Advancements in Soft Soil Stabilization by Employing Novel Materials through Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methodology

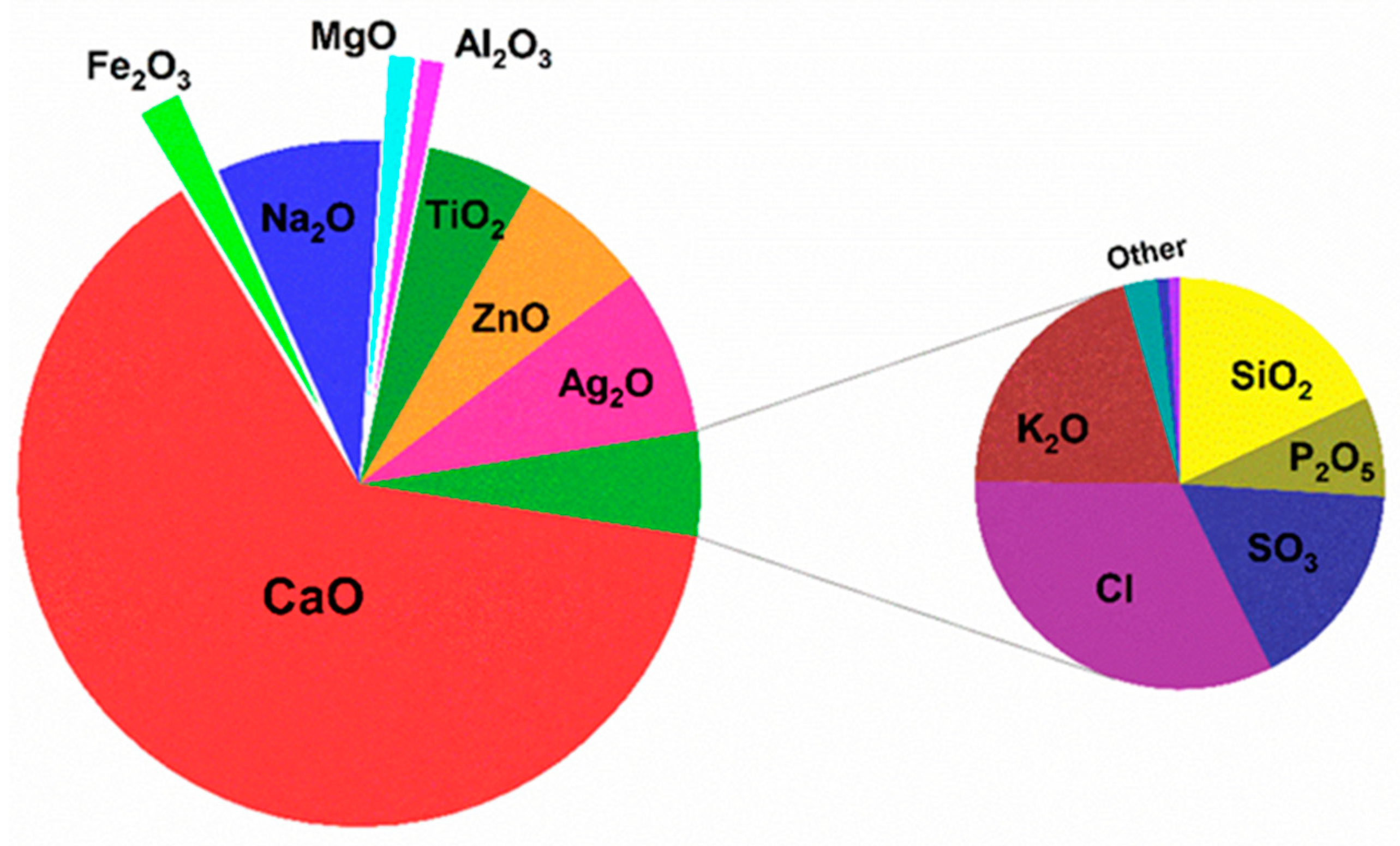

2.1. Materials

2.2. Sample Preparation and Experimental Procedure

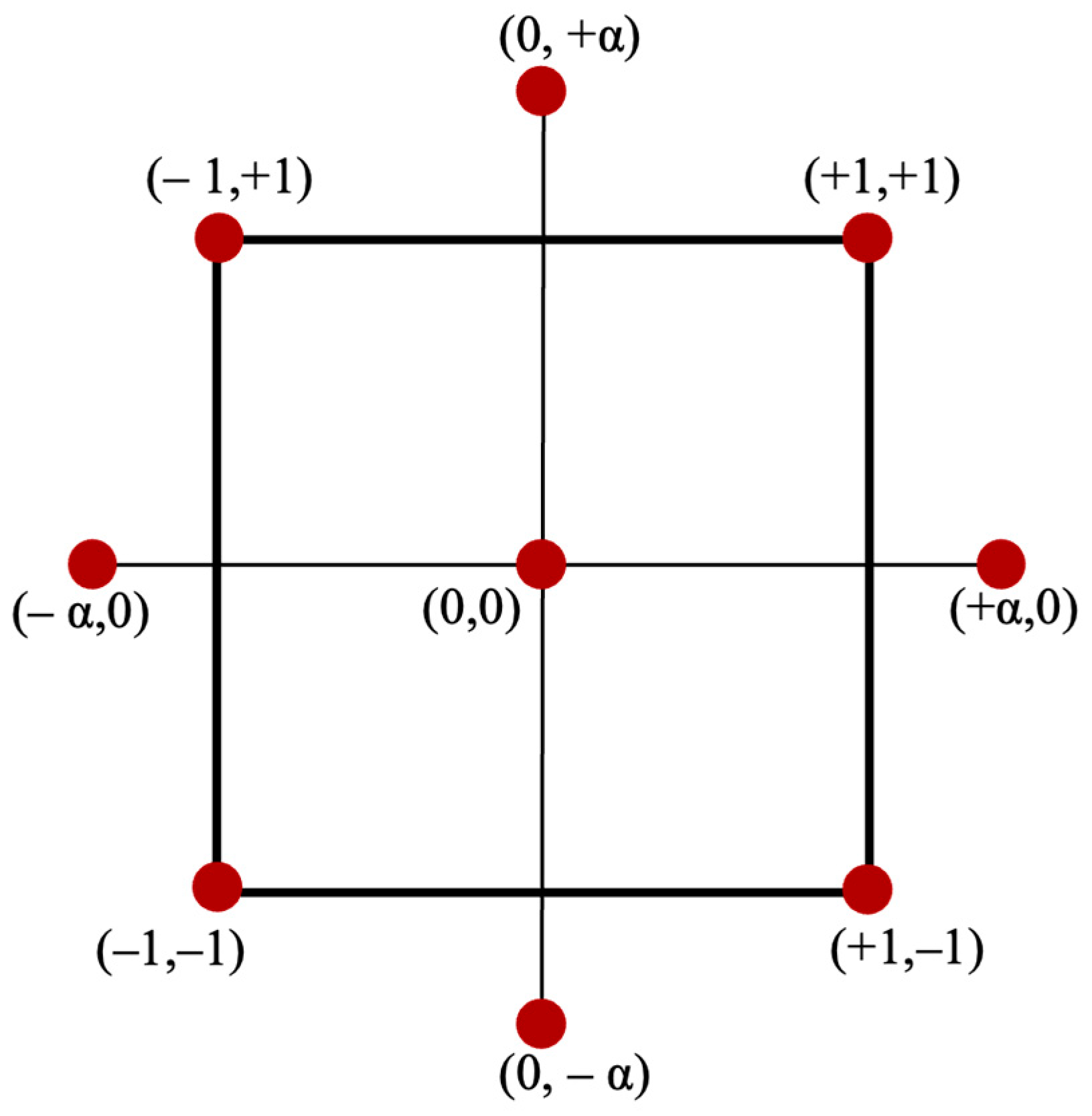

2.3. Response Surface Methodology (RSM)

2.3.1. General

2.3.2. Development of Response Model

3. Results and Discussion

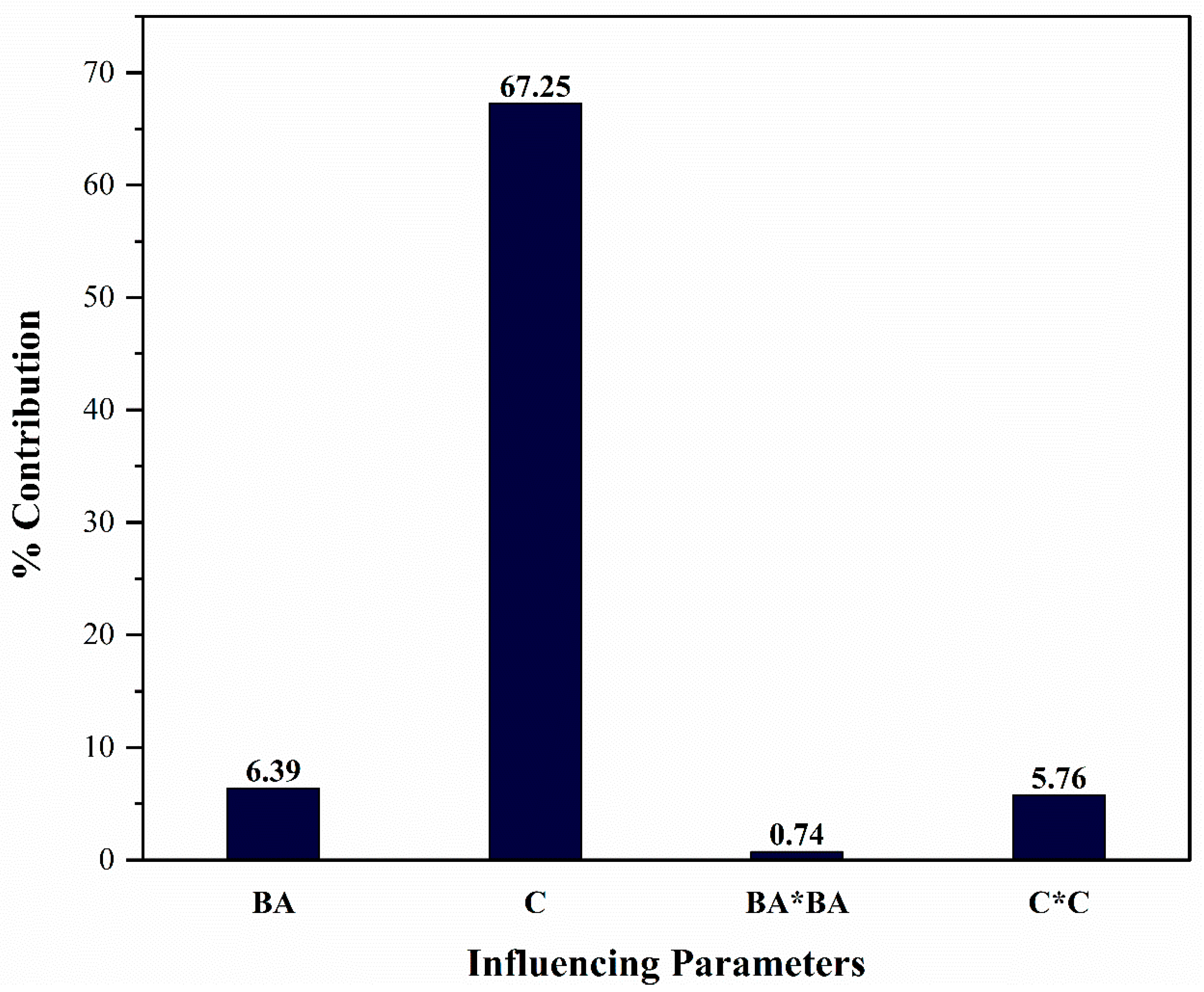

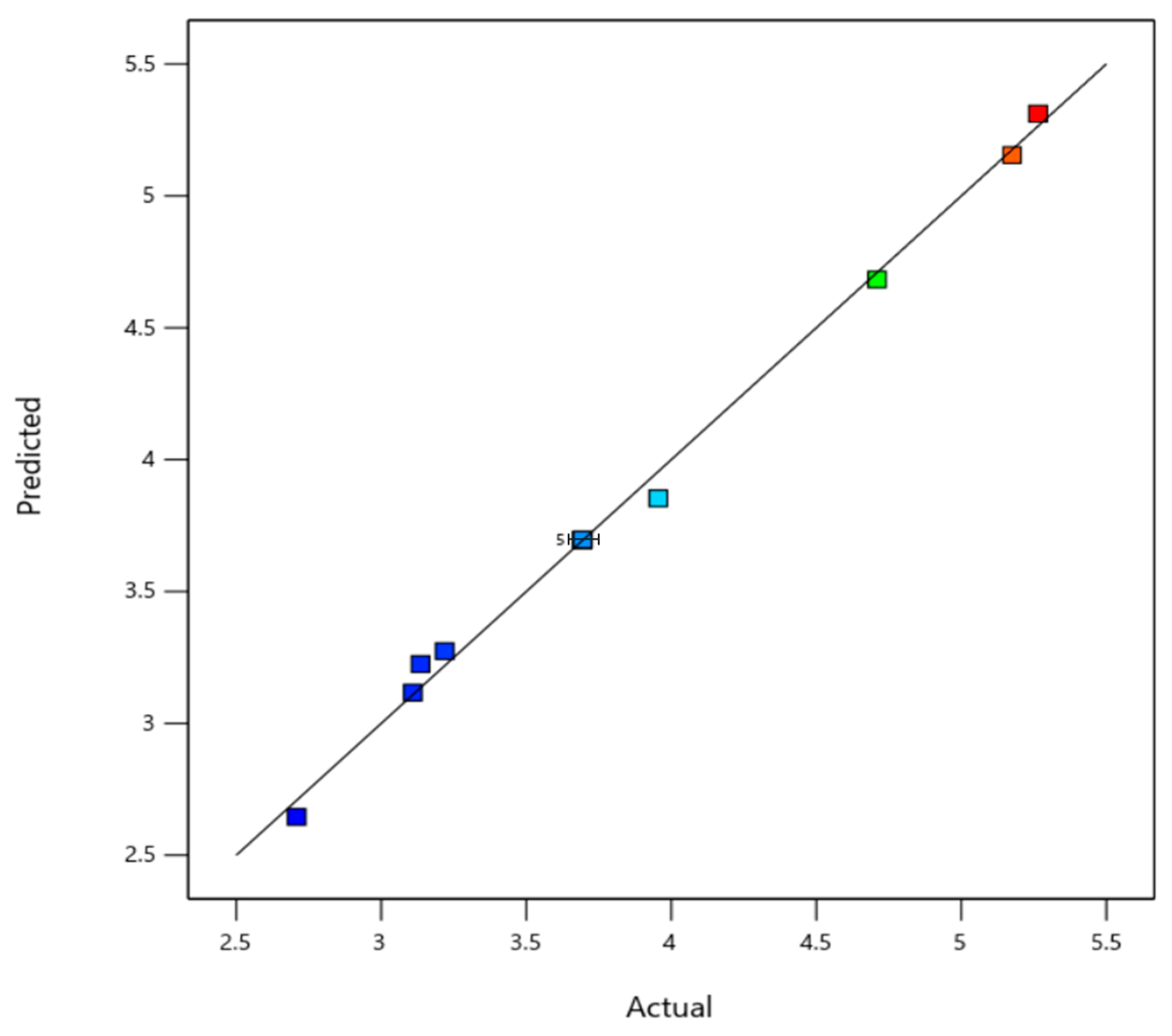

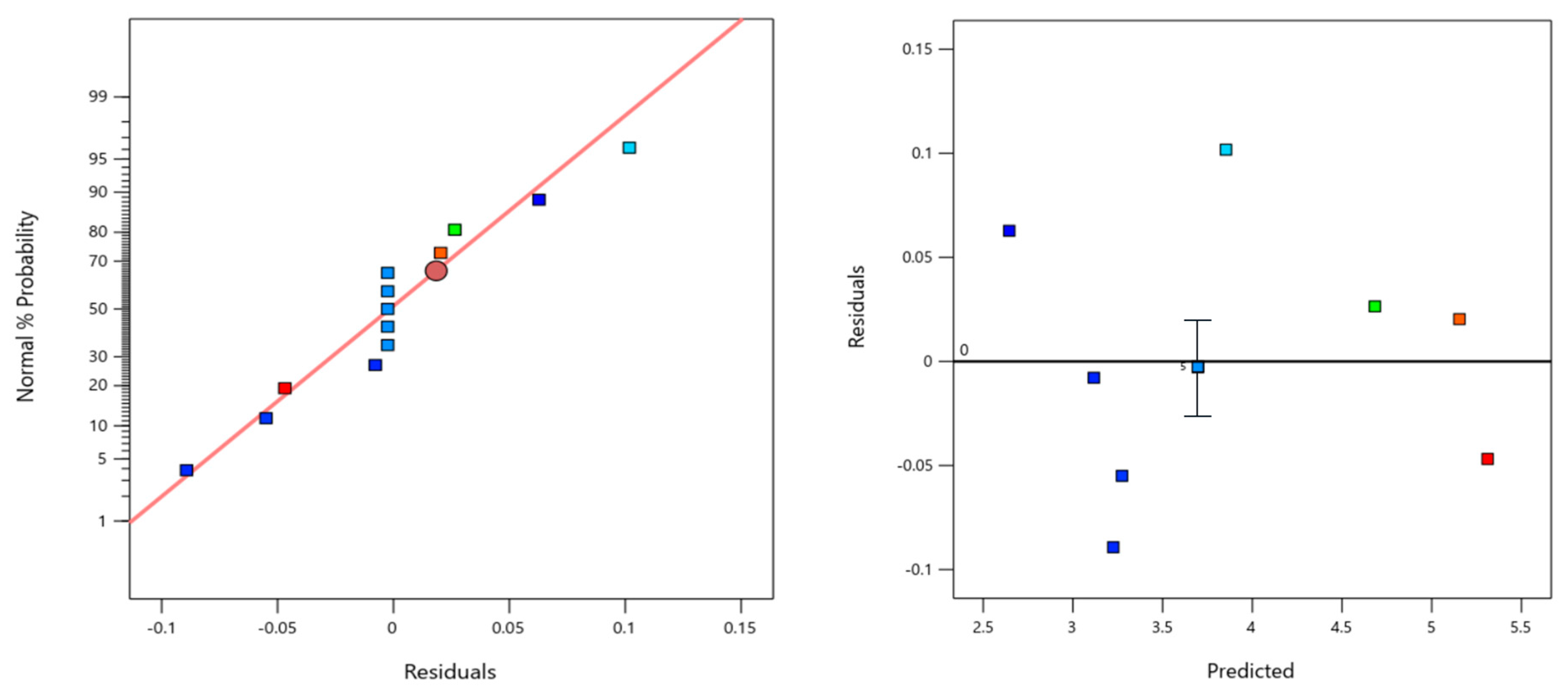

3.1. Statistical Assessment of Experimental Results and Model Adequacy

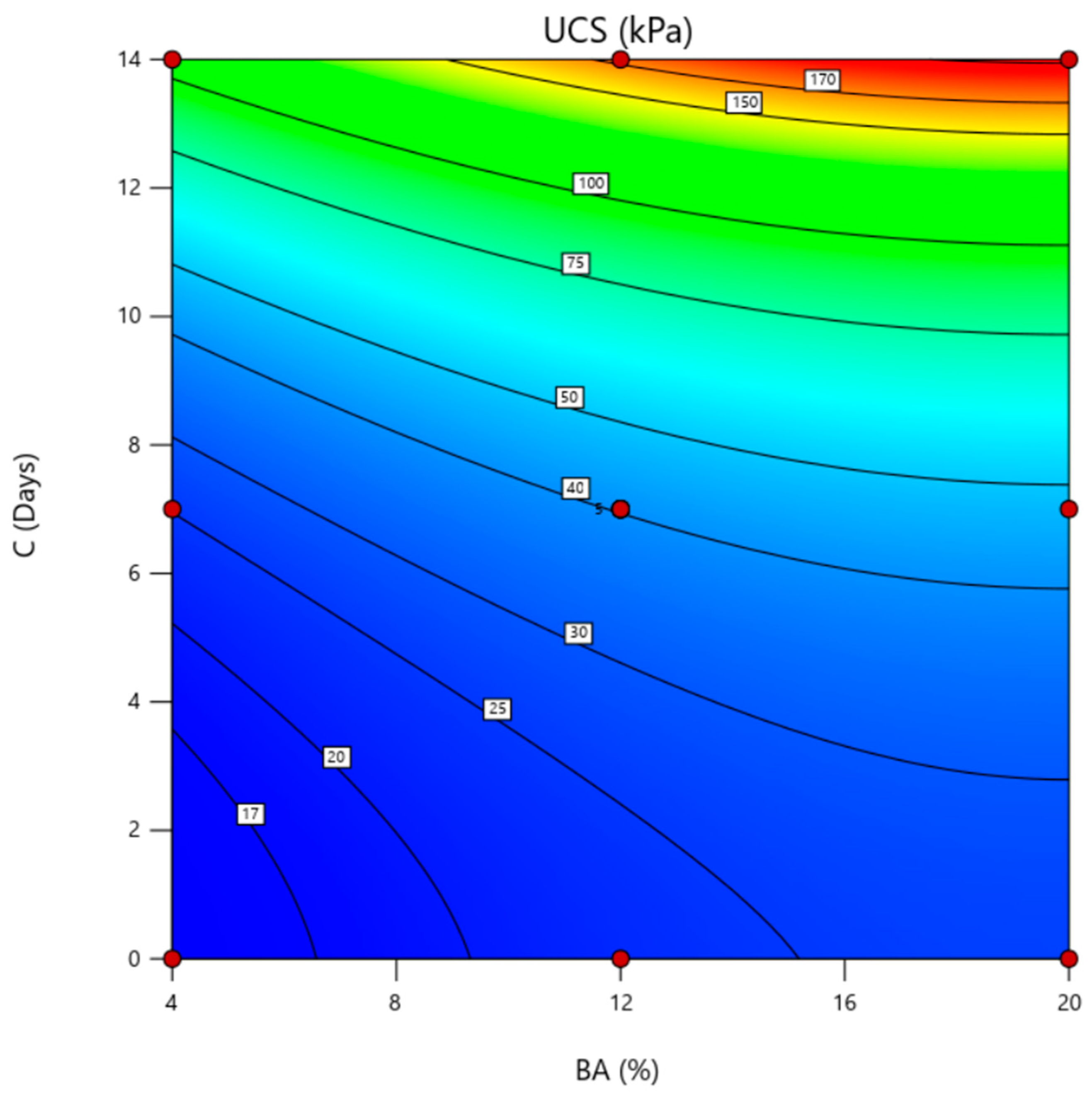

3.2. Optimization of Variables

4. Conclusions

