Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study

Abstract

Featured Application

Abstract

1. Introduction

2. Effect of Emissions on Atmospheric CO2 and Global Temperature

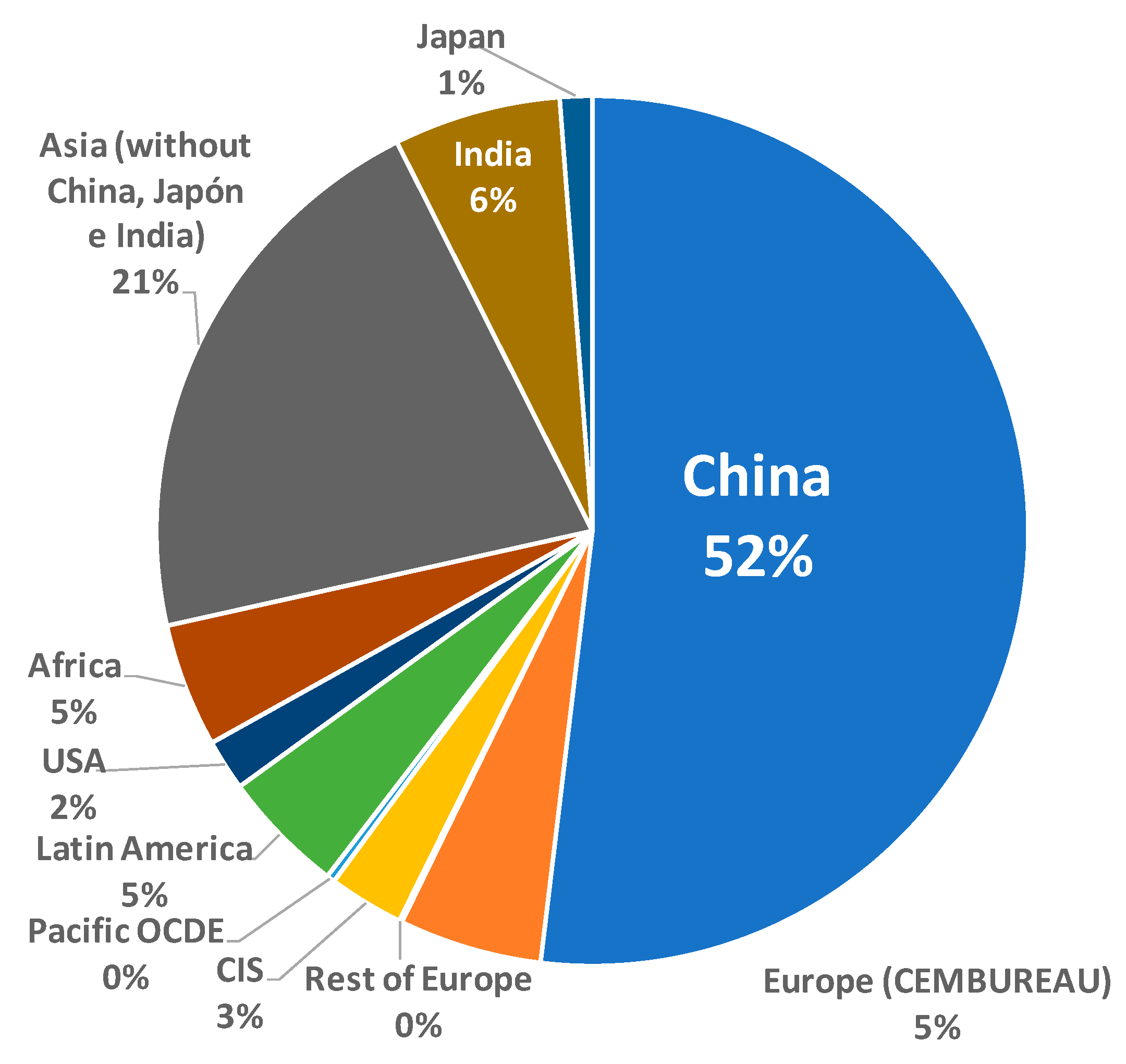

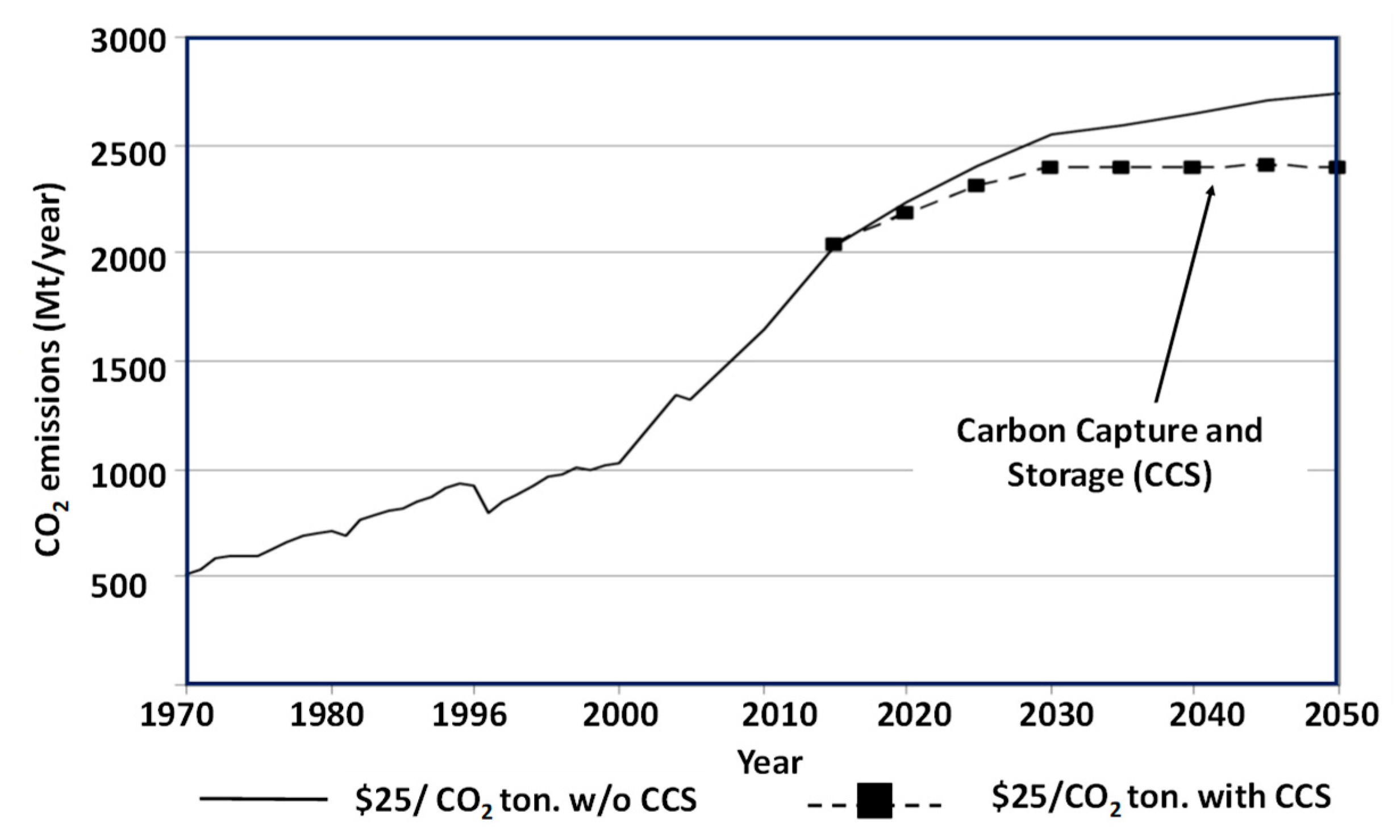

3. Carbon Dioxide Emissions by the Cement Sector

4. Carbon Dioxide Uptake by Concrete

5. Methodology

6. Results and Discussion

6.1. Maximum Amount of Carbon Dioxide that Can Be Absorbed

6.2. Carbon Dioxide Uptake by the Spanish Cements

6.3. Carbon Dioxide Indicators for Concretes

7. Conclusions

- Carbon dioxide absorption attributed to the Spanish cements produced from 2005 to 2015 was estimated at 31,290,753 tons when using the simplified methodology, i.e., applying a factor of 0.20 during the service life and 0.03 for the end-of-life and secondary use.

- The net carbon dioxide emissions related to the Portland cement clinker industry (CO2 released in clinker fabrication minus CO2 uptake by concrete carbonation) should be implemented in the climatic models of the next IPCC assessment report.

