Abstract

This paper proposes a novel control approach for a robot gripper in which the impedance control, fuzzy logic control, and iterative learning control are combined in the same control schema. The impedance control is used to keep the gripping force at the desired value. The fuzzy impedance controller is designed to estimate the best impedance parameters in real time when gripping unknown objects. The iterative learning control process is employed to optimize the sample dataset for designing the rule base to enhance the effectiveness of the fuzzy impedance controller. Besides, the real-time gripping force estimator is designed to keep an unknown object from sliding down when picking it up. The simulation and experiment are implemented to verify the proposed method. The comparison with another control method is also made by repeating the experiments under equivalent conditions. The results show the feasibility and superiority of the proposed method.

1. Introduction

The robot gripper is a useful and important component of an automated system. It is often used to pick up and place a given object on an assembly line in production. It is also used for complex tasks such as assembly of microelectronic components, surgery, etc., or in areas that have hazardous conditions such as high temperature or toxic chemicals [1]. There are many actuation principles used in grippers with mechanical, pneumatic, hydraulic, electric, or piezoelectric actuators, etc. Along with the development of technology, the grippers have been brought to a new level. The grippers not only grip, pick up, and place objects to a new position but also are equipped with sensing capabilities to adapt to changing environments [2].

In automated production, one of the important requirements of grippers is the ability to safely grasp and hold fragile objects of varying stiffness and shapes. Using flexible grippers is one of the solutions. In [3], embedded sensors are used to ensure the safe and optimal behavior of the gripper. The authors establish soft computing methods including extreme learning machines and support vector regression to achieve the prediction of optimal input displacement of the gripper. The authors of [4] deal with a multiobjective optimization problem using a genetic algorithm, while [5] establishes a direct force control for a three-finger adaptive robot gripper by using a proportional-integral-derivative (PID) control to grasp objects without damaging them. Suebsomran [6] proposes a new design to control a robot gripper based on the grasping force method. The force controller is designed by using a PID control algorithm with different control gains and objects tuning by experiment methods. A high-speed multifinger reconfigurable gripper is presented in [7]. The gripper can grasp parts with varying geometrical and physical properties at high speed and accelerations. In [8], the authors use a force-sensitive resistor (FSR) to grasp novel objects adaptively with minimal gripping force. A laser-based optical slip sensor is embedded in its fingers to prevent the object from sliding down. The authors of [9] deal with a microgripper driven by piezoelectric actuators. The authors propose an adaptive online estimation scheme to calculate uncertain parameters in the dynamics model and the Kalman filter to predict the system output. Although there is a lot of research in literature, novel control applications are being studied to enhance gripper performance. This paper proposes an intelligent control approach for a robot gripper with the main objective of controlling the optimal gripping force in real time for unknown objects.

The impedance control is used to keep the gripping force at the desired value. Impedance control is an indirect force control method and very popular in interaction control because of its robustness and feasibility [10,11,12,13,14]. However, in the impedance control method, the interaction force is changed from environment to environment and even within the same environment over time. Therefore, it is hard to determine the desired parameters of the impedance controller. In [15], the authors propose a new simple stable force tracking impedance control scheme. The main idea is to minimize the force error directly by using a simple adaptive gain when tracking an unknown environment. In [16], a novel adaptive impedance control is proposed for the robotic manipulator in assisting the operator to perform the human–robot cooperative task. It can optimize the impedance parameters with little information about the model. The authors of [17] use the equilibrium point control theory and reinforcement learning to determine the impedance parameters for contact tasks. In [18], The gradient-following and betterment schemes are employed to obtain the desired impedance model, subject to unknown environments. In [19,20,21,22], the combination of fuzzy logic and traditional impedance control is proposed to enhance the control performance.

