Performance of Smart Materials-Based Instrumentation for Force Measurements in Biomedical Applications: A Methodological Review

Abstract

1. Introduction

2. Review Method

3. Smart Materials

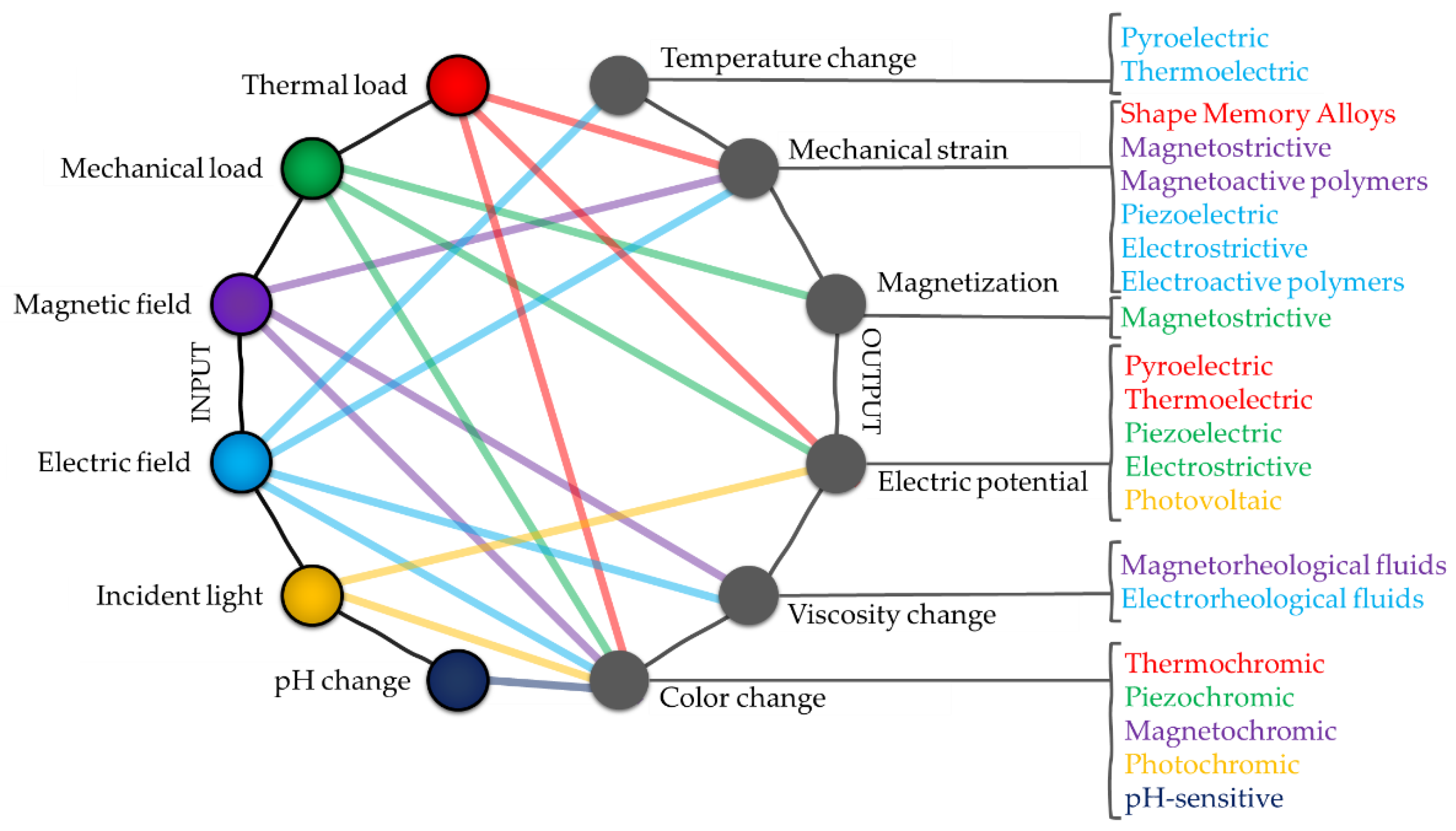

3.1. Classification of Smart Materials

3.2. Types of Smart Materials

- Transiency—SMs are capable of responding to multiple stimuli and existing in a variety of states;

- Immediacy—SMs’ response time is usually quick, and they can respond in real-time;

- Self-actuation—SMs’ inherent property and refers to the ability to change appearance and shape;

- Selectivity—SMs reaction is distinct and predictable;

- Directness—SMs action and reaction take place in the same place.

