High Precision Hybrid Torque Control for 4-DOF Redundant Parallel Robots under Variable Load

Abstract

1. Instruction

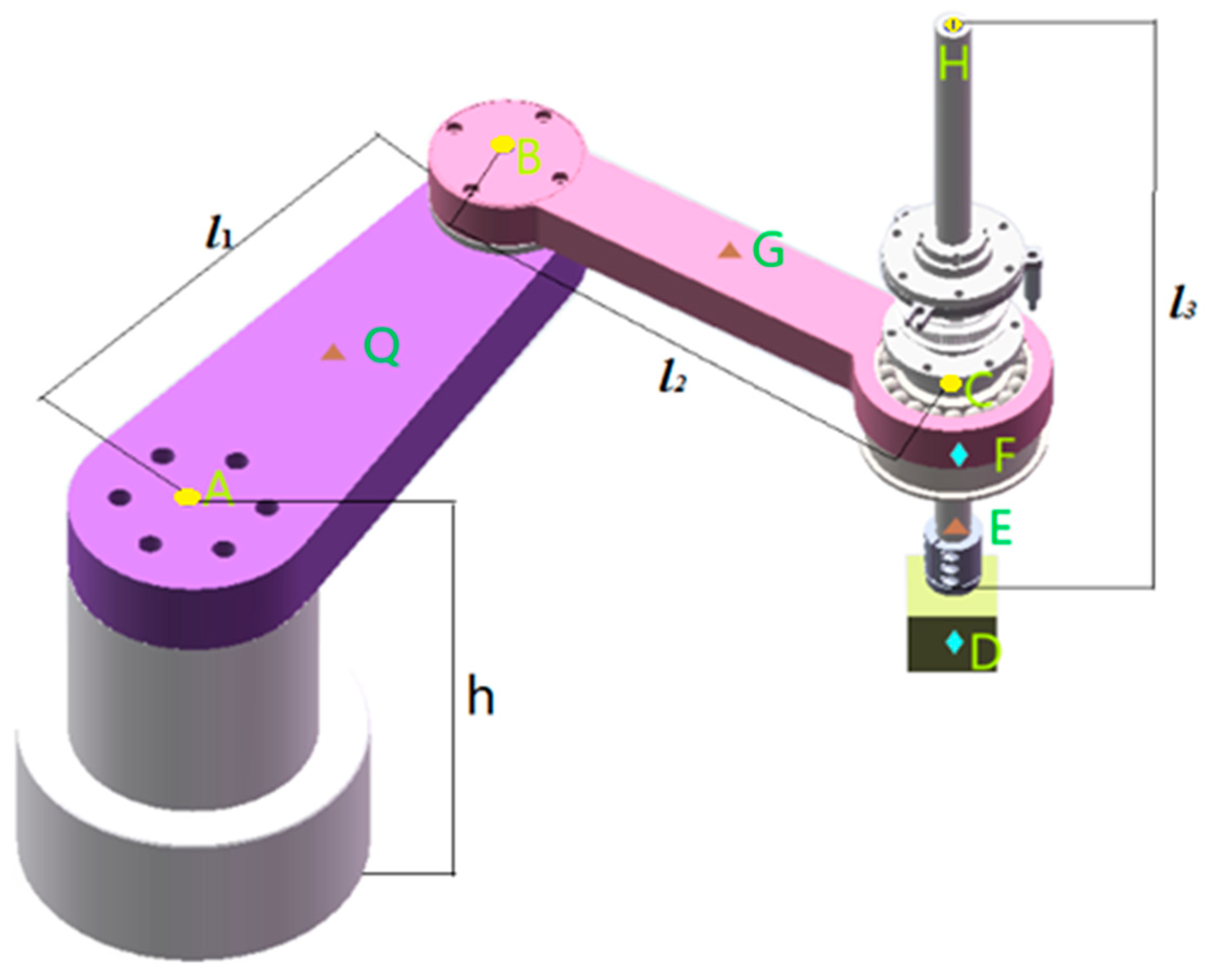

2. Construction of Time-Varying Dynamics Model of 4-DOF Redundant Parallel Robots under Variable Load

