Influence of Degree of Saturation (DOS) on Dynamic Behavior of Unbound Granular Materials

Abstract

:1. Introduction

1.1. Moisture-Damage Mechanisms in Unbound Granular Pavement Materials (UGMs)

1.2. Optimum Moisture Content and the Degree of Saturation (DOS)

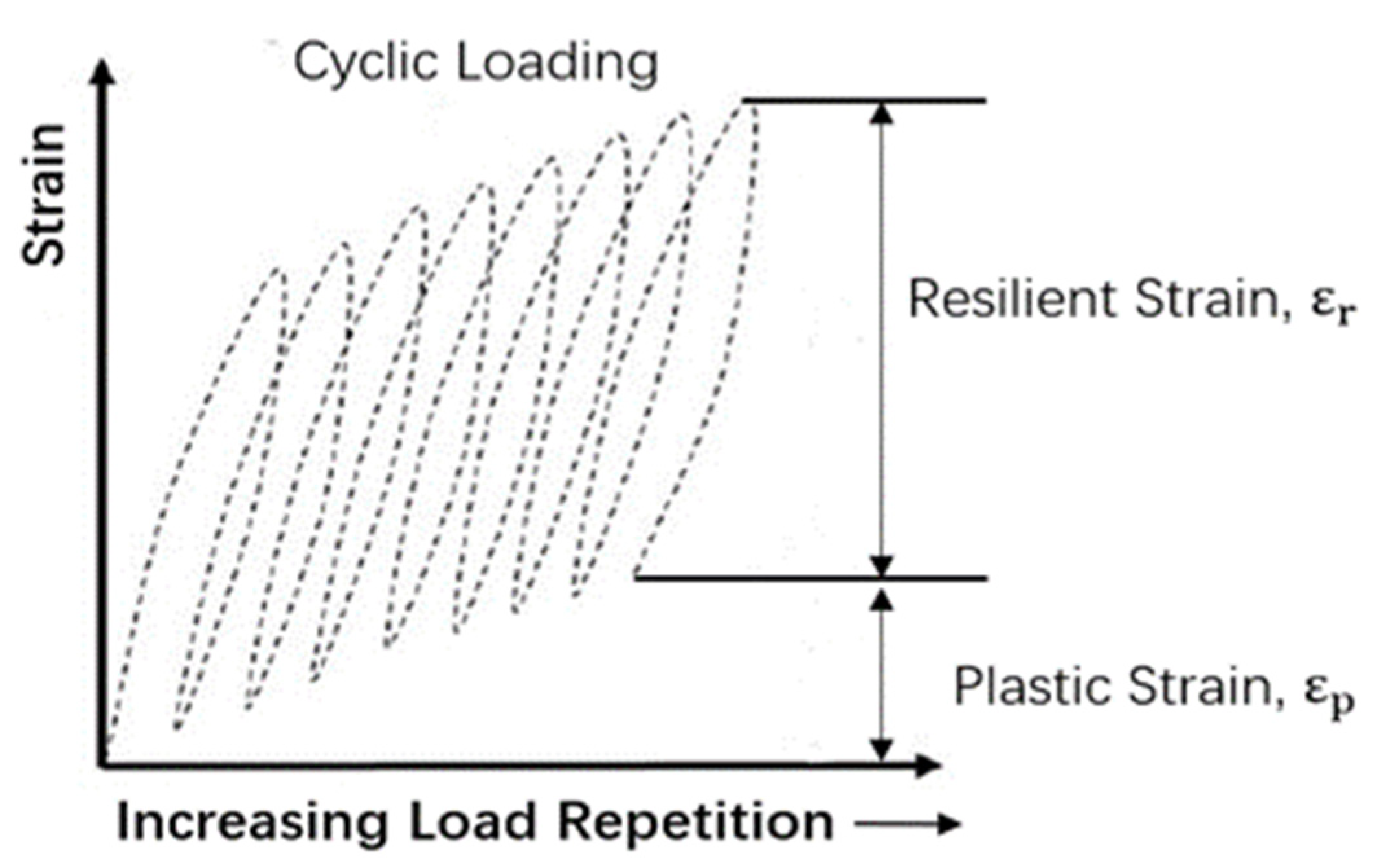

1.3. Traffic Loading Response and Repeated Load Triaxial Test

1.4. Effect of DOS on the Dynamic Response of UGMs

1.5. Identification of Problems and Objectives

2. Experimental Investigation