3.2.1. Piezoelectric Materials

3.2.2. Shape Memory Alloys

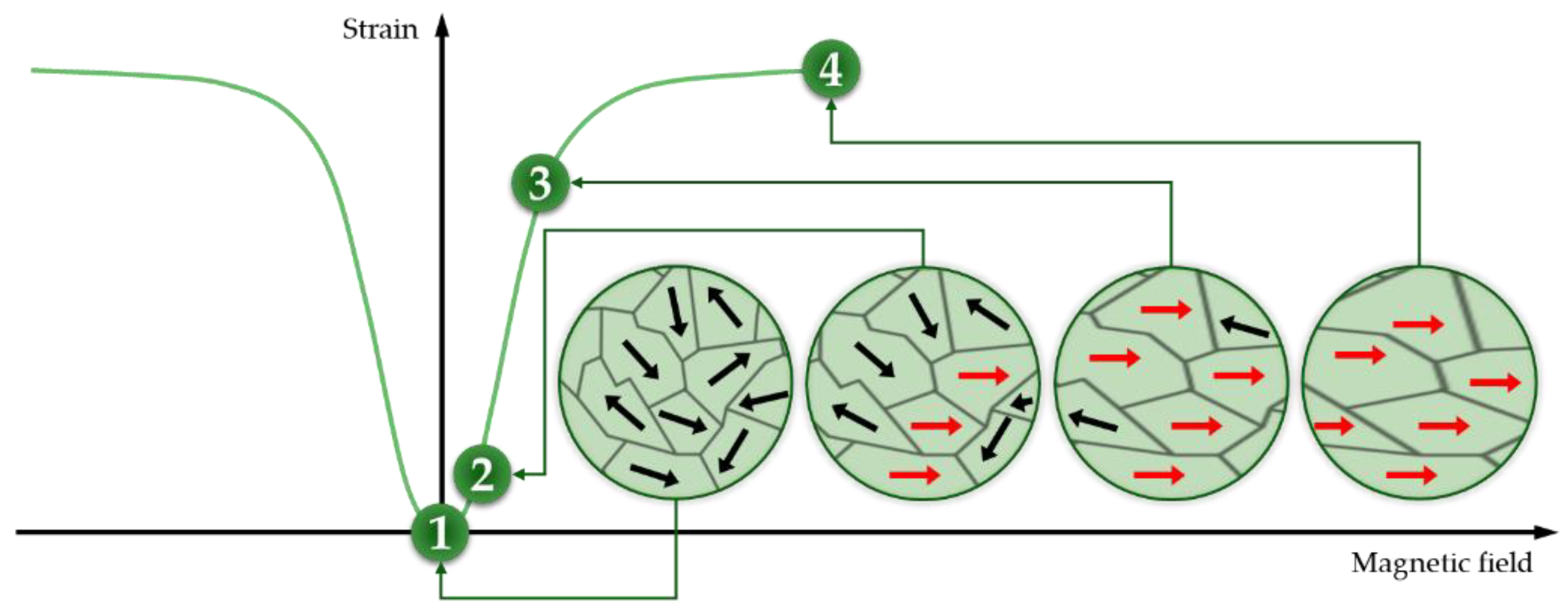

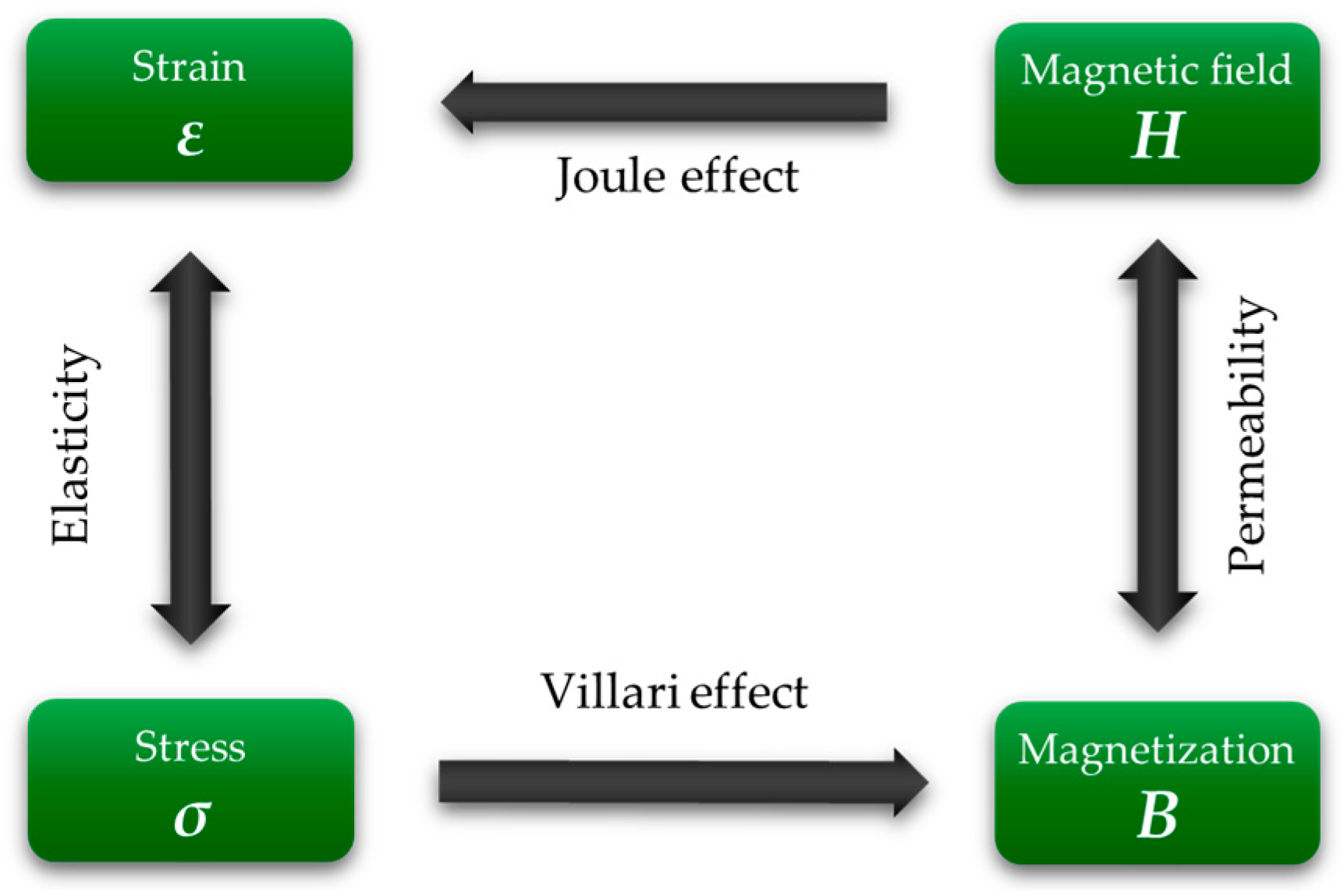

3.2.3. Magnetostrictive and Electrostrictive Materials

- Magnetic domains have a random orientation when no magnetic field is applied. Therefore, no change in size occurs;

- By magnetizing, a small region of the magnetic domain is reoriented in the same direction as the magnetic field, and the strain starts to occur;

- As the magnetization increases, the number of magnetic domains that align increases. Moreover, a linear relationship between the applied magnetic field and strain can be found (points 2 to 3);

- When all magnetic domains align to the magnetic field, there is no further strain.

3.2.4. Optical Fibers

4. Applications of Smart Materials

Biomedical Field of Application

- devices and systems for diagnostics and monitoring;

- surgical instruments and therapeutic devices;

- implants, prostheses, and rehabilitation devices.

5. Force Measurement for Biomedical Applications

5.1. Force Measurement Using Piezoelectric Materials

5.1.1. Electric Charge Measurement

5.1.2. Resonance Frequency Measurement

5.1.3. Electrical Impedance Measurement

5.1.4. Capacitance Measurement

5.1.5. Decay Time Measurement

5.2. Force Measurement Using Shape Memory Effect

5.3. Force Measurement Using Magnetostrictive Materials

5.4. Force Measurement Using Optical Fibers

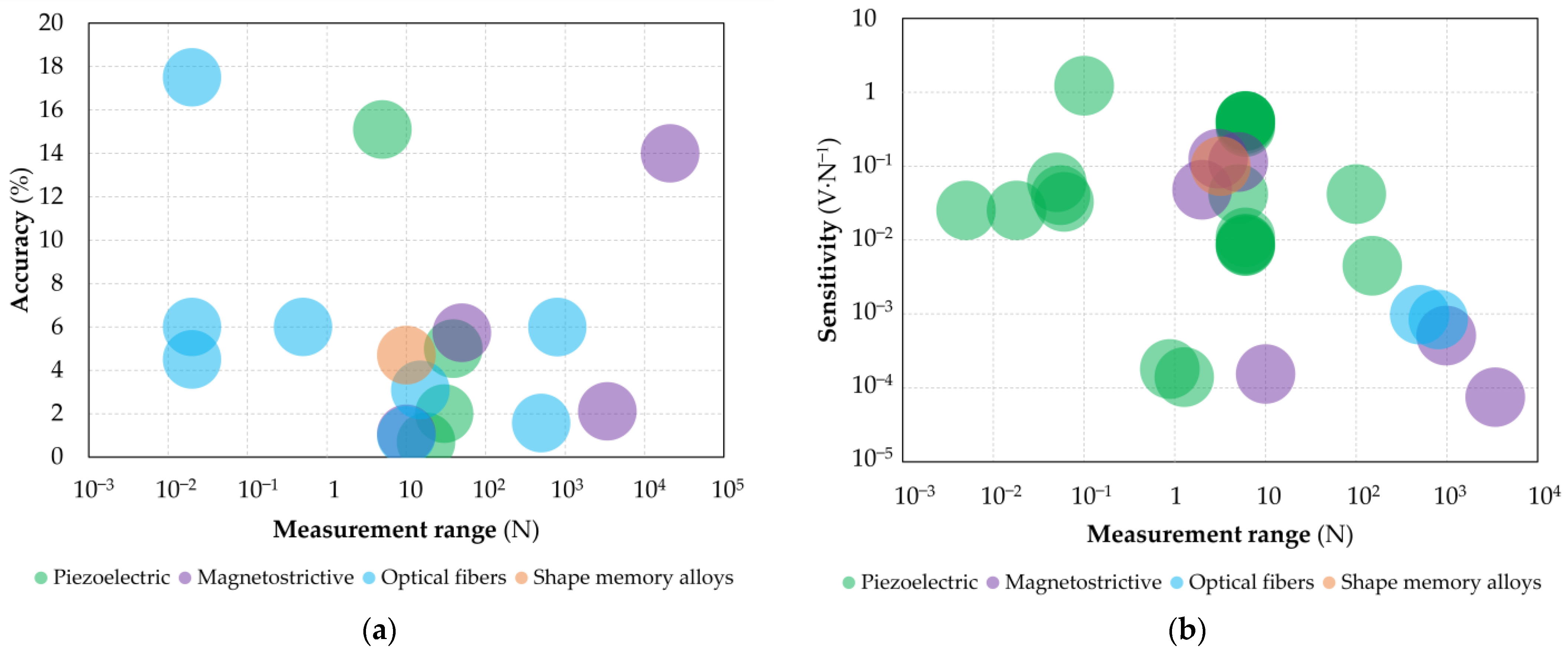

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schwartz, M.M. Encyclopedia of Smart Materials, 1st ed.; Wiley-Interscience: New York, NY, USA, 2002; ISBN 978-0471177807. [Google Scholar]

