Influence of Wet Ageing on Beef Quality Traits

(This article belongs to the Section Animal Products)

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Meat Samples Collection

2.2. Wet Ageing Specification

2.3. Chemical and Physical Meat Analysis

2.4. Statistical Analysis

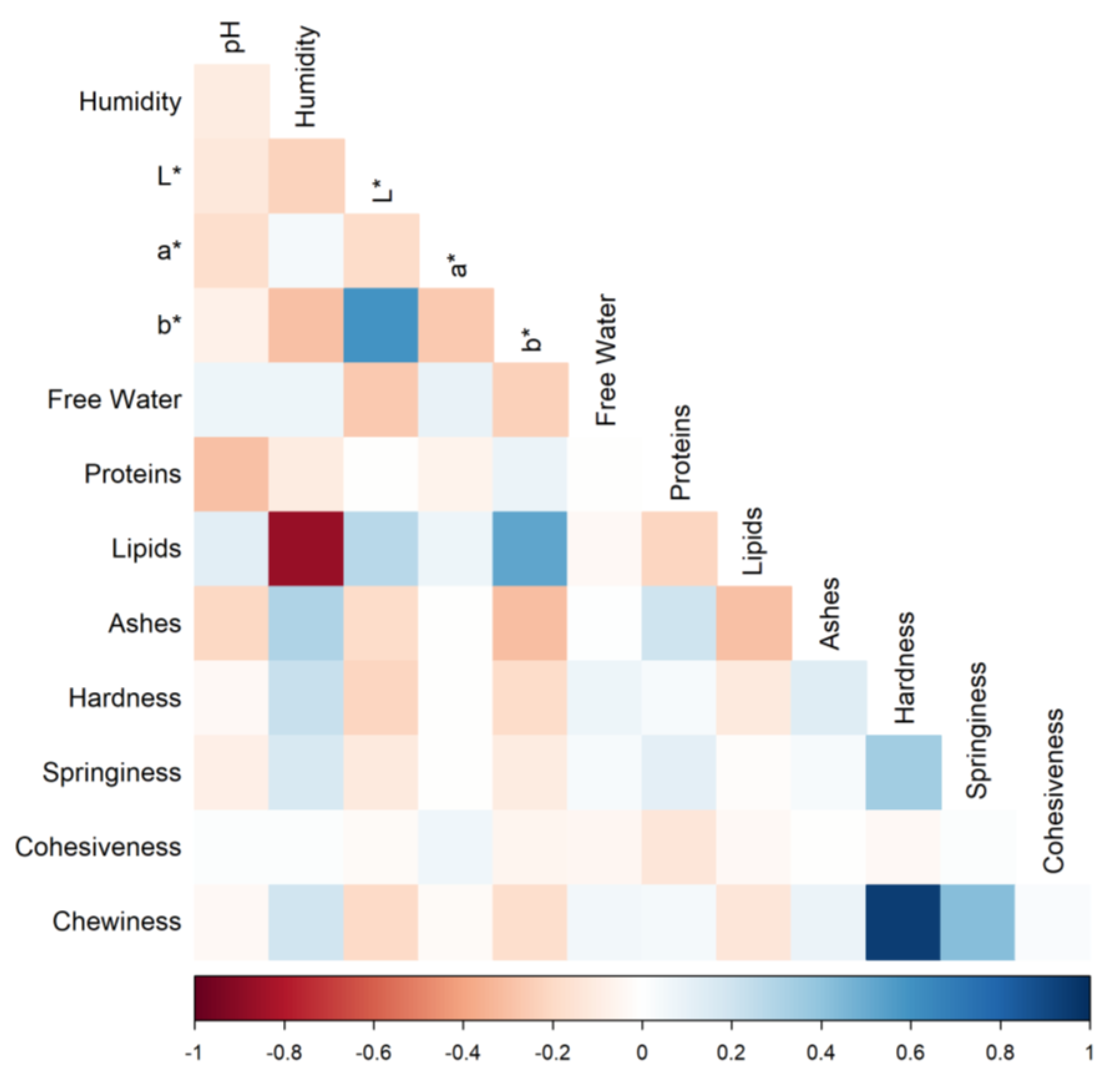

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- World Livestock 2011: Livestock in Food Security; McLeod, A.; Food and Agriculture Organization of the United Nations (Eds.) Food and Agriculture Organization of the United Nations: Rome, Italy, 2011; ISBN 978-92-5-107013-0. Available online: https://www.fao.org/3/i2373e/i2373e.pdf (accessed on 11 November 2022).

