Introduction of a New Index of Field Operations Efficiency

Abstract

1. Introduction

2. Materials and Methods

2.1. Overview

- (1)

- Generation of the fixed entities. This step includes the generation of the headland passes, and the field-work tracks (presented in Section “Fixed Entities”).

- (2)

- Generation of connectors. Four types of connectors that connects the fixed entities are generated (presented in Section “Generation of Connectors”).

- (3)

- Generation of a continuous path for field coverage. Formulation of the field coverage problem as the problem of traversing an undirected weighted graph (presented in Section “Continuous Path Generation”).

- The coordinates of the edges of the polygon representing the field boundary (B);

- The machine’s effective operating width (w);

- The driving angle (θ), which defines the direction of tracks (in relation to the Universal Transverse Mercator (UTM)-Easting axis);

- The number of headland passes (h).

- The minimum turning radius of the vehicle (r).

- The coordinates of the location of the field gate where vehicles can enter and exit the field (E).

- The fieldwork pattern (F), which determines the traversing order of the track sequence.

- (a)

- Path generation for fields with obstacles is not considered.

- (b)

- The methodology can only be applied to non-capacitated field operations such as tillage, plough, and so on.

2.2. Generation of Continuous Path

2.2.1. Fixed Entities

- (a)

- Headland pass (H): A headland pass is a concentric path covering the headland area at the same width as the operating width , of the implement which is made up of a set of sequentially clockwise ordered points. An inner boundary between the headland area and the work area is created at a distance half of the operating width w/2 from the last headland passes, the area enclosed by the inner boundary is denoted the field body area.

- (b)

- Row (R): The field body area is covered by parallel rows that transect the area. The width of each row equals the operating width w of the machine.

- (c)

- Field-work track (T): A track is represented by two ending points is the central line of a row and is used as the guidance line for the machine to cover each row.

2.2.2. Generation of Connectors

- Gate-to-headland connector (G2H): A connection path between the field gate and the first headland pass. The G2H connectors provide the path for the agricultural vehicles to enter and exit the field area.

- Headland-to-headland connector (H2H): A connection path between two adjacent headland passes. These connectors are used for agricultural vehicles to move between headland passes.

- Track-to-headland connector (T2H): A connection path between a track end and a headland pass for agricultural vehicles to drive from a track to a headland pass or vice versa.

- Track-to-track connector (T2T): A connection path between a track end and another track end.

2.2.3. Continuous Path Generation

- is a function for headland traversing path generation, which finds all adjacent vertices {} of that directly link with in the graph based on the given direction .

- finds the shortest path with a sequence of vertices from a source vertex to a target vertex on the graph (by implementing the Dijkstra’s algorithm [16].

- returns the two vertex ids which correspond to edge in sequence when or in sequence when .

- returns the edge that links .

- returns the last vertex of path .

| Algorithm 1. Pseudo codes for continuous path generation. | ||

| Initialization: | ||

| Pathis initialized as set=that starts at gate. | ||

| path generation: | ||

| Get all edges with type, | ||

| While | ||

| Apply to get all adjacent vertices of the last vertex of path ; | ||

| ; | ||

| Then add e to path; and removefrom; | ||

| Else if,then add headland connector e to path. | ||

| End | ||

| path generation: | ||

| ; | ||

| # Find the path from last vertex ofto starting vertex of track edge; | ||

| For) do: | ||

| ; # Add vertices of track edgeto path | ||

| ; # Add path that is from end vertex ofto start vertex ofto path | ||

| ; # Add vertices of track edgeto path | ||

| End | ||

| path generation: | ||

| ; # Exiting field from last vertex of path | ||

2.2.4. Distance-Based Field Efficiency

2.3. Sample Fields Scenarios

- (a)

- (b)

- Machinery system: Three different types of machinery with different implements were considered in terms of sizes and maneuverability (minimum turning radius). Specifically, a large sized machine with a minimum turning radius of 6 m, a medium sized machine with a minimum turning radius of 4.5 m, and a small sized unit with minimum turning radius of 3 m, were selected. The selected implements’ width ranged from 3 m to 12 m. The specific test setups of machinery and implements (Table 1) have been selected as typical configurations implemented in field operation management assessments [17,18].