- A response surface methodology (RSM) model was developed to predict the unconfined compressive strength (UCS) of stabilised soft soil. The model consists of a quadratic equation with natural log transformation to express the nonlinear relationship between the input variables and UCS. The input variables in this model are the percentage of biomedical waste ash (BA) and the curing period (C).

- The statistical significance of the model and input parameters were validated through analysis of variance (ANOVA), showing the contribution of each parameter to the UCS value of the stabilised soil. The results from ANOVA showed that curing time had a more significant impact on the UCS than BA. The p-values and F-values obtained from ANOVA indicate that the model and its parameters are statistically significant.

- This study found that both the percentage of BA and curing time have an impact on the UCS of the stabilised soil. Increasing the amount of ash led to an increase in the strength of soil; however, the curing time was found to have an even more substantial impact on the UCS, as with more time, the cementitious compounds were able to form and bond the particles together. This conclusion highlights the importance of allowing for sufficient curing time in order to achieve excellent soil stabilization results.

- Through the RSM model, an optimization analysis was conducted to determine the ideal combination of biomedical waste ash percentage and curing period that maximises the UCS. It was found that the optimal dosage for biomedical waste ash was 19.912% and the optimal curing period was 14 days, as predicted by the model, to produce a maximum UCS value of 203.008 kPa. This process ensures effective and efficient use of materials for soil stabilization.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nayak, D.; Sarvade, P.G.; Shankara H. N., U.; Pai, J.B. Mineralogical Characterization of Lithomargic Clay Deposits along the Coastal Belt of Udupi Region of South India. J. Compos. Sci. 2023, 7, 170. [Google Scholar] [CrossRef]

- Nayak, D.; Sarvade, P.G.; Shankara H. N., U.; Kumar, M.P. Mineralogical Analysis of Lithomargic Clay Deposits along the Coastal Belt of Uttara Kannada Region in South India. J. Adv. Res. Appl. Sci. Eng. Technol. 2024, 39, 117–134. [Google Scholar]

