3.1. Optimisation of the Extraction Performance

The process implemented was designed to appraise the effect of three crucial extraction variables,

CCD, R

L/S, and pH, and to identify possible synergistic functions between them. Evaluation of the fitted model and the suitability of response surface were based on the ANOVA and lack-of-fit test (

Table 2), by considering the closeness of the predicted and measured values (

Table 3). The second-degree polynomial equations (mathematical models), considering only the significant terms, are presented in

Table 4, along with the square correlations coefficients (R

2) of the models, which are indicators of the total variability around the mean determined by the model. Because all total R

2 of the models were equal or higher than 0.97, and the

p-value for lack of fit (assuming a confidence interval of 95%) was highly significant for all models, it can be argued that equations exhibited excellent fit to the experimental data. The contour plots constructed on the basis of the models, which are presented on a comparative arrangement in

Figure 2, provide an at-a-glance image of how the experimental variables affected response (Y

TP), but also illustrate the differences between the three CDs used.

For the extraction with β-CD, CCD was found to exert a non-significant effect, suggesting that any shift in CCD within the range tested cannot impact YTP. The same was observed for HP-β-CD, but for m-β-CD, this variable was highly significant (p = 0.0047). This outcome strongly indicated that the nature of the CD used may play a key role in extraction. On the other hand, no cross term between m-β-CD concentration and either RL/S or pH was significant, showing that combined effects did not occur. Contrary to those, for the extractions performed with any CD, both RL/S and pH were significant.

Quadratic effects of these variables were also significant for the extractions with β-CD and m-β-CD, but for HP-β-CD, a significant quadratic effect was seen only for pH. Moreover, for HP-β-CD and m-β-CD, cross terms of RL/S and pH were significant too, demonstrating that combinations of these two variables may have either a negative (HP-β-CD) or positive (m-β-CD) influence on the extraction yield.

The desirability function (

Figure 3) enabled the estimation of the optimal predicted response for each CD tested (

Table 5). The Y

TP achieved with HP-β-CD and m-β-CD were identical and significantly higher than that obtained with β-CD (

p < 0.05). This finding highlighted the prominent role of the nature of the CD used for the extraction. In support of this are pertinent results on the extraction of olive pomace polyphenols, where HP-β-CD exhibited superior extraction capacity compared with either m-β-CD or γ-CD [

11]. Data on polyphenol extraction from pomegranate fruit were in the same line [

12], stressing the superiority of HP-β-CD against β-CD as a polyphenol extraction booster. In opposition, anthocyanin extraction was more efficient with β-CD rather than HP-β-CD [

13]. Such discrepancies might emerge from the different encapsulating capacity of the CDs used towards structurally unrelated polyphenolic constituents. Indeed, examinations with pure polyphenols (catechin) demonstrated a more efficient encapsulation with β-CD than HP-β-CD or m-β-CD [

14]. Therefore, the higher-performance extraction of

S. fruticosa polyphenols observed with m-β-CD might reflect the manifestation of such phenomena. Given that the modelling performed revealed significant effect of

CCD only for m-β-CD, then it could be postulated that m-β-CD interacted more strongly with

S. fruticosa polyphenols than β-CD or HP-β-CD within the

CCD limits tested.

For all CDs, optimum R

L/S varied closely within 93–100 mL g

−1 (

Table 5). This outcome showed that the influence exerted by R

L/S on the extraction performance was not significantly affected by the structure of CD. The magnitude of R

L/S is related with the concentration gradient between the liquid phase (extraction medium) and the surface of the solid particle, which is directly involved in mass transfer. If R

L/S is below a certain limit, then the equilibria established may not favor fast diffusion of the solute during extraction, owing to non-negligible resistance to mass transfer [

15]. Several examinations on polyphenol extraction from plant tissues using conventional organic solvents suggested R

L/S optima between 81 [

16] and 100 mL g

−1 [

17,

18,

19]. Considering that the average R

L/S value in this study was 96 mL g

−1, it could be argued that an aqueous medium containing any of the CDs assayed would behave as a common solvent in this regard.