- (c)

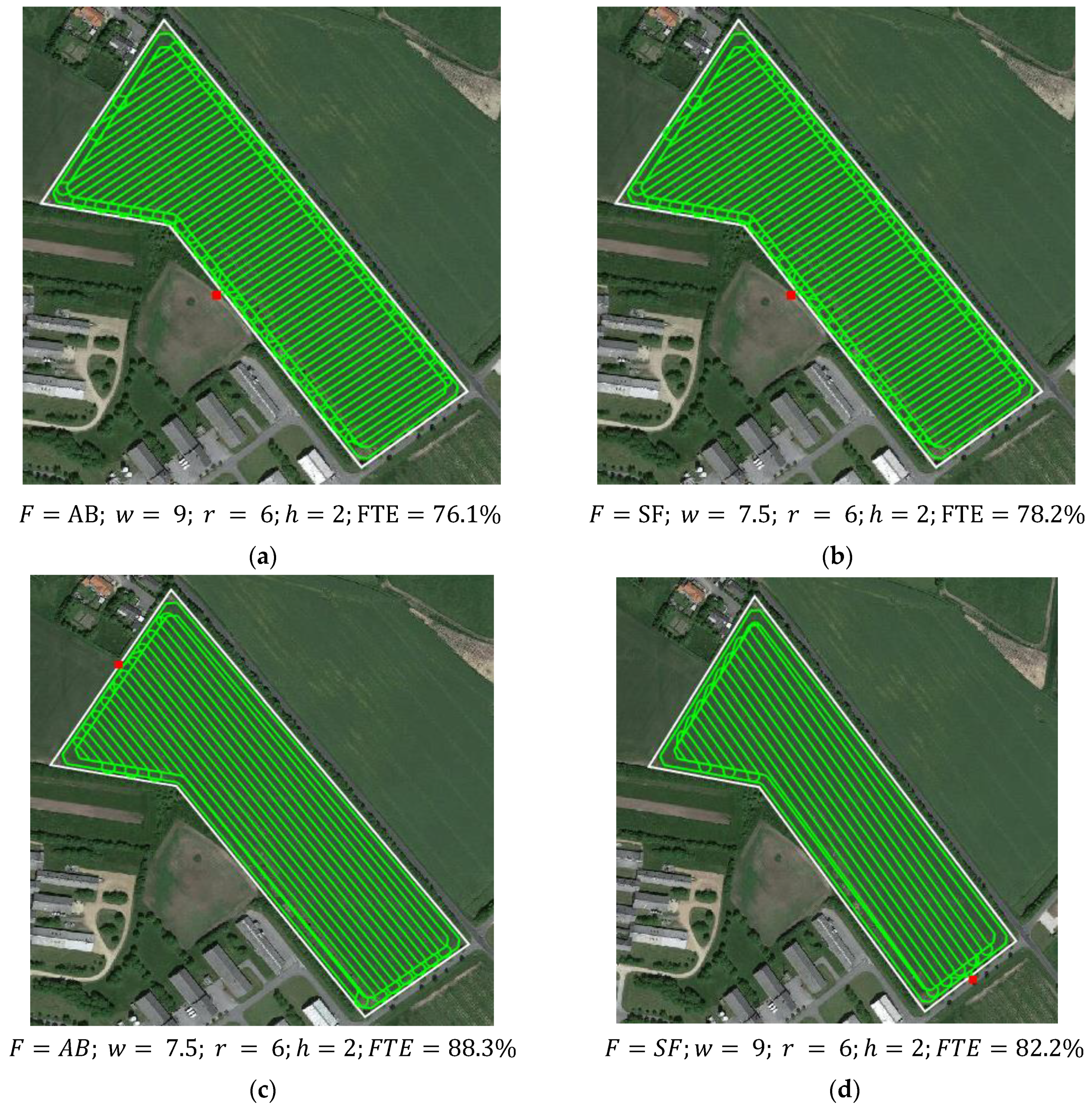

- Fieldwork pattern: Three different common used fieldwork patterns (Figure 9a, AB; Figure 9b, SF; and Figure 9c, BL) were selected for the assessment. Each fieldwork pattern is represented mathematically with the traversal function, which produces the traversal sequence of the field tracks. The specific traversal functions of these three patterns are provided in Bochtis et al. (2013) [17]. The fieldwork pattern defines the traversal sequence of field-work tracks, thereby determining the total non-working turning distance in the headland area, and subsequently determining how efficient the machinery performs, in terms of distance covered [21].

- (d)

- Driving direction: The driving direction is an important factor in determining the number of tracks and their length, and subsequently affecting the field efficiency. Four driving directions ( = , , , and ) were selected.