- Bogue, R. Smart Materials: A Review of Capabilities and Applications. Assem. Autom. 2014, 34, 16–22. [Google Scholar] [CrossRef]

- Kamila, S. Introduction, Classification and Applications of Smart Materials: An Overview. Am. J. Appl. Sci. 2013, 10, 876–880. [Google Scholar] [CrossRef]

- Ghareeb, N.; Farhat, M. Smart Materials and Structures: State of the Art and Applications. Nano Tech. Appl. 2018, 1, 1–5. [Google Scholar] [CrossRef]

- Qader, I.N.; Kok, M.; Dagdelen, F.; Aydogdu, Y.; Qader, I.N. A Review of Smart Materials: Researches and Applications. El-Cezerî J. Sci. Eng. 2019, 6, 755–788. [Google Scholar] [CrossRef]

- Bahl, S.; Nagar, H.; Singh, I.; Sehgal, S. Smart Materials Types, Properties and Applications: A Review. Mater. Today Proc. 2020, 28, 1302–1306. [Google Scholar] [CrossRef]

- Sharma, P.K.; Singh, T. Smart Materials: A Review of Capabilities and Applications. Int. J. Sci. Eng. Res. 2019, 10, 169–176. [Google Scholar]

- Damodharan, J.; Sreedharan, A.; Ramalingam, T. A Review on Smart Materials, Types and Applications. Int. J. Eng. Technol. Sci. Res. 2018, 5, 649–653. [Google Scholar]

- Lane, R.; Craig, B. Materials That Sense and Respond: An Introduction to Smart Materials; The AMPTIAC Quarterly: Rome, NY, USA, 2003; Volume 7. [Google Scholar]

- Thompson, B.S.; Gandhi, M.V.; Kasiviswanathan, S. An Introduction to Smart Materials and Structures. Mater. Des. 1992, 13, 3–9. [Google Scholar] [CrossRef]

- Addington, M.; Schodek, D.L. Smart Materials and Technologies: For the Architecture and Design Professions, 1st ed.; Architectural Press: Oxford, UK, 2004; ISBN 978-0750662253. [Google Scholar]

- Takagi, T. A Concept of Intelligent Materials. J. Intell. Mater. Syst. Struct. 1990, 1, 149–156. [Google Scholar] [CrossRef]

- Spillman, W.B.; Sirkis, J.S.; Gardiner, P.T. Smart Materials and Structures: What Are They? Smart. Mater. Struct. 1996, 5, 247. [Google Scholar] [CrossRef]

- Mandal, S.K.; Maity, A.; Narayan Ray, D. Smart Materials—Scopes and Prospects. Elixir Mech. Engg. 2013, 65, 20154–20163. [Google Scholar]

- Ölander, A. An Electrochemical Investigation of Solid Cadmium-Gold Alloys. J. Am. Chem. Soc. 1932, 54, 3819–3833. [Google Scholar] [CrossRef]

- Rogers, C.A. Smart Materials, Structures and Mathematical Issues; CRC Press: Blacksburg, VA, USA, 1988. [Google Scholar]

- Olabi, A.-G. (Ed.) Encyclopedia of Smart Materials, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 978-0128157336. [Google Scholar]

- Correia, R.; James, S.; Lee, S.W.; Morgan, S.P.; Korposh, S. Biomedical Application of Optical Fibre Sensors. J. Opt. 2018, 20, 073003. [Google Scholar] [CrossRef]

- Fairweather, J.A. Designing with Active Materials: An Impedance Based Approach; Rensselaer Polytechnic Institute: New York, NY, USA, 1998. [Google Scholar]

- Ferrara, M.; Bengisu, M. Materials That Change Color—Smart Materials Intelligent Design; SpringerBriefs in Applied Sciences and Technology; Springer International Publishing: Cham, Switzerland, 2014; ISBN 978-3-319-00289-7. [Google Scholar]

- Parida, B.; Iniyan, S.; Goic, R. A Review of Solar Photovoltaic Technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Bai, Y.; Siponkoski, T.; Peräntie, J. Ferroelectric, Pyroelectric, and Piezoelectric Properties of a Photovoltaic Perovskite Oxide. Appl. Phys. Lett 2017, 110, 63903. [Google Scholar] [CrossRef]

- Mohd Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A Review of Shape Memory Alloy Research, Applications and Opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Mohamed, A.S.Y. Smart Materials Innovative Technologies in Architecture; Towards Innovative Design Paradigm. Energy Procedia 2017, 115, 139–154. [Google Scholar] [CrossRef]

- Liseli, J.B.; Agnus, J.; Lutz, P.; Rakotondrabe, M. An Overview of Piezoelectric Self-Sensing Actuation for Nanopositioning Applications: Electrical Circuits, Displacement, and Force Estimation. IEEE Trans. Instrum. Meas. 2020, 69, 2–14. [Google Scholar] [CrossRef]

- Ivan, I.A.; Aljanaideh, O.; Agnus, J.; Lutz, P.; Rakotondrabe, M. Quasi-Static Displacement Self-Sensing Measurement for a 2-DOF Piezoelectric Cantilevered Actuator. IEEE Trans. Ind. Electron. 2017, 64, 6330–6337. [Google Scholar] [CrossRef]

- Mir, S.H.; Nagahara, L.A.; Thundat, T.; Mokarian-Tabari, P.; Furukawa, H.; Khosla, A. Review—Organic-Inorganic Hybrid Functional Materials: An Integrated Platform for Applied Technologies. J. Electrochem. Soc. 2018, 165, B3137–B3156. [Google Scholar] [CrossRef]

- Roy, I.; Gupta, M.N. Smart Polymeric Materials: Emerging Biochemical Applications. Chem. Biol. 2003, 10, 1161–1171. [Google Scholar] [CrossRef] [PubMed]

- Kim, J. Multifunctional Smart Biopolymer Composites as Actuators. In Biopolymer Composites in Electronics; Sadasivuni, K.K., Cabibihan, J.-J., Ponnamma, D., Al-Maadeed, M.A.S.A., Kim, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 311–331. ISBN 978-0081009741. [Google Scholar]

- Hajalilou, A.; Amri Mazlan, S.; Lavvafi, H.; Shameli, K. Field Responsive Fluids as Smart Materials, 1st ed.; Engineering Materials; Springer: Singapore, 2016; ISBN 978-9811024948. [Google Scholar]

- Meyer, Y.; Lachat, R.; Akhras, G. A Review of Manufacturing Techniques of Smart Composite Structures with Embedded Bulk Piezoelectric Transducers. Smart Mater. Struct. 2019, 28, 053001. [Google Scholar] [CrossRef]

- Curie, J.; Curie, P. Développement Par Compression de l’électricité Polaire Dans Les Cristaux Hémièdres à Faces Inclinées. Bull. Minéralogie 1880, 3, 90–93. [Google Scholar] [CrossRef]

- Heywang, W.; Lubitz, K.; Wersing, W. Piezoelectricity, 1st ed.; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2008; Volume 114, ISBN 978-3-540-68680-4. [Google Scholar]

- Cady, W.G. Piezoelectricity: An Introduction to the Theory and Applications of Electromechanical Phenomena in Crystals, 2nd ed.; Dover Publications: New York, NY, USA, 1964; Volume 2. [Google Scholar]

- Gupta, S. Introduction to Ferroelectrics and Related Materials. In Ferroelectric Materials for Energy Harvesting and Storage; Woodhead Publishing: Cambridge, UK, 2020; pp. 1–41. ISBN 978-0081028025. [Google Scholar]

- Wu, Y.; Ma, Y.; Zheng, H.; Ramakrishna, S. Piezoelectric Materials for Flexible and Wearable Electronics: A Review. Mater. Des. 2021, 211, 110164. [Google Scholar] [CrossRef]

- ANSI/IEEE Std 176-1987; Institute of Electrical and Electronics Engineers IEEE Standard on Piezoelectricity: An American National Standard. American National Standards Institute: Washington, DC, USA; IEEE Ultrasonics, Ferroelectrics, and Frequency Control Society (UFFC-S) Seattle Chapter: Piscataway, NJ, USA, 1988; pp. 8–10.

