Sustainability-Oriented Innovation in the Textile Manufacturing Industry: Pre-Consumer Waste Recovery and Circular Patterns

Abstract

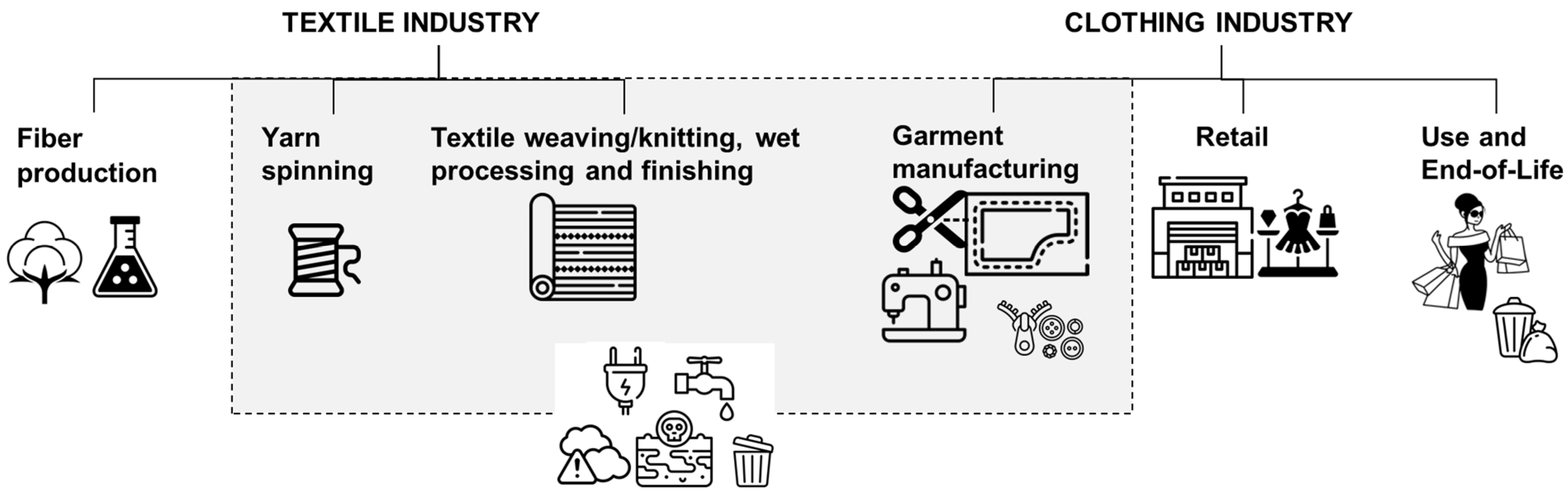

1. Introduction

- improving product design to reduce the use of resources and polluting substances and facilitate the repair and reprocessing phase;

- extending the use phase, improving the quality of garments, and making consumers more aware;

- integrating end-of-life solutions into the value chain to facilitate reuse or reprocessing through process innovation

- R1.

- Which innovations have the potential to improve the sustainability of the textile manufacturing value chain?

- R2.

- How do they enable the achievement of circular economy objectives?

2. Methodology

- post-consumer textile waste since it requires the analysis of reverse logistics, involving a higher number of actors and more complex strategies, and raises additional technological issues deserving separate analysis;

- fast fashion issues that relate to consumers’ behavior;

- the non-woven sector, which faces specific sustainability challenges and can be related to the reuse of post-consumer textile;

- e-textile, which hopefully will evolve sustainably, but currently it does not impact the sustainability of the existing textile manufacturing industry;

- social impacts, a theme often under-investigated and that poses specific geographical and ethical challenges and deserves a specific analysis.