The fuzzy logic [23] can deal with nonlinear and uncertain systems, so it can be used to estimate the optimal impedance parameters in real time. However, its effectiveness depends on the rule base, which is built on the initial sample dataset. This paper proposes a combination of iterative learning control (ILC), fuzzy logic, and impedance control. The ILC based on the gradient descent algorithm [24,25] is used to determine the impedance parameters in unknown environments. However, the ILC process takes time for the impedance parameter to converge to the desired optimal value. Therefore, it is not conducive to perform in real time. Instead, it is performed with various sample objects to synthesize a sample dataset of optimal impedance parameters. This dataset is then used to design the rule base of the fuzzy impedance controller, which will run in real time to estimate the optimal parameters of impedance control under each given condition.

Another important requirement of grippers is to keep an unknown object from sliding down after gripping and picking it up. In [26], the authors develop a microlaser Doppler velocimeter as a sensor to detect whether a grasped object is slipping or not. In [27,28], a biomimetic tactile sensor is used to detect and classify slip events. These methods require complicated installation at the contact between the gripper’s finger and the object. In this paper, a six-axis force/torque sensor (FTS) mounted on the gripper will be used to design the gripping force estimator, which will calculate the appropriate gripping force in real time to keep the unknown object from sliding down instead of trying to detect slippage. The FTS is simple to mount and avoids direct contact with the object. It also proves effective when it is possible to quickly and accurately estimate the optimal gripping force when picking objects up.

The main contribution of this paper is the proposal of an optimal fuzzy impedance controller, which can operate in real time to safely grasp and hold fragile and unknown objects of varying stiffness and shapes. The optimal fuzzy impedance controller is the combining schema of the impedance control, fuzzy logic control, and ILC. Many studies mention the combination of impedance control and fuzzy logic but do not specify the process of building the sample data for designing the rule base, which plays a very important role in determining the effectiveness of the fuzzy controller. In this study, the ILC process is employed to optimize the sample dataset for designing the rule base to enhance the effectiveness of the fuzzy impedance controller. Besides, the design of the gripping force estimator based on an FTS is a simple but effective application proposal in keeping an unknown object from sliding down when picking it up. Compared with other methods, such as PID control, the proposed method has advantages in that the control parameters are automatically estimated in real time and the force control has higher accuracy and stability. Its effectiveness has been verified by conducting the simulation, experiment, and comparison.

The following content of the paper is organized as follows: Section 2 describes the control schema and system description. Section 3 presents the impedance iterative learning control. Section 4 describes the fuzzy impedance controller. Section 5 presents the simulations, experiments, and comparisons. Section 6 discusses the results. Section 7 is the conclusion.

