3.1. Motor Model and Operation Constraints

The motor MG1 is taken as an example for modeling. The PMSM with three-phase and four-pair poles is selected, whose parameters are shown in

Table 3.

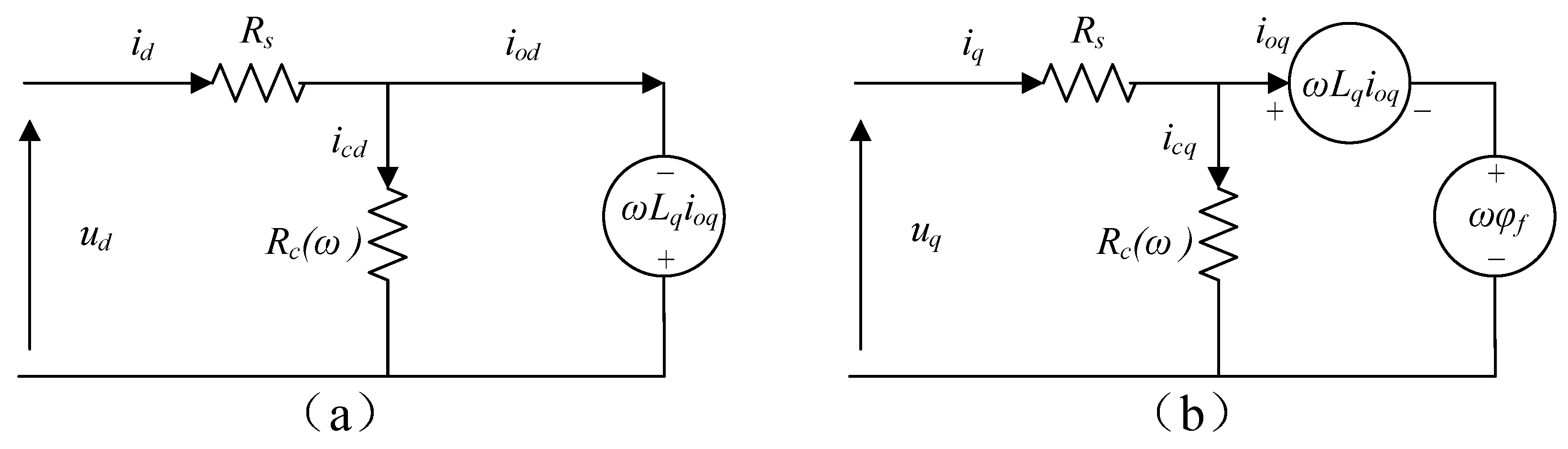

There is always power loss in the working process of a motor, which leads to the fluctuation of speed and torque. The iron loss model can not only reflect the changes of motor voltage, current, flux, and torque, but can also express the changes of the controllable loss including copper loss and iron loss caused by the winding current, which is widely used in the PMSM loss modeling [

17]. The equivalent circuit diagram of the PMSM dynamic model employed in this paper is shown in

Figure 3. Considering the loss caused by the stator eddy current and hysteresis effect, an iron loss resistance

is added to the equivalent circuit in parallel.

The voltage equivalent equations of the dynamic model are as follows.

The iron loss resistance

is calculated by [

18]:

Due to the limits of battery voltage, temperature, the bearing capacity of components, and PWM (pulse width modulation) modulation methods, the current and voltage supply capacity of the inverter is limited respectively to

and

. The motor armature current

and terminal voltage

expression and constraints are as follows:

The expressions of electromagnetic torque

and the motion equation of the PMSM are as follows:

The relationship between

is as follows:

3.2. Speed-Torque-Current Map Integrated Current Control

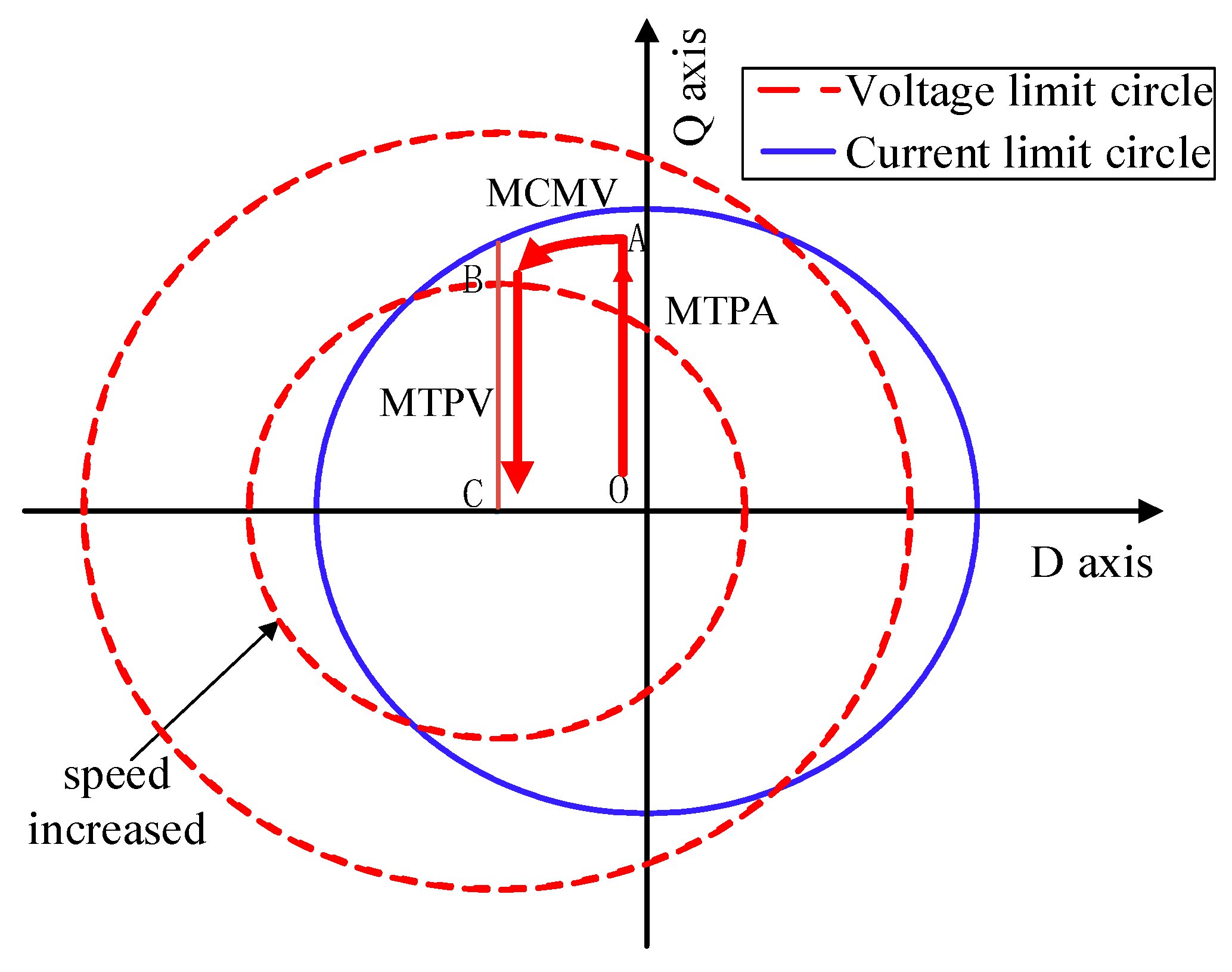

At present, the control strategies of the motor current mainly include the maximum torque current ratio (MTPA) control, maximum current voltage (MCMV) control, and maximum torque voltage ratio (MTPV) control.

