Enhancement of Bioreactor Performance Using Acclimatised Seed Sludge in Anaerobic Treatment of Chicken Slaughterhouse Wastewater: Laboratory Achievement, Energy Recovery, and Its Commercial-Scale Potential

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Physicochemical Characterisation of CSWW

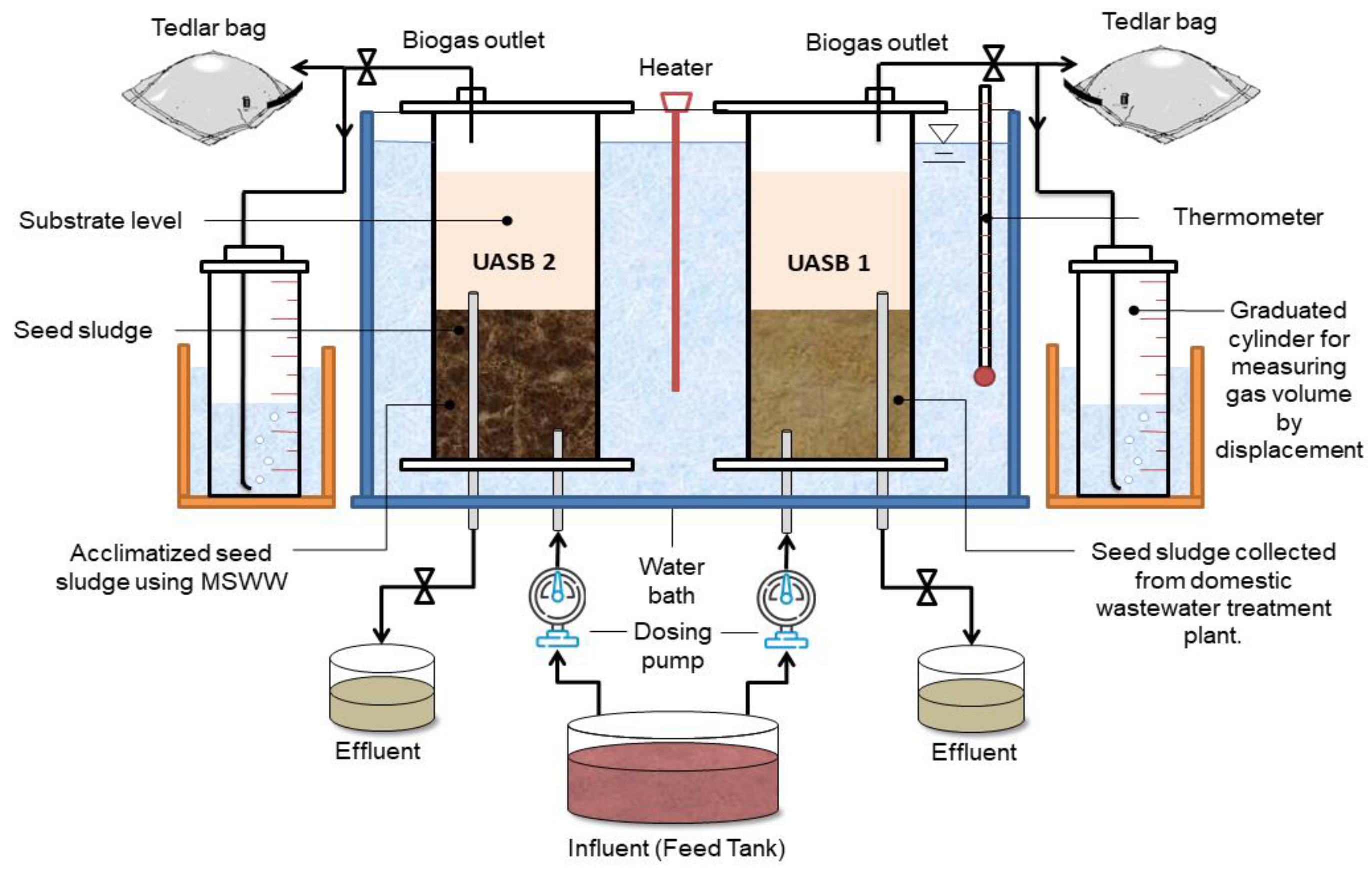

2.2. Reactor Design

2.3. Modified Synthetic Wastewater for Acclimatisation Process

2.4. Analytical Method

2.5. Energy Recovery

3. Results and Discussion

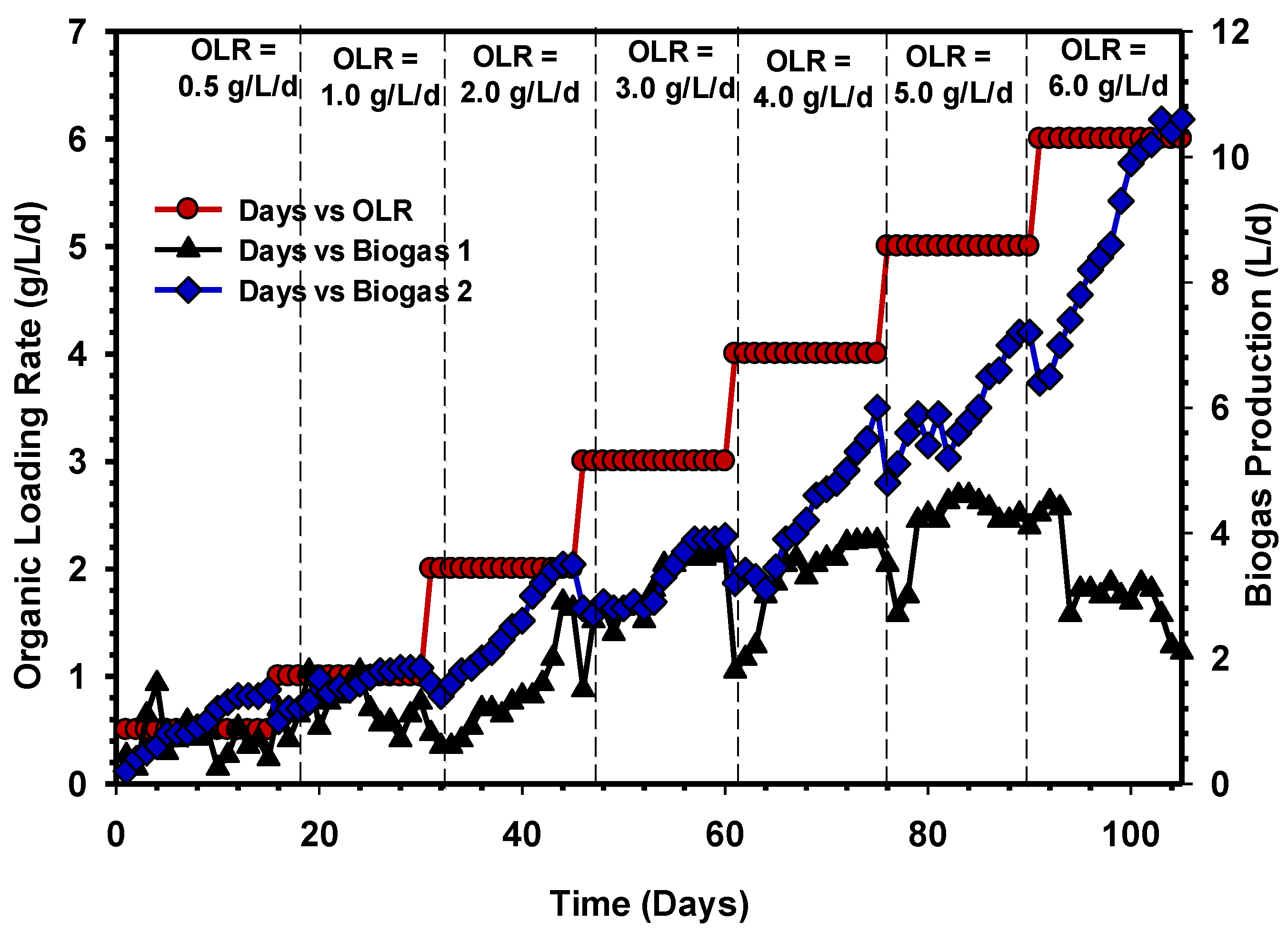

3.1. Acclimatisation of UASB 2 with MSWW

3.2. COD Removal Efficiency

3.3. Biogas, Methane, and Specific Methane Productions (SMPs)

3.4. TAN Concentrations of the Reactors

3.5. IA/PA Ratio and pH Profile Variations of the UASB Reactors

3.6. Fats, Oil, and Grease (FOG) Concentration in the UASB Reactors

3.7. VFA Formation in the UASB Reactors

3.8. Summary of Bioreactor Performances and Energy Recovery from Laboratory-Scale and Commercial-Scale Anaerobic Reactor

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Angelidaki, I.; Sanders, W. Assessment of the anaerobic biodegradability of macropollutants. Rev. Environ. Sci. Biotechnol. 2004, 3, 117–129. [Google Scholar] [CrossRef]

