1. Introduction

In the USA, Australia and Europe, the number of slaughtered horses is decreasing. In Belgium for example, the number of slaughtered horses decreased from 21,390 slaughtered horses in 2001 to only 5895 horses in 2018 [

1]. Annually, about 5 million horses are slaughtered worldwide [

2]. In 2018, China was the country that slaughtered the most horses worldwide—more specifically, about 1.59 million [

2]. In the same year, 389,153 horses were slaughtered in South America [

2]. However, to this day, the circumstances in which horses are transported give rise to discussion [

3].

Animals should be handled as carefully as possible at all times, including during the transportation process to the slaughterhouse. The animals should undergo as little stress as possible, on the one hand for welfare reasons, but also to prevent any deterioration in the quality of the horse meat. Quality loss can occur as a result of excessive stress, bruises or injuries [

4,

5,

6,

7]. Suboptimal ambient parameters such as temperature, relative humidity, ammonia and carbon dioxide concentration in the air can cause stress, but also inappropriate infrastructure and psychological stressors. Examples of psychological stressors are the determination of dominance rank, and transport activities such as loading, unloading and the transport itself. In addition, activities that are part of the management of the animals, such as the weaning of young animals, weighing of animals or changing housing, can also cause stress [

8].

The conditions of (non-commercial) transports of sport and company horses and the response of these horses to transport are well studied [

9,

10]. On the other hand, commercial transport of horses is studied to a lesser extent. Furthermore, most studies in which horses are transported untethered in groups involve healthy horses that are used to being transported [

9,

11,

12,

13,

14]. Studies investigating slaughter horse transports or horses that were sold as slaughter horses are less numerous [

13,

15,

16,

17,

18,

19]. However, from those studies it is clear that a number of transport-related factors influence horse welfare. Journey distance and time [

20,

21], loading density [

7,

15,

22,

23], handling [

7,

24,

25], new environments [

24], potentially re-grouping or mixing with unfamiliar animals [

24], fasting and deprivation of water [

24], the myriad of trailer designs [

7,

23], driving behaviour [

7], road type and quality [

7,

22,

24], traffic conditions [

24], suspension systems and building materials of the trailers [

15,

23], environmental conditions in the trailer [

7,

22], and weather conditions [

15,

23,

26] all affect horse welfare.

According to Morgan [

27], the thermoneutral zone of a horse is on average between 5 °C and 25 °C. Another study defines the thermoneutral zone between −1 °C and 24 °C [

27]. The differences in estimation of the thermoneutral zone are, among other things, probably due to acclimatization, body condition and climate [

28]. For example, the upper limit of the thermoneutral zone lowers with increasing humidity. At a relative humidity (RH) of more than 50%, it gets harder for the animals to dissipate heat to the environment [

29]. The temperature humidity index (THI) is a useful parameter to estimate the thermal comfort of organisms [

30].

Legislation involving animal welfare differs between countries. At the same time, meat is traded from countries with less stringent welfare requirements, like Argentina [

31,

32,

33] and Uruguay [

34], to countries with higher welfare requirements, like members of the European Union. The European Union (EU) sets welfare requirements at the time of killing for companies willing to export animal products to the EU (Council Regulation (EC) No 1099/2009) [

35], but does not impose direct requirements on the transport of those animals to the slaughterhouses in third countries. The international Horse Meat Federation [

36], on the other hand, expects its members to meet the requirements set in their “Manual for the Animal Welfare of horses during transport and slaughtering”, which is based on existing legislation and international guidelines [

36].

The first aim of this study was to characterize the current practices of the commercial horse transport from collection points to slaughterhouses in Argentina and Uruguay. Secondly, potential risk factors for horse welfare were detected.