2. Control Schema and System Description

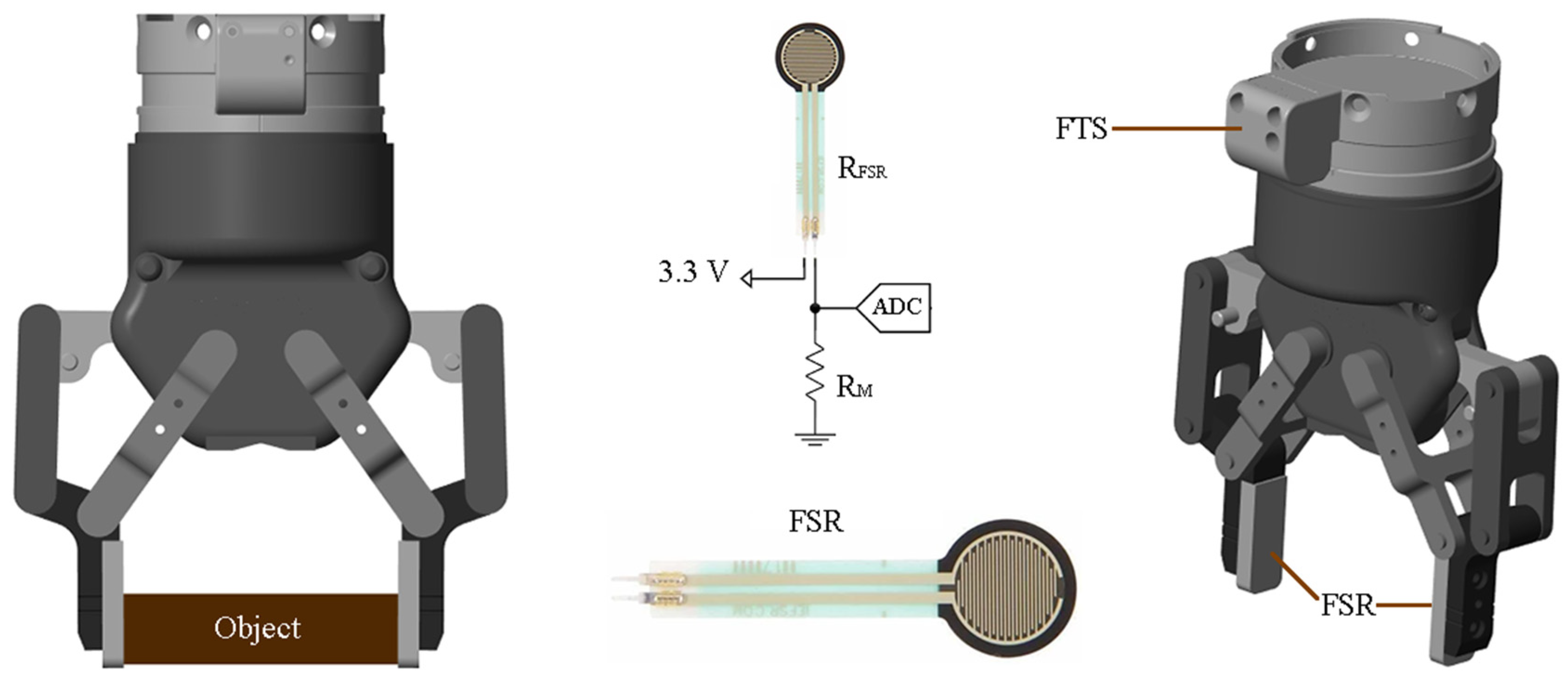

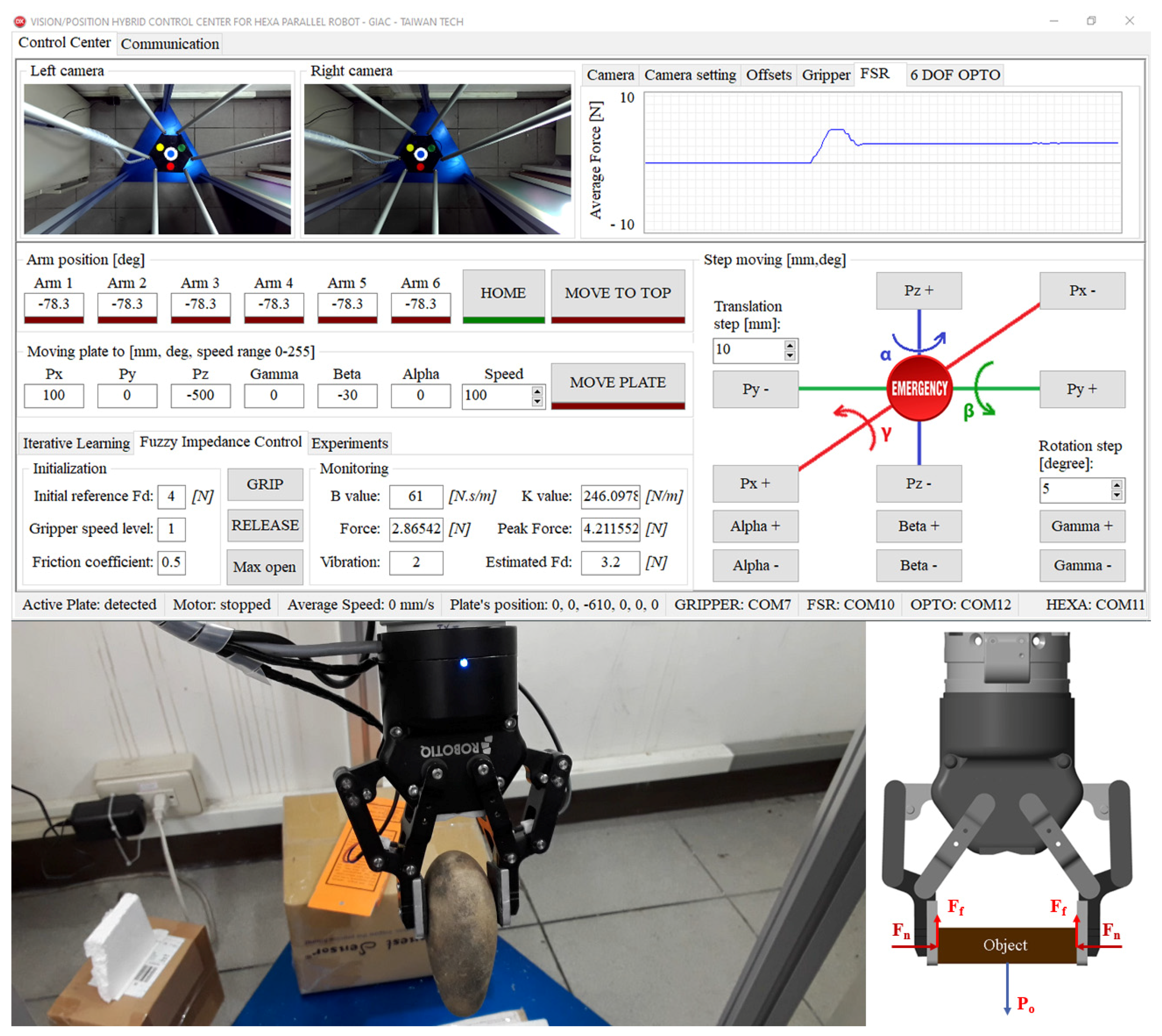

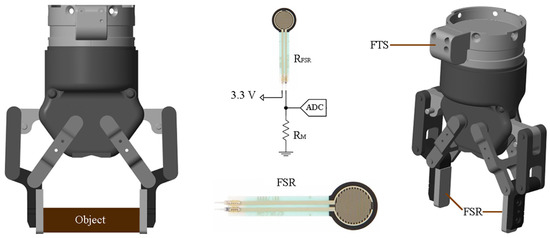

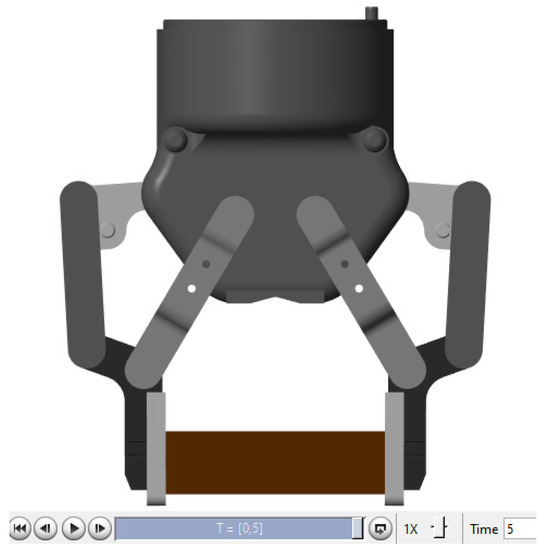

Figure 1 illustrates the model of the two-finger gripper used to apply the optimal fuzzy impedance controller. The FSR is fitted below the finger pads to provide gripping force value. The gripper is attached to the FTS fixed on the end effector of the Hexa robot. The FTS measures the weight of the object, which is gripped and picked up.

