Design and Self-Calibration Method of a Rope-Driven Cleaning Robot for Complex Glass Curtain Walls

Abstract

:1. Introduction

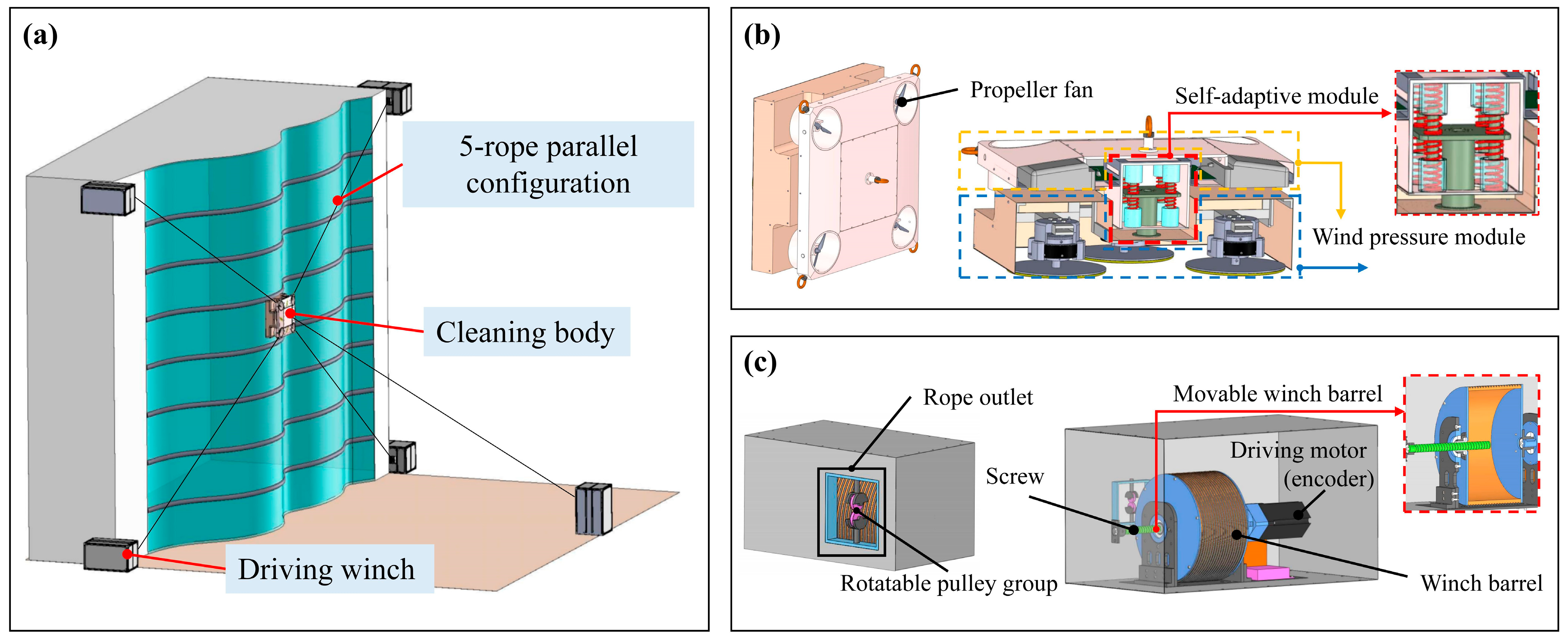

2. Structural Design of the Cleaning Robot

2.1. System Overall

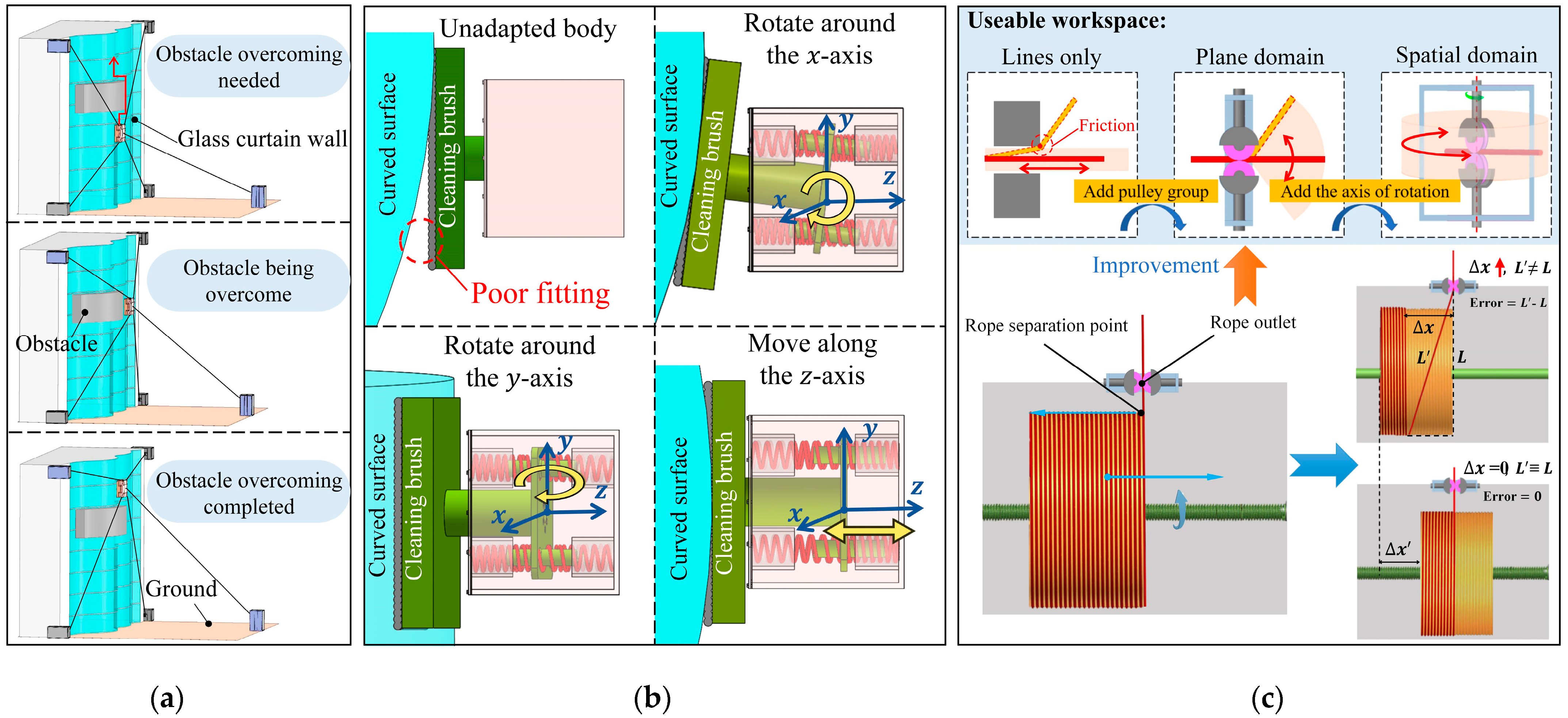

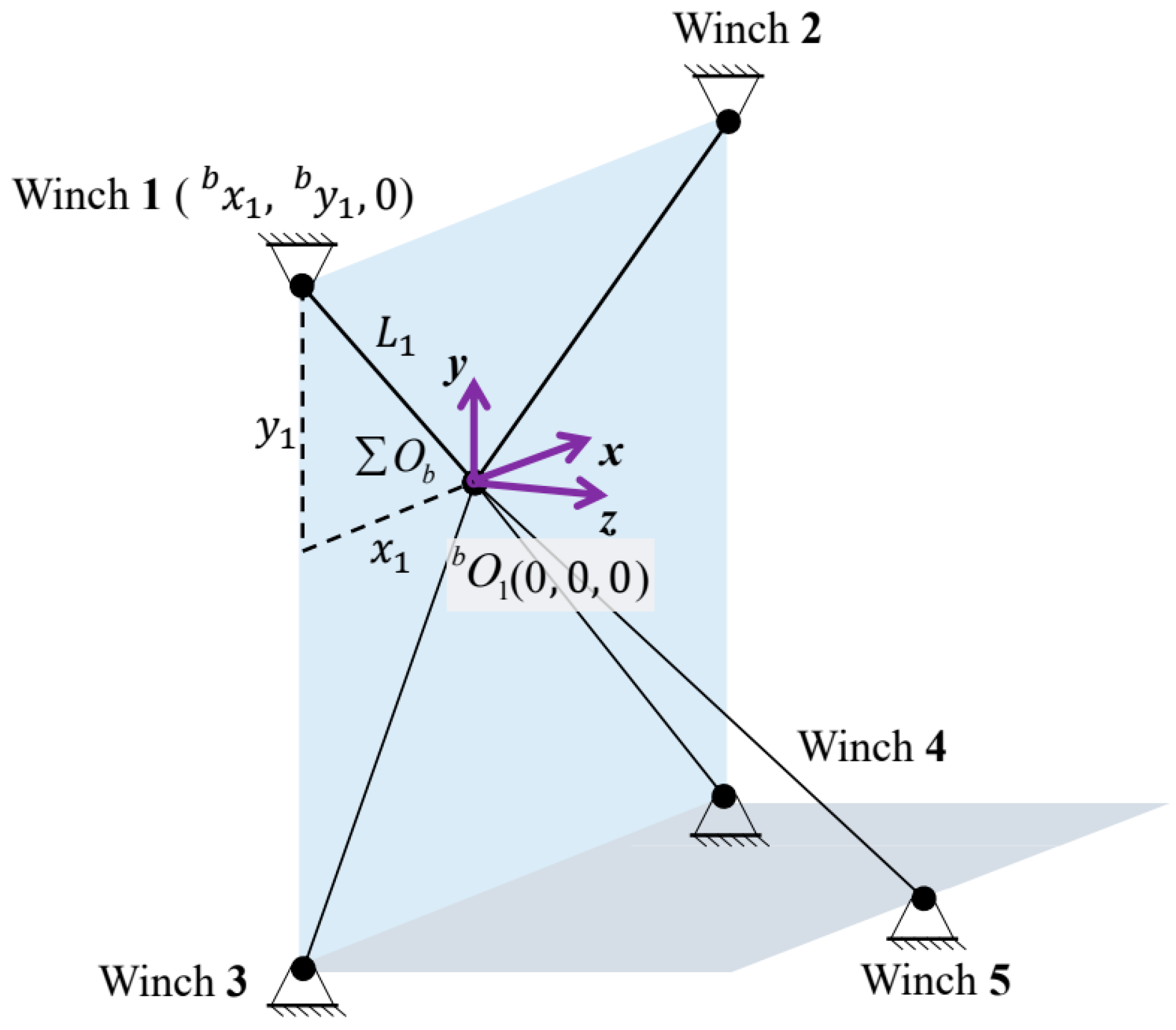

2.1.1. 5-Rope Parallel Configuration

2.1.2. Self-Adaptive Cleaning Body

2.1.3. Self-Compensating Driving Winch

2.2. Working Principle

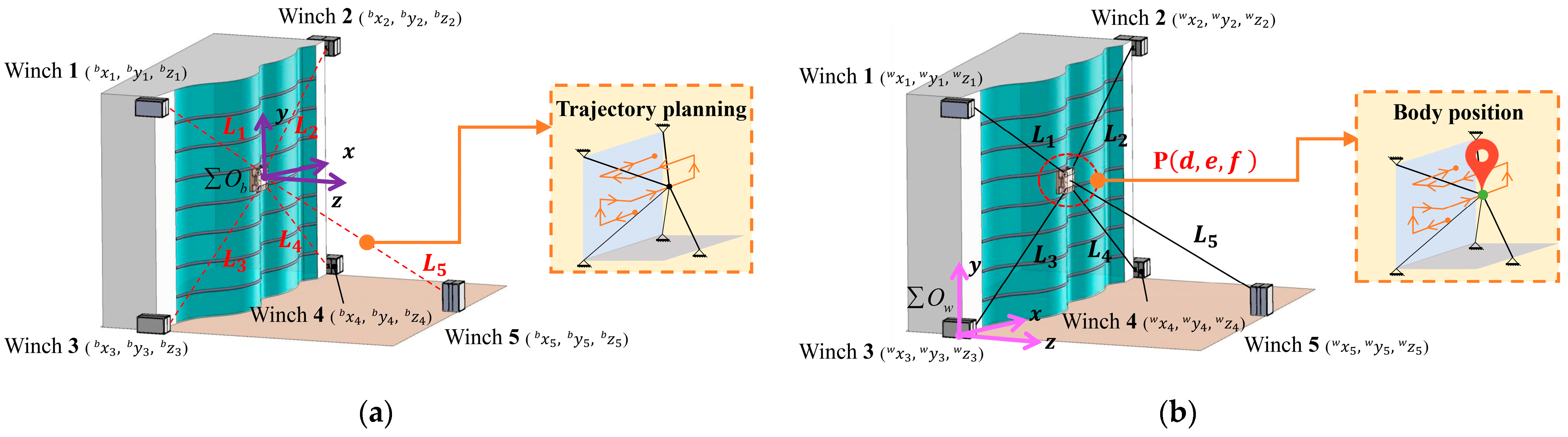

3. Kinematic Model

3.1. Rope Length Solution

3.2. Body Position Solution

