Research on Multi-Mode Control of Electro-Hydraulic Variable Displacement Pump Driven by Servo Motor

Abstract

1. Introduction

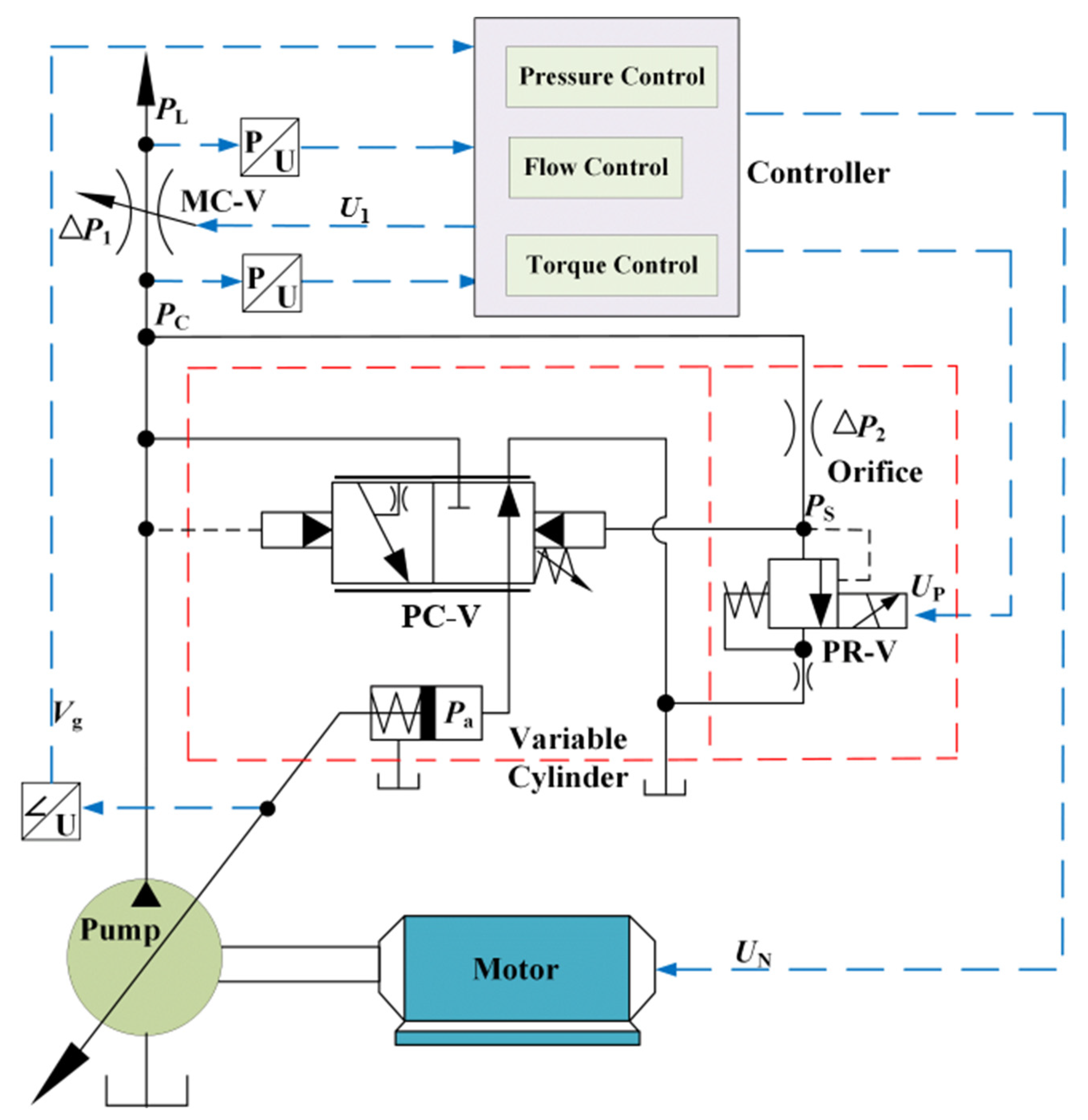

2. System Principle

2.1. System Introduction

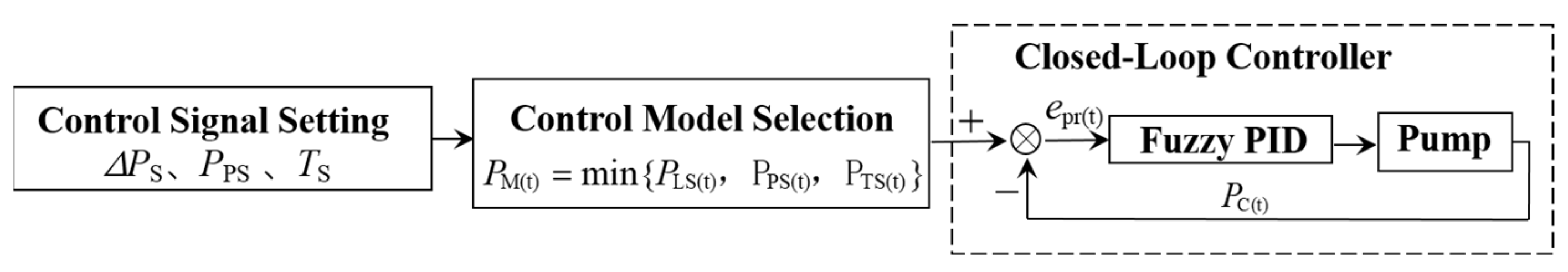

2.2. Multi-Mode Control Strategy

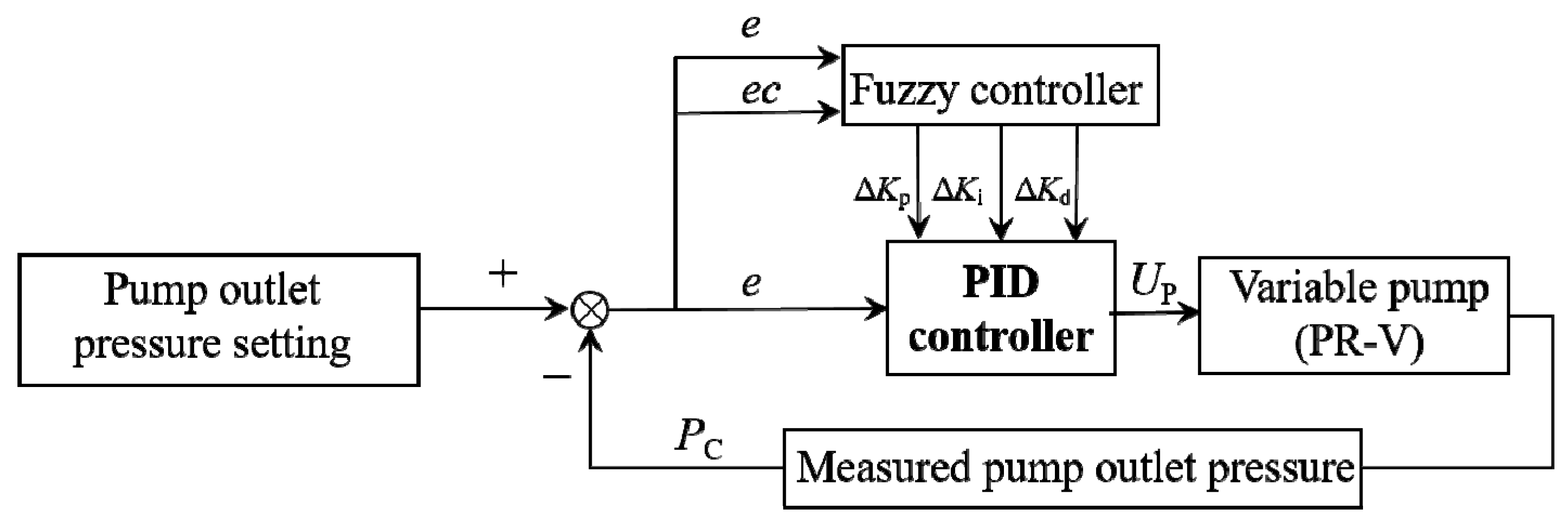

2.2.1. Strategy in Pressure Control Mode

2.2.2. Strategy in Flow Control Mode

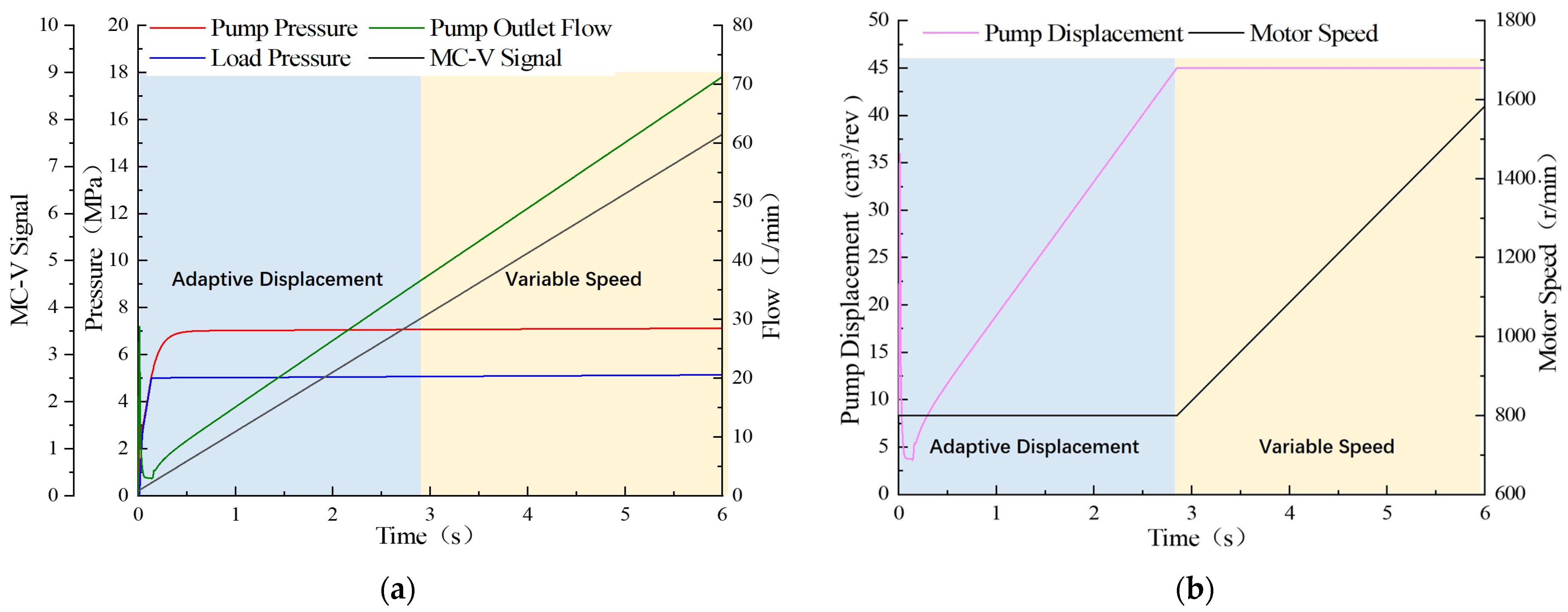

- (1)

- The flow voltage signal of MC-V is small, U ≤ U1m, the motor runs at an idle speed, and variable pump displacement is adjusted to meet MC-V flow demand;

- (2)

- The flow voltage signal of MC-V is large, U > U1m, the pump works at maximum displacement, and the motor speed is adjusted to meet MC-V flow demand.

