Energy-Saving Performance and Production Accuracy of the Direct-Pressure Tire Curing Technology with an Expandable Steel Internal Mold

Abstract

:1. Introduction

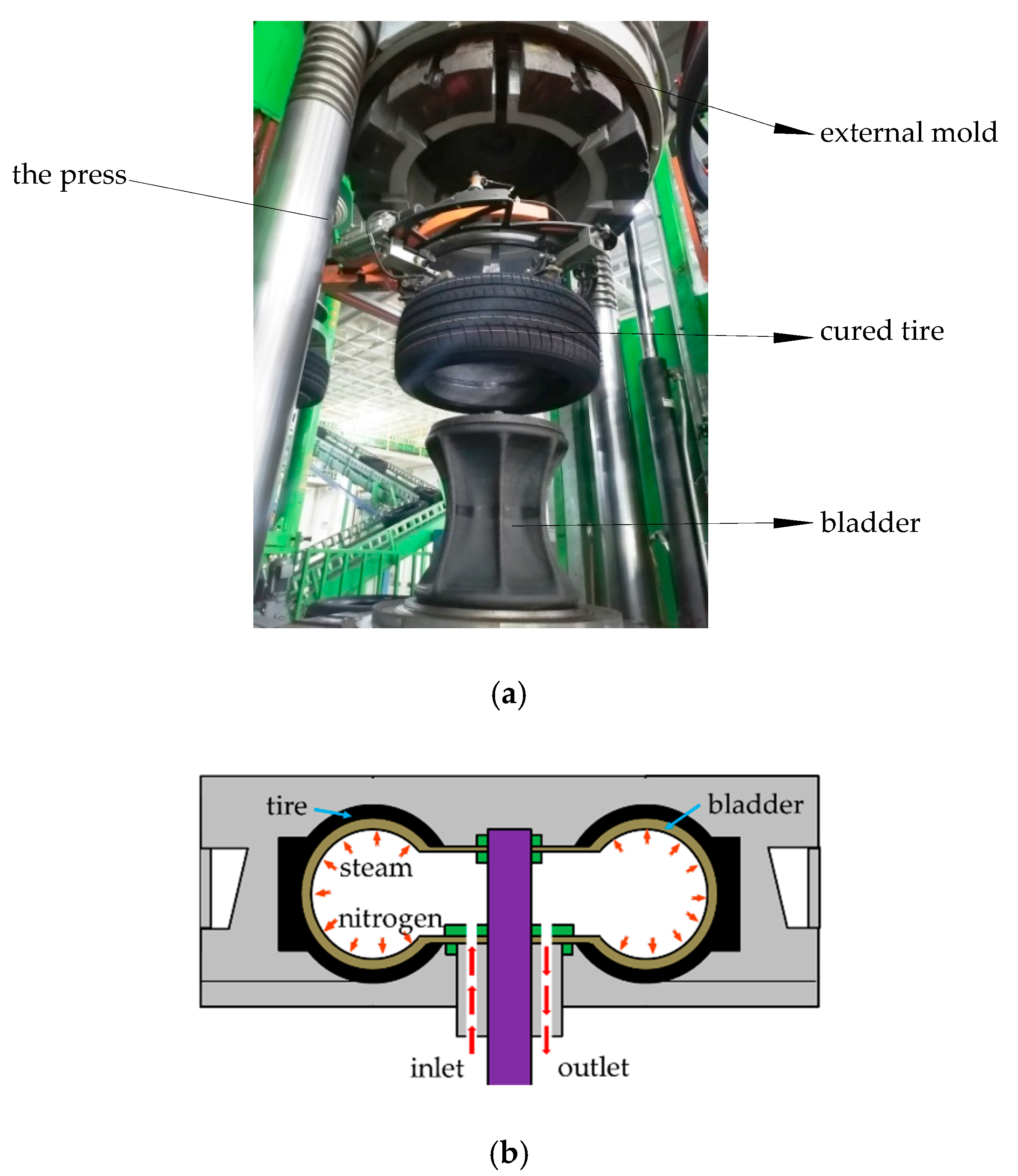

2. Development of Direct-Pressure Vulcanization Equipment

2.1. Steel Internal Mold

2.2. Electromagnetic Induction Heating System

2.3. Process Validation

3. Finite Element Analysis of the Process

3.1. Material Characterization

3.1.1. Thermal Conductivity Test

3.1.2. Thermal Conductivity of Core-Rubber Composite Material

3.2. Finite Element Model

3.3. Model Verification

4. Characteristics of Direct-Pressure Vulcanization Technology

4.1. Energy-Saving Performance

4.1.1. Vulcanization Efficiency

4.1.2. Energy Consumption

4.2. Production Accuracy

4.2.1. Non-Uniformity and Unbalance

4.2.2. Uniformity of SOC

4.2.3. Physical Properties

5. Conclusions

- (1)

- Based on the same process temperature, the new technology reduced vulcanization energy consumption by 86%.

