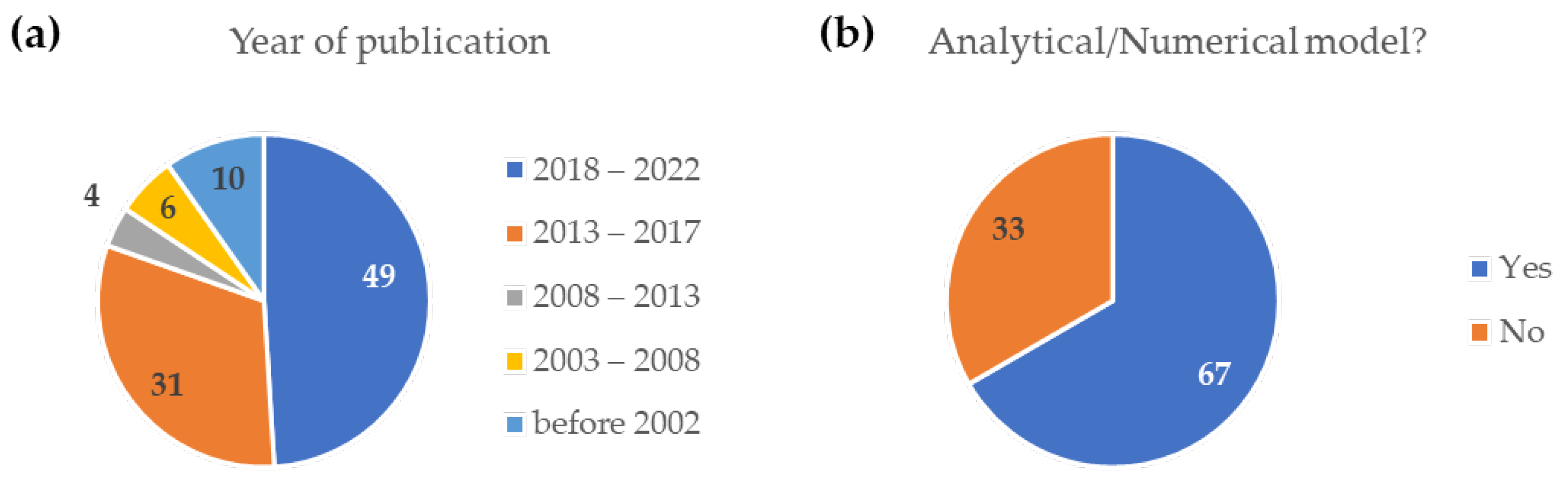

2.1. McKibben Muscle

2.2. Straight Fibers

2.3. Linear Bidirectional Actuator

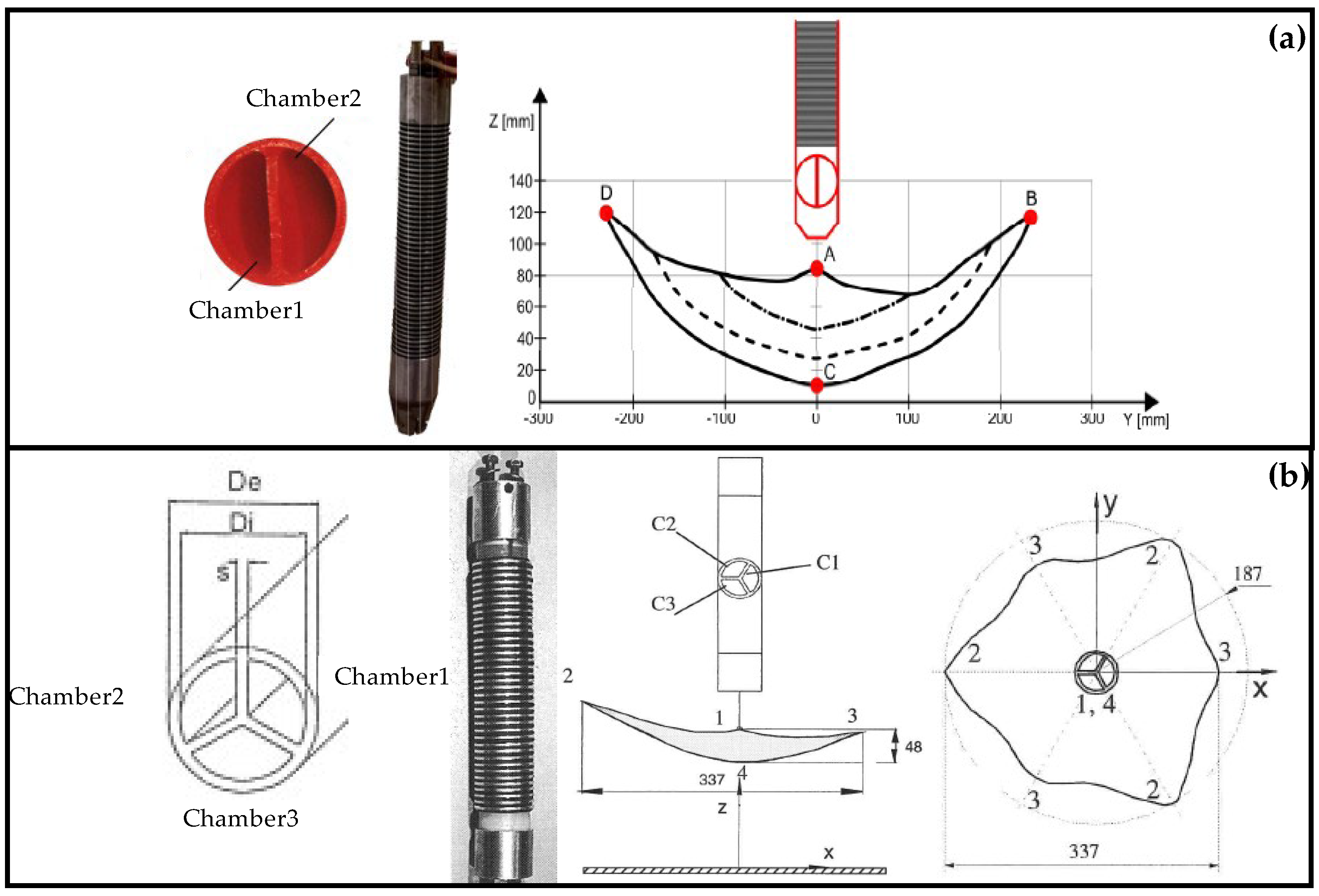

2.4. Bending Pneumatic Actuator

