The validity and accuracy of the proposed method were verified by designing a numerical combustion model using ANSYS FLUENT 16.0 and carrying out a series of CFD simulations. Python 3.6 software was applied to process the data.

3.1. Simulation Model

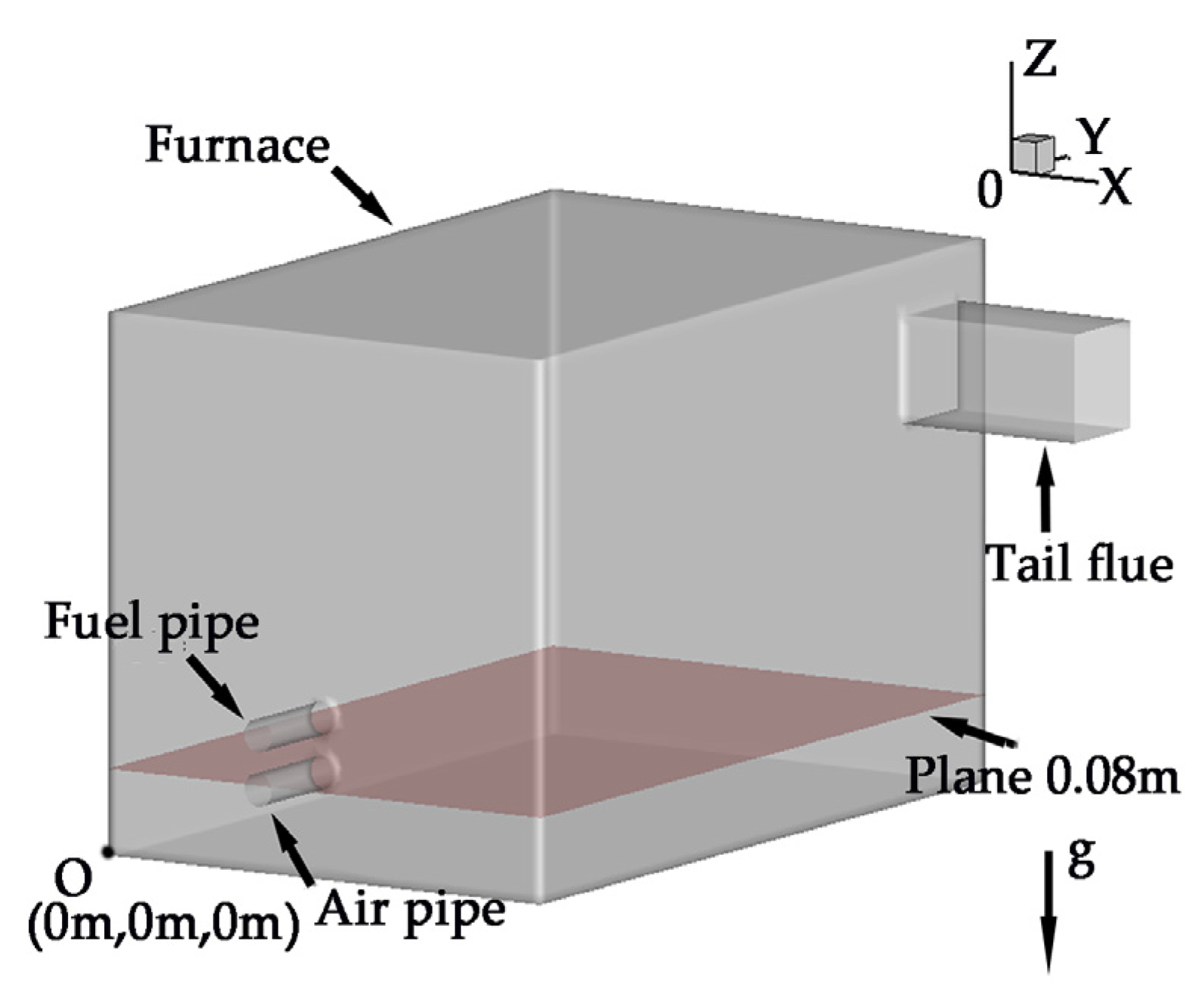

In the test model, gas fuel (propane) and air entered a burner through different pipes, and a mixture of gas fuel and air burned in the furnace. The furnace dimensions were 0.8 m in length, 0.5 m in width, and 0.5 m in height. The radius of the air pipe and fuel pipe was 0. 016 m. The coordinates of the air pipe center and fuel pipe center were 0.25, 0, and 0.1 m and 0.25, 0, and 0.15 m, respectively. The tail flue transverse dimensions were 0.15 m in width, 0.15 m in height, and 0.2 m in length.

