Exploring Rotational Grazing and Crossbreeding as Options for Beef Production to Reduce GHG Emissions and Feed-Food Competition through Farm-Level Bio-Economic Modeling

Abstract

:Simple Summary

Abstract

1. Introduction

2. Material and Method

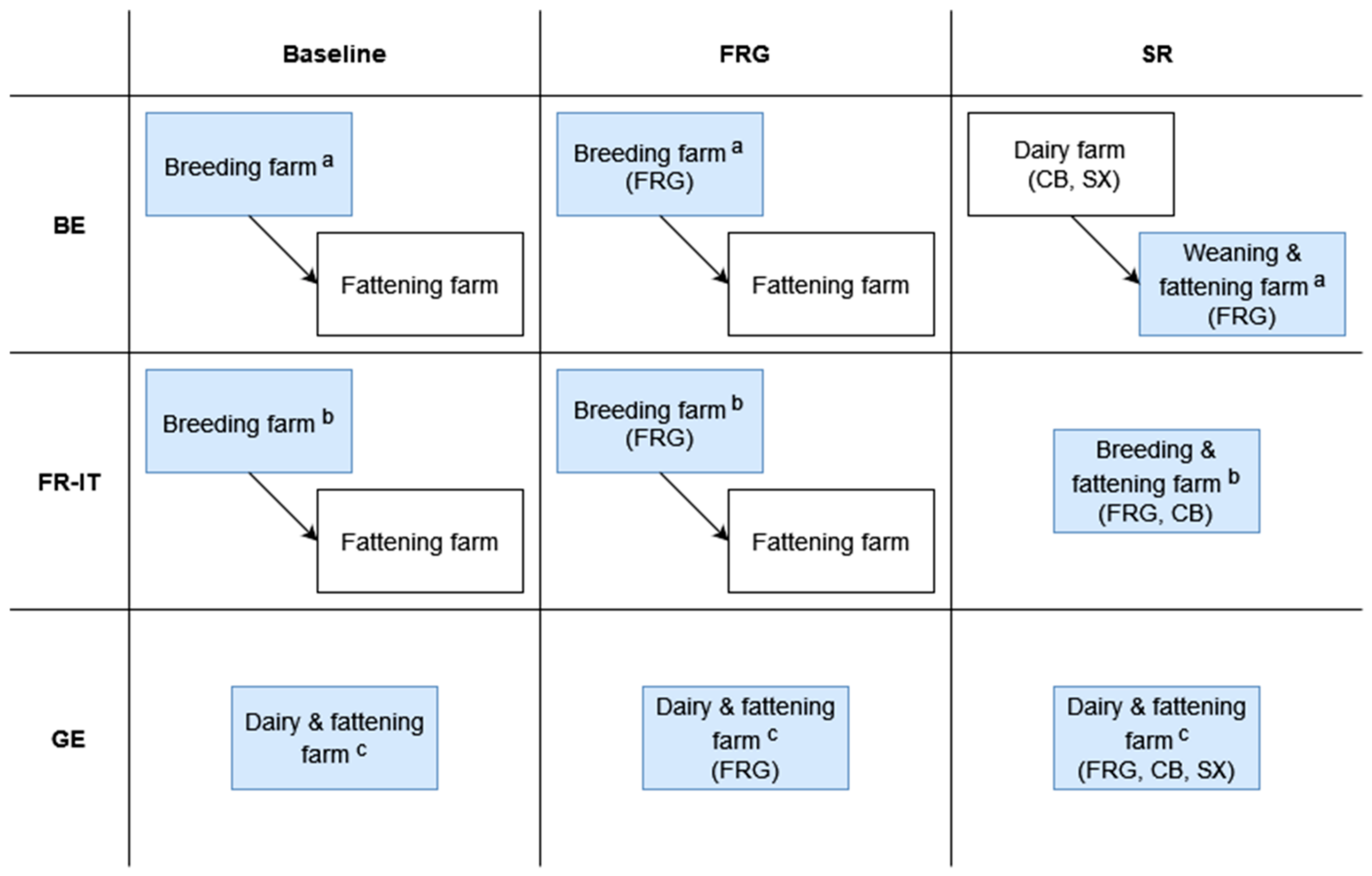

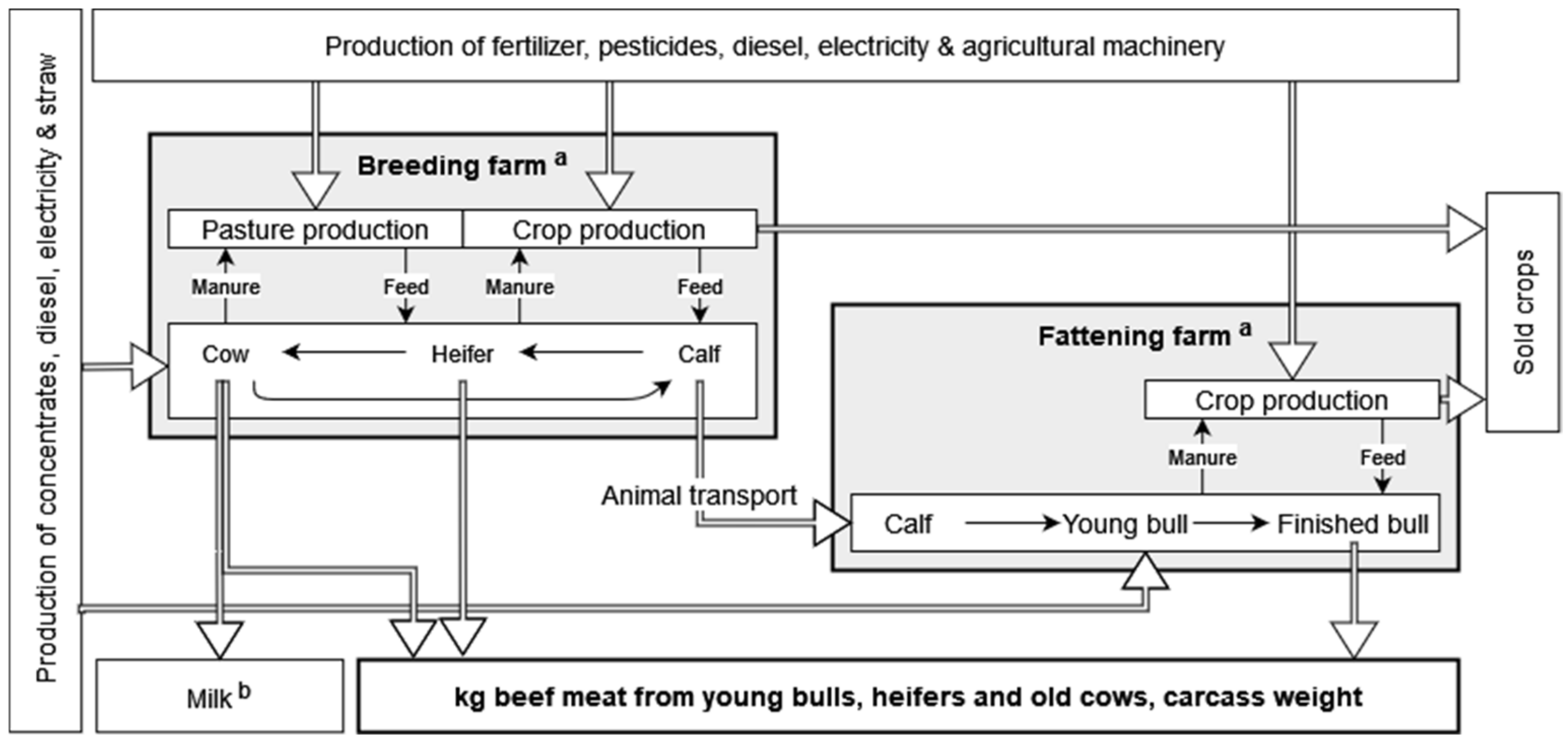

2.1. The Three Beef Production Systems

- -

- The first system articulates two Belgian (BE) farms. The first one is an integrated crop-livestock farm. It holds a suckler cow herd of the Belgian Blue breed and sells the weaned male offspring, cereals, and sugar beet. The weanlings are transferred to a second farm in the system where they are fattened indoors using maize silage and concentrates as feed;

- -

- The second system starts on a suckler cow farm located in the Massif Central, France (FR-IT-B). The farm keeps a herd of Charolais and Salers cows. The herd valorizes pastures during the summer and is kept indoors during the winter. The weaned calves are shipped to a second farm in Italy, where they are fattened indoors using maize silage and concentrates for feeding;

- -

- The third farm is an integrated crop-dairy farm fattening its own male offspring of the Holstein breed. The animals are fattened indoors using maize silage and concentrates as feed. Besides cattle production, the farm is also involved in cash-crop production (cereals and sugar beet).

2.2. Scenarios

- -