2.5. Self-Sensing Actuator

2.6. Air-Pocket

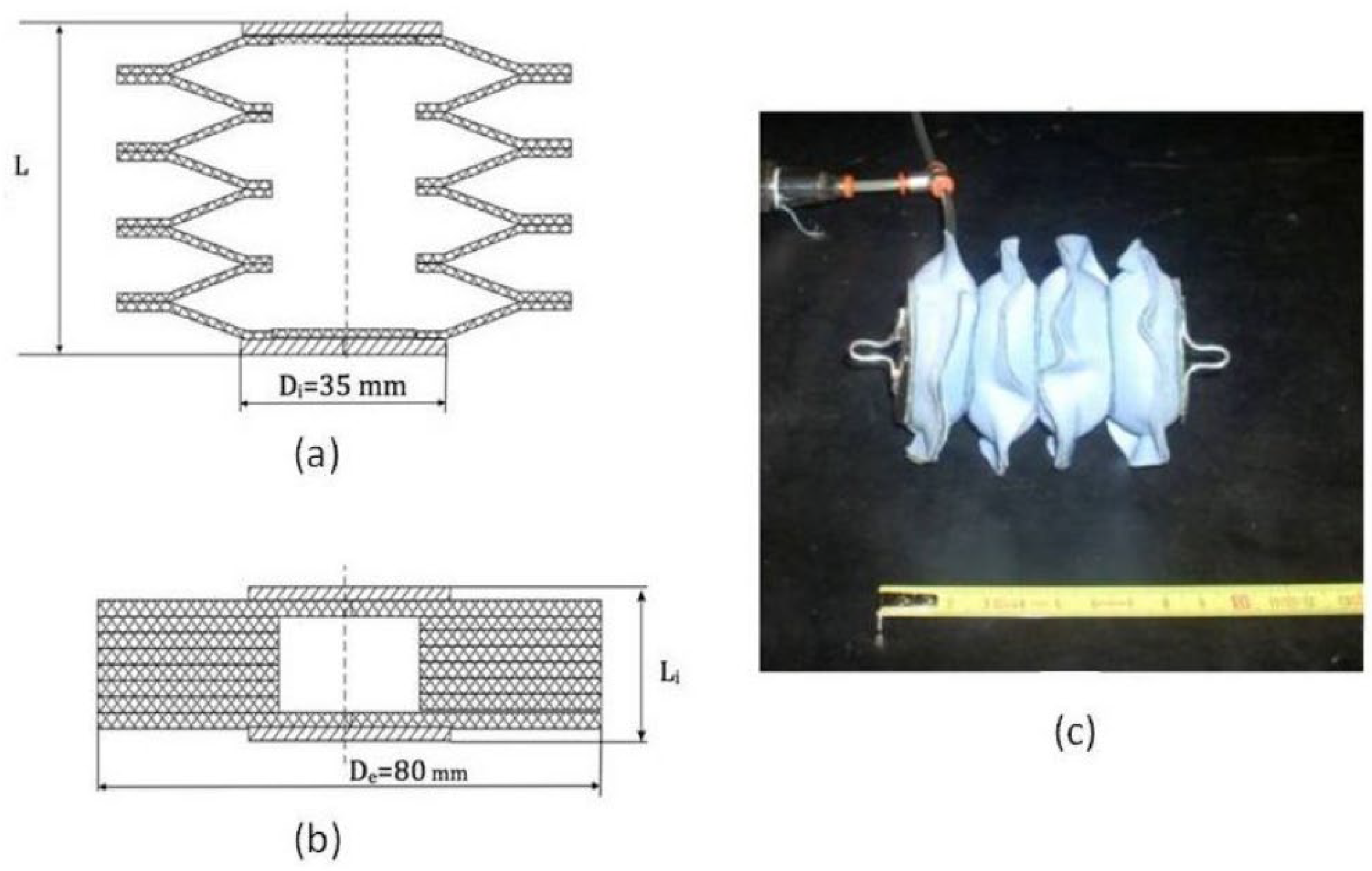

2.7. Bellow Muscle

3. Applications

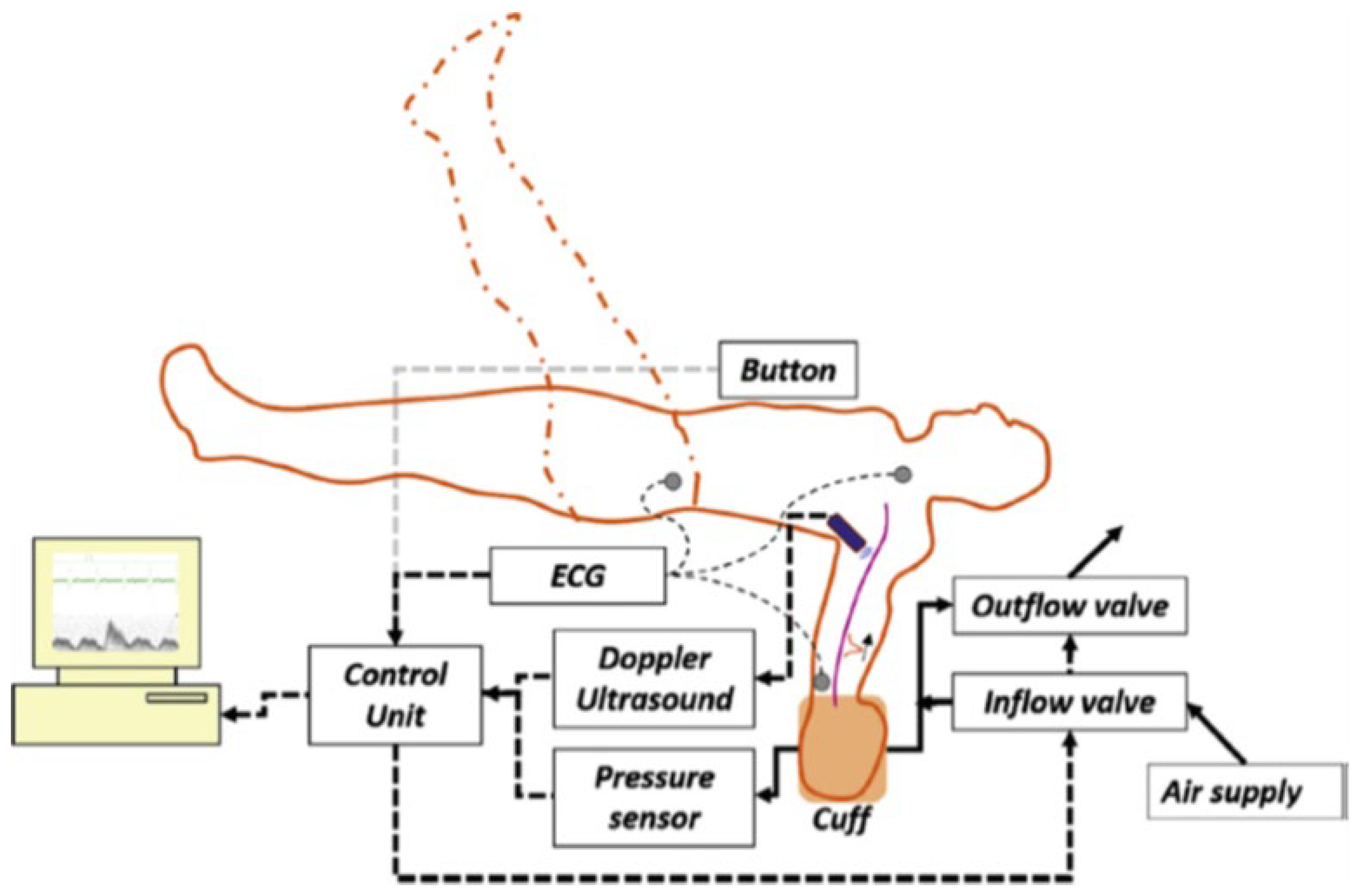

3.1. Clinical Investigation and Medical Research

