Risk Management of a Fusion Facility: Radiation Protection and Safety Integrated Approach for the Sorgentina-RF Project

Abstract

:1. Introduction

2. Materials and Methods

2.1. Radiation Protection Analysis

- The primary neutronic field resulting from fusion reactions;

- The gamma radiation generated from neutrons’ interaction with the machine components and the shielding;

- The gamma radiation emitted by activated products in the machine components and in the shielding;

- Activated dust generated in the machine components;

- Activated corrosion products (ACPs) generated in the cooling loops after the activation of the pipes’ inner surface and of the corrosion products in the cooling fluid that reach high neutron flux regions of the circuit;

- Activated cooling water;

- Activated air (mainly 41Ar);

- Wastes containing gamma emitters.

- Optimal spatial arrangement and organization of the premises;

- Appropriate ventilation system;

- Installation of special equipment;

- Adequate solutions for the management and storage of solid and liquid waste and airborne and liquid effluent;

- Working procedures aimed to the safe management of activities involving the risks of exposure to ionizing radiation;

- Monitoring programs and systems.

2.2. Safety Analysis

- Component identification;

- Process functions for each component;

- Safety functions for each component;

- Component failure modes;

- Possible causes associated to a specific failure mode;

- Possible consequences in terms of machine damage, radioactive inventory mobilization through the different containment barriers, and dose to workers and population;

- Means of detection;

- Automatic actions on detection;

- Automatic means to prevent the causes or mitigate the consequences of failure;

- Identification of the representative PIEs for a single elementary failure.