- Edokpayi, J.N.; Odiyo, J.O.; Durowoju, O.S. Household Hazardous Waste Management in—Impact of Wastewater on Surface Water Quality in sub-Saharan Africa Developing Countries: A Case Study of South Africa. Water Qual. 2017, 18, 1–16. [Google Scholar]

- Musa, M.A.; Idrus, S. Physical and biological treatment technologies of slaughterhouse wastewater: A review. Sustainability 2021, 13, 4656. [Google Scholar] [CrossRef]

- Shim, S.; Reza, A.; Kim, S.; Ahmed, N.; Won, S.; Ra, C. Simultaneous removal of pollutants and recovery of nutrients from high-strength swine wastewater using a novel integrated treatment process. Animals 2020, 10, 835. [Google Scholar] [CrossRef] [PubMed]

- Hernández, S.C.; Jiménez, L.D.; García, J.A.B. Potential of energy production from slaughterhouse wastewater. Interciencia 2018, 43, 558–565. [Google Scholar]

- Xu, G.; Liu, X.; Wang, Q.; Xiong, R.; Hang, Y. Effects of screenhouse cultivation and organic materials incorporation on global warming potential in rice fields. Environ. Sci. Pollut. Res. 2017, 24, 6581–6591. [Google Scholar] [CrossRef] [PubMed]

