A Modeling of Twisted and Coiled Polymer Artificial Muscles Based on Elastic Rod Theory

Abstract

:1. Introduction

2. Modelling Methods

2.1. Modeling of Elastic Bar Buckling and Kinking

2.2. Derivation of TCP Muscles Actuation Mechanism

3. Experiments

3.1. Thermo-Mechanical Properties Test of Silver Coated Nylon 6

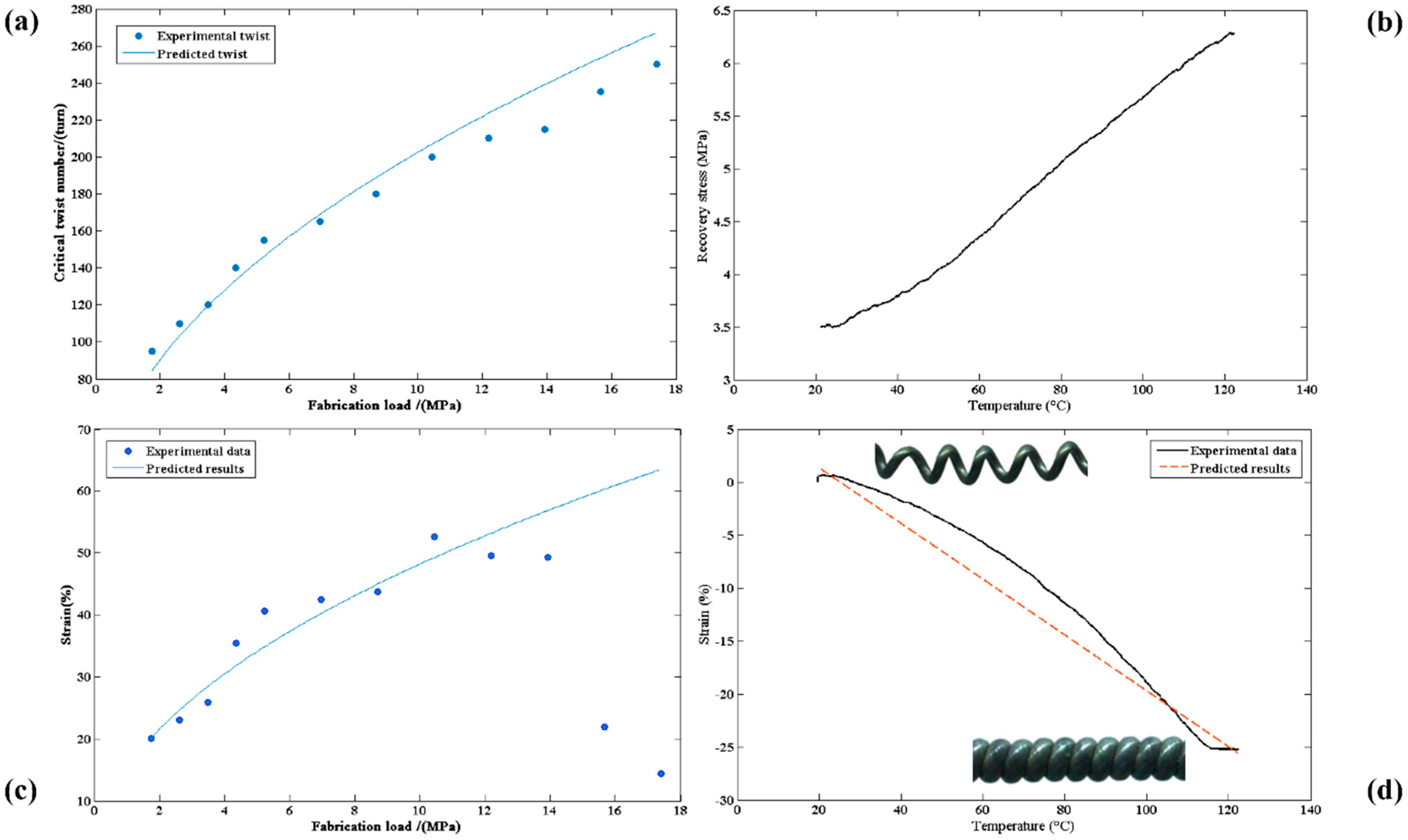

3.2. Strain of TCP Muscles under Different Fabrication Load

3.3. Isometric Recovery Stress of TCP Muscles

3.4. Recovery Strain of TCP Muscles During Heating

4. Results and Discussion

4.1. Twist Number, Maximum Actuation Stroke, and Fabrication Load

4.2. Actuation Strain and Working Load

4.3. Maximum Work Capacity

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Trivedi, D.; Rahn, C.D.; Kier, W.M.; Walker, I.D. Soft robotics: Biological inspiration, state of the art, and future research. Appl. Bionics Biomech. 2008, 5, 99–117. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [Green Version]

- Pyo, D.; Lim, J.M.; Mun, S.; Yun, S. Silver-Nanowires Coated Pitch-Tuned Coiled Polymer Actuator for Large Contractile Strain under Light-Loading. Int. J. Precis. Eng. Manuf. 2018, 19, 1895–1900. [Google Scholar] [CrossRef]

- Shigemune, H.; Sugano, S.; Nishitani, J.; Yamauchi, M.; Hosoya, N.; Hashimoto, S.; Maeda, S. Dielectric Elastomer Actuators with Carbon Nanotube Electrodes Painted with a Soft Brush. Actuators 2018, 7, 51. [Google Scholar] [CrossRef] [Green Version]

- Verma, M.; Ainla, A.; Yang, D.; Harburg, D.; Whitesides, G.M. A Soft Tube-Climbing Robot. Soft Robot. 2017, 5, 133–137. [Google Scholar] [CrossRef]

