Influence of Approaching Excavation on Adjacent Segments for Twin Tunnels

Abstract

:1. Introduction

2. Case Studied Tunnels

3. Description of Numerical Simulations

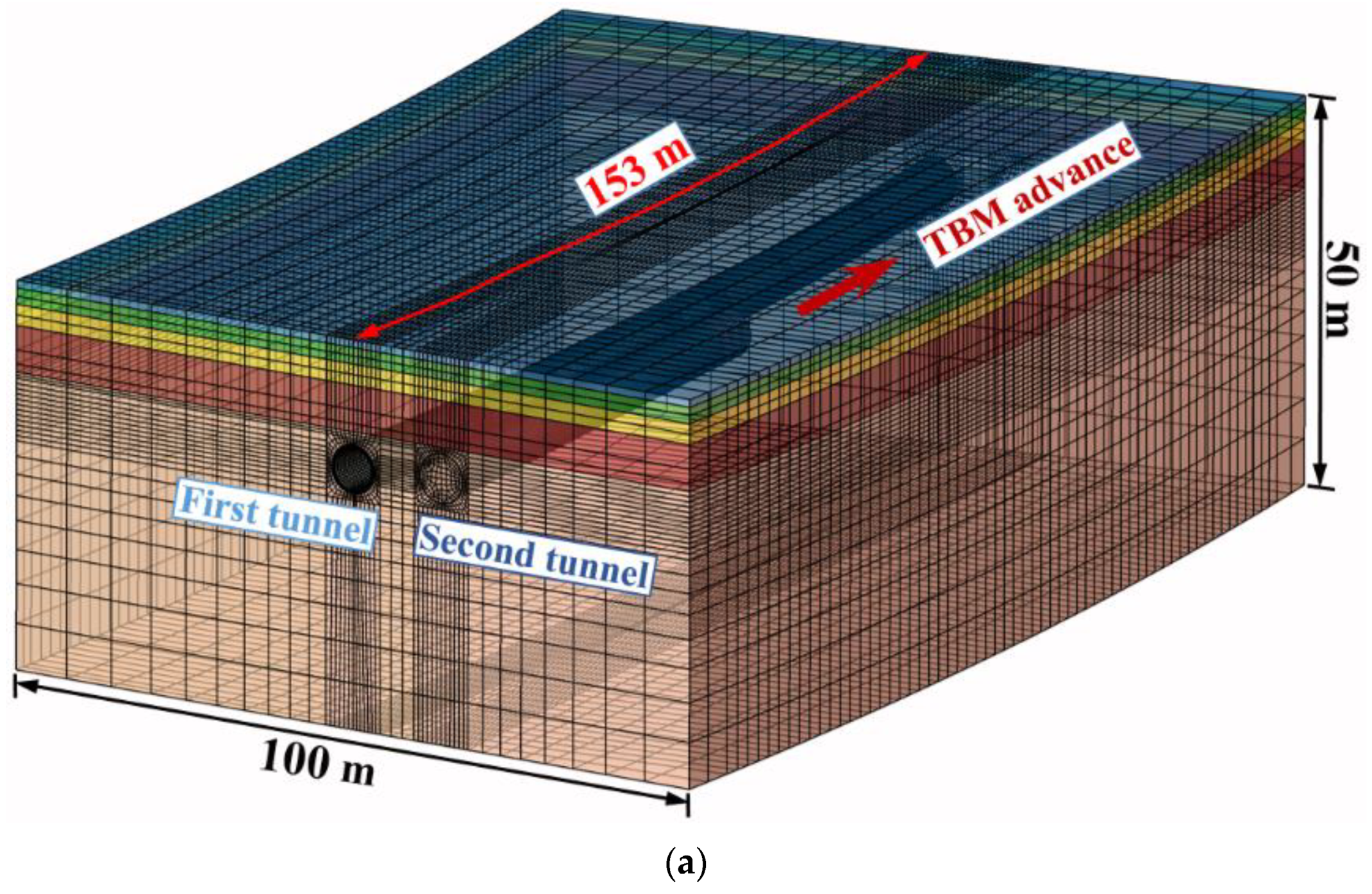

3.1. Numerical Models

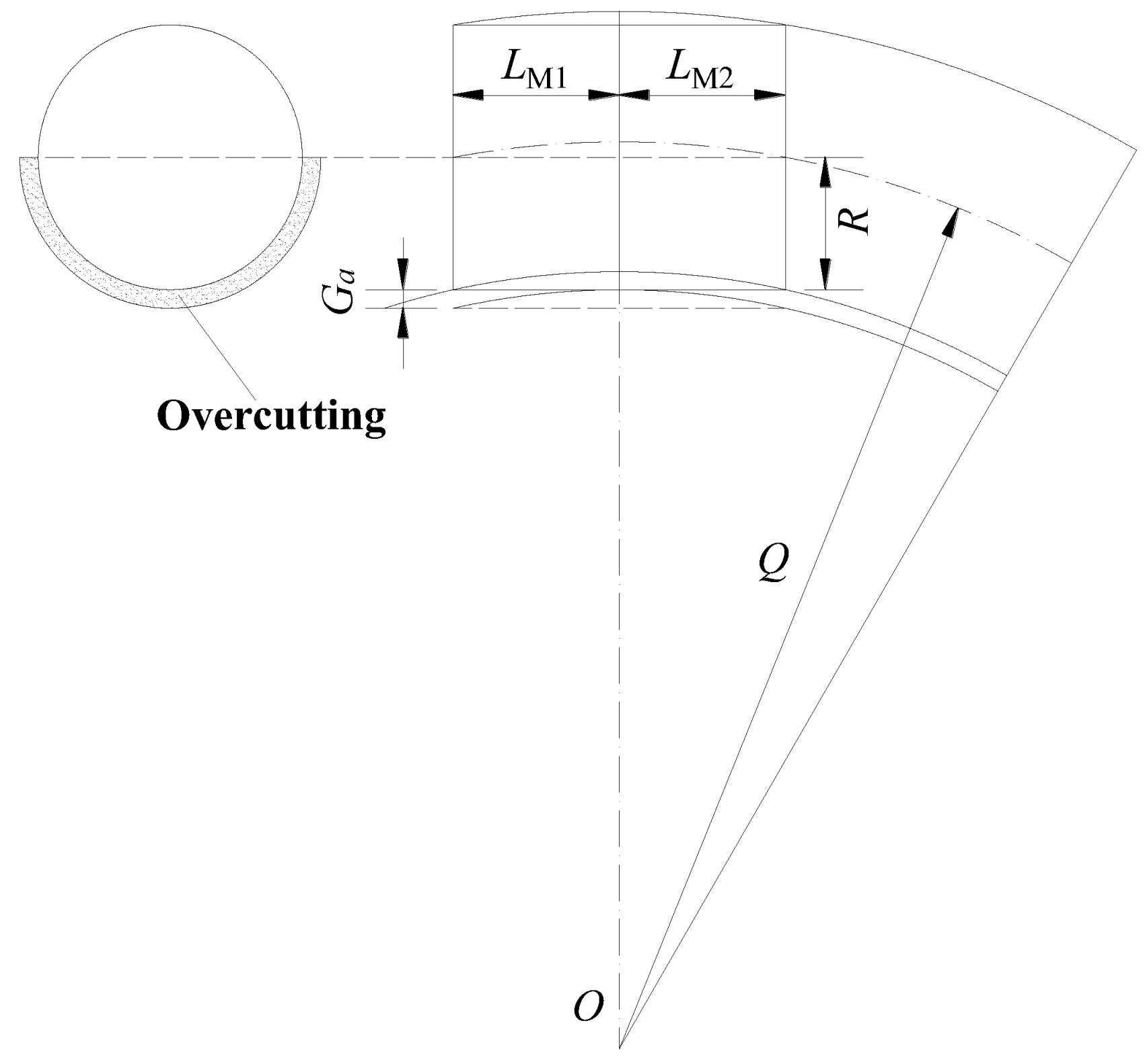

3.2. Characteristics of Three-Dimensional Entity

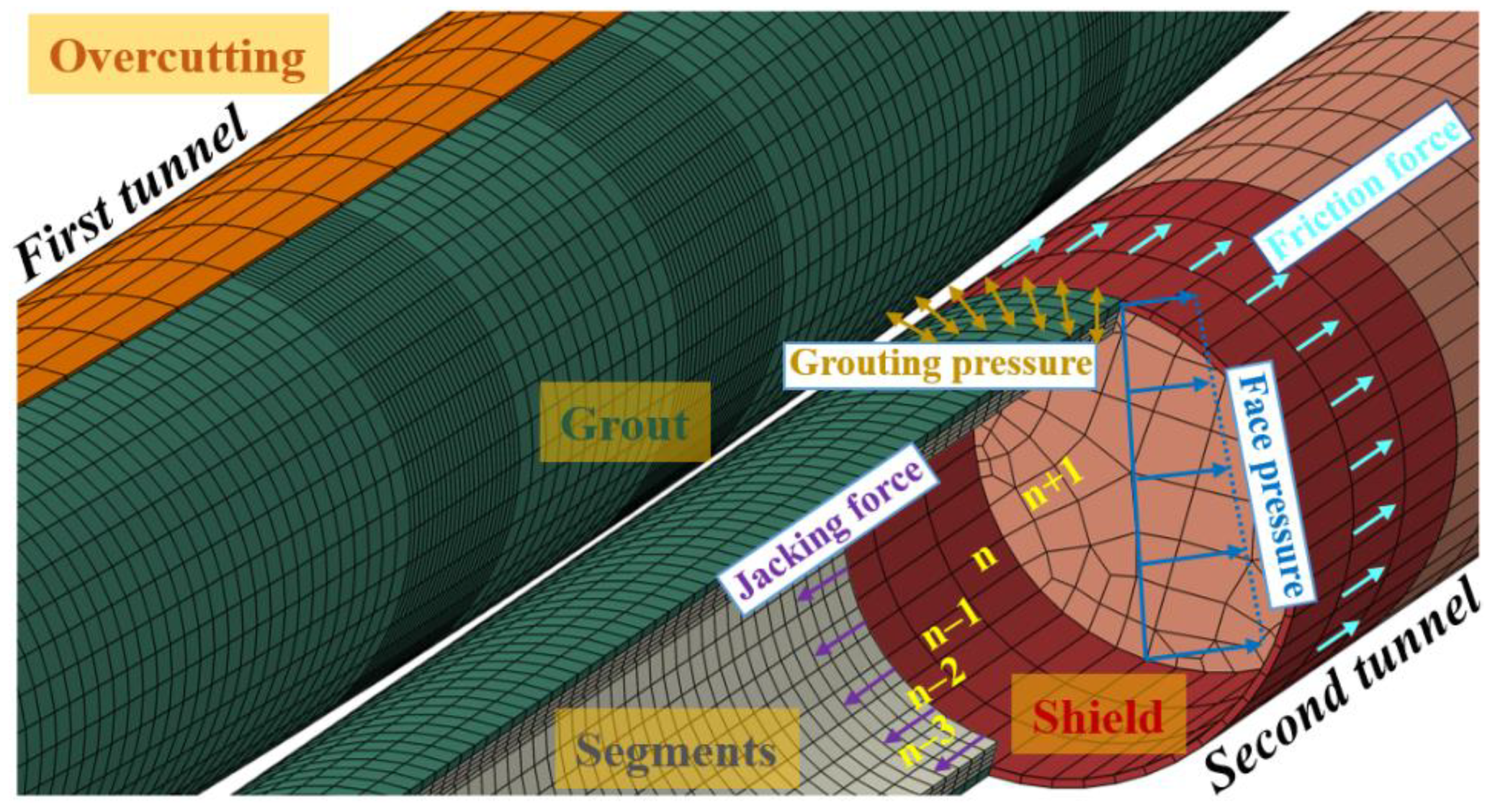

3.3. Modelling of Construction Loadings

- It is assumed that the pressure exerted by the TBM on the excavation face varies linearly with elevation according to ground density. The reference pressure at the tunnel axis is usually set as half of the sum of stresses at the tunnel crown and invert [40]. During the actual construction, an additional pressure of about 15 kPa is enforced on the excavation face [41]. As a result, the face pressures at the axes of the first and second tunnels are assumed as 141 kPa and 148 kPa, respectively.

- It is assumed that the grouting pressure acting on both the ground and segment is uniform distribution, and is related to the ground overburden pressure at tunnel crown [42]. As a result, the grouting pressures acting on the first and second tunnels are assumed as 3.3 bar and 3.1 bar, respectively.

- In order to simplify the simulation, the total force of hydraulic jacks is loaded equally on the circumferential surface of the installed segment [27]. For both the first curved tunnel and the second straight-line tunnel, the jacking force per unit area is about 2.1 MPa. However, it is worth noting that the direction of the jacking force vector is not perpendicular to the acting surface for the first curved tunnel. In other words, an angle between it and the central axis of the newly installed segment exists to achieve a curved trajectory.

- In ABAQUS, the friction force indirectly exerted on the soil is simulated via a contact pair consisting of the excavation interface and the shield skin. Furthermore, the Coulomb friction law is assumed, and the friction coefficient is set as 0.25 [30].