- Mainardis, M.; Buttazzoni, M.; Goi, D. Up-flow anaerobic sludge blanket (Uasb) technology for energy recovery: A review on state-of-the-art and recent technological advances. Bioengineering 2020, 7, 43. [Google Scholar] [CrossRef]

- Idrus, S.; Banks, C.J.; Heaven, S. Assessment of the potential for biogas production from wheat straw leachate in upflow anaerobic sludge blanket digesters. Water Sci. Technol. 2012, 66, 2737–2744. [Google Scholar] [CrossRef]

- Alqaralleh, R.; Kennedy, K.; Delatolla, R.; Sartaj, M. Biogas Recovery from Hyper-Thermophilic Anaerobic Co-Digestion of Thickened Waste Activated Sludge, Organic Fraction of Municipal Solid Waste and Fat, Oil and Grease. J. Bioremediat. Biodegrad. 2017, 8, 408. [Google Scholar]

- Moerland, M.J.; Perez, L.C.; Sobrino, M.E.R.V.; Chatzopoulos, P.; Meulman, B.; de Wilde, V.; Zeeman, G.; Buisman, C.J.N.; van Eekert, M.H.A. Thermophilic (55 °C) and hyper-thermophilic (70 °C) anaerobic digestion as novel treatment technologies for concentrated black water. Bioresour. Technol. 2021, 340, 125705. [Google Scholar] [CrossRef] [PubMed]