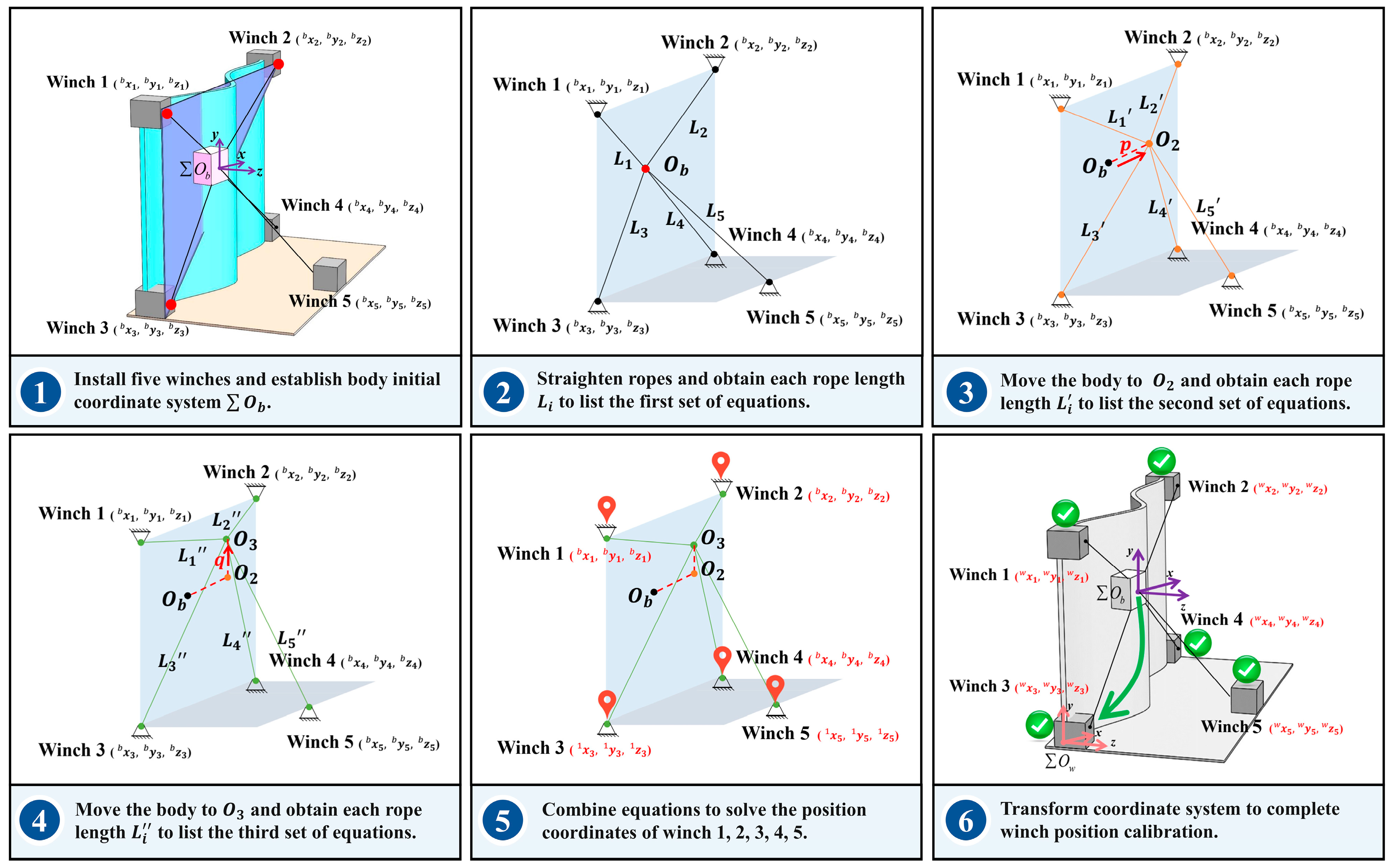

4. Self-Calibration of Winch Position Parameters

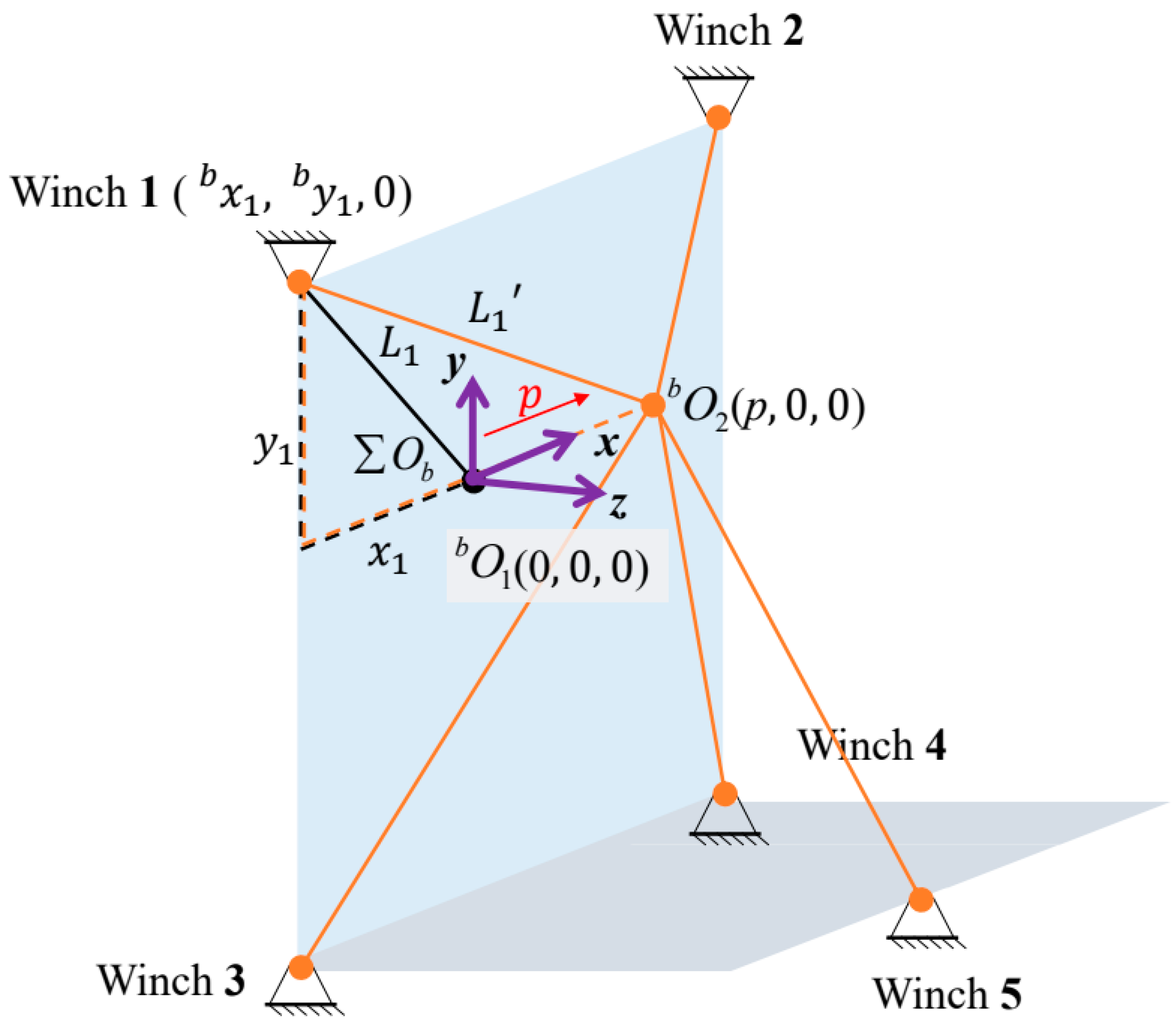

4.1. Self-Calibration Principle

- (1)

- Install four winches at different corners of the wall and the other winch on the ground to settle the robot configuration. Select the plane formed by three points of winches (1, 2, and 3) as the simplified wall, and only straighten the ropes of these three to assign the body’s position, which is placed anywhere on this plane, as the initial position (the first gauge point), which is defined as the origin of .

- (2)

- Keep the body at , straighten all five ropes, and acquire their rope lengths through encoders. Because the distance between the body and each winch is equal to the corresponding rope length, the first set of distance–rope length equivalent equations can be listed.

- (3)

- Coordinately control each rope to move the body along the x-axis direction for p, from to , which is the second gauge point. Similar to step (2), list the second set of equivalent equations.

- (4)

- From , coordinately control the ropes again to pull the body vertically upward for q to , which is the third gauge point. Similar to step (2), list the third set of equivalent equations.

- (5)

- Combine the above three equation groups from steps (2)–(4), and then the spatial position coordinate of each winch in can be solved separately.

- (6)

- Establish a work coordinate system with winch 3 as the origin to visually display the whole working area for subsequent robot trajectory planning. Based on the coordinate of winch 3 in , transform the acquired winch coordinates from to , and the spatial position coordinate of each winch in can be solved. The calibration is completed.