- Vineis, P.; Stringhini, S.; Porta, M. The Environmental Roots of Non-Communicable Diseases (NCDs) and the Epigenetic Impacts of Globalization. Environ. Res. 2014, 133, 424–430. [Google Scholar] [CrossRef] [PubMed]

- OECD. OECD-FAO Agricultural Outlook (Edition 2021); Organisation for Economic Co-operation and Development: Rome, Italy, 2021; Available online: https://www.fao.org/documents/card/en/c/cb5339en/ (accessed on 11 November 2022).

- World Cancer Research Fund Food, Nutrition, Physical Activity, and the Prevention of Cancer: A Global Perspective. Choice Rev. Online 2008, 45, 45–5024. [CrossRef]

- World Health Organization Diet, Nutrition and the Prevention of Chronic Diseases. World Health Organ. Tech. Rep. Ser. 2003, 916, 1–149.

- Albertí, P.; Ripoll, G.; Goyache, F.; Lahoz, F.; Olleta, J.L.; Panea, B.; Sañudo, C. Carcass Characterisation of Seven Spanish Beef Breeds Slaughtered at Two Commercial Weights. Meat Sci. 2005, 71, 514–521. [Google Scholar] [CrossRef] [PubMed]

- Terjung, N.; Witte, F.; Heinz, V. The Dry Aged Beef Paradox: Why Dry Aging Is Sometimes Not Better than Wet Aging. Meat Sci. 2021, 172, 108355. [Google Scholar] [CrossRef]

- Revilla, I.; Vivar-Quintana, A.M. Effect of Breed and Ageing Time on Meat Quality and Sensory Attributes of Veal Calves of the “Ternera de Aliste” Quality Label. Meat Sci. 2006, 73, 189–195. [Google Scholar] [CrossRef]

- Crivelli, F.; Tirloni, E.; Bernardi, C.; Sgoifo Rossi, C.A.; Stella, S. Wet Bone-in Ageing and Effect on Beef Quality Technological Parameters. J. Food Sci. Technol. 2019, 56, 5538–5543. [Google Scholar] [CrossRef]

- Wang, F.; Liang, R.; Zhang, Y.; Gao, S.; Zhu, L.; Niu, L.; Luo, X.; Mao, Y.; Hopkins, D.L. Effects of Packaging Methods Combined with Frozen Temperature on the Color of Frozen Beef Rolls. Meat Sci. 2021, 171, 108292. [Google Scholar] [CrossRef]

- Ribeiro, F.A.; Lau, S.K.; Pflanzer, S.B.; Subbiah, J.; Calkins, C.R. Color and Lipid Stability of Dry Aged Beef during Retail Display. Meat Sci. 2021, 171, 108274. [Google Scholar] [CrossRef]

- Nair, M.N.; Canto, A.C.V.C.S.; Rentfrow, G.; Suman, S.P. Muscle-Specific Effect of Aging on Beef Tenderness. LWT 2019, 100, 250–252. [Google Scholar] [CrossRef]

- Miller, M.F.; Carr, M.A.; Ramsey, C.B.; Crockett, K.L.; Hoover, L.C. Consumer Thresholds for Establishing the Value of Beef Tenderness. J. Anim. Sci. 2001, 79, 3062–3068. [Google Scholar] [CrossRef] [PubMed]

- Stenström, H.; Li, X.; Hunt, M.C.; Lundström, K. Consumer Preference and Effect of Correct or Misleading Information after Ageing Beef Longissimus Muscle Using Vacuum, Dry Ageing, or a Dry Ageing Bag. Meat Sci. 2014, 96, 661–666. [Google Scholar] [CrossRef] [PubMed]

- AOAC Official Methods of AnalysisTM, 21st Edition. 2019. Available online: https://www.aoac.org/official-methods-of-analysis-21st-edition-2019/ (accessed on 11 November 2022).