- Jahandari, S.; Li, J.; Saberian, M.; Shahsavarigoughari, M. Experimental study of the effects of geogrids on elasticity modulus, brittleness, strength, and stress-strain behavior of lime stabilized kaolinitic clay. GeoResJ 2017, 13, 49–58. [Google Scholar] [CrossRef]

- Bilondi, M.P.; Toufigh, M.M.; Toufigh, V. Using calcium carbide residue as an alkaline activator for glass powder–clay geopolymer. Constr. Build. Mater. 2018, 183, 417–428. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Miraki, H.; Shariatmadari, N.; Ghadir, P.; Jahandari, S.; Tao, Z.; Siddique, R. Clayey soil stabilization using alkali-activated volcanic ash and slag. J. Rock Mech. Geotech. Eng. 2022, 14, 576–591. [Google Scholar] [CrossRef]

- Prakasan, S.; Palaniappan, S.; Gettu, R. Study of energy use and CO2 Emissions in the Manufacturing of Clinker and Cement. J. Inst. Eng. India Ser. A 2020, 101, 221–232. [Google Scholar] [CrossRef]

- Bushlaibi, A.H.; Alshamsi, A.M. Efficiency of curing on partially exposed high-strength concrete in hot climate. Cem. Concr. Res. 2002, 32, 949–953. [Google Scholar] [CrossRef]

- Ghadir, P.; Ranjbar, N. Clayey soil stabilization using geopolymer and Portland cement. Constr. Build. Mater. 2018, 188, 361–371. [Google Scholar] [CrossRef]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

- Karatai, T.R.; Kaluli, J.W.; Kabubo, C.; Thiong’o, G. Soil Stabilization Using rice husk ash and natural lime as an alternative to cutting and filling in road construction. J. Constr. Eng. Manag. 2017, 143, 04016127. [Google Scholar] [CrossRef]

- Raja, K.; Venkatachalam, S.; Vishnuvardhan, K.; Krishnan, R.S.R.; Selvan, V.T.; Vetriselvan, N. A review on soil stabilization using rice husk ash and lime sludge. Mater. Today Proc. 2022, 65, 1205–1212. [Google Scholar] [CrossRef]

- Darsi, B.P.; Molugaram, K.; Madiraju, S.V.H. Subgrade black cotton soil stabilization using ground granulated blast-furnace slag (GGBS) and lime, an inorganic mineral. Environ. Sci. Proc. 2021, 6, 15. [Google Scholar] [CrossRef]

- Wang, X.; Kim, S.; Wu, Y.; Liu, Y.; Liu, T.; Wang, Y. Study on the optimization and performance of GFC soil stabilizer based on response surface methodology in soft soil stabilization. Soils Found. 2023, 63, 101278. [Google Scholar] [CrossRef]

- Gupta, S.; Kumar, S. Mechanical and microstructural analysis of soft kaolin clay stabilized by GGBS and dolomite-based geopolymer. Constr. Build. Mater. 2024, 421, 135702. [Google Scholar] [CrossRef]

- Wu, J.; Liu, Q.; Deng, Y.; Yu, X.; Feng, Q.; Yan, C. Expansive soil modified by waste steel slag and its application in subbase layer of highways. Soils Found. 2019, 59, 955–965. [Google Scholar] [CrossRef]

- Kumar, A.; Saha, S.; Chattaraj, R. Soft clay stabilization with steel slag. In Recent Developments in Sustainable Infrastructure: Select Proceedings of ICRDSI 2019; Springer: Singapore, 2020; pp. 141–149. [Google Scholar]

- Renjith, R.; Robert, D.; Setunge, S.; Costa, S.; Mohajerani, A. Optimization of fly ash based soil stabilization using secondary admixtures for sustainable road construction. J. Clean. Prod. 2021, 294, 126264. [Google Scholar] [CrossRef]

- Phummiphan, I.; Horpibulsuk, S.; Rachan, R.; Arulrajah, A.; Shen, S.L.; Chindaprasirt, P. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material. J. Hazard. Mater. 2018, 341, 257–267. [Google Scholar] [CrossRef] [PubMed]

- Miranda, T.; Leitão, D.; Oliveira, J.; Corrêa-Silva, M.; Araújo, N.; Coelho, J.; Fernández-Jiménez, A.; Cristelo, N. Application of alkali-activated industrial wastes for the stabilisation of a full-scale (sub) base layer. J. Clean. Prod. 2020, 242, 118427. [Google Scholar] [CrossRef]

- Murmu, A.L.; Dhole, N.; Patel, A. Stabilisation of black cotton soil for subgrade application using fly ash geopolymer. Road Mater. Pavement Des. 2018, 21, 867–885. [Google Scholar] [CrossRef]

- Salimi, M.; Ghorbani, A. Mechanical and compressibility characteristics of a soft clay stabilized by slag-based mixtures and geopolymers. Appl. Clay Sci. 2020, 184, 105390. [Google Scholar] [CrossRef]

- Abdila, S.R.; Abdullah, M.M.A.B.; Ahmad, R.; Nergis, D.D.B.; Rahim, S.Z.A.; Omar, M.F.; Sandu, A.V.; Vizureanu, P.; Syafwandi. Potential of Soil Stabilization Using Ground Granulated Blast Furnace Slag (GGBFS) and Fly Ash via Geopolymerization Method: A Review. Materials 2022, 15, 375. [Google Scholar] [CrossRef]

- Armistead, S.J.; Rawlings, A.E.; Smith, C.C.; Staniland, S.S. Biopolymer stabilization/solidification of soils: A rapid, micro-macro, cross-disciplinary approach. Environ. Sci. Technol. 2020, 54, 13963–13972. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.-M.; Im, J.; Cho, G.-C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Bozyigit, I.; Javadi, A.; Altun, S. Strength properties of xanthan gum and guar gum treated kaolin at different water contents. J. Rock Mech. Geotech. Eng. 2021, 13, 1160–1172. [Google Scholar] [CrossRef]

- Ni, J.; Li, S.S.; Ma, L.; Geng, X.Y. Performance of soils enhanced with eco-friendly biopolymers in unconfined compression strength tests and fatigue loading tests. Constr. Build. Mater. 2020, 263, 120039. [Google Scholar] [CrossRef]