- Cheng, L.; Liu, W.; Hou, Z.G.; Yu, J.; Tan, M. Neural-Network-Based Nonlinear Model Predictive Control for Piezoelectric Actuators. IEEE Trans. Ind. Electron. 2015, 62, 7717–7727. [Google Scholar] [CrossRef]

- Sun, L.; Huang, W.M.; Ding, Z.; Zhao, Y.; Wang, C.C.; Purnawali, H.; Tang, C. Stimulus-Responsive Shape Memory Materials: A Review. Mater. Des. 2012, 33, 577–640. [Google Scholar] [CrossRef]

- Naresh, C.; Bose, P.S.C.; Rao, C.S.P. Shape Memory Alloys: A State of Art Review. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012054. [Google Scholar] [CrossRef]

- Olabi, A.G.; Grunwald, A. Design and Application of Magnetostrictive Materials. Mater. Des. 2008, 29, 469–483. [Google Scholar] [CrossRef]

- Wahi, S.K.; Kumar, M.; Santapuri, S.; Dapino, M.J. Computationally Efficient Locally Linearized Constitutive Model for Magnetostrictive Materials. J. Appl. Phys. 2019, 125, 215108. [Google Scholar] [CrossRef]

- Dapino, M.J.; Smith, R.C.; Calkins, F.T.; Flatau, A.B. A Magnetoelastic Model for Villari-Effect Magnetostrictive Sensors; Center for Research in Scientific Computation, North Carolina State University: Raleigh, NC, USA, 2002. [Google Scholar] [CrossRef]

- Apicella, V.; Clemente, C.S.; Davino, D.; Leone, D.; Visone, C. Review of Modeling and Control of Magnetostrictive Actuators. Actuators 2019, 8, 45. [Google Scholar] [CrossRef]

- Keswani, B.C.; Patil, S.I.; Kolekar, Y.D.; Ramana, C.V. Improved Magnetostrictive Properties of Cobalt Ferrite (CoFe2O4) by Mn and Dy Co-Substitution for Magneto-Mechanical Sensors. J. Appl. Phys. 2019, 126, 174503. [Google Scholar] [CrossRef]

- Clark, A.E.; Savage, H.T. Magnetostriction of Rare Earth-Fe2 Compounds under Compressive Stress. J. Magn. Magn. Mater. 1983, 31–34, 849–851. [Google Scholar] [CrossRef]

- Turtelli, R.S.; Kriegisch, M.; Atif, M.; Grössinger, R. Co-Ferrite—A Material with Interesting Magnetic Properties. IOP Conf. Ser. Mater. Sci. Eng. 2014, 60, 012020. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Eda, H.; Shimizu, J. Application of Giant Magnetostrictive Materials to Positioning Actuators. In Proceedings of the 1999 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Atlanta, GA, USA, 23 September 1999; pp. 215–220. [Google Scholar]

- Hom, C.L.; Shankar, N. Fully Coupled Constitutive Model for Electrostrictive Ceramic Materials. J. Intell. Mater. Syst. Struct. 1994, 5, 795–801. [Google Scholar] [CrossRef]

- Uchino, K. Electrostrictive Actuators: Materials and Applications. Am. Ceram. Soc. Bull. 1986, 65, 647–652. [Google Scholar]

- Newnham, R.E.; Sundar, V.; Yimnirun, R.; Su, J.; Zhang, Q.M. Electrostriction: Nonlinear Electromechanical Coupling in Solid Dielectrics. J. Phys. Chem. B 1997, 101, 10141–10150. [Google Scholar] [CrossRef]

- Park, S.E. Relaxor Based Ferroelectric Single Crystals for Electro-Mechanical Actuators. Mater. Res. Innov. 1997, 1, 20–25. [Google Scholar] [CrossRef]

- Eric Cross, L. Relaxor Ferroelecirics. Ferroelectrics 1987, 76, 241–267. [Google Scholar] [CrossRef]

- Somwan, S.; Ngamjarurojana, A.; Limpichaipanit, A. Dielectric, Ferroelectric and Induced Strain Behavior of PLZT 9/65/35 Ceramics Modified by Bi2O3 and CuO Co-Doping. Ceram. Int. 2016, 42, 10690–10696. [Google Scholar] [CrossRef]

- Zhang, Q.; Pan, W.; Bhalla, A.; Cross, L.E. Electrostrictive and Dielectric Response in Lead Magnesium Niobate–Lead Titanate (0.9PMN·0.1PT) and Lead Lanthanum Zirconate Titanate (PLZT 9.5/65/35) under Variation of Temperature and Electric Field. J. Am. Ceram. Soc. 1989, 72, 599–604. [Google Scholar] [CrossRef]

- Damjanovic, D.; Newnham, R.E. Electrostrictive and Piezoelectric Materials for Actuator Applications. J. Intell. Mater. Syst. Struct. 1992, 3, 190–208. [Google Scholar] [CrossRef]

- Coutte, J.; Dubus, B.; Debus, J.C.; Granger, C.; Jones, D. Design, Production and Testing of PMN–PT Electrostrictive Transducers. Ultrasonics 2002, 40, 883–888. [Google Scholar] [CrossRef]

- Shah, R.Y.; Agrawal, Y.K. Introduction to Fiber Optics: Sensors for Biomedical Applications. Indian J. Pharm. Sci. 2011, 73, 17. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z. Fundamentals of Optical Fiber Sensors, 1st ed.; Wiley: Hoboken, NJ, USA, 2012; ISBN 9780470575406. [Google Scholar]

- Barrias, A.; Casas, J.R.; Villalba, S. A Review of Distributed Optical Fiber Sensors for Civil Engineering Applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, Y.H.; Park, K.S.; Eom, J.B.; Kim, M.J.; Rho, B.S.; Choi, H.Y. Interferometric Fiber Optic Sensors. Sensors 2012, 12, 2467–2486. [Google Scholar] [CrossRef] [PubMed]

- IMARC Group. Smart Materials Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022–2027; IMARC Group: Noida, India, 2022. [Google Scholar]

- Su, M.; Song, Y. Printable Smart Materials and Devices: Strategies and Applications. Chem. Rev. 2022, 122, 5144–5164. [Google Scholar] [CrossRef]

- Fapanni, T.; Sardini, E.; Serpelloni, M.; Tonello, S. 3D Electrochemical Sensor and Microstructuration Using Aerosol Jet Printing. Sensors 2021, 21, 7820. [Google Scholar] [CrossRef]

- Fapanni, T.; Borghetti, M.; Sardini, E.; Serpelloni, M. Novel Piezoelectric Sensor by Aerosol Jet Printing in Industry 4.0. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT, Rome, Italy, 5 June 2020; pp. 379–383. [Google Scholar]

- Ellingford, C.; Zhang, R.; Wemyss, A.M.; Zhang, Y.; Brown, O.B.; Zhou, H.; Keogh, P.; Bowen, C.; Wan, C. Self-Healing Dielectric Elastomers for Damage-Tolerant Actuation and Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 7595–7604. [Google Scholar] [CrossRef]

- Wang, B.; Facchetti, A.; Wang, B.; Facchetti, A. Mechanically Flexible Conductors for Stretchable and Wearable E-Skin and E-Textile Devices. Adv. Mater. 2019, 31, 1901408. [Google Scholar] [CrossRef]

- Someya, T.; Amagai, M. Toward a New Generation of Smart Skins. Nat. Biotechnol. 2019, 37, 382–388. [Google Scholar] [CrossRef]

- Al-khafajiy, M.; Baker, T.; Chalmers, C.; Asim, M.; Kolivand, H.; Fahim, M.; Waraich, A. Remote Health Monitoring of Elderly through Wearable Sensors. Multimed. Tools Appl. 2019, 78, 24681–24706. [Google Scholar] [CrossRef]

- Wang, L.; Lou, Z.; Jiang, K.; Shen, G. Bio-Multifunctional Smart Wearable Sensors for Medical Devices. Adv. Intell. Syst. 2019, 1, 1900040. [Google Scholar] [CrossRef]