- In the BE system, the fattening farm is removed from the system while the breeding farm in the system is transformed into a growing-fattening farm. A dairy farm is added to the system to supply male calves entering the growing-fattening farm. The dairy farm keeps a herd of 70 cows of the Holstein breed. For the renewal, some cows are inseminated with female Holstein-sexed semen while others are inseminated with male-sexed semen of the Belgian Blue breed. The calves enter the growing-fattening farm when 3 weeks old at the cost of EUR 200. They are raised and fattened on grasslands and repurposed stables of the initial suckler cow enterprise. The bulls are grazing from April to October. Based on the performances observed by [11,26], the bulls are sold when 19 months old with a carcass weight of 330 kg (carcass yield 55%), a conformation score of U-R, and a fat score of 2–3. A price of EUR 3.4/kg carcass was therefore considered based on the official Belgian prices [27];

- -

- In the redesigned scenario of the FR system, the fattening farm in Italy is removed from the system, and the finishing period is happening at the French breeding farm. Furthermore, the Charolais breed cows are inseminated with the Angus breed. The Angus breed is known for its ability to valorize grass resources and the high fatness score of its meat [28], resulting in higher selling prices. The bulls are slaughtered when 14-month-old at a carcass weight of 300 kg with a price premium of EUR 0.4 per kg carcass weight, adding up to a total price of EUR 4.18/kg carcass;

- -

- In the German redesigned scenario, the farm uses crossbreeding and sexed semen to reduce the number of breeding heifers to the herd renewal needs and produce high-yielding Belgian Blue by Holstein crossbred male calves. The calves are fattened at the farm and sold at the age of 21 months at a carcass weight of 413 kg and a price of EUR 3.8/kg carcass.