MTPA control is a control method aiming to obtain the maximum output torque with the minimum input of a stator current vector within the limits of voltage and current [

19,

20]. The control equation of its boundary line is as follows:

MCMV control is one of the weak magnetic control methods. Its characteristic is that the current vector and voltage vector are the limits of the current and the voltage of the inverter bus, respectively [

21]. When the motor speed is adjusted to a certain speed of

, the control equation of (

,

) in this region is as follows:

MTPV control enables the motor to achieve the maximum speed by making full use of the voltage vector supplied by the inverter [

22,

23,

24]. For the tab-mounted PMSM, the reference current vector and the voltage control equation of MTPV is as follows:

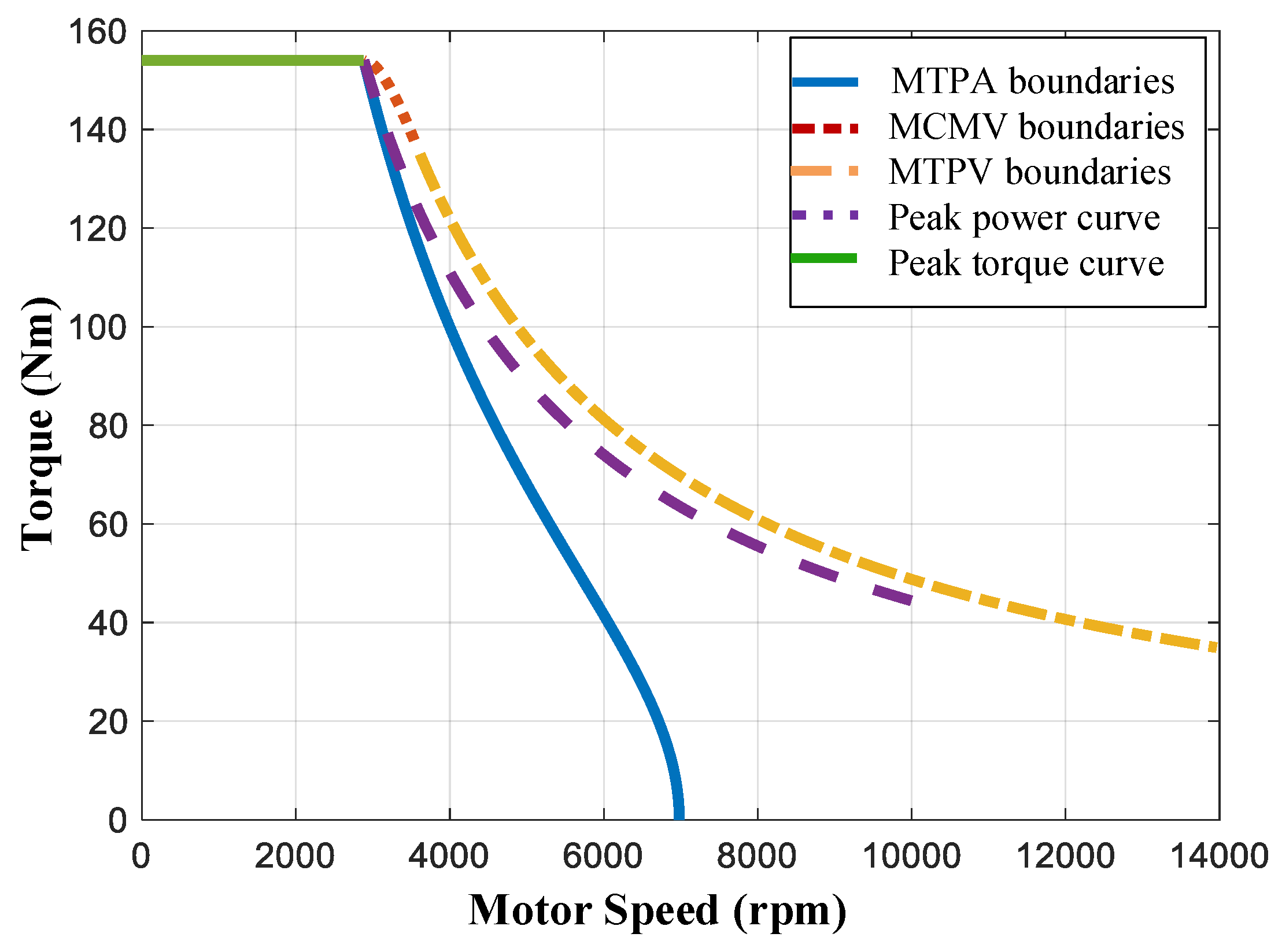

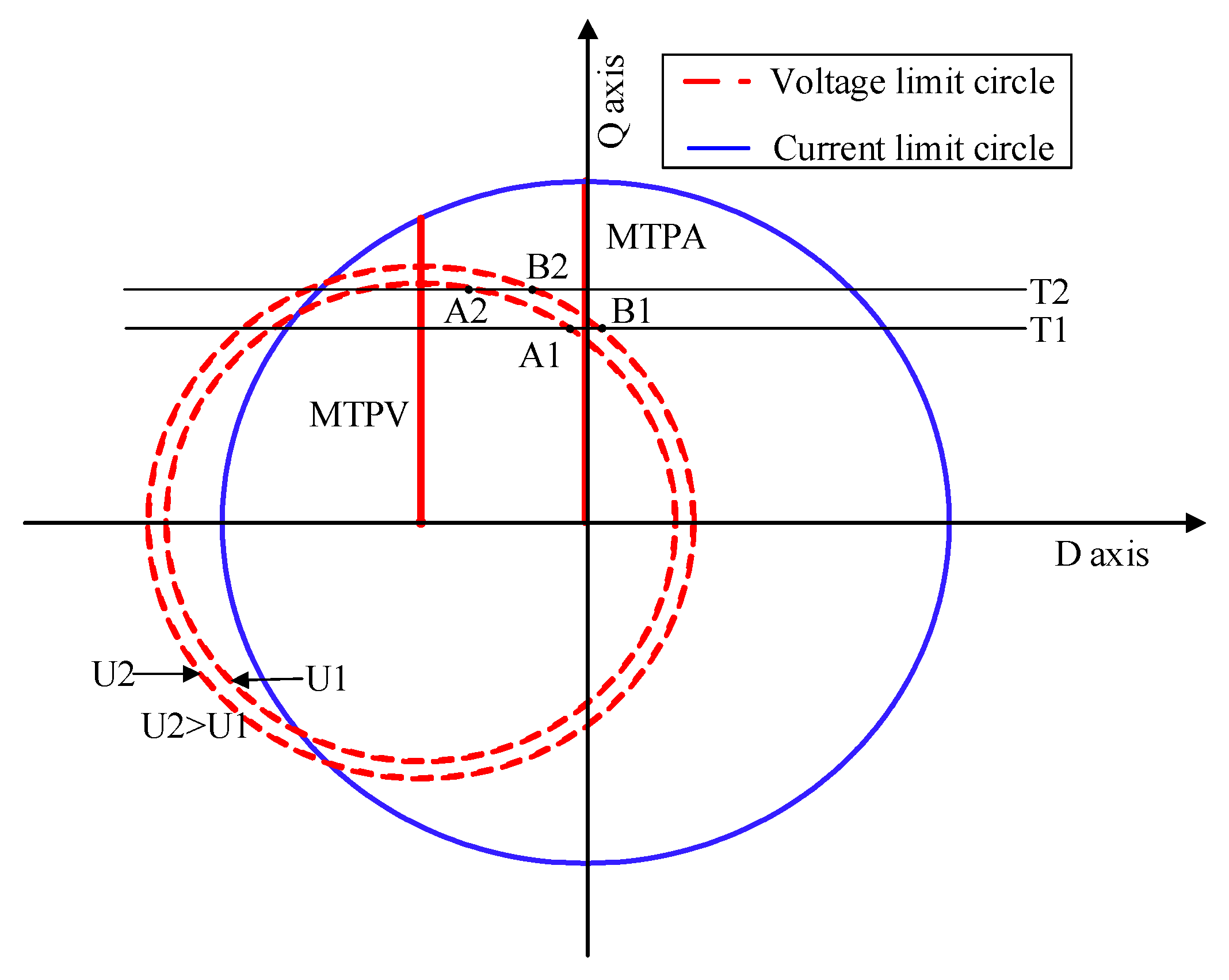

To sum up, the running trajectories of the boundaries of the three control strategies in the d-q coordinate system are shown in