- Chorsi, M.T.; Curry, E.J.; Chorsi, H.T.; Das, R.; Baroody, J.; Purohit, P.K.; Ilies, H.; Nguyen, T.D.; Chorsi, M.T.; Ilies, H.; et al. Piezoelectric Biomaterials for Sensors and Actuators. Adv. Mater. 2019, 31, 1802084. [Google Scholar] [CrossRef]

- Patel, S.K.; Behera, B.; Swain, B.; Roshan, R.; Sahoo, D.; Behera, A. A Review on NiTi Alloys for Biomedical Applications and Their Biocompatibility. Mater. Today Proc. 2020, 33, 5548–5551. [Google Scholar] [CrossRef]

- Gao, C.; Zeng, Z.; Peng, S.; Shuai, C. Magnetostrictive Alloys: Promising Materials for Biomedical Applications. Bioact. Mater. 2022, 8, 177–195. [Google Scholar] [CrossRef]

- Nazempour, R.; Zhang, Q.; Fu, R.; Sheng, X. Biocompatible and Implantable Optical Fibers and Waveguides for Biomedicine. Materials 2018, 11, 1283. [Google Scholar] [CrossRef]

- Hoskins, P.R.; Martin, K.; Thrush, A. Diagnostic Ultrasound, Third Edition: Physics and Equipment, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2019; ISBN 9780429649806. [Google Scholar]

- Ma, H.K.; Chen, R.H.; Yu, N.S.; Hsu, Y.H. A Miniature Circular Pump with a Piezoelectric Bimorph and a Disposable Chamber for Biomedical Applications. Sens. Actuators A Phys. 2016, 251, 108–118. [Google Scholar] [CrossRef]

- Zainal, M.A.; Sahlan, S.; Mohamed Ali, M.S. Micromachined Shape-Memory-Alloy Microactuators and Their Application in Biomedical Devices. Micromachines 2015, 6, 879–901. [Google Scholar] [CrossRef]

- Lyu, Z.; Xu, Q. Recent Design and Development of Piezoelectric-Actuated Compliant Microgrippers: A Review. Sens. Actuators A Phys. 2021, 331, 113002. [Google Scholar] [CrossRef]

- Tandon, B.; Blaker, J.J.; Cartmell, S.H. Piezoelectric Materials as Stimulatory Biomedical Materials and Scaffolds for Bone Repair. Acta Biomater. 2018, 73, 1–20. [Google Scholar] [CrossRef]

- Rajabi, A.H.; Jaffe, M.; Arinzeh, T.L. Piezoelectric Materials for Tissue Regeneration: A Review. Acta Biomater. 2015, 24, 12–23. [Google Scholar] [CrossRef] [PubMed]

- Ali, F.; Raza, W.; Li, X.; Gul, H.; Kim, K.H. Piezoelectric Energy Harvesters for Biomedical Applications. Nano Energy 2019, 57, 879–902. [Google Scholar] [CrossRef]

- Narita, F.; Wang, Z.; Kurita, H.; Li, Z.; Shi, Y.; Jia, Y.; Soutis, C. A Review of Piezoelectric and Magnetostrictive Biosensor Materials for Detection of COVID-19 and Other Viruses. Adv. Mater. 2021, 33, 2005448. [Google Scholar] [CrossRef] [PubMed]

- Petrini, L.; Migliavacca, F. Biomedical Applications of Shape Memory Alloys. J. Metall. 2011, 2011, 1–15. [Google Scholar] [CrossRef]

- Tung, A.T.; Park, B.H.; Liang, D.H.; Niemeyer, G. Laser-Machined Shape Memory Alloy Sensors for Position Feedback in Active Catheters. Sens. Actuators A Phys. 2008, 147, 83. [Google Scholar] [CrossRef]

- Sohn, J.W.; Kim, G.W.; Choi, S.B. A State-of-the-Art Review on Robots and Medical Devices Using Smart Fluids and Shape Memory Alloys. Appl. Sci. 2018, 8, 1928. [Google Scholar] [CrossRef]

- Sabahi, N.; Chen, W.; Wang, C.H.; Kruzic, J.J.; Li, X. A Review on Additive Manufacturing of Shape-Memory Materials for Biomedical Applications. JOM 2020, 72, 1229–1253. [Google Scholar] [CrossRef]

- Ashuri, T.; Armani, A.; Jalilzadeh Hamidi, R.; Reasnor, T.; Ahmadi, S.; Iqbal, K. Biomedical Soft Robots: Current Status and Perspective. Biomed. Eng. Lett. 2020, 10, 369–385. [Google Scholar] [CrossRef]

- Hsiao, J.H.; Chang, J.Y.; Cheng, C.M. Soft Medical Robotics: Clinical and Biomedical Applications, Challenges, and Future Directions. Adv. Robot. 2019, 33, 1099–1111. [Google Scholar] [CrossRef]

- Tosi, D.; Schena, E.; Molardi, C.; Korganbayev, S. Fiber Optic Sensors for Sub-Centimeter Spatially Resolved Measurements: Review and Biomedical Applications. Opt. Fiber Technol. 2018, 43, 6–19. [Google Scholar] [CrossRef]

- Battista, L.; Sciuto, S.A.; Scorza, A. Preliminary Evaluation of a Fiber-Optic Sensor for Flow Measurements in Pulmonary Ventilators. In Proceedings of the 2011 IEEE International Symposium on Medical Measurements and Applications, Bari, Italy, 28 July 2011; pp. 29–34. [Google Scholar]

- Gan, J.; Zhang, J.; Ge, M.F.; Tu, X. Designs of Compliant Mechanism-Based Force Sensors: A Review. IEEE Sens. J. 2022, 22, 8282–8294. [Google Scholar] [CrossRef]

- Roriz, P.; Carvalho, L.; Frazão, O.; Santos, J.L.; Simões, J.A. From Conventional Sensors to Fibre Optic Sensors for Strain and Force Measurements in Biomechanics Applications: A Review. J. Biomech. 2014, 47, 1251–1261. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, M.G.; Kim, B.; Sun, Y. A Superelastic Alloy Microgripper with Embedded Electromagnetic Actuators and piezoelectric Force Sensors: A Numerical and Experimental Study. Smart Mater. Struct. 2005, 14, 1265. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, P.; Wang, Y.; Dong, Z.; Xi, N. The Modeling and Experiments of a PVDF Mirco-Force Sensor. In Proceedings of the 2008 3rd IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Sanya, China, 11 April 2008; pp. 60–64. [Google Scholar]

- Wang, Y.R.; Zheng, J.M.; Ren, G.Y.; Zhang, P.H.; Xu, C. A Flexible Piezoelectric Force Sensor Based on PVDF Fabrics. Smart Mater. Struct. 2011, 20, 045009. [Google Scholar] [CrossRef]

- Xie, Y.; Sun, D.; Tse, H.Y.G.; Liu, C.; Cheng, S.H. Force Sensing and Manipulation Strategy in Robot-Assisted Microinjection on Zebrafish Embryos. IEEE/ASME Trans. Mechatron. 2011, 16, 1002–1010. [Google Scholar] [CrossRef]

- Ren, G.; Cai, F.; Li, B.; Zheng, J.; Xu, C. Flexible Pressure Sensor Based on a Poly(VDF-TrFE) Nanofiber Web. Macromol. Mater. Eng. 2013, 298, 541–546. [Google Scholar] [CrossRef]

- Yu, P.; Liu, W.; Gu, C.; Cheng, X.; Fu, X. Flexible Piezoelectric Tactile Sensor Array for Dynamic Three-Axis Force Measurement. Sensors 2016, 16, 819. [Google Scholar] [CrossRef]

- Ting, Y.; Suprapto; Nugraha, A.; Chiu, C.W.; Gunawan, H. Design and Characterization of One-Layer PVDF Thin Film for a 3D Force Sensor. Sens. Actuators A Phys. 2016, 250, 129–137. [Google Scholar] [CrossRef]