- Folch, J.; Lees, M.; Sloane Stanley, G.H. A Simple Method for the Isolation and Purification of Total Lipides from Animal Tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef] [PubMed]

- Novaković, S.; Tomašević, I. A Comparison between Warner-Bratzler Shear Force Measurement and Texture Profile Analysis of Meat and Meat Products: A Review. IOP Conf. Ser. Earth Environ. Sci. 2017, 85, 012063. [Google Scholar] [CrossRef] [Green Version]

- Grau, R.; Hamm, R. Eine einfache Methode zur Bestimmung der Wasserbindung im Muskel. Naturwissenschaften 1953, 40, 29–30. [Google Scholar] [CrossRef]

- Wei, T.; Simko, V.; Levy, M.; Xie, Y.; Jin, Y.; Zemla, J.; Freidank, M.; Cai, J.; Protivinsky, T. Corrplot: Visualization of a Correlation Matrix. Available online: https://CRAN.R-project.org/package=corrplot (accessed on 11 November 2022).

- Bates, D.; Mächler, M.; Bolker, B.; Walker, S. Fitting Linear Mixed-Effects Models Using Lme4. J. Stat. Softw. 2015, 67, 1–48. [Google Scholar] [CrossRef]

- Lenth, R.V.; Buerkner, P.; Herve, M.; Love, J.; Riebl, H.; Singmann, H. Emmeans: Estimated Marginal Means, Aka Least-Squares Means. 2021. Available online: https://github.com/rvlenth/emmeans (accessed on 11 November 2022).

- Ha, Y.; Hwang, I.; Ba, H.V.; Ryu, S.; Kim, Y.; Kang, S.M.; Kim, J.; Kim, Y.; Cho, S. Effects of Dry- and Wet-Ageing on Flavor Compounds and Eating Quality of Low Fat Hanwoo Beef Muscles. Food Sci. Anim. Resour. 2019, 39, 655–667. [Google Scholar] [CrossRef] [Green Version]

- Borgogno, M.; Saccà, E.; Corazzin, M.; Favotto, S.; Bovolenta, S.; Piasentier, E. Eating Quality Prediction of Beef from Italian Simmental Cattle Based on Experts’ Steak Assessment. Meat Sci. 2016, 118, 1–7. [Google Scholar] [CrossRef]

- Sirtori, F.; Crovetti, A.; Acciaioli, A.; Pugliese, C.; Bozzi, R.; Campodoni, G.; Franci, O. Effect of Dietary Protein Level on Carcass Traits and Meat Properties of Cinta Senese Pigs. Animal 2014, 8, 1987–1995. [Google Scholar] [CrossRef]

- Sirtori, F.; Bozzi, R.; Franci, O.; Calamai, L.; Crovetti, A.; Bonelli, A.; Benvenuti, D.; Aquilani, C.; Pugliese, C. Effects of Genotype and Salting Time on Chemical, Physical and Sensorial Traits of a New Pig Seasoned Meat Product ‘Cuore Di Spalla’. Ital. J. Anim. Sci. 2019, 18, 898–909. [Google Scholar] [CrossRef] [Green Version]

- Garner, C.M.; Unruh, J.A.; Hunt, M.C.; Boyle, E.A.E.; Houser, T.A. Effects of Subprimal Type, Quality Grade, and Aging Time on Display Color of Ground Beef Patties. Meat Sci. 2014, 98, 301–309. [Google Scholar] [CrossRef] [PubMed]

- Clinquart, A.; Ellies-Oury, M.P.; Hocquette, J.F.; Guillier, L.; Santé-Lhoutellier, V.; Prache, S. Review: On-Farm and Processing Factors Affecting Bovine Carcass and Meat Quality. Animal 2022, 16, 100426. [Google Scholar] [CrossRef]

- Santos, D.; Monteiro, M.J.; Voss, H.-P.; Komora, N.; Teixeira, P.; Pintado, M. The Most Important Attributes of Beef Sensory Quality and Production Variables That Can Affect It: A Review. Livest. Sci. 2021, 250, 104573. [Google Scholar] [CrossRef]

- Tomasevic, I.; Djekic, I.; Font-i-Furnols, M.; Terjung, N.; Lorenzo, J.M. Recent Advances in Meat Color Research. Curr. Opin. Food Sci. 2021, 41, 81–87. [Google Scholar] [CrossRef]

- Xu, M.M.; Kaur, M.; Pillidge, C.J.; Torley, P.J. Effect of Protective Cultures on Spoilage Bacteria and the Quality of Vacuum-Packaged Lamb Meat. Food Biosci. 2022, 50, 102148. [Google Scholar] [CrossRef]