3. Results

3.1. Descriptive Analysis

3.1.1. Year of Publication

3.1.2. Distribution Across Journals

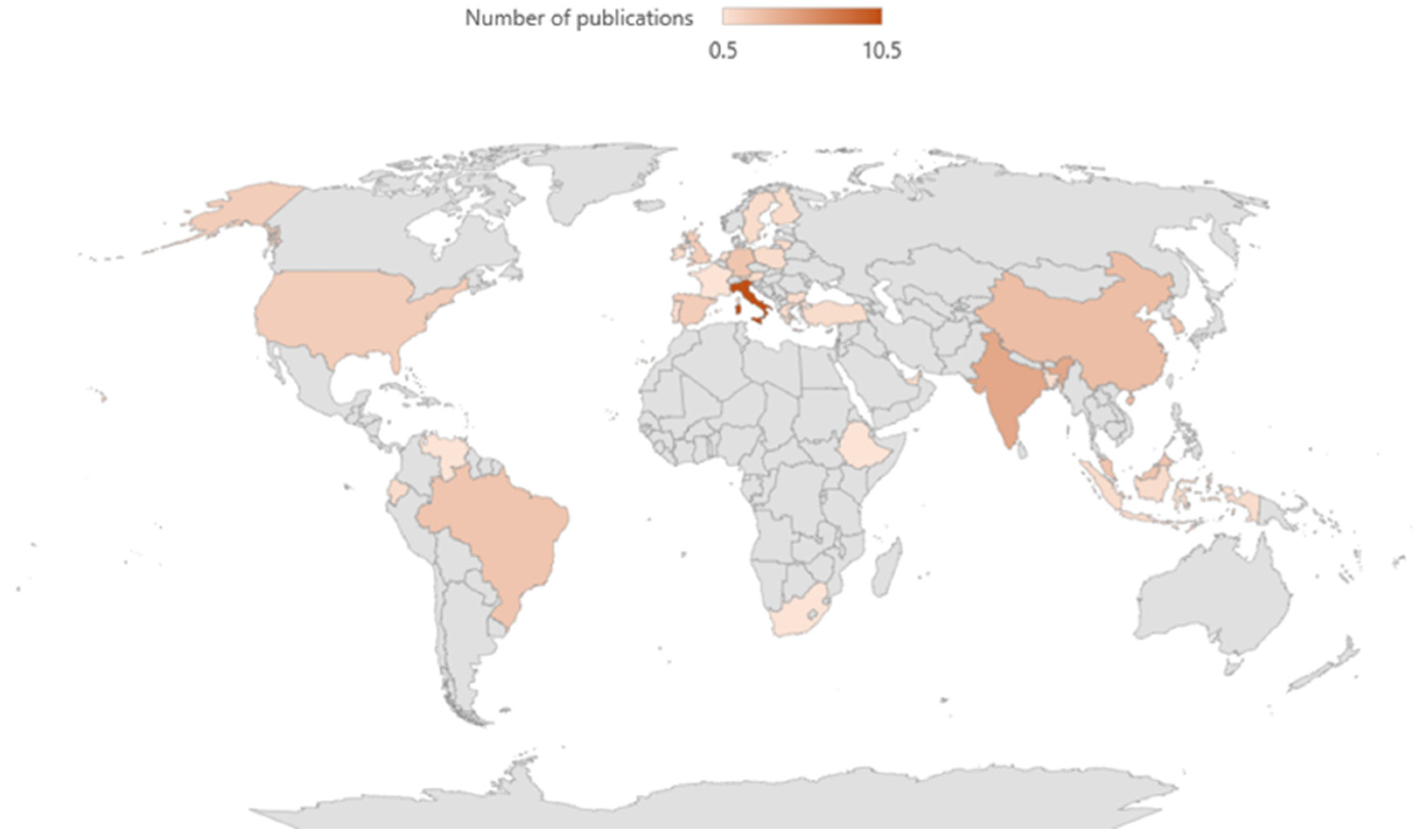

3.1.3. Distribution by Region

3.2. Thematic Analysis

3.2.1. Industry 4.0 and the Digital Transformation

3.2.2. Design Innovations and Innovative Raw Materials

3.2.3. Waste Recovery Within the Value Chain and Environmental Remediation

3.2.4. Textile Waste as New Raw Material (Outside the Textile Value Chain)

3.2.5. Organizational Strategies and Business Model Innovation

4. Discussion

4.1. Circular Economy Goals Achievement

4.2. Support for the UN Sustainable Development Goals Implementation

4.3. Open Issues and Future Research Directions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Journal | Number of Papers |

|---|---|

| Journal of Cleaner Production | 6 |

| Sustainability | 5 |

| AUTEX Research Journal | 2 |

| Biomass Conversion and Biorefinery | 2 |

| Research Journal of Textile and Apparel | 1 |

| Waste Management & Research: The Journal for a Sustainable Circular Economy | 1 |

| Competitiveness Review: An International Business Journal | 1 |

| The Journal of the Textile Institute | 1 |

| Environmental Science and Pollution Research | 1 |

| Applied Sciences | 1 |

| Nano-Structures & Nano-Objects | 1 |

| Sustainable Production and Consumption | 1 |

| International Journal of Precision Engineering and Manufacturing-Green Technology | 1 |