2.2.3. Torque Control Strategy

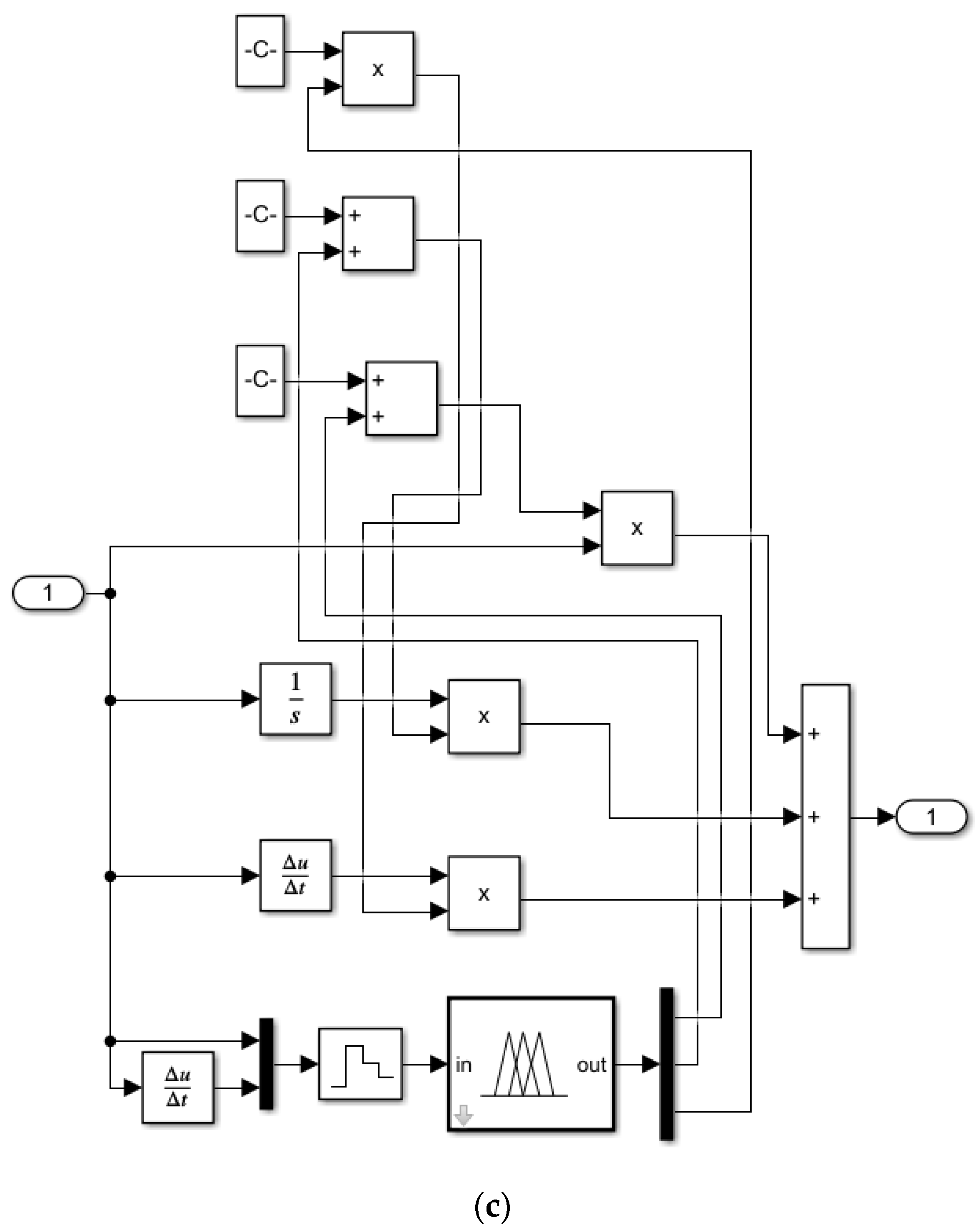

2.2.4. Controller Design

3. Simulation Analysis

- (1)

- Set the pump pressure step signal and compare the effect of fuzzy PID and PID control on the pump pressure;

- (2)

- Set the load pressure incremental signal and verify the feasibility of a multi-mode control strategy when the electro-hydraulic power source is in the three different control modes;

- (3)

- Set the MC-V opening incremental signal and verify the feasibility of the LSSM composite flow control strategy;

- (4)

- Set the incremental signal of the MC-V pressure difference, verify the feasibility of variable pressure difference control, and analyze its energy-saving effect.