Figure 1.

The model of the two-finger gripper in SimMechanics (MATLAB).

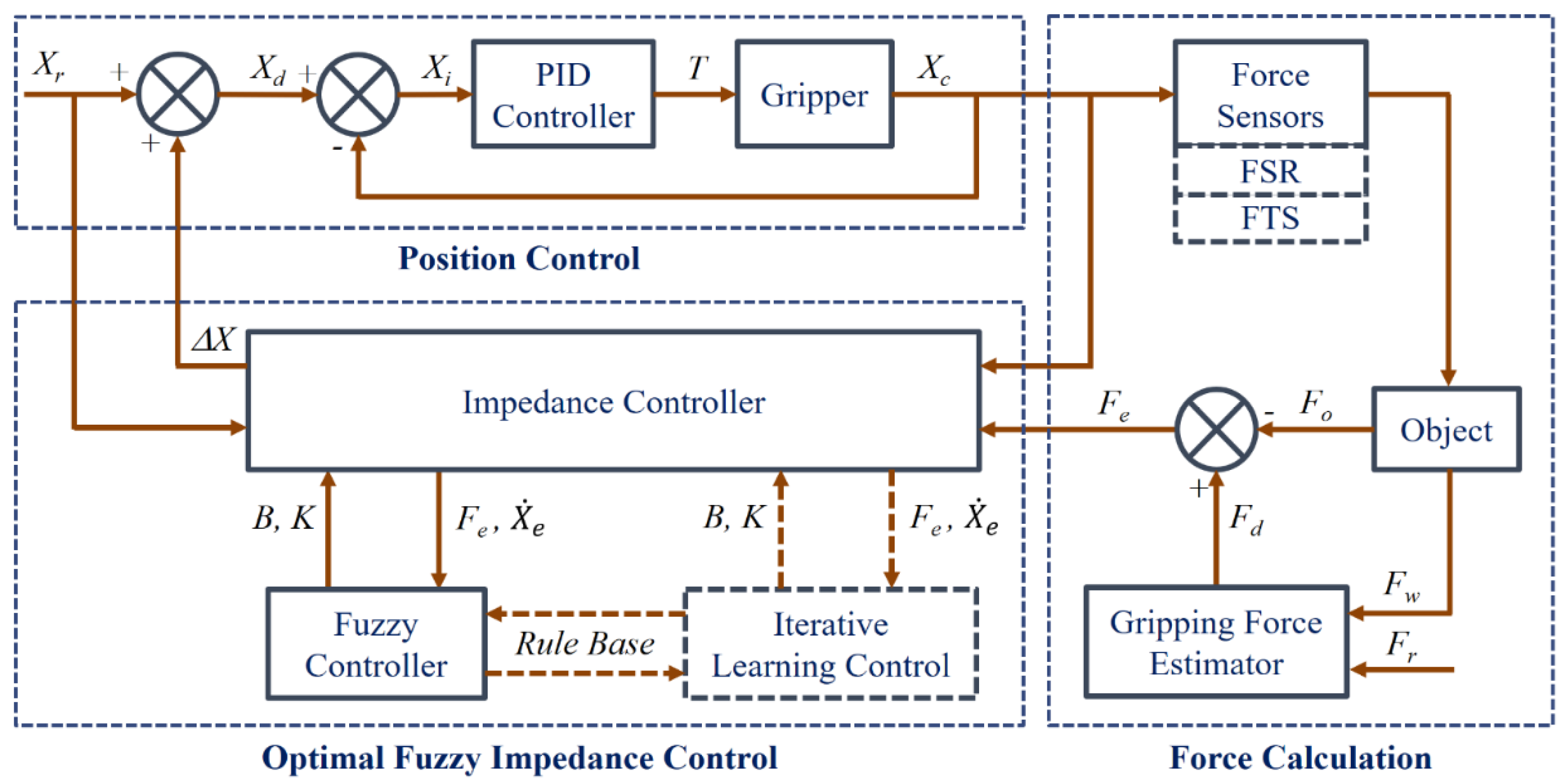

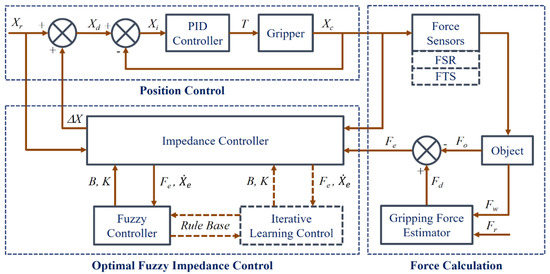

Figure 2 is the architecture of the optimal fuzzy impedance controller, including three blocks: position control, force calculation, and optimal fuzzy impedance control.

Figure 2.

The architecture of the optimal fuzzy impedance control for the gripper.

The position control block, using a common PID controller, is responsible for controlling the position of the fingers to the desired position . The value is determined by the initial reference position and the position compensation . For picking up objects of unknown shape and size, the value is set relative to the gripper’s fully closed position.

The force calculation block includes FSR and FTS. The gripping force is measured by the FSR. The object weight is measured by the FTS. is the initial gripping force defined by the user. At the beginning of the gripping process, the desired gripping force is assigned by the value of . When the gripper starts to pick the object up, based on the value , it will calculate an appropriate value to prevent the object from sliding down. The calculation is presented in Section 3.4.

The optimal fuzzy impedance control block has three sub-blocks: impedance controller, ILC, and fuzzy controller. The impedance controller calculates the position compensation value for the position control block based on the force error , the initial reference position of fingers , and the current position of fingers . It is the key control, which ensures the gripping force is always kept at a sufficient force. The ILC is derived from the gradient descent algorithm to find optimal parameters and of the impedance control in unknown environments. This is the initial learning process. For each kind of object (with various hardness) and various closing speed, the ILC is performed to find an optimal data of impedance parameters. By changing the object material, closing speed, and repeating the ILC, an optimal dataset of impedance control is built for further creating a rule base for the fuzzy controller. Based on this rule base, the fuzzy