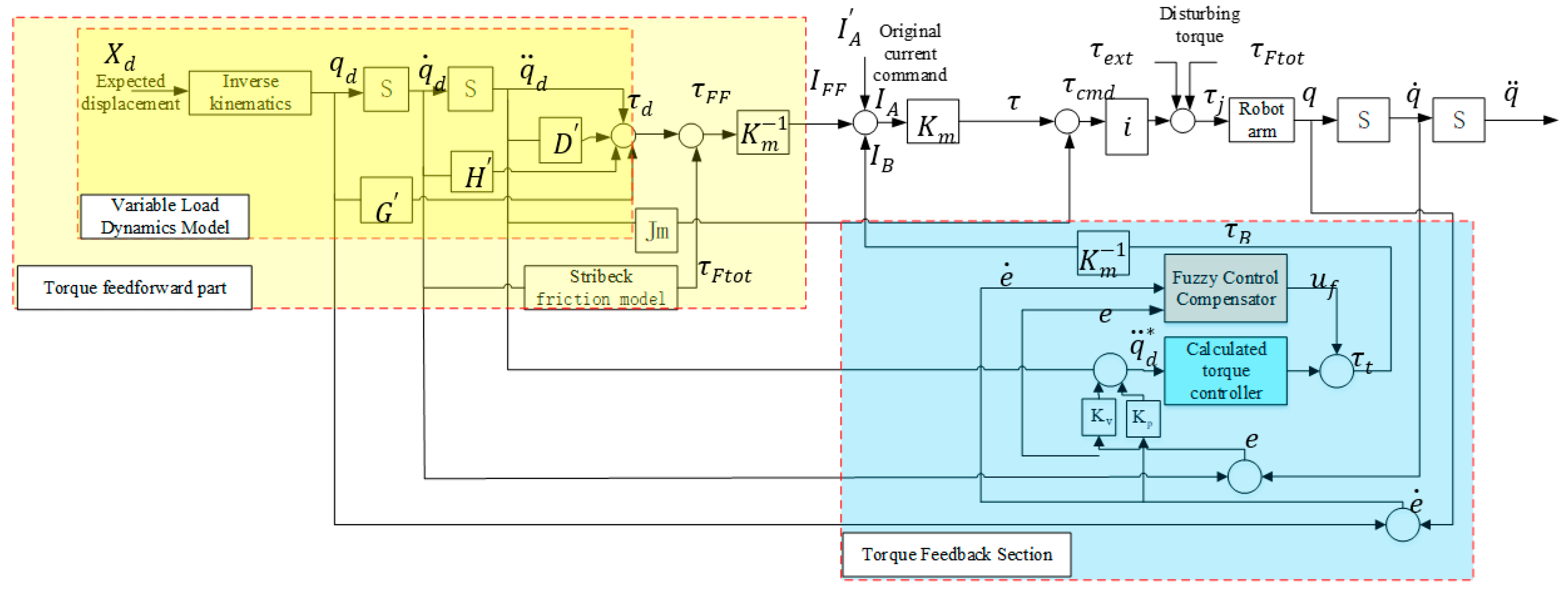

3. Establishment of Hybrid Torque Control Model

3.1. Feedforward Control of Variable Load Disturbance and Friction Torque

3.2. Calculation and Fuzzy Torque Feedback Control

3.2.1. Calculation Torque Controller Design