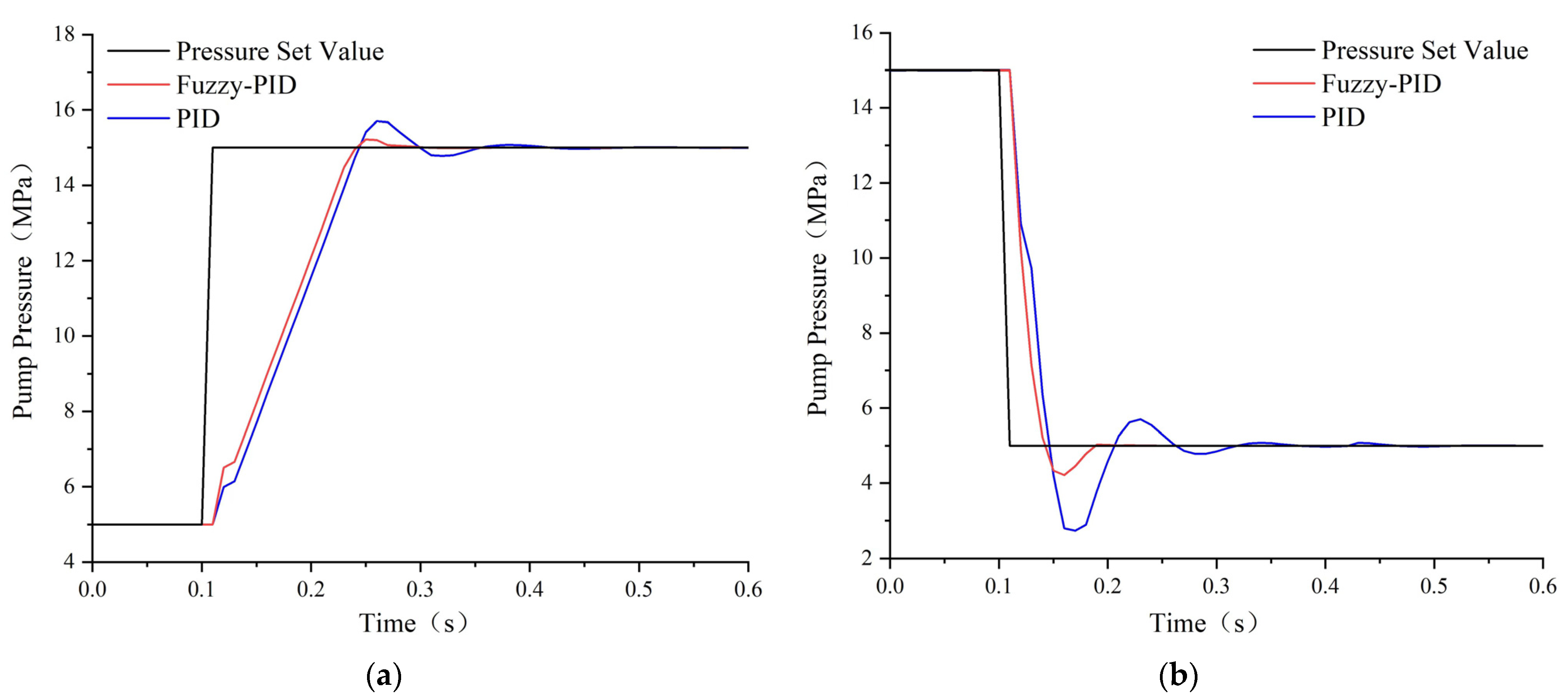

3.1. Comparative Analysis of Fuzzy PID and PID Simulation

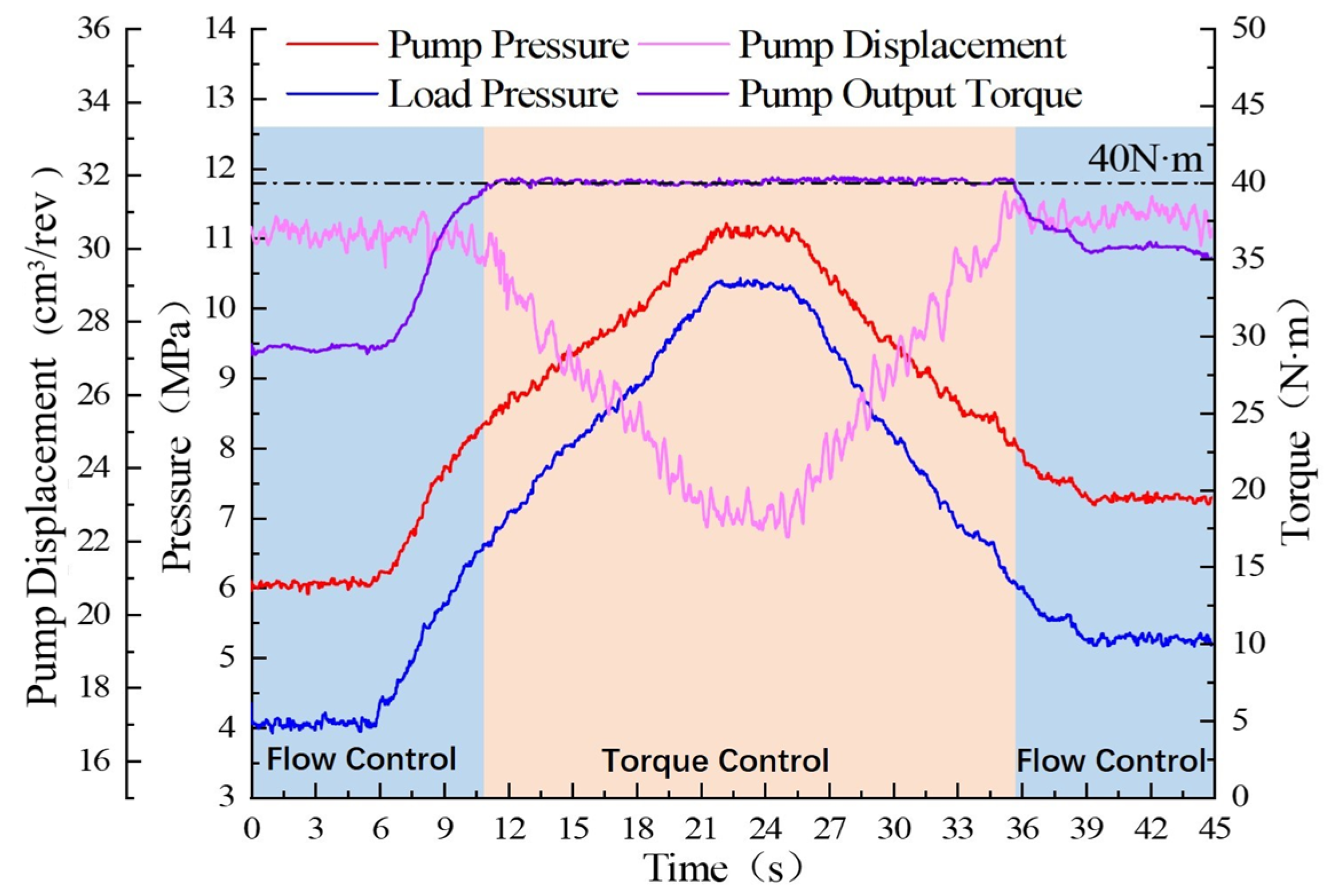

3.2. Flow-Torque-Pressure Composite Control Simulation Analysis

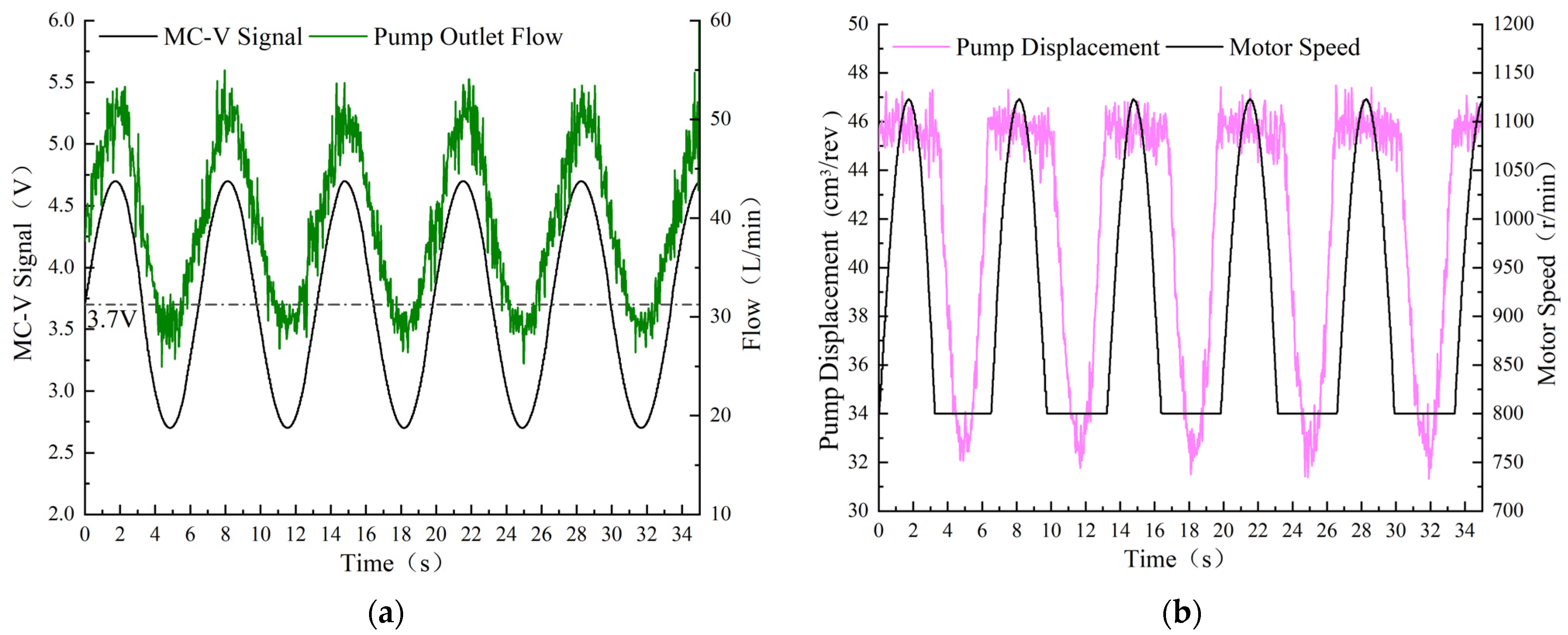

3.3. Adaptive Displacement-Variable Speed Composite Flow Control Simulation Analysis

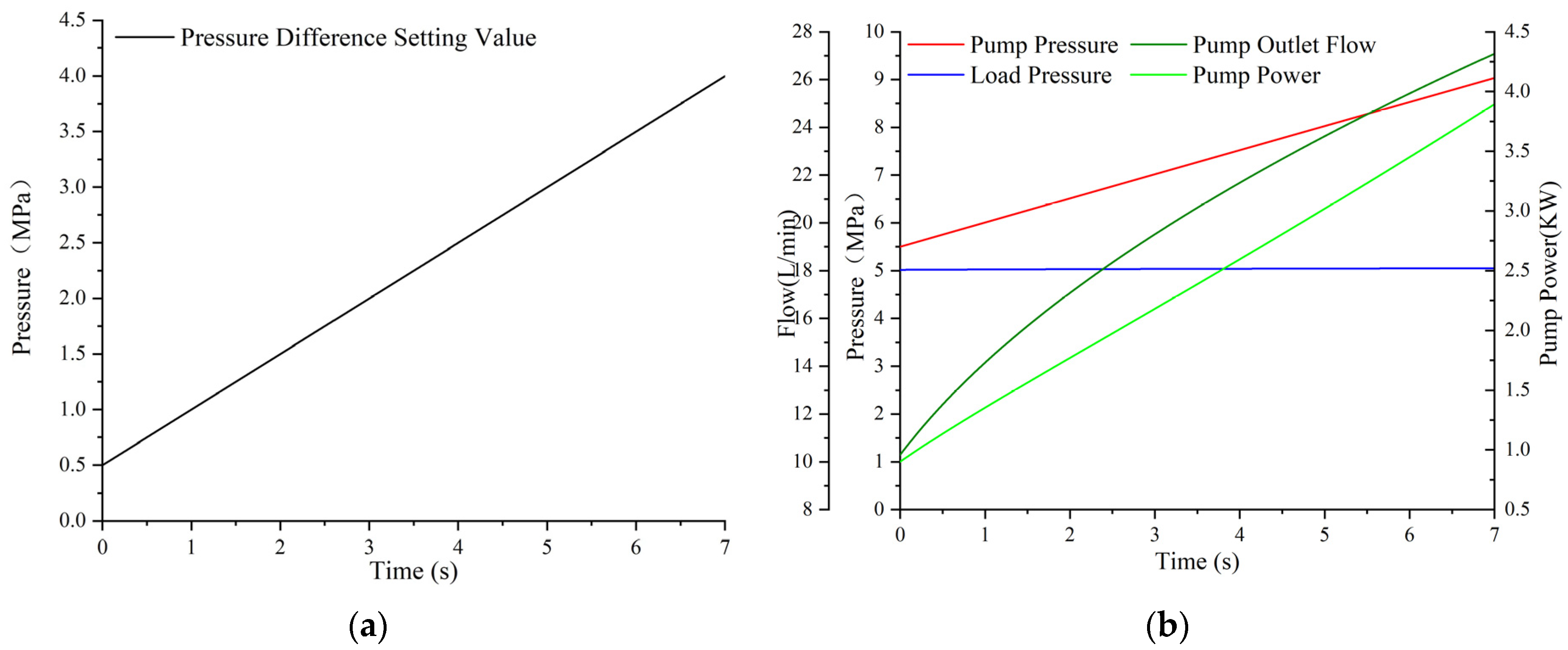

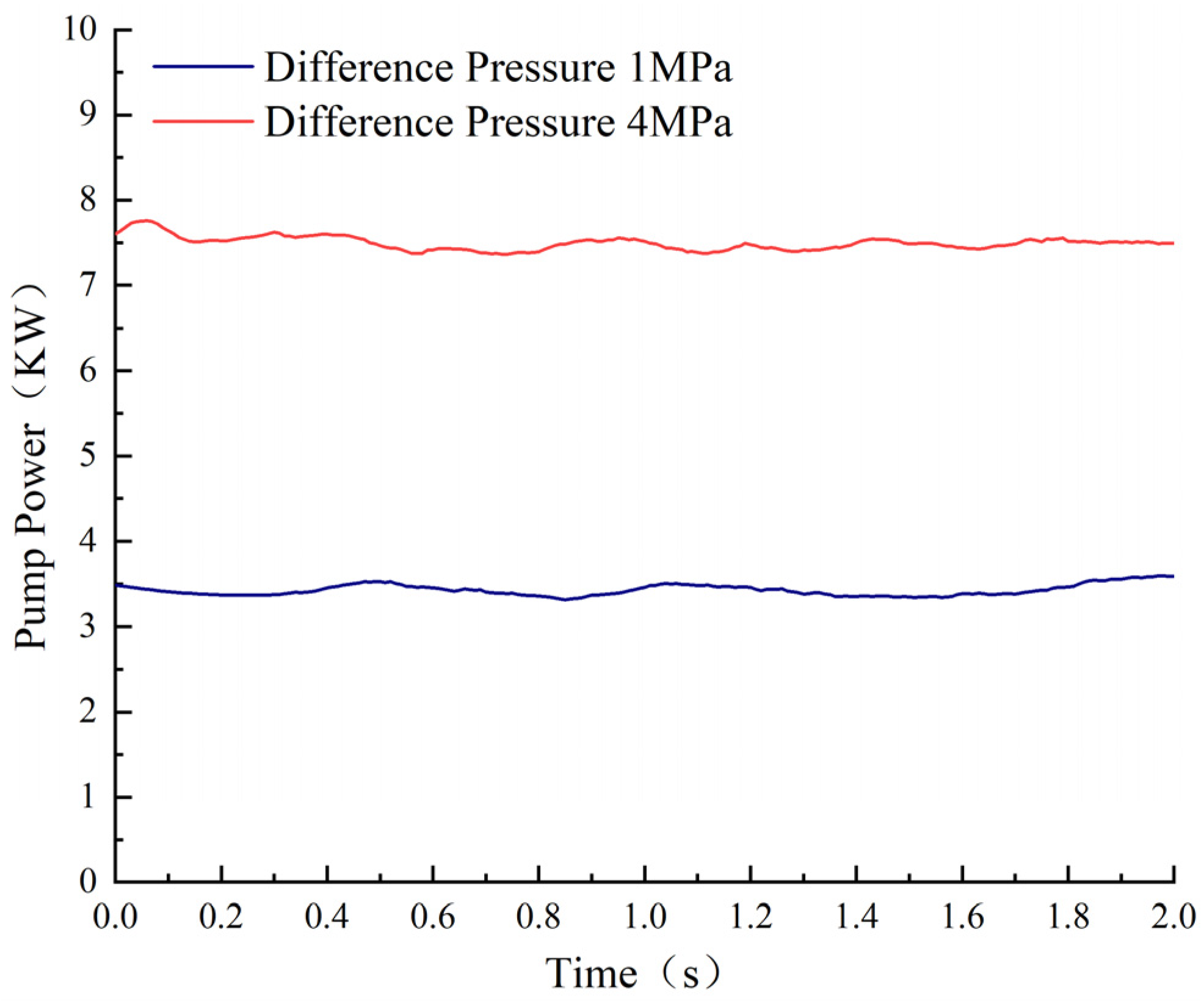

3.4. Simulation Analysis of Variable Differential Pressure Load Sensitive Control

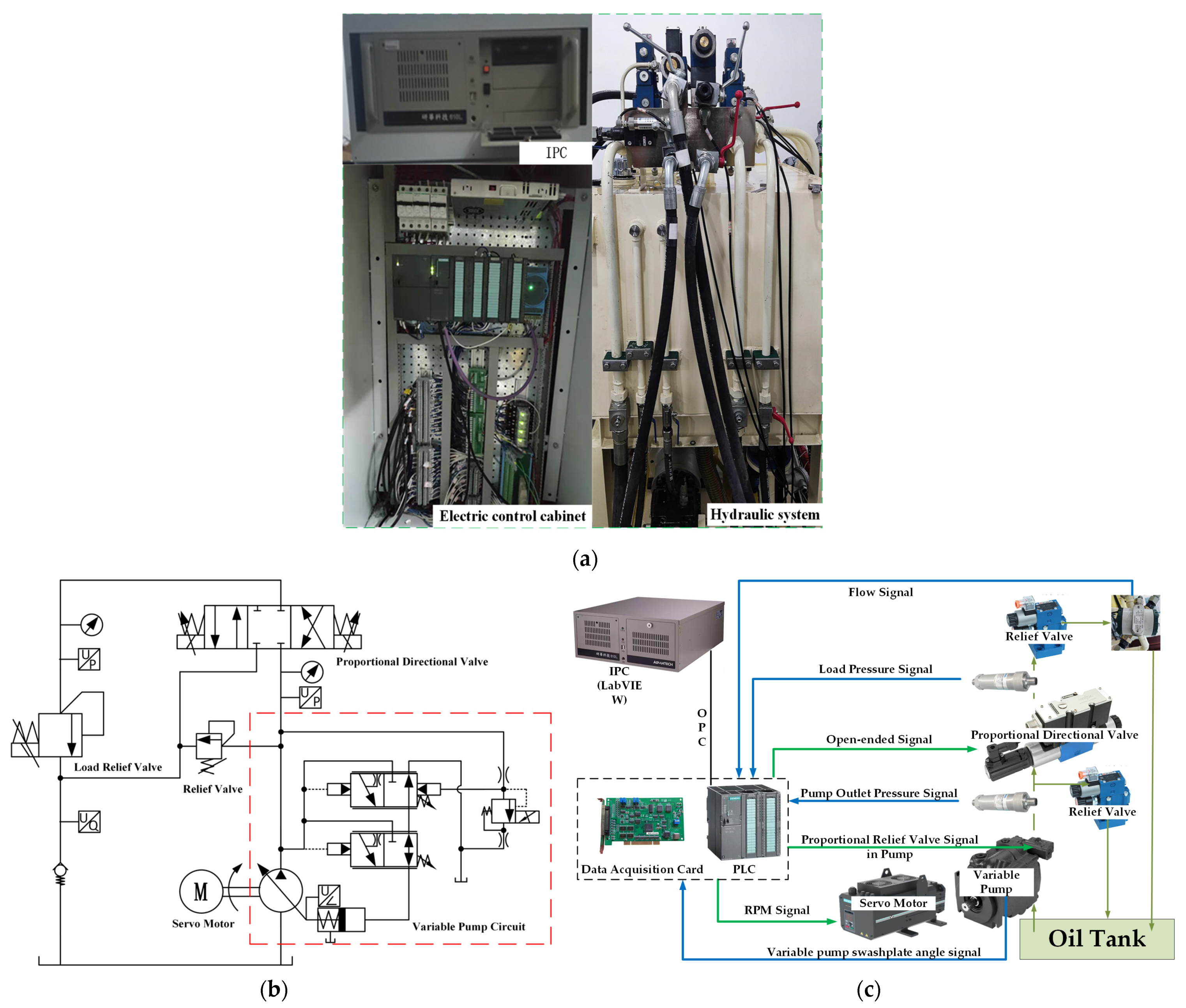

4. Experimental Studies

4.1. Build a Test Bench

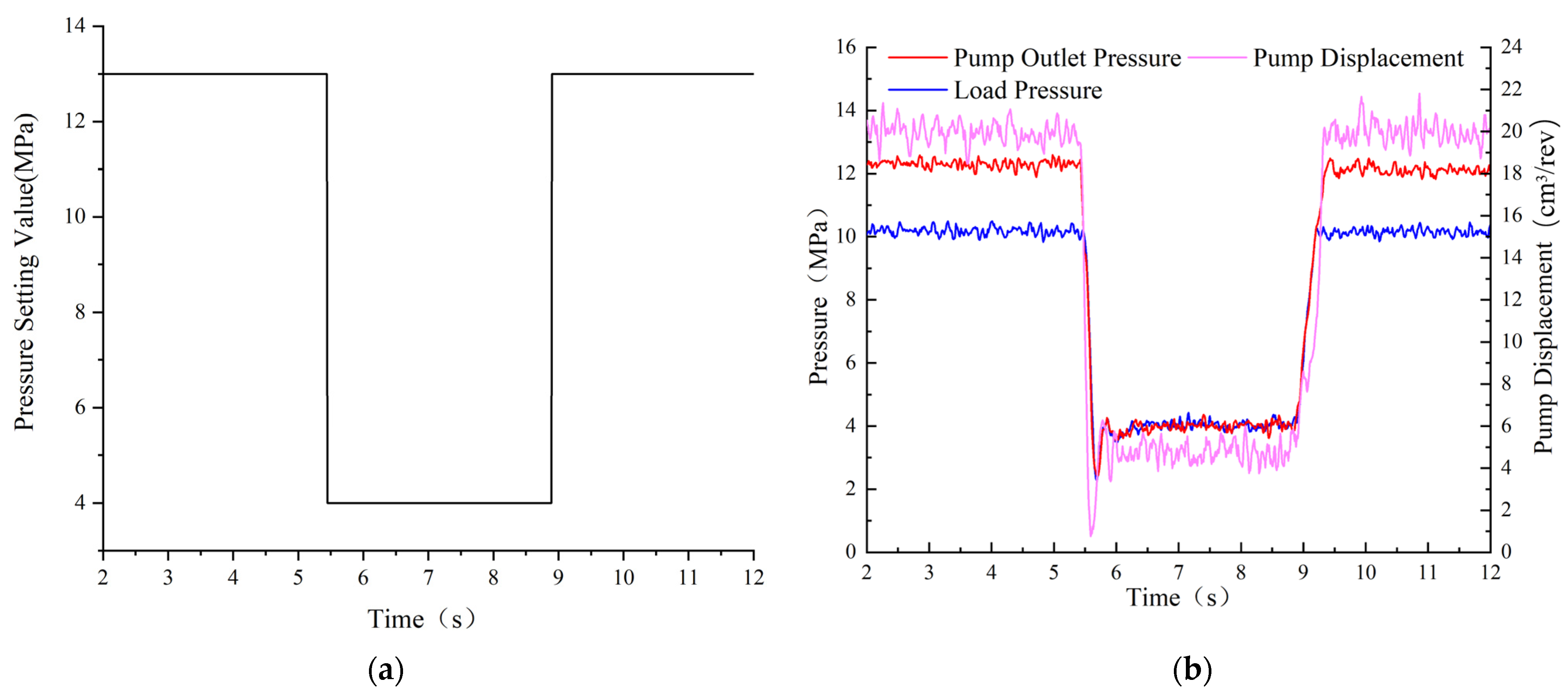

4.2. Pressure Control Analysis

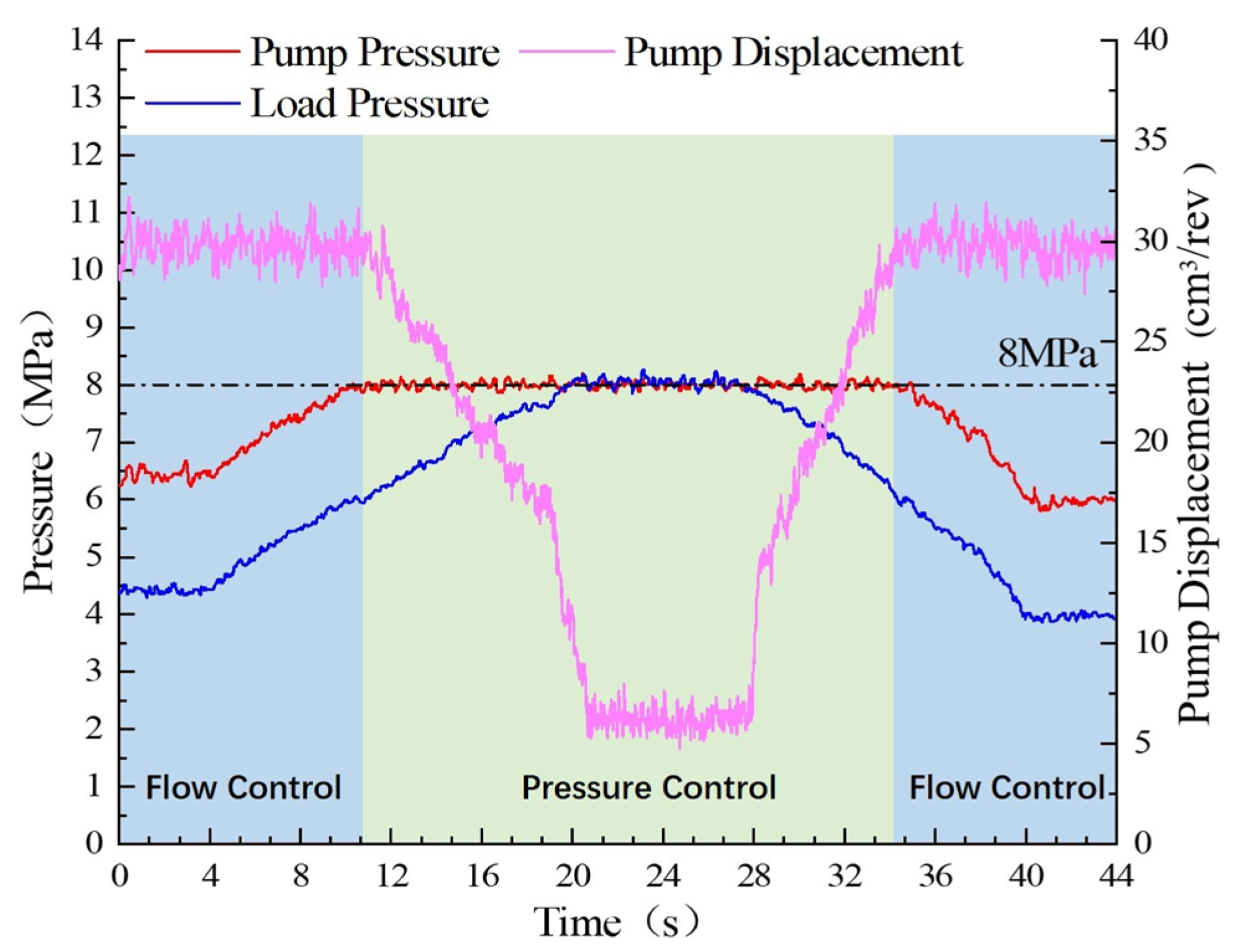

4.3. Flow Control Analysis

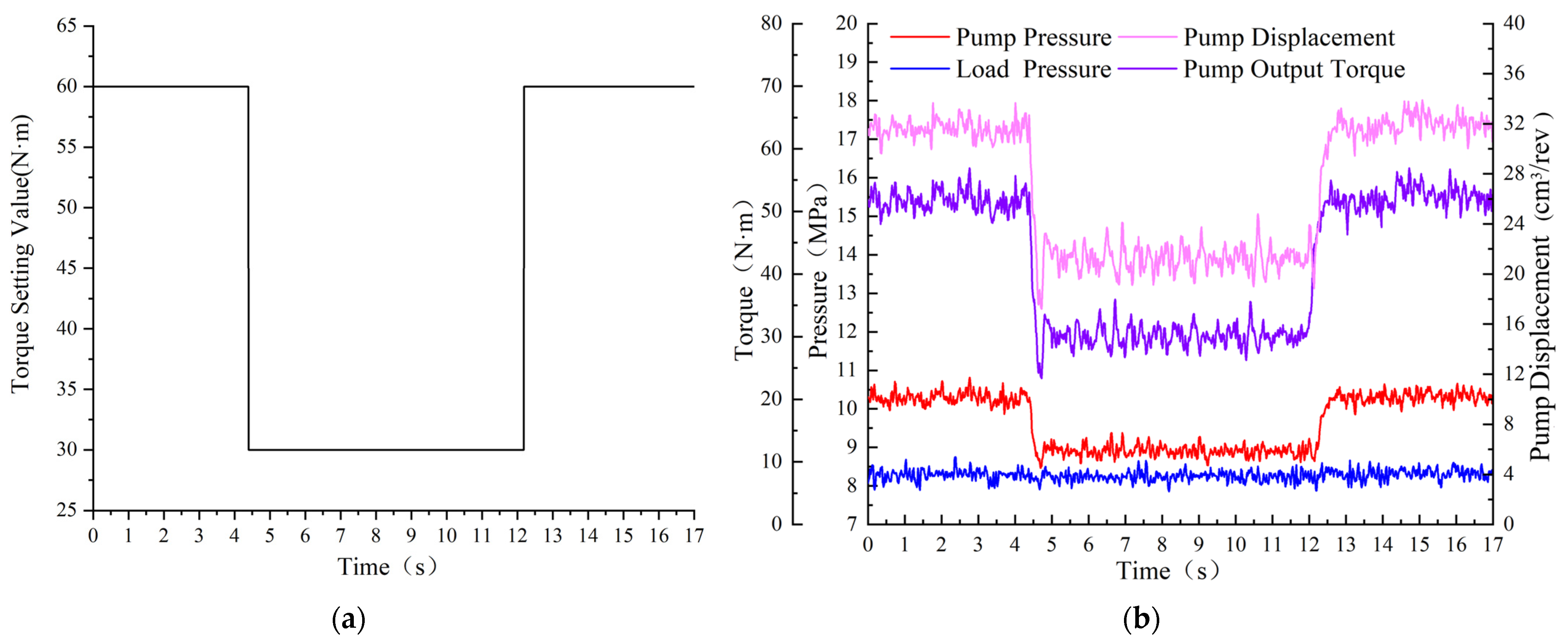

4.4. Torque Control Analysis

5. Summary

- (1)

- Fuzzy PID control has a faster response time, more stable control, and better tracking effect on pump outlet pressure compared with PID controllers;