3.2. Treatment of Cardiovascular Diseases

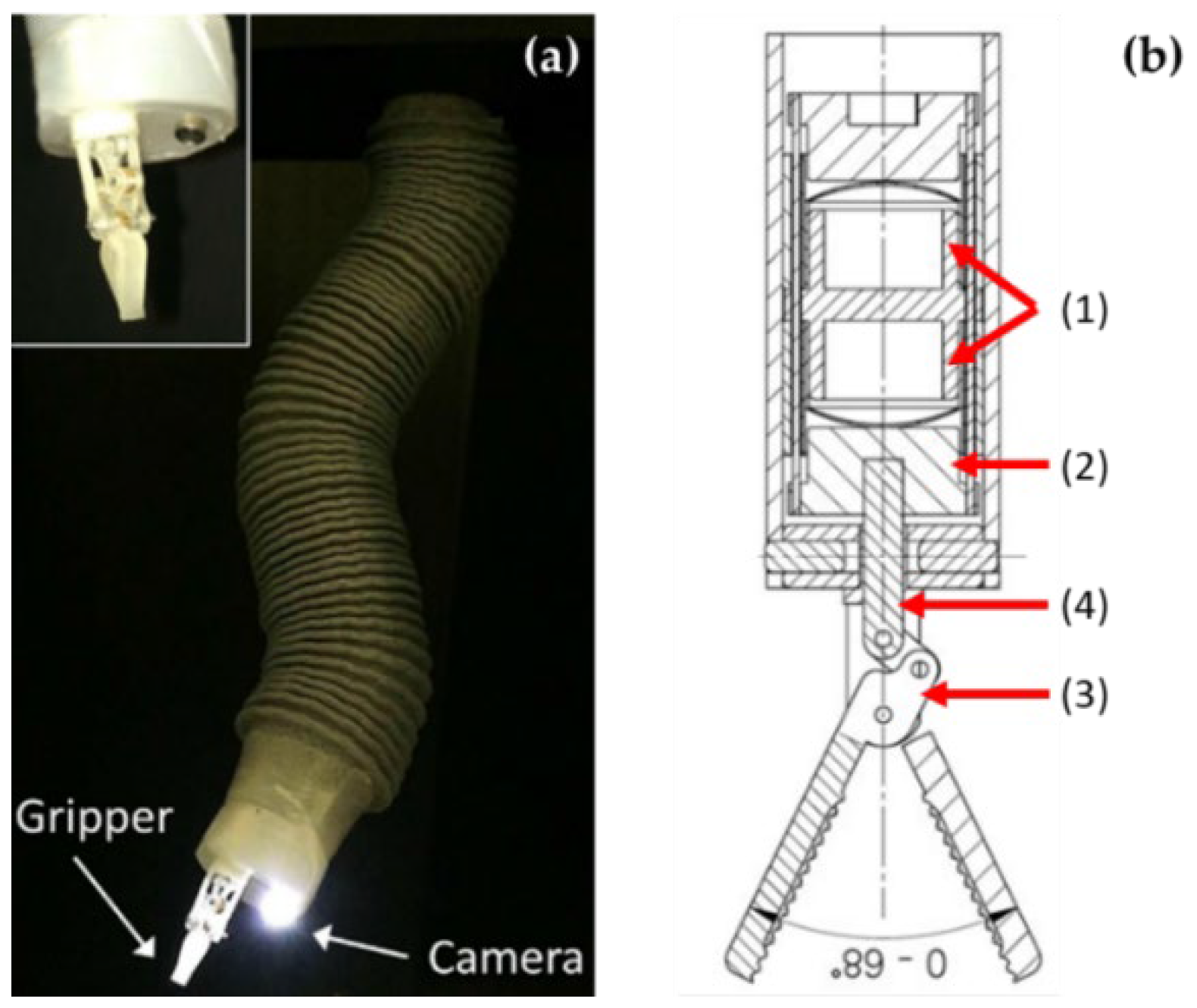

3.3. Minimally Invasive Surgery

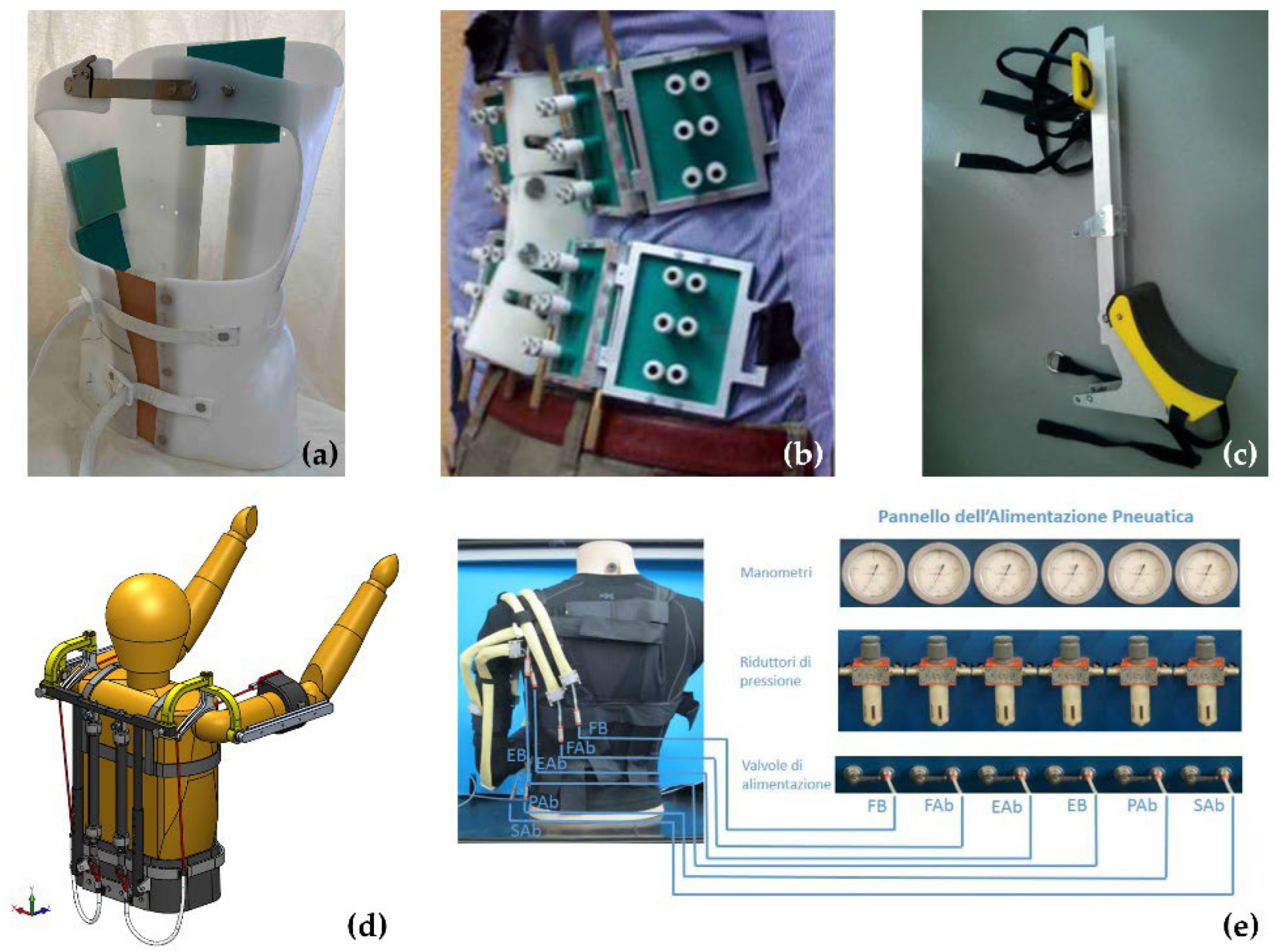

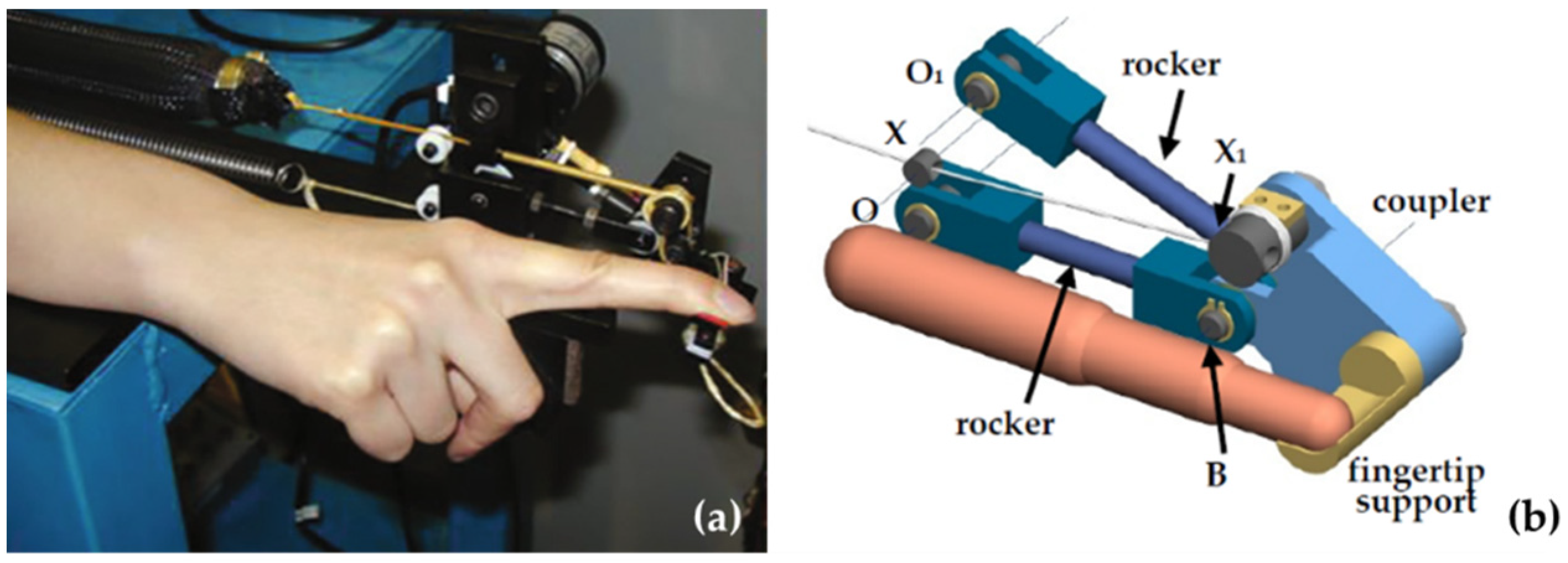

3.4. Rehabilitation and Wearable Device

3.5. Other Applications

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Year | 1st Author | Ref. | PAM 1 | Model | Application 2 |