- This simplified model developed by experts in the mortar and concrete carbonation field should be validated by each country. Thus, it will allow the national climate change offices to implement these methodologies in the national greenhouse gas inventories.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- The Intergovernmental Panel on Climate Change. IPCC 2013: Summary for Policymakers. In Climate change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, 1st ed.; Stocker, T.F., Qin, D., Plattner, G.-K., Tignor, M.M.B., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: New York, NY, USA, 2013; pp. 1–203. [Google Scholar]

- The Intergovernmental Panel on Climate Change (IPCC). Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, 1st ed.; Edenhofer, O.R., Pichs-Madruga, Y., Sokona, E., Farahani, S., Kadner, K., Seyboth, A., Adler, I., Baum, S., Brunner, P., Eickemeier, B., et al., Eds.; Cambridge University Press: New York, NY, USA, 2014; pp. 1–1523. [Google Scholar]

- The European Space Agency. Available online: http://www.esa.int/Applications/Observing_the_Earth/Methane_and_carbon_dioxide_on_the_rise (accessed on 9 December 2019).

- The European Cement Association (CEMBUREAU). Activity Report, 1st ed.; CEMBUREAU: Brussels, Belgium, 2017; pp. 1–42. Available online: https://cembureau.eu/media/1716/activity-report-2017.pdf (accessed on 16 October 2019).

- World Business Council for Sustainable Development (WBCSD); Cement Sustainability Initiative’s (CSI). Cement Industry Energy and CO2 Performance. Getting the Numbers Right (GNR) Project, 1st ed.; World Business Council for Sustainable Development: Geneva, Switzerland, 2018; Available online: http://www.wbcsdcement.org/index.php/key-issues/climate-protection/gnr-database (accessed on 10 September 2019).

- Elzinga, D.; Bennett, S.; Best, D.; Burnard, K.; Cazzola, P.; D’Ambrosio, D.; Dulac, J.; Fernandez Pales, A.; Hood, C.; LaFrance, M.; et al. Energy Technology Perspectives 2015: Mobilising Innovation to Accelerate Climate Action, 1st ed.; International Energy Agency (IEA) Publications: Paris, France, 2015; pp. 1–412. [Google Scholar]

- García-Gusano, D.; Herrera, I.; Garraín, D.; Lechón, Y.; Cabal, H. Life Cycle Assessment of the Spanish Cement Industry: Implementation of Environmental-Friendly Solutions. Clean Technol. Environ. Policy 2014, 17, 59–73. [Google Scholar] [CrossRef]

- Hoenig, V.; Hoppe, H.; Emberger, B. Carbon Capture Technology—Options and Potentials for the Cement Industry, 1st ed.; European Cement Research Academy (ECRA): Düsseldorf, Germany, 2007; pp. 1–96. [Google Scholar]

- International Energy Agency (IEA). Energy Technology Perspectives. Scenarios & Strategies to 2050, 1st ed.; IEA/OECD: Paris, France, 2006. [Google Scholar]

- Morandeau, A.; Thiery, M.; Dangla, P. Investigation of the carbonation mechanism of CH and CSH in terms of kinetics, microstructure changes and moisture properties. Cem. Concr. Res. 2014, 56, 153–170. [Google Scholar] [CrossRef]

- Sevelsted, T.F.; Skibsted, J. Carbonation of C–S–H and C–A–S–H samples studied by 13C, 27Al and 29Si MAS NMR spectroscopy. Cem. Concr. Res. 2015, 71, 56–65. [Google Scholar] [CrossRef]

- Zhou, Q.; Glasser, F. Kinetics and mechanism of the carbonation of ettringite. Adv. Cem. Res. 2000, 12, 131–136. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford: London, UK, 1997; pp. 1–459. [Google Scholar]

- Goñi, S.; Gaztañaga, M.; Guerrero, A. Role of cement type on carbonation attack. J. Mater. Res. 2002, 17, 1834–1842. [Google Scholar] [CrossRef]

- Andrade, C.; Sanjuán, M.A. Updating Carbon Storage Capacity of Spanish Cements. Sustainability 2018, 10, 4806. [Google Scholar] [CrossRef]

- Sanjuán, M.A.; Estévez, E.; Argiz, C.; del Barrio, D. Effect of curing time on granulated blast-furnace slag cement mortars carbonation. Cem. Concr. Compos. 2018, 90, 257–265. [Google Scholar] [CrossRef]

- Sanjuán, M.A.; Piñeiro, A.; Rodríguez, O. Ground granulated blast furnace slag efficiency coefficient (k value) in concrete. Applications and limits. Mater. Constr. 2011, 61, 303–313. [Google Scholar] [CrossRef]

