Model of Predictive Maintenance of Machines and Equipment

Abstract

:1. Introduction

- determining the basic level of maintenance labor intensity,

- creating the maintenance labor intensity standard,

- creating an operational maintenance plan according to the specificity of the business.

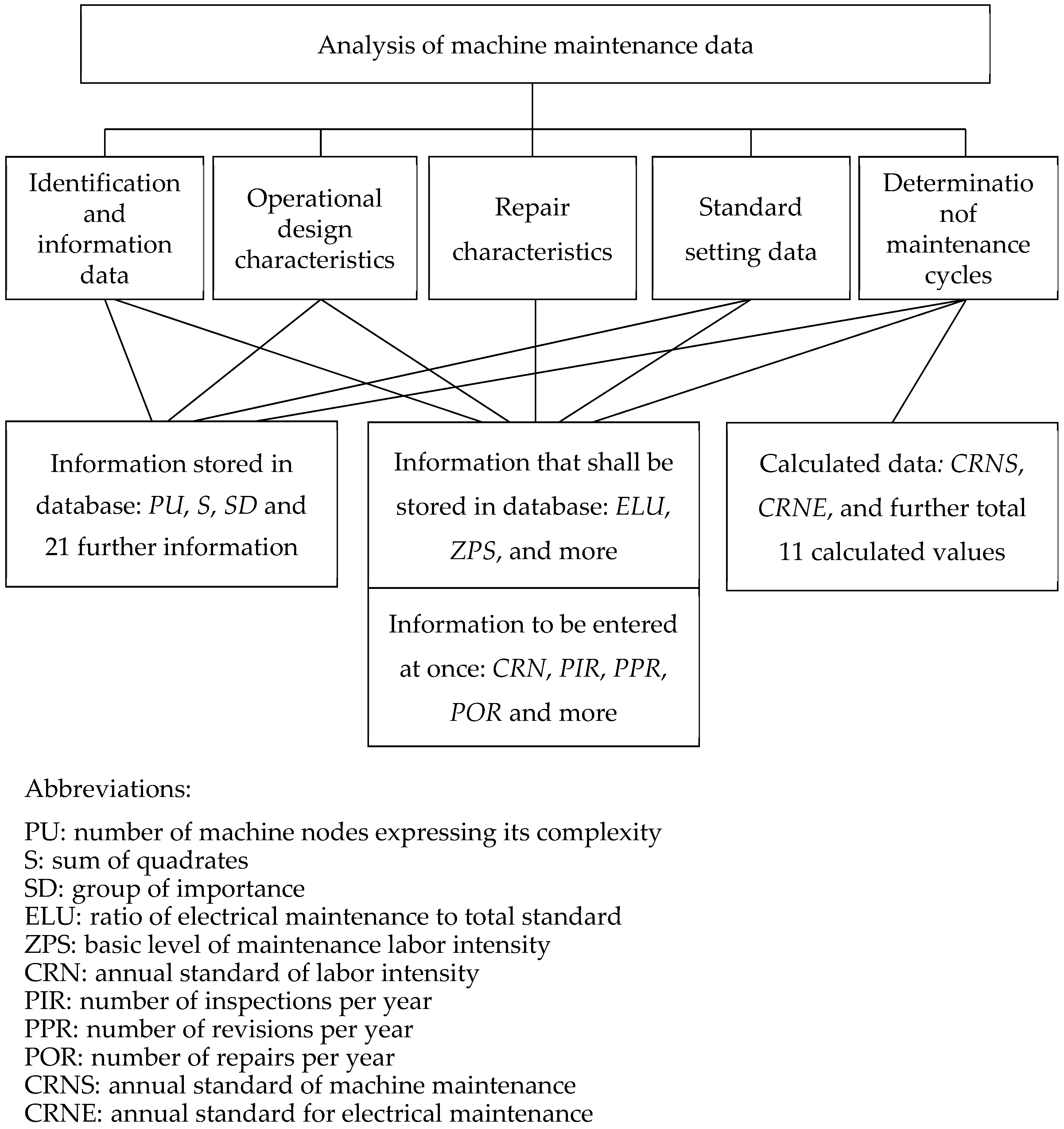

- identification of the essential means,

- design and operation characteristics,

- reliability and maintenance characteristics,

- data to determine the maintenance standard,

- data to determine the maintenance cycle/periodicity (capacity, spare parts, equipment, etc.).