2.3. Overview of the FarmDyn Model

2.4. Sustainability Indicators

2.5. Sensitivity Analysis

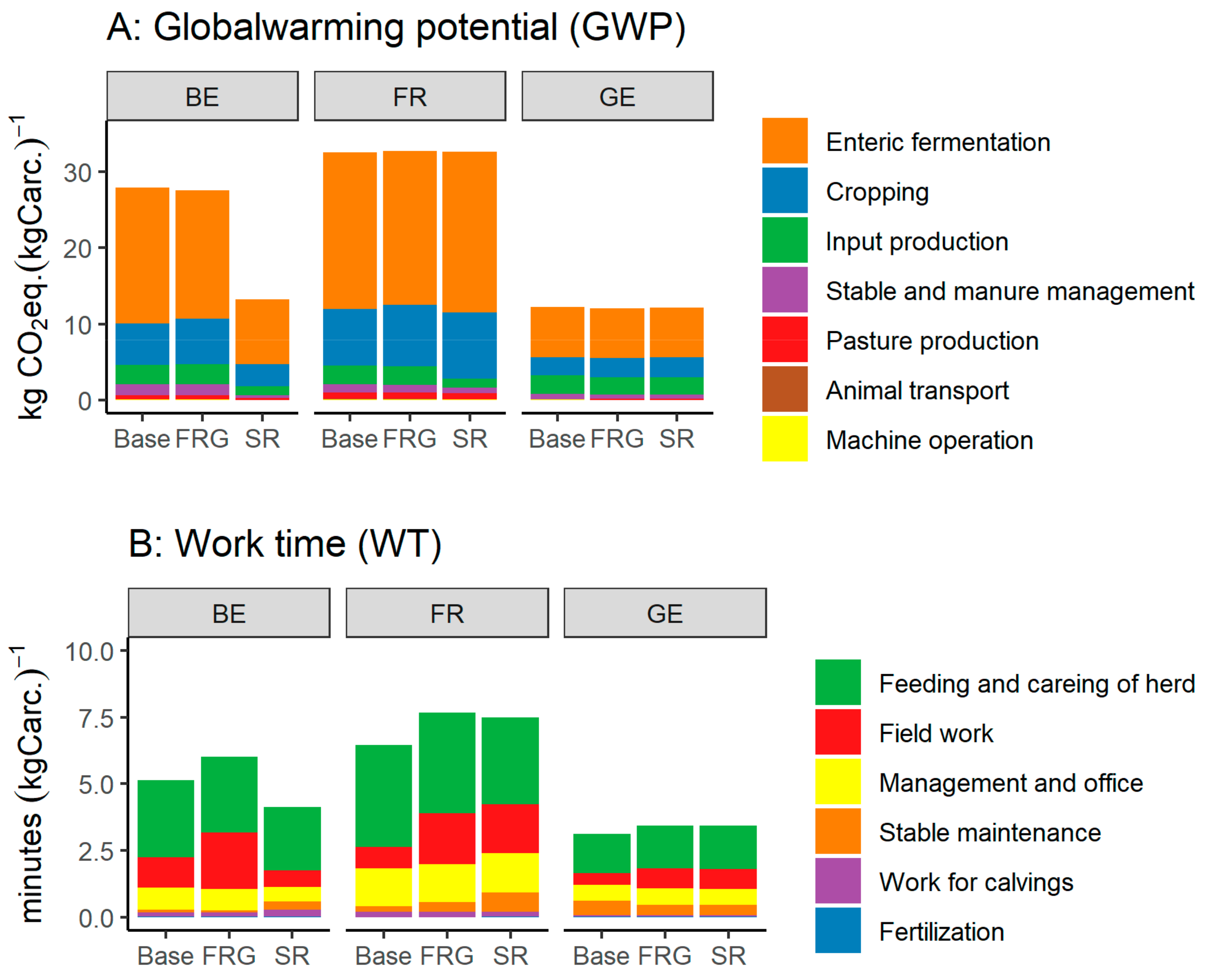

3. Results

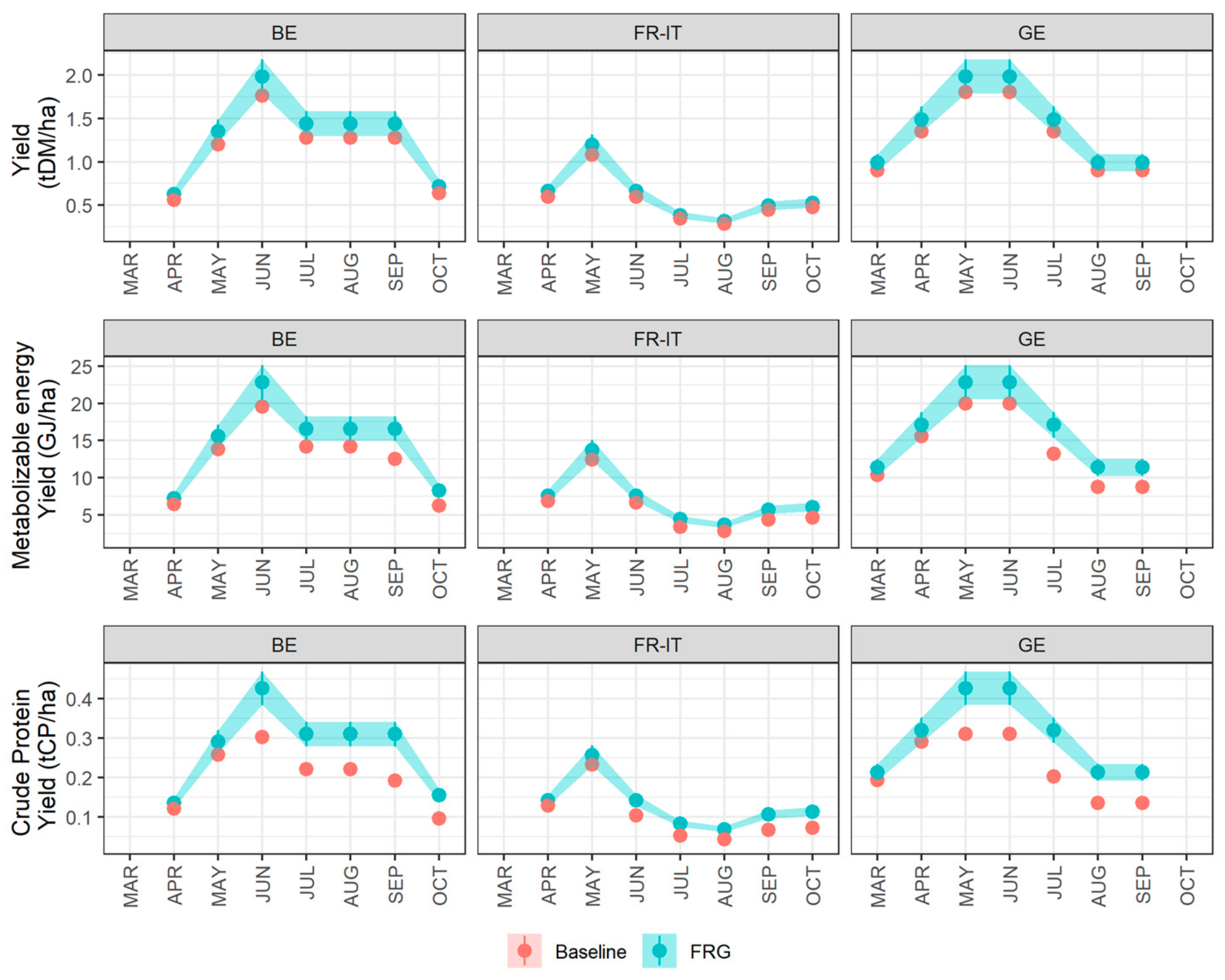

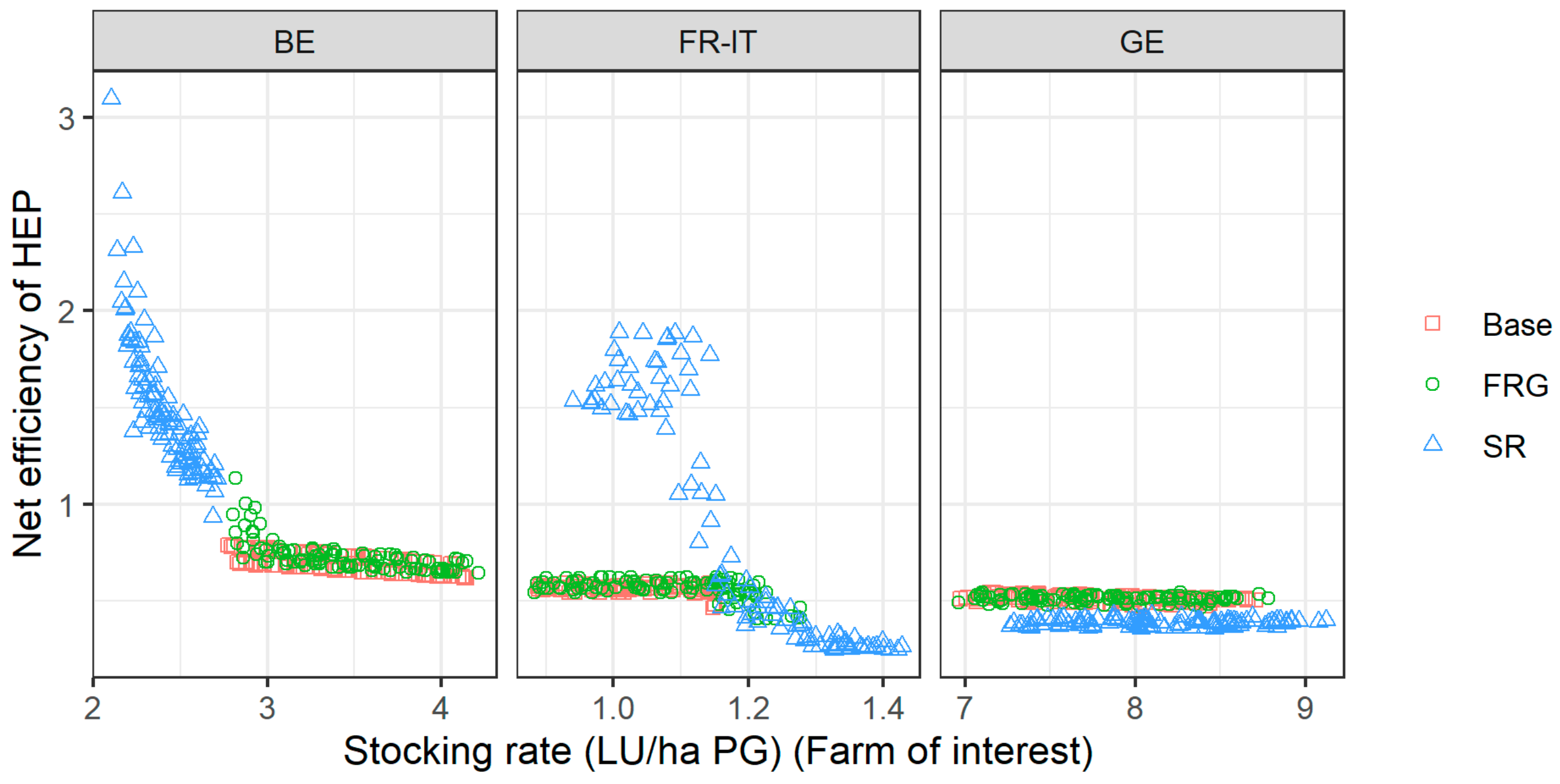

3.1. FRG Scenarios

3.2. SR Scenarios

4. Discussion

4.1. Fast Rotational Grazing

4.2. System Redesign

4.3. Relevance of the Modeling Framework to Redesign Production Systems

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Source/Sub-Source | Pollutant | Methodology | Tier |

|---|---|---|---|

| Enteric fermentation | CH4 | IPCC (2019) | 2 |

| Manure management | CH4 | IPCC (2019) | 2 |

| NH3, N2O, NOx, N2 | EEA (2016) | 2 | |

| Particulate matter | EEA (2013) | 2 | |

| Pasture | CH4 | IPCC (2019) | 2 |

| NH3 | EEA (2016) | 2 | |

| N2O, NOx, N2 | IPCC (2019) | 1 | |