Figure 4. OA, AB, and BC represent the running trajectories of the three control strategies (MTPA, MCMV, and MTPV) in the d-q coordinate system, respectively.

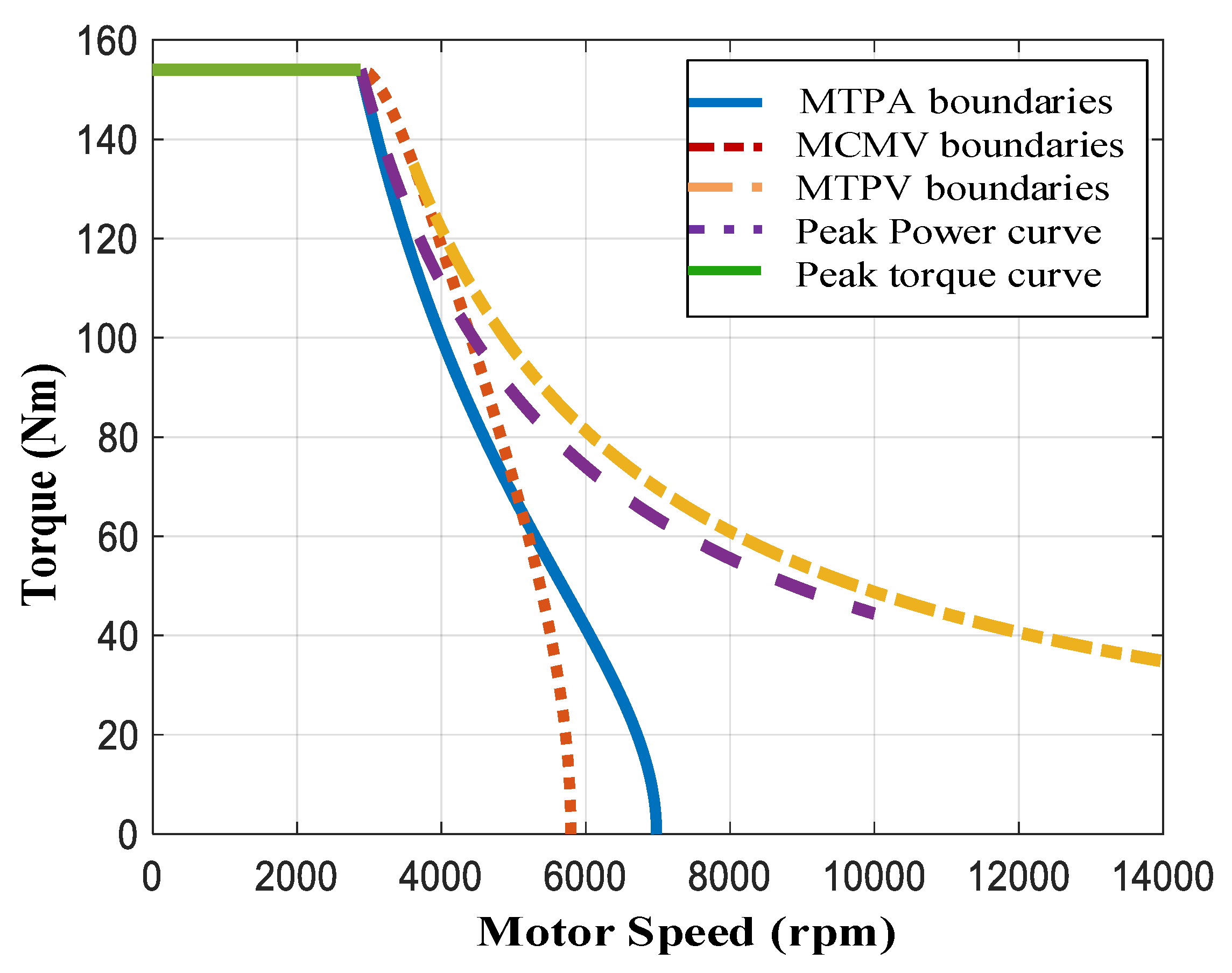

To analyze the influence of different current control strategies on the motor speed–torque characteristics, the external characteristics under different strategies are obtained, as shown in

Figure 5.

Aiming to combine the advantages of the above three control strategies, a comprehensive control strategy is proposed in this paper to expand the motor working range to its maximum within the scope of the inverter bus capacity. The principles of the comprehensive control strategy are as follows:

- (a)

The MTPA control strategy is adopted in the peak torque area to minimize the copper loss and iron loss.

- (b)

In the high-torque region of the weak magnetic field, the MCMV control is adopted to transit to the MTPV control range.