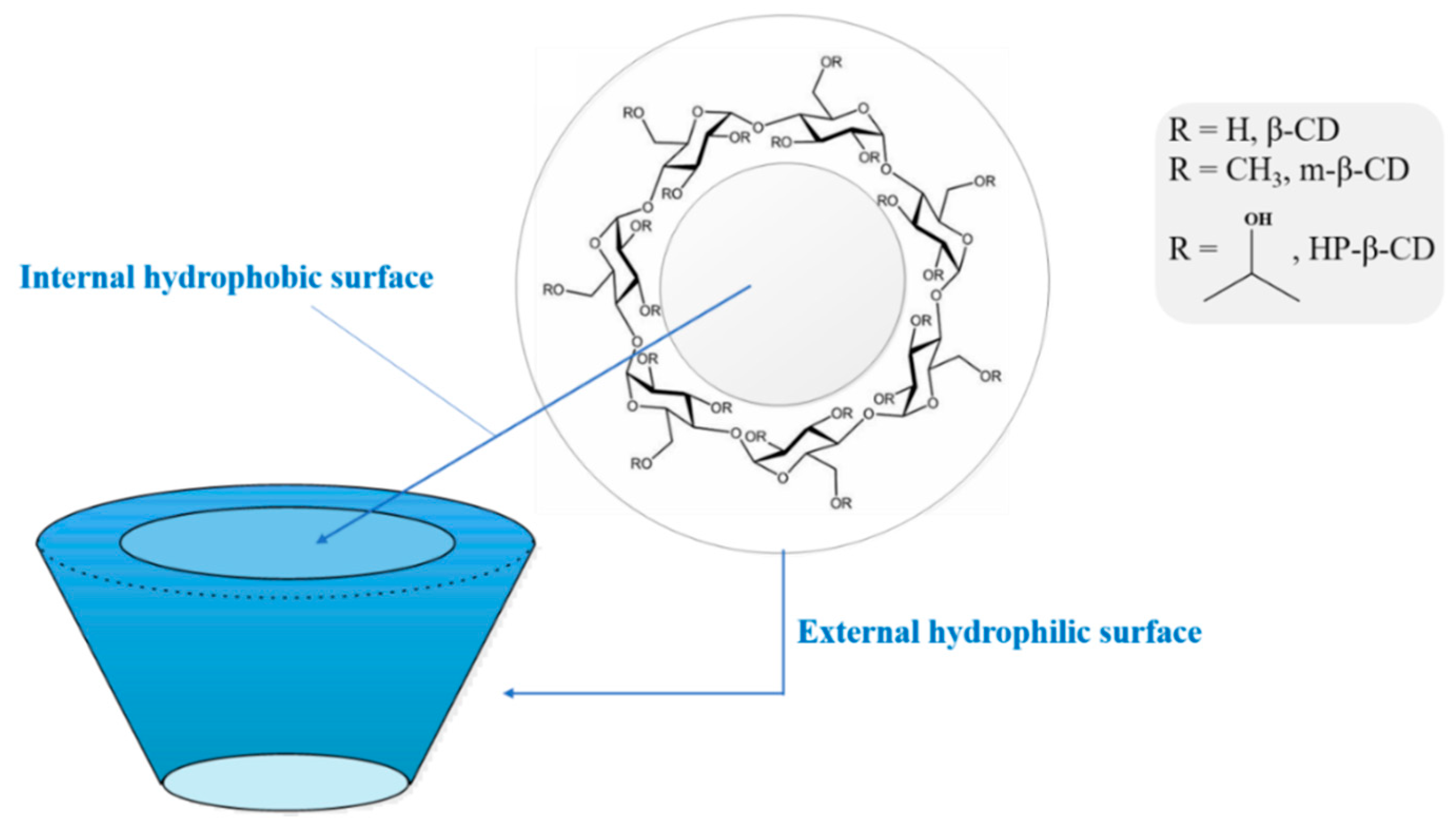

The statistically significant effects of pH revealed by the models for the extraction with any of the CDs assayed pointed emphatically to the role of the pH in the extraction performance. For all CDs, the optimal pH was below 5, which evidenced that extractions were favoured at acidic pH. One possible reason for this might be related to the ionisation of the phenolic hydroxyl groups, which possess weak acidity. Assuming that encapsulation of polyphenols within the CD cavity is the main effect that enhances extraction, then polyphenol dissociation would increase their polarity, leading to weaker interactions with CD cavity, which is hydrophobic. As dissociation would increase at a higher pH, it would be likely that suppression of dissociation at pH < 5 would maintain polyphenols in their molecular (non-dissociated) form, hence promoting more powerful polyphenol–CD interactions. In support of such a hypothesis were results on naproxen interactions with β-CD, where increasing pH was demonstrated to provoke instability on the inclusion complex, a fact ascribed to lower affinity of charged drug for the hydrophobic β-CD cavity [

20].