- Nygaard, P.V.; Leemann, A. Carbon Dioxide Uptake of Reinforced Concrete Structures Due to Carbonation. Abteilung Beton/Bauchemie. Cemsuisse projekt 201106, 1st ed.; EMPA: Dübendorf, Switzertland, 2012; pp. 1–65. [Google Scholar]

- Xi, F.; Davis, S.J.; Ciais, P.; Crawford-Brown, D.; Guan, D.; Pade, C.; Shi, T.; Syddall, M.; Lv, J.; Ji, L.; et al. Substantial global carbon uptake by cement carbonation. Nat. Geosci. 2016, 9, 880–883. [Google Scholar] [CrossRef]

- Steinour, H.H. Some effects of carbon dioxide on mortars and concrete discussion. J. Am. Concr. Inst. 1959, 30, 905–907. [Google Scholar] [CrossRef]

- Pade, C.; Guimaraes, M. The CO2 uptake of concrete in a 100 year perspective. Cem. Concr. Res. 2007, 37, 1348–1356. [Google Scholar] [CrossRef]

- Gajda, J.; Miller, F.M. Concrete as a Sink for Atmospheric Carbon Dioxide: A Literature Review and Estimation of CO2 Absorption by Portland Cement Concrete. R&D Serial N°2255, 1st ed.; PCA: Chicago, IL, USA, 2000. [Google Scholar]

- Talukdar, S.; Banthia, N.; Grace, J.; Cohen, S. Carbonation in concrete infrastructure in the context of global climate change: Part 2—Canadian urban simulations. Cem. Concr. Compos. 2012, 34, 931–935. [Google Scholar] [CrossRef]

- Andersson, R.; Fridh, K.; Stripple, H.; Häglund, M. Calculating CO2 Uptake for Existing Concrete Structures during and after Service Life. Environ. Sci. Technol. 2013, 47, 11625–11633. [Google Scholar] [CrossRef] [PubMed]

- Galán, I.; Andrade, C.; Mora, P.; Sanjuán, M.A. Sequestration of CO2 by Concrete Carbonation. Environ. Sci. Technol. 2010, 44, 3181–3186. [Google Scholar] [CrossRef] [PubMed]

- Stripple, H.; Ljungkrantz, C.; Gustafsson, T. CO2 Uptake in Cement-Containing Products. Background and Calculation Models for IPCC Implementation, 1st ed.; Report number: B 2309; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2018; pp. 20–30. Available online: https://cembureau.eu/media/1753/ivl-report-co2-uptake-in-cement-containing-products-isbn-number-b2309.pdf (accessed on 16 October 2019).

- CEN. Sustainability of Construction Works—Environmental Product Declarations—Product Category Rules for Concrete and Concrete Elements. Annex BB (Informative). CO2 Uptake by Carbonation—Guidance on Calculation; European Committee for Standardization (CEN): Brussels, Belgium, 2016. [Google Scholar]

- Sanjuán, M.A.; Argiz, C. The new European standard on common cements specifications, EN-197-1:2011. Mater. Constr. 2012, 62, 425–430. [Google Scholar] [CrossRef]

- EU Technical Expert Group on Sustainable Finance. Financing a Sustainable European Economy. Taxonomy Technical Report, 1st ed.; European Commission: Brussels, Belgium, 2019; pp. 191–196. Available online: https://ec.europa.eu/info/sites/info/files/business_economy_euro/banking_and_finance/documents/190618-sustainable-finance-teg-report-taxonomy_en.pdf (accessed on 16 October 2019).

- Flato, G.; Marotzke, J.; Abiodun, B.; Braconnot, P.; Chou, S.C.; Collins, W.; Cox, P.; Driouech, F.; Emori, S.; Eyring, V.; et al. Evaluation of Climate Models. In Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, 1st ed.; Stocker, T.F., Qin, D., Plattner, G.-K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: Cambridge, UK, 2013; pp. 741–866. [Google Scholar]

- Andrade, C.; Sanjuán, M.A.; Rebolledo, N. Reliability calibration by carbonation exposure class deemed-to-satisfy prescriptions of Spanish concretes. Concreto Construções 2018, 91, 97–102. Available online: http://ibracon.org.br/Site_revista/Concreto_Construcoes/ebook/edicao91/files/assets/basic-html/index.html#102 (accessed on 16 October 2019).