|---|---|---|---|---|---|

| 1997 | Ferraresi, C. | [36] | BPA | YES | - |

| 1997 | Ferraresi, C. | [51] | BPA+Self-sensing | YES | - |

| 2001 | Ferraresi, C. | [29] | MKM+SFM | YES | - |

| 2001 | Cataudella, C. | [49] | BPA | YES | Fish Robot |

| 2001 | Belforte, G. | [50] | BPA | NO | - |

| 2003 | Ferraresi, C. | [33] | BPA | NO | Fish Robot |

| 2003 | Carello, M. | [35] | BPA | NO | Gripper |

| 2007 | Raparelli, T. | [76] | BM | NO | Orthosis |

| 2010 | Antonelli, M.G. | [58] | AP | YES | Orthosis |

| 2012 | Belforte, G. | [43] | SFM | NO | - |

| 2013 | Cianchetti, M. | [52] | BPA | NO | MIS |

| 2014 | Belforte, G. | [31] | MKM+SFM+BM | NO | - |

| 2014 | Ferraresi, C. | [45] | Bidirectional | YES | - |

| 2014 | Belforte, G. | [60] | BM | YES | Active Suit |

| 2014 | Ferraresi, C. | [67] | AP | YES | IPC |

| 2015 | Ranzani, T. | [53] | BPA | NO | MIS |

| 2016 | Ranzani, T. | [25] | BPA | YES | MIS |

| 2016 | Cacucciolo, V. | [30] | BPA | YES | - |

| 2016 | Manuello Bertetto, A. | [32] | BPA | NO | Fish Robot |

| 2016 | Ferraresi, C. | [68] | AP | YES | IPC |

| 2016 | Maffiodo, D. | [69] | AP | YES | IPC |

| 2017 | De Falco, I. | [1] | BPA | YES | MIS |

| 2017 | Belforte, G. | [38] | MKM | YES | - |

| 2017 | Antonelli, M.G. | [39] | MKM | YES | - |

| 2017 | Manuello Bertetto, A. | [57] | AP | NO | IPC |

| 2017 | Antonelli, M.G. | [72] | BPA | YES | MIS |

| 2018 | Durante, F. | [40] | SFM | YES | - |

| 2018 | Antonelli, M.G. | [41] | SFM | YES | - |

| 2018 | Belforte, G. | [44] | SFM | NO | - |

| 2018 | Messere, A. | [61] | AP | NO | IPC |

| 2018 | Messere, A. | [62] | AP | NO | IPC |

| 2018 | Antonelli, M.G. | [75] | AP | NO | Rehabilitation Device |

| 2018 | Durante, F. | [77] | MKM | YES | Exoskeleton |

| 2018 | Belforte, G. | [80] | MKM | YES | Active Suit |

| 2019 | Franco, W. | [2] | MKM | YES | MIS |

| 2019 | Hassan, T. | [47] | Bidirectional | YES | - |

| 2019 | Ferraresi, C. | [55] | AP | YES | IPC |

| 2019 | Ferraresi, C. | [56] | AP | YES | IPC |

| 2019 | Franco, W. | [73] | MKM | YES | MIS |

| 2019 | De Benedictis, C. | [74] | MKM | YES | Rehabilitation Device |

| 2020 | Muscolo, G.G. | [46] | Bidirectional | YES | Soft Robotics |

| 2020 | Antonelli, M.G. | [48] | BPA | YES | Gripper |

| 2020 | Ermini, L. | [63] | AP | NO | IPC |

| 2020 | Bottero, S. | [81] | Bidirectional | YES | Soft Robotics |

| 2021 | Durante, F. | [42] | SFM | YES | - |

| 2021 | Ermini, L. | [64] | AP | NO | IPC |

| 2021 | Magnetti Gisolo, S. | [78] | MKM | YES | Exoskeleton |

| 2022 | Lorenzon, L. | [54] | Self-sensing | NO | - |

| 2022 | Mannella, D. | [59] | AP | YES | Ulcer Prevention |

| 2022 | Bellusci, M. | [71] | AP | YES | Ulcer Prevention |

| 2022 | Paterna, M. | [79] | MKM | YES | Exoskeleton |

References

- De Falco, I.; Cianchetti, M.; Menciassi, A. A Soft Multi-Module Manipulator with Variable Stiffness for Minimally Invasive Surgery. Bioinspir. Biomim. 2017, 12, 056008. [Google Scholar] [CrossRef] [PubMed]

- Franco, W.; Maffiodo, D.; De Benedictis, C.; Ferraresi, C. Dynamic Modeling and Experimental Validation of a Haptic Finger Based on a McKibben Muscle. Mech. Mach. Sci. 2019, 66, 251–259. [Google Scholar] [CrossRef]

- Chen, G.; Pham, M.T.; Maalej, T.; Fourati, H.; Moreau, R.; Sesmat, S. A Biomimetic Steering Robot for Minimally Invasive Surgery Application. In Advances in Robot Manipulators; Hall, E., Ed.; IntechOpen Limited: London, UK, 2010; pp. 1–25. [Google Scholar]

- Klein, J.; Spencer, S.J.; Allington, J.; Minakata, K.; Wolbrecht, E.T.; Smith, R.; Bobrow, J.E.; Reinkensmeyer, D.J. Biomimetic Orthosis for the Neurorehabilitation of the Elbow and Shoulder (BONES). In Proceedings of the 2nd Biennial IEEE/RAS-EMBS International Conference on Biomedical Robotics and Biomechatronics, Scottsdale, AZ, USA, 19–22 October 2008; pp. 535–541. [Google Scholar]

- Lyu, M.; Chen, W.; Ding, X.; Wang, J.; Bai, S.; Ren, H. Design of a Biologically Inspired Lower Limb Exoskeleton for Human Gait Rehabilitation. Rev. Sci. Instrum. 2016, 87, 104301. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.; Ahn, K.H.; Nam, S.K.; Hyun, D.J. Upper Extremity Exoskeleton System to Generate Customized Therapy Motions for Stroke Survivors. Rob. Auton. Syst. 2022, 154, 104128. [Google Scholar] [CrossRef]

- Zeilig, G.; Weingarden, H.; Zwecker, M.; Dudkiewicz, I.; Bloch, A.; Esquenazi, A. Safety and Tolerance of the ReWalk Exoskeleton Suit for Ambulation by People with Complete Spinal Cord Injury: A Pilot Study. J. Spinal Cord Med. 2012, 35, 96–101. [Google Scholar] [CrossRef] [Green Version]

- Polygerinos, P.; Lyne, S.; Wang, Z.; Nicolini, L.F.; Mosadegh, B.; Whitesides, G.M.; Walsh, C.J. Towards a Soft Pneumatic Glove for Hand Rehabilitation. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems (IROS), Tokyo, Japan, 3–7 November 2013; pp. 1512–1517. [Google Scholar]

- Chen, S.; Wang, Z.; Li, Y.; Tang, J.; Wang, X.; Huang, L.; Fang, Z.; Xu, T.; Xu, J.; Guo, F.; et al. Safety and Feasibility of a Novel Exoskeleton for Locomotor Rehabilitation of Subjects With Spinal Cord Injury: A Prospective, Multi-Center, and Cross-Over Clinical Trial. Front. Neurorobot. 2022, 16, 1–15. [Google Scholar] [CrossRef]

- Kim, S.; Asbeck, A.T.; Cutkosky, M.R.; Provancher, W.R. SpinybotII: Climbing Hard Walls with Compliant Microspines. In Proceedings of the 2005 International Conference on Advanced Robotics, ICAR ’05, Seattle, WA, USA, 18–20 July 2005; Volume 2005, pp. 601–606. [Google Scholar]

- Rollinson, D.; Choset, H. Pipe Network Locomotion with Snake Robot. J. Field Robot. 2014, 33, 322–336. [Google Scholar] [CrossRef]

- Cianchetti, M.; Calisti, M.; Margheri, L.; Kuba, M.; Laschi, C. Bioinspired Locomotion and Grasping in Water: The Soft Eight-Arm OCTOPUS Robot. Bioinspir. Biomim. 2015, 10, 035003. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Picardi, G.; Chellapurath, M.; Iacoponi, S.; Laschi, C.; Calisti, M. Surveying and Cleaning Plastic Pollution in the Sediment: SILVER+ Approach. In OCEANS 2019-Marseille; IEEE: Marseille, France, 2019; pp. 1–8. [Google Scholar]