| Advances in Science and Technology | 1 |

| Journal of Business & Industrial Marketing | 1 |

| Vision: The Journal of Business Perspective | 1 |

| International Journal on Interactive Design and Manufacturing | 1 |

| Molecules | 1 |

| Nature Sustainability | 1 |

| SN Applied Sciences | 1 |

| Journal of Material Cycles and Waste Management | 1 |

| Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences | 1 |

| Sustainable Chemistry and Pharmacy | 1 |

| Ecotoxicology and Environmental Safety | 1 |

| Journal of Environmental Management | 1 |

| International Journal of Recent Technology and Engineering | 1 |

| International Journal of Production Economics | 1 |

| Sustainable Environment | 1 |

| Authors, Year, and Ref. | Industry 4.0 | Product/ Process Design and Resources IN 1 | Resources OUT 1 | Waste Recovery 1 and Environmental Remediation | Business Model |

|---|---|---|---|---|---|

| Larsson, 2018, [5] | ✔ | ||||

| Piribauer and Bartl, 2019, [59] | ✔ | ||||

| Gupta et al., 2019, [49] | ✔ | ||||

| Denuwara et al., 2019, [7] | ✔ | ||||

| Kędzia and Dziuba, 2020, [44] | ✔ | ||||

| Provin et al., 2021, [46] | ✔ | ||||

| Moran et al., 2021, [31] | ✔ | ||||

| Stenton et al., 2021, [50] | ✔ | ||||

| Siderius and Poldner, 2021, [37] | ✔ | ✔ | |||

| Kim et al., 2022, [60] | ✔ | ✔ | |||

| Rese et al., 2022, [34] | ✔ | ✔ | |||

| Bressanelli et al., 2022, [61] | ✔ | ✔ | |||

| D’Itria and Colombi, 2022, [47] | ✔ | ||||

| Ruan et al., 2022, [36] | ✔ | ✔ | |||

| Al-Tohami et al., 2022, [21] | ✔ | ✔ | |||

| Magri and Ciarletta, 2023, [43] | ✔ | ✔ | |||

| De Ponte et al., 2023, [29] | ✔ | ||||

| Harsanto et al., 2023, [28] | ✔ | ✔ | ✔ | ✔ | |

| Arnold et al., 2023, [65] | ✔ | ✔ | |||

| Fu et al., 2023, [51] | ✔ | ||||

| Sharma and Singh, 2023, [42] | ✔ | ✔ | |||

| Hira and Alam, 2023, [24] | ✔ | ||||

| Dominidiato et al., 2023, [35] | ✔ | ✔ | ✔ | ||

| Battesini Teixeira et al., 2023, [64] | ✔ | ✔ | |||

| Pizzicato et al., 2023, [53] | ✔ | ||||

| Chand et al., 2023, [62] | ✔ | ✔ | |||

| Kulkarni et al., 2023, [63] | ✔ | ||||

| Ramos et al., 2023, [39] | ✔ | ||||

| Gorse et al., 2024, [52] | ✔ | ||||

| Rahaman and Kahn, 2024, [54] | ✔ | ||||

| Petrillo et al., 2024, [45] | ✔ | ||||

| Pundir et al., 2024, [56] | ✔ | ||||

| Bao et al., 2024, [48] | ✔ | ||||

| Mikucioniene et al., 2024, [55] | ✔ | ✔ | |||

| Ferlito, 2024, [41] | ✔ | ✔ | |||

| Marovska et al., 2024, [58] | ✔ | ||||

| Lee et al., 2024, [40] | ✔ | ||||

| Ermini et al., 2024, [66] | ✔ | ||||

| Saha et al., 2024, [26] | ✔ | ✔ | ✔ | ✔ |

References

- Ellen MacArthur Foundation A New Textiles Economy: Redesigning Fashion’s Future. 2017, pp. 1–150. Available online: http://www.ellenmacarthurfoundation.org/publications (accessed on 10 December 2024).

- Kousar, S.; Shafqat, U.; Kausar, N.; Pamucar, D.; Karaca, Y.; Salman, M.A. Sustainable Energy Consumption Model for Textile Industry Using Fully Intuitionistic Fuzzy Optimization Approach. Comput. Intell. Neurosci. 2022, 2022, 5724825. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Tan, Y.; Huang, J.; Zhu, G.; Yin, R.; Tao, X.; Tian, X. Industrialization of open- and closed-loop waste textile recycling towards sustainability: A review. J. Clean. Prod. 2024, 436, 140676. [Google Scholar] [CrossRef]

- Oliveira Neto, G.C.d.; Cesar da Silva, P.; Tucci, H.N.P.; Amorim, M. Reuse of water and materials as a cleaner production practice in the textile industry contributing to blue economy. J. Clean. Prod. 2021, 305, 127075. [Google Scholar] [CrossRef]