| Field and pasture/manure application | NH3 | EEA (2016) | 2 |

| N2O, NOx, N2 | IPCC (2019) | 1 | |

| Field and pasture/fertilizer application | NH3 | EEA (2016) | 2 |

| N2O, NOx, N2 | IPCC (2019) | 1 | |

| Field/lime application | CO2 | IPCC (2019) | 1 |

| Field/crop residues | N2O, N2 | IPCC (2019) | 1 |

| Field | Particulate matter | EEA (2016) | 1 |

| Field and pasture | NO3− | Richner (2014) | |

| P | Prasuhn (2006) | ||

| Indirect N2O | N2O | IPCC (2019) | 1 |

| BE | FR-IT | GE | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Base | FRG | SR | Base | FRG | SR | Base | FRG | SR | |

| Revenues (k EUR) | 307 | 318 | 418 | 113 | 113 | 121 | 792 | 800 | 812 |

| Beef (k EUR) | 201 | 201 | 285 | 69 | 69 | 79 | 125 | 125 | 142 |

| Crop (k EUR) | 53 | 64 | 98 | 260 | 267 | 263 | |||

| Subsidies (k EUR) | 52 | 52 | 35 | 44 | 44 | 42 | 56 | 56 | 56 |

| Variable costs (k EUR) | 104 | 106 | 157 | 22 | 21 | 18 | 270 | 269 | 273 |

| Buy cost (k EUR) | 55 | 54 | 111 | 11 | 10 | 8 | 143 | 144 | 148 |

| Feed (k EUR) | 22 | 20 | 33 | 5 | 5 | 2 | 33 | 34 | 37 |

| Profit (k EUR) | 169 | 178 | 217 | 71 | 74 | 85 | 391 | 401 | 407 |

| Prod HEP (kg) | 13,812 | 17,715 | 29,632 | 1926 | 1926 | 2141 | 76,081 | 79,267 | 76,916 |

| Animal (kg) | 6906 | 6906 | 15,217 | 1926 | 1926 | 2141 | 36,702 | 36,702 | 35,895 |

| Productivity (kg/ha) | 115 | 147 | 243 | 20 | 20 | 22 | 281 | 292 | 282 |

References

- McLeod, A.; Food and Agriculture Organization of the United Nations. World Livestock 2011: Livestock in Food Security; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011. [Google Scholar]

