Implementation of Smart Materials for Actuation of Traditional Valve Technology for Hybrid Energy Systems

Abstract

:1. Introduction

2. Design and Material

2.1. Material Properties and Theory of Shape Memory Alloys

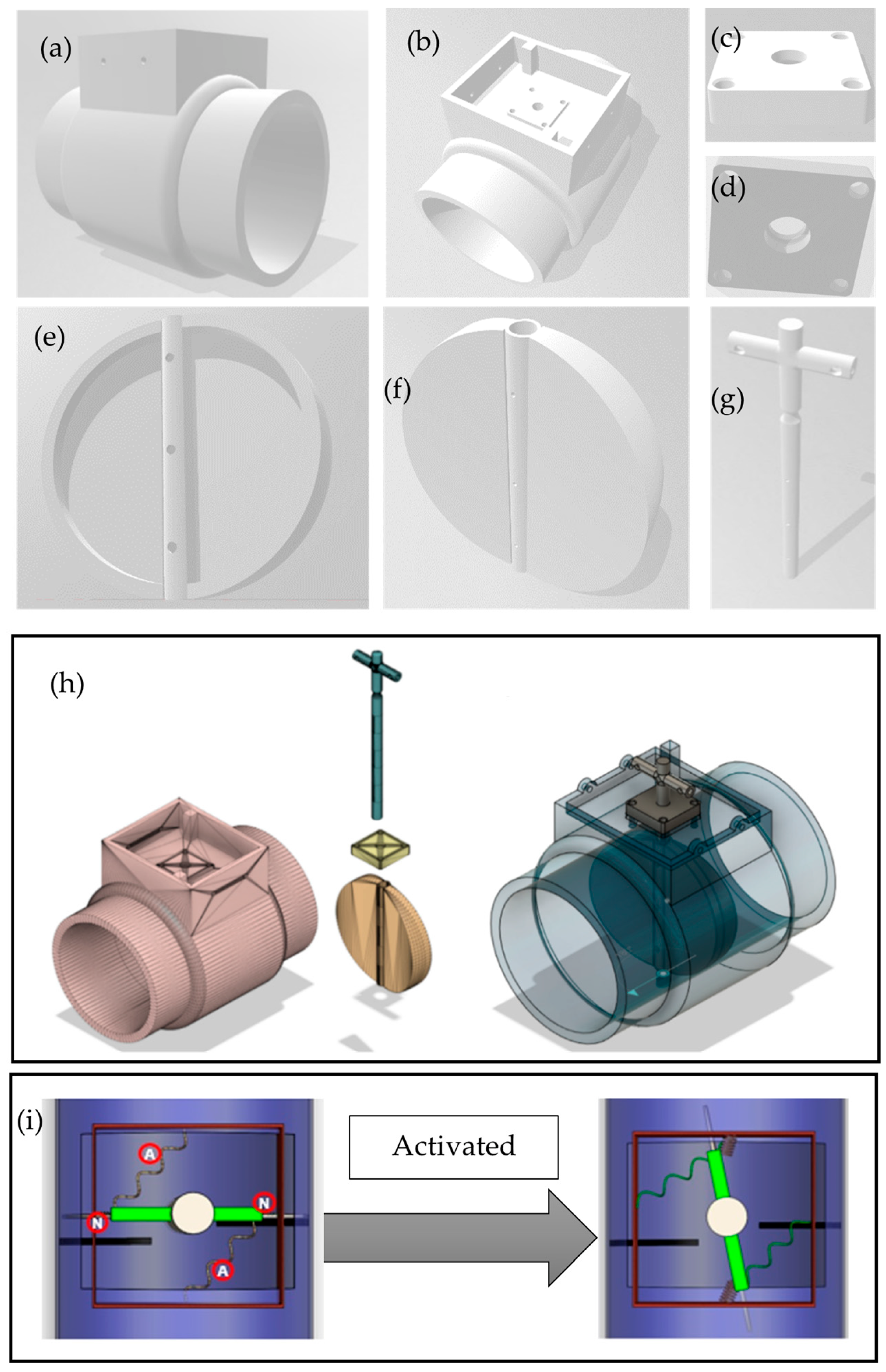

2.2. Valve Design

- Redirection of airflow;

- Placement of SMA actuating springs;

- Light rotating parts (for springs to actuate easily);

- Leakproof;

- SMA springs wiring.