- Sadeghi, A.; Mondini, A.; Del Dottore, E.; Mattoli, V.; Beccai, L.; Taccola, S.; Lucarotti, C.; Totaro, M.; Mazzolai, B. A Plant-Inspired Robot with Soft Differential Bending Capabilities. Bioinspir. Biomim. 2017, 12, 015001. [Google Scholar] [CrossRef] [Green Version]

- Rus, D.; Tolley, M.T. Design, Fabrication and Control of Soft Robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Guo, L.; Li, K.; Cheng, G.; Zhang, Z.; Xu, C.; Ding, J. Design and Experiments of Pneumatic Soft Actuators. Robotica 2021, 39, 1806–1815. [Google Scholar] [CrossRef]

- Alici, G.; Mui, B.; Cook, C. Bending Modeling and Its Experimental Verification for Conducting Polymer Actuators Dedicated to Manipulation Applications. Sens. Actuators A Phys. 2006, 126, 396–404. [Google Scholar] [CrossRef]

- Mirfakhrai, T.; Madden, J.D.W.; Baughman, R.H. Polymer Artificial Muscles. Mater. Today 2007, 10, 30–38. [Google Scholar] [CrossRef]

- Small, W., IV; Wilson, T.S.; Benett, W.J.; Loge, J.M.; Maitland, D.J. Laser-Activated Shape Memory Polymer Intravascular Thrombectomy Device. Opt. Express 2005, 13, 8204. [Google Scholar] [CrossRef] [PubMed]

- Copaci, D.; Blanco, D.; Moreno, L.E. Flexible Shape-Memory Alloy-Based Actuator: Mechanical Design Optimization According to Application. Actuators 2019, 8, 63. [Google Scholar] [CrossRef] [Green Version]

- Villoslada, A.; Flores, A.; Copaci, D.; Blanco, D.; Moreno, L. High-Displacement Flexible Shape Memory Alloy Actuator for Soft Wearable Robots. Robot. Auton. Syst. 2015, 73, 91–101. [Google Scholar] [CrossRef]

- Takashima, K.; Imazawa, T.; Cho, H. Variable-Stiffness and Deformable Link Using Shape-Memory Material and Jamming Transition Phenomenon. J. Robot. Mechatron. 2022, 34, 466–477. [Google Scholar] [CrossRef]

- Ionov, L. Hydrogel-Based Actuators: Possibilities and Limitations. Mater. Today 2014, 17, 494–503. [Google Scholar] [CrossRef]

- Amend, J.R.; Brown, E.; Rodenberg, N.; Jaeger, H.M.; Lipson, H. A Positive Pressure Universal Gripper Based on the Jamming of Granular Material. IEEE Trans. Robot. 2012, 28, 341–350. [Google Scholar] [CrossRef]

- Ranzani, T.; Cianchetti, M.; Gerboni, G.; De Falco, I.; Menciassi, A. A Soft Modular Manipulator for Minimally Invasive Surgery: Design and Characterization of a Single Module. IEEE Trans. Robot. 2016, 32, 187–200. [Google Scholar] [CrossRef]

- Hartzell, C.M.; Choi, Y.T.; Wereley, N.M.; Leps, T.J.G. Performance of a Magnetorheological Fluid-Based Robotic End Effector. Smart Mater. Struct. 2019, 28, 035030. [Google Scholar] [CrossRef]

- Xie, D.; Ma, Z.; Liu, J.; Zuo, S. Pneumatic Artificial Muscle Based on Novel Winding Method. Actuators 2021, 10, 100. [Google Scholar] [CrossRef]

- Fracczak, L.; Nowak, M.; Koter, K. Flexible Push Pneumatic Actuator with High Elongation. Sens. Actuators A Phys. 2021, 321, 112578. [Google Scholar] [CrossRef]

- Ferraresi, C.; Franco, W.; Manuello Bertetto, A. Flexible Pneumatic Actuators: A Comparison between the McKibben and the Straight Fibres Muscle. J. Robot. Mechatron. 2001, 13, 56–63. [Google Scholar] [CrossRef]

- Cacucciolo, V.; Renda, F.; Poccia, E.; Laschi, C.; Cianchetti, M. Modelling the Nonlinear Response of Fi Bre- Reinforced Bending Fluidic Actuators. Smart Mater. Struct. 2016, 25, 105020. [Google Scholar] [CrossRef] [Green Version]

- Belforte, G.; Eula, G.; Ivanov, A.; Sirolli, S. Soft Pneumatic Actuators for Rehabilitation. Actuators 2014, 3, 84–106. [Google Scholar] [CrossRef] [Green Version]

- Manuello Bertetto, A.; Cadeddu, A.; Besalduch, L.A.; Ricciu, R.; Ferraresi, C. Energy Balance and Mechanical Behaviour of a Flexible Pneumatic Actuator for Fish-like Propulsion. Int. J. Mech. Control 2016, 17, 23–30. [Google Scholar]

- Ferraresi, C.; Manuello Bertetto, A.; Costamagna, A.; Gollè, D. Integrated Fin-Actuator Systems for a marine robot. In Proceedings of the 12th International Workshop on Robotics in Alpe-Adria-Danube Region (RAAD), Cassino, Italy, 7–10 May 2003. [Google Scholar]

- Kojima, A.; Okui, M.; Nakamura, T. Development of Soft Pneumatic Actuators Using High-Strain Elastic Materials with Stress Anisotropy of Short Fibers. Proceedings 2020, 64, 41. [Google Scholar] [CrossRef]

- Carello, M.; Ferraresi, C.; Visconte, C. A New Flexible Pneumatic Finger for a Fruit Harvesting Hand. In Proceedings of the 7th International Symposium on Fluid Control, Measurement and Visualization, Sorrento, Italy, 25–28 August 2003. [Google Scholar]

- Ferraresi, C.; Manuello Bertetto, A.; Mazza, L. Design and Realisation of a Flexible Pneumatic Actuator for Robotics. In Proceedings of the 5th Scandinavian International Conference on Fluid Power, SICFP ’97, Linkoping, Sweden, 28–30 May 1997; pp. 29–43. [Google Scholar]

- Walker, J.; Zidek, T.; Harbel, C.; Sanghyun, Y.; Strickland, F.S.; Kumar, S.; Shin, M. Soft Robotics: A Review of Recent Developments of Pneumatic Soft Actuators. Actuators 2020, 9, 3. [Google Scholar] [CrossRef] [Green Version]

- Belforte, G.; Raparelli, T.; Sirolli, S.A. A Novel Geometric Formula for Predicting Contractile Force in McKibben Pneumatic Muscles. Int. J. Autom. Technol. 2017, 11, 368–377. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Beomonte Zobel, P.; Durante, F.; Raparelli, T. Numerical Modelling and Experimental Validation of a McKibben Pneumatic Muscle Actuator. J. Intell. Mater. Syst. Struct. 2017, 28, 2737–2748. [Google Scholar] [CrossRef]