- Mottet, A.; de Haan, C.; Falcucci, A.; Tempio, G.; Opio, C.; Gerber, P. Livestock: On our plates or eating at our table? A new analysis of the feed/food debate. Glob. Food Secur. 2017, 14, 1–8. [Google Scholar] [CrossRef]

- Nijdam, D.; Rood, T.; Westhoek, H. The price of protein: Review of land use and carbon footprints from life cycle assessments of animal food products and their substitutes. Food Policy 2012, 37, 760–770. [Google Scholar] [CrossRef]

- Ertl, P.; Klocker, H.; Hörtenhuber, S.; Knaus, W.; Zollitsch, W. The net contribution of dairy production to human food supply: The case of Austrian dairy farms. Agric. Syst. 2015, 137, 119–125. [Google Scholar] [CrossRef]

- Laisse, S.; Baumont, R.; Dusart, L.; Gaudré, D.; Rouillé, B.; Benoit, M.; Veysset, P.; Rémond, D.; Peyraud, J.-L. L’efficience nette de conversion des aliments par les animaux d’élevage: Une nouvelle approche pour évaluer la contribution de l’élevage à l’alimentation humaine. INRAE Prod. Anim. 2018, 31, 269–288. [Google Scholar] [CrossRef]

- Mosnier, C.; Jarousse, A.; Madrange, P.; Balouzat, J.; Guillier, M.; Pirlo, G.; Mertens, A.; Oriordan, E.; Pahmeyer, C.; Hennart, S.; et al. Evaluation of the contribution of 16 European beef production systems to food security. Agric. Syst. 2021, 190, 103088. [Google Scholar] [CrossRef]

- Eurostat Data Browser: Bovine Population—Annual Data. Available online: https://ec.europa.eu/eurostat/databrowser/view/APRO_MT_LSCATL/default/table?lang=en (accessed on 2 February 2023).

- Meynard, J.-M. L’agroécologie, un nouveau rapport aux savoirs et à l’innovation. OCL Oilseeds Fats Crops Lipids 2017, 24, D303. [Google Scholar] [CrossRef] [Green Version]

- Melchior, A.; Legein, L.; Mertens, A.; Stilmant, D.; Balouzat, J.; Mosnier, C.; Dimon, P.; Echevarria, L.; Madrange, P.; Pineau, C.; et al. Involving stakeholders in the definition of pathways for more sustainable beef farming systems. In Proceedings of the IFSA 2022 Conference, Évora, Portugal, 10–14 April 2022; p. 15. [Google Scholar]

- Undersander, D.; Albert, B.; Cosgrove, D.; Johnson, D.; Peterson, P. Pastures for Profit: A Guide to Rotational Grazing (A3529); Cooperative Extensiton Publications, University of Wisconsin-Extension: Madison, WI, USA, 1993. [Google Scholar]

- Keane, M.G.; Moloney, A.P. Comparison of pasture and concentrate finishing of Holstein Friesian, Aberdeen Angus ×Holstein Friesian and Belgian Blue ×Holstein Friesian steers. Ir. J. Agric. Food Res. 2010, 49, 11–26. [Google Scholar]

- Sepchat, B.; Vazeille, K.; Troquier, C.; Prache, S.; Note, P. Evaluation des performances de jeunes bovins croisés finis à l’herbe dans deux systèmes d’élevage de montagne conduits en agriculture biologique. In Proceedings of the Rencontres Recherches Ruminants, Paris, France, 2–3 December 2020; p. 5. Available online: https://hal.inrae.fr/hal-03203322 (accessed on 29 November 2022).

- Pittarello, M.; Probo, M.; Perotti, E.; Lonati, M.; Lombardi, G.; Enri, S.R. Grazing Management Plans improve pasture selection by cattle and forage quality in sub-alpine and alpine grasslands. J. Mt. Sci. 2019, 16, 2126–2135. [Google Scholar] [CrossRef]

- Vazeille, K.; Veysset, P.; Note, P.; Sepchat, B.; Salle, G.; d’Hour, P.; Prache, S. Conception interdisciplinaire de systèmes d’élevage allaitant herbagers à faibles intrants: L’exemple de l’expérimentation système Salamix. In Proceedings of the Rencontres autour des Recherches sur les Ruminants (3R 2018), Paris, France, 5–6 December 2018; Volume 24, pp. 26–29. [Google Scholar]