- (2)

- The pump could switch well between pressure, flow, and torque modes according to the load pressure change, and the multi-mode switches are smooth;

- (3)

- The precision of pressure and torque control is relatively high, with control errors of 0.2% and 0.16%, respectively;

- (4)

- Compared with load-sensitive adaptive displacement regulation, the LSSM composite flow regulation strategy has a larger flow range and a more stable control effect. The pump output flow could automatically choose variable speed fixed displacement regulation or variable displacement fixed speed regulation based on the estimated flow rate. The output flow rate and power of the pump increase with the increase in the pressure difference of the main control valve. Reducing the pressure difference according to the actual working conditions could effectively reduce energy consumption.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Zhang, X.; Quan, L.; Zhang, H. Research on energy consumption of injection molding machine driven by five different types of electro-hydraulic power units. J. Clean. Prod. 2020, 242, 118355. [Google Scholar] [CrossRef]

- Yan, Z.; Ge, L.; Quan, L. Energy-Efficient Electro-Hydraulic Power Source Driven by Variable-Speed Motor. Energies 2022, 15, 4804. [Google Scholar] [CrossRef]

- Lovrec, D.; Kastrevc, M.; Ulaga, S. Electro-hydraulic load sensing with a speed-controlled hydraulic supply system on forming-machines. Int. J. Adv. Manuf. Technol. 2009, 41, 1066–1075. [Google Scholar] [CrossRef]

- Huang, H.; Jin, R.; Li, L.; Liu, Z. Improving the Energy Efficiency of a Hydraulic Press Via Variable-Speed Variable-Displacement Pump Unit. ASME J. Dyn. Sys. Meas. Control 2018, 140, 111006. [Google Scholar] [CrossRef]