4.2. Self-Calibration Method

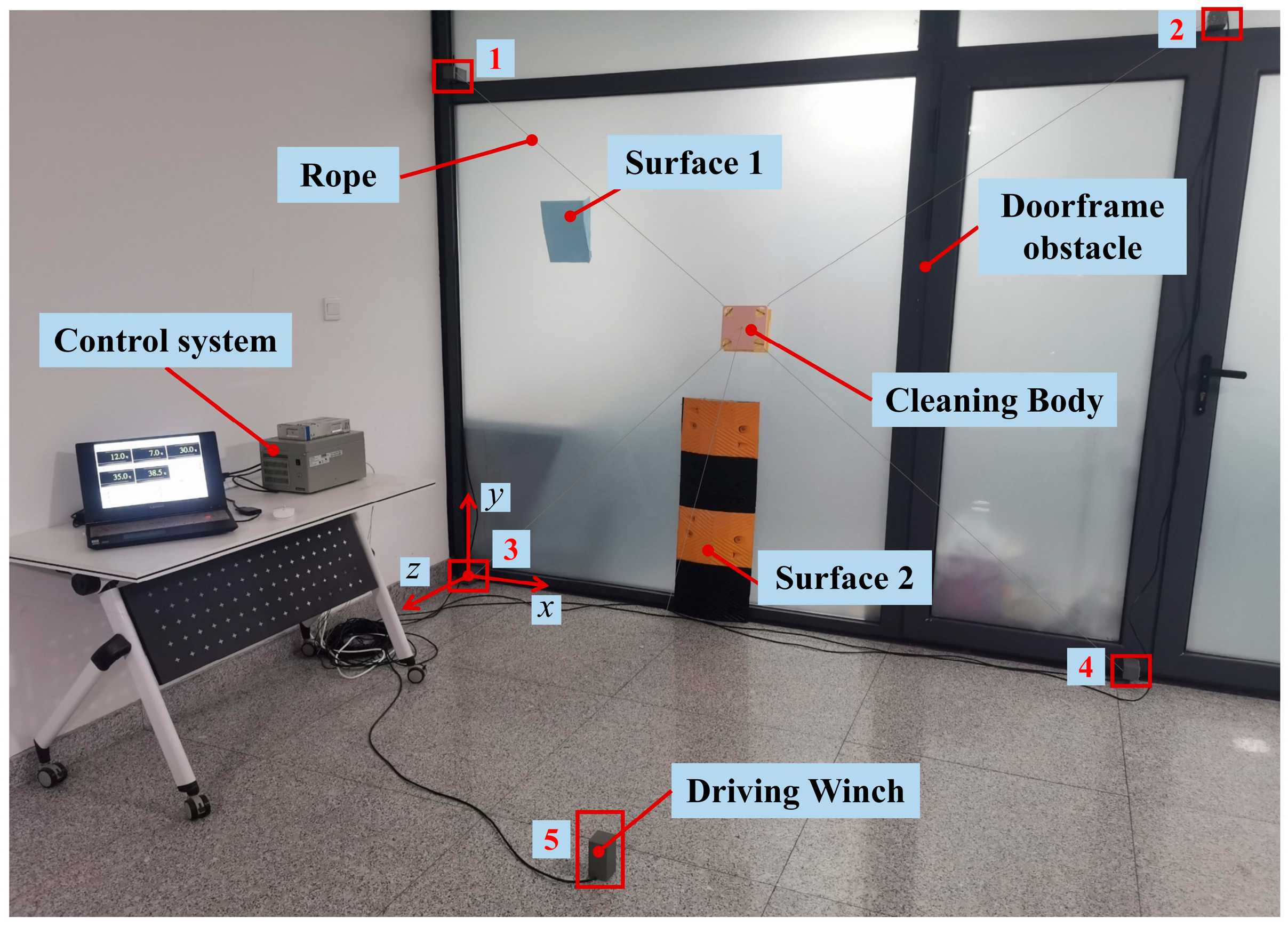

5. Experiment Verification and Analysis

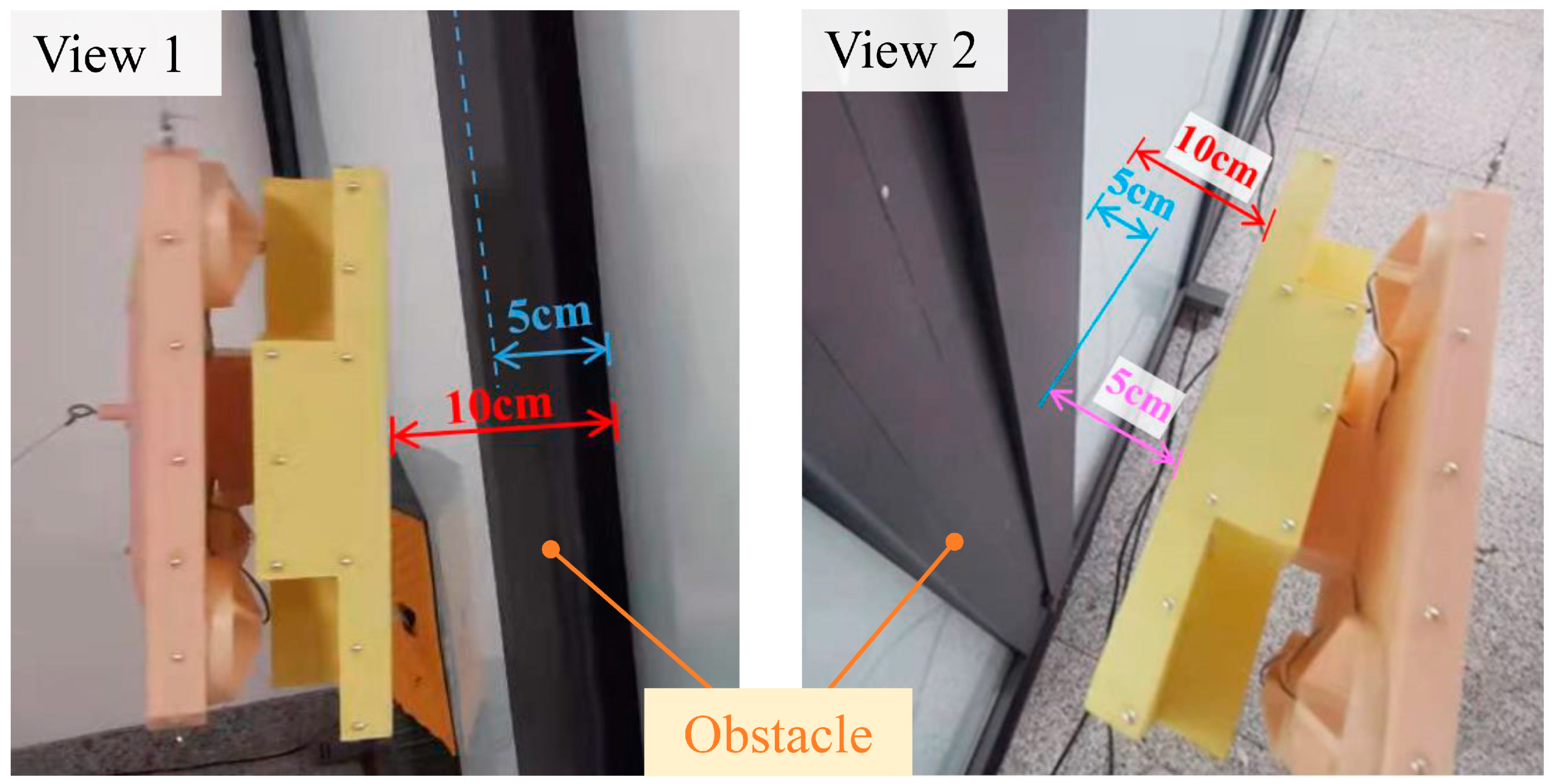

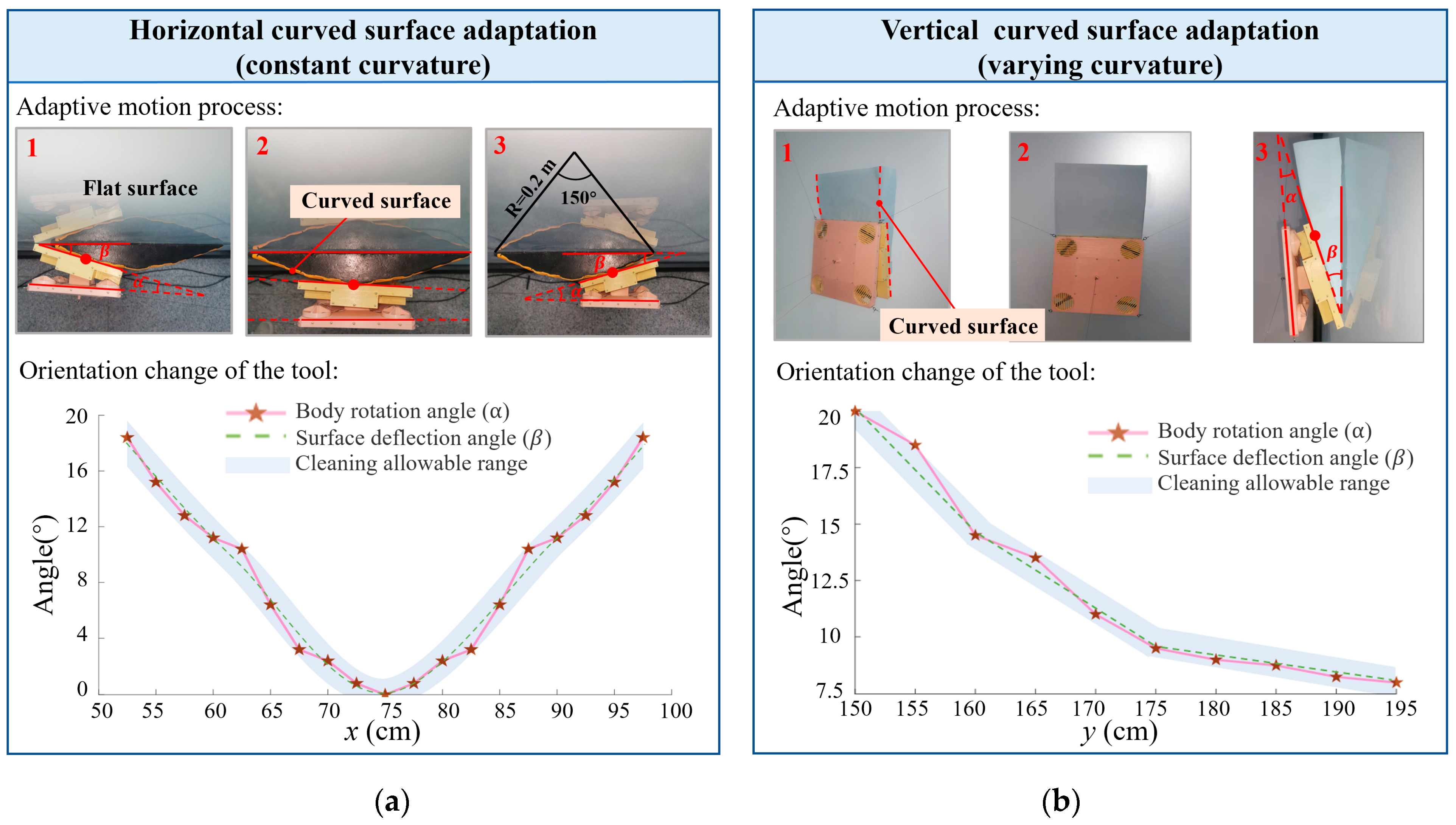

5.1. Overcoming Obstacles and Surface Adaption Experiments

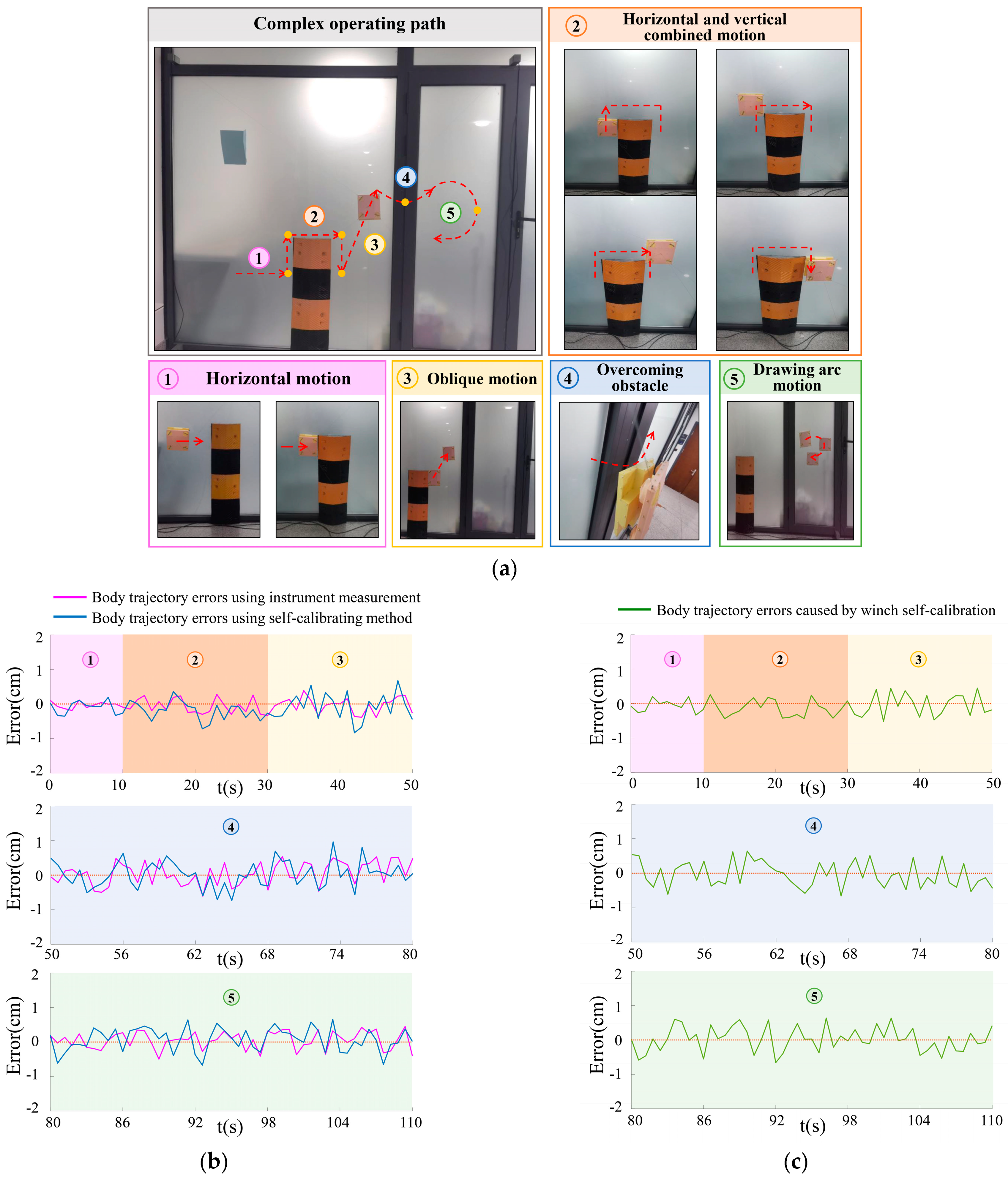

5.2. Trajectory Following Experiment

5.3. Winch Calibration Experiment

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, C.; Ma, F.; Wang, R. The operation characteristics analysis of a novel glass curtain wall system by using simulation and test. J. Build. Eng. 2022, 51, 104311. [Google Scholar] [CrossRef]

- Yan, H.; Niu, H.; Chang, Q.; Zhao, P.; He, B. Study on Dynamic Characteristics of Pipeline Jet Cleaning Robot. Actuators 2024, 13, 49. [Google Scholar] [CrossRef]

- Guo, T.; Deng, Z.D.; Liu, X. Development of a new hull adsorptive underwater climbing robot using the Bernoulli negative pressure effect. Ocean Eng. 2022, 243, 110306. [Google Scholar] [CrossRef]

- Bisht, R.S.; Pathak, P.M.; Panigrahi, S.K. Design and development of a glass facade cleaning robot. Mech. Mach. Theory 2022, 168, 104585. [Google Scholar] [CrossRef]