3.4. Shield Tunneling Process

4. Numerical Analysis Results and Comparisons

4.1. Influence of Approaching Excavation on Ground Displacements

4.1.1. Ground Surface Settlement

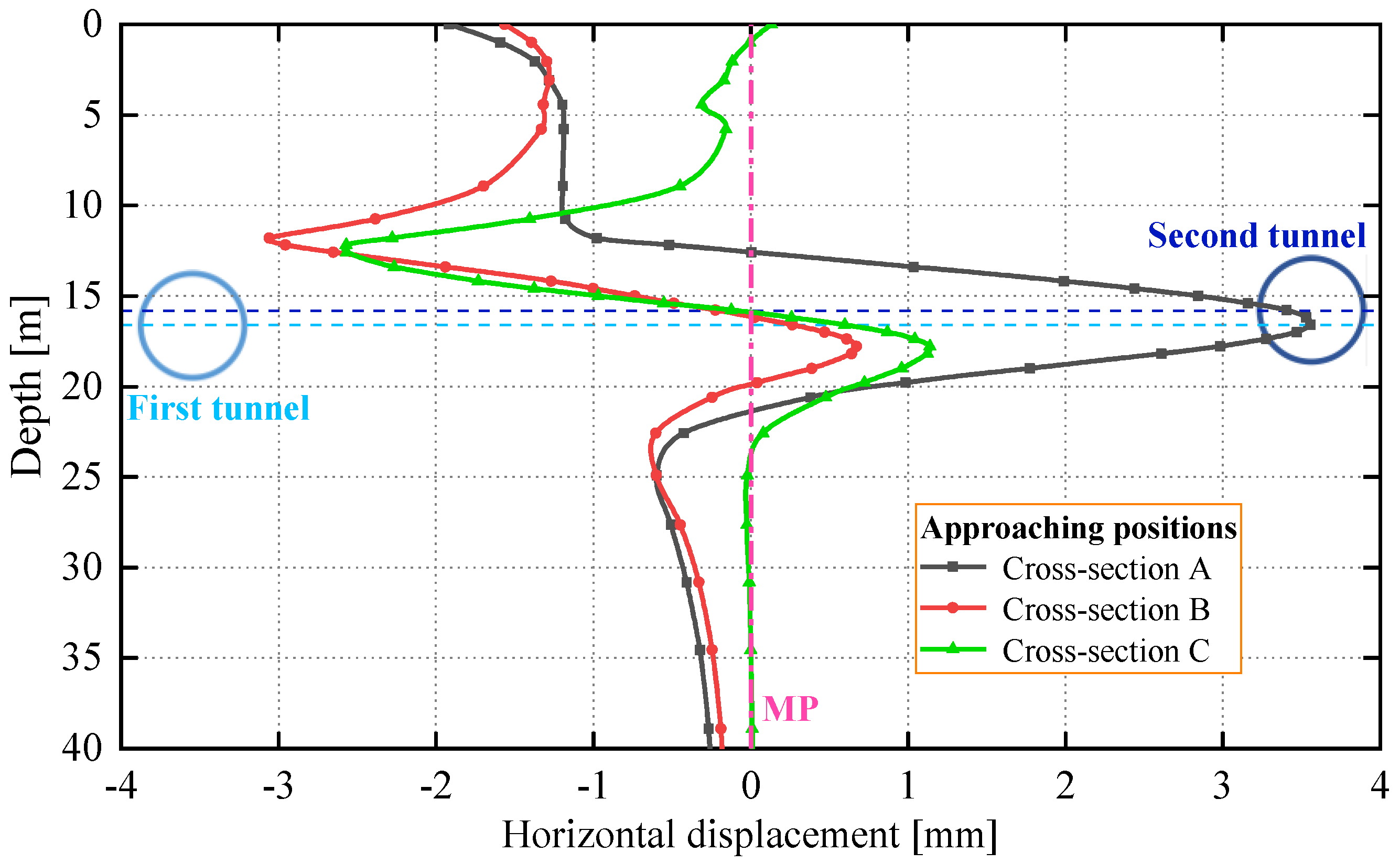

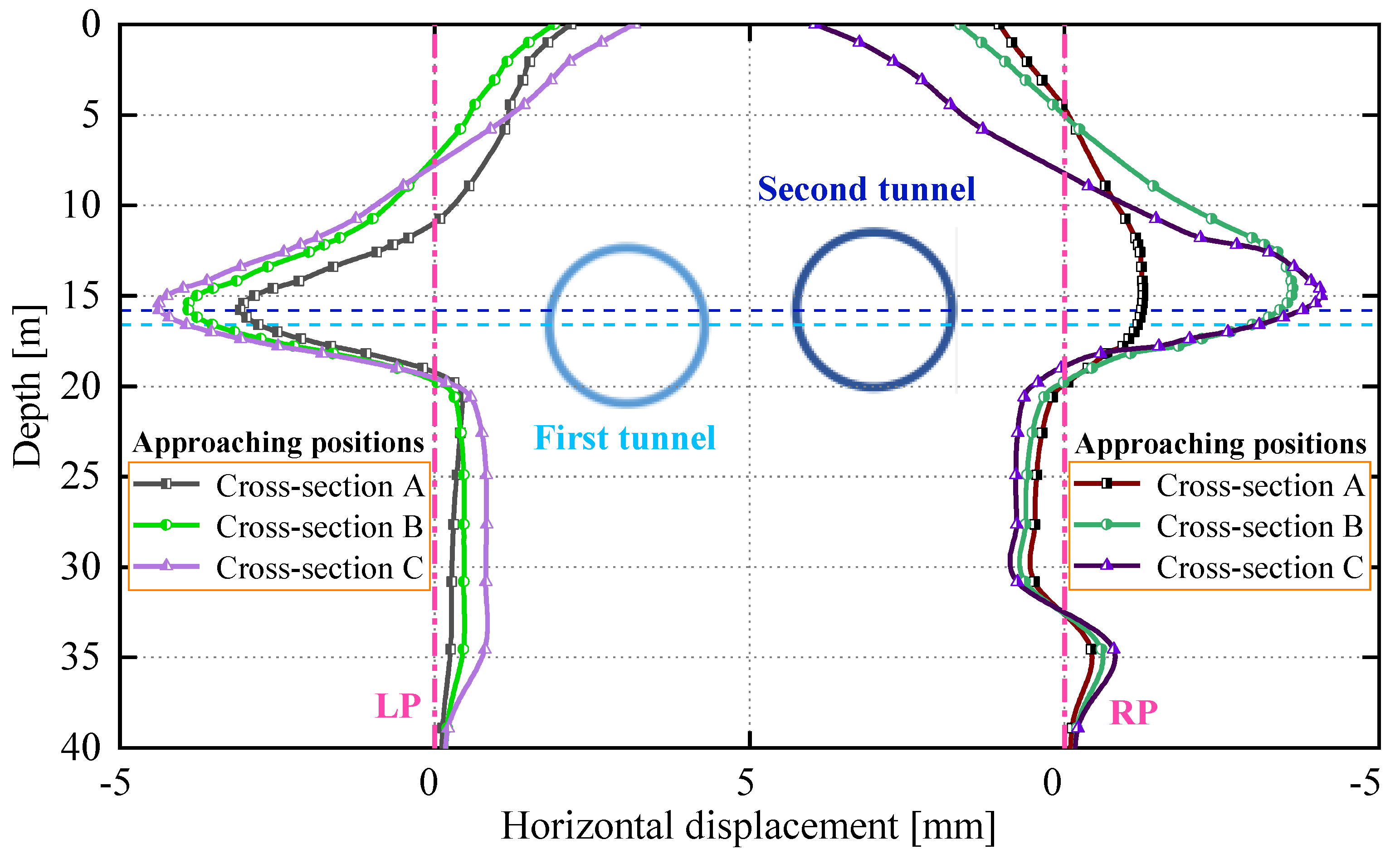

4.1.2. Horizontal Ground Displacement

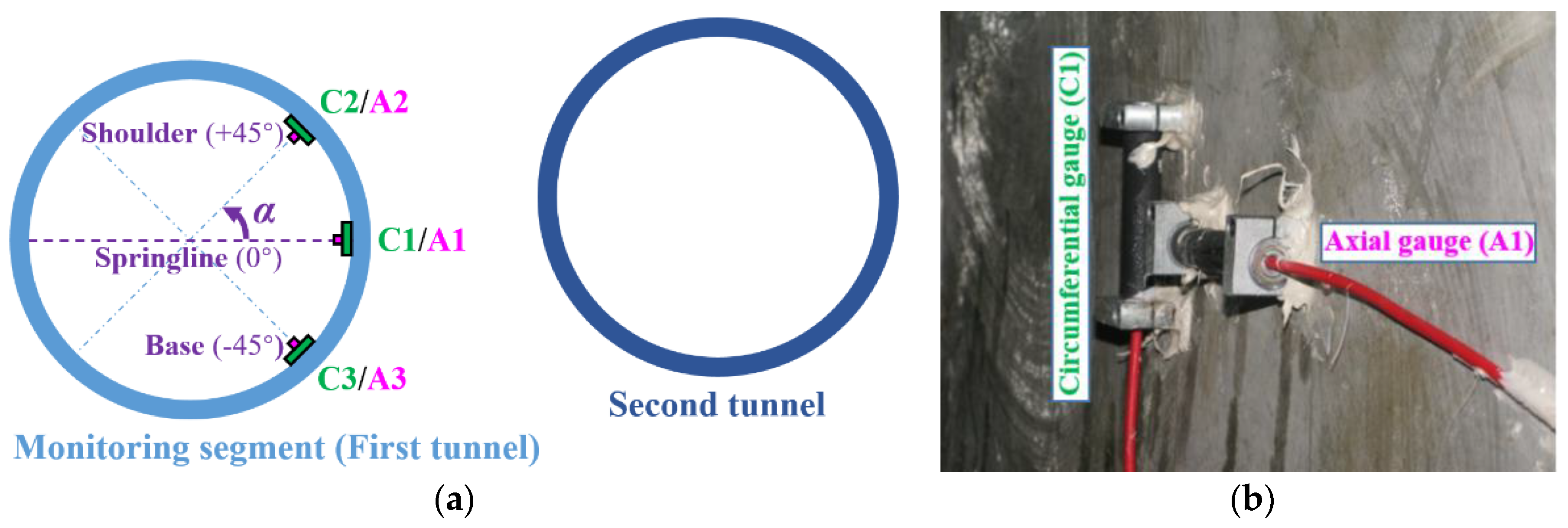

4.2. Influence of Approaching Excavation on Adjacent Tunnel

4.3. Comparison of Numerical and Monitored Results

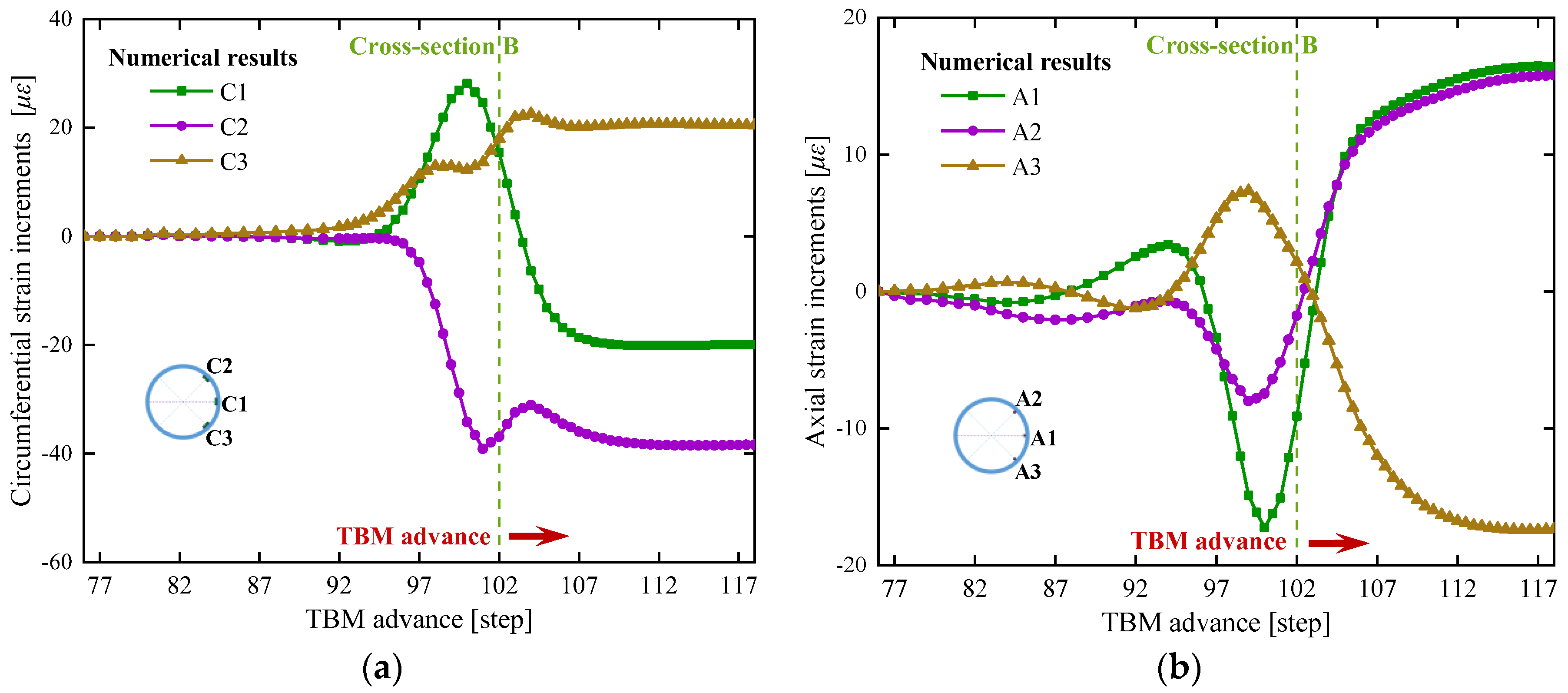

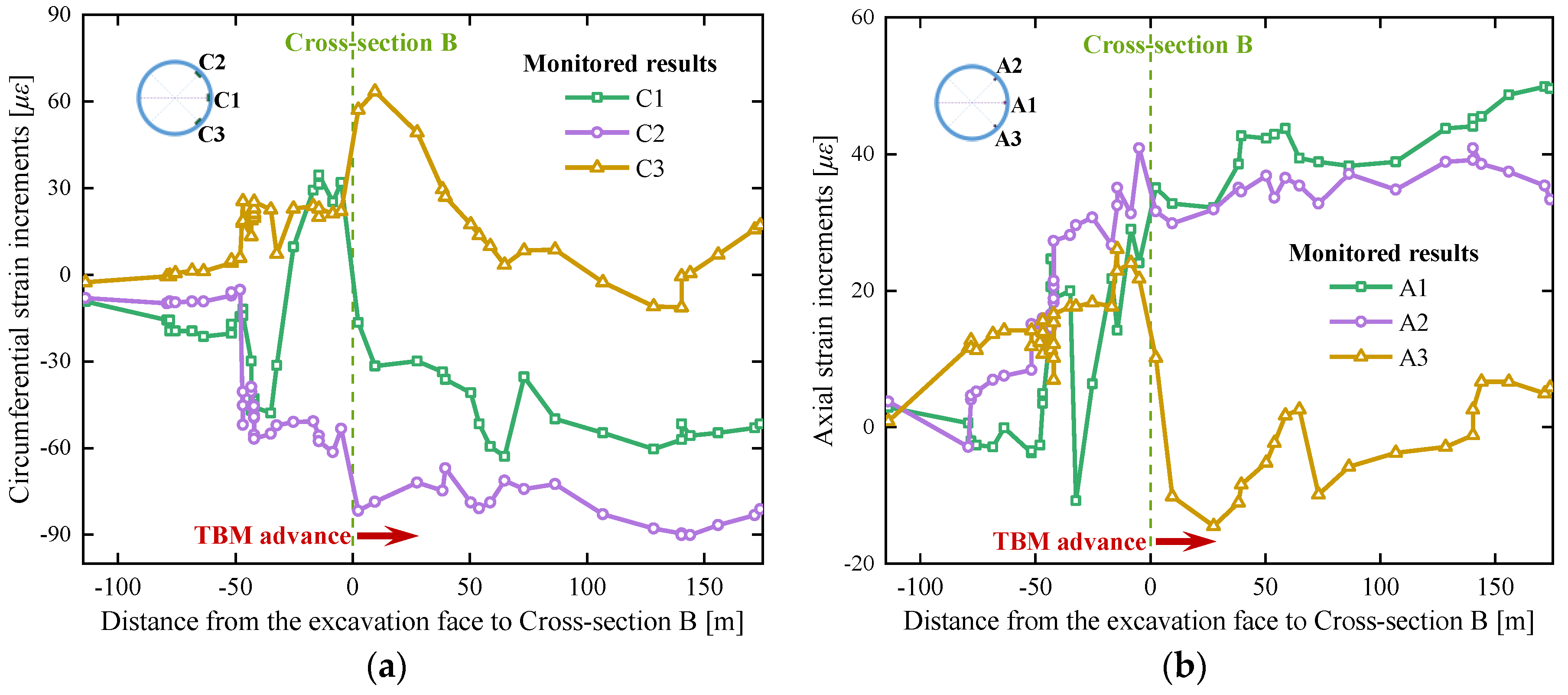

- The circumferential strain increment at C1 firstly develops as tensile strain; then fluctuates towards the reverse direction; finally stabilizes in the compressive strain state. The circumferential strain increment at C2 mainly fluctuates within the range of compressive strain. These variations indicate that the impact of the approaching excavation is significant on the measured segment at the tunnel springline and shoulder regions, which are mainly subject to the circumferential compression.

- The circumferential strain increment at C3 firstly develops as tensile strain and subsequently stabilizes. It shows that the impact of the approaching excavation is slight on the measured segment at the tunnel base region.