- Wei, Y.; Xu, Q. Design of a PVDF-MFC Force Sensor for Robot-Assisted Single Cell Microinjection. IEEE Sens. J. 2017, 17, 3975–3982. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Yousefi, A.A. Piezoelectric Sensor Based on Electrospun PVDF-MWCNT-Cloisite 30B Hybrid Nanocomposites. Org. Electron. 2017, 50, 121–129. [Google Scholar] [CrossRef]

- Li, Y.J.; Wang, G.C.; Cui, H.Y.; Cao, S.K.; Wang, X.Y. Dynamic Characteristics and Optimization Research on PVDF Piezoelectric Film Force Sensor for Steel Ball Cold Heading Machine. ISA Trans. 2019, 94, 265–275. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Lin, K.; Xu, L.; Cao, J.; Gao, S. A Piezoelectric Force Sensing and Gesture Monitoring-Based Technique for Acupuncture Quantification. IEEE Sens. J. 2021, 21, 26337–26344. [Google Scholar] [CrossRef]

- Royandi, M.A.; Hung, J.P. Design of the Force Measurement Device Using Piezoelectric Sensor. Smart Sci. 2019, 7, 218–229. [Google Scholar] [CrossRef]

- Ngalamou, L.; Noury, N.; Chamberod, E.; Benech, P. Analysis of the Sensitivity and the Temperature Influence of a Static Force Sensor Based on a PVDF Resonator. Sens. Actuators A Phys. 1996, 57, 173–177. [Google Scholar] [CrossRef]

- Gehin, C.; Barthod, C.; Teisseyre, Y. Design and Characterisation of a New Force Resonant Sensor. Sens. Actuators A Phys. 2000, 84, 65–69. [Google Scholar] [CrossRef]

- Barthod, C.; Teisseyre, Y.; Géhin, C.; Gautier, G. Resonant Force Sensor Using a PLL Electronic. Sens. Actuators A Phys. 2003, 104, 143–150. [Google Scholar] [CrossRef]

- Safour, S.; Bernard, Y. Static Force Transducer Based on Resonant Piezoelectric Structure: Root Cause Investigation. Smart Mater. Struct. 2017, 26, 055012. [Google Scholar] [CrossRef]

- Volf, J.; Novák, V.; Stebila, J.; Kvasnová, P.; Ryženko, V.; Novák, D. Measurement of Static Forces up to 50 N Using Piezo Ceramics PZK 850. Measurement 2021, 176, 109033. [Google Scholar] [CrossRef]

- Wang, Y.J.; Huang, R.Y.; Sue, C.Y.; Wang, Y.T. Triaxis Static Force Sensing for Langevin-Type Ultrasonic Tools Using Lead-Zirconate-Titanate Ceramic Rings. IEEE Sens. J. 2021, 21, 22518–22526. [Google Scholar] [CrossRef]

- Lin, C.H.; Tsai, M.C.; Hsiao, S.W. Static Force Measurement for Automation Assembly Systems. Sens. Actuators A Phys. 2012, 187, 147–153. [Google Scholar] [CrossRef]

- Purohit, P.; Yadav, Y.K.; Titus, S.S.K. Low Force Measurement Based on Impedance of a Piezo-Resonator. Mapan—J. Metrol. Soc. India 2017, 32, 293–296. [Google Scholar] [CrossRef]

- Kim, K.; Kim, T.; Kim, J.; Jiang, X. A Face-Shear Mode Piezoelectric Array Sensor for Elasticity and Force Measurement. Sensors 2020, 20, 604. [Google Scholar] [CrossRef]

- Liu, C.; Zhuang, Y.; Nasrollahi, A.; Lu, L.; Haider, M.F.; Chang, F.K. Static Tactile Sensing for a Robotic Electronic Skin via an Electromechanical Impedance-Based Approach. Sensors 2020, 20, 2830. [Google Scholar] [CrossRef]

- Sekalski, P.; Napieralski, A.; Fouaidy, M.; Bosotti, A.; Paparella, R. Measurement of Static Force at Liquid Helium Temperature. Meas. Sci. Technol. 2007, 18, 2356. [Google Scholar] [CrossRef]

- Ozeri, S.; Shmilovitz, D. Static Force Measurement by Piezoelectric Sensors. In Proceedings of the 2006 IEEE International Symposium on Circuits and Systems, Kos, Greece, 11 September 2006; pp. 5179–5182. [Google Scholar]

- Sedmák, P.; Šittner, P.; Pilch, J.; Curfs, C. Instability of Cyclic Superelastic Deformation of NiTi Investigated by Synchrotron X-ray Diffraction. Acta Mater. 2015, 94, 257–270. [Google Scholar] [CrossRef]

- Lan, C.C.; Fan, C.H. An Accurate Self-Sensing Method for the Control of Shape Memory Alloy Actuated Flexures. Sens. Actuators A Phys. 2010, 163, 323–332. [Google Scholar] [CrossRef]

- Ruth, D.J.S.; Dhanalakshmi, K. Shape Memory Alloy Wire for Force Sensing. IEEE Sens. J. 2017, 17, 967–975. [Google Scholar] [CrossRef]

- Mozhi, G.T.; Dhanalakshmi, K.; Sundareswari, M.B. Design Aspects of Shape Memory Wire Based Resonant Force Measurement System. Measurement 2022, 198, 111313. [Google Scholar] [CrossRef]

- Baudendistel, T.A.; Turner, M.L. A Novel Inverse-Magnetostrictive Force Sensor. IEEE Sens. J. 2007, 7, 245–250. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Liu, H.F.; Wang, F.J.; Liu, W.; Ge, C.Y. A Novel Magnetostrictive Static Force Sensor Based on the Giant Magnetostrictive Material. Measurement 2011, 44, 88–95. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Liu, H.F.; Wang, F.J.; Ge, C.Y. Research on a Novel Force Sensor Based on Giant Magnetostrictive Material and Its Model. J. Alloys Compd. 2011, 509, 1760–1767. [Google Scholar] [CrossRef]

- Ghodsi, M.; Mirzamohamadi, S.; Talebian, S.; Hojjat, Y.; Sheikhi, M.; Al-Yahmedi, A.; Özer, A. Analytical, Numerical and Experimental Investigation of a Giant Magnetostrictive (GM) Force Sensor. Sens. Rev. 2015, 35, 357–365. [Google Scholar] [CrossRef]

- Li, Y.; Wang, B.; Li, Y.; Zhang, B.; Weng, L.; Huang, W.; Liu, H. Design and Output Characteristics of Magnetostrictive Tactile Sensor for Detecting Force and Stiffness of Manipulated Objects. IEEE Trans. Industr. Inform. 2019, 15, 1219–1225. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, B.; Li, Y.; Huang, W.; Li, Y. Magnetostrictive Tactile Sensor Array for Object Recognition. IEEE Trans. Magn. 2019, 55, 4002207. [Google Scholar] [CrossRef]

- Weng, L.; Xie, G.; Zhang, B.; Huang, W.; Wang, B.; Deng, Z. Magnetostrictive Tactile Sensor Array for Force and Stiffness Detection. J. Magn. Magn. Mater. 2020, 513, 167068. [Google Scholar] [CrossRef]

- Yu, S.; Wang, B.; Dong, L. Study on Micro Force Sensor and Its Signal Acquisition System Based on Android and Arduino. IEEJ Trans. Electr. Electron. Eng. 2020, 15, 1384–1389. [Google Scholar] [CrossRef]

- Shu, L.; Yang, J.; Li, B.; Deng, Z.; Dapino, M.J. Impact Force Sensing with Magnetostrictive Fe-Ga Alloys. Mech. Syst. Signal Process. 2020, 139, 106418. [Google Scholar] [CrossRef]

- Mirzamohamadi, S.; Sheikhi, M.M.; Karafi, M.R.; Ghodsi, M.; Ghorbanirezaei, S. Novel Contactless Hybrid Static Magnetostrictive Force-Torque (CHSMFT) Sensor Using Galfenol. J. Magn. Magn. Mater. 2022, 553, 168969. [Google Scholar] [CrossRef]

- Song, H.; Kim, K.; Lee, J. Development of Optical Fiber Bragg Grating Force-Reflection Sensor System of Medical Application for Safe Minimally Invasive Robotic Surgery. Rev. Sci. Instrum. 2011, 82, 074301. [Google Scholar] [CrossRef]