3. Results

3.1. Effect of Field Shape on FTE

3.2. Effect of Fieldwork Pattern on FTE

3.3. Effect of Driving Direction on FTE

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hunt, D. Farm Power and Machinery Management; IOWA University Press: Iowa City, IA, USA, 2001; Volume I, pp. 77–93. [Google Scholar]

- Bochtis, D.D.; Sørensen, C.G.; Busato, P.; Hameed, I.A.; Rodias, E.; Green, O.; Papadakis, G. Tramline establishment in controlled traffic farming based on operational machinery cost. Biosyst. Eng. 2010, 107, 221–231. [Google Scholar] [CrossRef]

- Lampridi, M.G.; Kateris, D.; Vasileiadis, G.; Marinoudi, V.; Pearson, S.; Sørensen, C.G.; Balafoutis, A.; Bochtis, D. A Case-Based Economic Assessment of Robotics Employment in Precision Arable Farming. Agronomy 2019, 9, 175. [Google Scholar] [CrossRef]

- Busato, P.; Berruto, R.; Saunders, C. Logistics and efficiency of grain harvest and transport systems in a south australian context. In American Society of Agricultural and Biological Engineers Annual International Meeting 2008, ASABE 2008; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2008; Volume 9, pp. 5336–5347. [Google Scholar]

- Li, Y.L.; Yi, S.P. Improving the efficiency of spatially selective operations for agricultural robotics in cropping field. Span. J. Agric. Res. 2013, 11, 56–63. [Google Scholar] [CrossRef]

- Grisso, R.D.; Kocher, M.F.; Adamchuk, V.I.; Jasa, P.J.; Schroeder, M.A. Field efficiency determination using traffic pattern indices. Appl. Eng. Agric. 2004, 20, 563–572. [Google Scholar] [CrossRef]

- Oksanen, T. Shape-describing indices for agricultural field plots and their relationship to operational efficiency. Comput. Electron. Agric. 2013, 98, 252–259. [Google Scholar] [CrossRef]

- Vizzari, M.; Santaga, F.; Benincasa, P. Sentinel 2-Based Nitrogen VRT Fertilization in Wheat: Comparison between Traditional and Simple Precision Practices. Agronomy 2019, 9, 278. [Google Scholar] [CrossRef]

- Scudiero, E.; Teatini, P.; Manoli, G.; Braga, F.; Skaggs, T.; Morari, F. Workflow to Establish Time-Specific Zones in Precision Agriculture by Spatiotemporal Integration of Plant and Soil Sensing Data. Agronomy 2018, 8, 253. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Sørensen, C.G.; Jørgensen, R.N.; Green, O. Modelling of material handling operations using controlled traffic. Biosyst. Eng. 2009, 103, 397–408. [Google Scholar] [CrossRef][Green Version]

- Skou-Nielsen, N.; Villa-Henriksen, A.; Green, O.; Edwards, G.T.C. Creating a statistically representative set of Danish agricultural field shapes to robustly test route planning algorithms. Adv. Anim. Biosci. 2017, 8, 615–619. [Google Scholar] [CrossRef]

- Zandonadi, R.S.; Luck, J.D.; Stombaugh, T.S.; Shearer, S.A. Evaluating field shape descriptors for estimating off-target application area in agricultural fields. Comput. Electron. Agric. 2013, 96, 217–226. [Google Scholar] [CrossRef]

- Larson, J.A.; Velandia, M.M.; Buschermohle, M.J.; Westlund, S.M. Effect of field geometry on profitability of automatic section control for chemical application equipment. Precis. Agric. 2016, 17, 18–35. [Google Scholar] [CrossRef]

- Martelloni, L.; Fontanelli, M.; Pieri, S.; Frasconi, C.; Caturegli, L.; Gaetani, M.; Grossi, N.; Magni, S.; Pirchio, M.; Raffaelli, M.; et al. Assessment of the Cutting Performance of a Robot Mower Using Custom Built Software. Agronomy 2019, 9, 230. [Google Scholar] [CrossRef]

- Dubins, L.E. On Curves of Minimal Length with a Constraint on Average Curvature, and with Prescribed Initial and Terminal Positions and Tangents. Am. J. Math. 1957, 79, 497–516. [Google Scholar] [CrossRef]

- Chen, J. Dijkstra’s shortest path algorithm. J. Formaliz. Math. 2003, 15, 237–247. [Google Scholar]

- Bochtis, D.D.; Sørensen, C.G.; Busato, P.; Berruto, R. Benefits from optimal route planning based on B-patterns. Biosyst. Eng. 2013, 115, 389–395. [Google Scholar] [CrossRef]

- Rodias, E.; Berruto, R.; Busato, P.; Bochtis, D.; Sørensen, C.; Zhou, K. Energy Savings from Optimised In-Field Route Planning for Agricultural Machinery. Sustainability 2017, 9, 1956. [Google Scholar] [CrossRef]

- Gunnarsson, C.; Vågström, L.; Hansson, P.A. Logistics for forage harvest to biogas production-Timeliness, capacities and costs in a Swedish case study. Biomass Bioenergy 2008, 32, 1263–1273. [Google Scholar] [CrossRef]