- Ni, J.; Hao, G.-L.; Chen, J.-Q.; Ma, L.; Geng, X.-Y. The optimisation analysis of sand-clay mixtures stabilised with xanthan gum biopolymers. Sustainability 2021, 13, 3732. [Google Scholar] [CrossRef]

- Zinchenko, A.; Sakai, T.; Morikawa, K.; Nakano, M. Efficient stabilization of soil, sand, and clay by a polymer network of biomass-derived chitosan and carboxymethyl cellulose. J. Environ. Chem. Eng. 2022, 10, 107084. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Lopes, L.; Reis, M.S. Advanced predictive modelling applied to the chemical stabilisation of soft soils. Proc. Inst. Civ. Eng. Geotech. Eng. 2022, 175, 461–471. [Google Scholar]

- Gu, X.; Yu, B.; Dong, Q.; Deng, Y. Application of secondary steel slag in subgrade: Performance evaluation and enhancement. J. Clean. Prod. 2018, 181, 102–108. [Google Scholar] [CrossRef]

- WHO Health-Care Waste. 2018. Available online: https://www.who.int/news-room/fact-sheets/detail/health-care-waste (accessed on 12 May 2024).

- Ojha, P.C.; Satpathy, S.S.; Ojha, A.K.; Sukla, L.B.; Pradhan, D. Overcoming challenges due to enhanced biomedical waste generation during COVID-19 pandemic. Sci. Total Environ. 2022, 832, 155072. [Google Scholar] [CrossRef]

- Ilyas, S.; Srivastava, R.R.; Kim, H. Disinfection technology and strategies for COVID-19 hospital and bio-medical waste management. Sci. Total Environ. 2020, 749, 141652. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, H.; Wei, G.; Zhang, N.; Qiao, H.; Gong, Y.; Yu, X.; Zhou, J.; Wu, Y. A review on emergency disposal and management of medical waste during the COVID-19 pandemic in China. Sci. Total Environ. 2022, 810, 152302. [Google Scholar] [CrossRef]

- Behera, B.C. Challenges in handling COVID-19 waste and its management mechanism: A Review. Environ. Nanotechnol. Monit. Manag. 2021, 15, 100432. [Google Scholar] [CrossRef]

- Kothari, R.; Sahab, S.; Singh, H.M.; Singh, R.P.; Singh, B.; Pathania, D.; Singh, A.; Yadav, S.; Allen, T.; Singh, S.; et al. COVID-19 and waste management in Indian scenario: Challenges and possible solutions. Environ. Sci. Pollut. Res. 2021, 28, 52702–52723. [Google Scholar] [CrossRef]

- Rajor, A.; Xaxa, M.; Mehta, R. An overview on characterization, utilization and leachate analysis of biomedical waste incinerator ash. J. Environ. Manag. 2012, 108, 36–41. [Google Scholar] [CrossRef]

- Patel, K.M.; Devatha, C.P. Investigation on leaching behaviour of toxic metals from biomedical ash and its controlling mechanism. Environ. Sci. Pollut. Res. 2019, 26, 6191–6198. [Google Scholar] [CrossRef]

- Dung, T.T.T.; Vassilieva, E.; Swennen, R.; Cappuyns, V. Release of trace elements from bottom ash from hazardous waste incinerators. Recycling 2018, 3, 36. [Google Scholar] [CrossRef]

- Ramesh Kumar, A.; Vaidya, A.N.; Singh, I.; Ambekar, K.; Gurjar, S.; Prajapati, A.; Hippargi, G.; Kale, G.; Bodkhe, S. Leaching characteristics and hazard evaluation of bottom ash generated from common biomedical waste incinerators. J. Environ. Sci. Health Part A 2021, 56, 1069–1079. [Google Scholar] [CrossRef]

- Anastasiadou, K.; Christopoulos, K.; Mousios, E.; Gidarakos, E. Solidification/stabilization of fly and bottom ash from medical waste incineration facility. J. Hazard. Mater. 2012, 207–208, 165–170. [Google Scholar] [CrossRef]

- Genazzini, C.; Giaccio, G.; Ronco, A.; Zerbino, R. Cement-based materials as containment systems for ash from hospital waste incineration. Waste Manag. 2005, 25, 649–654. [Google Scholar] [CrossRef] [PubMed]

- Akyıldız, A.; Köse, E.T.; Yıldız, A. Compressive strength and heavy metal leaching of concrete containing medical waste incineration ash. Constr. Build. Mater. 2017, 138, 326–332. [Google Scholar] [CrossRef]

- Khanzada, G.M.; Memon, B.A.; Oad, M.; Khanzada, M.A.; Lashari, A.M. Effect of bio-medical waste on compressive strength of concrete cylinders. Quaid-E-Awam Univ. Res. J. Eng. Sci. Technol. Nawabshah 2020, 18, 29–35. [Google Scholar]

- Manjunath, B.; Di Mare, M.; Ouellet-Plamondon, C.M.; Bhojaraju, C. Exploring the potential use of incinerated biomedical waste ash as an eco-friendly solution in concrete composites: A review. Constr. Build. Mater. 2023, 387, 131595. [Google Scholar] [CrossRef]

- Matalkah, F. Recycling of hazardous medical waste ash toward cleaner utilization in concrete mixtures. J. Clean. Prod. 2023, 400, 136736. [Google Scholar] [CrossRef]

- Chen, H.-J.; Lin, H.-C.; Tang, C.-W. Application of the taguchi method for optimizing the process parameters of producing controlled low-strength materials by using dimension stone sludge and lightweight aggregates. Sustainability 2021, 13, 5576. [Google Scholar] [CrossRef]

- Demir, F.; Derun, E.M. Modelling and optimization of gold mine tailings based geopolymer by using response surface method and its application in Pb2+ removal. J. Clean. Prod. 2019, 237, 117766. [Google Scholar] [CrossRef]

- Pinheiro, C.; Rios, S.; da Fonseca, A.V.; Fernández-Jiménez, A.; Cristelo, N. Application of the response surface method to optimize alkali activated cements based on low-reactivity ladle furnace slag. Constr. Build. Mater. 2020, 264, 120271. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Caldeira, J.B.; Branco, R.; Morais, P.V. Enhancing the Strength of Mine Residue Soil by Bioremediation Combined with Biopolymers. Appl. Sci. 2023, 13, 10550. [Google Scholar] [CrossRef]