- Gou, C.; Yang, Z.; Huang, J.; Wang, H.; Xu, H.; Wang, L. Effects of temperature and organic loading rate on the performance and microbial community of anaerobic co-digestion of waste activated sludge and food waste. Chemosphere 2014, 105, 146–151. [Google Scholar] [CrossRef]

- Daud, M.K.; Rizvi, H.; Akram, M.F.; Ali, S.; Rizwan, M.; Nafees, M.; Jin, Z.S. Review of upflow anaerobic sludge blanket reactor technology: Effect of different parameters and developments for domestic wastewater treatment. J. Chem. 2018, 2018, 1596319. [Google Scholar] [CrossRef] [Green Version]

- Chollom, M.N.; Rathilal, S.; Swalaha, F.M.; Bakare, B.F.; Tetteh, E.K. Lab Scale Study of Hrt and Olr Optimization in a Uasb Treating Slaughterhouse Wastewater. CBU Int. Conf. Proc. 2018, 6, 1030–1035. [Google Scholar] [CrossRef] [Green Version]

- Musa, M.A.; Idrus, S.; Hasfalina, C.M.; Daud, N.N.N. Effect of organic loading rate on anaerobic digestion performance of mesophilic (UASB) reactor using cattle slaughterhouse wastewater as substrate. Int. J. Environ. Res. Public Health 2018, 15, 2220. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torkian, A.; Eqbali, A.; Hashemian, S.J. The effect of organic loading rate on the performance of UASB reactor treating slaughterhouse effluent. Resour. Conserv. Recycl. 2003, 40, 1–11. [Google Scholar] [CrossRef]

- Batubara, F.; Ritonga, N.A.; Turmuzi, M. Start-Up of Upflow Anaerobic Sludge Blanket (UASB) Reactor Treating Slaughterhouse Wastewater. J. Phys. Conf. Ser. 2018, 1116, 042008. [Google Scholar] [CrossRef]

- Loganath, R.; Mazumder, D. Performance study on organic carbon, total nitrogen, suspended solids removal and biogas production in hybrid UASB reactor treating real slaughterhouse wastewater. J. Environ. Chem. Eng. 2018, 6, 3474–3484. [Google Scholar] [CrossRef]

- Rajakumar, R.; Meenambal, T.; Saravanan, P.M.; Ananthanarayanan, P. Treatment of poultry slaughterhouse wastewater in hybrid upflow anaerobic sludge blanket reactor packed with pleated poly vinyl chloride rings. Bioresour. Technol. 2012, 103, 116–122. [Google Scholar] [CrossRef]

- Musa, M.A.; Idrus, S.; Man, H.C.; Daud, N.N.N. Performance comparison of conventional and modified upflow anaerobic sludge blanket (UASB) reactors treating high-strength cattle slaughterhouse wastewater. Water 2019, 11, 806. [Google Scholar] [CrossRef] [Green Version]

- Debik, E.; Coskun, T. Use of the Static Granular Bed Reactor (SGBR) with anaerobic sludge to treat poultry slaughterhouse wastewater and kinetic modeling. Bioresour. Technol. 2009, 100, 2777–2782. [Google Scholar] [CrossRef]

- Gallardo, G.; Rodriguez, J.A.; Antonio, I.D.; Martinez, S.Y. Effect of Inoculum and Substratum on Cod Removal of Slaughterhouse. In Proceedings of the XV National Congress of Biotechnology and Bioengineering, Cancun, Mexico, 23–28 June 2013. [Google Scholar]

- Jung, K.W.; Kim, D.H.; Shin, H.S. Application of a simple method to reduce the start-up period in a H 2-producing UASB reactor using xylose. Int. J. Hydrog. Energy 2013, 38, 7253–7258. [Google Scholar] [CrossRef]