- Lee, H.J.; Choe, J.; Kim, M.; Kim, H.C.; Yoon, J.W.; Oh, S.W.; Jo, C. Role of Moisture Evaporation in the Taste Attributes of Dry- and Wet-Aged Beef Determined by Chemical and Electronic Tongue Analyses. Meat Sci. 2019, 151, 82–88. [Google Scholar] [CrossRef]

- Lee, M.S.; Apple, J.K.; Yancey, J.W.S.; Sawyer, J.T.; Johnson, Z.B. Influence of Wet-Aging on Bloom Development in the Longissimus Thoracis. Meat Sci. 2008, 80, 703–707. [Google Scholar] [CrossRef]

- Field, R.A.; Riley, M.L.; Chang, Y.-O. Free Amino Acid Changes in Different Aged Bovine Muscles and Their Relationship to Shear Values. J. Food Sci. 1971, 36, 611–612. [Google Scholar] [CrossRef]

- Ruiz de Huidobro, F.; Miguel, E.; Onega, E.; Blázquez, B. Changes in Meat Quality Characteristics of Bovine Meat during the First 6 Days Post Mortem. Meat Sci. 2003, 65, 1439–1446. [Google Scholar] [CrossRef]

- Vieira, C.; Cerdeño, A.; Serrano, E.; Lavín, P.; Mantecón, A.R. Breed and Ageing Extent on Carcass and Meat Quality of Beef from Adult Steers (Oxen). Livest. Sci. 2007, 107, 62–69. [Google Scholar] [CrossRef]

- Monteils, V.; Sibra, C.; Ellies-Oury, M.-P.; Botreau, R.; De la Torre, A.; Laurent, C. A Set of Indicators to Better Characterize Beef Carcasses at the Slaughterhouse Level in Addition to the EUROP System. Livest. Sci. 2017, 202, 44–51. [Google Scholar] [CrossRef]

- Birhanu, A.F. Pre-Slaughter Stress, Management of Stress and Its Effect on Meat and Carcass Quality. IJFSA 2020, 4, 30–37. [Google Scholar] [CrossRef]