- Tun, T.T.; Elara, M.R.; Kalimuthu, M. Glass facade cleaning robot with passive suction cups and self-locking trapezoidal lead screw drive. Autom. Constr. 2018, 96, 180–188. [Google Scholar] [CrossRef]

- Sinkar, A.; Pandey, A.; Mehta, C. Design and development of wall climbing hexapod robot with SMA actuated suction gripper. Procedia Comput. Sci. 2018, 133, 222–229. [Google Scholar] [CrossRef]

- Vega-Heredia, M.; Elara Mohan, R.; Wen, T.Y. Design and modelling of a modular window cleaning robot. Autom. Constr. 2019, 103, 268–278. [Google Scholar] [CrossRef]

- Kim, T.; Kim, J.; Seo, K.; Kim, H.; Lee, G.; Kim, J.; Kim, H. Design and control of a cleaning unit for a novel wall-climbing robot. Appl. Mech. Mater. 2014, 541, 1092–1096. [Google Scholar] [CrossRef]

- Seo, T.; Jeon, Y.; Park, C.; Kim, J. Survey on glass and facade-cleaning robots: Climbing mechanisms, cleaning methods, and applications. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 367–376. [Google Scholar] [CrossRef]

- Schraft, R.; Bräuning, U.; Orlowski, T.; Hornemann, M. Automated cleaning of windows on standard facades. Autom. Constr. 2000, 9, 489–501. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, J.; Zong, G. Sky Cleaner 3: A real pneumatic climbing robot for glass-wall cleaning. IEEE Robot. Autom. Mag. 2006, 13, 32–41. [Google Scholar] [CrossRef]