- Liu, X.; Iordachita, I.I.; He, X.; Taylor, R.H.; Kang, J.U. Miniature Fiber-Optic Force Sensor Based on Low-Coherence Fabry-Pérot Interferometry for Vitreoretinal Microsurgery. Biomed. Opt. Express 2012, 3, 1062–1076. [Google Scholar] [CrossRef]

- Moerman, K.M.; Sprengers, A.M.J.; Nederveen, A.J.; Simms, C.K. A Novel MRI Compatible Soft Tissue Indentor and Fibre Bragg Grating Force Sensor. Med. Eng. Phys. 2013, 35, 486–499. [Google Scholar] [CrossRef]

- Polygerinos, P.; Seneviratne, L.D.; Razavi, R.; Schaeffter, T.; Althoefer, K. Triaxial Catheter-Tip Force Sensor for MRI-Guided Cardiac Procedures. IEEE/ASME Trans. Mechatron. 2013, 18, 386–396. [Google Scholar] [CrossRef]

- He, X.; Handa, J.; Gehlbach, P.; Taylor, R.; Iordachita, I. A Submillimetric 3-DOF Force Sensing Instrument with Integrated Fiber Bragg Grating for Retinal Microsurgery. IEEE Tran.s Biomed. Eng. 2014, 61, 522–534. [Google Scholar] [CrossRef]

- Saccomandi, P.; Caponero, M.A.; Polimadei, A.; Francomano, M.; Formica, D.; Accoto, D.; Tamilia, E.; Taffoni, F.; Di Pino, G.; Schena, E. An MR-Compatible Force Sensor Based on FBG Technology for Biomedical Application. In Proceedings of the 2014 36th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, EMBC 2014, Chicago, IL, USA, 26–30 August 2014; pp. 5731–5734. [Google Scholar] [CrossRef]

- Bützer, T.L.; Rinderknecht, M.D.; Johannes, G.H.; Popp, W.L.; Lehner, R.; Lambercy, O.; Gassert, R.; Bützer, T.L.; Rinderknecht, M.D.; Johannes, G.H.; et al. Design and Evaluation of a Fiber-Optic Grip Force Sensor with Compliant 3D-Printable Structure for (f)MRI Applications. J. Sens. 2016, 2016, 6248178. [Google Scholar] [CrossRef]

- Al-Mai, O.; Ahmadi, M.; Albert, J. A Compliant 3-Axis Fiber-Optic Force Sensor for Biomechanical Measurement. IEEE Sens. J. 2017, 17, 6549–6557. [Google Scholar] [CrossRef]

- Shin, D.; Kim, H.-U.; Kulkarni, A.; Kim, T. Development and Evaluation of Tri-Axial Fiber Bragg Grating Force Sensor for Catheter. In Proceedings of the Eurosensors 2017, Paris, France, 24 August 2017; Volume 1, p. 549. [Google Scholar]

- Lv, C.; Wang, S.; Shi, C. A High-Precision and Miniature Fiber Bragg Grating-Based Force Sensor for Tissue Palpation During Minimally Invasive Surgery. Ann. Biomed. Eng. 2020, 48, 669–681. [Google Scholar] [CrossRef]

- Huang, W. On the Selection of Shape Memory Alloys for Actuators. Mater. Des. 2002, 23, 11–19. [Google Scholar] [CrossRef]

- Rakotondrabe, M.; Ivan, I.A. Development and Dynamic Modeling of a New Hybrid Thermopiezoelectric Microactuator. IEEE Trans. Robot. 2010, 26, 1077–1085. [Google Scholar] [CrossRef]

- Zaszczyńska, A.; Gradys, A.; Sajkiewicz, P. Progress in the Applications of Smart Piezoelectric Materials for Medical Devices. Polymers 2020, 12, 2754. [Google Scholar] [CrossRef]

- Cauchi, M.; Grech, I.; Mallia, B.; Mollicone, P.; Sammut, N. The Effects of Cold Arm Width and Metal Deposition on the Performance of a U-Beam Electrothermal MEMS Microgripper for Biomedical Applications. Micromachines 2019, 10, 167. [Google Scholar] [CrossRef]

- Masood, M.U.; Saleem, M.M.; Khan, U.S.; Hamza, A. Design, Closed-Form Modeling and Analysis of SU-8 Based Electrothermal Microgripper for Biomedical Applications. Microsyst. Technol. 2019, 25, 1171–1184. [Google Scholar] [CrossRef]

- Belfiore, N.P.; Bagolini, A.; Rossi, A.; Bocchetta, G.; Vurchio, F.; Crescenzi, R.; Scorza, A.; Bellutti, P.; Sciuto, S.A. Design, Fabrication, Testing and Simulation of a Rotary Double Comb Drives Actuated Microgripper. Micromachines 2021, 12, 1263. [Google Scholar] [CrossRef] [PubMed]

- Pengwang, E.; Rabenorosoa, K.; Rakotondrabe, M.; Andreff, N. Scanning Micromirror Platform Based on MEMS Technology for Medical Application. Micromachines 2016, 7, 24. [Google Scholar] [CrossRef] [PubMed]

| Material | Input | Output | ||

|---|---|---|---|---|

| Piezoelectric | Electric field | Mechanical strain | ||

| Mechanical load | Electric potential | |||

| Pyroelectric | Thermal load | Electric potential | ||

| Electric field | Temperature change | |||

| Thermoelectric | Thermal load | Electric potential | ||

| Electric field | Temperature change | |||

| Shape memory alloys | Thermal load | Mechanical strain | ||

| Magnetic field | ||||

| Magneto- |  | strictive | Magnetic field | Mechanical strain |

| Mechanical load | Magnetization | |||

| Electro- | Electric field | Mechanical strain | ||

| Mechanical load | Electric potential | |||

| Magneto- |  | active polymers | Magnetic field | Mechanical strain |

| Electro- | Electric field | |||

| Photovoltaic | Incident light | Electric potential | ||

| Magneto- |  | rheological fluids | Magnetic field | Viscosity change |

| Electro- | Electric field | |||

| Photo- |  | chromic | Incident light | Color change |

| Thermo- | Thermal load | |||

| Magneto- | Magnetic field | |||

| Electro- | Electric field | |||

| Piezo- | Mechanical load | |||

| pH-sensitive | pH change | Color change | ||

| Material | Measurement Range (N) | Accuracy | Sensitivity | Linearity (%) | Ref. |

|---|---|---|---|---|---|

| PVDF film | (0–5) × 10−3 (0–18) × 10−3 | N.A. | 25.3 mV·N−1 | 6.5 | [93] |

| PVDF cantilever beam | (0–3) × 10−6 | N.A. | 0.112 V·µN−1 | N.A. | [94] |

| PVDF fabrics | 3–5 | N.A. | 42 mV·N−1 | N.A. | [95] |

| PVDF film | (0.35–1.5) × 10−3 | N.A. | 1–4.3 mV·µN−1 | N.A. | [96] |

| P(VDF-TrFE) nanofibers (1) | (20–60) × 10−3 (15–50) × 10−3 (15–55) × 10−3 | N.A. | 32.9 mV·N−1 60.5 mV·N−1 40.6 mV·N−1 | N.A. | [97] |

| PVDF film (2) | 0–0.5 0–0.5 0–1.5 | N.A. | 14.93 pC·N−1 14.92 pC·N−1 6.62 pC·N−1 | 2.45 2.37 1.74 | [98] |

| PVDF film (2) | 0–6 | N.A. | 0.34 V·N−1 0.37 V·N−1 0.41 V·N−1 | N.A. | [99] |

| 0–6 | N.A. | 0.41 V·N−1 0.41 V·N−1 0.4 V·N−1 | N.A. | ||

| PVDF-MFC films | (0–100) × 10−3 | N.A. | 1.23 mV·mN−1 | N.A. | [100] |

| PVDF nanofibers | 0–6 | N.A. | 8.3 ± 1.2 mV·N−1 | N.A. | [101] |

| PVDF-MWCNT-Cloisite 30B nanofibers (1) | 0–6 | N.A. | 10.9 ± 1.3 mV·N−1 9.0 ± 1.6 mV·N−1 8.4 ± 0.9 mV·N−1 | N.A. | |