| Parameter | Mean | sd |

|---|---|---|

| pH | 5.66 | 0.09 |

| Humidity | 73.83 | 1.14 |

| L* | 39.93 | 2.03 |

| a* | 21.70 | 1.29 |

| b* | 5.63 | 1.17 |

| Free Water | 0.58 | 0.04 |

| Proteins | 20.94 | 0.58 |

| Lipids | 1.12 | 0.72 |

| Ashes | 1.04 | 0.05 |

| Hardness | 1.89 | 0.52 |

| Springiness | 0.90 | 0.02 |

| Cohesiveness | 0.42 | 0.04 |

| Chewiness | 0.73 | 0.25 |

| Parameter | Humidity (%) | Protein (%) | Intramuscular Fat (%) | Ash (%) |

|---|---|---|---|---|

| Breed | ||||

| Charolais | 73.40 (0.52) | 20.74 b (0.39) | 1.79 a (0.31) | 1.02 (0.05) |

| Crossbred | 74.13 (0.33) | 21.01 b (0.26) | 1.13 b (0.20) | 1.06 (0.03) |

| Limousine | 74.28 (0.36) | 21.42 a (0.28) | 0.86 c (0.22) | 1.05 (0.04) |

| Romagnola | 74.31 (0.40) | 20.95 b (0.32) | 1.00 b,c (0.25) | 1.05 (0.04) |

| Animal Age | ||||

| 1 | 73.71 (0.55) | 21.44 (0.45) | 1.16 (0.32) | 1.00 (0.06) |

| 2 | 74.18 (0.35) | 20.91 (0.27) | 1.09 (0.21) | 1.05 (0.04) |

| 3 | 74.07 (0.35) | 20.95 (0.27) | 1.20 (0.22) | 1.06 (0.04) |

| 4 | 74.15 (0.36) | 20.81 (0.28) | 1.33 (0.22) | 1.08 (0.04) |

| EUROP-conformation | ||||

| E | 74.79 (0.69) | 22.14 (0.54) | 0.65 (0.42) | 1.04 (0.07) |

| U | 73.67 (0.20) | 21.01 (0.16) | 1.29 (0.12) | 1.03 (0.02) |

| R | 73.92 (0.24) | 21.02 (0.19) | 1.04 (0.14) | 1.06 (0.02) |

| O | 73.72 (0.97) | 19.94 (0.76) | 1.80 (0.60) | 1.05 (0.11) |

| Step1 | ||||

| 0 | 73.62 (0.63) | 21.19 a (0.49) | 1.19 (0.39) | 1.04 (0.07) |

| 1 | 73.99 (0.36) | 21.03 a (0.28) | 1.36 (0.22) | 1.06 (0.04) |

| 2 | 74.23 (0.35) | 20.63 b (0.27) | 1.29 (0.21) | 1.06 (0.04) |

| 3 | 74.26 (0.36) | 21.26 a (0.28) | 0.94 (0.22) | 1.02 (0.04) |

| Parameter | pH | Humidity % | L* | a* | b* | Freewater | Hardness | Cohesiveness | Chewiness | Springiness |

|---|---|---|---|---|---|---|---|---|---|---|

| Breed | ||||||||||

| Charolais | 5.60 a (0.04) | 72.98 b (0.56) | 41.96 (1.21) | 22.07 (0.43) | 6.99 (0.57) | 0.54 (0.02) | 1.35 (0.18) | 0.42 (0.02) | 0.51 (0.07) | 0.90 (0.09) |

| Crossbred | 5.55 a (0.03) | 73.65 b (0.40) | 41.32 (0.84) | 22.05 (0.31) | 6.34 (0.41) | 0.56 (0.01) | 1.45 (0.13) | 0.43 (0.01) | 0.56 (0.05) | 0.90 (0.07) |

| Limousine | 5.52 b (0.03) | 74.14 a (0.43) | 41.93 (0.90) | 21.90 (0.33) | 6.75 (0.43) | 0.55 (0.01) | 1.35 (0.14) | 0.44 (0.01) | 0.52 (0.05) | 0.90 (0.07) |

| Romagnola | 5.48 b (0.03) | 73.94 a,b (0.49) | 41.13 (1.03) | 22.21 (0.38) | 7.04 (0.50) | 0.55 (0.02) | 1.28 (0.16) | 0.43 (0.01) | 0.49 (0.06) | 0.90 (0.08) |

| Wet Ageing | ||||||||||

| T0 | 5.52 c (0.03) | 74.13 a (0.41) | 41.09 c (0.87) | 22.28 (0.33) | 6.41 b ( 0.42) | 0.55 a (0.01) | 1.81 a (0.14) | 0.40 d (0.01) | 0.67 a (0.05) | 0.90 (0.00) |

| T4 | 5.53 b c (0.03) | 73.80 b (0.41) | 41.28 c (0.87) | 21.98 (0.33) | 6.80 a ( 0.42) | 0.56 a (0.01) | 1.37 b (0.14) | 0.42 c (0.01) | 0.51 b (0.05) | 0.89 (0.00) |

| T9 | 5.56 a (0.03) | 73.48 c (0.41) | 41.80 b (0.87) | 22.03 (0.33) | 6.95 a ( 0.42) | 0.55 a (0.01) | 1.21 c (0.14) | 0.44 b (0.01) | 0.47 b (0.05) | 0.89 (0.00) |

| T14 | 5.54 b (0.03) | 73.29 d (0.41) | 42.18 a (0.87) | 21.95 (0.33) | 6.98 a ( 0.42) | 0.54 b (0.01) | 1.03 d (0.14) | 0.46 a (0.01) | 0.42 c (0.05) | 0.89 (0.00) |

| Animal Age | ||||||||||

| 1 | 5.52 (0.04) | 73.43 (0.56) | 41.91 (1.71) | 22.45 (0.43) | 6.93 (0.56) | 0.54 (0.02) | 1.29 a,b (0.18) | 0.44 (0.02) | 0.51 a,b (0.15) | 0.89 (0.01) |

| 2 | 5.55 (0.03) | 73.80 (0.42) | 41.91 (0.88) | 21.72 (0.33) | 6.76 (0.42) | 0.55 (0.02) | 1.45 a (0.14) | 0.42 (0.01) | 0.55 a (0.05) | 0.89 (0.00) |