- Glick, P.; Suresh, S.A.; Ruffatto, D.; Cutkosky, M.R.; Tolley, M.T.; Parness, A. A Soft Robotic Gripper with Gecko-Inspired Adhesive. IEEE Robot. Autom. Lett. 2018, 3, 903–910. [Google Scholar] [CrossRef]

- Ohta, P.; Valle, L.; King, J.; Low, K.; Yi, J.; Atkeson, C.G.; Park, Y.-L. Design of a Lightweight Soft Robotic Arm Using Pneumatic Artificial Muscles and Inflatable Sleeves. Soft Robot. 2018, 5, 204–215. [Google Scholar] [CrossRef] [Green Version]

- Hošovský, A.; Pitel, J.; Zidek, K.; Tóthová, M.; Sarosi, J.; Cveticanin, L. Dynamic characterization and simulation of two-link soft robot arm with pneumatic muscles. Mech. Mach. Theory 2016, 103, 98–116. [Google Scholar] [CrossRef]

- Cveticanin, L.; Žukovič, M.; Biró, I.; Sarosi, J. Mathematical investigation of the stability condition and steady state position of a pneumatic artificial muscle—Mass system. Mech. Mach. Theory 2018, 125, 196–206. [Google Scholar] [CrossRef]

- Li, S.; Vogt, D.M.; Rus, D.; Wood, R.J. Fluid-driven origami-inspired artificial muscles. Proc. Natl. Acad. Sci. USA 2017, 114, 13132–13137. [Google Scholar] [CrossRef] [Green Version]

- Li, W.-B.; Zhang, W.-M.; Zou, H.-X.; Peng, Z.-K.; Meng, G. A Fast Rolling Soft Robot Driven by Dielectric Elastomer. IEEE-ASME Trans. Mechatron. 2018, 23, 1630–1640. [Google Scholar] [CrossRef]

- Bozlar, M.; Punckt, C.; Korkut, S.; Zhu, J.; Foo, C.C.; Suo, Z.; Aksay, I.A. Dielectric elastomer actuators with elastomeric electrodes. Appl. Phys. Lett. 2012, 101, 91907. [Google Scholar] [CrossRef] [Green Version]

- Koh, S.J.A.; Li, T.; Zhou, J.; Zhao, X.; Hong, W.; Zhu, J.; Suo, Z. Mechanisms of large actuation strain in dielectric elastomers. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 504–515. [Google Scholar] [CrossRef]