- Larsson, J.K.J. Digital innovation for sustainable apparel systems: Experiences based on projects in textile value chain development. Res. J. Text. Appar. 2018, 22, 370–389. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Motamed, B.; Ramakrishna, S.; Naebe, M. Death by waste: Fashion and textile circular economy case. Sci. Total Environ. 2020, 718, 137317. [Google Scholar] [CrossRef]

- Denuwara, N.; Maijala, J.; Hakovirta, M. Sustainability benefits of RFID technology in the apparel industry. Sustainability 2019, 11, 6477. [Google Scholar] [CrossRef]

- Dissanayake, D.G.K.; Weerasinghe, D. Managing post-industrial textile waste: Current status and prospects for Sri Lanka. J. Text. Inst. 2021, 112, 1804–1810. [Google Scholar] [CrossRef]

- Desore, A.; Narula, S.A. An overview on corporate response towards sustainability issues in textile industry. Environ. Dev. Sustain. 2018, 20, 1439–1459. [Google Scholar] [CrossRef]

- Manshoven, S.; Christis, M.; Vercalsteren, A.; Arnold, M.; Nicolau, M.; Lafond, E.; Mortensen, L.F.; Coscieme, L. Eionet Report—ETC/WMGE 2019/6 Textiles and the Environment in a Circular Economy; European Environment Agency (EEA): Copenhagen, Denmark, 2019. [Google Scholar]

- Nyika, J.; Dinka, M. Sustainable management of textile solid waste materials: The progress and prospects. Mater. Today Proc. 2022, 62, 3320–3324. [Google Scholar] [CrossRef]

- Roy Choudhury, A.K. Environmental impacts of the textile industry and its assessment through life cycle assessment. In Roadmap to Sustainable Textiles and Clothing, Environmental and Social Aspects of Textiles and Clothing Supply Chain; Springer Science+Business Media: Singapore, 2014; ISBN 9789812871107. [Google Scholar]

- Kasemset, C.; Chernsupornchai, J.; Pala-Ud, W. Application of MFCA in waste reduction: Case study on a small textile factory in Thailand. J. Clean. Prod. 2015, 108, 1342–1351. [Google Scholar] [CrossRef]

- Rapsikevičienė, J.; Gurauskienė, I.; Jučienė, A. Model of industrial textile waste management. Environ. Res. Eng. Manag. 2019, 75, 43–55. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Available online: https://www.ellenmacarthurfoundation.org/ (accessed on 10 December 2024).

- Abdelmeguid, A.; Afy-Shararah, M.; Salonitis, K. Towards circular fashion: Management strategies promoting circular behaviour along the value chain. Sustain. Prod. Consum. 2024, 48, 143–156. [Google Scholar] [CrossRef]

- H&M. Available online: https://hmgroup.com/sustainability/circularity-and-climate/circularity/ (accessed on 31 January 2025).

- Patagonia. Available online: https://www.patagonia.com/stories/our-quest-for-circularity/story-96496.html (accessed on 31 January 2025).

- Mishra, P.K.; Izrayeel, A.M.D.; Mahur, B.K.; Ahuja, A.; Rastogi, V.K. A comprehensive review on textile waste valorization techniques and their applications. Environ. Sci. Pollut. Res. 2022, 29, 65962–65977. [Google Scholar] [CrossRef] [PubMed]

- Madhav, S.; Ahamad, A.; Singh, P.; Mishra, P.K. A review of textile industry: Wet processing, environmental impacts, and effluent treatment methods. Environ. Qual. Manag. 2018, 27, 31–41. [Google Scholar] [CrossRef]

- Al-Tohamy, R.; Ali, S.S.; Li, F.; Okasha, K.M.; Mahmoud, Y.A.G.; Elsamahy, T.; Jiao, H.; Fu, Y.; Sun, J. A critical review on the treatment of dye-containing wastewater: Ecotoxicological and health concerns of textile dyes and possible remediation approaches for environmental safety. Ecotoxicol. Environ. Saf. 2022, 231, 113160. [Google Scholar] [CrossRef]

- Adams, R.; Jeanrenaud, S.; Bessant, J.; Denyer, D.; Overy, P. Sustainability-oriented Innovation: A Systematic Review. Int. J. Manag. Rev. 2016, 18, 180–205. [Google Scholar] [CrossRef]

- Chopra, S.S.; Dong, L.; Kaur, G.; Len, C.; Ki Lin, C.S. Sustainable process design for circular fashion: Advances in sustainable chemistry for textile waste valorisation. Curr. Opin. Green Sustain. Chem. 2023, 39, 100747. [Google Scholar] [CrossRef]

- Hira, F.A.; Alam, M.M. A Bibliometric Research Trend Analysis on Emerging Technology in the Textile Industry. Vision 2023, 0, 1–17. [Google Scholar] [CrossRef]