- Witney, B. Choosing & Using Farm Machines; Longman Higher Education: Essex, UK, 1988. [Google Scholar]

- Bochtis, D.; Griepentrog, H.W.; Vougioukas, S.; Busato, P.; Berruto, R.; Zhou, K. Route planning for orchard operations. Comput. Electron. Agric. 2015, 113, 51–60. [Google Scholar] [CrossRef]

- Zhou, K.; Leck Jensen, A.; Bochtis, D.D.; Sørensen, C.G. Simulation model for the sequential in-field machinery operations in a potato production system. Comput. Electron. Agric. 2015, 116, 173–186. [Google Scholar] [CrossRef]

- Zhou, K.; Jensen, A.L.; Bochtis, D.D.; Sørensen, C.G. Quantifying the benefits of alternative fieldwork patterns in a potato cultivation system. Comput. Electron. Agric. 2015, 119, 228–240. [Google Scholar] [CrossRef]

- Zhou, K.; Leck Jensen, A.; Sørensen, C.G.; Busato, P.; Bothtis, D.D. Agricultural operations planning in fields with multiple obstacle areas. Comput. Electron. Agric. 2014, 109, 12–22. [Google Scholar] [CrossRef]

- Boryga, M.; Graboś, A.; Kołodziej, P.; Gołacki, K.; Stropek, Z. Trajectory Planning with Obstacles on the Example of Tomato Harvest. Agric. Agric. Sci. Procedia 2015, 7, 27–34. [Google Scholar] [CrossRef]

- Hameed, I.A.; Bochtis, D.D.; Sørensen, C.G.; Jensen, A.L.; Larsen, R. Optimized driving direction based on a three-dimensional field representation. Comput. Electron. Agric. 2013, 91, 145–153. [Google Scholar] [CrossRef]

- Hameed, I.A.; la Cour-Harbo, A.; Osen, O.L. Side-to-side 3D coverage path planning approach for agricultural robots to minimize skip/overlap areas between swaths. Robot. Auton. Syst. 2016, 76, 36–45. [Google Scholar] [CrossRef]

- Hameed, I.A.; Bochtis, D.D.; Sørensen, C.G.; Vougioukas, S. An object-oriented model for simulating agricultural in-field machinery activities. Comput. Electron. Agric. 2012, 81, 24–32. [Google Scholar] [CrossRef]

- Jensen, M.F.; Bochtis, D.; Sørensen, C.G. Coverage planning for capacitated field operations, part II: Optimisation. Biosyst. Eng. 2015, 139, 149–164. [Google Scholar] [CrossRef]

| Large size machine | 6 | 4.5 | 7.5 | 9 | 10.5 | 12 |

| Medium size machine | 4.5 | 4.5 | 6 | 7.5 | 9 | - |

| Small size machine | 3 | 3 | 4.5 | 6 | - | - |

| Field Shape | Scenario Returning Minimum FTE | Scenario Returning Maximum FTE | ||||||

|---|---|---|---|---|---|---|---|---|

| Pattern | Width (m) | Radius (m) | Direction (Degrees) | Pattern | Width (m) | Radius (m) | Direction (Degrees) | |

| SQR | SF | 12 | 6 | 30 | BL | 4.5 | 3 | 0 |

| STD | SF | 12 | 6 | 30 | BL | 3 | 3 | 0 |

| R41 | AB | 4.5 | 6 | 30 | AB | 6 | 3 | 90 |

| R21 | SF | 12 | 6 | 30 | AB | 4.5 | 3 | 90 |

| REN | SF | 12 | 6 | 30 | BL | 3 | 3 | 0 |

| BPL | SF | 9 | 6 | 60 | AB | 6 | 3 | 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, K.; Bochtis, D.; Jensen, A.L.; Kateris, D.; Sørensen, C.G. Introduction of a New Index of Field Operations Efficiency. Appl. Sci. 2020, 10, 329. https://doi.org/10.3390/app10010329

Zhou K, Bochtis D, Jensen AL, Kateris D, Sørensen CG. Introduction of a New Index of Field Operations Efficiency. Applied Sciences. 2020; 10(1):329. https://doi.org/10.3390/app10010329

Chicago/Turabian StyleZhou, Kun, Dionysis Bochtis, Allan Leck Jensen, Dimitrios Kateris, and Claus Grøn Sørensen. 2020. "Introduction of a New Index of Field Operations Efficiency" Applied Sciences 10, no. 1: 329. https://doi.org/10.3390/app10010329

APA StyleZhou, K., Bochtis, D., Jensen, A. L., Kateris, D., & Sørensen, C. G. (2020). Introduction of a New Index of Field Operations Efficiency. Applied Sciences, 10(1), 329. https://doi.org/10.3390/app10010329