- Durante, F.; Antonelli, M.G.; Beomonte Zobel, P.; Raparelli, T. Development of a Straight Fibers Pneumatic Muscle. Int. J. Autom. Technol. 2018, 12, 413–423. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Beomonte Zobel, P.; D’Ambrogio, W.; Durante, F.; Raparelli, T. An Analytical Formula for Designing McKibben Pneumatic Muscles. Int. J. Mech. Eng. Technol. 2018, 9, 320–337. [Google Scholar]

- Durante, F.; Antonelli, M.G.; Beomonte Zobel, P.; Raparelli, T. A Procedure for the Fatigue Life Prediction of Straight Fibers Pneumatic Muscles. Actuators 2021, 10, 300. [Google Scholar] [CrossRef]

- Belforte, G.; Eula, G.; Appendino, S. Design and Development of Innovative Textile Pneumatic Muscles. J. Text. Inst. 2012, 103, 733–743. [Google Scholar] [CrossRef]

- Belforte, G.; Eula, G.; Ivanov, A.; Raparelli, T.; Sirolli, S. Study and Experimentation of Innovative Textile Pneumatic Muscle Prototypes. Mech. Mach. Sci. 2018, 49, 854–861. [Google Scholar] [CrossRef]

- Ferraresi, C.; Franco, W.; Quaglia, G. A Novel Bi-Directional Deformable Fluid Actuator. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 2799–2809. [Google Scholar] [CrossRef] [Green Version]

- Muscolo, G.G.; Fontana, M. A Novel Linear Pneumatic Actuator with Tunable Compliance Constraint. Int. J. Mech. Control 2020, 21, 73–85. [Google Scholar]

- Hassan, T.; Cianchetti, M.; Moatamedi, M.; Mazzolai, B.; Laschi, C.; Dario, P. Finite-Element Modeling and Design of a Pneumatic Braided Muscle Actuator With Multifunctional Capabilities. IEEE/ASME Trans. Mechatron. 2019, 24, 109–119. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Beomonte Zobel, P.; D’ambrogio, W.; Durante, F. Design Methodology for a Novel Bending Pneumatic Soft Actuator for Kinematically Mirroring the Shape of Objects. Actuators 2020, 9, 113. [Google Scholar] [CrossRef]

- Cataudella, C.; Ferraresi, C.; Manuello Bertetto, A. Flexible Actuator for Oscillating Tail Marine Robot. Int. J. Mech. 2001, 2, 13–21. [Google Scholar]

- Belforte, G.; Dabbene, F.; Ferraresi, C.; Gay, P.; Manuello Bertetto, A. Sensorizzazione e Controllo Di Un Manipolatore Pneumatico Flessibile. In Proceedings of the XXX Convegno Nazionale dell’Associazione Italiana per l’Analisi delle Sollecitazioni, Alghero, Italy, 12–15 September 2001; pp. 1387–1396. [Google Scholar]

- Ferraresi, C.; Manuello Bertetto, A.; Mazza, L. Studio Della Sensorizzazione Di Un Manipolatore Pneumatico Flessibile. In Proceedings of the 41° Convegno Nazionale ANIPLA, Turin, Italy, 5–7 November 1997; pp. 503–511. [Google Scholar]

- Cianchetti, M.; Ranzani, T.; Gerboni, G.; De Falco, I.; Laschi, C.; Menciassi, A. STIFF-FLOP Surgical Manipulator: Mechanical Design and Experimental Characterization of the Single Module. In Proceedings of the 2013 IEEE International Conference on Intelligent Robots ans Systems (IROS), Tokyo, Japan, 3–7 November 2013; pp. 3576–3581. [Google Scholar]

- Ranzani, T.; Gerboni, G.; Cianchetti, M.; Menciassi, A. A Bioinspired Soft Manipulator for Minimally Invasive Surgery. Bioinspir. Biomim. 2015, 10, 035008. [Google Scholar] [CrossRef]

- Lorenzon, L.; Beccali, G.; Maselli, M.; Cianchetti, M. A Self-Sensing Inverse Pneumatic Artificial Muscle. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics, RoboSoft 2022, Edinburgh, UK, 4–8 April 2022; pp. 817–822. [Google Scholar] [CrossRef]

- Ferraresi, C.; De Benedictis, C.; Maffiodo, D.; Franco, W.; Messere, A.; Pertusio, R.; Roatta, S. Design and Simulation of a Novel Pneumotronic System Aimed to the Investigation of Vascular Phenomena Induced by Limb Compression. J. Bionic Eng. 2019, 16, 550–562. [Google Scholar] [CrossRef]

- Ferraresi, C.; De Benedictis, C.; Maffiodo, D.; Franco, W.; Messere, A.; Pertusio, R.; Roatta, S. A Novel Pneutronic Device for the Investigation of Compression-Induced Physiological Phenomena: Modeling and Experimental Testing. In New Trends in Medical and Service Robotics. Mechanism and Machine Science; Carbone, G., Ceccarelli, M., Pisla, D., Eds.; Springer: Cham, Switzerland, 2019; pp. 182–190. ISBN 978-3-030-00329-6. [Google Scholar] [CrossRef]

- Manuello Bertetto, A.; Meili, S.; Ferraresi, C.; Maffiodo, D.; Crisafulli, A.; Concu, A. A Mechatronic Pneumatic Device to Improve Diastolic Function by Intermittent Action on Lower Limbs. Int. J. Autom. Technol. 2017, 11, 501–508. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Beomonte Zobel, P.; Raimondi, P.; Raparelli, T.; Costanzo, G. An Innovative Brace with Pneumatic Thrusts for Scoliosis Treatment. Int. J. Des. Nat. Ecodynamics 2010, 5, 354–367. [Google Scholar] [CrossRef]

- Mannella, D.; Bellusci, M.; Graziani, F.; Ferraresi, C.; Muscolo, G.G. Modelling, Design and Control of a New Seat-Cushion for Pressure Ulcers Prevention. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2022, 236, 592–602. [Google Scholar] [CrossRef]

- Belforte, G.; Eula, G.; Ivanov, A.; Visan, A.L. Bellows Textile Muscle. J. Text. Inst. 2014, 105, 356–364. [Google Scholar] [CrossRef]

- Messere, A.; Tschakovsky, M.; Seddone, S.; Lulli, G.; Franco, W.; Maffiodo, D.; Ferraresi, C.; Roatta, S. Hyper-Oxygenation Attenuates the Rapid Vasodilatory Response to Muscle Contraction and Compression. Front. Physiol. 2018, 9, 1078. [Google Scholar] [CrossRef] [Green Version]