- Jain, S.; Kalapurackal, J.J. A Systematic Review of Green Apparel Manufacturing. Environ. Res. Eng. Manag. 2023, 79, 124–133. [Google Scholar] [CrossRef]

- Saha, K.; Dey, P.K.; Kumar, V. A comprehensive review of circular economy research in the textile and clothing industry. J. Clean. Prod. 2024, 444, 141252. [Google Scholar] [CrossRef]

- Siliņa, L.; Dāboliņa, I.; Lapkovska, E. Sustainable textile industry—Wishful thinking or the new norm: A review. J. Eng. Fiber. Fabr. 2024, 19, 1–27. [Google Scholar] [CrossRef]

- Harsanto, B.; Primiana, I.; Sarasi, V.; Satyakti, Y. Sustainability Innovation in the Textile Industry: A Systematic Review. Sustainability 2023, 15, 1549. [Google Scholar] [CrossRef]

- De Ponte, C.; Liscio, M.C.; Sospiro, P. State of the art on the Nexus between sustainability, fashion industry and sustainable business model. Sustain. Chem. Pharm. 2023, 32, 100968. [Google Scholar] [CrossRef]

- Abbate, S.; Centobelli, P.; Cerchione, R.; Nadeem, S.P.; Riccio, E. Sustainability trends and gaps in the textile, apparel and fashion industries. Environ. Dev. Sustain. 2024, 26, 2837–2864. [Google Scholar] [CrossRef]

- Moran, C.A.; Eichelmann, E.; Buggy, C.J. The challenge of “Depeche Mode” in the fashion industry–Does the industry have the capacity to become sustainable through circular economic principles, a scoping review. Sustain. Environ. 2021, 7, 1975916. [Google Scholar] [CrossRef]

- Luján-Ornelas, C.; Güereca, L.P.; Franco-García, M.-L.; Heldeweg, M. A Life Cycle Thinking Approach to Analyse Sustainability in the Textile Industry: A Literature Review. Sustainability 2020, 12, 10193. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Rese, A.; Baier, D.; Rausch, T.M. Success factors in sustainable textile product innovation: An empirical investigation. J. Clean. Prod. 2022, 331, 129829. [Google Scholar] [CrossRef]

- Dominidiato, M.; Guercini, S.; Milanesi, M.; Tunisini, A. Supplier-customer relationships for sustainability-led innovation in the textile industry. J. Bus. Ind. Mark. 2023, 39, 15–26. [Google Scholar] [CrossRef]

- Ruan, X.; Ding, N.; Yang, J. Dual-level eco-efficiency analysis in sustainable management: An empirical study on textile manufacturers and supply chains in China. J. Environ. Manag. 2022, 304, 114227. [Google Scholar] [CrossRef]

- Siderius, T.; Poldner, K. Reconsidering the Circular Economy Rebound effect: Propositions from a case study of the Dutch Circular Textile Valley. J. Clean. Prod. 2021, 293, 125996. [Google Scholar] [CrossRef]

- Pereira, F.; Carvalho, V.; Vasconcelos, R.; Soares, F. A Review in the Use of Artificial Intelligence in Textile Industry; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2022; pp. 377–392. [Google Scholar]

- Ramos, L.; Rivas-Echeverría, F.; Pérez, A.G.; Casas, E. Artificial intelligence and sustainability in the fashion industry: A review from 2010 to 2022. SN Appl. Sci. 2023, 5, 387. [Google Scholar] [CrossRef]

- Lee, W.; Sajadieh, S.M.M.; Choi, H.K.; Park, J.; Noh, S.D. Application of Reinforcement Learning to Dyeing Processes for Residual Dye Reduction. Int. J. Precis. Eng. Manuf. Green Technol. 2024, 11, 743–763. [Google Scholar] [CrossRef]

- Ferlito, R. Industry 4.0 and sustainability: The case of the Italian textile district of Prato. Compet. Rev. 2024, 34, 995–1016. [Google Scholar] [CrossRef]

- Sharma, A.; Singh, B.J. Evolution of modified LSS 4.0 model for sustainable Indian textile industry: A narrative review. Int. J. Interact. Des. Manuf. 2023. [Google Scholar] [CrossRef]

- Magri, M.; Ciarletta, P. Mathematics meets the fashion industry on path to product innovation and sustainability. Proc. R. Soc. A Math. Phys. Eng. Sci. 2023, 479. [Google Scholar] [CrossRef]

- Kędzia, K.; Dziuba, R. A system for personalized clothing production as a model for supporting the competitiveness of SMEs on the example of Lodz Province. Autex Res. J. 2020, 20, 93–99. [Google Scholar] [CrossRef]