- Oehmichen, K.; Thrän, D. Fostering renewable energy provision from manure in Germany—Where to implement GHG emission reduction incentives. Energy Policy 2017, 110, 471–477. [Google Scholar] [CrossRef]

- De Oliveira, A.C.L.; Renato, N.D.S.; Martins, M.A.; de Mendonça, I.M.; Moraes, C.A.; Resende, M.D. Modeling for estimating and optimizing the energy potential of animal manure and sewage in small and medium-sized farms. J. Clean. Prod. 2021, 319, 128562. [Google Scholar] [CrossRef]

- Fuchsz, M.; Kohlheb, N. Comparison of the environmental effects of manure- and crop-based agricultural biogas plants using life cycle analysis. J. Clean. Prod. 2015, 86, 60–66. [Google Scholar] [CrossRef]

- Wresta, A.; Andriani, D.; Saepudin, A.; Sudibyo, H. Economic analysis of cow manure biogas as energy source for electricity power generation in small scale ranch. Energy Procedia 2015, 68, 122–131. [Google Scholar] [CrossRef] [Green Version]

- Behera, M.; Ghangrekar, M.M. Performance of microbial fuel cell in response to change in sludge loading rate at different anodic feed pH. Bioresour. Technol. 2009, 100, 5114–5121. [Google Scholar] [CrossRef] [PubMed]

- Rosli, N.S.; Idrus, S.; Daud, N.N.; Ahsan, A. Assessment of potential biogas production from rice straw leachate in upflow anaerobic sludge blanket reactor. Int. J. Smart Grid Clean Energy 2016, 5, 135–143. [Google Scholar] [CrossRef] [Green Version]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering: Treatment and Reuse, 4th ed.; McGraw Hill Inc.: New York, NY, USA, 2003. [Google Scholar]

- Rodger, B.; Bridgewater, L. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Hakawati, R.; Smyth, B.M.; McCullough, G.; de Rosa, F.; Rooney, D. What is the most energy efficient route for biogas utilization: Heat, electricity or transport? Appl. Energy 2017, 206, 1076–1087. [Google Scholar] [CrossRef] [Green Version]

- Khanal, S.K.; Li, Y. Biogas Production and Application. In Bioenergy: Principles and Applications, 1st ed.; Wiley Blackwell: Hoboken, NJ, USA, 2017; pp. 338–360. [Google Scholar]

- Pan, M.; Huang, X.; Wu, G.; Hu, Y.; Yang, Y.; Zhan, X. Performance of denitrifying phosphate removal via nitrite from slaughterhouse wastewater treatment at low temperature. Water 2017, 9, 818. [Google Scholar] [CrossRef] [Green Version]

- Musa, M.A.; Idrus, S. Effect of hydraulic retention time on the treatment of real cattle slaughter house wastewater and biogas production from HUASB reactor. Water 2020, 12, 490. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Liu, S.; Mi, L.; Li, Z.; Yuan, Y.; Yan, Z.; Liu, X. Effects of feedstock ratio and organic loading rate on the anaerobic mesophilic co-digestion of rice straw and cow manure. Bioresour. Technol. 2015, 189, 319–326. [Google Scholar] [CrossRef] [PubMed]

- Fang, C.; Boe, K.; Angelidaki, I. Biogas production from potato-juice, a by-product from potato-starch processing, in upflow anaerobic sludge blanket (UASB) and expanded granular sludge bed (EGSB) reactors. Bioresour. Technol. 2011, 102, 5734–5741. [Google Scholar] [CrossRef] [PubMed]

- Basitere, M.; Rinquest, Z.; Njoya, M.; Sheldon, M.S.; Ntwampe, S.K.O. Treatment of poultry slaughterhouse wastewater using a static granular bed reactor (SGBR) coupled with ultrafiltration (UF) membrane system. Water Sci. Technol. 2017, 76, 106–114. [Google Scholar] [CrossRef] [PubMed]