- Kelly, D.N.; Conroy, S.B.; Murphy, C.P.; Sleator, R.D.; Berry, D.P. Feed and production efficiency of young crossbred beef cattle stratified on a terminal total merit index1. Transl. Anim. Sci. 2020, 4, txaa106. [Google Scholar] [CrossRef]

- Kearney, M.; O’Riordan, E.; McGee, M.; Breen, J.; Crosson, P. Farm-level modelling of bioeconomic, greenhouse gas emissions and feed-food performance of pasture-based dairy-beef systems. Agric. Syst. 2022, 203, 103530. [Google Scholar] [CrossRef]

- Kuhn, T.; Möhring, N.; Töpel, A.; Jakob, F.; Britz, W.; Bröring, S.; Pich, A.; Schwaneberg, U.; Rennings, M. Using a bio-economic farm model to evaluate the economic potential and pesticide load reduction of the greenRelease technology. Agric. Syst. 2022, 201, 103454. [Google Scholar] [CrossRef]

- Britz, W.; Ciaian, P.; Gocht, A.; Kanellopoulos, A.; Kremmydas, D.; Müller, M.; Petsakos, A.; Reidsma, P. A design for a generic and modular bio-economic farm model. Agric. Syst. 2021, 191, 103133. [Google Scholar] [CrossRef]

- Reidsma, P.; Janssen, S.; Jansen, J.; van Ittersum, M.K. On the development and use of farm models for policy impact assessment in the European Union—A review. Agric. Syst. 2018, 159, 111–125. [Google Scholar] [CrossRef]

- Veysset, P.; Lherm, M.; Bébin, D. Energy consumption, greenhouse gas emissions and economic performance assessments in French Charolais suckler cattle farms: Model-based analysis and forecasts. Agric. Syst. 2010, 103, 41–50. [Google Scholar] [CrossRef]

- Delmotte, S.; Couderc, V.; Mouret, J.-C.; Lopez-Ridaura, S.; Barbier, J.-M.; Hossard, L. From stakeholders narratives to modelling plausible future agricultural systems. Integrated assessment of scenarios for Camargue, Southern France. Eur. J. Agron. 2017, 82, 292–307. [Google Scholar] [CrossRef]

- Pahmeyer, C.; Britz, W. Economic opportunities of using crossbreeding and sexing in Holstein dairy herds. J. Dairy Sci. 2020, 103, 8218–8230. [Google Scholar] [CrossRef]

- Kokemohr, L.; Escobar, N.; Mertens, A.; Mosnier, C.; Pirlo, G.; Veysset, P.; Kuhn, T. Life Cycle Sustainability Assessment of European beef production systems based on a farm-level optimization model. J. Clean. Prod. 2022, 379, 134552. [Google Scholar] [CrossRef]

- Oates, L.G.; Undersander, D.J.; Gratton, C.; Bell, M.M.; Jackson, R.D. Management-Intensive Rotational Grazing Enhances Forage Production and Quality of Subhumid Cool-Season Pastures. Crop Sci. 2011, 51, 892–901. [Google Scholar] [CrossRef] [Green Version]

- Paine, L.K.; Undersander, D.; Casler, M.D. Pasture Growth, Production, and Quality Under Rotational and Continuous Grazing Management. J. Prod. Agric. 1999, 12, 569–577. [Google Scholar] [CrossRef]

- Keane, M.G. A comparison of finishing strategies to fixed slaughter weights for Holstein Friesian and Belgian Blue × Holstein Friesian steers. Ir. J. Agric. Food Res. 2010, 49, 41–54. [Google Scholar]

- Wallonie Agriculture SPW, ‘Prix du Marché des Produits Agricoles. Available online: https://agriculture.wallonie.be/prix-du-marche-des-produits-agricoles (accessed on 3 February 2023).

- Chambaz, A.; Scheeder, M.; Kreuzer, M.; Dufey, P.-A. Meat quality of Angus, Simmental, Charolais and Limousin steers compared at the same intramuscular fat content. Meat Sci. 2003, 63, 491–500. [Google Scholar] [CrossRef] [PubMed]

- Kuhn, T.; Enders, A.; Gaiser, T.; Schäfer, D.; Srivastava, A.K.; Britz, W. Coupling crop and bio-economic farm modelling to evaluate the revised fertilization regulations in Germany. Agric. Syst. 2020, 177, 102687. [Google Scholar] [CrossRef]

- Britz, W.; Lengers, B.; Kuhn, T.; Schäfer, D. A Highly Detailed Template Model for Dynamic Optimization of Farms; Model Documentation; Institute for Food and Resource Economics, University of Bonn: Bonn, Germany, 2014. [Google Scholar]

- Bayerische Landesanstalt für Landwirtschaft. Zifo2–Zielwert Futteroptimierung; Bayerische Landesanstalt für Landwirtschaft: Poing, Germany, 2016; Available online: http://www.zifo-bayern.de/ (accessed on 2 February 2023).