- (c)

MTPV control is used to extend the speed range of the motor in the high-speed region of the weak magnetic field.

With the above principles, the external characteristic boundary of current control is obtained, as shown in

Figure 6. Compared with the single current control strategy, the designed comprehensive control strategy has a wider speed range under the same torque, which improves the utilization ratio of the input current vector and voltage vector and maximizes the overall working range of the motor.

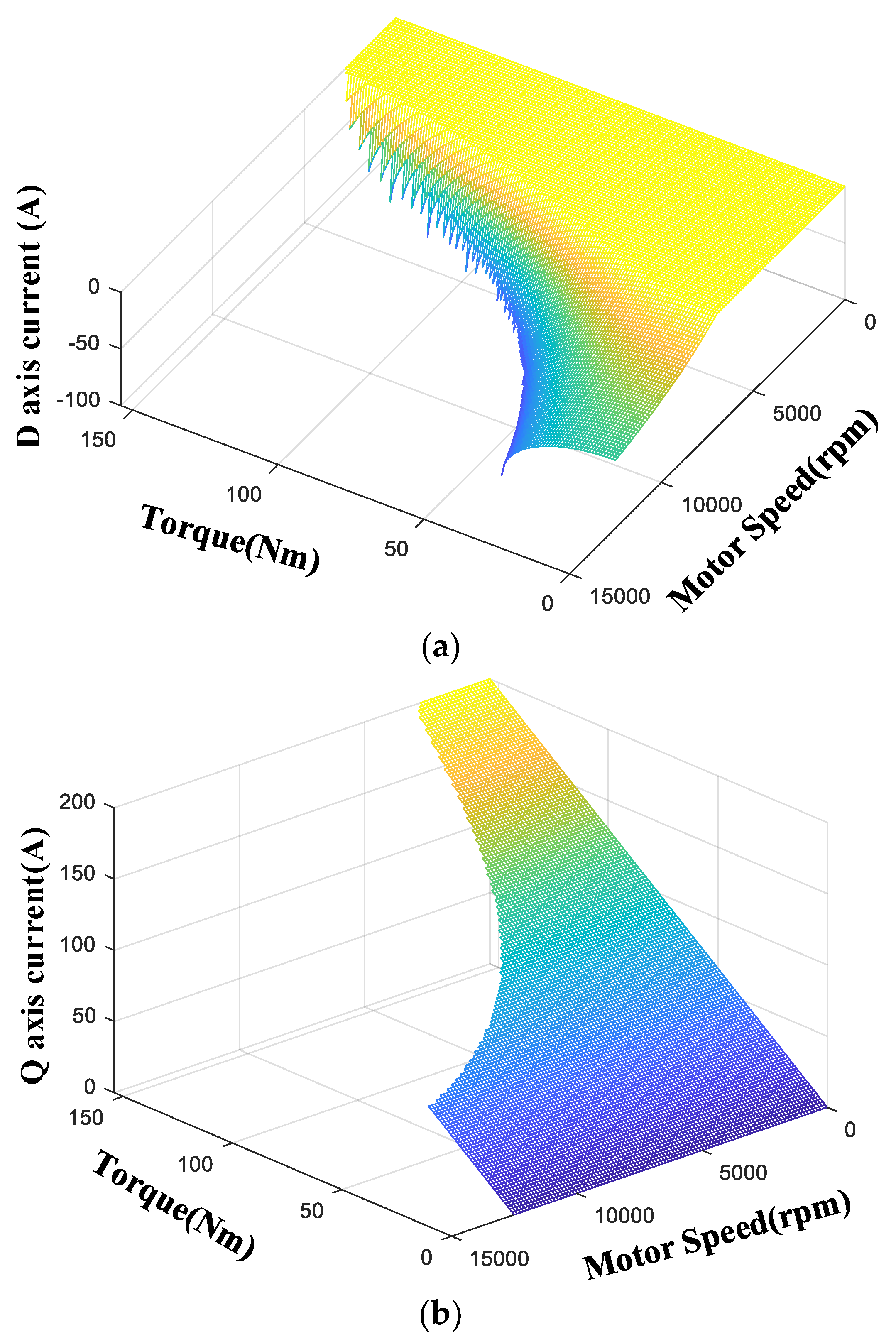

Based on the designed current control boundary curve, the speed and torque are traversed and substituted into Equations (8) and (9) to obtain the current of the d axis and q axis of all the work points. The resulting speed–torque–current map of the d-axis and q-axis are shown in

Figure 7.