- Tong, Z.; Wu, S.; Tong, S.; Yue, Y. Energy-saving technologies for construction machinery: A review of electro-hydraulic pump-valve coordinated system. J. Zhejiang Univ. Sci. A 2020, 21, 331–349. [Google Scholar] [CrossRef]

- Ge, L.; Quan, L.; Zhang, X.; Zhao, B.; Yang, J. Efficiency improvement and evaluation of electric hydraulic excavator with speed and displacement variable pump. Energy Convers. Manag. 2017, 150, 62–71. [Google Scholar] [CrossRef]

- Yan, Z. Characteristics of high energy-efficient Electro-hydraulic power source driven by servo motor and variable pump. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 1525–1536. [Google Scholar] [CrossRef]

- Liu, B.; Yan, Z.; Ge, L.; Quan, L. Electric Drive Hydraulic Power Source Characteristics of Small Hydraulic Excavator. Trans. Chin. Soc. Agric. Mach. 2019, 50, 387–393. [Google Scholar]

- Sun, Z.; Zeng, Q.; Wan, L.; Xiao, Y. Dynamic Response Analysis of the Bi-Tandem Axial Piston Pump with Dual-Loop Positive Flow Control under Pressure Disturbance. Actuators 2023, 12, 260. [Google Scholar] [CrossRef]

- Liao, W.; Chen, S.; Chen, C. Research of negative flow control characteristics for axial piston pump based on hydraulic and mechanical co-simulation. In Proceedings of the 2012 3rd International Conference on System Science, Engineering Design and Manufacturing Informatization, Chengdu, China, 20–21 October 2012; pp. 79–83. [Google Scholar]

- Tian, X.; Stump, P.; Vacca, A.; Fiorati, S.; Pintore, F. Power-Saving Solutions for Pre-Compensated Load-Sensing Systems on Mobile Machines. Trans. ASABE 2021, 64, 1435–1448. [Google Scholar] [CrossRef]

- Nurmi, J.; Mattila, J. Global Energy-Optimal Redundancy Resolution of Hydraulic Manipulators: Experimental Results for a Forestry Manipulator. Energies 2017, 10, 647. [Google Scholar] [CrossRef]