| 3 | 5.54 (0.03) | 73.81 (0.42) | 41.43 (0.88) | 21.95 (0.33) | 6.71 (0.43) | 0.54 (0.02) | 1.46 a (0.14) | 0.42 (0.01) | 0.56 a (0.05) | 0.90 (0.00) |

| 4 | 5.55 (0.03) | 73.65 (0.43) | 41.09 (0.91) | 22.11 (0.34) | 6.73 (0.43) | 0.56 (0.01) | 1.22 b (0.14) | 0.43 (0.01) | 0.46 b (0.05) | 0.89 (0.00) |

| EUROP-conformation | ||||||||||

| E | 5.46 b (0.05) | 74.83 a (0.84) | 41.66 (1.77) | 22.54 (0.66) | 6.73 (0.85) | 0.54 (0.03) | 1.46 a (0.27) | 0.44 (0.02) | 0.59 (0.11) | 0.91 (0.01) |

| U | 5.62 a (0.01) | 73.12 b (0.23) | 42.15 (0.47) | 21.51 (0.17) | 7.17 (0.23) | 0.57 (0.01) | 1.31 b (0.07) | 0.43 (0.01) | 0.56 (0.03) | 0.89 (0.01) |

| R | 5.60 a (0.02) | 73.59 a (0.26) | 41.66 (1.77) | 21.80 (0.20) | 6.47 (0.26) | 0.57 (0.01) | 1.46 a (0.08) | 0.43 (0.01) | 0.50 (0.03) | 0.88 (0.00) |

| O | 5.47 a,b (0.08) | 73.17 a,b (1.18) | 41.29 (2.50) | 22.38 (0.92) | 6.77 (1.20) | 0.52 (0.04) | 1.20 b (0.39) | 0.42 (0.03) | 0.43 (0.15) | 0.88 (0.00) |

| Step1 | ||||||||||

| 0 | 5.49 (0.05) | 73.60 a,b (0.77) | 41.30 (1.61) | 21.89 (0.60) | 7.24 a (0.78) | 0.55 (0.02) | 1.59 a (0.25) | 0.43 (0.02) | 0.60 (0.10) | 0.89 (0.01) |

| 1 | 5.54 (0.03) | 73.25 b (0.41) | 42.09 (0.86) | 21.95 (0.32) | 7.08 a (0.41) | 0.55 (0.01) | 1.20 b (0.13) | 0.43 (0.01) | 0.53 (0.05) | 0.89 (0.00) |

| 2 | 5.56 (0.03) | 73.72 a (0.41) | 42.13 (0.86) | 22.14 (0.32) | 6.64 b (0.41) | 0.55 (0.01) | 1.36 a (0.13) | 0.43 (0.01) | 0.50 (0.05) | 0.89 (0.00) |

| 3 | 5.55 (0.03) | 74.13 a (0.42) | 40.82 (0.89) | 22.24 (0.33) | 6.17 b (0.43) | 0.55 (0.01) | 1.28 a,b (0.14) | 0.43 (0.01) | 0.46 (0.05) | 0.90 (0.00) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sirtori, F.; Parrini, S.; Fabbri, M.C.; Aquilani, C.; Dal Prà, A.; Crovetti, A.; Brajon, G.; Bozzi, R. Influence of Wet Ageing on Beef Quality Traits. Animals 2023, 13, 58. https://doi.org/10.3390/ani13010058

Sirtori F, Parrini S, Fabbri MC, Aquilani C, Dal Prà A, Crovetti A, Brajon G, Bozzi R. Influence of Wet Ageing on Beef Quality Traits. Animals. 2023; 13(1):58. https://doi.org/10.3390/ani13010058

Chicago/Turabian StyleSirtori, Francesco, Silvia Parrini, Maria Chiara Fabbri, Chiara Aquilani, Aldo Dal Prà, Alessandro Crovetti, Giovanni Brajon, and Riccardo Bozzi. 2023. "Influence of Wet Ageing on Beef Quality Traits" Animals 13, no. 1: 58. https://doi.org/10.3390/ani13010058

APA StyleSirtori, F., Parrini, S., Fabbri, M. C., Aquilani, C., Dal Prà, A., Crovetti, A., Brajon, G., & Bozzi, R. (2023). Influence of Wet Ageing on Beef Quality Traits. Animals, 13(1), 58. https://doi.org/10.3390/ani13010058