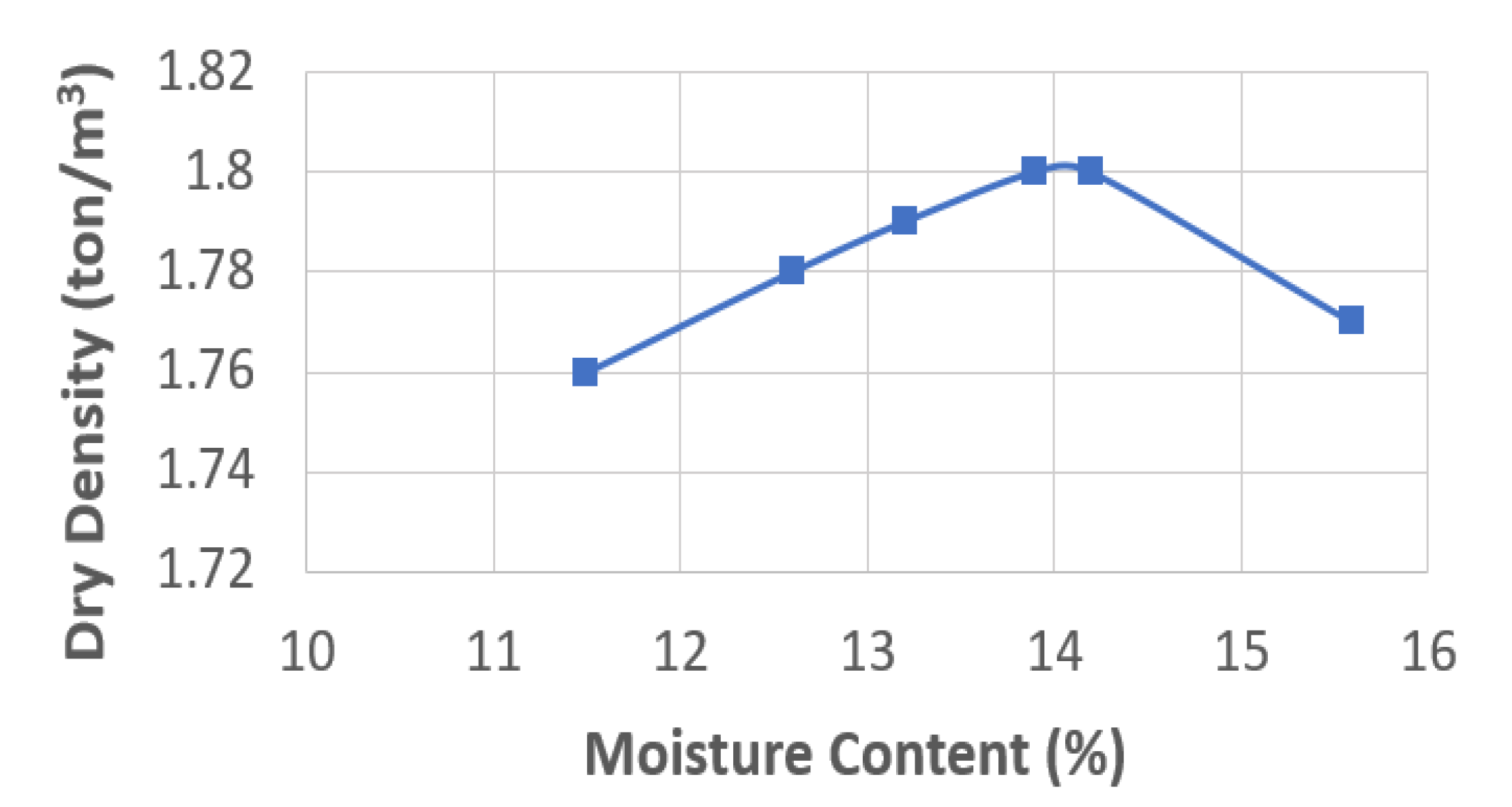

2.1. Material and Specimen Preparation

2.2. Testing Equipment

2.3. Testing Sequences

3. Results and Discussion

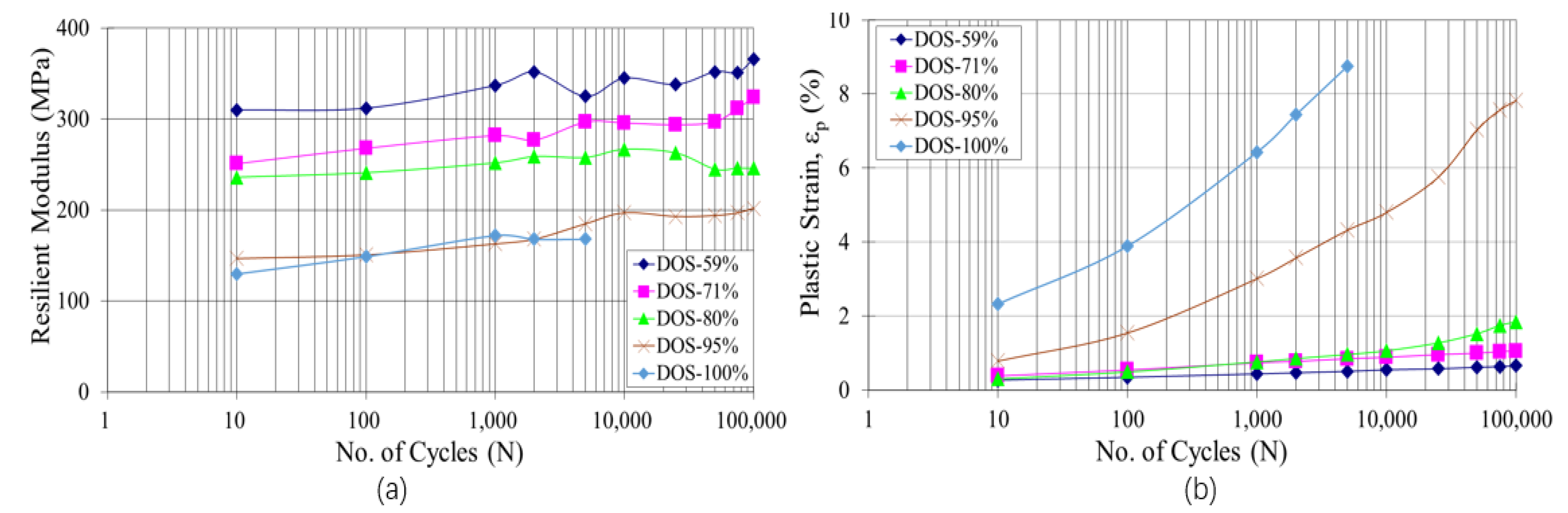

3.1. RLT Test Results with Different Applied Deviator Stresses

3.2. The Comparison between Different Deviator Stresses at Similar DOS

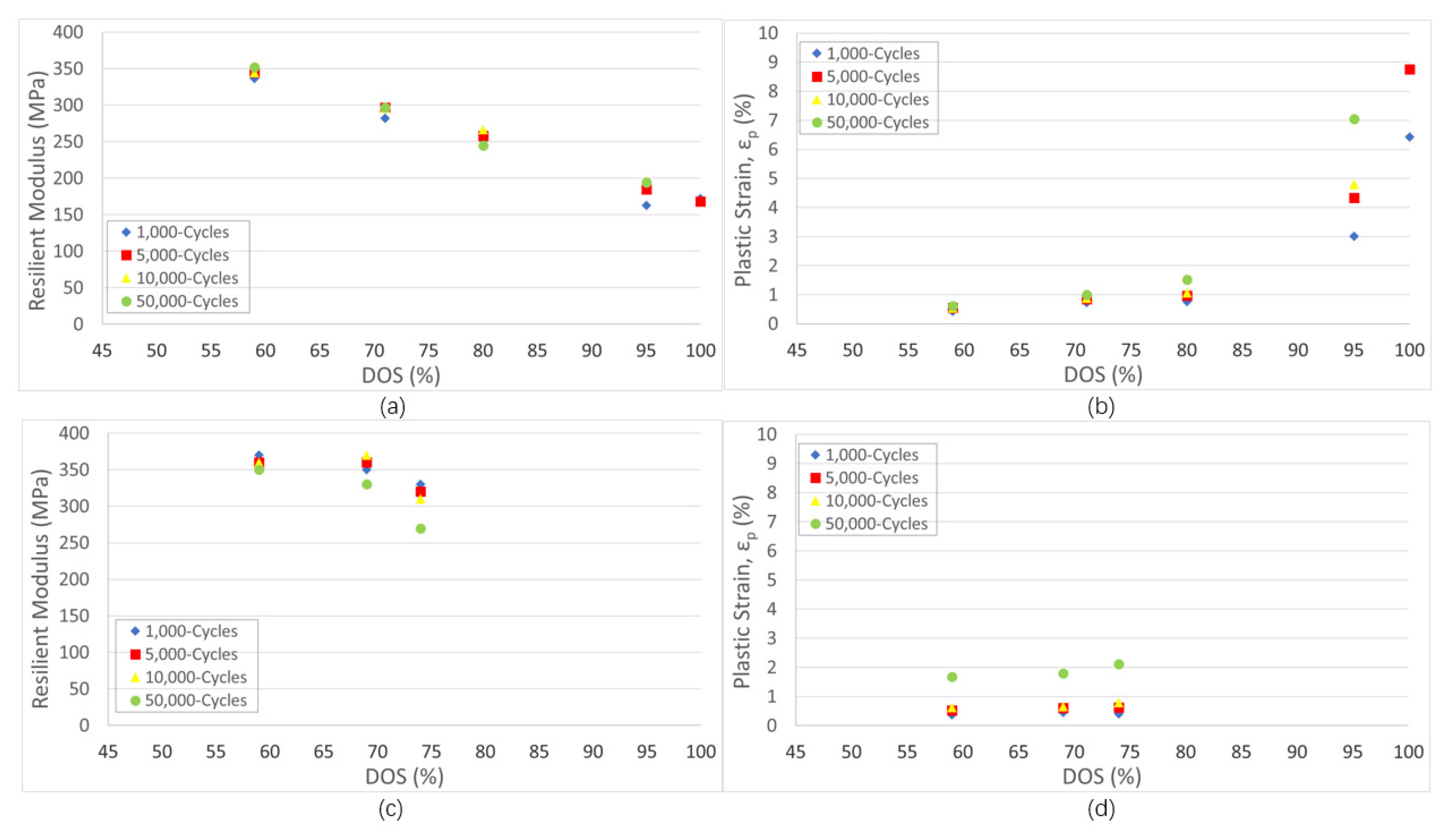

3.3. Resilient Modulus and Plastic Strain with Certain Number of Cycles under Varied DOS

4. Conclusions

- (i)

- The resilient modulus of tested UGMs that had both 425 and 625 kPa deviator stresses applied illustrated a decreasing trend in the increase in the DOS. After that, the accumulated plastic strain of the tested aggregates of both the 425 and 625 kPa deviator stresses applied presented an increasing trend with the increase in the DOS. This type of behavior was reported previously by Arulrajah et al. [47,48] and Soliman and Shalaby [50]. With regard to the sensitivity to the moisture of the tested UGMs, Arulrajah et al. [47,48] claimed that there were higher limits of plastic strain and lower limits of resilient modulus, especially at higher DOS. This phenomenon was also observed in this research. The resilient modulus declined and the plastic strain at certain loading cycles increased with the rise in DOS at an increasing rate. When the DOS was over 75%, the plastic strain of the tested subbase UGMs showed a particularly higher sensitivity to moisture.