2.3. Boundary Conditions

3. Experimental Section

3.1. 3D Printing of the Valve

3.2. Instruments

3.3. Testing Setup

3.4. Experimental Method

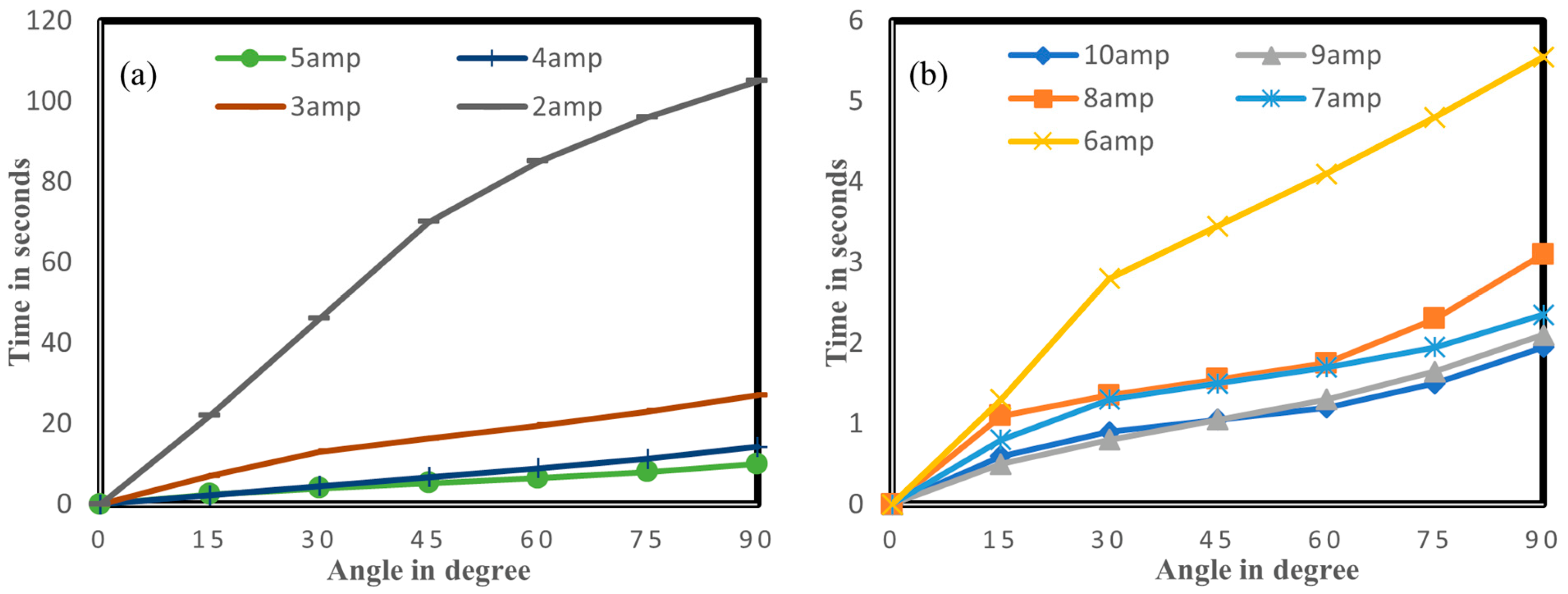

3.4.1. SMA Spring Compression Time

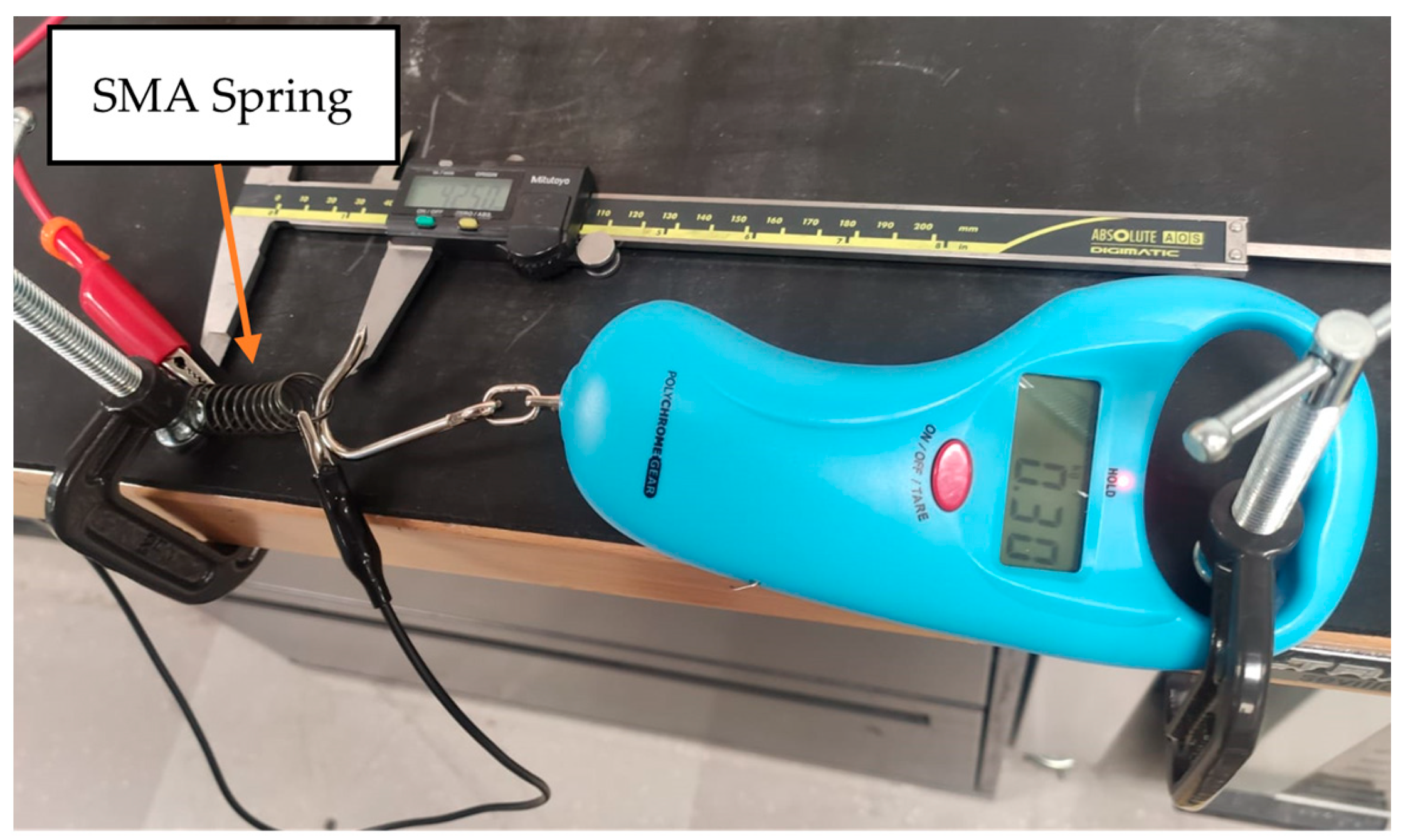

3.4.2. Spring Load Capacity Test

3.4.3. Actuation Time and Flow Output Test of the Valve

4. Result and Discussion

4.1. Mechanical Properties of SMA Springs

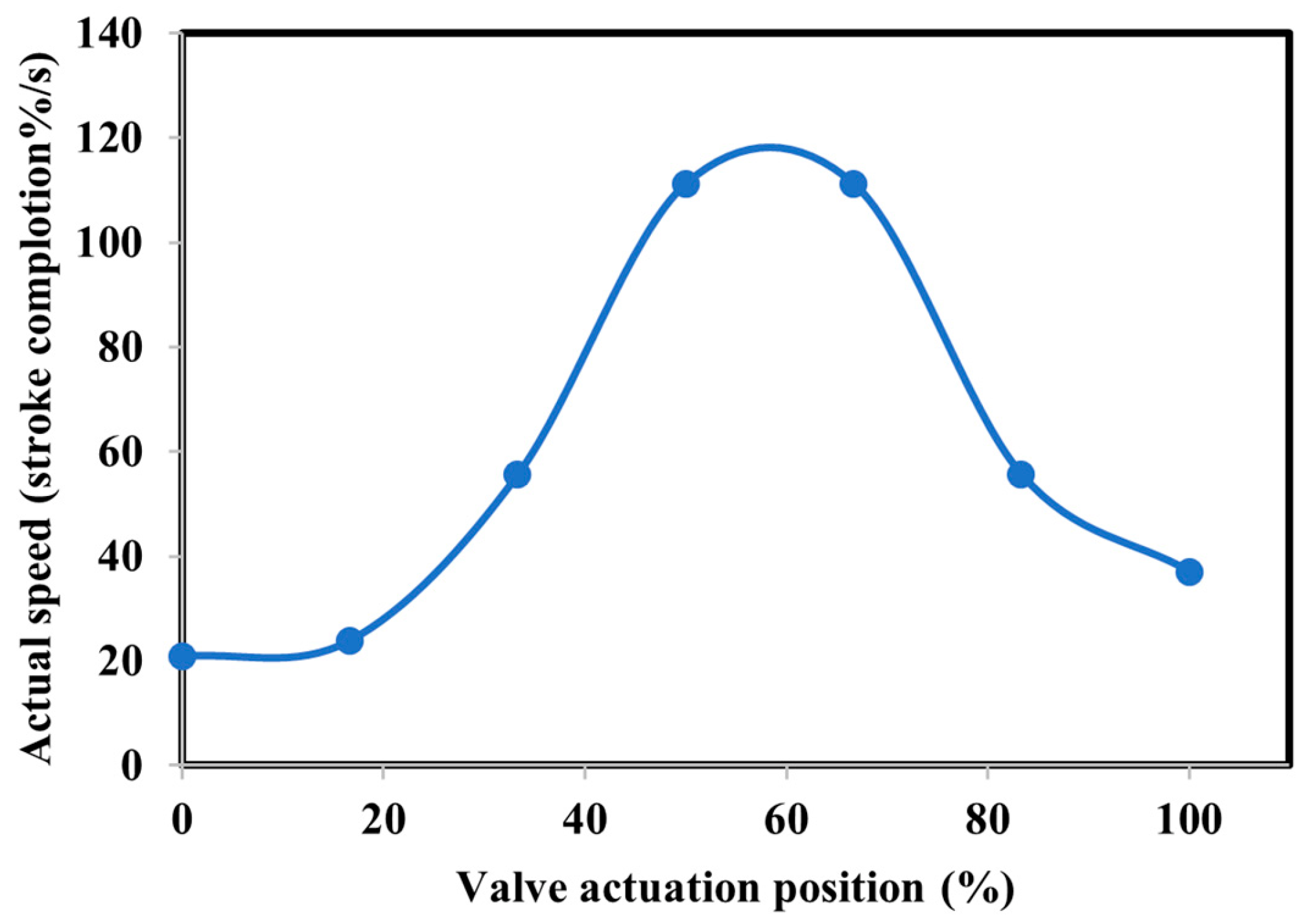

4.2. Actuation of 3D Printed Valve with SMA Springs

4.3. Flow Control of the 3D Printed Valve

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burman, A.; Møster, E.; Abrahamsson, P. On the Influence of Functional Materials on Engineering Design. Res. Eng. Des. 2000, 12, 39. [Google Scholar] [CrossRef]

- 1/2 Description Specifications Accessories Data Sheets CAD Video Repair Parts. Available online: https://www.valworx.com/product/electric-actuated-butterfly-valve-3-lug-epdm-12-or-24-vdc/electric-actuated-butterfly-valves-lug-style-on-off?utm_source=google&utm_medium=surfaces&utm_campaign=Surfaces (accessed on 14 September 2022).

- In Air Actuated Butterfly Valve, Wafer, EPDM|Valworx. Available online: https://www.valworx.com/product/air-actuated-butterfly-valve-3-waferepdmdouble-acting/air-actuated-butterfly-valves-wafer/ (accessed on 27 September 2022).