Figure 1 shows the geometry of the simulation model.

The simulation data from the plane at 0.08 m of the furnace height were used to test the proposed method and to present the reconstruction results.

Tetrahedral grids were employed for the fuel pipe and the air pipe. The furnace was structured by hexahedral grids to improve mesh quality. Five different mesh grids with node numbers of 452,997, 609,363, 784,370, 1,019,816 and 1,210,028, were used to test the mesh independency. The grid convergence index (GCI) [

38] was also used in this test:

where

is the safety factor and

is the order of grid convergence.

is the highest temperature in the simulation result using the k-grid,

is the highest temperature in the simulation result using the k + 1 grid,

is the grid nodes number in the k grid, and

is the grid nodes number in the k + 1 grid.

The convergence condition is defined as follows:

GCI converges when

.

As shown in

Table 1, c in the 784,370 grid nodes is 0.91, and the 784,370, 1,019,816 and 1,210,028 grid nodes are in the asymptotic range of convergence. In consideration of the efficiency and accuracy, 784,370 grid nodes were used in the simulation model.

The basic governing equations in the simulation process were the conservation equations of mass, momentum, energy, species, and ideal gas state equation [

39], which are as follows:

(1) Mass conservation equation:

(2) Momentum conservation equation:

(3) Energy conservation equation:

(4) Species conservation equation:

(5) Ideal gas state equation:

where

is the density gas mixture,

is time,

is the velocity of the gas mixture,

is the static pressure,

is the stress tensor,

is the gravitational body force,

is the external body forces,

is the energy content per unit mass of the gas mixture,

is the effective conductivity,

is the temperature of the gas mixture,

is the enthalpy of the species i gas,

is the diffusion flux of the species i gas,

is the heat of other sources,

is the mass fraction of the species i gas,

is the net rate of production of the species i gas in chemical reactions,

is the rate of creation with the addition of the dispersed phase plus any other sources,

is the universal gas constant, and

is the molecular weight of the species i gas.

In the simulations, the standard turbulence model and the second-order upwind difference scheme were used. The other model constants were set to the default values. The species model was set to “Species Transport”, and the mixture material was set to “propane–air”. The radiation model was set to “P1” and the absorption coefficient was set to “wsggm-domain-based”. The “Eddy-Dissipation” model was used as the turbulence–chemistry interaction model.

The solution method was “SIMPLE”. The gradient was set to “Least Squares Cell-Based”, the pressure was set to “Second Order”, and the momentum and turbulent kinetic energy were set to “Second-Order Upwind”. The “energy” residual convergence was set to 10-5, and the others were set to 10-3. Observation points temperature and mass balance were also important factors in the determination of convergence.

For boundary conditions, the outlet was set to “outflow”. The fuel inlet boundary was set to “velocity-inlet”, and the air inlet boundary was set to “velocity-inlet”. The boundary conditions of the walls were set as “Stationary Wall” and “No Slip”. The near-wall treatment was set as “Standard Wall Functions”. Considering the water-cooling jacket that is used in real applications, for convenience, the wall temperature was set as 343.15 K.

As the dataset shows features of the temperature field, it means a lot to the proposed method and directly influences the accuracy of the reconstruction results. Therefore, a wide range of boundary conditions were used to carry out a sufficient number of simulation results. A sample dataset was established by the CFD results whose boundary conditions were fuel velocities of 0.44, 0.54, …, 1.14 m/s, with the air velocities being determined by the excess air coefficient ().

Six test cases were also set up to test the reconstruction results. The boundary conditions of the test cases are shown in

Table 2.

In order to test the proposed method in different conditions, firstly, a small fuel velocity 0.58m/s was used in this study. This was in the scope of 0.44 to 1.14 m/s, which was used for setting up the dataset. After that, 1.23 m/s was used to show the performance of the proposed method in the high-speed situation; 1.23 m/s was out of the range of 0.44 to 1.14 m/s, the reconstruction results in this boundary condition test whether the application range of the proposed method would be limited by the dataset boundary conditions. Furthermore, the CFD result with the fuel velocity set to 1.33 m/s and excess air coefficient set to 1.1 was used as a special test case.