- Jeon, E.-D.; Lee, K.-U.; Lee, C.-K. Development of a New Clean Development Mechanism Methodology for the Quantification of Greenhouse Gas in Calcium Sulfoaluminate Cement. Sustainability 2019, 11, 1482. [Google Scholar] [CrossRef]

- Wang, X.-Y. Impact of Climate Change on the Optimization of Mixture Design of Low-CO2 Concrete Containing Fly Ash and Slag. Sustainability 2019, 11, 3394. [Google Scholar] [CrossRef]

- Pearce, T.D.; Rodríguez, E.H.; Fawcett, D.; Ford, J.D. How Is Australia Adapting to Climate Change Based on a Systematic Review? Sustainability 2018, 10, 3280. [Google Scholar] [CrossRef]

| Carbon Dioxide Emissions Reduction (Per Ton of Clinker or Cementitious) | Grey Clinker | Cementitious |

|---|---|---|

| Gross carbon dioxide emissions | −9% | Data −13% |

| Net carbon dioxide emissions | −17% | −21% |

| Main Types | Type Name | Type Notation | Clínker, K | Minor Additional Constituents | Factor (Kcement/KCEM I) | Factor (Kcement/KCEM I) | CO2,max, |

|---|---|---|---|---|---|---|---|

| kg CO2/tcement | |||||||

| CEM I | Portland cement | CEM I | 95–100 | 0–5 | 95/95 = 1 | 1 | 490 |

| CEM II | Portland slag cement | CEM II/A-S CEM II/B-S | 80–88 | 0–5 | 80/95–94/95 | 0.84–0.99 | 410–480 |

| 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 340–410 | |||

| Portland/silica fume cement | CEM II/A-D | 90–94 | 0–5 | 90/95–94/95 | 0.95–0.99 | 460–480 | |

| Portland pozzolana cement | CEM II/A-P | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 410–480 | |

| CEM II/B-P | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 340–410 | ||

| CEM II/A-Q | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 410–480 | ||

| CEM II/B-Q | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 340–410 | ||

| Portland–fly ash cement | CEM II/A-V | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 410–480 | |

| CEM II/B-V | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 340–410 | ||

| CEM II/A-W | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 410–480 | ||

| CEM II/B-W | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 340–410 | ||

| Portland-burnt shale cement | CEM II/A-T | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 410–480 | |

| CEM II/B-T | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 340–410 | ||

| Portland limestone cement | CEM II/A-L | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 410–480 | |

| CEM II/B-L | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 340–410 | ||

| CEM II/A-LL | 80–94 | 0–5 | 80/95–94/95 | 0.84–0.99 | 410–480 | ||

| CEM II/B-LL | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 340–410 | ||

| Portland composite cement | CEM II/A-M | 80–88 | 0–5 | 80/95–94/95 | 0.84–0.99 | 410–480 | |

| CEM II/B-M | 65–79 | 0–5 | 65/95–79/95 | 0.68–0.83 | 340–410 | ||

| CEM III | Blast furnace cement | CEM III/A | 35–64 | 0–5 | 35/95–64/95 | 0.37–0.67 | 180–330 |

| CEM III/B | 20–34 | 0–5 | 20/95–34/95 | 0.21–0.36 | 100–180 | ||

| CEM III/C | 5–19 | 0–5 | 5/95–19/95 | 0.05–0.20 | 30–100 | ||

| CEM IV | Pozzolanic cement | CEM IV/A | 65–89 | 0–5 | 65/95–89/95 | 0.68–0.94 | 340–460 |

| CEM IV/B | 45–64 | 0–5 | 45/95–64/95 | 0.47–0.67 | 230–330 | ||

| CEM V | Composite cement | CEM V/A | 40–64 | 0–5 | 40/95–64/95 | 0.42–0.67 | 210–330 |

| CEM V/B | 20–38 | 0–5 | 20/95–38/95 | 0.21–0.40 | 100–200 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study. Appl. Sci. 2020, 10, 339. https://doi.org/10.3390/app10010339

Sanjuán MÁ, Andrade C, Mora P, Zaragoza A. Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study. Applied Sciences. 2020; 10(1):339. https://doi.org/10.3390/app10010339

Chicago/Turabian StyleSanjuán, Miguel Ángel, Carmen Andrade, Pedro Mora, and Aniceto Zaragoza. 2020. "Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study" Applied Sciences 10, no. 1: 339. https://doi.org/10.3390/app10010339

APA StyleSanjuán, M. Á., Andrade, C., Mora, P., & Zaragoza, A. (2020). Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study. Applied Sciences, 10(1), 339. https://doi.org/10.3390/app10010339