- Labatut, R.A.; Angenent, L.T.; Scott, N.R. Conventional mesophilic vs. thermophilic anaerobic digestion: Atrade-off between performance and stability? Water Res. 2014, 53, 249–258. [Google Scholar] [CrossRef]

- Sakar, S.; Yetilmezsoy, K.; Kocak, E. Anaerobic digestion technology in poultry and livestock waste treatment—A literature review. Waste Manag. Res. 2009, 27, 3–18. [Google Scholar] [CrossRef]

- Tangkathitipong, P.; Intanoo, P.; Butpan, J.; Chavadej, S. Separate production of hydrogen and methane from biodiesel wastewater with added glycerin by two-stage anaerobic sequencing batch reactors (ASBR). Renew. Energy 2017, 113, 1077–1085. [Google Scholar] [CrossRef]

- Mata-Alvarez, J. Fundamentals of the anaerobic digestion process. In Biomethanization of the Organic Fraction of Municipal Solid Wastes; IWA Publishing: London, UK, 2003; pp. 14–20. [Google Scholar]

- Fantozzi, F.; Buratti, C. Anaerobic digestion of mechanically treated OFMSW: Experimental data on biogas/methane production and residues characterization. Bioresour. Technol. 2011, 102, 8885–8892. [Google Scholar] [CrossRef]

- Morales-Polo, C.; Cledera-Castro, M.D.M.; Moratilla Soria, B.Y. Reviewing the anaerobic digestion of food waste: From waste generation and anaerobic process to its perspectives. Appl. Sci. 2018, 8, 1804. [Google Scholar] [CrossRef] [Green Version]

- Ghaniyari-Benis, S.; Borja, R.; Monemian, S.A.; Goodarzi, V. Anaerobic treatment of synthetic medium-strength wastewater using a multistage biofilm reactor. Bioresour. Technol. 2009, 100, 1740–1745. [Google Scholar] [CrossRef]

- Jeganathan, J.; Nakhla, G.; Bassi, A. Long-term performance of high-rate anaerobic reactors for the treatment of oily wastewater. Environ. Sci. Technol. 2006, 40, 6466–6472. [Google Scholar] [CrossRef]

- Marcos, A.C.; Al-Kassir, A.; Cuadros, F.; Yusaf, T. Treatment of slaughterhouse waste water mixed with serum from lacteal industry of extremadura in Spain to produce clean energy. Energies 2017, 10, 765. [Google Scholar] [CrossRef] [Green Version]

- Basitere, M.; Njoya, M.; Rinquest, Z.; Ntwampe, S.K.O.; Sheldon, M.S. Performance evaluation and kinetic parameter analysis for static granular bed reactor (SGBR) for treating poultry slaughterhouse wastewater at mesophilic condition. Water Pract. Technol. 2019, 14, 259–268. [Google Scholar] [CrossRef]

- Borja, R.; Banks, C.J.; Wang, Z. Effect of organic loading rate on anaerobic treatment of slaughterhouse wastewater in a fluidised-bed reactor. Bioresour. Technol. 1995, 52, 157–162. [Google Scholar] [CrossRef]

- Jensen, P.D.; Mehta, C.M.; Carney, C.; Batstone, D.J. Recovery of energy and nutrient resources from cattle paunch waste using temperature phased anaerobic digestion. Waste Manag. 2016, 51, 72–80. [Google Scholar] [CrossRef] [PubMed]

- Ugurlu, A.; Forster, C.F. The impact of shock loadings on the performance of thermophilic anaerobic filters with porous and non-porous packings. Bioresour. Technol. 1992, 39, 23–30. [Google Scholar] [CrossRef]