| PVDF film | 0–6 | N.A. | 8.8 ± 1.6 mV·N−1 | N.A. | |

| PVDF film | 0–640 | N.A. | 14.6 pC·N−1 | 0.197 | [102] |

| PVDF film | 0.33–1.27 0.23–0.88 | N.A. | 0.14 mV·N−1 0.18 mV·N−1 | N.A. | [103] |

| PZT disk | 0–100 | N.A. | 42 mV·N−1 | N.A. | [104] |

| PVDF film (3) | 0–350 0–750 0–800 | N.A. | 0.92 kHz·N−1 0.4 kHz·N−1 0.26 kHz·N−1 | 2.5 7 7 | [105] |

| PZT disk | 0–17.7 | 0.7% | 6.6 Hz·N−1 | 3.5 | [106] |

| PZT | 10.8–30 | 2% | 10.5 Hz·N−1 | 3.6 | [107] |

| PZT ring | 50–1500 | N.A. | 1.9 Hz·N−1 | 6.7 | [108] |

| PZK 850 (4) | 0–50 | N.A. | −2.32 mV·N−1 −0.68 mV·N−1 | N.A. | [109] |

| PZT-QA ring | ± 150 | N.A. | 4.5 mV·N−1 | N.A. | [110] |

| PZT disk | 0.5–5 | 15.1% | 2200 Ω·N−1 | 25.4 | [111] |

| PZT-5 disk | 4.9–39 | 5% | N.A. | N.A. | [112] |

| PMN-PT plate | 0.1–2 | N.A. | 51 Ω·N−1 | 4.3 | [113] |

| PZT plate | 0.5–2.5 | N.A. | 1.8%·N−1 | 11.2 | [114] |

| PZT piezostack | (0.7–4) × 103 | N.A. | 25 nF·kN−1 | 3.6 | [115] |

| PZT disk | 14.1–141.3 | N.A. | 1 µsec·N−1 | 11.9 | [116] |

| Material | Measurement Range (N) | Accuracy | Sensitivity | Linearity (%) | Ref. |

|---|---|---|---|---|---|

| Flexinol® (NiTiNOL) wire | 1.7–3.2 | N.A. | N.A. | N.A. | [118] |

| Flexinol® (NiTiNOL) wire | 0.3–10 | 4.7% | 0.1 V·N−1 | 0.1 | [119] |

| Flexinol® (NiTiNOL) wire | 0.785–2.45 | N.A. | 0.8 Hz·N−1 | N.A. | [120] |

| Material | Measurement Range (N) | Accuracy | Sensitivity | Linearity (%) | Ref. |

|---|---|---|---|---|---|

| Fe-Ni ring | (0.1–21) × 103 | 14% | N.A. | N.A. | [121] |

| Terfenol-D rod | 0–1000 | N.A. | −0.4 mV·N−1 | 4.41 | [122,123] |

| Terfenol-D rod | 98.1–981 | N.A. | 0.51 mV·N−1 | 2.8 | [124] |

| Galfenol cantilever beam | 0–5 | N.A. | 114 mV·N−1 | 3 | [125] |

| Galfenol wire | 0–2 | N.A. | 48.07 mV·N−1 | N.A. | [126] |

| Galfenol wire | 0–3 | N.A. | 126 mV·N−1 | N.A. | [127] |

| Galfenol film | 0–10 | 1.07% | 0.154 mV·N−1 | 1.5 | [128] |

| Galfenol tapered I beam | 0–50 | 5.73% | 2.7 mT·N−1 | N.A. | [129] |

| Galfenol rod | 196–3400 | 2.11% | 0.075 mV·N−1 | 3.75 | [130] |

| Material | Measurement Range (N) | Accuracy | Sensitivity | Linearity (%) | Ref. |

|---|---|---|---|---|---|

| FBG | 0–10 | 0.1 N | N.A. | N.A. | [131] |

| Single-mode optical fibers | (5–18) × 10−3 | N.A. | 43.2 nm·mN−1 | N.A. | [132] |

| FBG | 0–15 | 3.1% | N.A. | N.A. | [133] |

| Optical fibers (1) | 0–0.5 | 6% | 1 N−1 1 N−1 0.5 N−1 | 4% | [134] |

| FBG (1) | ±20 × 10−3 ±20 × 10−3 (−10–20) × 10−3 | ±1.2 mN ±0.9 mN ±3.5 mN | N.A. | N.A. | [135] |

| FBG (2) | 0–4.2 (0–250) × 10−3 (0–250) × 10−3 | N.A. | −0.07 ÷ −0.11 nm·N−1 6.8 nm·N−1 0.27 nm·N−1 | N.A. | [136] |

| Optical fibers (3) | 0–800 0–500 | 5.99% 1.57% | 0.843 ± 0.003 mV·N−1 0.978 ± 0.005 mV·N−1 | 10.3 ± 0.1 2.37 ± 0.22 | [137] |

| Optical fibers (1) | 0–140 0–140 0–1000 | N.A. | N.A. | N.A. | [138] |

| FBG | (98–490) × 10−3 | N.A. | N.A. | N.A. | [139] |

| FBG | 0–5 | N.A. | 392 pm·N−1 | 0.97 | [140] |

|

| Material | Ref. | Application |

|---|---|---|

| Piezoelectric | [93,94] | Micromanipulation |

| [95] | Physiological parameters sensing | |

| [96,100] | Robot-assisted microinjection | |

| [97] | Pressure sensor | |

| [98] | Tactile sensor | |

| [102] | Cold heading monitoring | |

| [103] | Acupuncture monitoring | |

| [106,107] | Weight measurement | |

| [109] | Robotics | |

| [110] | Ultrasonic tools | |

| [111] | Automation assembly system | |

| [113] | Elasticity measurement | |

| [114] | Tactile sensor for robotic gripper | |

| Shape memory alloys | [118,119,120] | Strain feedback |

| Magnetostrictive | [121] | Car brake system |

| [125] | Stiffness measurement | |

| [126] | Tactile sensor for object recognition | |

| [127] | Tactile sensor for stiffness measurement | |

| [128] | Industrial control, robotics | |

| [129] | Impact force sensor | |

| [130] | Drilling, machining, power transmission | |

| Optical fibers | [131,140] | Minimally invasive surgery |

| [132,135] | Vitreoretinal microsurgery | |

| [133] | Soft tissue indentation | |

| [134] | Cardiac ablation | |

| [136] | Object manipulation | |

| [137] | Grip force measurement | |

| [138] | Ground reaction force measurement, collision detection | |

| [139] | Catheter |

| Material | Advantages | Drawbacks |

|---|---|---|

| Piezoelectric |

|

|

| Shape memory alloys |

|

|

| Magnetostrictive |

|

|

| Optical fibers |

|

|

| Strain gauges |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bocchetta, G.; Fiori, G.; Sciuto, S.A.; Scorza, A. Performance of Smart Materials-Based Instrumentation for Force Measurements in Biomedical Applications: A Methodological Review. Actuators 2023, 12, 261. https://doi.org/10.3390/act12070261

Bocchetta G, Fiori G, Sciuto SA, Scorza A. Performance of Smart Materials-Based Instrumentation for Force Measurements in Biomedical Applications: A Methodological Review. Actuators. 2023; 12(7):261. https://doi.org/10.3390/act12070261

Chicago/Turabian StyleBocchetta, Gabriele, Giorgia Fiori, Salvatore Andrea Sciuto, and Andrea Scorza. 2023. "Performance of Smart Materials-Based Instrumentation for Force Measurements in Biomedical Applications: A Methodological Review" Actuators 12, no. 7: 261. https://doi.org/10.3390/act12070261

APA StyleBocchetta, G., Fiori, G., Sciuto, S. A., & Scorza, A. (2023). Performance of Smart Materials-Based Instrumentation for Force Measurements in Biomedical Applications: A Methodological Review. Actuators, 12(7), 261. https://doi.org/10.3390/act12070261