- (ii)

- With the increase in the applied deviator stress, the resilient modulus of the tested aggregates under around 60% and 70% degrees of saturation presented an increasing tendency. The increasing trend of resilient modulus with a larger deviator stress of UGMs was studied by Craciun [19] and Arulrajah et al. [49].

- (iii)

- With the increase in the applied vertical cyclic stress, the accumulated plastic strain of the aggregates under 60% and 70% degrees of saturation increased significantly after a large number of cycles of 20,000.

- (iv)

- The resilient modulus of the specimens, which were applied a larger vertical cyclic load, reduced more distinctly after the number of cycles increased to 10,000.

- (v)

- The resilient modulus of the tested aggregates applied different cyclic deviator stresses of 425 kPa and 625 kPa approximately linearly decreased as the DOS increased with a certain number of cycles up to 50,000. For a certain number of cycles, the accumulated plastic strain of the tested aggregates increased approximately linearly as the DOS increased from 59% to 80%. After that, the plastic strain increased significantly as the sample tended to be fully saturated. At a higher DOS level, the resistance to the plastic strain of tested UGMs was found to decline beyond the accepted limit. The results of the repeated load triaxial tests could indicate that the tested subbase UGMs at a DOS of around 75% is a feasible subbase material when the pavements encounter extreme moisture infiltration. The results of the study by Atherulrajah et al. [48,49] for UGMs showed a similar picture. They found that moisture contents in the range of 65–90% were the optimum moisture content of pavement subbase UGMs.

5. Further Research

Author Contributions

Funding

Conflicts of Interest

References

- Australian Standard, Soil Strength and Consolidation Tests: Determination of the Resilient Modulus and Permanent Deformation of Granular Unbound Pavement Materials, 1289.6.8.1. Standards Australia, Sydney, Australia. 1995. Available online: https://trid.trb.org/view/1203019 (accessed on 14 February 2021).

- Austroads, Austroads Repeated Load Triaxial Test Method: Determination of Permanent Deformation and Resilient Modulus Characteristics of Unbound Granular Materials Under Drained Conditions, AG-PT/T053. Austroads Publication. 2007. Available online: https://austroads.com.au/publications/pavement/agpt-t053-07 (accessed on 14 February 2021).

- Huang, Y. Pavement Analysis and Design; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- USGS. Mineral Yearbook; United State Geological Services: New York, NY, USA, 2000.

- Nguyen, B. Resilient Behavior of Fine-Grained and Granular Materials for the Design of Flexible Pavements. Ph.D. thesis, RMIT University, Melbourne, Australia, 2016. [Google Scholar]

- Werkmeister, S.; Dawson, A.; Wellner, F. Pavement design model for unbound granular materials. J. Transp. Eng. 2004, 130, 665–674. [Google Scholar] [CrossRef]

- Cogan, J.; Gratchev, I.; Wang, G. Rainfall-induced shallow landslides caused by ex-Tropical Cyclone Debbie, 31st March 2017. Landslides 2018, 15, 1215–1221. [Google Scholar] [CrossRef]

- Podlaha, A.; Bowen, S.; Darbinyan, C.; Lörinc, M. Global Catastrophe Recap-April 2017 (PDF). Aon Benfield Analytics. 2017. Available online: http://thoughtleadership.aonbenfield.com/Documents/201707-if-1h-global-recap.pdf (accessed on 14 February 2021).

- Bureau of Meteorology. Tropical Cyclones in Queensland. Available online: http://www.bom.gov.au/cyclone/about/eastern.shtml#history (accessed on 20 November 2017).