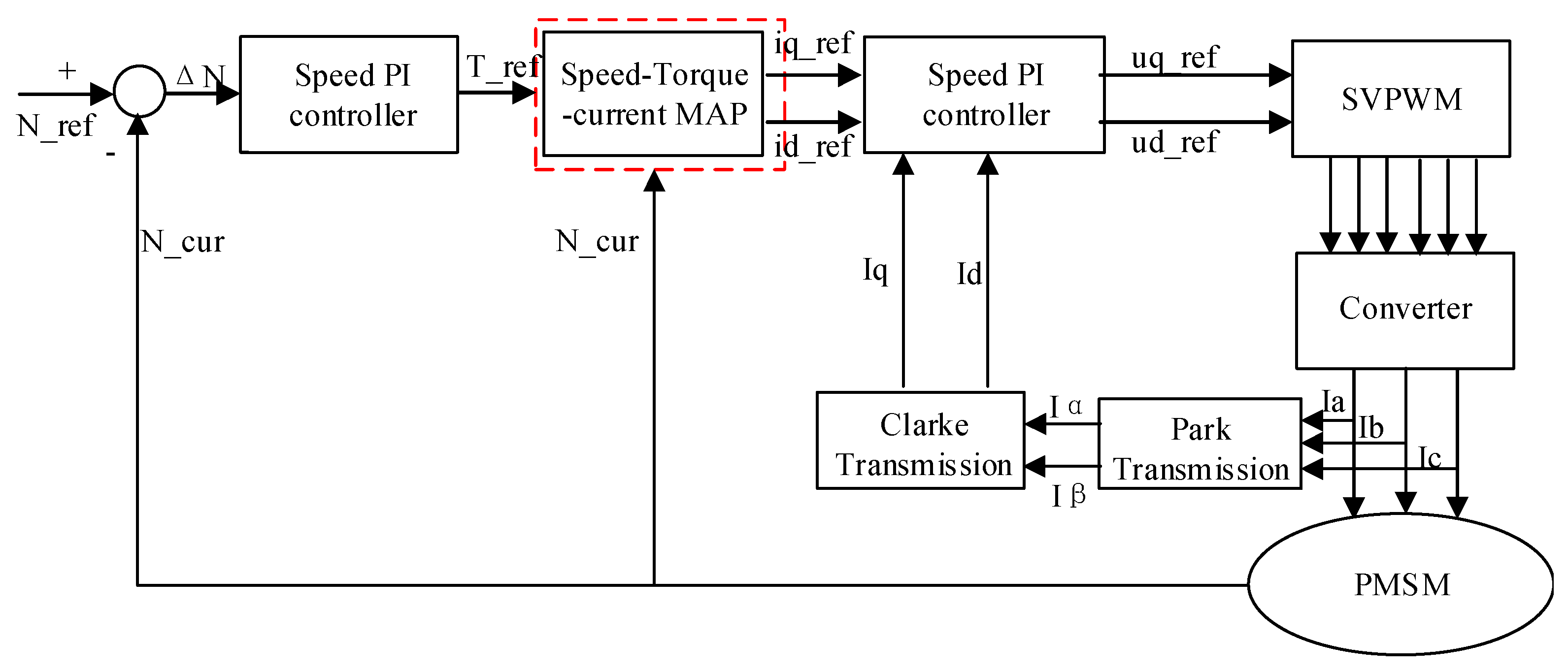

3.3. Motor Vector Control Strategy

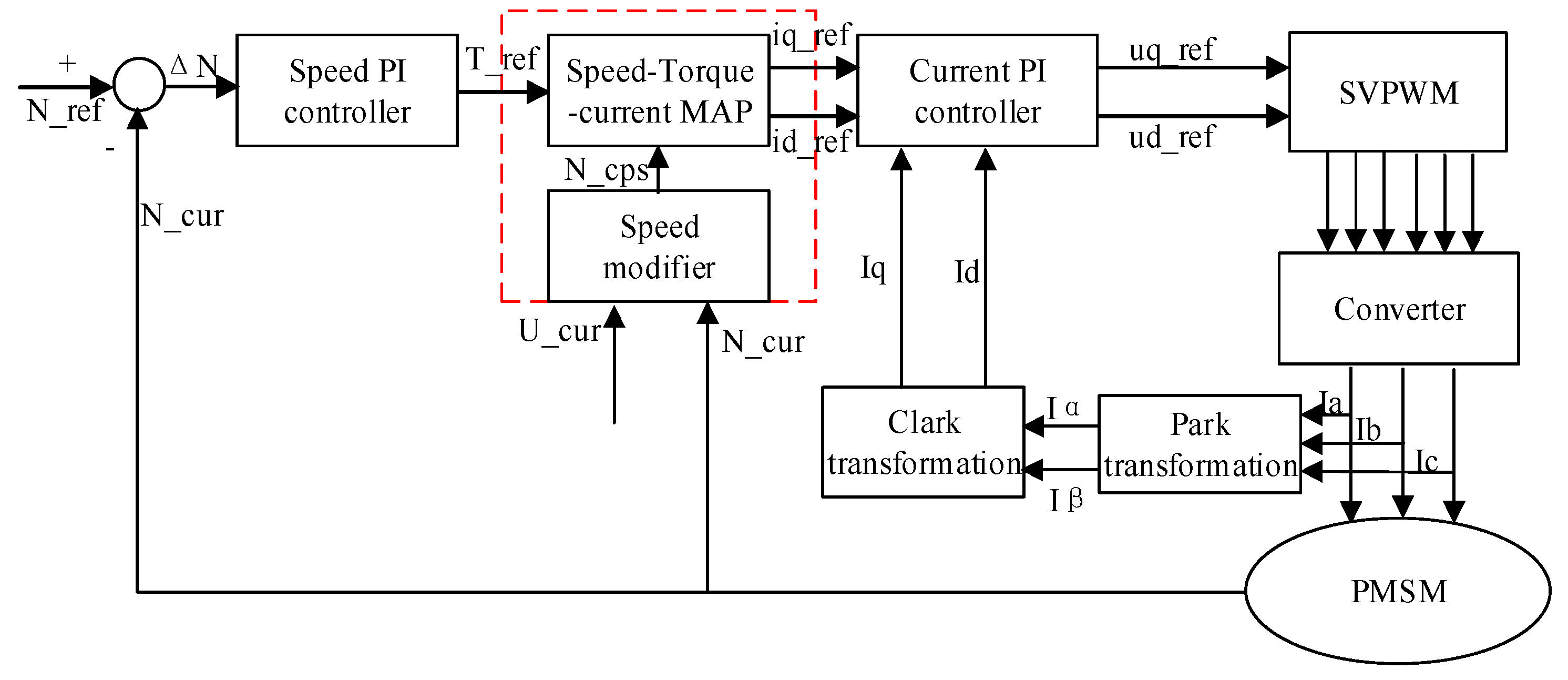

In order to solve the nonlinear problem of the PMSM current in the weak magnetic region, a vector control strategy is designed for the motor based on the speed–torque–current map, as shown in

Figure 8. When the motor runs in the weak magnetic region, the d and q-axis currents are obtained using the lookup table method. This method avoids the control problems caused by the nonlinear current, which in turn extends the weak magnetic working region of the motor. It is convenient to obtain the current in the deep weak magnetic region by using the lookup table. Besides, the following problems can also be solved: it is difficult to obtain the current simply by using the weak magnetic PI controller, and the dynamic response of the motor is slow.

As shown in

Figure 8, a speed–torque–current map link is added to the vector control strategy between the speed control link and the current control link. The output reference torque

of the speed loop and the actual motor speed are the inputs to this link. The reference currents of the d and q axes corresponding to the current speed and the target torque can be obtained by a lookup table. Since the speed–torque–current map contains the information of the weak magnetic region (including the deep weak magnetic region), the currents of the d and q axes are constrained in the voltage limit circle and current limit circle. It solves the transition problems of current control in different working ranges and the problem of torque fluctuation caused by current or voltage over-saturation.

Charging and discharging are always present in the driving process of pure electric vehicles, which leads to the change of battery SOC (state of charge). The relationship between the battery voltage and SOC is shown in

Figure 9. The change of the battery voltage causes the dynamic change of bus voltage amplitude [

25], which in turn affects the d-axis current and q-axis current, as well as the speed and torque characteristics of the motor.