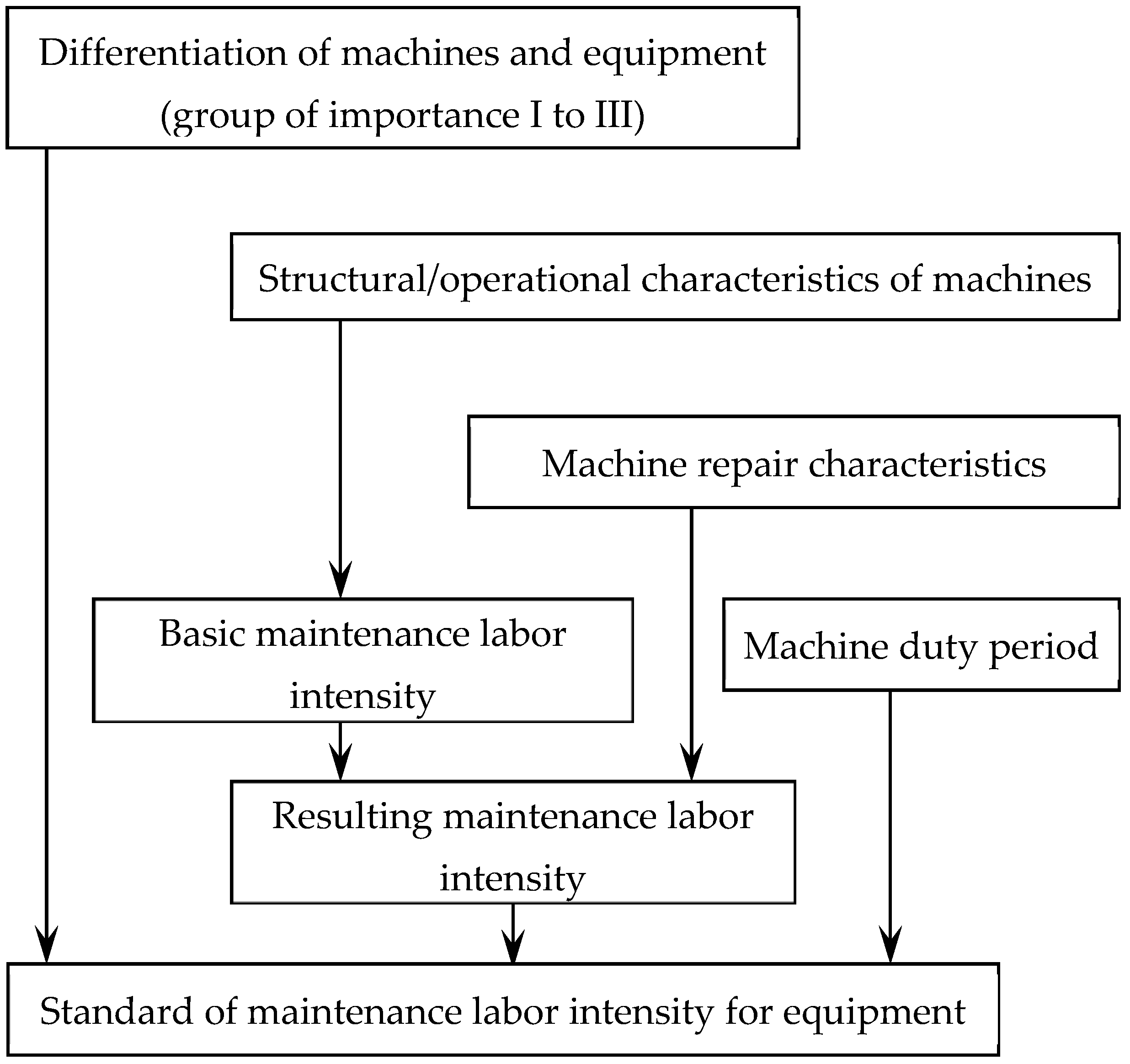

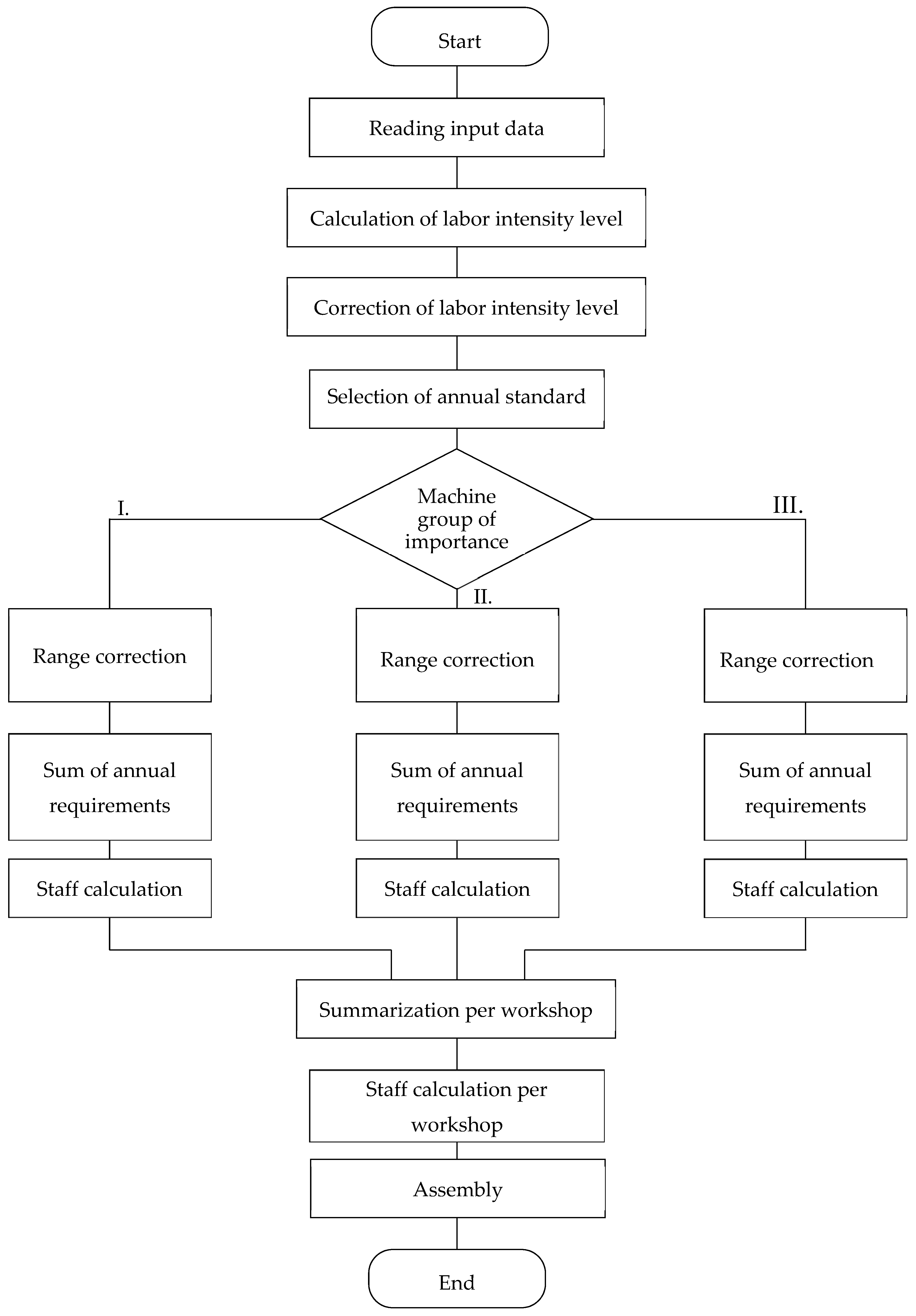

2. Model of Basic Level of Labor Intensity

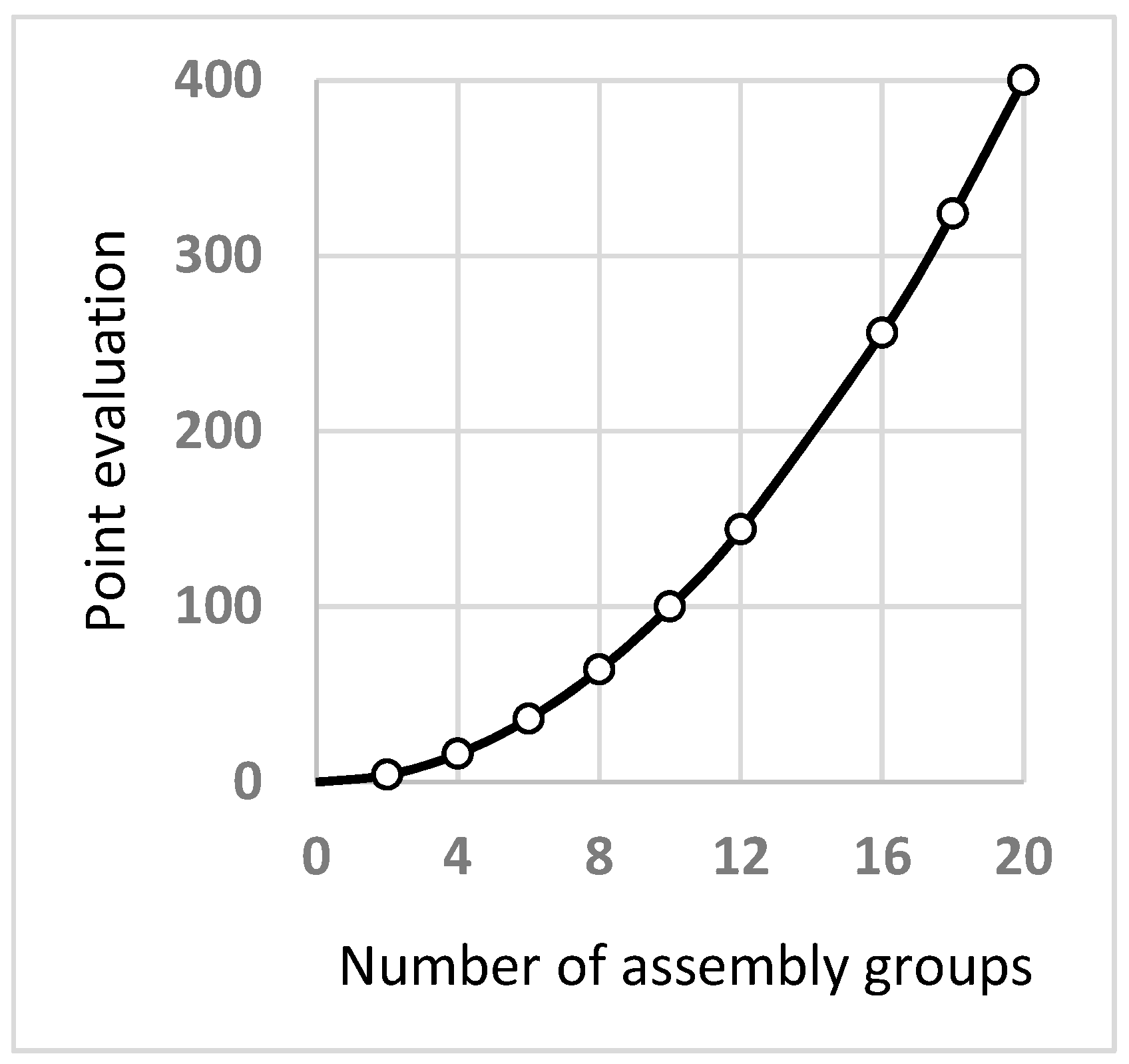

- enter values A, B, C, and D for the technical level of the machine, its weight, and the basic level of accuracy;

- enter the characteristics of the number of groups, technical level, weight, and level of accuracy;

- we gradually calculate the number of points for each characteristic, and we determine the basic level of maintenance from their sum.