3.2.2. Fuzzy Controller Design

4. Simulation and Experiment

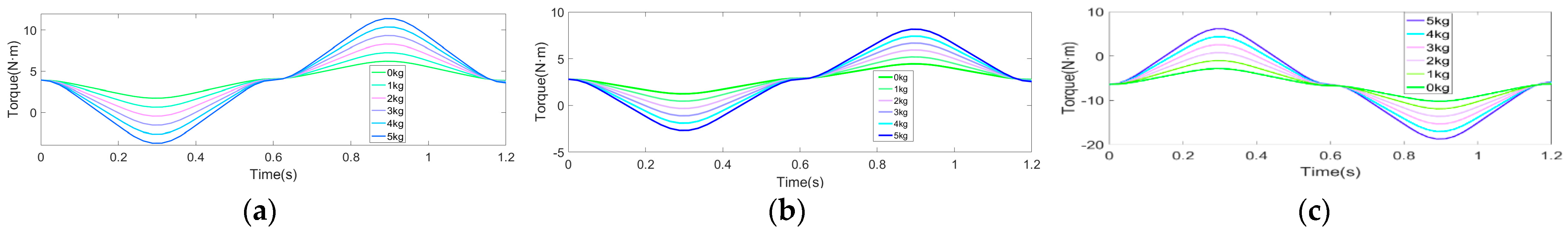

4.1. Simulation Results

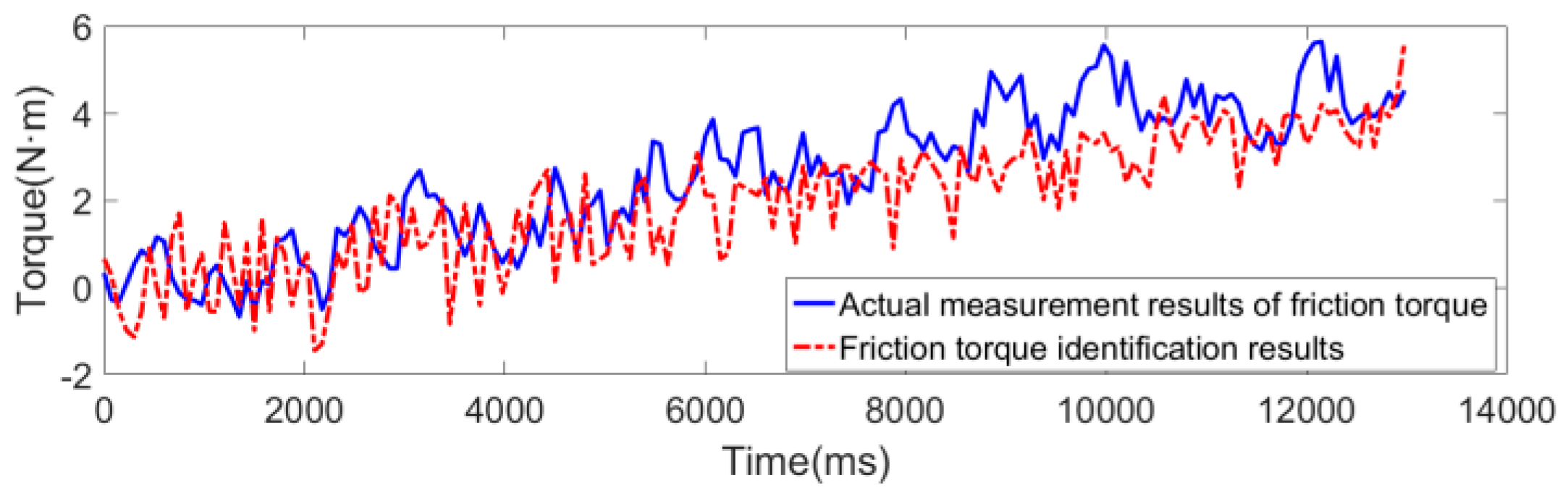

Parameter Identification Results of Stribeck Friction Model

4.2. Experiment