2. Materials and Methods

Between November 2016 and October 2017, a total of 23 horse transports in Argentina and Uruguay were monitored from loading at a collection point to one of the three selected horse slaughterhouses. A total of 596 half-bred horses with an average weight of 415 (±38) kg were picked up at 18 collection points and were transported to Lamar (Argentina), Frigorífico General Pico (Argentina) and Sarel (Uruguay). The transports were spread throughout a year, so that a number of transports were monitored in each season. A total of six transports took place in the spring (November 2016), six in the summer (March 2017), six in the fall (June 2017) and five in the winter (October 2017). Each season two transports per slaughterhouse were monitored, except for October 2017. At that time, only one transport to Frigorífico General Pico was followed up. The transports were carried out with different types of transport vehicles. In this study, three types of vehicles are distinguished, namely trucks, tractor–trailers and truck–trailers (

Figure 1). A truck is a pulling vehicle with one inseparable loading space and is therefore a single unit. In the case of a tractor–trailer, the towing vehicle can be (dis)connected from the trailer via a fifth-wheel coupling. Finally, a truck–trailer is a truck, as defined above, with a trailer connected to it through a drawbar. This transport combination therefore exists of two separated loading spaces.

The transports were monitored and supervised by the same researcher. The researcher also mounted the sensors and cameras in the trailers and recorded specific transport data. In each trailer the horses were filmed. The camera (Trophy Cam model 119437, Bushnell, China) filmed fragments of one minute at intervals of about 100 seconds. On average, 38.9% (±3.8)% of each transport was filmed. After the transports, the footage was viewed, and the behaviour and interactions of the horses were analysed. During the analysis of the videos, it was noted per trailer how many horses fell and whether the animals fought ‘hardly or not’, ‘averagely’ or ‘a lot’. A fall was considered to be a loss of balance in which parts of the body other than the hooves touched the ground. If the horse could restore equilibrium without other body parts touching the ground, this was called stumbling. Furthermore, the temperature, relative humidity (RH) and dew point were automatically recorded (EL-USB-2, Lascar Electronics, Wiltshire, UK) every five minutes in each loading space. These data were automatically written to an excel file. For the analysis of the environmental parameters, the thermoneutral zone used by Morgan [

27], namely between 5 °C and 25 °C, is taken as the starting point. In addition, the temperature humidity index (THI) is calculated using the following formula [

37], with T, temperature in °C, RH expressed as a number between 0 and 1:

The timing of various operations such as loading and unloading, the duration and distance of the transport, the number of intermediate stops for (police) checks, as well as the stocking density, dimensions and characteristics of the loading spaces were recorded. The observer noted what tools the drivers, which are the persons that handle the horses, used. Furthermore, the characteristics and dimensions of loading docks were registered. The openness of the side walls was categorised as ‘open’ when the surroundings could be seen easily through the wall, ‘half open’ when the view through the side walls was limited, and ‘solid’ when the horses could not see anything through the side walls of the loading dock. All the parameters that were considered during this investigation are listed in the

Appendix A in

Table A1 and

Table A2.

The data were processed using SAS Enterprise Guide and SAS 9.4. Averages and standard deviations were calculated using the PROC UNIVARIATE procedure. Correlations between the environmental parameters in the front and rear trailer were calculated using the regression (PROC REG) procedure. The frequency procedure (PROC FREQ) was used for all frequency calculations and generalized linear mixed models (PROC GLIMMIX) were used to identify which parameters influenced the degree of aggression and falling of horses during transport.

3. Results

3.1. Loading Dock

In 17 of the 18 collection points, a loading dock was present to facilitate the loading of the horses. From two collection points, horses were picked up more than once. However, only one loading dock was used for two transports. In one collection point, the loading dock did not have a slope, since the transport vehicle could be parked so that surface of the loading area was at the same level as the floor of the trailer. Therefore, this loading deck was excluded from the averages (

Table 1). The slope of the loading docks was on average 17.4° (±3.6)°, which equals 31.5% (±7.0)% (

Table 1). Seven out of 21 loading docks had a slope steeper than 20.0° (36.4%) and the slope of all but one loading dock was steeper than 10.0° (17.6%). The length of the loading dock (measured on the surface of the loading dock) was 4.01 (±0.90) m and the height was 1.18 (±0.17) m (

Table 1).