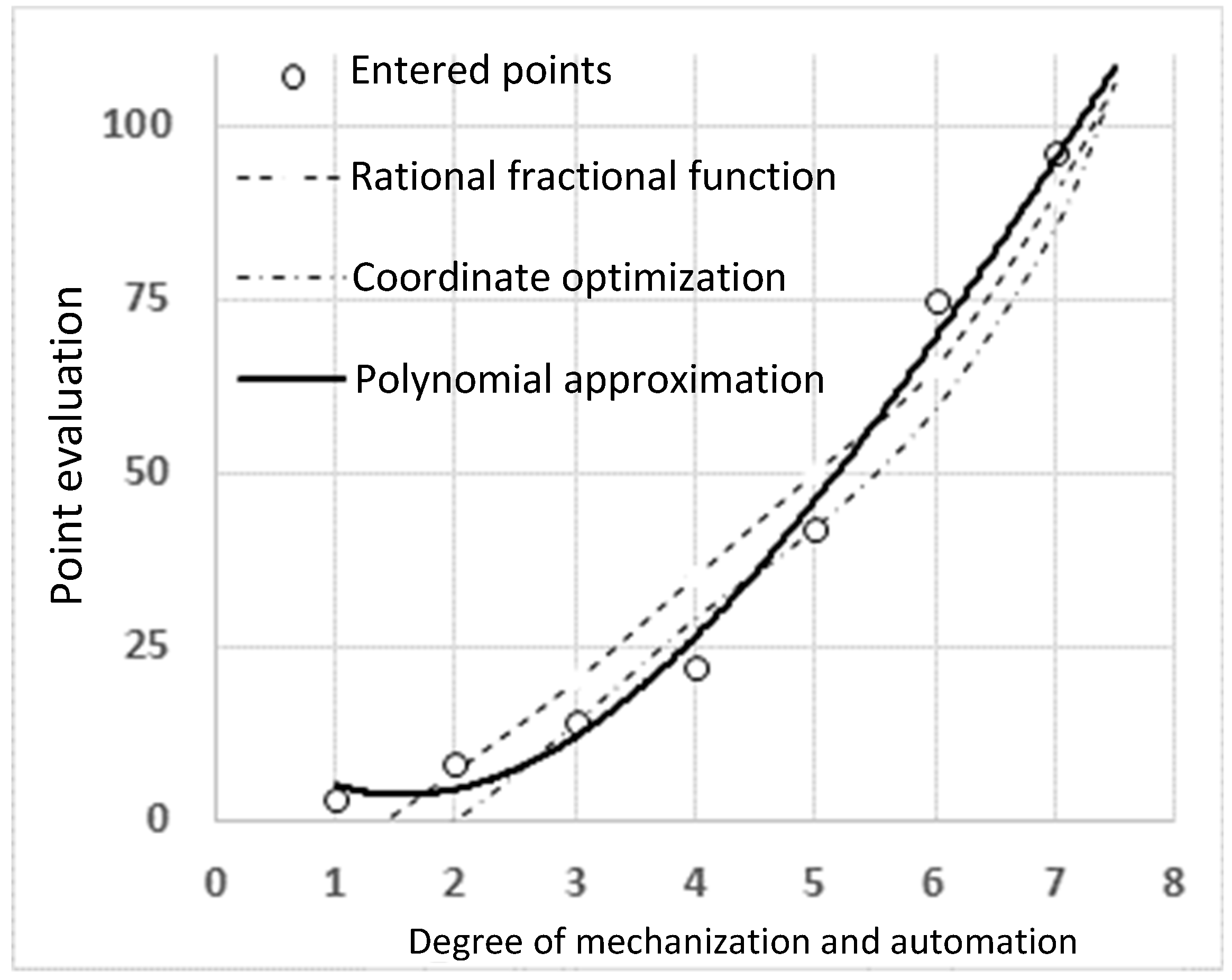

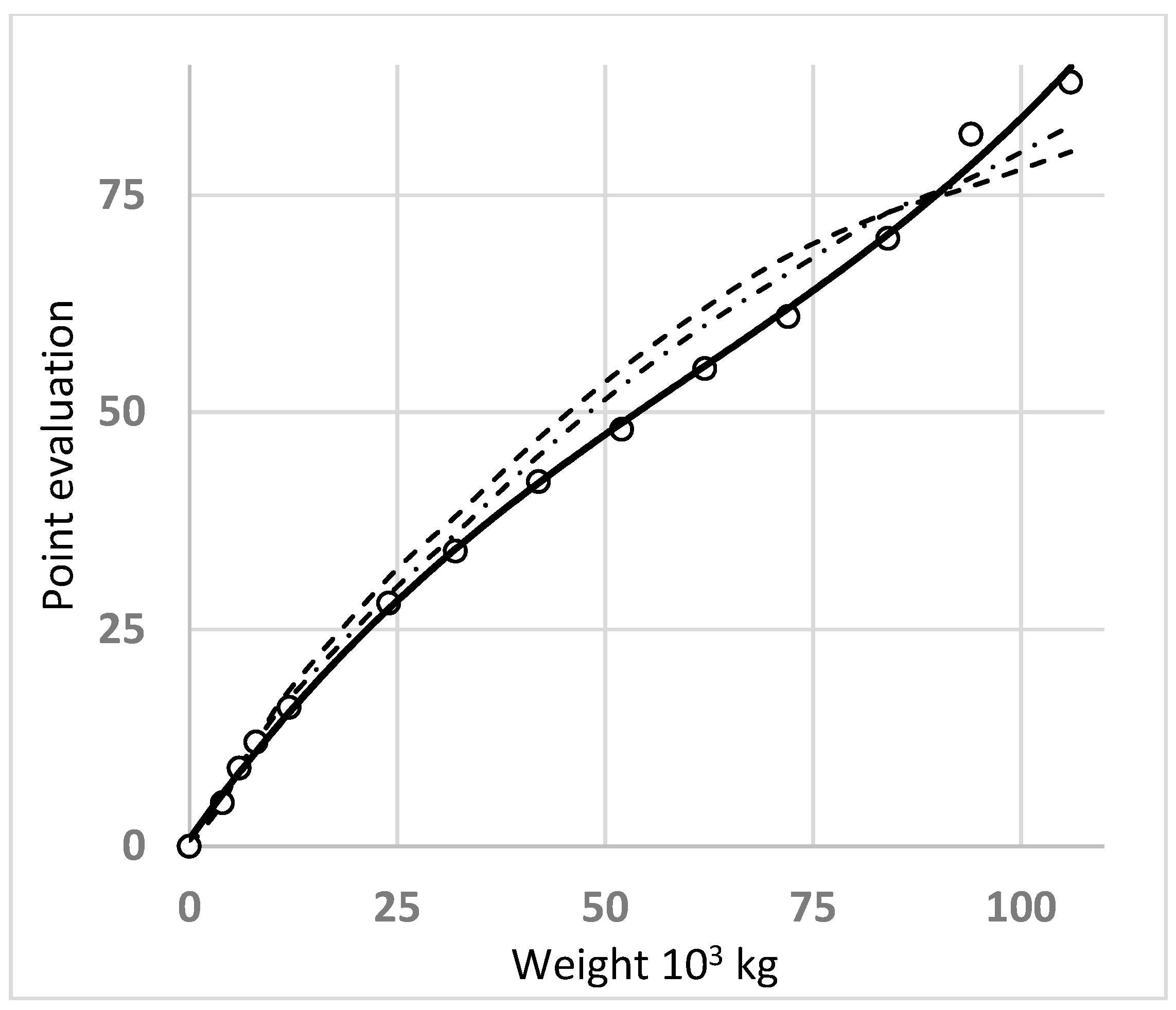

- for the sum of points, the model using the polynomial;

- for the basic level of operational maintenance, the model using a rational fractional function;

- for coefficients, the model using the least squares method.