controller calculates the best impedance parameters simultaneously when the gripper fingers touch on the object surface. If the fuzzy controller cannot match any rule in the rule base, the ILC is recalled to calculate new appropriate parameters of the impedance control. If these parameters make the control reach the desired state, they will be analyzed to create new rules and added to the rule base.

3. Impedance Iterative Learning Control

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation as well as the experimental conclusions that can be drawn.

3.1. The Impedance Control

This section presents the basic structure of the impedance controller, which keeps the gripping force at the desired value. The model of impedance control can be expressed as:

where , , and represent inertia, damping, and stiffness parameters, respectively. and are the reference and current positions of the fingers of the gripper, respectively. is the force error, which is based on the desired force and the current gripping force .

The dynamic behavior of the model is determined by the damping ratio , which is expressed as:

For gripping the object with a sufficient force and without oscillation, the damping ratio must be greater than or equal to one (critical damped or overdamped). In practice, it is adjusted to be greater than one (overdamped state) to both eliminate oscillation and ensure the desired gripping force.

3.2. The Iterative Learning Control

The ILC is proposed to optimize the impedance parameters for various objects and closing speeds. The inertia parameter is fixed at an apparent value selected by the experiment based on the mass of the gripper fingers. Because the damping ratio is fixed, only the damping parameter is updated during the ILC process. The stiffness parameter is calculated by Equation (2).

The gradient descent ILC algorithm [24] is applied to derive the learning law. The general form of this algorithm is expressed as:

where is the iteration number. is the input applied to the ILC process. is the learning gain. is the transfer function of the nominal model. is the output error. The product determines the direction of the update vector.