The surface of the loading docks consisted of only soil (26.1%), a combination of soil and wood (26.1%), only wood (13.0%), concrete (partly) covered with soil (8.7%), a combination of soil and grit (8.7%) or straw (4.4%). The side walls of the loading docks were, on average, 1.59 (±0.22)-m-high and constructed from wood—mostly planks (82.6%), but round wooden beams (4.3%) in one instance. The side walls of three (13.0%) loading docks were categorised as ‘open’, seven (30.4%) as ‘half open’ and 10 (43.5%) as ‘solid’. Of three (13.0%) loading docks, the kind of side wall construction was not registered.

3.2. Loading

Loading the horses took an average of 12.2 (±7.1) minutes per transport and 0.49 (±0.27) minutes per horse (

Table 2). Spread over three transports, five horses (0.84%) had to be led into the trailer with a halter: three horses in one loading did not want to enter the trailer and twice one horse refused to enter the trailer. In the end, two of these horses could not be loaded at all. The trucks left the collection points 8.3 (±4.4) minutes after the loading process was completed. In total, 73.9% of the transports departed in the morning, on average at 11:15 a.m. (±1:31; between 9:25 a.m. and 3:20 p.m.).

Figure 2 shows the arrival and departure times of the transports.

Tools such as a flag, whip or stick were used to drive the horses on the trailers. We define a stick as a narrow, long and little or not flexible object to drive the horses with. A whip is a thin, not very flexible stick, with or without a handle on it. In this context, a flag is a stick with a piece or ribbons of textile or plastic, so that the movements of the object are more visible to the horses. Flags were used in 22 (95.7%) of the 23 transports. Four times (17.4%) a whip or a stick was used and three times (13.0%) a rider on horseback drove the slaughter horses onto the trailer. The tools were not used to hit or poke animals on sensitive body parts, but to give visual signals. Occasionally, the horses were gently touched with the stick, whip or flag, but not to the extent that the touch could cause pain or discomfort.

Divided over 13 loads, a total of 23 (3.86%) horses stumbled during loading, with a maximum of five horses during one loading. Five falling horses were noted, spread over three loadings. During a loading in which three horses stumbled, also three horses fell and during two other loads, in which respectively three and five horses stumbled, one horse fell each time. No falls were noted in other loadings. The falls were caused by pushing and/or fights among horses. One of the fallen horses was ran over by the other horses when the group abruptly turned around in the narrowing space towards the loading ramp. The abrupt turn of the group was caused by the directions of the drivers.

Horses enter the transport vehicles through trapdoors, which are guillotine-type doors. Internal doors were also trapdoors. During 13 of the 23 transports, at least one horse bumped its head against the trapdoor. In five transports, three or more horses (maximum eight) bumped their heads against the trapdoor. The height of the trapdoors where horses hit their heads varied between 1.51 and 1.81 m.

3.3. Environmental Parameters

The lowest trailer temperature observed during transport was 6.0 °C, while the maximum temperature was 35.5 °C (

Table 3). In the trailers, the temperature never dropped below the lower limit of the thermoneutral zone, being 5.0 °C. The upper limit of the thermoneutral zone, 25.0 °C, was exceeded during 14 of the 23 (60.9%) transports. During six (26.1%) transports, the average temperature in the trailer was above 25.0 °C and during five (21.7%) transports, the minimum temperature in the trailer exceeded 25.0 °C. For seven (30.4%) transports, the maximum temperature was above or equal to 30.0 °C. There was a strong correlation between the front and rear load for both average, minimum and maximum temperatures (

Table 4).