- (2)

- The new technology breaks the interlocking of internal temperature and pressure. Through finite element simulation, the traditional process was improved and curing efficiency was increased by 22.5%, with the internal temperature of vulcanization raised from 185 to 205 °C.

- (3)

- The uniformity and balance of the tire was improved, with both RFV and couple unbalance mass reduced.

- (4)

- The temperature difference between the upper and lower sidewall of the raw tire was reduced from 11 to 3 °C, and the uniformity of degree of curing of sidewalls was clearly improved.

- (5)

- Physical properties of the rubber parts of the finished tire were improved, which was especially significant for the sidewalls.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guo, J.; Li, H.; Yang, H.; Zhang, S. A collaborative detection approach for internal steam leakage of tire vulcanization workshop with artificial immune algorithm. J. Comput. Appl. Math. 2018, 37, 4219–4236. [Google Scholar]

- Wang, Y.; Su, B.; Wu, J. Simulation and optimization of giant radial tire vulcanization process. Procedia Eng. 2012, 31, 723–726. [Google Scholar] [CrossRef] [Green Version]

- Gough, J. Calculation of times and temperatures for press vulcanization of thick rubber pads. Rubber Chem. Technol. 2017, 90, 89–107. [Google Scholar] [CrossRef]

- Pandya, M.; Patel, R.N.; Amarnath, S.K.P. Determination of time delay and rate of temperature change during tyre curing (vulcanizing) cycle. Procedia Eng. 2013, 51, 828–833. [Google Scholar] [CrossRef] [Green Version]

- Su, B.; Wu, J.; Cui, Z. Modeling of truck tire curing process by an experimental and numerical method. Iran. Polym. J. 2015, 24, 583–593. [Google Scholar] [CrossRef]

- Karaağaç, B.; Aytac, A.; Deniz, V. Application of radiation technology to rubber and tire industries. J. Biol. Chem. 2014, 42, 23–34. [Google Scholar] [CrossRef]

- Manaila, E.; Martin, D.; Zuga, S.D. Combined Effects of Microwaves, Electron Beams and Polyfunctional Monomers on Rubber Vulcanization. J. Microwave Power Electromagn. Energy 2008, 43, 26–34. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, J. Vulcanization Process of Rubber Tires with the Use of Microwaves. U.S. Patent Application No. 12/513,968, 15 April 2010. [Google Scholar]

- Makul, N.; Rattanadecho, P. Microwave pre-curing of natural rubber-compounding using a rectangular wave guide. Int. Commun. Heat Mass 2010, 37, 914–923. [Google Scholar] [CrossRef]

- Mitamura, H.; Adachi, S.; Okada, K.; Fukumoto, H.; Inoue, K. Apparatus for Heating a Green Tire. U.S. Patent No. 7,078,660, 18 July 2006. [Google Scholar]

- Okada, K.; Toshima, M.; Murata, T.; Fujieda, Y. Tire Vulcanizer. U.S. Patent No. 8,414,278, 9 April 2013. [Google Scholar]

- Jeong, K.M.; Kim, K.W.; Beom, H.G. Finite Element Analysis of Nonuniformity of Tires with Imperfections. TST 2007, 35, 226–238. [Google Scholar]

- Meijuan, Y.; Yuankan, D.; Gall, R. Effects of variations in geometry and material on the non-uniformity of tires. TST 2001, 29, 56–64. [Google Scholar] [CrossRef]

- Pottinger, M.G. Uniformity: A Crucial Attribute of Tire/Wheel Assemblies. TST 2010, 38, 24–46. [Google Scholar] [CrossRef]

- Yang, W.M.; Jin, Y.Z. Tire Direct-Pressure Shaping and Electromagnetic Induction Heating Curing Method and Apparatus. U.S. Patent No. 9,751,271, 5 September 2017. [Google Scholar]

- Yang, W.M.; Jin, Y.Z. Tire Direct-Pressure Shaping and Electromagnetic Induction Heating Curing Method and Apparatus. U.S. Patent No. 9,827,725, 28 November 2017. [Google Scholar]

- Holman, J.P. Heat Transfer, 10th ed.; McGraw-Hill Education: New York, NY, USA, 2009; pp. 51–52. [Google Scholar]

- Steen, J.; Aben, W.J.; Wapenaar, K.D. Optimization of the vulcanization process of rubber products. Polym. Eng. Sci. 1993, 33, 183–189. [Google Scholar] [CrossRef]

- Gent, A.N.; Walter, J.D. The Pneumatic Tire; The National Highway Traffic Safety Administration, Department of Transportation: Washington, DC, USA, 2005; pp. 15–31.