2.3. The Integrated Approach

3. Results

3.1. Radiation Protection Activities

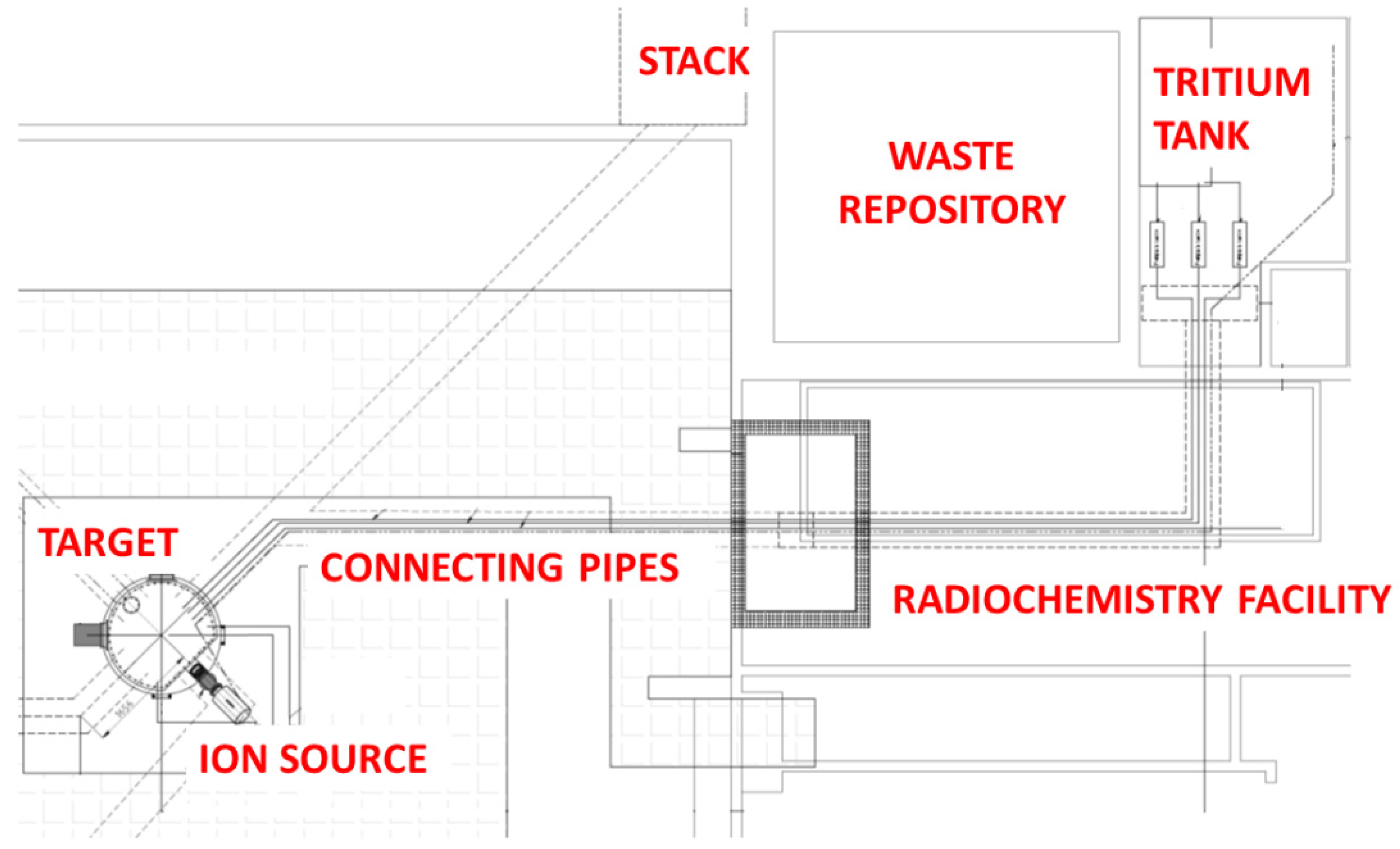

3.1.1. Site Arrangement and Organization of Premises

3.1.2. Ventilation System

3.1.3. Special Equipment

3.1.4. Radioactive Waste

3.1.5. Working Procedures

3.1.6. Monitoring Programs and Systems

3.1.7. Licensing

3.2. Integrated Analysis of the Target System

FMEA Application

4. Discussion

4.1. Description of the Most Representative Incidental Sequence

4.2. Design Actions and Safety Provisions

- Pressure sensors in the VC and in the ion source;

- Temperature sensors on the bearings;

- A system to control the vibrations (i.e., rigid displacements) of the bearings;

- A system of torque control (i.e., mechanical control) on the motor for the rotation because, if the motor current increases, it means that the bearings are failing;

- A current sensor in the ion source that detects if the beam stops;

- Tritium sensors in the bunker so that, when the concentration exceeds the threshold, the air expulsion system is automatically diverted to an oxidation bed, which captures the tritium: this way there is more permeation than expulsion of tritium to the environment, with a highly reduced dose to the workers and the public;

- A second containment barrier around the seals of the VC, with less high vacuum;

- A program of periodic preventive maintenance on the seals of the VC and the bearings.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pietropaolo, A.; Andreoli, F.; Angelone, M.; Vetrella, U.B.; Fiore, S.; Loreti, S.; Pagano, G.; Pilotti, R.; Pillon, M. The Frascati Neutron Generator: A multipurpose facility for physics and engineering. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2018; p. 012004. [Google Scholar] [CrossRef] [Green Version]

- Pietropaolo, A.; Contessa, G.M.; Farini, M.; Fonnesu, N.; Marinari, R.; Moro, F.; Rizzo, A.; Scaglione, S.; Terranova, N.; Utili, M.; et al. SORGENTINA-RF project: Fusion neutrons for 99Mo medical radioisotope. Eur. Phys. J. Plus 2021, 136, 1140. [Google Scholar] [CrossRef]

- Capogni, M.; Pietropaolo, A.; Quintieri, L.; Angelone, M.; Boschi, A.; Capone, M.; Cherubini, N.; De Felice, P.; Dodaro, A.; Duatti, A.; et al. 14 MeV neutrons for 99Mo/99mTc production: Experiments, simulations and perspectives. Molecules 2018, 23, 1872. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IAEA. Non-HEU Production Technologies for Molybdenum-99 and Technetium-99m; IAEA Nuclear Energy Series No. NF-T-5.4; IAEA: Vienna, Austria, 2013. [Google Scholar]

- NEA-OECD. The Supply of Medical Radioisotopes: An Assessment of Long-Term Global Demand for Technetium-99m; NEA: Paris, France, 2011. [Google Scholar]

- International Atomic Energy Agency. Development and Application of Level 1 Probabilistic Safety Assessment for Nuclear Power Plants; IAEA: Vienna, Austria, 2010. [Google Scholar]

- International Atomic Energy Agency. Applications of Probabilistic Safety Assessment (PSA) for Nuclear Power Plants; IAEA: Vienna, Austria, 2001. [Google Scholar]