- Petrillo, A.; Rehman, M.; Baffo, I. Digital and Sustainable Transition in Textile Industry through Internet of Things Technologies: A Pakistani Case Study. Appl. Sci. 2024, 14, 5380. [Google Scholar] [CrossRef]

- Provin, A.P.; Regina de Aguiar Dutra, A.; Machado, M.M.; Vieira Cubas, A.L. New materials for clothing: Rethinking possibilities through a sustainability approach—A review. J. Clean. Prod. 2021, 282, 124444. [Google Scholar] [CrossRef]

- D’Itria, E.; Colombi, C. Biobased Innovation as a Fashion and Textile Design Must: A European Perspective. Sustainability 2022, 14, 570. [Google Scholar] [CrossRef]

- Bao, H.; Hong, Y.; Yan, T.; Xie, X.; Zeng, X. A systematic review of biodegradable materials in the textile and apparel industry. J. Text. Inst. 2024, 115, 1173–1192. [Google Scholar] [CrossRef]

- Gupta, R.; Shukla, V.K.; Agarwal, P. Sustainable transformation in modest fashion through “RPET technology” and “Dry-uye” process, using recycled pet plastic. Int. J. Recent Technol. Eng. 2019, 8, 5415–5421. [Google Scholar]

- Stenton, M.; Houghton, J.A.; Kapsali, V.; Blackburn, R.S. Review the potential for regenerated protein fibres within a circular economy: Lessons from the past can inform sustainable innovation in the textiles industry. Sustainability 2021, 13, 2328. [Google Scholar] [CrossRef]

- Fu, C.; Wang, Z.; Gao, Y.; Zhao, J.; Liu, Y.; Zhou, X.; Qin, R.; Pang, Y.; Hu, B.; Zhang, Y.; et al. Sustainable polymer coating for stainproof fabrics. Nat. Sustain. 2023, 6, 984–994. [Google Scholar] [CrossRef]

- Görse, E.; Mancar, M.; Ayvaz, N.; Durur, G. Ecological Approaches in Yarn Dyeing. Advances in Science and Technology. 2024, 146, 15–22. [Google Scholar]

- Pizzicato, B.; Pacifico, S.; Cayuela, D.; Mijas, G.; Riba-Moliner, M. Advancements in Sustainable Natural Dyes for Textile Applications: A Review. Molecules 2023, 28, 5954. [Google Scholar] [CrossRef]

- Rahaman, M.T.; Khan, M.S.H. Applications of green nano textile materials for environmental sustainability and functional performance: Past, present and future perspectives. Nano-Struct. Nano-Objects 2024, 40, 101332. [Google Scholar] [CrossRef]

- Mikucioniene, D.; Mínguez-García, D.; Repon, M.R.; Milašius, R.; Priniotakis, G.; Chronis, I.; Kiskira, K.; Hogeboom, R.; Belda-Anaya, R.; Díaz-García, P. Understanding and addressing the water footprint in the textile sector: A review. AUTEX Res. J. 2024, 24, 20240004. [Google Scholar] [CrossRef]

- Pundir, A.; Thakur, M.S.; Radha; Goel, B.; Prakash, S.; Kumari, N.; Sharma, N.; Parameswari, E.; Senapathy, M.; Kumar, S.; et al. Innovations in textile wastewater management: A review of zero liquid discharge technology. Environ. Sci. Pollut. Res. 2024, 31, 12597–12616. [Google Scholar] [CrossRef]

- Holkar, C.R.; Jadhav, A.J.; Pinjari, D.V.; Mahamuni, N.M.; Pandit, A.B. A critical review on textile wastewater treatments: Possible approaches. J. Environ. Manag. 2016, 182, 351–366. [Google Scholar] [CrossRef]

- Marovska, G.; Dushkova, M.; Angelova, G.; Brazkova, M.; Brink, H.; Haneklaus, N.; Menkov, N.; Slavov, A. Rose and lavender industrial by-products application for adsorption of Acid Orange 7 from aqueous solution. Biomass Convers. Biorefinery 2024, 14, 22703–22716. [Google Scholar]

- Piribauer, B.; Bartl, A. Textile recycling processes, state of the art and current developments: A mini review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef]

- Kim, T.; Kim, D.; Park, Y. Recent progress in regenerated fibers for “green” textile products. J. Clean. Prod. 2022, 376, 134226. [Google Scholar] [CrossRef]

- Bressanelli, G.; Visintin, F.; Saccani, N. Circular Economy and the evolution of industrial districts: A supply chain perspective. Int. J. Prod. Econ. 2022, 243, 108348. [Google Scholar] [CrossRef]