- The variation of axial strain increment at A2 is similar to that at A1. The fluctuation amplitude of the former is smaller than that of the latter one. These variations indicate that the impact of the approaching excavation is significant on the measured segment at the tunnel springline and shoulder regions, which are mainly subject to the tensile compression.

- The axial strain increment with small value at A3 firstly develops as tensile strain; then fluctuates towards the reverse direction; finally stabilizes in the compressive strain state.

5. Optimization of Construction Schemes

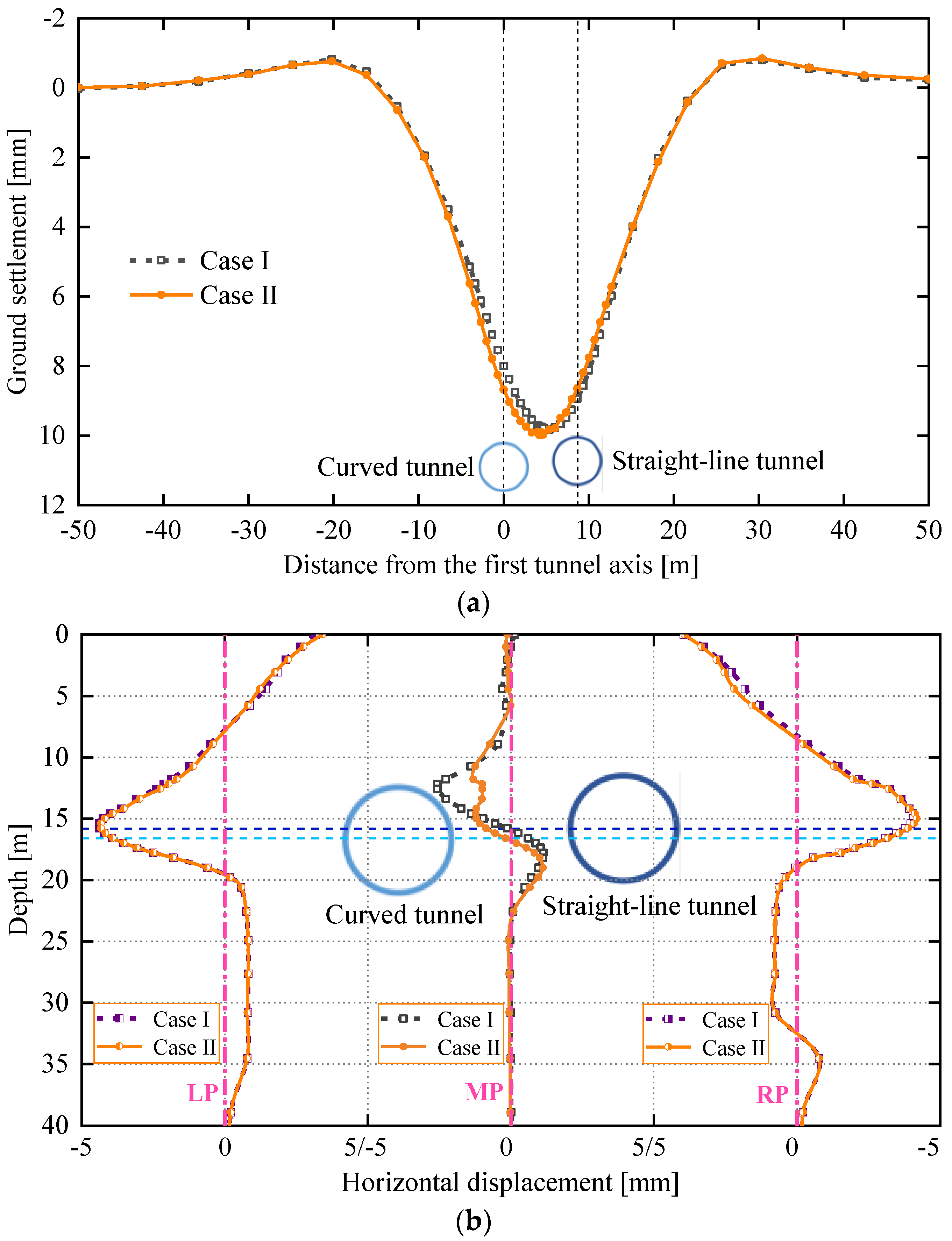

5.1. Ground Displacement

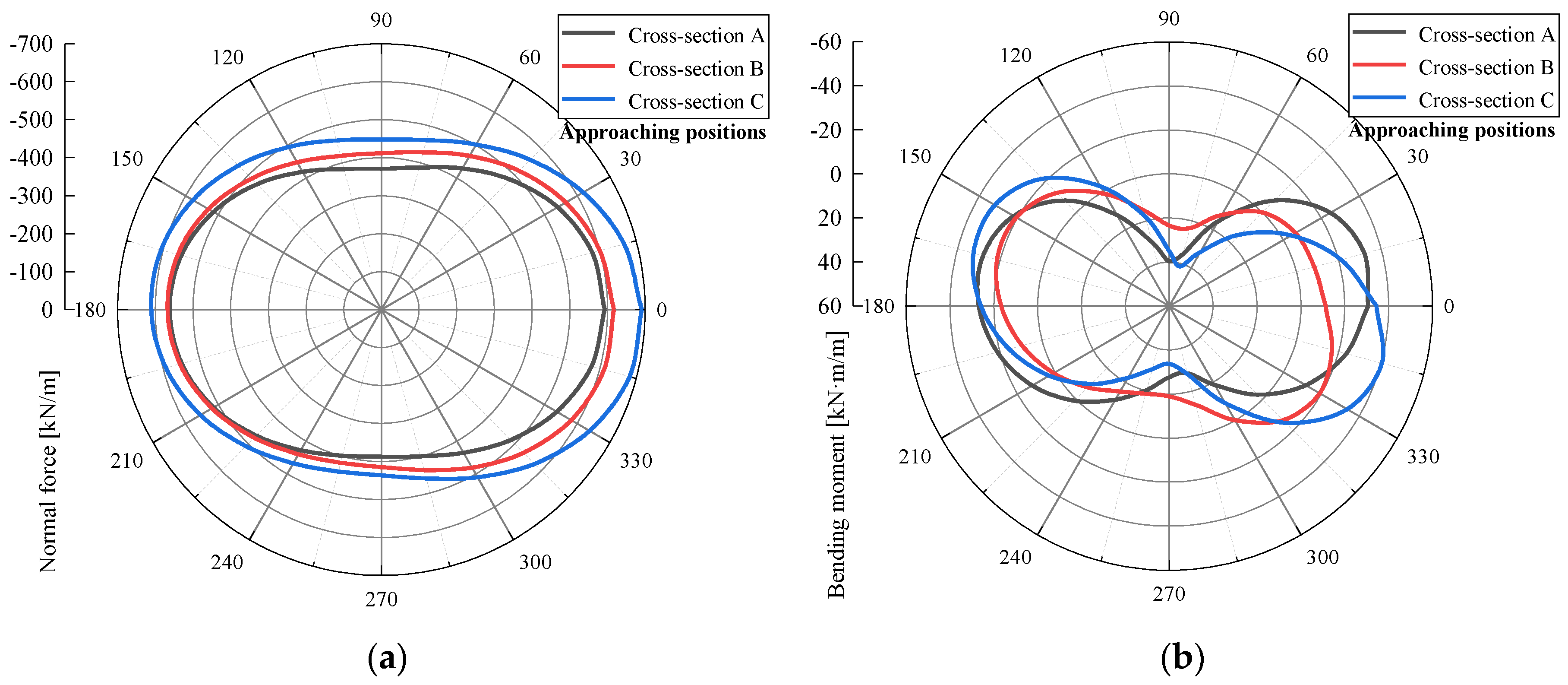

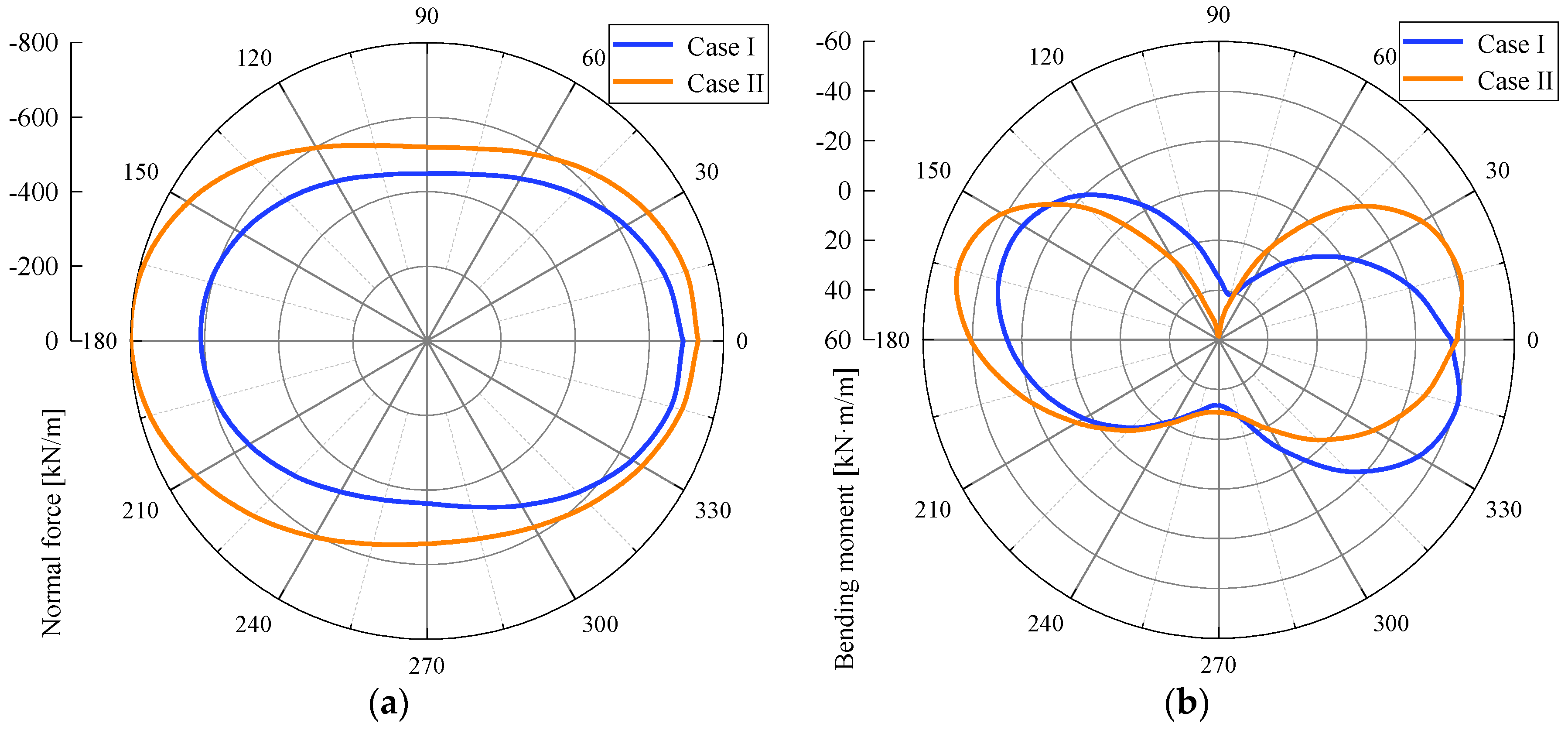

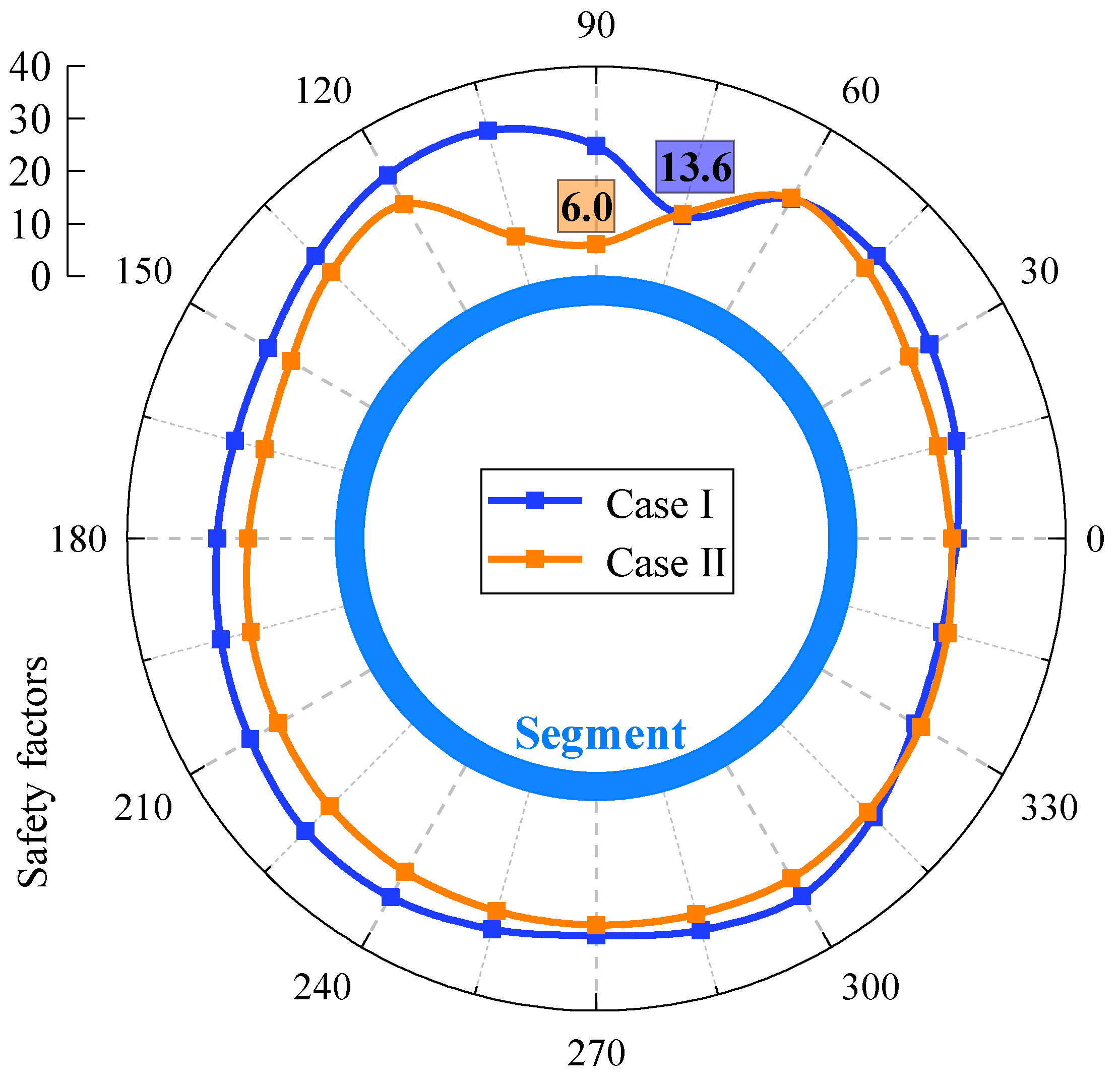

5.2. Internal Forces in the Segment

6. Conclusions

- (1)

- The deformation of the measured segment is asymmetric with respect to the tunnel axis due to the influence of the overcutting. Under the influence of lateral pressing effect induced by approaching excavation, a pronounced asymmetric and increased ovalization is presented on the measured segment when the second tunnel approaches the measured cross-section.