- Pan, Y.; Li, Y.; Liang, D. The influence of dynamic swash plate vibration on outlet flow ripple in constant power variable-displacement piston pump. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4914–4933. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, H.; Tian, S.; Qin, X. Performances analysis of a novel load-sensing hydraulic system with overriding differential pressure control. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 4331–4343. [Google Scholar]

- Salomaa, V.; Minav, T.; Mattila, J.; Pietola, M. Efficiency Study of an Electro-Hydraulic Excavator. Fluid Power Networks: Proceedings: 19th–21th March 2018: International Fluid Power Conference; RWTH Aachen University: Aachen, Germany, 2018; pp. 372–385. [Google Scholar]

- Chu, M.; Kang, Y.; Chen, Y.; Chang, Y. The Swashplate Angle Control of a Variable Displacement Pump with an Electro-Hydraulic Proportional Valve. Mater. Sci. Forum 2008, 594, 389–400. [Google Scholar] [CrossRef]

- Wei, C.; Wang, X.; Chen, Y.; Wu, H.; Chen, Y. Adaptive Fuzzy Power Management Strategy for Extended-Range Electric Logistics Vehicles Based on Driving Pattern Recognition. Actuators 2023, 12, 410. [Google Scholar] [CrossRef]

- Won, D.; Kim, W.; Tomizuka, M. High Gain Observer Based Integral Sliding Mode Control for Position Tracking of Electro-hydraulic Servo Systems. IEEE/ASME Trans. Mechatron. 2017, 22, 2695–2704. [Google Scholar] [CrossRef]

- Liao, Y.; Zhao, W.; Feng, J.; Lian, Z. Optimization of the Control Performance of a Novel 3/2 Water Proportional Directional Valve with a Special Position Following Servo Mechanism. IEEE/ASME Trans. Mechatron. 2024, 1–10. [Google Scholar] [CrossRef]

- Vilanova, R.; Alfaro, V.M. Robust PID Control: An Overview. Rev. Iberoam. De Autom. E Inform. Ind. 2011, 8, 141–158. [Google Scholar] [CrossRef]

- Somefun, O.A.; Akingbade, K.; Dahunsi, F. The dilemma of PID tuning. Annu. Rev. Control 2021, 52, 65–74. [Google Scholar]

- Kuantama, E.; Vesselenyi, T.; Dzitac, S.; Tarca, R. PID and Fuzzy-PID Control Model for Quadcopter Attitude with Disturbance Parameter. Int. J. Comput. Commun. Control 2017, 12, 519–532. [Google Scholar] [CrossRef]

- Esfandyari, M.; Fanaei, M.A.; Zohreie, H. Adaptive fuzzy tuning of PID controllers. Neural Comput. Appl. 2013, 23, S19–S28. [Google Scholar] [CrossRef]

- Anis, Y.H.; Kassem, S.A. Performance of constant power operated swash plate axial piston pumps with fuzzy logic controllers. In Proceedings of the ASME 2013 International Mechanical Engineering Congress and Exposition, San Diego, CA, USA, 15–21 November 2013; pp. 15–21. [Google Scholar]

- Cheng, M.; Zhang, J.; Xu, B.; Ding, R.; Yang, G. Anti-windup scheme of the electronic load sensing pump via switched flow/power control. Mechatronics 2019, 61, 1–11. [Google Scholar] [CrossRef]

- Lingenfelter, K.R.; Bruns, A.; Daley, C. Electronic Load Sense Control with Electronic Variable Load Sense Relief, Variable Working Margin, and Electronic Torque Limiting. U.S. Patent 9759212B2, 12 September 2017. [Google Scholar]

- Lin, T.; Lin, Y.; Ren, H.; Chen, H.; Li, Z.; Chen, Q. A double variable control load sensing system for electric hydraulic excavator. Energy 2021, 223, 119999. [Google Scholar] [CrossRef]

- Kim, J.H.; Jeon, C.S.; Hong, Y.S. Constant pressure control of a swash plate type axial piston pump by varying both volumetric displacement and shaft speed. Int. J. Precis. Eng. Manuf. 2015, 16, 2395–2401. [Google Scholar] [CrossRef]

- Wang, W.; Wang, B. An Energy-Saving Control Strategy with Load Sensing for Electro-Hydraulic Servo Systems. Stroj. Vestn. J. Mech. Eng. 2016, 62, 709–716. [Google Scholar] [CrossRef]

| er | ||||||||

|---|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZO | PS | PM | PB | ||

| e | NB | NB/NB/PS | NB/NM/PS | NM/NM/ZO | ZO/ZO/ZO | PM/PM/NS | PB/PM/NS | ZO/ZO/PB |

| NM | PB/NB/NS | PB/NB/NS | PM/NM/NS | PM/NM/NS | PS/NS/NS | ZO/ZO/ZO | ZO/ZO/NS | |

| NS | PM/NM/NB | PM/NM/NB | PS/NS/NM | PS/NS/NS | ZO/ZO/NS | NS/PS/ZO | NM/PS/PS | |

| ZO | PS/NM/NB | PS/NS/NM | ZO/NS/NM | ZO/ZO/NS | ZO/PS/ZO | PS/PS/ZO | PS/PM/PS | |

| PS | PM/NS/NB | PM/NS/NM | ZO/ZO/NS | ZO/PS/NS | ZO/PS/PS | PS/PM/ZO | PS/PM/PS | |

| PM | PM/ZO/NM | PM/ZO/NS | PM/ZO/NS | PS/PM/NS | PS/PM/PS | PM/PB/ZO | PM/PB/PS | |

| PB | PB/ZO/PS | PB/ZO/ZO | PM/PS/ZO | PM/PM/ZO | PM/PB/PS | PB/PB/ZO | PB/PB/PM | |

| Parameters | Value |

|---|---|

| Maximum displacement of hydraulic pump (cm3/rev) | 45 |

| Maximum limiting pressure of the hydraulic pump (MPa) | 26 |

| Pressure limiting valve set pressure (MPa) | 30 |

| Rated speed of servo motor (r/min) | 1800 |

| Servo motor setting speed range (r/min) | 800–1800 |

| Rated torque of servo motor (N·m) | 105 |

| Main control valve opening signal when motor 800 r/min, pump 45 cm3/rev (V) | 3.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Yan, Y.; Li, L.; Chao, Q.; Jin, K.; Liu, Z. Research on Multi-Mode Control of Electro-Hydraulic Variable Displacement Pump Driven by Servo Motor. Actuators 2024, 13, 190. https://doi.org/10.3390/act13050190

Zhang Z, Yan Y, Li L, Chao Q, Jin K, Liu Z. Research on Multi-Mode Control of Electro-Hydraulic Variable Displacement Pump Driven by Servo Motor. Actuators. 2024; 13(5):190. https://doi.org/10.3390/act13050190

Chicago/Turabian StyleZhang, Zhiqiang, Yupeng Yan, Lin Li, Qun Chao, Kunshan Jin, and Zhiqi Liu. 2024. "Research on Multi-Mode Control of Electro-Hydraulic Variable Displacement Pump Driven by Servo Motor" Actuators 13, no. 5: 190. https://doi.org/10.3390/act13050190

APA StyleZhang, Z., Yan, Y., Li, L., Chao, Q., Jin, K., & Liu, Z. (2024). Research on Multi-Mode Control of Electro-Hydraulic Variable Displacement Pump Driven by Servo Motor. Actuators, 13(5), 190. https://doi.org/10.3390/act13050190