- Yang, H.D.; Guo, J.H.; Liu, G.S. Energy anomaly detection in tire curing by using data integration and forecasting techniques. J. Sci. Ind. Res. 2012, 71, 385–391. [Google Scholar]

- Gudadhe, M.; Lohakare, P. Energy Analysis in Tire Manufacturing Industries. IJMENT 2015, 6, 112–119. [Google Scholar]

| Internal Mold | External Mold | |||

|---|---|---|---|---|

| Top Heating Plate | Bottom Heating Plate | Container | ||

| AC Power supply | 380 V/50 Hz | 380 V/50 Hz | 380 V/50 Hz | 380 V/50 Hz |

| Max. Power of Controller (KW) | 3 | 15 | 15 | 15 |

| Number of Controllers | 7 | 1 | 1 | 2 |

| Resonance Mode | Half-bridge | Full-bridge | Full-bridge | Full-bridge |

| Inductance (μH) | 90 | 150 | 150 | 150 |

| Frequency (KHz) | 18–22 | 18–22 | 18–22 | 18–22 |

| Location | Maximum Difference | Maximum Error | ||

|---|---|---|---|---|

| Temperature | t50 | Temperature | t50 | |

| Node 2 | 7 °C | 23 s | 3.78% | 3.58% |

| Node 8 | 5 °C | 17 s | 2.70% | 2.64% |

| Node 10 | 6 °C | 36 s | 3.24% | 5.55% |

| Component | Chafer Node 1 | Shoulder Node 10 | Apex Node 2 | Tread Node 8 | Belt Node 7 | Liner Node 3 |

|---|---|---|---|---|---|---|

| Traditional cure(s) | 388 | 723 | 446 | 604 | 473 | 492 |

| DPCT(s) | 315 | 643 | 328 | 615 | 538 | 489 |

| Cure Temperature (°C) | 185 | 190 | 195 | 200 | 205 | 210 |

| T50(s) | 643 | 621 | 600 | 579 | 560.4 | 543.6 |

| Method | Internal Heating (Kgce) | External Heating (Kgce) | Total (Kgce) |

|---|---|---|---|

| Steam | 1.36 | 2.04 | 3.4 |

| Induction heating | 0.184 | 0.276 | 0.46 |

| Items | Traditional | DCPT | ||

|---|---|---|---|---|

| Mean | RSD (%) | Mean | RSD (%) | |

| Nonuniformity | ||||

| RFV (N) | 11.13 | 22.06 | 9.26 | 18.6 |

| LFV (N) | 9.05 | 20.89 | 6.9 | 18.04 |

| RFV1H (N) | 5.87 | 22.48 | 4.66 | 17.34 |

| Conicity (CON; N) | 1.55 | 18.09 | 1.48 | 18.9 |

| Unbalance | ||||

| Static unbalance value (g cm) | 1058.51 | 21 | 946.72 | 17.75 |

| Couple unbalance mass (g) | 13.72 | 23.4 | 8.64 | 19.21 |

| Upper side compensating unbalance mass (Upper; g) | 22.72 | 25.65 | 17.33 | 17.63 |

| Lower side compensating unbalance mass (Lower; g) | 26.25 | 23.3 | 22.27 | 18.32 |

| Upper + Lower (g) | 48.97 | 24.39 | 39.6 | 18.02 |

| Items | Tread | Sidewall | ||

|---|---|---|---|---|

| Traditional | DPCT | Traditional | DPCT | |

| Density (g/cm3) | 1.154 | 1.159 | 1.110 | 1.101 |

| Hardness (shore A) | 58 | 59 | 47 | 52 |

| Tensile strength (TS; MPa) | 16.3 | 17.7 | 13.7 | 15.6 |

| Elongation at break (Eb; %) | 460 | 455 | 649 | 580 |

| Stress at 100% Elongation (MPa) | 2.3 | 2.3 | 1.3 | 1.3 |

| Stress at 200% Elongation (MPa) | 5.5 | 5.5 | 2.4 | 2.8 |

| Stress at 300% Elongation (MPa) | 9.9 | 10 | 4.4 | 5.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wang, B.; Liu, X.; Cheng, L.; Yan, H.; Ding, Q.; Tan, J.; Yang, W. Energy-Saving Performance and Production Accuracy of the Direct-Pressure Tire Curing Technology with an Expandable Steel Internal Mold. Appl. Sci. 2020, 10, 79. https://doi.org/10.3390/app10010079

Zhang J, Wang B, Liu X, Cheng L, Yan H, Ding Q, Tan J, Yang W. Energy-Saving Performance and Production Accuracy of the Direct-Pressure Tire Curing Technology with an Expandable Steel Internal Mold. Applied Sciences. 2020; 10(1):79. https://doi.org/10.3390/app10010079

Chicago/Turabian StyleZhang, Jinyun, Bogang Wang, Xiaoying Liu, Lisheng Cheng, Hua Yan, Quanyong Ding, Jing Tan, and Weimin Yang. 2020. "Energy-Saving Performance and Production Accuracy of the Direct-Pressure Tire Curing Technology with an Expandable Steel Internal Mold" Applied Sciences 10, no. 1: 79. https://doi.org/10.3390/app10010079