- (2)

- As the second tunnel approaches and keeps away from the measured cross-section, the peak value of the ground settlement at the monitoring cross-section always shifts toward the second tunnel, and the ground nearby the tunnel axis on both sides always moves outward. Under the influence of construction loadings, soil loss and ovalization of the segment, the approaching excavation reduces the horizontal displacements of the ground between twin tunnels and increases the ground settlements as well as the horizontal displacements of the ground on both sides.

- (3)

- When the second tunnel is far from the measured cross-section, the profiles of internal forces in the measured segment are asymmetric with respect to the curved tunnel axis, which is mainly affected by the overcutting. After that, the asymmetric characteristics become more striking due to the approaching excavation. As the second tunnel approaches and keeps away from the measured cross-section, the normal force increases gradually, whereas the bending moment first decreases and then increases. The maximum increments of normal force and bending moment are both located at the regions near the second tunnel.

- (4)

- For the curved tunnel and straight-line tunnel required for excavation in this project, the tunneling case of first along the curved trajectory and then along the straight-line trajectory will result in smaller internal forces of the segment. However, the construction case of first along the straight-line trajectory and then along the curved trajectory will result in a smaller horizontal displacement of the ground between twin tunnels.

- (5)

- The variations of strain increments obtained by numerical simulation agree well with the monitored results. The impact of the approaching excavation is significant on the measured segment at the tunnel springline and shoulder regions, which are mainly subject to the circumferential compression and axial tension.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.X.; Liu, C.; Huang, X.; Kwok, C.Y.; Teng, L. Three-dimensional finite-element analysis on ground responses during twin-tunnel construction using the URUP method. Tunn. Undergr. Space Technol. 2016, 58, 133–146. [Google Scholar] [CrossRef] [Green Version]

- Li, P.F.; Chen, K.Y.; Wang, F.; Li, Z. An upper-bound analytical model of blow-out for a shallow tunnel in sand considering the partial failure within the face. Tunn. Undergr. Space Technol. 2019, 91, 102989. [Google Scholar] [CrossRef]

- Wan, T.; Li, P.F.; Zheng, H.; Zhang, M.J. An analytical model of loosening earth pressure in front of tunnel face for deep-buried shield tunnels in sand. Comput. Geotech. 2019, 115, 103170. [Google Scholar] [CrossRef]

- Li, P.F.; Wang, F.; Fan, L.F.; Wang, H.D.; Ma, G.W. Analytical scrutiny of loosening pressure on deep twin-tunnels in rock formations. Tunn. Undergr. Space Technol. 2019, 83, 373–380. [Google Scholar] [CrossRef]

- Kim, S.H.; Burd, H.J.; Milligan, G.W.E. Model testing of closely spaced tunnels in clay. Géotechnique 1998, 48, 375–388. [Google Scholar] [CrossRef]

- Guo, W.; Wang, G.; Bao, Y.; Li, P.; Zhang, M.; Gong, Q.; Li, R.; Gao, Y.; Zhao, R.; Shen, S. Detection and monitoring of tunneling-induced riverbed deformation using GPS and BeiDou: A Case Study. Appl. Sci. 2019, 9, 2759. [Google Scholar] [CrossRef] [Green Version]

- Zhao, W.; Jia, P.J.; Zhu, L.; Cheng, C.; Han, J.Y.; Chen, Y.; Wang, Z.G. Analysis of the Additional Stress and Ground Settlement Induced by the Construction of Double-O-Tube Shield Tunnels in Sandy Soils. Appl. Sci. 2019, 9, 1399. [Google Scholar] [CrossRef] [Green Version]

- Yamaguchi, I.; Yamazaki, I.; Kiritani, Y. Study of ground-tunnel interactions of four shield tunnels driven in close proximity, in relation to design and construction of parallel shield tunnels. Tunn. Undergr. Space Technol. 1998, 13, 289–304. [Google Scholar] [CrossRef]

- Gao, S.M.; Chen, J.P.; Zuo, C.Q.; Wang, W. Monitoring of Three-dimensional Additional Stress and Strain in Shield Segments of Former Tunnels in the Construction of Closely-Spaced Twin Tunnels. Geotech. Geol. Eng. 2017, 35, 69–81. [Google Scholar] [CrossRef]

- Liang, R.; Xia, T.; Hong, Y.; Yu, F. Effects of above-crossing tunnelling on the existing shield tunnels. Tunn. Undergr. Space Technol. 2016, 58, 159–176. [Google Scholar] [CrossRef]

- Mindlin, R.D. Force at a point in the interior of a semi-infinite solid. J. Appl. Phys. 1936, 7, 195–202. [Google Scholar] [CrossRef]

- Kong, F.C.; Lu, D.C.; Du, X.L.; Shen, C.P. Elastic analytical solution of shallow tunnel owing to twin tunnelling based on a unified displacement function. Appl. Math. Model. 2019, 68, 422–442. [Google Scholar] [CrossRef]

- Chen, R.P.; Zhu, J.; Liu, W.; Tang, X.W. Ground movement induced by parallel EPB tunnels in silty soils. Tunn. Undergr. Space Technol. 2011, 26, 163–171. [Google Scholar] [CrossRef]

- Ocak, I. Interaction of longitudinal surface settlements for twin tunnels in shallow and soft soils: The case of Istanbul Metro. Environ. Earth Sci. 2013, 69, 1673–1683. [Google Scholar] [CrossRef]

- Hasanpour, R.; Chakeri, H.; Ozcelik, Y.; Denek, H. Evaluation of surface settlements in the Istanbul metro in terms of analytical, numerical and direct measurements. Bull. Eng. Geol. Environ. 2012, 71, 499–510. [Google Scholar] [CrossRef]

- Do, N.A.; Dias, D.; Oreste, P.; Djeran-Maigre, I. Three-dimensional numerical simulation of a mechanized twin tunnels in soft ground. Tunn. Undergr. Space Technol. 2014, 42, 40–51. [Google Scholar] [CrossRef]

- Wu, B.; Luo, Y.C.; Zang, J.B. Thermal Behavior of Tunnel Segment Joints Exposed to Fire and Strengthening of Fire-damaged Joints with Concrete-filled Steel Tubes. Appl. Sci. 2019, 9, 1781. [Google Scholar] [CrossRef] [Green Version]

- Zhao, C.; Lavasan, A.A.; Barciaga, T.; Kämper, C.; Mark, P.; Schanz, T. Prediction of tunnel lining forces and deformations using analytical and numerical solutions. Tunn. Undergr. Space Technol. 2017, 64, 164–176. [Google Scholar] [CrossRef]

- Wang, L.Z.; Sun, L.W.; Wang, Z.; Zhang, J. Field monitoring of a subsea shield tunnel during standpipe lifting. Tunn. Undergr. Space Technol. 2015, 45, 52–62. [Google Scholar] [CrossRef]

- Yang, F.; Cao, S.R.; Qin, G. Mechanical behavior of two kinds of prestressed composite linings: A case study of the Yellow River Crossing Tunnel in China. Tunn. Undergr. Space Technol. 2018, 79, 96–109. [Google Scholar] [CrossRef]

- Yu, H.T.; Cai, C.; Bobet, A.; Zhao, X.; Yuan, Y. Analytical solution for longitudinal bending stiffness of shield tunnels. Tunn. Undergr. Space Technol. 2019, 83, 27–34. [Google Scholar] [CrossRef]

- Afifipour, M.; Sharifzadeh, M.; Shahriar, K.; Jamshidi, H. Interaction of twin tunnels and shallow foundation at Zand underpass, Shiraz metro, Iran. Tunn. Undergr. Space Technol. 2011, 26, 356–363. [Google Scholar] [CrossRef]

- Nematollahi, M.; Dias, D. Three-dimensional numerical simulation of pile-twin tunnels interaction–Case of the Shiraz subway line. Tunn. Undergr. Space Technol. 2019, 86, 75–88. [Google Scholar] [CrossRef]