- Shao, L.; Xing, Y.; Li, J. Adsorption mechanism analysis of photovoltaic cleaning robot based on negative pressure adsorption. In Proceedings of the 2018 Chinese Control and Decision Conference (CCDC), Shenyang, China, 9–11 June 2018; pp. 4133–4137. [Google Scholar]

- Zhou, Q.; Li, X. Experimental investigation on climbing robot using rotation-flow adsorption unit. Robot. Auton. Syst. 2018, 105, 112–120. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kim, S.H.; Gil, M.S. The study on the integrated control system for curtain wall building facade cleaning robot. Autom. Constr. 2018, 94, 39–46. [Google Scholar] [CrossRef]

- Akinfiev, T.; Armada, M.; Nabulsi, S. Climbing cleaning robot for vertical surfaces. Ind. Robot 2009, 36, 352–357. [Google Scholar] [CrossRef]

- Dai, H. Design of high-altitude curtain wall cleaning robot. In Proceedings of the 2020 3rd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Shanghai, China, 4–6 December 2020; pp. 157–160. [Google Scholar]

- Seo, K.; Cho, S.; Kim, T. Design and stability analysis of a novel wall-climbing robotic platform (ROPE RIDE). Mech. Mach. Theory 2013, 70, 189–208. [Google Scholar] [CrossRef]