The convergence of Equation (3) is guaranteed if [24,25]:

The gripping process tracks the gripping force, so the output error is determined as:

The input of the ILC process in Equation (3) is the damping parameter . The transfer function is calculated based on the gradient scheme to ensure a gradual change of the gripping force by updating . It is derived as:

From Equations (3), (5), and (6), the learning law is formed as:

From Equations (4) and (6), the convergence condition of the ILC is determined as:

In each iteration of the ILC process, the learning gain is adjusted to satisfy the condition in Equation (8).

The ILC process is stopped if the following conditions are satisfied:

where is the iteration number. is the maximum overshoot of the gripping force. is the final force error. is the desired value.

3.3. The Implementation of ILC

The ILC process is described as follow:

STEP 1: Start the process

Starting with a certain object, the desired closing speed , and a desired gripping force .

STEP 2: Initialization

Loading the initial values of , , , , and .

STEP 3: Start a learning loop

Fully opening the fingers of the gripper. Clearing the temporary storage. Starting the gripping timer. The gripper gradually closes the fingers with the desired speed until the fingers touch on the object’s surface. The system starts to measure and track the value of .

STEP 4: Iterative learning

In each sample time, the system measures the contact force and calculates the values of and . The learning gain is determined by the condition in Equation (8). The new value of is calculated by Equation (7). The parameter is calculated by Equation (2). The new values of , , , and are added to the temporary storage as a record and loaded to the system for the next sample time. Repeating Step 4 with each sample time until the gripping force is stable or the gripping timer reaches a limit value.

STEP 5: End the learning loop

Checking the stopping condition in Equation (9). If it is satisfied, move to Step 6, otherwise, start a new loop from Step 3.

STEP 6: Finish the process

Recording the optimal values of ILC: each record in the temporary storage combines with the values and in Step 4 will create a new data record in the dataset.