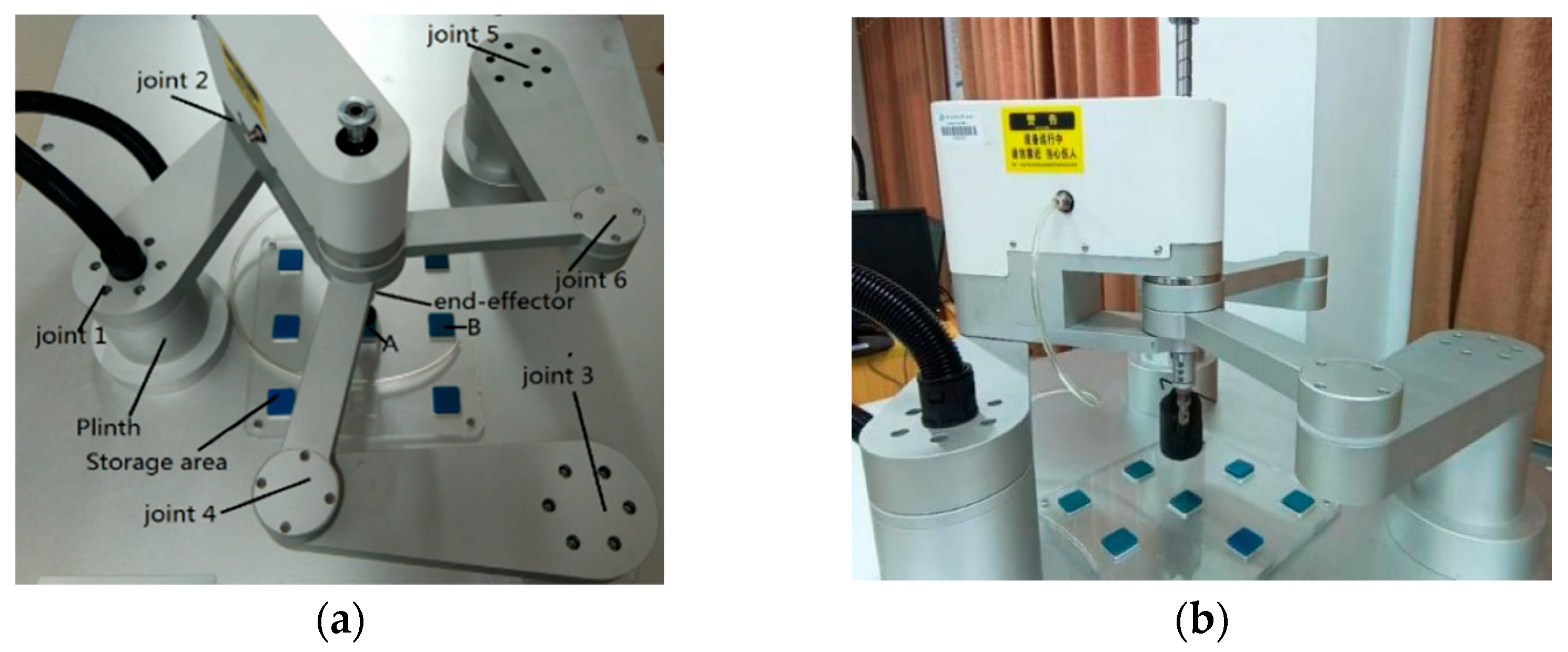

4.2.1. Experimental Design

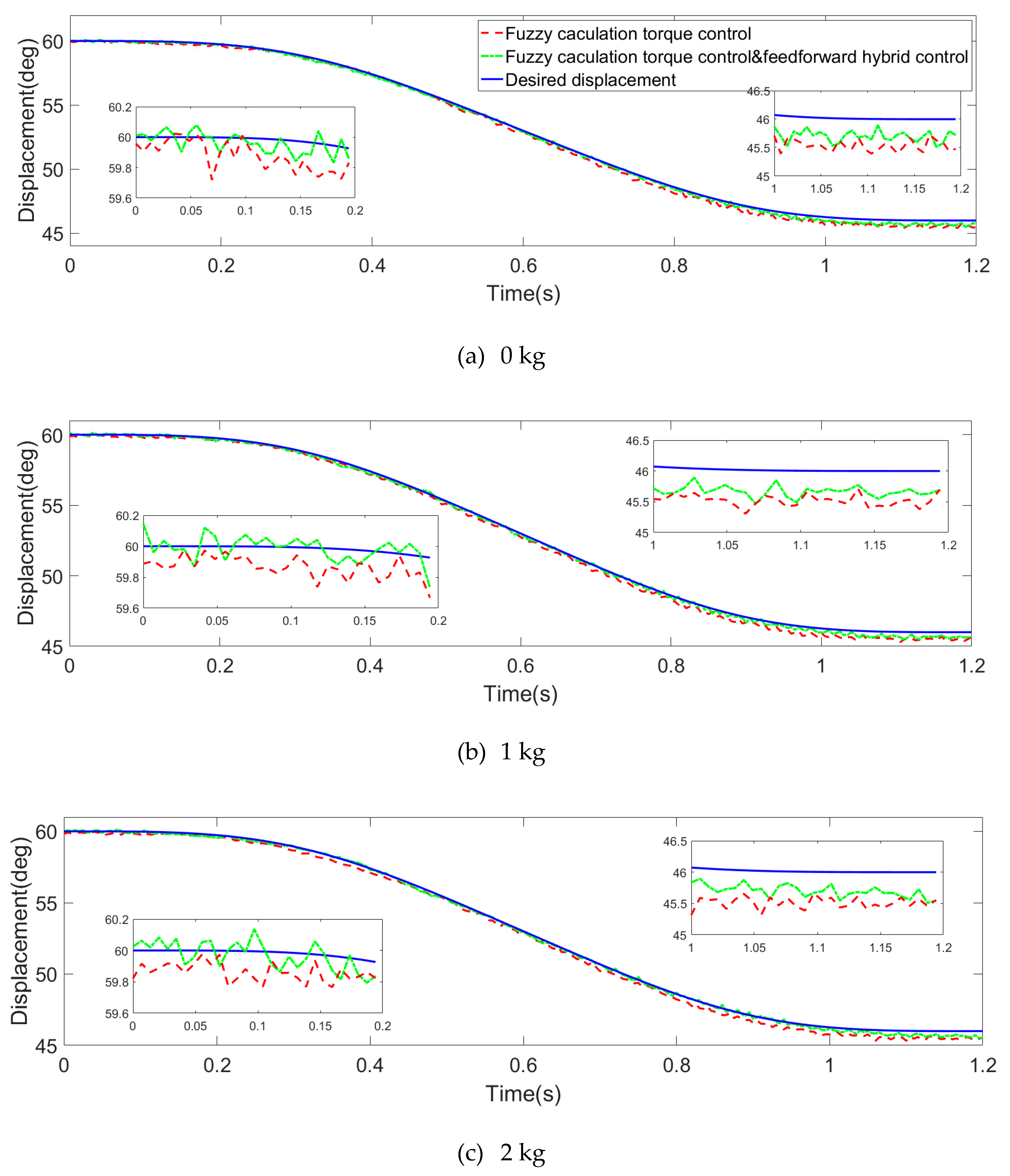

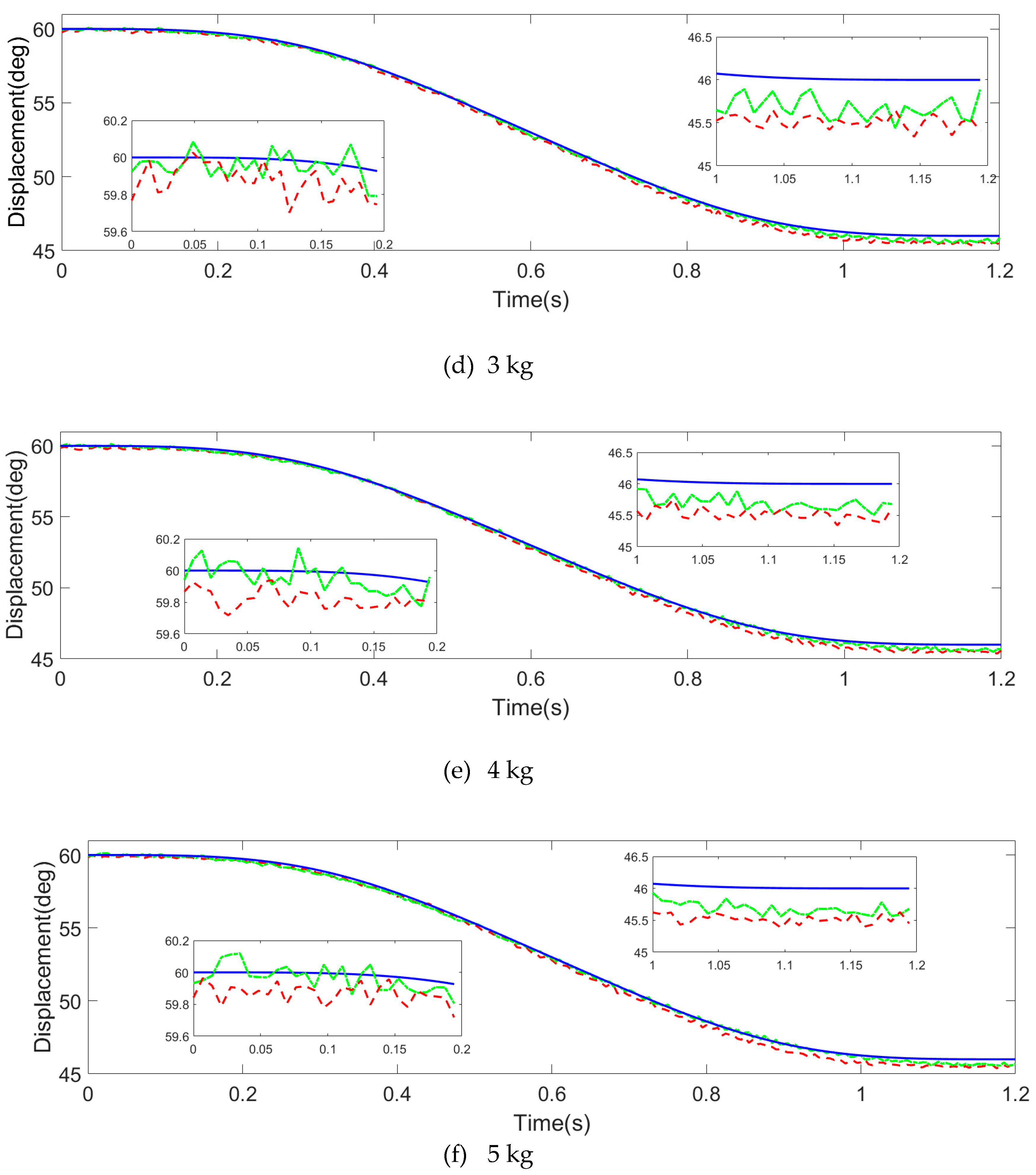

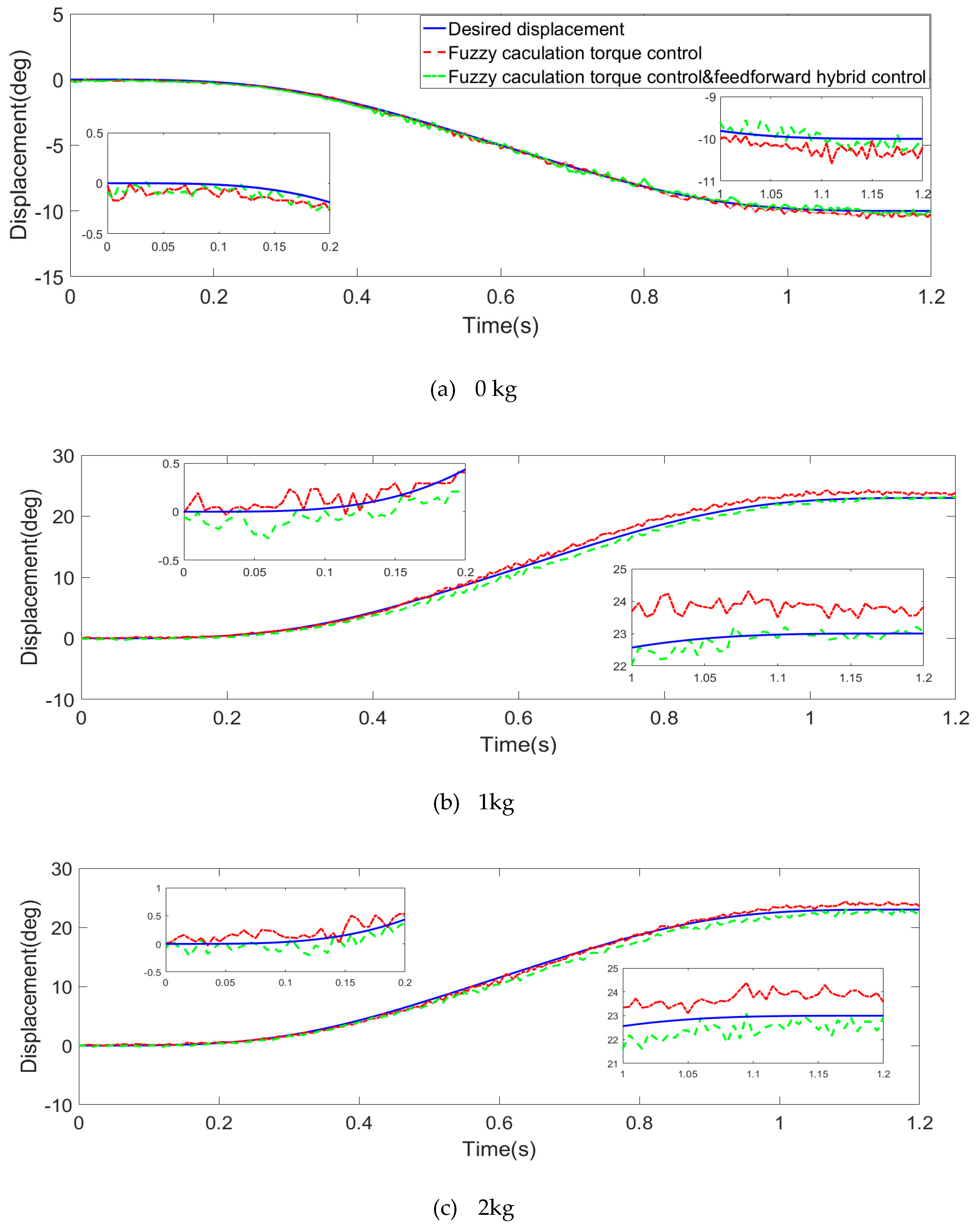

4.2.2. Experimental Results and Analysis

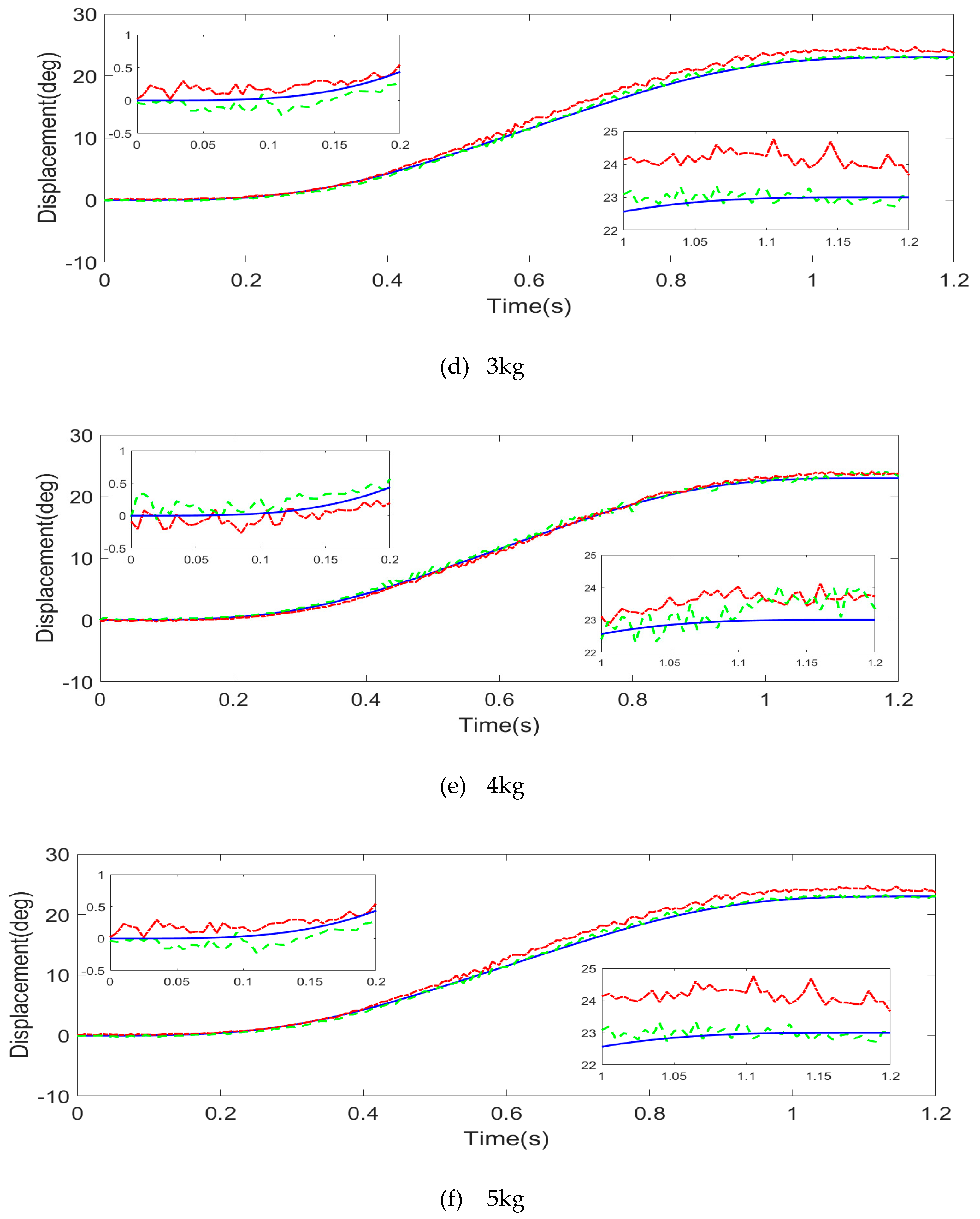

- (A)