- Mamidi, T.K.; Bandyopadhyay, S. Forward dynamic analyses of cable-driven parallel robots with constant input with applications to their kinetostatic problems. Mech. Mach. Theory 2021, 163, 104381. [Google Scholar] [CrossRef]

- Idà, E.; Mattioni, V. Cable-driven parallel robot actuators: State of the art and novel servo-winch concept. Actuators 2022, 11, 290. [Google Scholar] [CrossRef]

- González-Rodríguez, A.; Martín-Parra, A.; Juárez-Pérez, S.; Rodríguez-Rosa, D.; Moya-Fernández, F.; Castillo-García, F.J.; Rosado-Linares, J. Dynamic model of a novel planar cable driven parallel robot with a single cable loop. Actuators 2023, 12, 200. [Google Scholar] [CrossRef]

- Esfandiyar, H.; Daneshmand, S.; Kermani, D. On the control of a single flexible arm robot via Youla-Kucera parameterization. Robotica 2016, 34, 150–172. [Google Scholar] [CrossRef]

- Lu, B.; Fang, Y.; Sun, N. Nonlinear control for underactuated multi-rope cranes: Modeling, theoretical design and hardware experiments. Control Eng. Pract. 2018, 76, 123–132. [Google Scholar] [CrossRef]

- Zhang, Z.; Xie, G.; Shao, Z. Kinematic calibration of cable-driven parallel robots considering the pulley kinematics. Mech. Mach. Theory 2022, 169, 104648. [Google Scholar] [CrossRef]

- Esfandiyar, H.; Korayem, M.H. Accurate nonlinear modeling for flexible manipulators using mixed finite element formulation in order to obtain maximum allowable load. J. Mech. Sci. Technol. 2015, 29, 3971–3982. [Google Scholar] [CrossRef]

- Esfandiyar, H.; Korayem, M.H.; Haghpanahi, M. Large deformation modeling of flexible manipulators to determine allowable load. Struct. Eng. Mech. 2017, 62, 619–629. [Google Scholar]

- Elkmann, N.; Kunst, D.; Krueger, T. SIRIUSc—Facade cleaning robot for a high-rise building in Munich. In Climbing and Walking Robots; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1033–1040. [Google Scholar]

- Miermeister, P.; Lachele, M.; Boss, R. The cable robot simulator large scale motion platform based on cable robot technology. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 1 December 2016; pp. 3024–3029. [Google Scholar]

- Sun, C.; Gao, H.; Liu, Z. Design and optimization of three-degree-of-freedom planar adaptive cable-driven parallel robots using the cable wrapping phenomenon. Mech. Mach. Theory 2021, 166, 104475. [Google Scholar] [CrossRef]

- Yoo, S.; Kim, T.; Seo, M. Position-tracking control of dual-rope winch robot with rope slip compensation. IEEE/ASME Trans. Mechatron. 2021, 26, 1754–1762. [Google Scholar] [CrossRef]

- Sûr Efficace et Durable Avec des Résultats Transparents, The Netherlands 2019. Available online: https://www.kiterobotics.com (accessed on 18 March 2024).

- Sato, O.; Shimojima, K.; Furutani, R. Artefact calibration of parallel mechanism, kinematic calibration with a priori knowledge. Meas. Sci. Technol. 2004, 15, 1158. [Google Scholar] [CrossRef]

- Du, L.; Zhang, T.; Dai, X. Compliance error calibration for robot based on statistical properties of single joint. J. Mech. Sci. Technol. 2019, 33, 1861–1868. [Google Scholar] [CrossRef]

- Mauricio, A.; García-Murillo, M.A.; Cervantes-Sánchez, J.J.; Torres, F.J.; Moreno-Avalos, H.A. Identification of geometric parameters of a parallel robot by using a camera calibration technique. J. Mech. Sci. Technol. 2021, 35, 729–737. [Google Scholar]

- Capua, A.; Shapiro, A.; Shoval, S. Spider Bot: A cable suspended mobile robot. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 3437–3438. [Google Scholar]

- Wang, D.; Ahn, J.; Jung, J. Winch-integrated mobile end-effector for a cable-driven parallel robot with auto-installation. Int. J. Control Autom. Syst. 2017, 15, 2355–2363. [Google Scholar] [CrossRef]

| Component | x-Axis (m) | y-Axis (m) | z-Axis (m) |

|---|---|---|---|

| Winch 1 | 0 | 2.50 | 0 |

| Winch 2 | 3.00 | 2.50 | 0 |

| Winch 3 | 0 | 0 | 0 |

| Winch 4 | 3.00 | 0 | 0 |

| Winch 5 | 1.50 | 0 | 3.00 |

| Cleaning body | 1.37 | 1.12 | 0 |

| Doorframe obstacle | 1.84 | 1.12 | 0 |

| Curved surface 1 | 0.55 | 1.68 | 0 |

| Curved surface 2 | 1.30 | 0.43 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Li, Y.; Zhang, M.; Liu, Z.; Bai, Y.; Zhao, Z.; Su, X.; Li, M. Design and Self-Calibration Method of a Rope-Driven Cleaning Robot for Complex Glass Curtain Walls. Actuators 2024, 13, 272. https://doi.org/10.3390/act13070272

Wang J, Li Y, Zhang M, Liu Z, Bai Y, Zhao Z, Su X, Li M. Design and Self-Calibration Method of a Rope-Driven Cleaning Robot for Complex Glass Curtain Walls. Actuators. 2024; 13(7):272. https://doi.org/10.3390/act13070272

Chicago/Turabian StyleWang, Jingtian, Yuao Li, Minglu Zhang, Zonghou Liu, Yiyang Bai, Zhengyang Zhao, Xiuping Su, and Manhong Li. 2024. "Design and Self-Calibration Method of a Rope-Driven Cleaning Robot for Complex Glass Curtain Walls" Actuators 13, no. 7: 272. https://doi.org/10.3390/act13070272