- Sultana, M.; Chai, G.; Martin, T.; Chowdhury, S. A study on the flood affected flexible pavements in Australia. In Proceedings of the 9th International Conference on Road and Airfield Pavement Technology, Dalian, China, 9–13 August 2015; pp. 9–13. [Google Scholar]

- Sultana, M.; Chowdhury, S.; Chai, G.; Martin, T. Modelling rapid deterioration of flooded pavements. Road Transp. Res. A J. Aust. N. Z. Res. Pract. 2016, 25, 3–14. [Google Scholar]

- Sultana, M.; Chai, G.; Chowdhury, S.; Martin, T.; Anissimov, Y.; Rahman, A. Rutting and Roughness of Flood-Affected Pavements: Literature Review and Deterioration Models. J. Infrastruct. Sys. 2018, 24, 04018006. [Google Scholar] [CrossRef]

- Ahmed, A.; Hossain, M.; Pandey, P.; Sapkota, A.; Thian, B. Deformation Modeling of Flexible Pavement in Expansive Subgrade in Texas. Geosciences 2019, 9, 446. [Google Scholar] [CrossRef] [Green Version]

- Hedayati, M. Rainfall Induced Distress in Low Volume Pavements. Ph.D. Thesis, The University of Texas at Arlington, Arlington, TX, USA, 2014. [Google Scholar]

- AASHTO. Guide for Design of Pavement Structures. AASHTO. 1993. Available online: https://habib00ugm.files.wordpress.com/2010/05/aashto1993.pdf (accessed on 14 February 2021).

- Austroads, Predicting Structural Deterioration of Pavements at a Network Level–Interim Models, Sydney, NSW, Australia. 2010. Available online: https://austroads.com.au/publications/asset-management/ap-t159-10 (accessed on 14 February 2021).

- Papagiannakis, A.T.; Masad, E.A. Pavement Design and Material; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Haider, S.; Masud, M. Effect of moisture infiltration on flexible pavement performance using the AASHTOWare Pavement-ME. Advances in Materials and Pavement Prediction. In Proceedings of the International Conference on Advances in Materials and Pavement Performance Prediction (AM3P 2018), Doha, Qatar, 16–18 April 2018. [Google Scholar]

- Craciun, O. Matric Suction Response of Unbound Granular Base Materials Subject to Cyclic Loading. Ph.D. Thesis, University of New South Wales, Sydney, Australia, 2009. [Google Scholar]

- Rahman, M.; Erlingsson, S. Influence of moisture on Resilient Deformation behaviour of Unbound Granular Materials. In Proceedings of the 12th International Conference on Asphalt Pavements, ISAP 2014, Raleigh, NC, USA, 1–5 June 2014. [Google Scholar]

- Austroads, Guide to Pavement Technology Part 4A: Granular Base and Subbase Materials, AGPT04A-08. Austroads Publication. 2008. Available online: https://austroads.com.au/publications/pavement/agpt04a (accessed on 14 February 2021).

- Park, S.; Lytton, R.; Benson, F. Characterizing pavement subgrades in Texas. Env. Eng. Geosci. 1999, 3, 353–357. [Google Scholar]

- Transport and Main Roads, QLD, Test Method Q146, Degree of Saturation of Soils and Crushed Rock, Materials Testing Manual, Edition 4, Amendment 4. 2017. Available online: https://www.ipweaq.com/MRTS05%20Mod%20-%2031%20October%202017%20final%20version%20style.pdf (accessed on 14 February 2021).

- Brown, S. Soil mechanics in pavement engineering. Géotechnique 1996, 46, 383–426. [Google Scholar] [CrossRef] [Green Version]

- Mamlouk, M.; Zaniewski, J.; He, W. Analysis and design optimization of flexible pavement. J. Transp. Eng. 2000, 126, 161–167. [Google Scholar] [CrossRef]

- Kerkhoven, R.; Dormon, G. Some Considerations on the California Bearing Ratio Method for the Design of Flexible Pavements. Shell Petroleum Company. 1953. Available online: https://www.worldcat.org/title/some-considerations-on-the-california-bearing-ratio-method-for-the-design-of-flexible-pavements/oclc/475100213?referer=di&ht=edition (accessed on 14 February 2021).

- Saal, R.; Pell, P. Fatigue of bituminous road mixes. Colloid Polym. Sci. 1960, 171, 61–71. [Google Scholar] [CrossRef]

- Austroads. Guide to Pavement Technology Part 2: Pavement Structural Design. Austroads Publication. 2008. Available online: https://austroads.com.au/publications/pavement/agpt02 (accessed on 14 February 2021).