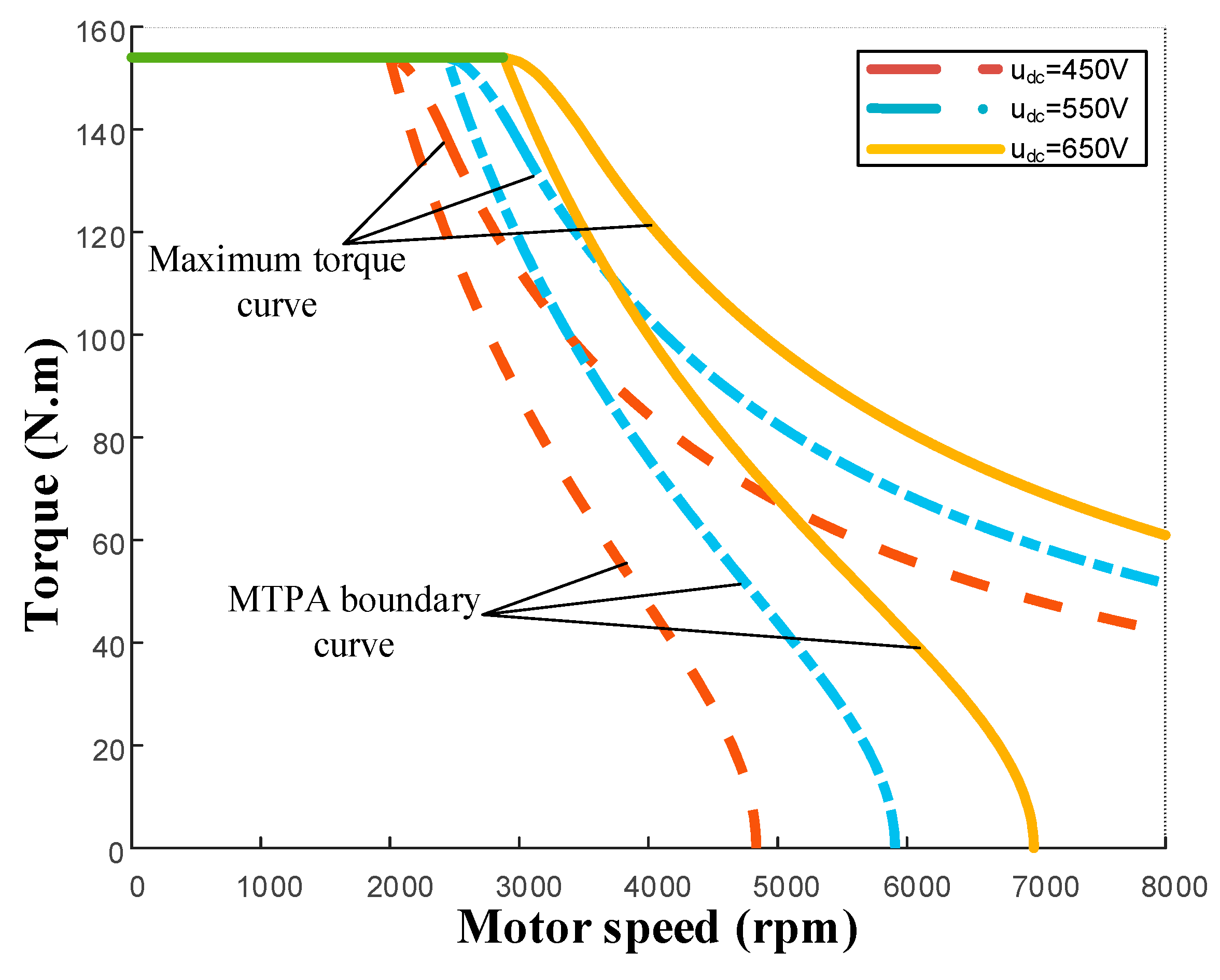

The external characteristics of the motor under different bus voltages are shown in

Figure 10.

It is shown in

Figure 10 that when the bus voltage decreases, the control boundary and the maximum torque boundary of the motor move to the left, which reduces the motor working range. If the influence of bus voltage variation is ignored, the operation of these areas cannot be controlled. When the voltage increases, the bus voltage cannot be fully utilized. When the voltage decreases, the working point may be outside the allowable motor working range, which leads to the over-current or over-voltage protection. The influence of bus current on the motor can also be seen from the perspective of current control of d and q axes, which is shown in

Figure 11. When the bus voltage is

, the motor works at points

and

to realize torques

and

, respectively. If the bus voltage increases from

to

, then the motor working points are

and

, which improves the utilization ratio of the bus voltage. On the contrary, if

and

are the required torques, the motor works at points

and

. If the bus voltage decreases from

to

and the control strategy still takes

and

as working points. In this situation, the current regulator saturates and loses its ability to regulate the current.

Considering the fluctuation of bus voltage, the relationship between the actual bus voltage

and the currents of the d and q axes is as follows:

Equation (15) indicates that the bus voltage fluctuation can be corrected by the motor speed. Specifically, when the bus voltage changes, the motor speed can be appropriately increased or decreased by

times to correct the voltage, as shown in the following equation:

Based on Equation (16), a speed modifier considering the influence of bus voltage is added to the speed–torque–current map link to develop a vector control strategy, as shown in

Figure 12. The real-time bus voltage

obtained from the voltage sensor is used as the input to the speed compensator, and variable

represents the speed after the compensation.