- Enieb, M.; Khalil, A.A.; Ahmed, A.S. Twin tunnel configuration for Greater Cairo metro line No. 4. Comput. Geotech. 2015, 68, 66–77. [Google Scholar]

- Tai, Q.M.; Zhang, D.L.; Fang, Q.; Sun, Y.; Yu, F.C.; Meng, M. Analysis of ground surface deformation induced by excavation of crossing metro tunnels in urban underground. Chin. J. Rock Mech. Eng. 2014, 33, 2472–2480. [Google Scholar]

- Mollon, G.; Dias, D.; Soubra, A.H. Probabilistic analyses of tunneling-induced ground movements. Acta Geotech. 2013, 8, 181–199. [Google Scholar] [CrossRef] [Green Version]

- Do, N.A.; Dias, D.; Oreste, P.; Djeran-Maigre, I. Three-dimensional numerical simulation for mechanized tunnelling in soft ground: The influence of the joint pattern. Acta Geotech. 2014, 9, 673–694. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Lavasan, A.A.; Barciaga, T.; Zarev, V.; Datcheva, M.; Schanz, T. Model validation and calibration via back analysis for mechanized tunnel simulations–The Western Scheldt tunnel case. Comput. Geotech. 2015, 69, 601–614. [Google Scholar] [CrossRef]

- Lambrughi, A.; Rodríguez, L.M.; Castellanza, R. Development and validation of a 3D numerical model for TBM-EPB mechanised excavations. Comput. Geotech. 2012, 40, 97–113. [Google Scholar] [CrossRef]

- Zheng, G.; Lu, P.; Diao, Y. Advance speed-based parametric study of greenfield deformation induced by EPBM tunneling in soft ground. Comput. Geotech. 2015, 65, 220–232. [Google Scholar] [CrossRef]

- Kasper, T.; Meschke, G. A 3D finite element simulation model for TBM tunnelling in soft ground. Int. J. Numer. Anal. Methods Geomech. 2004, 28, 1441–1460. [Google Scholar] [CrossRef]

- Chen, J.; Sugimoto, M. Analysis on shield operational parameters to steer articulated shield. Jpn. Geotech. Soc. Spec. Publ. 2016, 2, 1497–1500. [Google Scholar]

- Lo, K.Y.; Rowe, R.K. Predicting settlement due to tunnelling in clays. In Tunnelling in Soil and Rock; ASCE: Reston, VA, USA, 1984; pp. 46–76. [Google Scholar]

- Sigl, O.; Atzl, G. Design of bored tunnel linings for Singapore MRT North East Line C706. Tunn. Undergr. Space Technol. 1999, 14, 481–490. [Google Scholar] [CrossRef]

- Zhang, M.J.; Li, S.H.; Li, P.F. Numerical analysis of ground displacement and segmental stress and influence of yaw excavation loadings for a curved shield tunnel. Comput. Geotech. 2020, 118, 103325. [Google Scholar] [CrossRef]

- Li, P.F.; Zou, H.H.; Wang, F.; Xiong, H.C. An analytical mechanism of limit support pressure on cutting face for deep tunnels in the sand. Comput. Geotech. 2020, 119, 103372. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Z.; Regueiro, R.A. Pile and pile group response to tunnelling using a large diameter slurry shield—Case study in Shanghai. Comput. Geotech. 2014, 59, 21–43. [Google Scholar] [CrossRef]

- Meschke, G. From advance exploration to real time steering of TBMs: A review on pertinent research in the Collaborative Research Center “Interaction Modeling in Mechanized Tunneling. Undergr. Space 2018, 3, 1–20. [Google Scholar] [CrossRef]

- Li, P.F.; Wang, F.; Zhang, C.P.; Li, Z. Face stability analysis of a shallow tunnel in the saturated and multilayered soils in short-term condition. Comput. Geotech. 2019, 107, 25–35. [Google Scholar] [CrossRef]

- Kavvadas, M.; Litsas, D.; Vazaios, I.; Fortsakis, P. Development of a 3D finite element model for shield EPB tunnelling. Tunn. Undergr. Space Technol. 2017, 65, 22–34. [Google Scholar] [CrossRef]

- Zhu, J.F.; Xu, R.Q.; Liu, G.B. Analytical prediction for tunnelling-induced ground movements in sands considering disturbance. Tunn. Undergr. Space Technol. 2014, 41, 165–175. [Google Scholar] [CrossRef]

- Ninić, J.; Meschke, G. Simulation based evaluation of time-variant loadings acting on tunnel linings during mechanized tunnel construction. Eng. Struct. 2017, 135, 21–40. [Google Scholar] [CrossRef]

- Suwansawat, S.; Einstein, H.H. Describing settlement troughs over twin tunnels using a superposition technique. J. Geotech. Geoenvironmental Eng. 2007, 133, 445–468. [Google Scholar] [CrossRef]

- Chapman, D.N.; Ahn, S.K.; Hunt, D.V.L. Investigating ground movements caused by the construction of multiple tunnels in soft ground using laboratory model tests. Can. Geotech. J. 2007, 44, 631–643. [Google Scholar] [CrossRef]

- Liu, X.; Fang, Q.; Zhang, D.L.; Liu, Y. Energy-based prediction of volume loss ratio and plastic zone dimension of shallow tunnelling. Comput. Geotech. 2019, 118, 103343. [Google Scholar] [CrossRef]

- Ninić, J.; Freitag, S.; Meschke, G. A hybrid finite element and surrogate modelling approach for simulation and monitoring supported TBM steering. Tunn. Undergr. Space Technol. 2017, 63, 12–28. [Google Scholar] [CrossRef] [Green Version]

- Li, P.F.; Zhou, X.J. Mechanical behavior and shape optimization of lining structure for subsea tunnel excavated in weathered slot. China Ocean. Eng. 2015, 29, 875–890. [Google Scholar] [CrossRef]

| Type of Soil | Thickness (m) | Young’s Modulus (MPa) | Poisson Ratio | Cohesion (kPa) | Density (kN/m3) | Friction Angle (°) |

|---|---|---|---|---|---|---|

| Artificial fill | 1 | 18.5 | 0.25 | 16 | 16.5 | 12.2 |

| Sandy silt | 2.1 | 26 | 0.22 | 28 | 19.5 | 24.1 |

| Silty-fine sand | 2.7 | 35 | 0.26 | 0.2 | 20 | 26.8 |

| Round gravel | 6 | 45 | 0.3 | 0.3 | 20.5 | 35 |

| Sandy cobble | 38.2 | 130 | 0.18 | 0 | 21.5 | 40 |

| External Diameter (m) | Thickness (cm) | Length/Width (m) | Density (kN/m3) | Elastic Modulus (GPa) | Poisson Ratio | |

|---|---|---|---|---|---|---|

| Shield | 6.28 | 5.5 | 8 | 78 | 235 | 0.2 |

| Segment | 6 | 30 | 1.2 | 25 | 34.5 | 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Li, P.; Zhang, M.; Liu, Y. Influence of Approaching Excavation on Adjacent Segments for Twin Tunnels. Appl. Sci. 2020, 10, 98. https://doi.org/10.3390/app10010098

Li S, Li P, Zhang M, Liu Y. Influence of Approaching Excavation on Adjacent Segments for Twin Tunnels. Applied Sciences. 2020; 10(1):98. https://doi.org/10.3390/app10010098

Chicago/Turabian StyleLi, Shaohua, Pengfei Li, Mingju Zhang, and Yi Liu. 2020. "Influence of Approaching Excavation on Adjacent Segments for Twin Tunnels" Applied Sciences 10, no. 1: 98. https://doi.org/10.3390/app10010098

APA StyleLi, S., Li, P., Zhang, M., & Liu, Y. (2020). Influence of Approaching Excavation on Adjacent Segments for Twin Tunnels. Applied Sciences, 10(1), 98. https://doi.org/10.3390/app10010098