- Chou, Y.C.; Su, J.J. Biogas production by anaerobic co-digestion of dairy wastewater with the crude glycerol from slaughterhouse sludge cake transesterification. Animals 2019, 9, 618. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, J.; Zhao, Q.-B.; Laurens, L.L.M.; Jarvis, E.E.; Nagle, N.J.; Chen, S.; Frear, C.S. Mechanism, kinetics and microbiology of inhibition caused by long-chain fatty acids in anaerobic digestion of algal biomass. Biotechnol. Biofuels 2015, 8, 141. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, Y.; Wang, S.; Liu, Y.; Li, B.; Wang, B.; Peng, Y. Long-term effect of pH on short-chain fatty acids accumulation and microbial community in sludge fermentation systems. Bioresour. Technol. 2015, 197, 56–63. [Google Scholar] [CrossRef]

- Kundu, P.; Debsarkar, A.; Mukherjee, S. Treatment of slaughter house wastewater in a sequencing batch reactor: Performance evaluation and biodegradation kinetics. Biomed. Res. Int. 2013, 2013, 134872. [Google Scholar] [CrossRef] [Green Version]

- Fatima, F.; Du, H.; Kommalapati, R.R. Treatment of Poultry Slaughterhouse Wastewater with Membrane Technologies: A Review. Water 2021, 13, 1905. [Google Scholar] [CrossRef]

- Ezekiel, B.O.; Oyekola, P.O.; Ovaha, O.; Mohamed, A.; Lambrache, N. Bird feather removal machine: Design and development. Int. J. Recent Technol. Eng. 2019, 8, 406–410. [Google Scholar]

- MY, N.A.; Ibrahim, C.E.; Salmiyah, S.; SA, S.H.; Kamaruddin, D. Small-scale biogas plant in a dairy farm. Malays. J. Vet. Res. 2012, 3, 49–54. [Google Scholar]

| Parameters | Unit | Average Value |

|---|---|---|

| pH | - | 7.08 ± 0.50 |

| Temperature | °C | 26.7 ± 0.5 |

| COD | mg/L | 14,350 ± 300 |

| TSSs | mg/L | 2335 ± 100 |

| VSSs | mg/L | 1524 ± 150 |

| FOG | mg/L | 6820 ± 100 |

| TN | mg/L | 3033 ± 200 |

| Colour | Pt–Co | 12,300 ± 100 |

| Turbidity | FAU | 8500 ± 50 |

| Materials | Quantity | Unit |

|---|---|---|

| Yeast (granular form) | 23 | g |

| Urea | 2 | g |

| Ammonium phosphate (NH4)2HPO4 | 3.4 | g |

| Condensed Milk | 140 | mL |

| Chicken’s pure blood | 5.75 | mL |

| Tap water | To make up to 1 L |

| Parameter | Unit | LS | CS |

|---|---|---|---|

| OLR | gCOD/L/day | 5.0 | 5.0 b |

| SMP | LCH4/gCOD | 0.27 | 0.27 b |

| Energy in kJ/kgCOD a | kJ/kgCOD | 9678.42 | 9678.42 |

| Energy in kWh/kgCOD a | kWh/kgCOD | 2.69 | 2.69 |

| Energy Recovery in kWh | kWh | 0.0562 | 790.49 |

| Energy yield in kWh | kWh | 0.0185 | 260.86 |

| OLR (gCOD/L/day) | COD in (g/L) | COD out (g/L) | COD Removal (%) | Biogas Production ( L) | Methane Content (%) | SMP (LCH4/gCODadded) | pH | IA/PA Ratio | TAN (mg/L) | TSSs (mg/L) | FOG (mg/L) | Colour (Pt-Co) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 |

| 0.5 | 0.86 | 0.12 | 0.14 | 85.7 | 83.6 | 0.73 | 1.40 | 75 | 85 | 0.10 | 0.43 | 7.01 | 6.84 | 0.170 | 0.120 | 42 | 86 | 10 | 7 | 39 | 28 | 86 | 95 |