- Lubecki, M.; Stosiak, M.; Skačkauskas, P.; Karpenko, M.; Deptuła, A.; Urbanowicz, K. Development of Composite Hydraulic Actuators: A Review. Actuators 2022, 11, 365. [Google Scholar] [CrossRef]

- Mohith, S.; Upadhya, A.R.; Navin, K.P.; Kulkarni, S.M.; Rao, M. Recent trends in piezoelectric actuators for precision motion and their applications: A review. Smart Mater. Struct. 2020, 30, 013002. [Google Scholar] [CrossRef]

- Apicella, V.; Clemente, C.S.; Davino, D.; Leone, D.; Visone, C. Review of Modeling and Control of Magnetostrictive Actuators. Actuators 2019, 8, 45. [Google Scholar] [CrossRef] [Green Version]

- Ruth, D.J.S.; Dhanalakshmi, K.; Nakshatharan, S.S. Bidirectional angular control of an integrated sensor/actuator shape memory alloy based system. Measurement 2015, 69, 210–221. [Google Scholar] [CrossRef]

- Renata, C.; Kalairaj, M.S.; Chen, H.M.; Lau, G.K.; Huang, W.M. Buttons on Demand Sliding Mechanism Driven by Smart Materials and Mechanical Design. Actuators 2021, 10, 251. [Google Scholar] [CrossRef]

- Rajagopalan, R.; Petruska, A.J.; Howard, D. A Bi-State Shape Memory Material Composite Soft Actuator. Actuators 2022, 11, 86. [Google Scholar] [CrossRef]

- Kostov, M.; Todorov, T.; Mitrev, R.; Kamberov, K.; Nikolov, R. A Study of a Bistable Reciprocating Piston Pump Driven by Shape Memory Alloys and Recuperative Springs. Actuators 2023, 12, 90. [Google Scholar] [CrossRef]

- Straub, F.K.; Merkley, D.J. Design of a smart material actuator for rotor control. In Smart Structures and Materials 1995: Smart Structures and Integrated Systems; SPIE: Bellingham, WA, USA, 1997. [Google Scholar]

- Cortez-Vega, R.; Chairez, I.; Luviano-Juárez, A.; Feliu-Batlle, V. A hybrid dynamic model of shape memory alloy spring actuators. Measurement 2018, 114, 340–353. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Hassan, S.; Billah, K.M.M.; Hall, S.E.; Sepulveda, S.; Regis, J.E.; Marquez, C.; Cordova, S.; Whitaker, J.; Robison, T.; Keating, J.; et al. Selective Laser Sintering of High-Temperature Thermoset Polymer. J. Compos. Sci. 2022, 6, 41. [Google Scholar] [CrossRef]

- Chavez, L.A.; Ibave, P.; Hassan, S.; Hall-Sanchez, S.E.; Billah, K.M.M.; Leyva, A.; Marquez, C.; Espalin, D.; Torres, S.; Robison, T.; et al. Low-temperature selective laser sintering 3D printing of PEEK-Nylon blends: Impact of thermal post-processing on mechanical properties and thermal stability. J. Appl. Polym. Sci. 2022, 139, 52290. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. Powder bed fusion processes. In Laser Additive Manufacturing; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 55–77. [Google Scholar]

- Ahn, D.-G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf. Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Ziaee, M.; Crane, N.B. Binder jetting: A review of process, materials, and methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Del-Mazo-Barbara, L.; Ginebra, M.-P. Rheological characterisation of ceramic inks for 3D direct ink writing: A review. J. Eur. Ceram. Soc. 2021, 41, 18–33. [Google Scholar] [CrossRef]

- Regis, J.E.; Renteria, A.; Hall, S.E.; Hassan, S.; Marquez, C.; Lin, Y. Recent trends and innovation in additive manufacturing of soft functional materials. Materials 2021, 14, 4521. [Google Scholar] [CrossRef]

- Hassan, S.; Chavez, L.A.; Chou, C.-C.; Hall, S.E.; Tseng, T.-L.; Lin, Y. Mechanical response of shape-recovering metamaterial structures fabricated by additive manufacturing. Mater. Res. Express 2021, 8, 115801. [Google Scholar] [CrossRef]

- Yin, R.; Huang, Q.; Yang, H.; Lu, L.; Cao, L.; Ji, W.; Jiang, S.; Luo, Y.; Liu, F.; Sun, J.; et al. Integrated-optics pressure sensor with improved range and sensitivity based on a SiO2 arrayed waveguide grating (AWG) and a 3D printed stereolithography resin module. Measurement 2021, 183, 109781. [Google Scholar] [CrossRef]