- EC Radiation Protection 181. General Guidelines on Risk Management in External Beam Radiotherapy; Publications Office of the European Union: Luxembourg, 2015. [Google Scholar]

- Huq, M.S.; Fraass, B.A.; Dunscombe, P.B.; Gibbons, J.P., Jr.; Ibbott, G.S.; Mundt, A.J.; Mutic, S.; Palta, J.R.; Rath, F.; Thomadsen, B.R.; et al. The report of Task Group 100 of the AAPM: Application of risk analysis methods to radiation therapy quality management. Med. Phys. 2016, 43, 4209–4262. [Google Scholar] [CrossRef] [PubMed]

- International Atomic Energy Agency. Fundamental Safety Principles; IAEA: Vienna, Austria, 2006. [Google Scholar]

- International Atomic Energy Agency. IAEA Safety Glossary: 2018 Edition; IAEA: Vienna, Austria, 2019. [Google Scholar]

- Tosti, S.; Ghirelli, N. Tritium in Fusion: Production, Uses and Environmental Impact; Nova Science Publishers: Hauppauge, NY, USA, 2013. [Google Scholar]

- D’Arienzo, M.; Borgognoni, F.; Coniglio, A.; Daniele, A.; Sandri, S.; Tosti, S. Radiation dose due to tritium release from the ITER neutral beam injector. Fusion Eng. Des. 2010, 85, 2288–2291. [Google Scholar] [CrossRef]

- D’Arienzo, M.; Sandri, S.; Fellin, F.; Daniele, A.; Di Pace, L.; Coniglio, A. Assessment of radiation dose rate resulting from activated corrosion products in the PRIMA facility cooling loops. Fusion Eng. Des. 2011, 86, 2758–2761. [Google Scholar] [CrossRef]

- D’Avanzo, M.A.; Contessa, G.M.; Cocomello, G.; Mattozzi, M.; Pacilio, M.; Sandri, S.; Campanella, F. Review of operational indications on the design of facilities for radiopharmaceutical manufacturing in italy. Radioprotection 2021, 56, 137–144. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Safety of Nuclear Power Plants: Design; IAEA: Vienna, Austria, 2000. [Google Scholar]

- Lee, J.C.; McCormick, N.J. Risk and Safety Analysis of Nuclear Systems; Wiley J. & Sons Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- X-5 Monte Carlo Team. MCNP—A General Monte Carlo N-Particle Transport Code, Version 5; Los 592 Alamos National Laboratory: Los Alamos, NM, USA, 2003. [Google Scholar]

- Plompen, A.J.M.; Cabellos, O.; De Saint Jean, C.; Fleming, M.; Algora, A.; Angelone, M.; Archier, P.; Bauge, E.; Bersillon, O.; Blokhin, A.; et al. The joint evaluated fission and fusion nuclear data library, JEFF-3.3. Eur. Phys. J. A 2020, 56, 181. [Google Scholar] [CrossRef]

- Forrest, R.; Capote, R.; Otsuka, N.; Kawano, T.; Koning, A.J.; Kunieda, S.; Sublet, J.-C.; Watanabe, Y. FENDL-3 Library—Summary Documentation, INDC(NDS)-0628; IAEA: Vienna, Austria, 2012. [Google Scholar]

- Shultis, K.; Faw, R.E. Radiation Shielding; Prentice-Hall: Upper Saddle River, NJ, USA, 2000. [Google Scholar]

- Sandri, S.; Contessa, G.M.; D’Arienzo, M.; Guardati, M.; Guarracino, M.; Poggi, C.; Villari, R. A review of radioactive wastes production and potential environmental releases at experimental nuclear fusion facilities. Environments 2020, 7, 6. [Google Scholar] [CrossRef] [Green Version]

- Contessa, G.M.; D’Arienzo, M.; Frisoni, M.; Ferrari, P.; Panichi, R.; Moro, F.; Pietropaolo, A. Preliminary evaluations of the environmental impact for the production of 99Mo by fusion neutrons. Eur. Phys. J. Plus 2021, 136, 637. [Google Scholar] [CrossRef]