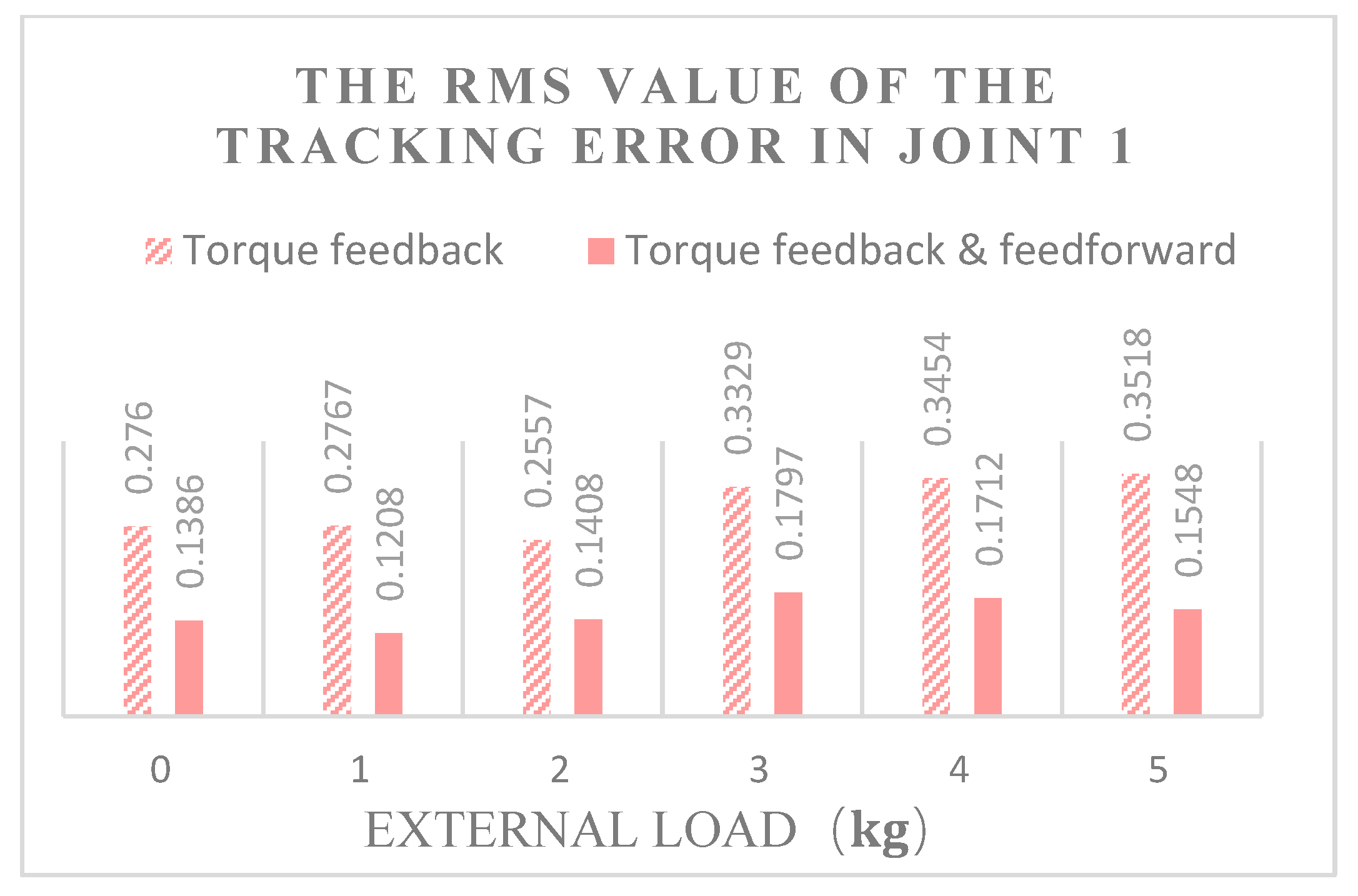

- Trajectory tracking error comparison

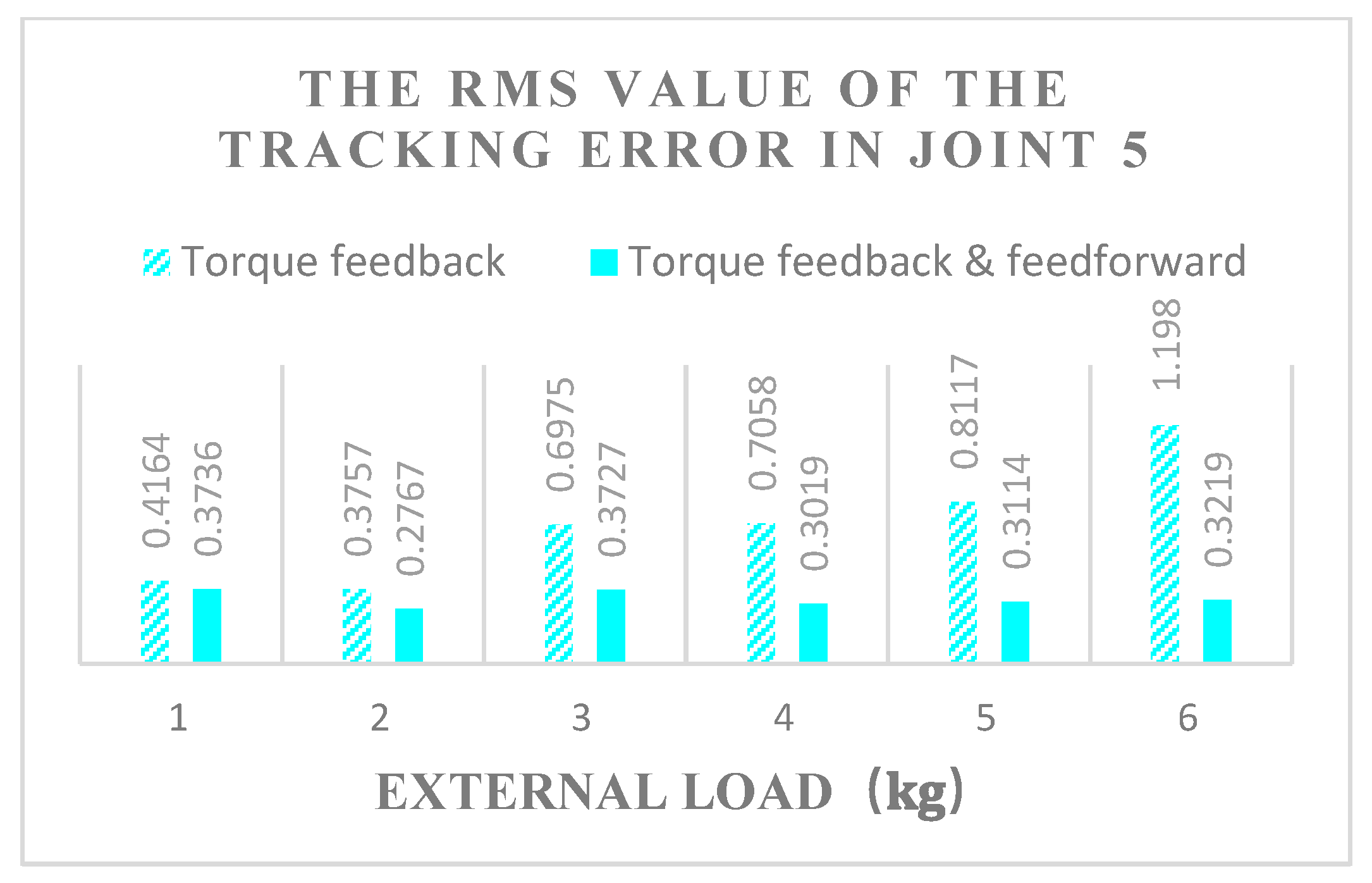

- (B)