The RH varied between 28.0% and 99.0% (

Table 3). There was a strong correlation between the front and rear loading space for both average, minimum and maximum humidity (

Table 4). There was no correlation between temperature and RH within the same loading space.

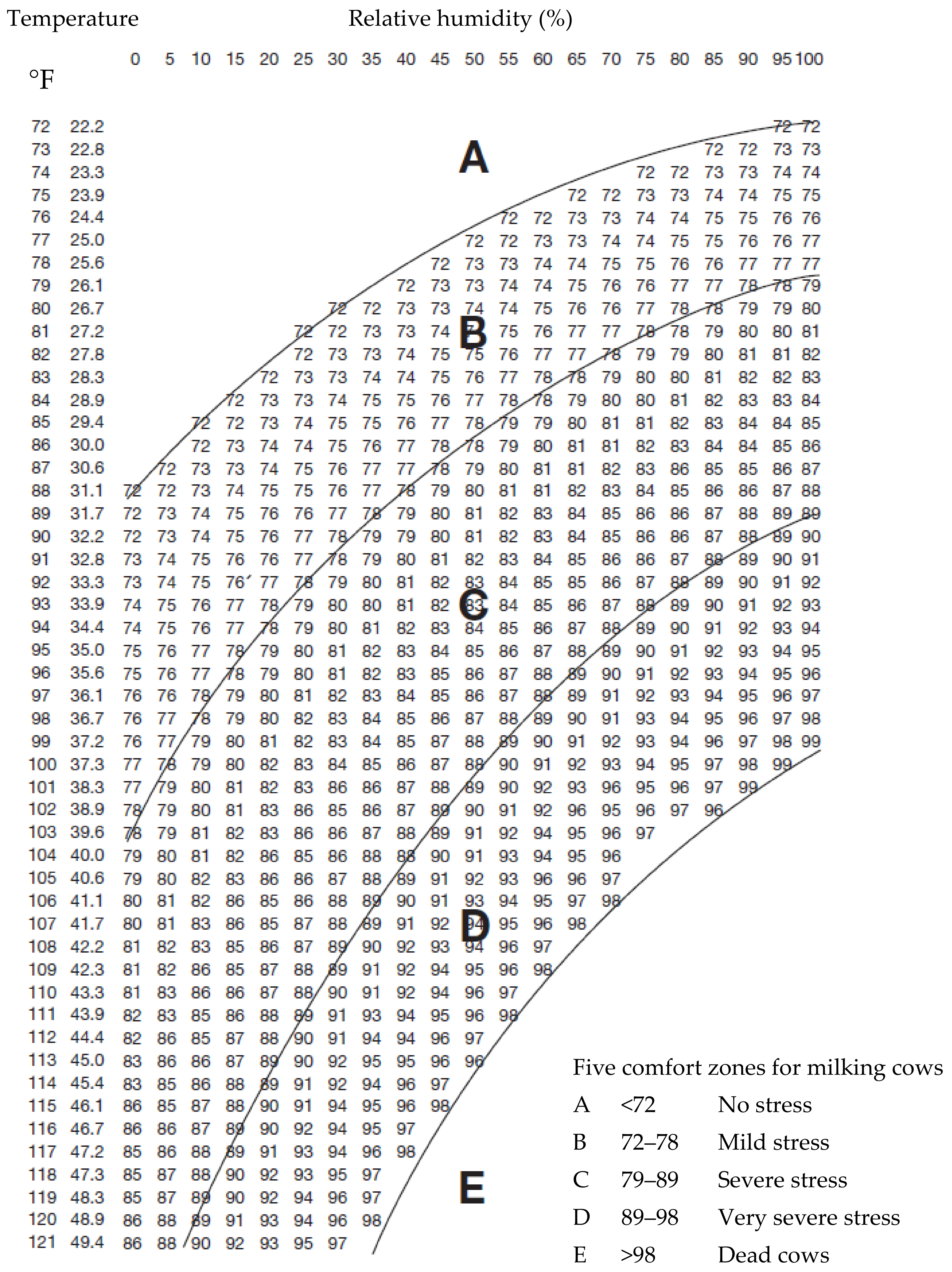

Due to the lack of a reference framework with limit values for heat stress in horses [