- Trivedi, J.S.; Nair, S.; Iyyunni, C. Optimum utilization of fly ash for stabilization of sub-grade soil using genetic algorithm. Procedia Eng. 2013, 51, 250–258. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Jin, Y.F.; Shen, J.S.; Hicher, P.Y. Optimization techniques for identifying soil parameters in geotechnical engineering: Comparative study and enhancement. Int. J. Numer. Anal. Methods Geomech. 2018, 42, 70–94. [Google Scholar] [CrossRef]

- Saad, A.H.; Nahazanan, H.; Yusuf, B.; Toha, S.F.; Alnuaim, A.; El-Mouchi, A.; Elseknidy, M.; Mohammed, A.A. A Systematic Review of Machine Learning Techniques and Applications in Soil Improvement Using Green Materials. Sustainability 2023, 15, 9738. [Google Scholar] [CrossRef]

- Francis, I.A.; Venantus, A. Models and optimization of rice husk ash-clay soil stabilization. J. Civ. Eng. Arch. 2013, 7, 1260. [Google Scholar]

- Onyelowe, K.; Alaneme, G.; Igboayaka, C.; Orji, F.; Ugwuanyi, H.; Van, D.B.; Van, M.N. Scheffe optimization of swelling, California bearing ratio, compressive strength, and durability potentials of quarry dust stabilized soft clay soil. Mater. Sci. Energy Technol. 2019, 2, 67–77. [Google Scholar] [CrossRef]

- Attah, I.C.; Okafor, F.O.; Ugwu, O.O. Experimental and optimization study of unconfined compressive strength of ameliorated tropical black clay. Eng. Appl. Sci. Res. 2021, 48, 238–248. [Google Scholar]

- Güllü, H.; Fedakar, H.I. Response surface methodology for optimization of stabilizer dosage rates of marginal sand stabilized with Sludge Ash and fiber based on UCS performances. KSCE J. Civ. Eng. 2016, 21, 1717–1727. [Google Scholar] [CrossRef]

- Shahbazi, M.; Rowshanzamir, M.; Abtahi, S.M.; Hejazi, S.M. Optimization of carpet waste fibers and steel slag particles to reinforce expansive soil using response surface methodology. Appl. Clay Sci. 2017, 142, 185–192. [Google Scholar] [CrossRef]

- Almajed, A.; Srirama, D.; Moghal, A.A.B. Response surface method analysis of chemically stabilized fiber-reinforced soil. Materials 2021, 14, 1535. [Google Scholar] [CrossRef] [PubMed]

- Anggraini, V.; Dassanayake, S.; Emmanuel, E.; Yong, L.L.; Kamaruddin, F.A.; Syamsir, A. Response surface methodology: The improvement of tropical residual soil mechanical properties utilizing calcined seashell powder and treated coir fibre. Sustainability 2023, 15, 3588. [Google Scholar] [CrossRef]

- Lindh, P.; Lemenkova, P. Geotechnical properties of soil stabilized with blended binders for sustainable road base applications. Constr. Mater. 2023, 3, 110–126. [Google Scholar] [CrossRef]

- Nayak, D.; Sarvade, P.G.; Udayashankar, H.N.; Maddodi, B.S.; Kumar, M.P. Correlation of Geotechnical and Mineralogical Properties of Lithomargic Clays in Uttara Kannada Region of South India. Geosciences 2024, 14, 92. [Google Scholar] [CrossRef]

- IS 2720 (Part VII); Methods of Test for Soils, Determination of Water Content, Dry Density Relationship Using Light Compaction. Indian Standards Institution: New Delhi, India, 1980.

- IS 2720 (Part X); Methods of Test for Soils, Determination of Unconfined Compressive Strength. Indian Standards Institution: New Delhi, India, 1991.

- Das, B.M. Advanced Soil Mechanics, 4th ed.; Taylor & Francis: Milton Park, UK, 2014. [Google Scholar]

- Consoli, N.C.; Prietto, P.D.M.; Carraro, J.A.H.; Heineck, K.S. Behavior of compacted soil-fly ash-carbide lime mixtures. J. Geotech. Geoenviron. Eng. 2001, 127, 774–782. [Google Scholar] [CrossRef]

- Bibak, H.; Khazaei, J.; Moayedi, H. Investigating the effect of a new industrial waste on strengthening the soft clayey soil. Geotech. Geol. Eng. 2019, 38, 1165–1183. [Google Scholar] [CrossRef]

- Abdi, M.R.; Ghalandarzadeh, A.; Shafiei-Chafi, L. Optimization of lime and fiber content for improvement of clays with different plasticity using response surface method (RSM). Transp. Geotech. 2022, 32, 100685. [Google Scholar] [CrossRef]

- Box, G.E.; Wilson, K.B. On the experimental attainment of optimum conditions. J. R. Stat. Soc. Ser. B Methodol. 1951, 13, 1–38. [Google Scholar] [CrossRef]

- Turkane, S.D.; Chouksey, S.K. Application of response surface method for optimization of stabilizer dosages in soil stabilization. Innov. Infrastruct. Solut. 2022, 7, 106. [Google Scholar] [CrossRef]

- Uppar, R.; Dinesha, P.; Kumar, S. Yield optimization of nonedible vegetable oil-based bio-lubricant using design of experiments. Environ. Dev. Sustain. 2024. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Zhang, J.; Deng, A.; Jaksa, M. Optimizing micaceous soil stabilization using response surface method. J. Rock Mech. Geotech. Eng. 2021, 13, 212–220. [Google Scholar] [CrossRef]

- Noolu, V.; Bingi, N.; Chavali, R.V.P. Assessing the synergistic effects of GGBS and glass fiber on expansive soil behavior using response surface methodology. J. Build. Pathol. Rehabil. 2024, 9, 32. [Google Scholar] [CrossRef]

- Al-Khafaji, R.; Dulaimi, A.; Jafer, H.; Mashaan, N.S.; Qaidi, S.; Obaid, Z.S.; Jwaida, Z. Stabilization of soft soil by a sustainable binder comprises ground granulated blast slag (GGBS) and cement kiln dust (CKD). Recycling 2023, 8, 10. [Google Scholar] [CrossRef]

- Yadu, L.; Tripathi, R.K. Effects of granulated blast furnace slag in the engineering behaviour of stabilized soft soil. Procedia Eng. 2013, 51, 125–131. [Google Scholar] [CrossRef]