- Duduta, M.; Hajiesmaili, E.; Zhao, H.; Wood, R.J.; Clarke, D.R. Realizing the potential of dielectric elastomer artificial muscles. Proc. Natl. Acad. Sci. USA 2019, 116, 2476–2481. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Jin, Z.; Peng, L.; Zhao, F.; Xiao, D.; Jin, Y.; Yu, G. Stretchable All-Gel-State Fiber-Shaped Supercapacitors Enabled by Macromolecularly Interconnected 3D Graphene/Nanostructured Conductive Polymer Hydrogels. Adv. Mater. 2018, 30, 1800124. [Google Scholar] [CrossRef]

- Haines, C.S.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.W.; Kim, S.H.; Fang, S.; De Andrade, M.J.; Göktepe, F.; et al. Artificial Muscles from Fishing Line and Sewing Thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef]

- Haines, C.S.; Li, N.; Spinks, G.M.; Aliev, A.E.; Di, J.; Baughman, R.H. New twist on artificial muscles. Proc. Natl. Acad. Sci. USA 2016, 113, 11709–11716. [Google Scholar] [CrossRef] [Green Version]

- Tang, X.; Li, K.; Liu, Y.; Zhou, D.; Zhao, J. A general soft robot module driven by twisted and coiled actuators. Smart Mater. Struct. 2019, 28, 035019. [Google Scholar] [CrossRef]

- Cho, K.H.; Jung, H.S.; Yang, S.Y.; Kim, Y.; Rodrigue, H.; Moon, H.; Koo, J.C.; Choi, H.R.; Hugo, R. Sliding Filament Joint Mechanism: Biomimetic Artificial Joint Mechanism for Artificial Skeletal Muscles. J. Mech. Robot. 2019, 11, 021004. [Google Scholar] [CrossRef]

- Wu, L.; Chauhan, I.; Tadesse, Y. A Novel Soft Actuator for the Musculoskeletal System. Adv. Mater. Technol. 2018, 3, 1700359. [Google Scholar] [CrossRef]

- Bahrami, S.; Dumond, P. Testing of Coiled Nylon Actuators for Use in Spastic Hand Exoskeletons. In Proceedings of the 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Honolulu, HI, USA, 17–21 July 2018; pp. 1853–1856. [Google Scholar]

- Wu, L.; De Andrade, M.J.; Saharan, L.K.; Rome, R.S.; Baughman, R.H.; Tadesse, Y. Compact and low-cost humanoid hand powered by nylon artificial muscles. Bioinspir. Biomim. 2017, 12, 026004. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Z. Stabilization of floating offshore wind turbines by artificial muscle based active mooring line force control. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016; pp. 2277–2282. [Google Scholar]

- Kim, S.H.; Lima, M.D.; Kozlov, M.; Haines, C.S.; Spinks, G.M.; Aziz, S.; Choi, C.; Sim, H.J.; Wang, X.; Lu, H.; et al. Harvesting temperature fluctuations as electrical energy using torsional and tensile polymer muscles. Energy Environ. Sci. 2015, 8, 3336–3344. [Google Scholar] [CrossRef] [Green Version]

- Almubarak, Y.; Tadesse, Y. Twisted and coiled polymer (TCP) muscles embedded in silicone elastomer for use in soft robot. Int. J. Intell. Robot. Appl. 2017, 1, 352–368. [Google Scholar] [CrossRef]

- Aziz, S.; Naficy, S.; Foroughi, J.; Brown, H.R.; Spinks, G.M. Controlled and scalable torsional actuation of twisted nylon 6 fiber. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1278–1286. [Google Scholar] [CrossRef] [Green Version]

- Moretti, G.; Cherubini, A.; Vertechy, R.; Fontana, M. Experimental characterization of a new class of polymeric-wire coiled transducers. In Behavior and Mechanics of Multifunctional Materials and Composites 2015; Goulbourne, N.C., Ed.; SPIE: Bellingham, WA, USA, 2015; Volume 9432. [Google Scholar]