38,

39], the THI is tested against the values used for dairy cattle. A THI of 72–78 is labelled as mild heat stress, while a THI between 79 and 89 stands for severe heat stress in dairy cattle [

40,

41,

42] (

Appendix A,

Figure A1). The THI ranged from 45.5–83.0 during transports (

Table 3). In 13 (57%) transports, the maximum THI exceeded 72, which is the lower limit for mild heat stress in cattle. For six (26%) transports, the average THI was above or equal to 72 and for four (17.4%) transports, the minimum THI was at least equal to 72. During six (26.1%) transports, the maximum THI value was between 78 and 89, the standard for severe heat stress in cattle. However, the average THI value always remained below 78. There was a strong correlation between the front and rear loading space for both average, minimum and maximum humidity (

Table 4). The average temperature, RH, dew point temperature and THI are shown per transport in

Appendix A Table A4.

3.4. Trucks

Different types of transport vehicles were used to carry out the 23 transports (see Materials and Methods). Some vehicles were used for multiple transports.

Table A3 in the

Appendix A shows the type of vehicle used for each transport and the frequency of use of the vehicle during the monitoring. Only one of the trucks had a roof consisting of a black sail. The average dimensions of the loading spaces are shown in

Table A3 in the

Appendix A. In 10 transports (43.5%) the front loading space was divided into several compartments: eight times (34.8%) into two compartments and twice (39.1%) into three. The rear loading space was divided into two (six times; 40.0%) or three (two times; 13.3%) compartments in eight (53.3%) of the 15 transports with two loading spaces.

The floor in all loading spaces was provided with wire mesh to prevent slipping of the horses. Different types of wire mesh could be distinguished. The most common were the standard wire mesh (

Figure 3a), where the rods are on top of each other and the rods do not bend between the crossings. This type of wire mesh was used in 20 (87.0%) transports. The curved wire mesh (

Figure 3b), which is bent between the crossings, was used in two transports, just like the diamond-shaped wire mesh with connections in one plane (

Figure 3c). In the

Appendix A Table A3 shows which type of wire mesh was found per transport and per trailer. The average mesh size was 26.0 ± 4.5 cm by 23.7 ± 4.8 cm. On average, the wire mesh was 1.29 ± 0.38 cm thick and mounted at a height of 2.60 ± 0.78 cm. In our observations, both on the spot and afterwards, no shoed horses were detected in any of the transports.

3.5. Trailer Density

The average density of the trailers was 1.40 (±0.33) m

2/horse or 308 (±53) kg/m

2.

Table 5 shows the average density in m

2/horse and kg/m

2 per trailer and per compartment. Average density varied between 0.94 m

2/horse and 2.45 m

2/horse. Stallions were not always separated from mares and geldings during transport. During at least five transports, one or more stallions were loaded. In at least two of these transports, the stallions were not separated from the other horses. Once, a stallion standing between mares was moved to another compartment before departure, because of his aggressive behaviour. In the other compartment however, the stallion was not separated from the other horses behind a fence or ropes either. To prevent further biting, a rope was tied tightly in the mouth. The stallion then stopped his aggressive behaviour. Several times a pony or a young horse was transported in the same compartment with significantly larger horses.