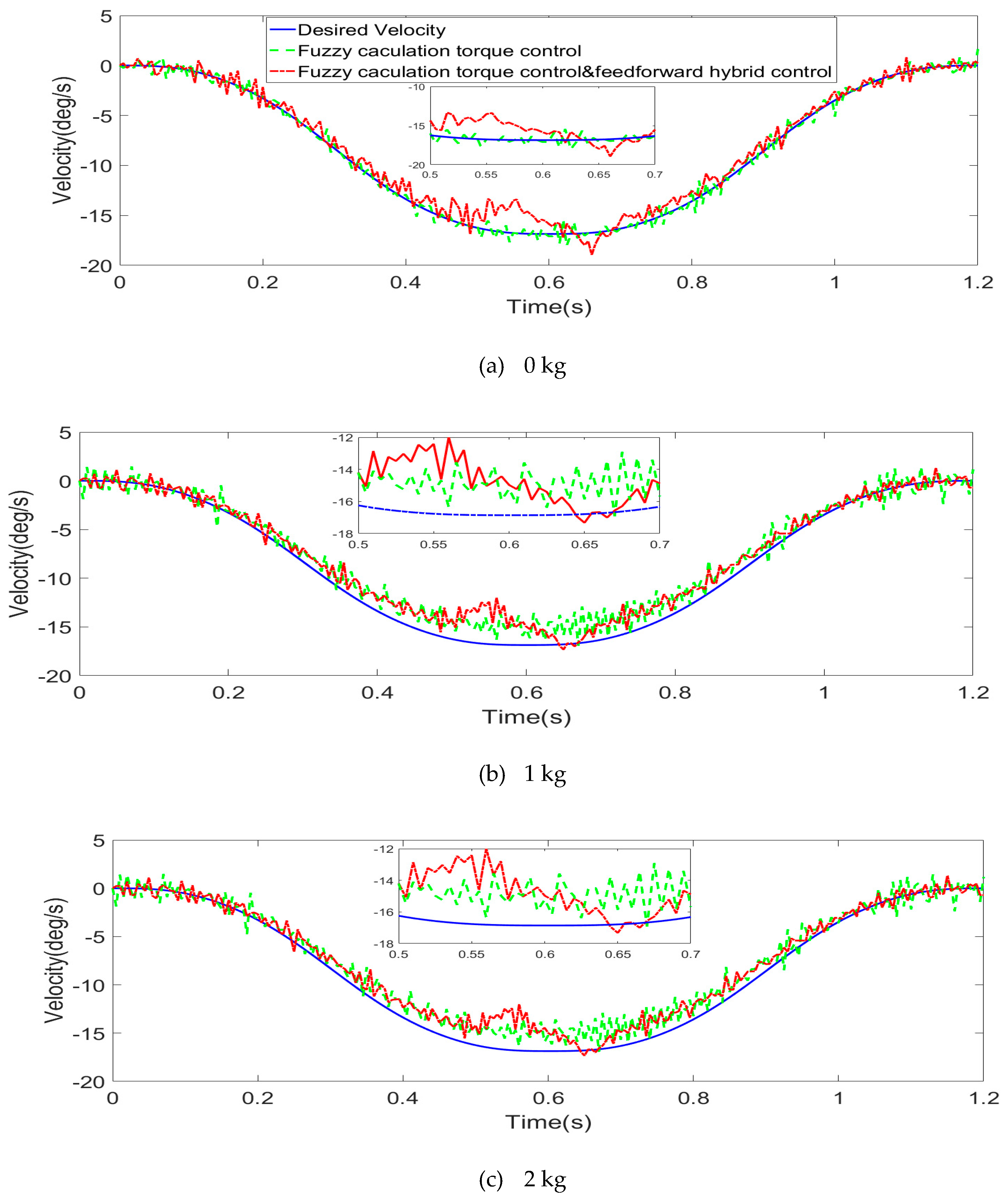

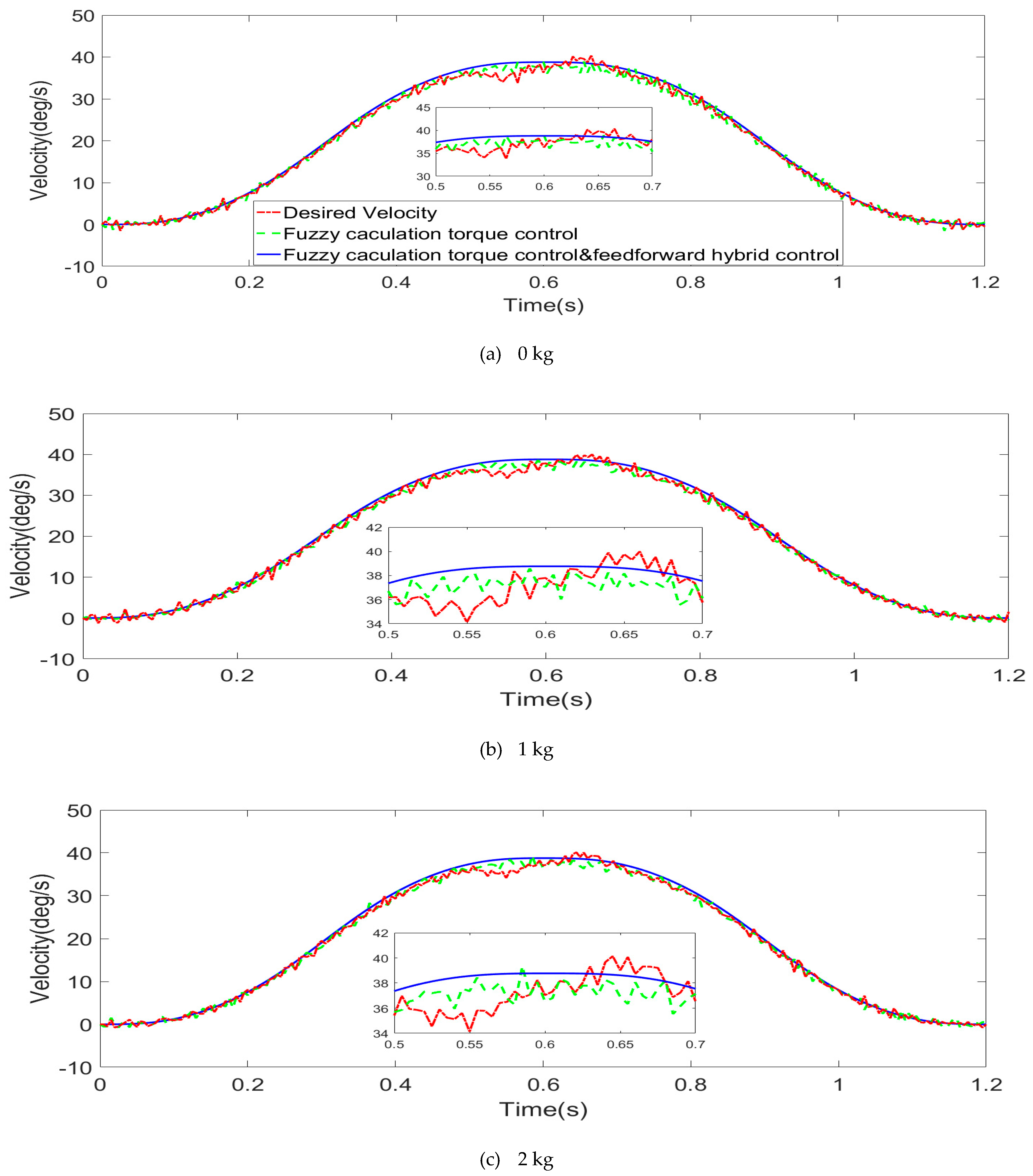

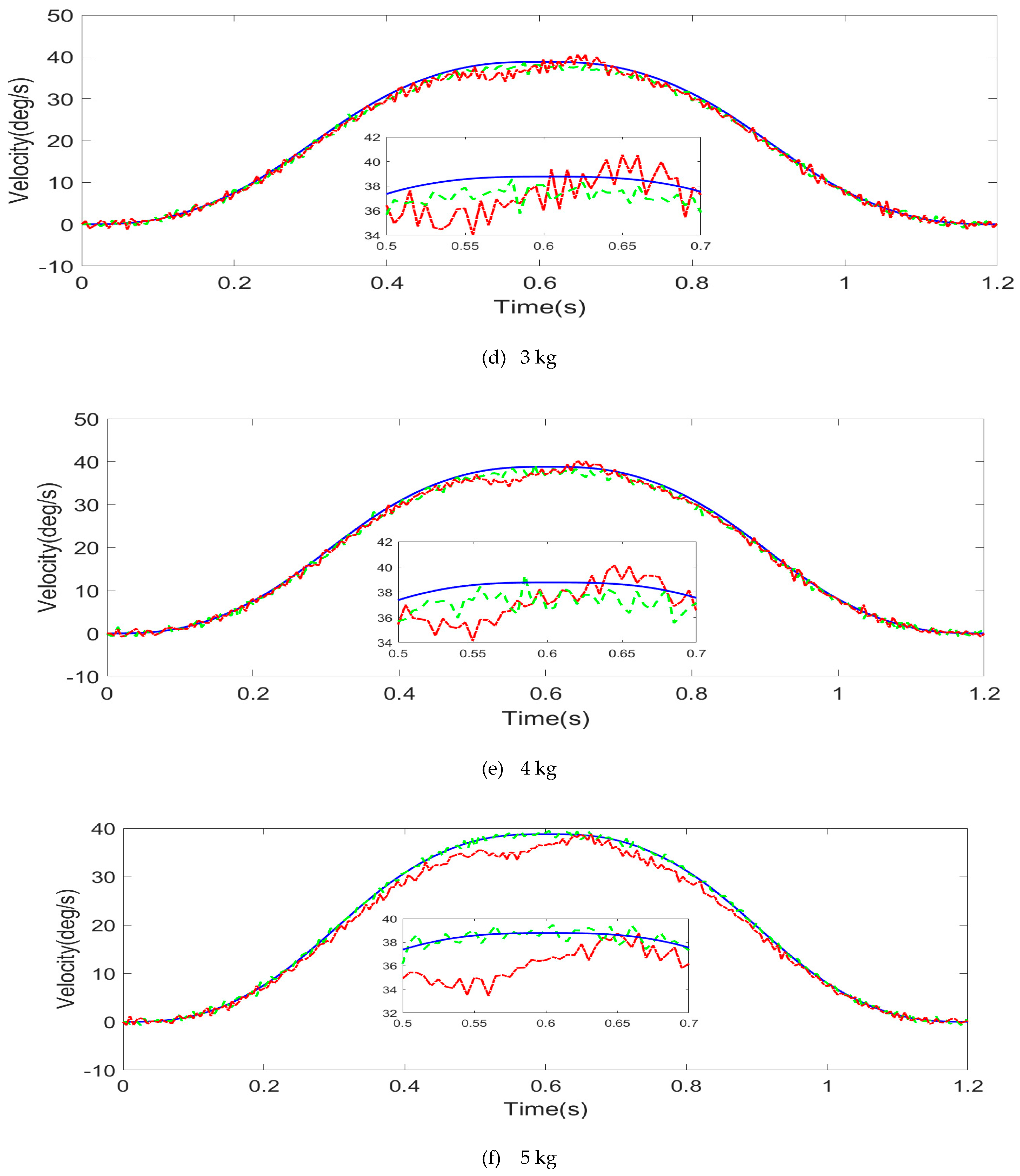

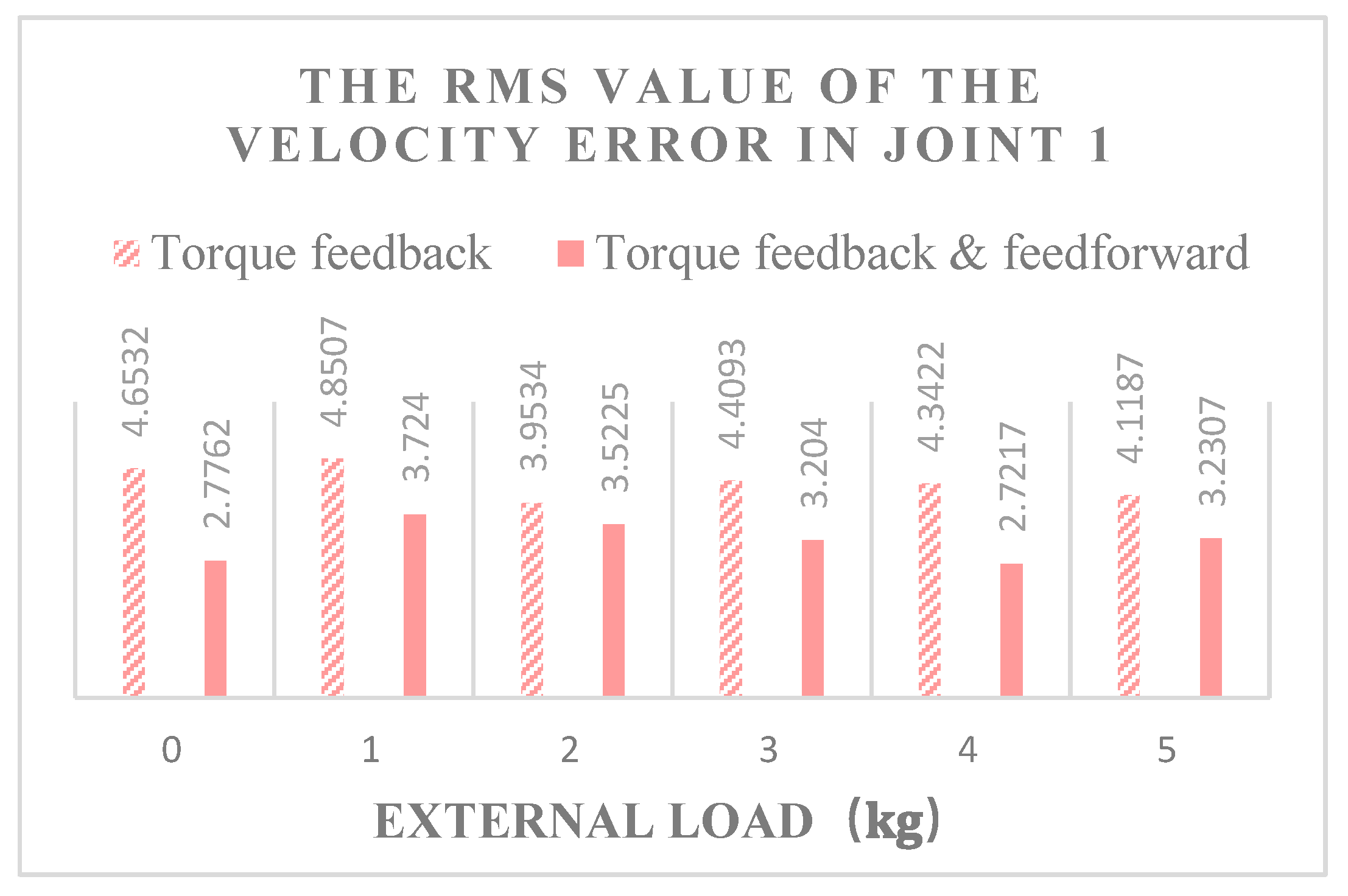

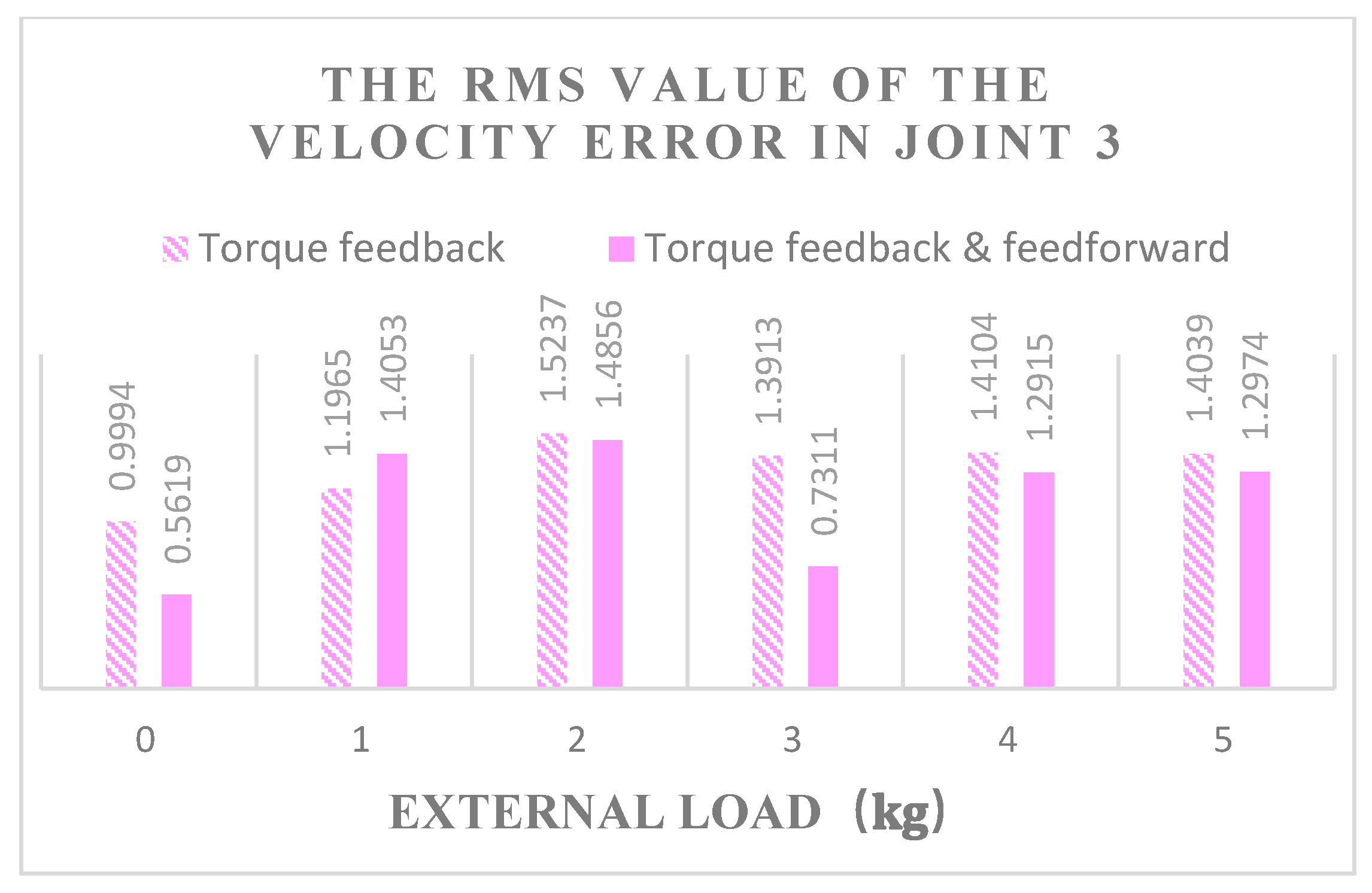

- Comparison of velocity stability

5. Conclusions

- When the robot’s joints move under variable load, compared with the fuzzy computational torque feedback, the fuzzy computational torque feedback and torque feedforward hybrid control decreased the RMS values of tracking errors by 49.87%, 70.48%, and 50.37%, respectively, and increased the kinematic precision at the same time.