- Semochkin, A.N. A device for producing artificial muscles from nylon fishing line with a heater wire. In Proceedings of the 2016 IEEE International Symposium on Assembly and Manufacturing (ISAM), Fort Worth, TX, USA, 21–22 August 2016; pp. 26–30. [Google Scholar]

- Li, T.; Wang, Y.; Liu, K.; Liu, H.-B.; Zhang, J.; Sheng, X.; Guo, D. Thermal actuation performance modification of coiled artificial muscle by controlling annealing stress. J. Polym. Sci. Part B Polym. Phys. 2017, 56, 383–390. [Google Scholar] [CrossRef]

- Cho, K.H.; Song, M.-G.; Jung, H.; Yang, S.Y.; Moon, H.; Koo, J.C.; Nam, J.-D.; Choi, H.R. Fabrication and modeling of temperature-controllable artificial muscle actuator. In Proceedings of the 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; pp. 94–98. [Google Scholar]

- Saharan, L.; Tadesse, Y. Fabrication Parameters and Performance Relationship of Twisted and Coiled Polymer Muscles. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016; Volume 14. [Google Scholar]

- Kim, K.; Cho, K.H.; Jung, H.S.; Yang, S.Y.; Kim, Y.; Park, J.H.; Jang, H.; Nam, J.-D.; Koo, J.C.; Moon, H.; et al. Double Helix Twisted and Coiled Soft Actuator from Spandex and Nylon. Adv. Eng. Mater. 2018, 20, 6. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Gere, J.M. Theory of Elastic Stability; McGraw-Hill: London, UK, 1961. [Google Scholar]

- Love, A.E.H. A Treatise on the Mathematical Theory of Elasticity; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Mirvakili, S.M.; Ravandi, A.R.; Hunter, I.W.; Haines, C.S.; Li, N.; Foroughi, J.; Naficy, S.; Spinks, G.M.; Baughman, R.H.; Madden, J.D.W. Simple and strong: Twisted silver painted nylon artificial muscle actuated by Joule heating. In Electroactive Polymer Actuators and Devices (EAPAD) 2014; SPIE: Bellingham, WA, USA, 2014; Volume 9056. [Google Scholar]

- Hiraoka, M.; Nakamura, K.; Arase, H.; Asai, K.; Kaneko, Y.; John, S.W.; Tagashira, K.; Omote, A. Power-efficient low-temperature woven coiled fibre actuator for wearable applications. Sci. Rep. 2016, 6, 36358. [Google Scholar] [CrossRef]

- Yip, M.C.; Niemeyer, G. On the Control and Properties of Supercoiled Polymer Artificial Muscles. IEEE Trans. Robot. 2017, 33, 689–699. [Google Scholar] [CrossRef]

- Spinks, G.M.; Bakarich, S.E.; Aziz, S.; Salahuddin, B.; Xin, H. Using force-displacement relations to obtain actuation parameters from artificial muscles. Sens. Actuators A Phys. 2019, 290, 90–96. [Google Scholar] [CrossRef]

- Rome, L.C.; Swank, D. The influence of temperature on power output of scup red muscle during cyclical length changes. J. Exp. Boil. 1992, 171, 261–281. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Zheng, W. A Modeling of Twisted and Coiled Polymer Artificial Muscles Based on Elastic Rod Theory. Actuators 2020, 9, 25. https://doi.org/10.3390/act9020025

Wu C, Zheng W. A Modeling of Twisted and Coiled Polymer Artificial Muscles Based on Elastic Rod Theory. Actuators. 2020; 9(2):25. https://doi.org/10.3390/act9020025

Chicago/Turabian StyleWu, Chunbing, and Wen Zheng. 2020. "A Modeling of Twisted and Coiled Polymer Artificial Muscles Based on Elastic Rod Theory" Actuators 9, no. 2: 25. https://doi.org/10.3390/act9020025

APA StyleWu, C., & Zheng, W. (2020). A Modeling of Twisted and Coiled Polymer Artificial Muscles Based on Elastic Rod Theory. Actuators, 9(2), 25. https://doi.org/10.3390/act9020025