- Bayerische Landesanstalt für Landwirtschaft. Gruber Tabelle zur Fütterung in der Rindermast, 24th ed.; Bayerische Landesanstalt für Landwirtschaft: Poing, Germany, 2020. [Google Scholar]

- Seidel, C.; Britz, W. Estimating a Dual Value Function as a Meta-Model of a Detailed Dynamic Mathematical Programming Model. Bio-Based Appl. Econ. 2020, 8, 75–99. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Kuratorium für Technik und Bauwesen in der Landwirtschaft. Betriebsplanung Landwirtschaft 2018/19: Daten für die Betriebsplanung in der Landwirtschaft, 26. Auflage; Kuratorium für Technik und Bauwesen in der Landwirtschaft: Darmstadt, Germany, 2018; Available online: https://www.ktbl.de/fileadmin/produkte/leseprobe/19524excerpt.pdf (accessed on 2 February 2023).

- Wilkinson, J.M. Re-defining efficiency of feed use by livestock. Animal 2011, 5, 1014–1022. [Google Scholar] [CrossRef] [Green Version]

- Diakité, Z.; Mosnier, C.; Baumont, R.; Brunschwig, G. Biotechnical and economic performance of mixed dairy cow-suckler cattle herd systems in mountain areas: Exploring the impact of herd proportions using the Orfee model. Livest. Sci. 2019, 229, 105–113. [Google Scholar] [CrossRef]

- Stassart, P.M.; Jamar, D. Steak up to the horns! Geojournal 2008, 73, 31–44. [Google Scholar] [CrossRef]

- De Vries, M.; van Middelaar, C.; de Boer, I. Comparing environmental impacts of beef production systems: A review of life cycle assessments. Livest. Sci. 2015, 178, 279–288. [Google Scholar] [CrossRef]

- Keane, M.; Drennan, M. A comparison of Friesian, Aberdeen Angus×Friesian and Belgian Blue×Friesian steers finished at pasture or indoors. Livest. Sci. 2008, 115, 268–278. [Google Scholar] [CrossRef]

- Balouzat, J.; Vaudaux, A.; Madrange, P. ‘Description of Beef Production’, Delivrable of the Sustainbeef Project 2.1. 2020. Available online: https://www6.inrae.fr/sustainbeef/content/download/3615/35093/version/1/file/SustainBeef+-+Delivrable+2.1.pdf (accessed on 2 February 2023).

| System | BE | FR-IT | GE | ||

|---|---|---|---|---|---|

| Farm a | BE-B | BE-F | FR-IT-B | FR-IT-F | GE |

| Country | Belgium | France | Italy | Germany | |

| Location | Wallonia | Massif Central | Veneto | North-Rhine-Westphalia | |

| No. males sold per year b | 78 | 120 | 38 | 227 | 56 |

| No. of cows | 155 | - | 79 | - | 130 |

| Beef output (estimated carcass weight) | 40,379 | 57,960 | 16,517 | 64,864 | 36,113 |

| Breed | Belgian Blue | Charolais and Salers | Holstein | ||

| Arable land | 54 ha | - | - | 33 ha | 198 ha |

| Grassland | 64 ha | - | 96 ha | - | 27 ha |

| Other activities | Cash-crop production | - | - | - | Dairy and cash-crop productions |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mertens, A.; Kokemohr, L.; Braun, E.; Legein, L.; Mosnier, C.; Pirlo, G.; Veysset, P.; Hennart, S.; Mathot, M.; Stilmant, D. Exploring Rotational Grazing and Crossbreeding as Options for Beef Production to Reduce GHG Emissions and Feed-Food Competition through Farm-Level Bio-Economic Modeling. Animals 2023, 13, 1020. https://doi.org/10.3390/ani13061020

Mertens A, Kokemohr L, Braun E, Legein L, Mosnier C, Pirlo G, Veysset P, Hennart S, Mathot M, Stilmant D. Exploring Rotational Grazing and Crossbreeding as Options for Beef Production to Reduce GHG Emissions and Feed-Food Competition through Farm-Level Bio-Economic Modeling. Animals. 2023; 13(6):1020. https://doi.org/10.3390/ani13061020

Chicago/Turabian StyleMertens, Alexandre, Lennart Kokemohr, Emilie Braun, Louise Legein, Claire Mosnier, Giacomo Pirlo, Patrick Veysset, Sylvain Hennart, Michaël Mathot, and Didier Stilmant. 2023. "Exploring Rotational Grazing and Crossbreeding as Options for Beef Production to Reduce GHG Emissions and Feed-Food Competition through Farm-Level Bio-Economic Modeling" Animals 13, no. 6: 1020. https://doi.org/10.3390/ani13061020

APA StyleMertens, A., Kokemohr, L., Braun, E., Legein, L., Mosnier, C., Pirlo, G., Veysset, P., Hennart, S., Mathot, M., & Stilmant, D. (2023). Exploring Rotational Grazing and Crossbreeding as Options for Beef Production to Reduce GHG Emissions and Feed-Food Competition through Farm-Level Bio-Economic Modeling. Animals, 13(6), 1020. https://doi.org/10.3390/ani13061020