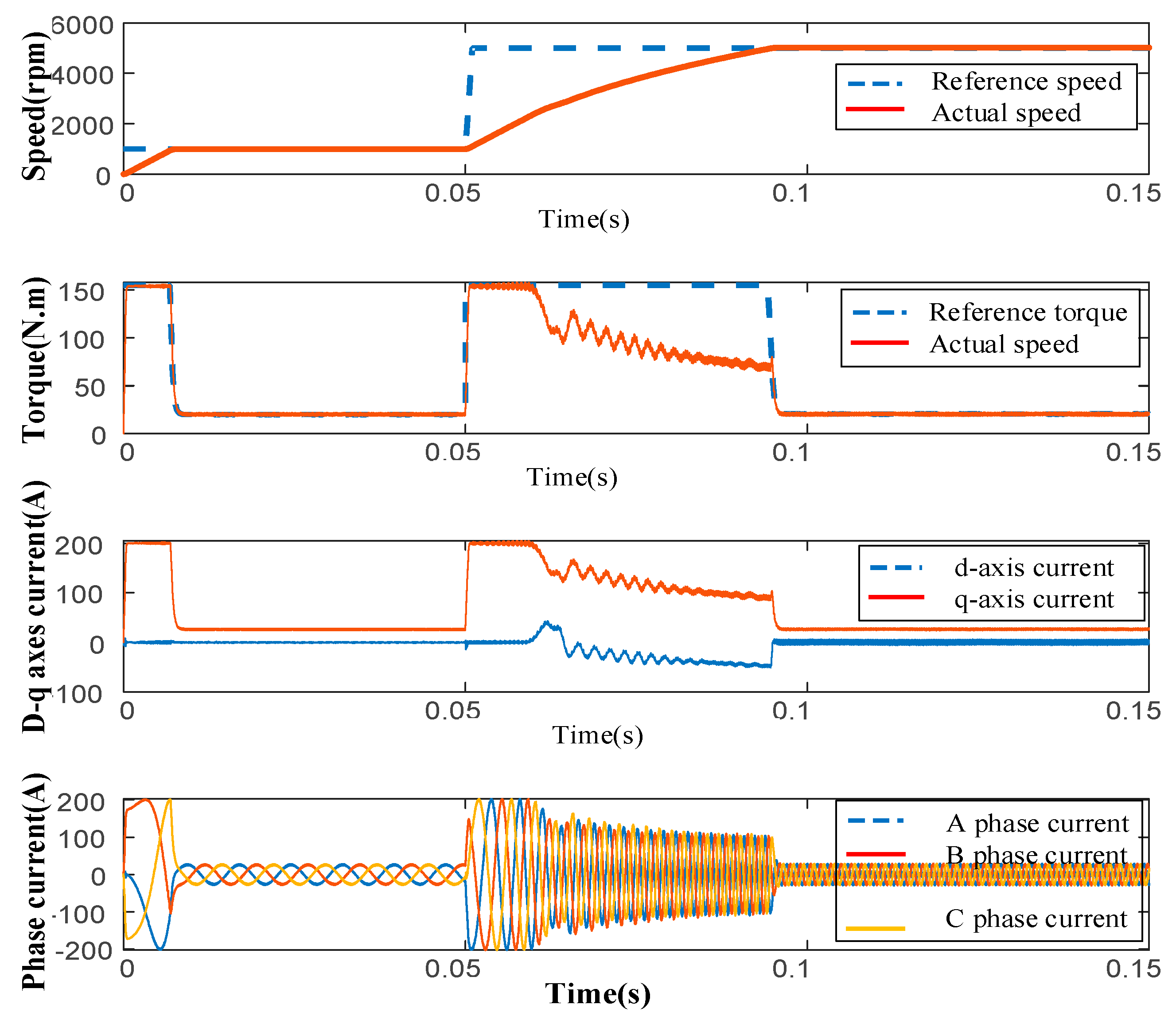

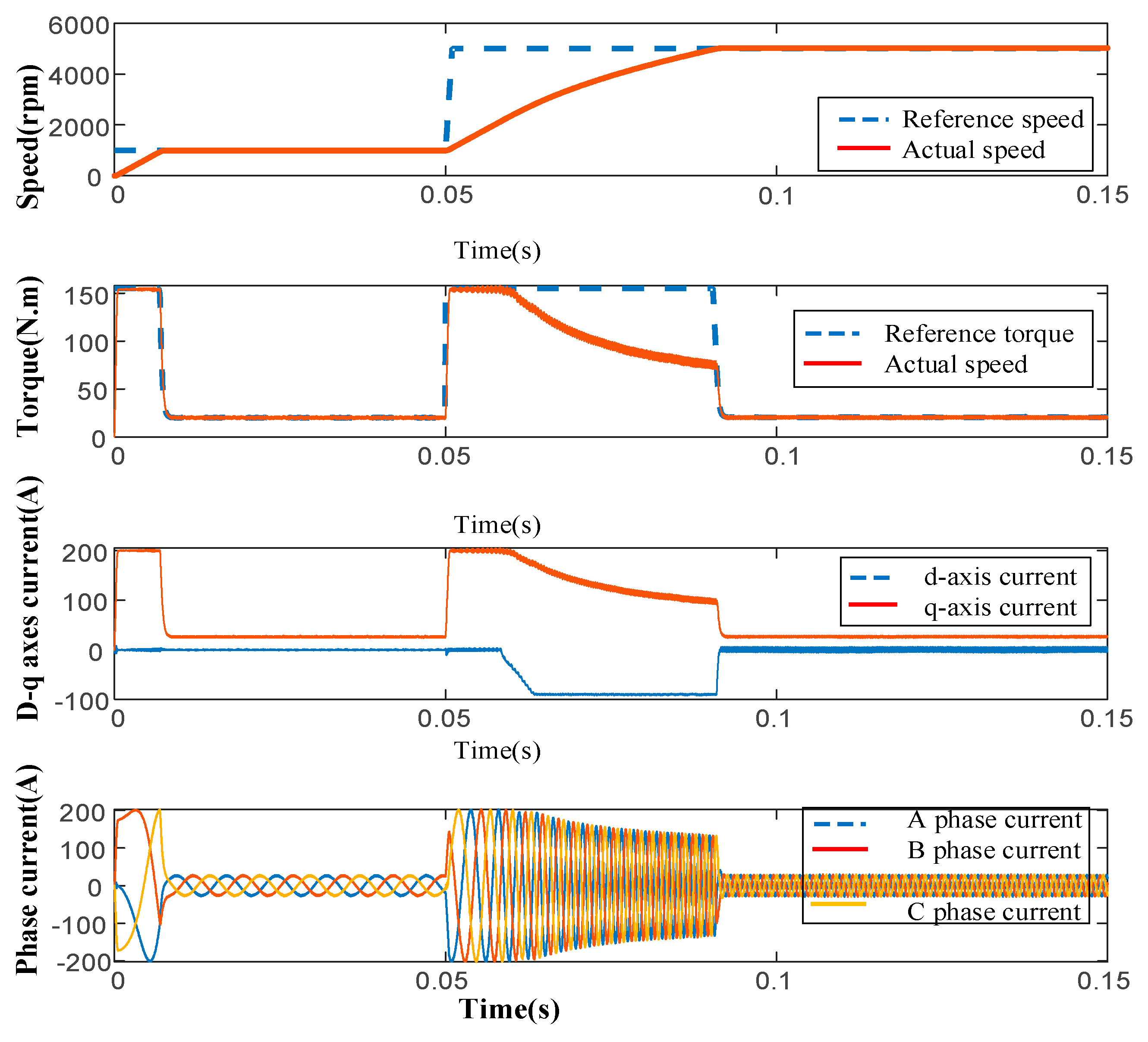

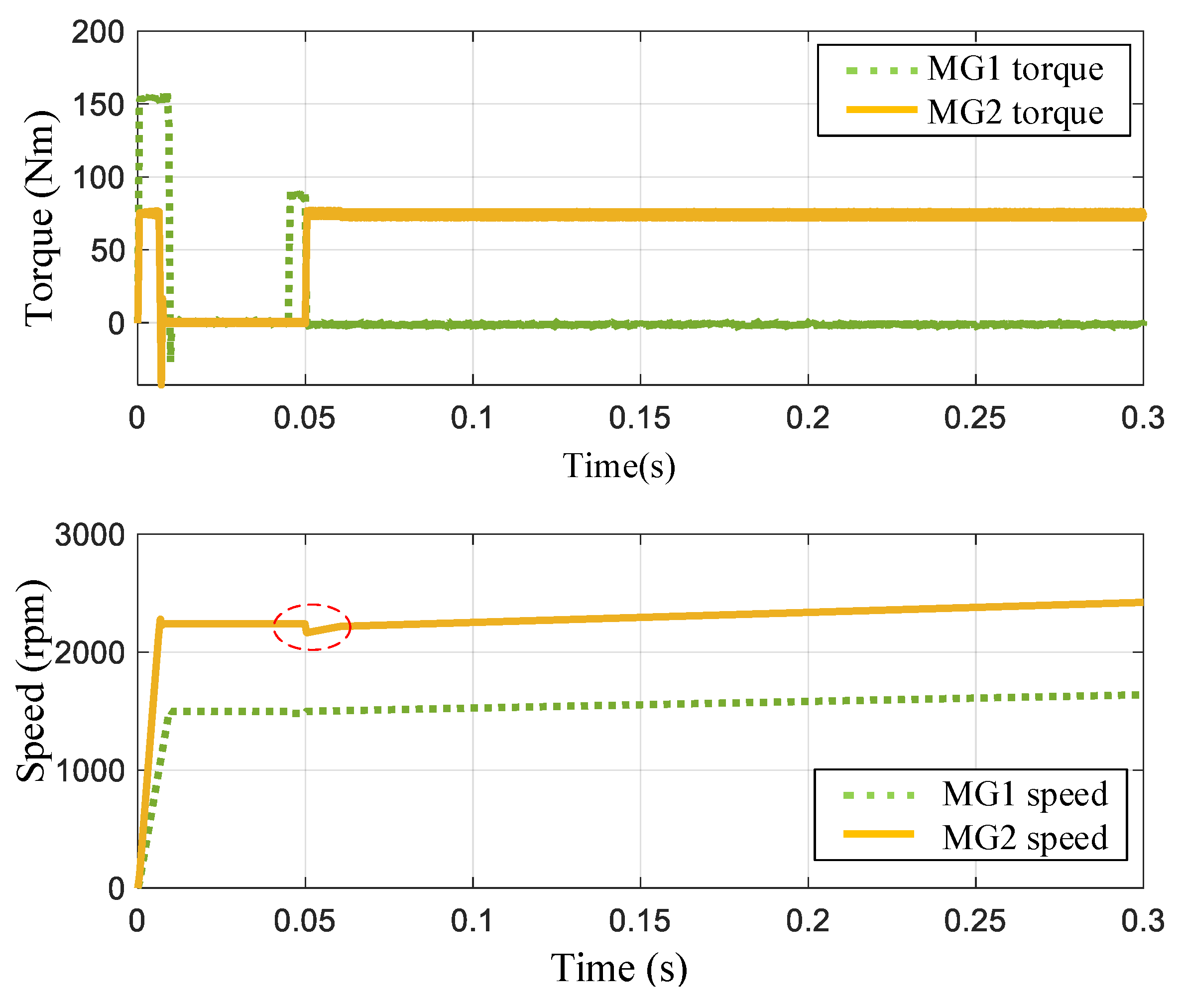

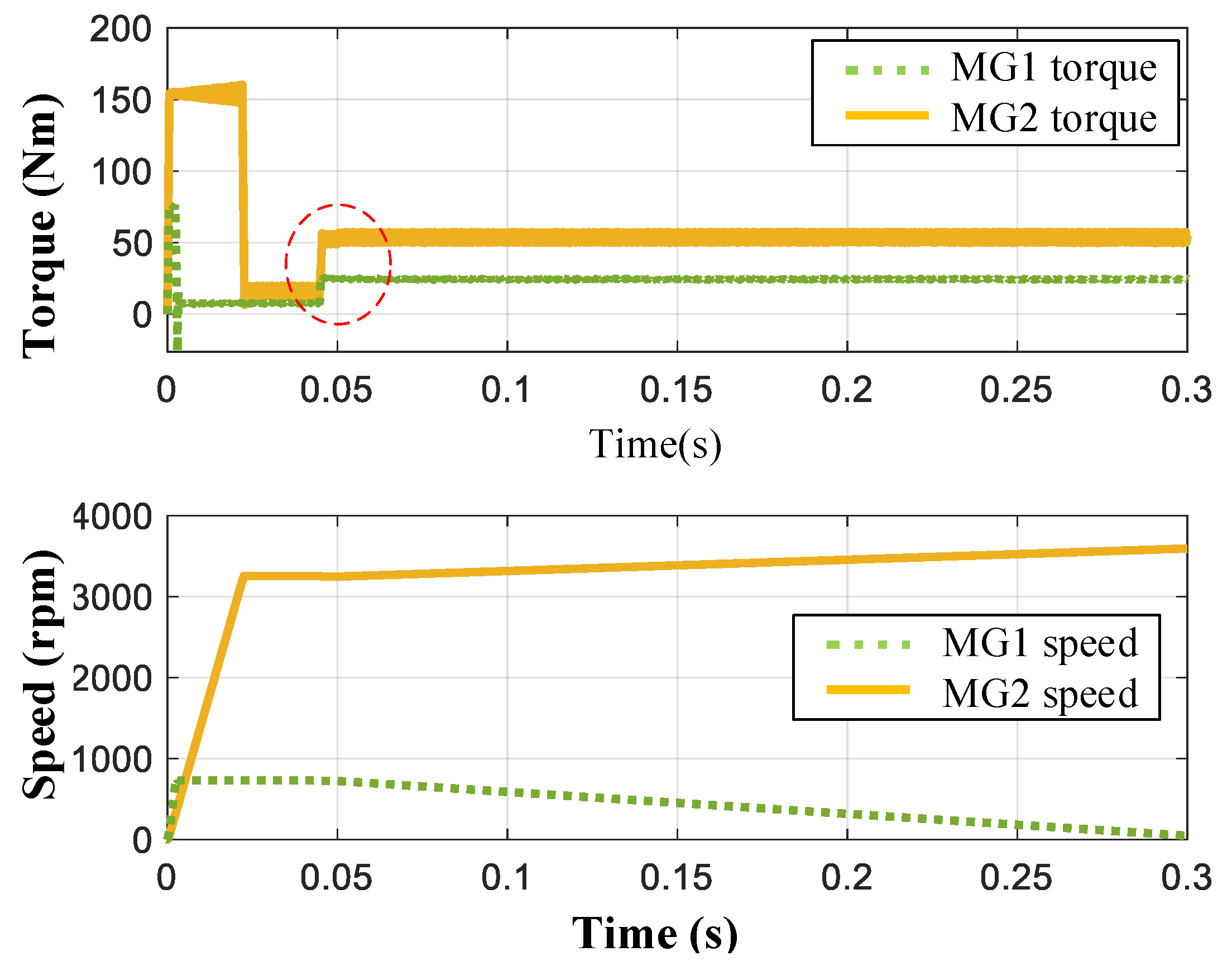

To validate the control effect of the proposed vector control strategy, a working condition is designed in which the bus voltage and load torque are 650 V and 20 Nm, respectively. Besides, the motor speed first accelerates from 0 to 1000 rpm, and then again accelerates from 1000 to 5000 rpm after the speed stabilizes for a short period (around 100 ms). The simulation results are shown in

Figure 13 and

Figure 14.

It is seen from

Figure 13 that in the process of speed regulation, torque and current fluctuate greatly due to the effect of the bus voltage changes. However, in

Figure 14, the current and torque fluctuations are greatly reduced during the speed regulation period (1000–5000 rpm), when the bus voltage changes are taken into consideration. The results in these two figures indicate that the speed modifier with bus voltage regulation well reduces the torque and current fluctuation in the speed regulation process, which is beneficial to the output speed–torque characteristics of the motor.