3. Mathematical Model of Maintenance Standard

- Calculation of the basic level of labor intensity is based on:

- machine complexity: ;

- technical level: ;

- weight: ;

- machine accuracy: ;

- total points: .

The basic level of labor intensity is then - Calculation of final degree of labor intensity is

- In the standards, find the number, type, and extent of maintenance operations for each machine according to .Note: The standard contains information on the annual norm of labor intensity in hours, number of inspections per year, extent of one inspection in hours, number of repairs per year, and the extent of one repair in hours.

- Breakdown of annual standard of labor intensity for:

- electrical maintenance: ,

- machine maintenance: .

- Maintenance staffing calculation

- total hours of annual standard:

- total hours of machine maintenance:

- total hours of electric maintenance:

- staffing total:

4. Model of Operational Maintenance Plan

- annual effective pool of the machine: .

- annual pool of one worker: .

- (a)

- Basic information or possible changes:

- machine importance group,

- way of use (shifts),

- repair characteristics,

- date of last repair,

- machine utilization in %,

- percentage of machine maintenance and electrical maintenance.

- (b)

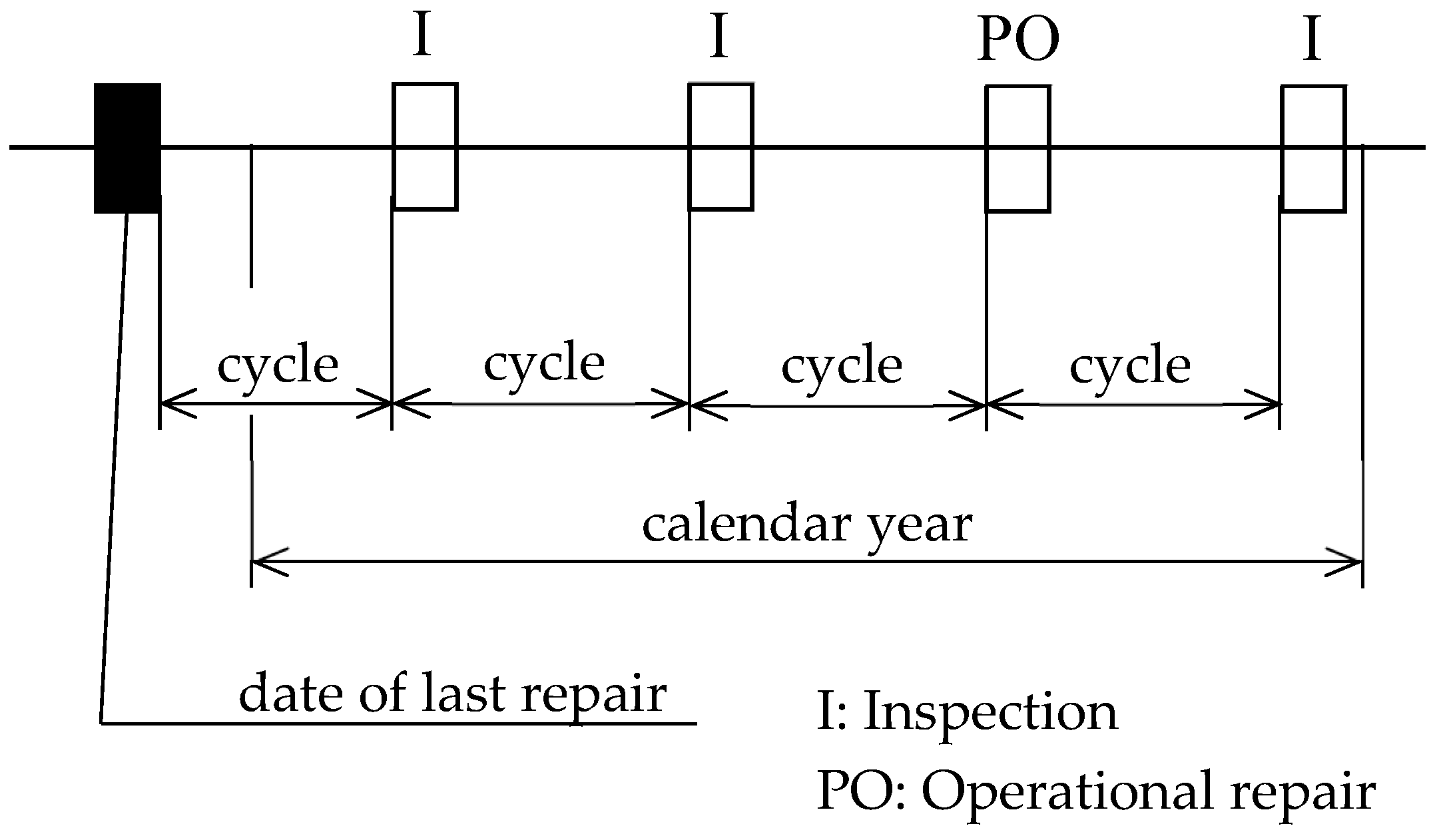

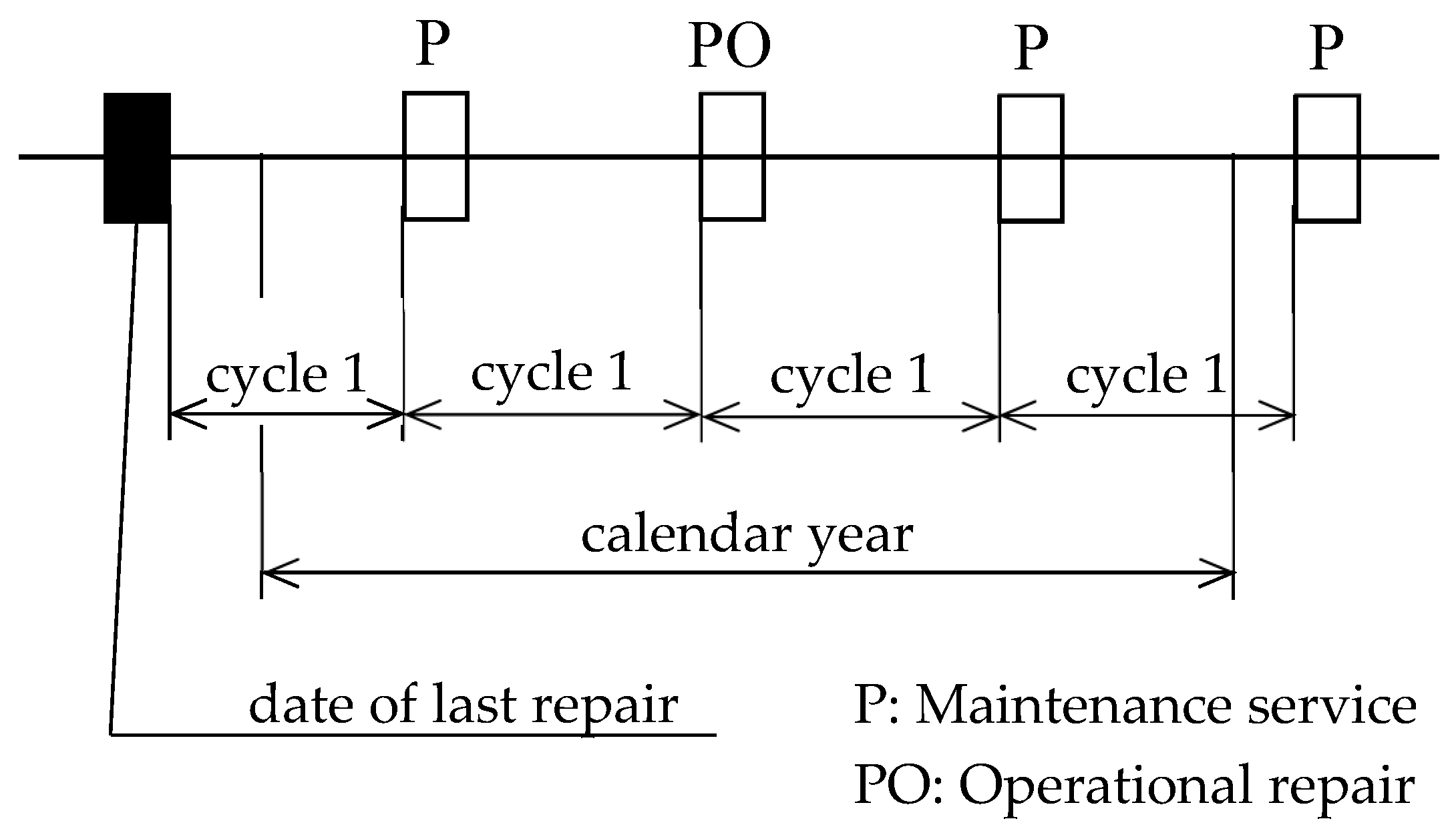

- Calculation of cycles (time between maintenance operations for machine importance groups I, II, and III).

- (c)

- Division of maintenance tasks into time series.

- (d)

- Symmetrical distribution of maintenance tasks, respecting the capacity limitation of maintenance staff, and the use and importance of the machine.

- Calculation of cycles, i.e., periodicity between maintenance activities for:

- Group of importance I: .

- Groups of importance II and III: .

Note: The group of importance I are unique machines, group II are standard machines, and group III are auxiliary machines and equipment. - Distribution of activities into a time series for:Group of importance (Figure 10):Group of importance II and III (Figure 11):

- Symmetrical distribution of maintenance operations with reduced utilization of workers’ capacity, taking into account the importance group of the machines.

5. Discussion

- Determination of the absolute values of indicators used (external-knowledge system, determination of variables based on user experience and recommendations of manufacturers, finding the range of indicator values based on maximizing the probability of trouble-free operation by the calculation and verification using statistical surveys from the existing representative, valid, and reliable data).