- Berthelot, C.; Podborochynski, D.; Marjerison, B. Saskatchewan field case study of triaxial frequency sweep characterization to predict failure of a granular base across increasing fines content and traffic speed applications. J. Transp. Eng. 2009, 135, 907–914. [Google Scholar]

- Sorsa, A.; Senadheera, S.; Birru, Y. Engineering Characterization of Subgrade Soils of Jimma Town, Ethiopia, for Roadway Design. Geosciences 2020, 10, 94. [Google Scholar]

- Lekarp, F.; Isacsson, U.; Dawson, A. State of the art. I: Resilient response of unbound aggregates. J. Transp. Eng. 2000, 126, 66–75. [Google Scholar] [CrossRef] [Green Version]

- Lekarp, F.; Isacsson, U.; Dawson, A. State of the art. II: Permanent strain response of unbound aggregates. J. Trans. Eng. 2000, 126, 76–83. [Google Scholar] [CrossRef] [Green Version]

- Castelli, F.; Cavallaro, A.; Grasso, S.; Lentini, V. Undrained Cyclic Laboratory Behavior of Sandy Soils. Geosciences 2019, 9, 512. [Google Scholar]

- Huang, H.; Luo, J.; Moaveni, M. Advanced Analytical Tool for Flexible Pavement Design and Evaluation. Airfield and Highway Pavements 2019: Design, Construction, Condition Evaluation, and Management of Pavements; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 61–71. [Google Scholar]

- Kucharczyk, K.; Głuchowski, A.; Miturski, M.; Sas, W. Influence of Load Frequency on Cohesive Soil Respond. Geosciences 2018, 8, 468. [Google Scholar] [CrossRef] [Green Version]

- Alnedawi, A.; Nepal, K.; Al-Ameri, R. Mechanistic behavior of open and dense graded unbound granular materials under traffic loads. Int. J. Geomate. 2018, 14, 124–129. [Google Scholar] [CrossRef]

- AASHTO. Guide T307: Standard Test Method for Determining the Resilient Modulus of Soil and Aggregate Materials. AASHTO. 2007. Available online: https://global.ihs.com/doc_detail.cfm?document_name=AASHTO%20T%20307&item_s_key=00489204 (accessed on 14 February 2021).

- Austroads. Pavement Design-A Guide to the Structural Design of Road Pavements; Austroads Publication: Sydney, Australia, 2012. [Google Scholar]

- Seed, H.; Chan, C.; Lee, C. Resilience characteristics of subgrade soils and their relation to fatigue failures in asphalt pavements. In Proceedings of the International Conference on the Structural Design of Asphalt Pavements, Michigan, MI, USA, 20–24 August 1962. [Google Scholar]

- Rada, G.; Witczak, M. Comprehensive evaluation of laboratory resilient moduli results for granular material. Transp. Resear. Rec. 1981, 810, 23–33. [Google Scholar]

- Wang, M.; Kong, L.; Zhao, C. Dynamic characteristics of lime-treated expansive soil under cyclic loading. J. Rock Mech. Geotech. Eng. 2012, 4, 352–359. [Google Scholar]

- Naji, K. Resilient modulus-moisture content relationships for pavement engineering applications. Int. J. Pavement Eng. 2018, 19, 651–660. [Google Scholar] [CrossRef]

- Heydinger, A. Evaluation of seasonal effects on subgrade soils. Transp. Resear. Rec. 2003, 1821, 47–55. [Google Scholar] [CrossRef]

- Uzan, J. Characterization of granular material. Transp. Resear. Rec. 1985, 1022, 52–59. [Google Scholar]

- Theyse, H. Stiffness, Strength, and Performance of Unbound Aggregate Material: Application of South African HVS and Laboratory Results to California Flexible Pavements; Report produced under the auspices of the California Partnered Pavement Research Program for the California Department of Transportation; University of California: Berkeley, CA, USA, 2002. [Google Scholar]