- Turkane, S.D.; Chouksey, S.K. Optimization of fly ash geopolymer dosage for California bearing ratio using response surface method. J. Build. Pathol. Rehabil. 2022, 7, 61. [Google Scholar] [CrossRef]

| Soil Characteristic | Value |

|---|---|

| Specific Gravity | 2.23 |

| Liquid Limit (%) | 44.40 |

| Plastic Limit (%) | 25.14 |

| Shrinkage Limit (%) | 16.43 |

| Maximum Unit Weight (kN/m3) | 15.99 |

| Optimum Moisture Content (%) | 17 |

| Unconfined Compressive Strength (kPa) | 14 |

| Element | Weight% | Atomic% |

|---|---|---|

| C | 0.28 | 0.56 |

| O | 41.55 | 63.44 |

| Mg | 0.71 | 0.72 |

| Al | 0.19 | 0.17 |

| Si | 0.52 | 0.45 |

| Cl | 1.01 | 0.70 |

| K | 0.74 | 0.46 |

| Ca | 54.84 | 33.42 |

| Ti | 0.16 | 0.08 |

| Totals | 100.00 | |

| Input Variables | Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| BA | 4 | 12 | 20 |

| C | 0 | 7 | 14 |

| Run Order | Experimental Design | Laboratory Experiments | Compaction Characteristics | UCS (kPa) | Error (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| BA | C | BA | C | MDD (g/cc) | OMC (%) | RSM-Predicted | Experimentally Observed | ||

| 1 | 0 | 0 | 12 | 7 | 1.450 | 21.0 | 40.45 | 40.2 | −0.62 |

| 2 | 0 | 0 | 12 | 7 | 1.450 | 21.0 | 40.45 | 40.2 | −0.62 |

| 3 | −1 | 1 | 4 | 14 | 1.648 | 17.6 | 107.77 | 111 | +2.91 |

| 4 | 1 | 0 | 20 | 7 | 1.394 | 27.2 | 46.99 | 52.2 | +9.98 |

| 5 | 0 | 0 | 12 | 7 | 1.450 | 21.0 | 40.45 | 40.2 | −0.62 |

| 6 | 0 | −1 | 12 | 0 | 1.450 | 21.0 | 22.65 | 22.4 | −1.12 |

| 7 | −1 | −1 | 4 | 0 | 1.648 | 17.6 | 14.15 | 15 | +5.67 |

| 8 | 0 | 1 | 12 | 14 | 1.450 | 21.0 | 172.43 | 176.8 | +2.47 |

| 9 | 1 | −1 | 20 | 0 | 1.394 | 27.2 | 26.31 | 25 | −5.24 |

| 10 | 0 | 0 | 12 | 7 | 1.450 | 21.0 | 40.45 | 40.2 | −0.62 |

| 11 | −1 | 0 | 4 | 7 | 1.648 | 17.6 | 25.03 | 23 | −8.83 |

| 12 | 0 | 0 | 12 | 7 | 1.450 | 21.0 | 40.45 | 40.2 | −0.62 |

| 13 | 1 | 1 | 20 | 14 | 1.394 | 27.2 | 202.35 | 193.4 | −4.63 |

| - | - | - | 16 * | 14 | 1.364 | 27.0 | 195.25 | 190 | −2.76 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7.35 | 4 | 1.84 | 512.75 | <0.0001 |

| BA | 0.5926 | 1 | 0.5926 | 165.25 | <0.0001 |

| C | 6.23 | 1 | 6.23 | 1736.95 | <0.0001 |

| BA2 | 0.0684 | 1 | 0.0684 | 19.07 | 0.0024 |

| C2 | 0.5333 | 1 | 0.5333 | 148.71 | <0.0001 |

| Residual | 0.0287 | 8 | 0.0036 | ||

| Lack of fit | 0.0287 | 4 | 0.0072 | ||

| Pure Error | 0.0000 | 4 | 0.0000 | ||

| Cor Total | 7.38 | 12 | |||

| R2 | 0.9961 | ||||

| Adjusted R2 | 0.9942 | Std. Dev. | 0.0599 | ||

| Predicted R2 | 0.9837 | Mean | 3.83 | ||

| Adeq Precision | 71.7946 | C.V% | 1.56 |

| Number | BA | C | UCS | Desirability |

|---|---|---|---|---|

| 1 | 19.912 | 14.000 | 203.008 | 1 |

| 2 | 19.797 | 14.000 | 202.999 | 1 |

| 3 | 19.717 | 14.000 | 202.981 | 1 |

| 4 | 19.969 | 13.999 | 202.972 | 1 |

| 5 | 19.650 | 14.000 | 202.971 | 1 |

| 6 | 18.852 | 14.000 | 202.392 | 0.999 |

| 7 | 18.791 | 14.000 | 202.321 | 0.999 |

| 8 | 18.470 | 14.000 | 201.888 | 0.998 |

| 9 | 18.287 | 14.000 | 201.595 | 0.997 |

| 10 | 18.026 | 14.000 | 201.123 | 0.997 |

| 11 | 16.728 | 14.000 | 197.795 | 0.990 |

| 12 | 16.663 | 14.000 | 197.586 | 0.990 |

| 13 | 14.032 | 14.000 | 186.071 | 0.967 |

| 14 | 13.125 | 14.000 | 180.825 | 0.957 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Somadas, P.; Sarvade, P.G.; Nayak, D. Advancements in Soft Soil Stabilization by Employing Novel Materials through Response Surface Methodology. Geosciences 2024, 14, 182. https://doi.org/10.3390/geosciences14070182

Somadas P, Sarvade PG, Nayak D. Advancements in Soft Soil Stabilization by Employing Novel Materials through Response Surface Methodology. Geosciences. 2024; 14(7):182. https://doi.org/10.3390/geosciences14070182

Chicago/Turabian StyleSomadas, Pooja, Purushotham G. Sarvade, and Deepak Nayak. 2024. "Advancements in Soft Soil Stabilization by Employing Novel Materials through Response Surface Methodology" Geosciences 14, no. 7: 182. https://doi.org/10.3390/geosciences14070182

APA StyleSomadas, P., Sarvade, P. G., & Nayak, D. (2024). Advancements in Soft Soil Stabilization by Employing Novel Materials through Response Surface Methodology. Geosciences, 14(7), 182. https://doi.org/10.3390/geosciences14070182