- D’Arienzo, M.; Malizia, A.; Contessa, G.M. Modelling mixing and transport of radioactive effluents in water reservoirs: An application to the operation of a fusion facility. Eur. Phys. J. Plus 2021, 136, 1045. [Google Scholar] [CrossRef]

- Sandri, S.; Contessa, G.M.; Guardati, M.; Guarracino, M.; Villari, R. Radiation Protection Design and Licensing for an Experimental Fusion Facility: The Italian and European Approaches. Fusion Sci. Technol. 2019, 75, 345–351. [Google Scholar] [CrossRef]

- Nie, B.; Yang, J.; Yuan, Y.; Li, F. Additional radiation dose due to atmospheric dispersion of tritium evaporated from a hypothetical reservoir. Appl. Radiat. Isot. 2021, 167, 109475. [Google Scholar] [CrossRef] [PubMed]

- Ambrosino, F.; Stellato, L.; Sabbarese, C. A case study on possible radiological contamination in the Lo Uttaro landfill site (Caserta, Italy). J. Phys. Conf. Ser. 2020, 1548, 012001. [Google Scholar] [CrossRef]

- Sandri, S.; Angelone, M.; Contessa, G.M.; Guardati, M.; Villari, R. Ionizing radiation monitoring requirements at the Divertor Tokamak Test facility. Fusion Eng. Des. 2020, 160, 112024. [Google Scholar] [CrossRef]

- Contessa, G.M.; Grandi, C.; Scognamiglio, M.; Genovese, E.; Sandri, S. Climate change and safety at work with ionizing radiations. Annali dell’Istituto Superiore Sanitą 2016, 52, 386–396. [Google Scholar] [CrossRef]

- U.S. Nuclear Regulatory Commission. Regulatory Guide 1.7—Control of Combustible Gas Concentrations in Containment Following a Loss of Coolant Accident; NUREG: Washington, DC, USA, 1978. [Google Scholar]

| PBS Element (Component) | Process Function | Safety Function | Failure Mode | Failure Cause | Consequence | Detection | Automatic Actions upon Detection |

|---|---|---|---|---|---|---|---|

| VC Seals | |||||||

| Provide vacuum leak tightness | |||||||

| Confine within the target | |||||||

| Leak | |||||||

| Ball bearings rupture; thermo-mechanical stress in structures; possible component damage; vibrations, fatigue; impact with heavy load | |||||||

| Ingress of air in VC; loss of vacuum; release of tritiated gas into the surroundings of the VC after pressure equalization | |||||||

| Pressure monitor; temperature monitor; tritium monitor in the bunker | |||||||

| Closing of the stack and expulsion of air through the tritium trap; beam stop | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Contessa, G.M.; Terranova, N.; Pinna, T.; Dongiovanni, D.N.; D’Arienzo, M.; Moro, F.; Ferrari, P.; Pietropaolo, A.; The SRF Collaboration. Risk Management of a Fusion Facility: Radiation Protection and Safety Integrated Approach for the Sorgentina-RF Project. Environments 2022, 9, 71. https://doi.org/10.3390/environments9060071

Contessa GM, Terranova N, Pinna T, Dongiovanni DN, D’Arienzo M, Moro F, Ferrari P, Pietropaolo A, The SRF Collaboration. Risk Management of a Fusion Facility: Radiation Protection and Safety Integrated Approach for the Sorgentina-RF Project. Environments. 2022; 9(6):71. https://doi.org/10.3390/environments9060071

Chicago/Turabian StyleContessa, Gian Marco, Nicholas Terranova, Tonio Pinna, Danilo Nicola Dongiovanni, Marco D’Arienzo, Fabio Moro, Paolo Ferrari, Antonino Pietropaolo, and The SRF Collaboration. 2022. "Risk Management of a Fusion Facility: Radiation Protection and Safety Integrated Approach for the Sorgentina-RF Project" Environments 9, no. 6: 71. https://doi.org/10.3390/environments9060071

APA StyleContessa, G. M., Terranova, N., Pinna, T., Dongiovanni, D. N., D’Arienzo, M., Moro, F., Ferrari, P., Pietropaolo, A., & The SRF Collaboration. (2022). Risk Management of a Fusion Facility: Radiation Protection and Safety Integrated Approach for the Sorgentina-RF Project. Environments, 9(6), 71. https://doi.org/10.3390/environments9060071