- Anadón, J.R.S. Large Force Shape Memory Alloy Linear Actuator. Master’s Thesis, University of Florida, Gainesville, FL, USA, 2002. [Google Scholar]

- Jacobsen, A.; Kristjánsdóttir, N.B. Shape Memory Alloys. Annu. Rev. Mater. Sci. 1988, 18, 25–45. [Google Scholar]

- Ma, J.; Huang, H.; Huang, J. Characteristics analysis and testing of SMA spring actuator. Adv. Mater. Sci. Eng. 2013, 2013, 823594. [Google Scholar] [CrossRef] [Green Version]

- Liang, C.; Rogers, C.A. Design of shape memory alloy springs with applications in vibration control. J. Intell. Mater. Syst. Struct. 1997, 8, 314–322. [Google Scholar] [CrossRef]

- Formentini, M.; Lenci, S. An innovative building envelope (kinetic façade) with Shape Memory Alloys used as actuators and sensors. Autom. Constr. 2018, 85, 220–231. [Google Scholar] [CrossRef]

- Singh, H.; Juikar, P.; Tiwari, T.N.; Lad, B.K.; Palani, I.A. Failure diagnosis & reliability assessment of NiTi shape memory alloy spring for micro-Actuators. In Proceedings of the 2015 International Conference on Robotics, Automation, Control and Embedded Systems (RACE), Chennai, India, 18–20 February 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Using PVC Pipe for Compressed Air. Available online: https://compressors.cp.com/en-us/expert-corner/blog/pvc-pipe-why-you-should-not-use-pvc-piping-for-your-compressed-air-system (accessed on 6 August 2022).

- Widyatama, U.; Rachman, Y.; Abdul, R.; Rachmat, H. Calculation Analysis of Cost of Production in Determining Product Selling Price. Available online: www.solidstatetechnology.us (accessed on 27 September 2022).

| Ms | Martensite start temperature upon cooling |

| Mf | Martensite finish temperature upon cooling |

| As | Reverse transformation start temperature upon heating |

| Af | Reverse transformation finish temperature upon heating |

| Wire Size | Mandrel Size | Pitch | Transition Temperature |

|---|---|---|---|

| 1 mm | 8 mm | 1 mm | 80 °C |

| Valve Condition | Inlet Flow | Outlet 1 Flow | Outlet 2 Flow |

|---|---|---|---|

| Fully Open | 60 L/min | 28 L/min | 28 L/min |

| Fully closed | 60 L/min | 6 L/min | 46 L/min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaman, S.; Leyva, A.; Hassan, M.S.; Valladolid, A.; Herrera, N.E.; Gomez, S.G.; Mahmud, M.S.; Tucker, D.; Haynes, C.; Lin, Y. Implementation of Smart Materials for Actuation of Traditional Valve Technology for Hybrid Energy Systems. Actuators 2023, 12, 131. https://doi.org/10.3390/act12030131

Zaman S, Leyva A, Hassan MS, Valladolid A, Herrera NE, Gomez SG, Mahmud MS, Tucker D, Haynes C, Lin Y. Implementation of Smart Materials for Actuation of Traditional Valve Technology for Hybrid Energy Systems. Actuators. 2023; 12(3):131. https://doi.org/10.3390/act12030131

Chicago/Turabian StyleZaman, Saqlain, Alba Leyva, Md Sahid Hassan, Ariztbe Valladolid, Nicolas E. Herrera, Sofia Gabriela Gomez, Md Shahjahan Mahmud, David Tucker, Comas Haynes, and Yirong Lin. 2023. "Implementation of Smart Materials for Actuation of Traditional Valve Technology for Hybrid Energy Systems" Actuators 12, no. 3: 131. https://doi.org/10.3390/act12030131

APA StyleZaman, S., Leyva, A., Hassan, M. S., Valladolid, A., Herrera, N. E., Gomez, S. G., Mahmud, M. S., Tucker, D., Haynes, C., & Lin, Y. (2023). Implementation of Smart Materials for Actuation of Traditional Valve Technology for Hybrid Energy Systems. Actuators, 12(3), 131. https://doi.org/10.3390/act12030131