- Determination of relative values of used indicators (size of relative intervals, determination of standard indicators, dependence between relative and absolute indicators, compensation of impermissible values of indicators, application of time factor in evaluation).

- Determination of values of complex indicators (weighting coefficients according to experts, scales with individual division according to machine characteristics, errors in determination).

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| coefficients | |

| coefficients | |

| sum of hours of total annual standard | |

| annual standard for electrical maintenance | |

| number of holiday days per year | |

| annual effective pool of workers | |

| annual pool–one worker | |

| daily working time | |

| range of one repair in hours | |

| total capacity of maintenance staff | |

| loss of capacity due to absence or performance of other tasks | |

| loss of capacity due to planned or unplanned repairs | |

| maintenance service | |

| operational repair | |

| machine accuracy | |

| number of machine nodes expressing its complexity | |

| sum of quadrates | |

| function parameter of the basic level of labor intensity | |

| method of use | |

| coefficients | |

| basic level of preventive maintenance | |

| annual standard of labor intensity | |

| annual standard of machine maintenance | |

| sum of hours of electrical maintenance | |

| ratio of electrical maintenance to total standard | |

| annual pool of a machine | |

| range of one repair in hours | |

| resulting level of labor intensity | |

| MW | machine weight |

| loss of capacity due to longer holiday, etc. | |

| group of importance | |

| number of inspections per year | |

| number of repairs per year | |

| number of revisions per year | |

| sum of hours of machine maintenance | |

| function parameter of the basic level of labor intensity | |

| basic level of maintenance labor intensity |

References

- Knopik, L.; Migawa, K. Multi-State Model of Maintenance Policy. Maint. Reliab. 2018, 20, 125–130. [Google Scholar] [CrossRef]

- Valis, D.; Pietrucha-Urbanik, K. Utilization of Diffusion Processes and Fuzzy Logic for Vulnerability Assessment. Eksploat. Niezawodn. Maint. Reliab. 2014, 16, 48–55. [Google Scholar]

- Diaz, N.; Pascual, R.; Ruggeri, F.; Droguett, E.L. Modeling Age Replacement Policy under Multiple Time Scales and Stochastic Usage Profiles. Int. J. Prod. Econ. 2017, 188, 22–28. [Google Scholar] [CrossRef]

- Gulati, R. Workbook to Accompany Maintenance and Reliability Best Practices; Industrial Press: New York, NY, USA, 2013. [Google Scholar]