- Messere, A.; Pertusio, R.; Macrì, C.; Maffiodo, D.; Franco, W.; De Benedictis, C.; Ferraresi, C.; Roatta, S. Delivery of Customizable Compressive Patterns to Human Limbs to Investigate Vascular Reactivity. Biomed. Phys. Eng. Express 2018, 4, 067003. [Google Scholar] [CrossRef]

- Ermini, L.; Ferraresi, C.; De Benedictis, C.; Roatta, S. Objective Assessment of Venous Pulse Wave Velocity in Healthy Humans. Ultrasound Med. Biol. 2020, 46, 849–854. [Google Scholar] [CrossRef]

- Ermini, L.; Chiarello, N.E.; De Benedictis, C.; Ferraresi, C.; Roatta, S. Venous Pulse Wave Velocity Variation in Response to a Simulated Fluid Challenge in Healthy Subjects. Biomed. Signal Process. Control 2021, 63, 102177. [Google Scholar] [CrossRef]

- Safar, M.E. Arterial Stiffness as a Risk Factor for Clinical Hypertension. Nat. Rev. Cardiol. 2018, 15, 97–105. [Google Scholar] [CrossRef] [PubMed]

- Boutouyrie, P.; Briet, M.; Collin, C.; Vermeersch, S.; Pannier, B. Assessment of Pulse Wave Velocity. Artery Res. 2008, 3, 3–8. [Google Scholar] [CrossRef]

- Ferraresi, C.; Maffiodo, D.; Hajimirzaalian, H. A Model-Based Method for the Design of Intermittent Pneumatic Compression Systems Acting on Humans. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2014, 228, 118–126. [Google Scholar] [CrossRef] [PubMed]

- Ferraresi, C.; Maffiodo, D.; Hajimirzaalian, H. Simulation and Control of a Robotic Device for Cardio-Circulatory Rehabilitation. In Advances in Robot Design and Intelligent Control; Borangiu, T., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 357–365. [Google Scholar] [CrossRef]

- Maffiodo, D.; De Nisco, G.; Gallo, D.; Audenino, A.; Morbiducci, U.; Ferraresi, C. A Reduced-Order Model-Based Study on the Effect of Intermittent Pneumatic Compression of Limbs on the Cardiovascular System. J. Eng. Med. 2016, 230, 279–287. [Google Scholar] [CrossRef]

- Schairer, J.R.; Stein, P.D.; Keteyian, S.; Fedel, F.; Ehrman, J.; Alam, M.; Henry, J.W.; Shaw, T. Left Ventricular Response to Submaximal Exercise in Endurance-Trained Athletes and Sedentary Adults. Am. J. Cardiol. 1992, 70, 930–933. [Google Scholar] [CrossRef]

- Bellusci, M.; Ferraresi, C.; Muscolo, G.G. Design and Control of a Reclining Chair with Soft Pneumatic Cushions. In Advances in Service and Industrial Robotics; Muller, A., Brandstötter, M., Eds.; Springer International Publishing: Cham, Switzerland, 2022; Volume 120, pp. 239–246. ISBN 9783031048692. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Beomonte Zobel, P.; Durante, F.; Gaj, F. Development and Testing of a Grasper for NOTES Powered by Variable Stiffness Pneumatic Actuation. Int. J. Med. Robot. Comput. Assist. Surg. 2017, 13, 1–12. [Google Scholar] [CrossRef]

- Franco, W.; Maffiodo, D.; De Benedictis, C.; Ferraresi, C. Use of McKibben Muscle in a Haptic Interface. Robotics 2019, 8, 13. [Google Scholar] [CrossRef] [Green Version]

- De Benedictis, C.; Franco, W.; Maffiodo, D.; Ferraresi, C. Hand Rehabilitation Device Actuated by a Pneumatic Muscle. Mech. Mach. Sci. 2019, 67, 102–111. [Google Scholar] [CrossRef]

- Antonelli, M.G.; Beomonte Zobel, P.; Durante, F.; Raparelli, T. Development and Pre-Clinical Investigation of a Massage Device for the Low Back. Int. J. Mech. Eng. Technol. 2018, 9, 742–754. [Google Scholar]

- Raparelli, T.; Beomonte Zobel, P.; Durante, F.; Antonelli, M.G.; Raimondi, P.; Costanzo, G. First Clinical Investigation on a Pneumatic Lumbar Unloading Orthosis. In Proceedings of the 2007 IEEE/ICME International Conference on Complex Medical Engineering, Beijing, China, 23–27 May 2007; pp. 1327–1330. [Google Scholar]

- Durante, F.; Antonelli, M.G.; Beomonte Zobel, P. Development of an Active Exoskeleton for Assisting Back Movements in Lifting Weights. Int. J. Mech. Eng. Robot. Res. 2018, 7, 353–360. [Google Scholar] [CrossRef]

- Magnetti Gisolo, S.; Muscolo, G.G.; Paterna, M.; De Benedictis, C.; Ferraresi, C. Feasibility Study of a Passive Pneumatic Exoskeleton for Upper Limbs Based on a Mckibben Artificial Muscle; Springer International Publishing: Cham, Switzerland, 2021; Volume 102, ISBN 9783030752590. [Google Scholar] [CrossRef]

- Paterna, M.; Magnetti Gisolo, S.; De Benedictis, C.; Muscolo, G.G.; Ferraresi, C. A Passive Upper-Limb Exoskeleton for Industrial Application Based on Pneumatic Artificial Muscles. Mech. Sci. 2022, 13, 387–398. [Google Scholar] [CrossRef]

- Belforte, G.; Eula, G.; Ivanov, A.; Raparelli, T.; Sirolli, S. Presentation of Textile Pneumatic Muscle Prototypes Applied in an Upper Limb Active Suit Experimental Model. J. Text. Inst. 2018, 109, 757–766. [Google Scholar] [CrossRef]

- Bottero, S.; Muscolo, G.G.; Ferraresi, C. A New Soft RCC Device with Pneumatic Regulation. Robotics 2020, 9, 98. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paterna, M.; De Benedictis, C.; Ferraresi, C. The Research on Soft Pneumatic Actuators in Italy: Design Solutions and Applications. Actuators 2022, 11, 328. https://doi.org/10.3390/act11110328

Paterna M, De Benedictis C, Ferraresi C. The Research on Soft Pneumatic Actuators in Italy: Design Solutions and Applications. Actuators. 2022; 11(11):328. https://doi.org/10.3390/act11110328

Chicago/Turabian StylePaterna, Maria, Carlo De Benedictis, and Carlo Ferraresi. 2022. "The Research on Soft Pneumatic Actuators in Italy: Design Solutions and Applications" Actuators 11, no. 11: 328. https://doi.org/10.3390/act11110328

APA StylePaterna, M., De Benedictis, C., & Ferraresi, C. (2022). The Research on Soft Pneumatic Actuators in Italy: Design Solutions and Applications. Actuators, 11(11), 328. https://doi.org/10.3390/act11110328