3.6. Aggression and Falling during Transport

The degree of aggression was assessed per loading space during 22 transports, of which 15 transports with a truck–trailer, together accounting for 38 loading spaces. A loading space refers to the space in one transport component. A truck therefore has one loading space just like a tractor–trailer, while a truck–trailer has two loading spaces. In 13 (34.2%) loading spaces, hardly any or no fights were registered. In 15 (39.5%) loading spaces, an average amount of fights was recorded, and a lot of fights were recorded in 11 (28.9%) loading spaces. No relation was found between the degree of aggression and the density (front loading space: p = 0.78; rear loading space: p = 0.25), the thickness of the wire mesh on the floor (front loading space: p = 0.23; rear loading space: p = 0.20), the transport duration (front loading space: p = 0.90; rear loading space: p = 0.98) or distance (front loading space: p = 0.93; rear loading space: p = 0.78), the average temperature (front loading space: p = 0.33; rear loading space: p = 0.79), the average dew point temperature (front loading space: p = 0.18; rear loading space: p = 0.99) and the average THI (front loading space: p = 0.28; rear loading space: p = 0.80). However, the degree of aggression differed between the front and rear loading spaces (p = 0.05). Splitting the rear loading space into two or more compartments resulted in less fighting than when the rear loadings spaces consisted of one compartment (p = 0.05). In the case of the front loading space (22 transports), no relation was found between compartmentalisation and the degree of fighting (p = 0.73). It should be noted, however, that the fighting behaviour in the rear loading space could only be monitored for 14 transports, since only 14 out of 15 truck–trailers had the rear loading spaces successfully filmed.

In only one journey did a horse fall twice. In the 22 other journeys, no horses fell, except once before departure. That horse was then removed from the truck and not taken to the slaughterhouse. No connection could be found between the degree of fighting and the falls of the horses, but this is likely due to the limited number of horses that fell during the journey.

3.7. Transport Distance and Duration

The transport distances from collection point to slaughterhouse ranged from 37–700 km (

Table 6). The transport time varied from 73–632 min (

Table 6). One transport lasted 480 min or eight hours, while two (8.7%) other transports lasted longer, more specifically 500 and 632 min. The horses were not unloaded during the journey and had no ability to eat or drink. The transport duration and distance were strongly correlated (r

2 = 0.94;

p < 0.0001) for the 23 observed transports: with increasing distance, the transport duration increased according to:

An average of 2.74 (±1.33) stops were inserted per transport, of which an average of 0.87 (±1.00) were inserted for police checks (

Table 6).

3.8. Unloading

After arrival, transporters had to wait for an average of 14.8 (±12.6) minutes before unloading (

Table 6). The unloading of the horses took on average 12.5 (±9.5) min per transport and 0.473 (±0.285) per horse (

Table 6). There was no correlation between the duration of loading and unloading (r

2 = 0.11;

p = 0.08).

5. Conclusions

Our study identified the current practices of the commercial horse transport from collection points to slaughterhouses in Argentina and Uruguay. Some risk factors have been detected and could be improved. The loading and unloading of the horses generally went quite smoothly. Better training of drivers and optimized infrastructure (a level ground surface before and on the loading dock, sufficiently high trapdoors, steepness of the loading docks, provision of steps or foot battens on the loading dock, etc.) can prevent a lot of confusion and chaos for the horses, and thereby improve welfare. Driving aids were always used correctly. Most journeys started before noon, implying that the horses were often transported during the hottest moments of the day.

Still, on the one hand, interpretation of THI values is difficult because of a lack of reference framework for horses. On the other hand, not all parameters that affect thermal comfort are included in the THI. Therefore, it is not clear from what point on welfare is compromised. Stocking densities were not always according to relevant guidelines and significantly smaller horses or stallions were not always separated from the other horses. No influence of environmental parameters or transport characteristics on the degree of fighting behaviour could be demonstrated. On the contrary, the degree of aggression differed between the front and rear loading spaces of the same transport vehicle, suggesting that animal-specific factors, rather than environmental factors, determine the occurrence of aggressive behaviour. The willingness of all actors involved—slaughterhouses, transporters, loading crew, etc.—to conduct this study and to address shortcomings, underscores the growing awareness of animal welfare issues in Argentina and Uruguay.