- Romaniuk, M. Optimization of Maintenance Costs of a Pipeline for a V-Shaped Hazard Rate of Multifunction Intensities. Maint. Reliab. 2018, 20, 46–56. [Google Scholar]

- Malinowski, J. A Newly Developed Method for Computing Reliability Measures in Water Supply Network. Oper. Res. Decis. 2016, 26, 49–64. [Google Scholar]

- Knopik, L. Charakterization of a Class of Lifetime Distributions. Control Cybern. 2006, 35, 1175–1180. [Google Scholar]

- Furch, J. Advanced Maintenance Systems of Military Vehicles. In Intelligent Technologies in Logistics and Mechatronics System ITELMS´2014; Kaunas University of Technology: Kaunas, Lithuania, 2014; pp. 96–103. [Google Scholar]

- Stodola, J.; Bartos, J. Study of the Possibilities of Recording the Basic Means of the Company in the Automatic Control System; Military Academy in Brno studies: Brno, Czech Republic, 2017; 121p. (In Czech) [Google Scholar]

- Janicek, P. System Conception of Selected Fields for Technicians—Searching for Connections. Part 1 and 2; CERM Academic Publishing House: Brno, Czech Republic, 2007; p. 1230. (In Czech) [Google Scholar]

- Bartos, J.; Stodola, J. Computer Programs: APROX, SOUROP, POLYNOM, ZSPU, PLUZPQ; Military Academy and University of Defence: Brno, Czech Republic, 2017. [Google Scholar]

- Computerized Maintenance Management System CMMS. Available online: http://www.act-in.cz/rizeni-udrzby-cmms?utm_source=sklik&utm_medium=cpc&utm_campaign=P2-CMMS-c5%beby+-+ostatn%c3%ad&utm_content=CMMS+Syst%c3%a9m+%c3%badr%c5%beby (accessed on 22 May 2019).

- ISO/IEC 15851:1999 Information Technology—Communication Protocol—Open MUMPS Interconnect. Available online: https://www.iso.org/standard/29269.html (accessed on 10 September 2019).

- Benchmarking Maintanance. NUMERICA s.r.o. Available online: http://www.benchmarkingudrzby.cz/ (accessed on 17 May 2019).

- Industrial Maintenance and Repair. Available online: https://www.henkel-adhesives.com/us/en/industries/industrial-maintenance-repair.html (accessed on 23 April 2019).

- Stodola, J. Mathematical Model of Basic Resource Maintenance. Proc. Mil. Acad. Brno Ser. B Tech. 1988, 34, 126–138. (In Czech) [Google Scholar]

- Valis, D.; Zak, L.; Walek, A.; Pietrucha-Urbanik, K. Selected mathematical functions used for operation data information. In Safety, Reliability and Risk Analysis: Beyond the Horizon; Taylor & Francis Group: London, UK, 2014; pp. 1303–1308. [Google Scholar]

- Jurca, V.; Hladik, T. Maintenance Data Evaluation. Eksploat. Niezawodn. Maintenence Reliab. 2006, 8, 15–18. [Google Scholar]

- Furch, J.; Smal, T. Expedient Repairs-Analysis of Possibilities and Needs. Adv. Mil. Technol. 2011, 6, 69–82. [Google Scholar]

- Schmidt, W.; Taylor, E. Simulation and Analysis of Industrial Systems; Irwin: Homewood, IL, USA, 1970. [Google Scholar]

- Valis, D.; Zak, L. Utilisation of Selected Mathematical Functions for Some Metal Oil Data Evaluation. In Reliability and Statistics in Transportation and Communication (RelStat’14); Transport and Telecommunication Institute: Riga, Latvia, 2014; pp. 344–354. [Google Scholar]

- Furch, J. Determination of Vehicle Durability Based on Life Cycle Costs and Failure Intensity. In Intelligent Technologies in Logistics and Mechatronics Systems ITELMS’2010; Kaunas University of Technology: Kaunas, Lithuania, 2010; pp. 23–26. [Google Scholar]

- Legat, V.; Mosna, F.; Ales, Z.; Jurca, V. Preventive maintenance models–Higher operational reliability. Eksploat. Niezawodn. Maintenence Reliab. 2017, 19, 134–141. [Google Scholar] [CrossRef]

- Novotny, P.; Hrabovsky, J.; Juracka, J.; Klima, J.; Hort, V. Effective Thrust Bearing Model for Simulations of Transient Rotor Dynamics. Int. J. Mech. Sci. 2019, 157, 374–383. [Google Scholar] [CrossRef]

- Enterprise Maintenance Management and Planning TechIS. Available online: https://www.techis.eu/vyuziti/?utm_source=seznam&utm medium=cpc&utm_campaign=VS_TechIS++mix_5299152297&utm_content=%c5%98%c3%adzen%c3%ad+%c3%badr%c5%beby (accessed on 30 April 2019).