3.3. Reconstruction Error Analysis

Equation (9) shows that the accuracy of the proposed method is associated with the number of POD basis vectors, sensor placement, and measurement noise. In the simulation test, measurement data were extracted from the CFD result. The measurement noise was artificially simulated by adding Gaussian noise to the sensor signal. These effects are discussed in this section.

3.3.1. Effect of the Number of POD Basis Vectors

In the reconstruction problem, the first few POD basis vectors contain most of the “energy”, and these basis vectors have a positive influence on the accuracy of the reconstruction result. The rest of the vectors contain less energy and are sensitive to noise. The noise may come from the measurement or calculation. In this situation, a large number of POD basis vectors means a high noise sensitivity. Therefore, in the reconstruction process, a proper number of POD basis vectors is needed.

A test was set up to investigate the changes in the reconstruction error with different numbers of POD basis vectors. In this test, 25 sensors were placed in random locations, the number of POD basis vectors varied from 1 to 15, the SNR of the noise varied from 40 to 50 dB, and the original measurement data without noise were used for comparison. As the sensor location and the noise were randomized for different conditions, the averages of reconstruction results of 1000 runs were used to draw a general conclusion.

Figure 3 shows the results for two test cases.

As shown in

Figure 3, the reconstruction error decreased at first and then increased with a large number of vectors. This phenomenon is more pronounced when the noise level increases. In both test cases, a reconstruction error with eight POD basis vectors was acceptable.

Reconstruction errors with eight POD basis vectors and 25 sensors in different test cases are shown in

Table 3.

As shown in

Table 3, in all of the conditions, using the first eight basis vectors could obtain a balance between noise sensitivity and reconstruction accuracy. Therefore, in this simulation scenario, the first eight POD basis vectors resulted in better performance.

3.3.2. Effect of Sample Rate

The proposed method provides a new way of using limited measurement data to get temperature information. These measurement data play a very important role in the reconstruction process, so the number of sensors has an effect on the reconstruction accuracy to a certain extent.

In this simulation test, the number of nodes on the object plane was approximately 4000. All of these nodes can be seen as a measuring point. Considering the measurement cost and reconstruction accuracy, a certain number of sensors is needed.

As mentioned above, methods based on POD require sensor numbers equal to or larger than the total number of basis vectors used. With eight POD basis vectors used for reconstruction, a 0.1% sample rate (four sensors) and a 0.2% sample rate (eight sensors) were not suitable for this problem.

For a general conclusion, the averages of the reconstruction errors from 1000 runs under different noise levels were compared, as the sample rate increased from 0.3% to 1.2%. These results are presented in

Figure 4.

As shown in

Figure 4, in all conditions, it is obvious that the reconstruction error decreased as the sample number increased from 0.3% to 1.2%. The greater the number of sensors used, the better the reconstruction solution. Another remarkable outcome is that using a high sample rate resulted in a decrease in the effect of noise. This indicates that, even with measurement noise, using the proposed method and moderate measurement data can yield a good reconstruction solution.

Reconstruction errors with a 0.3% sample rate (12 sensors) for different test cases are shown in

Table 4.

As shown in

Table 4, when the sample rate was 0.3% (12 sensors), the reconstruction errors were all less than 3%, which is an acceptable result. Considering the reconstruction accuracy and measurement cost, in this simulation test, a sample rate of 0.3% (12 sensors) was used in following analysis.

3.3.3. Effect of Sensor Placement

Sensor placement has a profound influence on reconstruction accuracy. Given random locations, different sensor distributions can result in different reconstruction solutions, and the errors between them are often larger than 1%. Optimal sensor placement can yield a better reconstruction result and lower measurement cost.

The proposed sensor placement optimization algorithm was tested by calculating the reconstruction results for optimal sensor placement and comparing them with those for random placement. The first eight basis vectors and 12 sensors were used in the reconstruction. Noise was also added to the original measurement data. The averages of the reconstruction errors from 1000 runs were used to obtain the overall result.

Figure 5 compares the results for different test cases.

As can be observed from the figure above, in all six test cases, optimal sensor placement could yield a better reconstruction resolution than placing sensors randomly. Although optimal sensor placement may not obtain the best solution, this approach is more adaptable in different conditions and is less sensitive to noise.

Overall, the results in this section suggest that the proposed method is feasible and can yield an acceptable reconstruction solution. The next section, therefore, shows the performance of the proposed method in a gas combustion experiment.