- Chand, S.; Chand, S.; Raula, B. Textile and apparel industries waste and its sustainable management approaches. J. Mater. Cycles Waste Manag. 2023, 25, 3132–3143. [Google Scholar] [CrossRef]

- Kulkarni, M.B.; Gavande, V.; Mahanwar, P.A.; Shah, A.R.; Shuib, R.K.; Khare, A.M.; Radhakrishnan, S. Review on biomass sheep wool–based polymer composites. Biomass Convers. Biorefinery 2023, 14, 30961–30982. [Google Scholar] [CrossRef]

- Battesini Teixeira, T.G.; de Medeiros, J.F.; Kolling, C.; Duarte Ribeiro, J.L.; Morea, D. Redesign in the textile industry: Proposal of a methodology for the insertion of circular thinking in product development processes. J. Clean. Prod. 2023, 397, 136588. [Google Scholar] [CrossRef]

- Arnold, M.G.; Pfaff, C.; Pfaff, T. Circular Business Model Strategies Progressing Sustainability in the German Textile Manufacturing Industry. Sustainability 2023, 15, 4595. [Google Scholar] [CrossRef]

- Ermini, C.; Visintin, F.; Boffelli, A. Understanding supply chain orchestration mechanisms to achieve sustainability-oriented innovation in the textile and fashion industry. Sustain. Prod. Consum. 2024, 49, 415–430. [Google Scholar] [CrossRef]

- European Commission. Available online: https://eippcb.jrc.ec.europa.eu/reference/textiles-industry (accessed on 15 December 2024).

- Cai, Y.J.; Choi, T.M. A United Nations’ Sustainable Development Goals perspective for sustainable textile and apparel supply chain management. Transp. Res. Part E Logist. Transp. Rev. 2020, 141, 102010. [Google Scholar] [CrossRef]

- Thakker, A.M.; Sun, D. Sustainable Development Goals for Textiles and Fashion. Environ. Sci. Pollut. Res. 2023, 30, 101989–102009. [Google Scholar] [CrossRef]

- Leal Filho, W.; Dinis, M.A.P.; Liakh, O.; Paço, A.; Dennis, K.; Shollo, F.; Sidsaph, H. Reducing the carbon footprint of the textile sector: An overview of impacts and solutions. Text. Res. J. 2024, 94, 1798–1814. [Google Scholar] [CrossRef]

- Mehta, S. Biodegradable textile polymers: A review of current scenario and future opportunities. Environ. Technol. Rev. 2023, 12, 441–457. [Google Scholar] [CrossRef]

- Yaqub, M.; Celebi, M.D.; Dilaver, M.; Bhagat, S.K.; Kobya, M.; Lee, W. Treating Textile Wastewater to Achieve Zero Liquid Discharge: A Comprehensive Techno-economic Analysis. Water Air Soil Pollut. 2023, 234, 651. [Google Scholar] [CrossRef]

- Buljan, J.; Emmanuel, K.V.; Viswanathan, M.; Bosnić, M.; Král, I. Analysis of flow and energy aspects of Zero Liquid Discharge (ZLD) technology in treatment of tannery effluents in Tamil Nadu, India. In Proceedings of the 34th IULTCS Congress: Science and Technology for Sustainability of Leather Impact Factor, Chennai, India, 5–8 February 2017; pp. 244–259. [Google Scholar]

- Jahan, N.; Tahmid, M.; Shoronika, A.Z.; Fariha, A.; Roy, H.; Pervez, M.N.; Cai, Y.; Naddeo, V.; Islam, M.S. A Comprehensive Review on the Sustainable Treatment of Textile Wastewater: Zero Liquid Discharge and Resource Recovery Perspectives. Sustainability 2022, 14, 15398. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- de Vries, A. The growing energy footprint of artificial intelligence. Joule 2023, 7, 2191–2194. [Google Scholar] [CrossRef]

- Yadav, V.S.; Majumdar, A. Mitigating the barriers of industrial symbiosis for waste management: An integrated decision-making framework for the textile and clothing industry. Waste Manag. Res. 2024, 42, 544–555. [Google Scholar] [CrossRef]

| Item | Description |

|---|---|

| Databases | Scopus, Web of Science |

| Keywords | Textile industry; sustainability; innovation; |

| resource recovery; circular economy | |

| Search fields | Title, Abstract, Keywords |

| Publication type | Journal and conference articles and reviews |

| Language | English |

| Time window | 2015–2024 |

| Other inclusion criteria | The articles focus on the textile/fashion manufacturing industry addressing sustainable solutions from a circular perspective |