Although accurate determination has shown that p

Ka may lie well above 7 for several substituted phenolics [

21], for some flavonols such as quercetin, which are frequently encountered in plant tissues, p

Ka1 may vary within 5.06 to 7.36 [

22]. In any case, at pH > 5, even limited dissociation of the most acidic phenolic hydroxyls could occur, provoking a significant increase in polyphenol polarity. This issue was also addressed in previous studies on polyphenol extraction with water/ethanol mixtures [

23,

24,

25], where optimal extraction pH for total polyphenols was always <5. In these cases, increased extraction yield was ascribed to higher solubility of non-dissociated polyphenols in ethanol-containing solvents and increased polyphenol stability at acidic pH.

Variations in

CCD concentration within the limits tested for β-CD and HP-β-CD were shown to exert non-significant impact on Y

TP, but it was not clear whether the presence of any CD used could affect Y

TP. To examine this, extractions were performed with each CD under optimised conditions, as well as with aqueous solutions under the same R

L/S and pH, without the addition of CD (

Table 6). In every case, it was demonstrated that addition of CDs provoked significantly higher Y

TP, highlighting the importance of the CDs used as aqueous extraction boosters. The highest difference in Y

TP was found for m-β-CD (22.06%), followed by HP-β-CD (19.32%) and β-CD (11.28%).

3.2. Extraction Kinetics and Temperature Effects

To appraise the temperature effects on polyphenol recovery, kinetics was traced using all three CDs over a range of 40 to 80 °C (

Figure 4). The model that could effectively describe the patterns recorded was second-order kinetics [

26]:

where Y

TP(t) and Y

TP(s) represent the TP yield at any time

t and at equilibrium (saturation), respectively.

k is the second-order extraction rate constant. When

t approaches 0, the initial extraction rate,

h, given as Y

TP(t)/

t, is defined as follows:

In

Table 7, the values determined for

k, Y

TP(s) and

h, using SigmaPlot

™ 12.5, can be seen. For all CDs, the three kinetic parameters exhibited an increase as a response to raising the temperature up to 80 °C.

The highest Y

TP(s) was achieved with m-β-CD (98.39 mg GAE g

−1 dm) at 80 °C, and it was only 5.3% lower than that achieved with 60% methanol (

Figure 5). Both β-CD and HP-β-CD were significantly less effective, giving Y

TP(s) 75.85 and 81.93 mg GAE g

−1 dm, respectively. To further assess the impact of temperature, samples obtained at the end of each treatment (180 min) were also assayed for antioxidant activity (

Figure 6). In line with Y

TP(s), extracts obtained with m-β-CD exhibited the highest A

AR (1112.51 μmol DPPH g

−1 dm), followed by HP-β-CD (836.17 μmol DPPH g

−1 dm) and β-CD (824.08 μmol DPPH g

−1 dm). The results for P

R were in concurrence, giving corresponding values of 241.88, 210.72, and 185.74 μmol AAE g

−1 dm. This outcome suggested that, using m-β-CD, polyphenol-enriched extracts with improved antioxidant characteristics may be produced at 80 °C.

The effect of temperature on

k was better illustrated by establishing correlations between

k and

T (

Figure 7). These correlations could be very effectively described using an exponential model [

27]:

k =

k0

where

k corresponds to the second-order extraction rate and

k0 to a pre-exponential factor. In

Table 8, the parameters

k0, a, and b, calculated by SigmaPlot

™ 12.5, are given analytically. Extraction with m-β-CD displayed the lowest b value, which suggested that it was the least affected by temperature, as opposed to the extraction with HP-β-CD. This finding evidenced that m-β-CD provided the most effective and the least energy-demanding extraction of polyphenols. To ascertain this and obtain a tentative estimation of the barriers required for the extraction with each CD tested, the activation energy was determined as follows [

28]:

where

Tref was chosen as the mean temperature of testing (60 °C) and

T = 40 °C.

kref and

k were the corresponding second-order extraction rate constants.

Ea is the activation energy (J mol

−1) and

R the universal gas constant (8.314 J K

−1 mol

−1).

Ea thus estimated for the extraction with β-CD, HP-β-CD, and m-β-CD were 7.18, 9.50, and 5.64 kJ mol

−1, respectively. This finding did confirm that the extraction with m-β-CD was the least energy-demanding process.