- Compared with simple torque feedback control, the hybrid torque control increased the velocity stability by 23.35%, 17.66%, and 25.04%, respectively; that is, the velocity stability of the hybrid torque control method was better than only the feedback torque control method.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Qi, Z.; Yan, R.; Liu, H.Q. Dynamic Parameter Identification of SCARA Robot Based on Stochastic Weighted Particle Swarm Optimization. J. Xi’an Jiaotong Univ. 2021, 55, 20–27. [Google Scholar]

- Cazalilla, J.; Vallés, M.; Mata, V.; Díaz-Rodríguez, M.; Valera, A. Adaptive control of a 3-DOF parallel manipulator considering payload handling and relevant parameter models. Robot. Comput. Integr. Manuf. 2014, 30, 468–477. [Google Scholar] [CrossRef]

- Lee, K.W.; Khalil, H.K. Adaptive output feedback control of robot manipulators using high-gain observer. Int. J. Control 1997, 67, 869–886. [Google Scholar] [CrossRef]

- Binbin, D.; Ling, Q.; Wang, S. Improvement of the conventional computed-torque control scheme with a variable structure compensator for delta robots with uncertain load. In Proceedings of the 2014 International Conference on Mechatronics and Control (ICMC), Jinzhou, China, 3–5 July 2014. [Google Scholar]

- Nguyen, V.T.; Su, S.F.; Wang, N.; Sun, W. Adaptive finite-time neural network control for redundant parallel manipulators. Asian J. Control 2020, 22, 2534–2542. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, H.; Zhang, D.; Luo, X.; Zou, Q. Fuzzy sliding mode control for a 3-DOF parallel manipulator with parameters uncertainties. Complexity 2020, 2020, 2565316. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Zhang, S. Adaptive neural dynamic surface control of robot manipulators with unknown loads. IEEE Trans. Ind. Electron. 2019, 67, 2332–2342. [Google Scholar]

- Lin, J.; Tan, J.; Xue, J.; Liu, G. Robust adaptive neural network control of robot manipulators with uncertain loads. IEEE Trans. Neural Netw. Learn. Syst. 2018, 29, 1004–1014. [Google Scholar]

- Hu, S.; Kang, H.; Tang, H.; Cui, Z.; Liu, Z.; Ouyang, P. Trajectory Optimization Algorithm for a 4-DOF Redundant Parallel Robot Based on 12-Phase Sine Jerk Motion Profile. Actuators 2021, 10, 80. [Google Scholar] [CrossRef]

- Do Thanh, T.; Kotlarski, J.; Heimann, B.; Ortmaier, T. Dynamics identification of kinematically redundant parallel robots using the direct search method. Mech. Mach. Theory 2012, 52, 277–295. [Google Scholar] [CrossRef]

- Gao, L.; Yuan, J.; Han, Z.; Wang, S.; Wang, N. A friction model with velocity, temperature and load torque effects for collaborative industrial robot joints. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017. [Google Scholar]

- Simoni, L.; Villagrossi, E.; Beschi, M.; Marini, A.; Pedrocchi, N.; Tosatti, L.M.; Visioli, A. On the Use of a Temperature Based Friction Model for a Virtual Force Sensor in Industrial Robot Manipulators. In Proceedings of the 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017. [Google Scholar]

- Jalon, D.; Garcia, J.; Bayo, E. Kinematic and Dynamic Simulation of Multibody Systems: The Real-Time Challenge; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Abbasimoshaei, A.; Mohammadimoghaddam, M.; Kern, T.A. Adaptive fuzzy sliding mode controller design for a new hand rehabilitation robot. In Proceedings of the Haptics: Science, Technology, Applications: 12th International Conference, EuroHaptics 2020, Leiden, The Netherlands, 6–9 September 2020; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Dong, L.; Tao, T.; Xuesong, M.; Dongsheng, Z. Decoupling identification method for linear characteristics and nonlinear friction of servo system. Chin. J. Sci. Instrum. 2010, 31, 782–788. [Google Scholar]

- Wu, X.; Liu, D.; He, M.; Gao, F.; Shao, G. Research on Modeling and Compensation of robot joint Friction. J. Instrum. 2018, 39, 44–50. [Google Scholar] [CrossRef]

- Kim, T.J.; Ahn, K.H.; Song, J.B. Friction Model of a Robot Joint Considering Torque and Moment Loads. Trans. Korean Soc. Mech. Eng. A 2021, 45, 27–34. [Google Scholar] [CrossRef]

- Wen, S. Tribology Principle; Tsinghua University Press: Beijing, China, 1990; pp. 7–11. [Google Scholar]

- Choi, J.H.; Sehoon, O.; Jinung, A. Sensorless Force Control with Observer for Multi-functional Upper Limb Rehabilitation Robot. J. Korea Robot. Soc. 2017, 12, 356–364. [Google Scholar] [CrossRef]

- Roveda, L.; Pallucca, G.; Pedrocchi, N.; Braghin, F.; Tosatti, L.M. Iterative learning procedure with reinforcement for high-accuracy force tracking in robotized tasks. IEEE Trans. Ind. Inform. 2017, 14, 1753–1763. [Google Scholar] [CrossRef]

- Hajnayeb, A.; Ghasemloonia, A. Nonparametric Identification of the Surgeon’s Hand Vibration in Haptic Devices. In Proceedings of the 2018 23rd International Conference on Methods & Models in Automation & Robotics (MMAR), Miedzyzdroje, Poland, 27–30 August 2018. [Google Scholar]

- Zubizarreta, A.; Marcos, M.; Cabanes, I.; Pinto, C.; Portillo, E. Redundant sensor based control of the 3RRR parallel robot. Mech. Mach. Theory 2012, 54, 1–17. [Google Scholar] [CrossRef]

- Serdar, K. Energy minimization for 3-RRR fully planar parallel manipulator using particle swarm optimization. Mech. Mach. Theory 2013, 62, 129–149. [Google Scholar]

- Harandi MR, J.; Khalilpour, S.A.; Taghirad, H.D.; Romero, J.G. Adaptive control of parallel robots with uncertain kinematics and dynamics. Mech. Syst. Signal Process. 2021, 157, 107693. [Google Scholar] [CrossRef]

- Moshaii, A.A.; Moghaddam, M.M.; Niestanak, V.D. Fuzzy sliding mode control of a wearable rehabilitation robot for wrist and finger. Ind. Robot. Int. J. Robot. Res. Appl. 2019, 46, 839–850. [Google Scholar] [CrossRef]

- Abbasi Moshaei, A.R.; Mohammadi Moghaddam, M.; Dehghan Neistanak, V. Analytical model of hand phalanges desired trajectory for rehabilitation and design a sliding mode controller based on this model. Modares Mech. Eng. 2020, 20, 129–137. [Google Scholar]

- Wenxiang, W.; Shiqiang, Z.; Xuanyin, W.; Huashan, L. Robot low speed control based on friction fuzzy modeling and compensation. Electr. Mach. Control. 2013, 17, 70–77. [Google Scholar]

| NB | NM | ZO | PM | PB | ||

|---|---|---|---|---|---|---|

| NB | NB | NB | NB | NM | NM | |

| NM | NM | NM | NM | NM | PM | |

| ZO | NB | NM | PM | PM | PB | |

| PM | NM | PM | PM | PM | PB | |

| PB | PM | PM | PB | PB | PB | |

| 0.11 | 0.14 | 11.077 | 4.0216 × 10−4 |

| Parameter | Quality (Kg) | Length (m) | Distance from Center of Mass to Joint (m) | Moment of Inertia Kg × m2 |

|---|---|---|---|---|

| 1 | 2.1 | 0.2440 | 0.1096 | 0.0252 |

| 2 | 8.5 | 0.2440 | 0.0957 | 0.0778 |

| 3 | 2.1 | 0.2440 | 0.1096 | 0.0252 |

| 4 | 0.4 | 0.2440 | 0.1260 | 0.0064 |

| 5 | 2.1 | 0.2440 | 0.1096 | 0.0252 |

| 6 | 0.4 | 0.2440 | 0.1260 | 0.0064 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Liu, H.; Kang, H.; Ouyang, P.; Liu, Z.; Cui, Z. High Precision Hybrid Torque Control for 4-DOF Redundant Parallel Robots under Variable Load. Actuators 2023, 12, 232. https://doi.org/10.3390/act12060232

Hu S, Liu H, Kang H, Ouyang P, Liu Z, Cui Z. High Precision Hybrid Torque Control for 4-DOF Redundant Parallel Robots under Variable Load. Actuators. 2023; 12(6):232. https://doi.org/10.3390/act12060232

Chicago/Turabian StyleHu, Shengqiao, Houcai Liu, Huimin Kang, Puren Ouyang, Zhicheng Liu, and Zhengjie Cui. 2023. "High Precision Hybrid Torque Control for 4-DOF Redundant Parallel Robots under Variable Load" Actuators 12, no. 6: 232. https://doi.org/10.3390/act12060232

APA StyleHu, S., Liu, H., Kang, H., Ouyang, P., Liu, Z., & Cui, Z. (2023). High Precision Hybrid Torque Control for 4-DOF Redundant Parallel Robots under Variable Load. Actuators, 12(6), 232. https://doi.org/10.3390/act12060232