| Parameter X | Entered Values | Deviations of Approximated Functions | ||

|---|---|---|---|---|

| Least Squares Method | Coordinate Method | Polynomial Method | ||

| 1 | 1 | 10.31 | 6.11 | −0.19 |

| 2 | 5 | 5.68 | 0.55 | 0.17 |

| 3 | 10 | 0.21 | −7.78 | 1.03 |

| 4 | 20 | −2.73 | −9.40 | −0.95 |

| 5 | 40 | 0.83 | −6.10 | −3.24 |

| 6 | 80 | 19.30 | 12.94 | 6.53 |

| 7 | 100 | 9.77 | 5.91 | −4.40 |

| 8 | 125 | −8.01 | −5.39 | 1.05 |

| Dispersion | 83.86 | 53.48 | 9.46 | |

| Parameter X | Entered Values | Deviations of Approximated Functions | ||

|---|---|---|---|---|

| Least Squares Method | Coordinate Method | Polynomial Method | ||

| 1 | 1 | 0.05 | −0.94 | −0.78 |

| 2 | 4 | 1.08 | 0.07 | −0.15 |

| 3 | 6 | 1.16 | 0.14 | −0.15 |

| 4 | 8 | 2.29 | 0.27 | −0.19 |

| 5 | 10 | 1.49 | 0.45 | −0.13 |

| 6 | 12 | 1.72 | 0.61 | 0.001 |

| 7 | 14 | 2.00 | 0.97 | 0.22 |

| 8 | 16 | 2.33 | 1.30 | 0.51 |

| 9 | 18 | 2.50 | 1.68 | 0.87 |

| 10 | 20 | 3.12 | 2.09 | 0.87 |

| 11 | 21 | 2.58 | 1.45 | 0.78 |

| 12 | 22 | 2.07 | 1.06 | 0.32 |

| 13 | 23 | 1.61 | 0.59 | −0.09 |

| 14 | 24 | 1.18 | 0.17 | −0.45 |

| 15 | 25 | 0.78 | −0.22 | −0.76 |

| 20 | 30 | −0.72 | −1.66 | −1.73 |

| 30 | 40 | −1.71 | −2.52 | −1.32 |

| 40 | 50 | −0.65 | −1.29 | 1.38 |

| 50 | 55 | −3.06 | −3.54 | 0.65 |

| 60 | 60 | −4.31 | −4.62 | 0.55 |

| 70 | 65 | −4.65 | −4.80 | −0.21 |

| 80 | 70 | −4.26 | −4.21 | −2.79 |

| 90 | 85 | 6.72 | 6.84 | 2.78 |

| 100 | 90 | 8.18 | 8.43 | −0.76 |

| Dispersion | 9.79 | 9.12 | 1.19 | |

| Basic Level of Maintenance | Entered Values | Deviations of Approximated Functions | ||

|---|---|---|---|---|

| Least Squares Method | Coordinate Method | Polynomial Method | ||

| 1 | 4–6 | −0.9–4.2 | −1.0–4.4 | 2.5–9.5 |

| 2 | 6–8 | 4.5–10.8 | 4.4–19.9 | 17.0–26.0 |

| 3 | 8–15 | 10.8–18.4 | 10.9–18.6 | 17.0–26.0 |

| 4 | 16–25 | 18.4–27.5 | 18.6–28.0 | 26.0–36.5 |

| 5 | 26–40 | 27.5–38.9 | 28.0–39.5 | 36.5–50.2 |

| 6 | 41–60 | 38.9–53.3 | 39.5–54.2 | 50.2–70.0 |

| 7 | 61–83 | 53.3–72.1 | 54.2–73.7 | 70.0–100.0 |

| 8 | 84–105 | 72.1–97.9 | 73.7 -99.6 | 100.0–150.5 |

| 9 | 106–135 | 97.9–135.2 | 99.6–137.5 | 150.5–212.0 |

| 10 | 136–245 | 135.2–194.2 | 137.5–197.3 | 212.0–308.0 |

| 11 | 246–330 | 194.2–301.3 | 197.3–305.5 | 308.0–387.5 |

| 12 | 331–400 | 301.3–555.9 | 305.5–560.0 | 387.5–409.3 |

| 13 | 401 and next | 555.9–1982 | 560.0–1906 | 409.3–423.2 |

| Dispersion | ||||

| No. | Number of Groups | Degree of Accuracy | Technical Level | Weight in t | Manual Sum of | Processing |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 3 | 2 | 24 | 4 |

| 2 | 4 | 4 | 2 | 4 | 33 | 5 |

| 3 | 5 | 2 | 4 | 5 | 57 | 6 |

| 4 | 6 | 11 | 3 | 7 | 71 | 7 |

| 5 | 7 | 6 | 4 | 10 | 95 | 8 |

| 6 | 8 | 12 | 4 | 15 | 121 | 9 |

| 7 | 9 | 9 | 5 | 50 | 185 | 10 |

| 8 | 10 | 50 | 7 | 30 | 290 | 11 |

| 9 | 15 | 11 | 6 | 40 | 366 | 12 |

| 10 | 18 | 80 | 7 | 100 | 594 | 13 |

| Serial Number | Sum Deviations | Sum Deviations | ||||

|---|---|---|---|---|---|---|

| Least Squares Method | Coordinate Method | Polynomial Method | Least Squares Method | Coordinate Method | Polynomial Method | |

| 1 | −1.3 | 5.7 | −1.0 | 0.0 | 1.0 | 0.0 |

| 2 | −7.0 | −0.8 | 0.0 | −1.0 | 0.0 | 0.0 |

| 3 | 1.2 | 7.9 | 1.0 | 1.0 | 1.0 | 1.0 |

| 4 | −2.2 | 4.8 | −1.2 | 0.0 | 0.0 | 0.0 |

| 5 | −0.4 | 7.3 | −0.4 | 0.0 | 0.0 | 0.0 |

| 6 | 1.9 | 9.6 | 1.7 | 0.0 | 0.0 | 0.0 |

| 7 | 2.3 | 9.6 | 2.5 | 0.0 | 0.0 | 0.0 |

| 8 | −8.1 | −3.4 | 5.7 | 0.0 | 1.0 | 0.0 |

| 9 | −18.6 | −11.7 | −7.9 | 0.0 | 0.0 | −1.0 |

| 10 | −18.0 | −14.3 | 5.3 | 0.0 | 0.0 | 95 |

| Dispersion | 80.2 | 70.9 | 13.6 | 0.2 | 0.3 | 902.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stodola, P.; Stodola, J. Model of Predictive Maintenance of Machines and Equipment. Appl. Sci. 2020, 10, 213. https://doi.org/10.3390/app10010213

Stodola P, Stodola J. Model of Predictive Maintenance of Machines and Equipment. Applied Sciences. 2020; 10(1):213. https://doi.org/10.3390/app10010213

Chicago/Turabian StyleStodola, Petr, and Jiří Stodola. 2020. "Model of Predictive Maintenance of Machines and Equipment" Applied Sciences 10, no. 1: 213. https://doi.org/10.3390/app10010213

APA StyleStodola, P., & Stodola, J. (2020). Model of Predictive Maintenance of Machines and Equipment. Applied Sciences, 10(1), 213. https://doi.org/10.3390/app10010213