- Guo, L.; Wang, J.; Cai, Y. Undrained deformation behavior of saturated soft clay under long-term cyclic loading. Soil Dyn. Earthq. Eng. 2013, 50, 28–37. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Aatheesan, T.; Bo, M. Geotechnical properties of recycled crushed brick in pavement applications. J. Mater. Civ. Eng. 2011, 23, 1444–1452. [Google Scholar]

- Arulrajah, A.; Piratheepan, J.; Ali, M.; Bo, M. Geotechnical properties of recycled concrete aggregate in pavement sub-base applications. Geotech. Test. J. 2012, 35, 743–751. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.; Bo, M. Resilient moduli response of recycled construction and demolition materials in pavement subbase applications. J. Mater. Civ. Eng. 2013, 25, 1920–1928. [Google Scholar] [CrossRef]

- Soliman, H.; Shalaby, A. Permanent deformation behavior of unbound granular base materials with varying moisture and fines content. Transport. Geotech. 2015, 4, 1–12. [Google Scholar] [CrossRef]

- Zhalehjoo, N.; Tolooiyan, A.; Mackay, R.; Bodin, D. The effect of instrumentation on the determination of the resilient modulus of unbound granular materials using advanced repeated load triaxial testing. Transport. Geotech. 2018, 14, 190–201. [Google Scholar] [CrossRef]

- Cerni, G.; Corradini, A.; Pasquini, E.; Cardone, F. Resilient behaviour of unbound granular materials through repeated load triaxial test: Influence of the conditioning stress. Road Mater. Pavement Des. 2015, 16, 70–88. [Google Scholar]

- Austroads. Guide to Pavement Technology Part 2: Pavement Structural Design, AGPT02-17. Austroads Publication. 2017. Available online: https://trid.trb.org/view/1498339 (accessed on 14 February 2021).

- Austroads. Long-Term Pavement Performance Study-Final Report, AP_T342-19. Austroads Publication. 2019. Available online: https://austroads.com.au/publications/asset-management/ap-t342-19 (accessed on 14 February 2021).

- Alonso-Marroquin, F.; Herrmann, H.J. Ratcheting of granular materials. Phys. Rev. Lett. 2004, 92, 054301. [Google Scholar] [CrossRef] [Green Version]

- García-Rojo, R.; Herrmann, H.J. Shakedown of unbound granular material. Granul. Matt. 2005, 7, 109–118. [Google Scholar] [CrossRef] [Green Version]

- Sun, Q.D.; Indraratna, B.; Nimbalkar, S. Effect of cyclic loading frequency on the permanent deformation and degradation of railway ballast. Géotechnique 2014, 64, 746–751. [Google Scholar] [CrossRef] [Green Version]

| σ3 (kPa) | σd (kPa) | Target DOS (%) | Treat Type | Actual DOS (%) |

|---|---|---|---|---|

| 125 | 425 | 60%–100% | OMC | 59% |

| Soaking | 71% | |||

| 80% | ||||

| 95% | ||||

| 100% | ||||

| 125 | 625 | 60%–75% | OMC | 59% |

| Soaking | 69% | |||

| 74% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Oh, E.; Ong, D.E.-L. Influence of Degree of Saturation (DOS) on Dynamic Behavior of Unbound Granular Materials. Geosciences 2021, 11, 89. https://doi.org/10.3390/geosciences11020089

Sun J, Oh E, Ong DE-L. Influence of Degree of Saturation (DOS) on Dynamic Behavior of Unbound Granular Materials. Geosciences. 2021; 11(2):89. https://doi.org/10.3390/geosciences11020089

Chicago/Turabian StyleSun, Junyu, Erwin Oh, and Dominic Ek-Leong Ong. 2021. "Influence of Degree of Saturation (DOS) on Dynamic Behavior of Unbound Granular Materials" Geosciences 11, no. 2: 89. https://doi.org/10.3390/geosciences11020089

APA StyleSun, J., Oh, E., & Ong, D. E. -L. (2021). Influence of Degree of Saturation (DOS) on Dynamic Behavior of Unbound Granular Materials. Geosciences, 11(2), 89. https://doi.org/10.3390/geosciences11020089