| 1.0 | 1.71 | 0.10 | 0.03 | 94.4 | 98.0 | 1.03 | 1.85 | 84 | 85 | 0.18 | 0.26 | 7.05 | 6.98 | 0.130 | 0.160 | 92 | 163 | 25 | 11 | 42 | 32 | 81 | 90 |

| 2.0 | 3.43 | 0.14 | 0.08 | 96.0 | 97.5 | 2.17 | 3.47 | 77 | 82 | 0.20 | 0.36 | 6.97 | 7.19 | 0.200 | 0.160 | 128 | 214 | 36 | 21 | 50 | 41 | 71 | 82 |

| 3.0 | 4.80 | 0.06 | 0.06 | 98.9 | 98.7 | 3.63 | 3.92 | 78 | 85 | 0.17 | 0.25 | 7.29 | 7.25 | 0.281 | 0.210 | 136 | 305 | 51 | 32 | 65 | 40 | 62 | 89 |

| 4.0 | 6.40 | 0.13 | 0.13 | 98.0 | 98.0 | 3.88 | 5.60 | 59 | 81 | 0.19 | 0.30 | 7.28 | 7.32 | 0.370 | 0.210 | 135 | 685 | 65 | 26 | 68 | 50 | 55 | 84 |

| 5.0 | 8.00 | 2.53 | 0.16 | 69.1 | 98.0 | 4.20 | 7.13 | 53 | 75 | 0.16 | 0.27 | 6.12 | 7.27 | 0.462 | 0.240 | 136 | 805 | 76 | 32 | 121 | 51 | 56 | 75 |

| 6.0 | 9.60 | 4.48 | 1.44 | 53.3 | 85.0 | 2.33 | 10.53 | 20 | 70 | 0.03 | 0.31 | 6.16 | 7.52 | 0.540 | 0.280 | 112 | 813 | 403 | 98 | 245 | 52 | 42 | 78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marzuki, T.N.T.M.; Idrus, S.; Musa, M.A.; Wahab, A.M.A.; Jamali, N.S.; Man, H.C.; Ng, S.N.M. Enhancement of Bioreactor Performance Using Acclimatised Seed Sludge in Anaerobic Treatment of Chicken Slaughterhouse Wastewater: Laboratory Achievement, Energy Recovery, and Its Commercial-Scale Potential. Animals 2021, 11, 3313. https://doi.org/10.3390/ani11113313

Marzuki TNTM, Idrus S, Musa MA, Wahab AMA, Jamali NS, Man HC, Ng SNM. Enhancement of Bioreactor Performance Using Acclimatised Seed Sludge in Anaerobic Treatment of Chicken Slaughterhouse Wastewater: Laboratory Achievement, Energy Recovery, and Its Commercial-Scale Potential. Animals. 2021; 11(11):3313. https://doi.org/10.3390/ani11113313

Chicago/Turabian StyleMarzuki, Tuan Nurfarhana Tuan Mohd, Syazwani Idrus, Mohammed Ali Musa, Abdul Malek Abdul Wahab, Nur Syakina Jamali, Hasfalina Che Man, and Sabrina Ng Muhamad Ng. 2021. "Enhancement of Bioreactor Performance Using Acclimatised Seed Sludge in Anaerobic Treatment of Chicken Slaughterhouse Wastewater: Laboratory Achievement, Energy Recovery, and Its Commercial-Scale Potential" Animals 11, no. 11: 3313. https://doi.org/10.3390/ani11113313

APA StyleMarzuki, T. N. T. M., Idrus, S., Musa, M. A., Wahab, A. M. A., Jamali, N. S., Man, H. C., & Ng, S. N. M. (2021). Enhancement of Bioreactor Performance Using Acclimatised Seed Sludge in Anaerobic Treatment of Chicken Slaughterhouse Wastewater: Laboratory Achievement, Energy Recovery, and Its Commercial-Scale Potential. Animals, 11(11), 3313. https://doi.org/10.3390/ani11113313