| Exclusion criteria | The articles do not consider post-consumer waste textile, consumers’ behavior and fast fashion issues, the non-woven sector, e-textile, and social impacts |

| Approach | Technology | Description | Advantages/Drawbacks |

|---|---|---|---|

| Physical | Adsorption | Adsorbed molecules or ions are attracted to a solid adsorbent surface (zeolites, alumina, silica gel, activated carbon) | Reusability of adsorbents, high efficiency, short time of treatment |

| Ion exchange | Separation is achieved by generating strong bonds between the resins used in a packed bed reactor and the solutes | Low cost, regeneration, simplicity, flexibility, high efficiency | |

| Membrane filtration | The membranes have small pores, so solutes larger than these pores are trapped; nano-filtration technology also uses electrostatic repulsion mechanisms; ultrafiltration removes organic dyes; reverse osmosis (RO) membrane | Simple and effective; the membranes need periodic replacement RO technology allows separation with no state change or thermal energy | |

| Chemical | Coagulation -flocculation | Metal salts and polymers can be used as coagulants, while flocculants are polymers increasing the aggregation of flocs so that they can be separated more easily | Cost-effective, pH-dependent, and producing concentrated sludge |

| Advanced oxidation | Based on the in situ generation of hydroxyl radicals (OH•), which are powerful oxidizing agents; photocatalysis, Fenton, photo-Fenton, ozonation, and electrochemical oxidation | Suitable for harsh conditions, quick and without the formation of sludge; expensive, pH-dependent, producing toxic by-products | |

| Electrochemical | Electrocoagulation, electro-Fenton (oxidation and coagulation), anodic oxidation | Does not require the addition of chemicals and produces no sludge; high electricity costs | |

| Biological | Enzyme-assisted degradation | To convert dye molecules into non-toxic products | Industrial enzymes: low cost, efficient, reliable, available in liquid form |

| Bacteria-assisted degradation | 100% efficiency in dye-containing textile wastewater biodegradation, and bacterial consortia frequently outperform a single strain in dye removal effectiveness | Ease of cultivation, high specific growth, versatile catalytic capability for mineralizing azo dyes | |

| Fungal-assisted degradation | Degradation and mineralization | Ability to accelerate their metabolism in order to achieve optimal environmental conditions | |

| Yeast-assisted degradation | Biosorption and reductive azo bond cleavage | Rapid growth rates, suitable for adverse environmental conditions |

| SOI 1 Area | CE Enabling Innovation | CE Objective |

|---|---|---|

| Industry 4.0 and digitalization | Process optimization (AI, IoT); Customization (3D virtual fitting, digital printing, AI, VR) | Waste reduction and recycling |

| Traceability (IoT, Blockchain, RFID) | ||

| Design innovations and innovative raw materials | Bio-based raw materials; natural dyes | Pollution reduction |

| Recycled raw materials; novel processes | Resource saving | |

| Waste recovery within the value chain and environmental remediation | Wastewater treatment | Pollution reduction |

| Contaminated soil and water treatment | Environmental remediation | |

| Textile production waste recovery | Waste reduction and recycling | |

| Textile waste as new raw material (outside the value chain) | Textile (production) waste recovery | Waste reduction and recycling |

| Organizational strategies and Business model innovation | Circular thinking strategies; sustainability reporting; collaboration along the supply chain | Waste reduction; remanufacturing and recycling; resource saving |

| Sustainable and recycled materials | Resource saving; waste reduction |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butturi, M.A.; Neri, A.; Mercalli, F.; Gamberini, R. Sustainability-Oriented Innovation in the Textile Manufacturing Industry: Pre-Consumer Waste Recovery and Circular Patterns. Environments 2025, 12, 82. https://doi.org/10.3390/environments12030082

Butturi MA, Neri A, Mercalli F, Gamberini R. Sustainability-Oriented Innovation in the Textile Manufacturing Industry: Pre-Consumer Waste Recovery and Circular Patterns. Environments. 2025; 12(3):82. https://doi.org/10.3390/environments12030082

Chicago/Turabian StyleButturi, Maria Angela, Alessandro Neri, Francesco Mercalli, and Rita Gamberini. 2025. "Sustainability-Oriented Innovation in the Textile Manufacturing Industry: Pre-Consumer Waste Recovery and Circular Patterns" Environments 12, no. 3: 82. https://doi.org/10.3390/environments12030082

APA StyleButturi, M. A., Neri, A., Mercalli, F., & Gamberini, R. (2025). Sustainability-Oriented Innovation in the Textile Manufacturing Industry: Pre-Consumer Waste Recovery and Circular Patterns. Environments, 12(3), 82. https://doi.org/10.3390/environments12030082