3.4. The Gripping Force Estimator

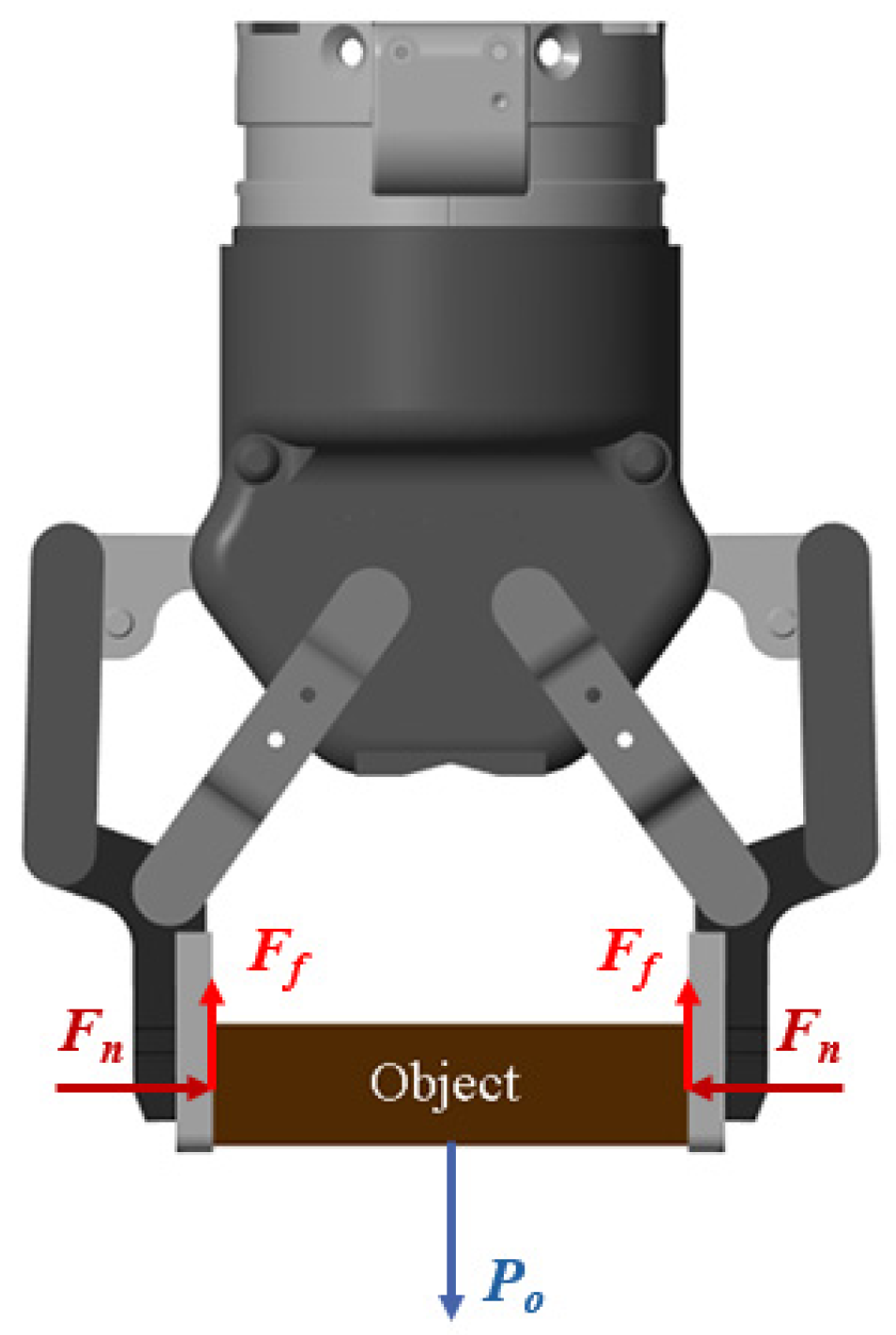

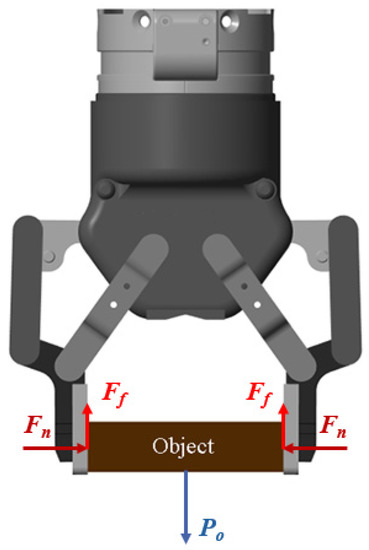

Figure 3 shows the force diagram of griping and picking up the object. is the weight of the object that is calculated from the parameters of FTS. is the gripping force of fingers. is the friction force. , where is the friction coefficient between the finger pad and the object surface. To prevent the object sliding down, the gripping force must be satisfied:

Figure 3.

Force diagram of gripping and picking up the object.

In the implementation, the gripping force is set as:

where is the antisliding coefficient.

The friction force is set approximately by experiment based on the materials of the finger pad and object surface. The antisliding coefficient is set according to the real model. In this study, is set to 1.4 for the best performance.

4. Fuzzy Impedance Controller

Through the experiment, the ILC works very well. However, the best impedance parameters found by ILC are only fit to a specific environmental condition, including object properties and closing speed. If the environment is changed, the ILC needs to be performed again. Therefore, the fuzzy impedance controller is proposed to calculate the best impedance parameters simultaneously based on the knowledge from training without repeating the ILC process.

4.1. The Data Collection for Designing Fuzzy Impedance Controller

The ILC process in Section 3.3 provides the data record of the best impedance parameters for a specific environment. By changing either the object hardness or desired closing speed and repeating this process many times, an optimal dataset is built for creating the rule base of the fuzzy impedance controller. It is necessary to note that the important parameters in the data record of the ILC learning process are the gripping force error , the closing speed , the optimal damping , the optimal stiffness , the maximum overshoot , and the final force error .

4.2. Fuzzy Logic Design

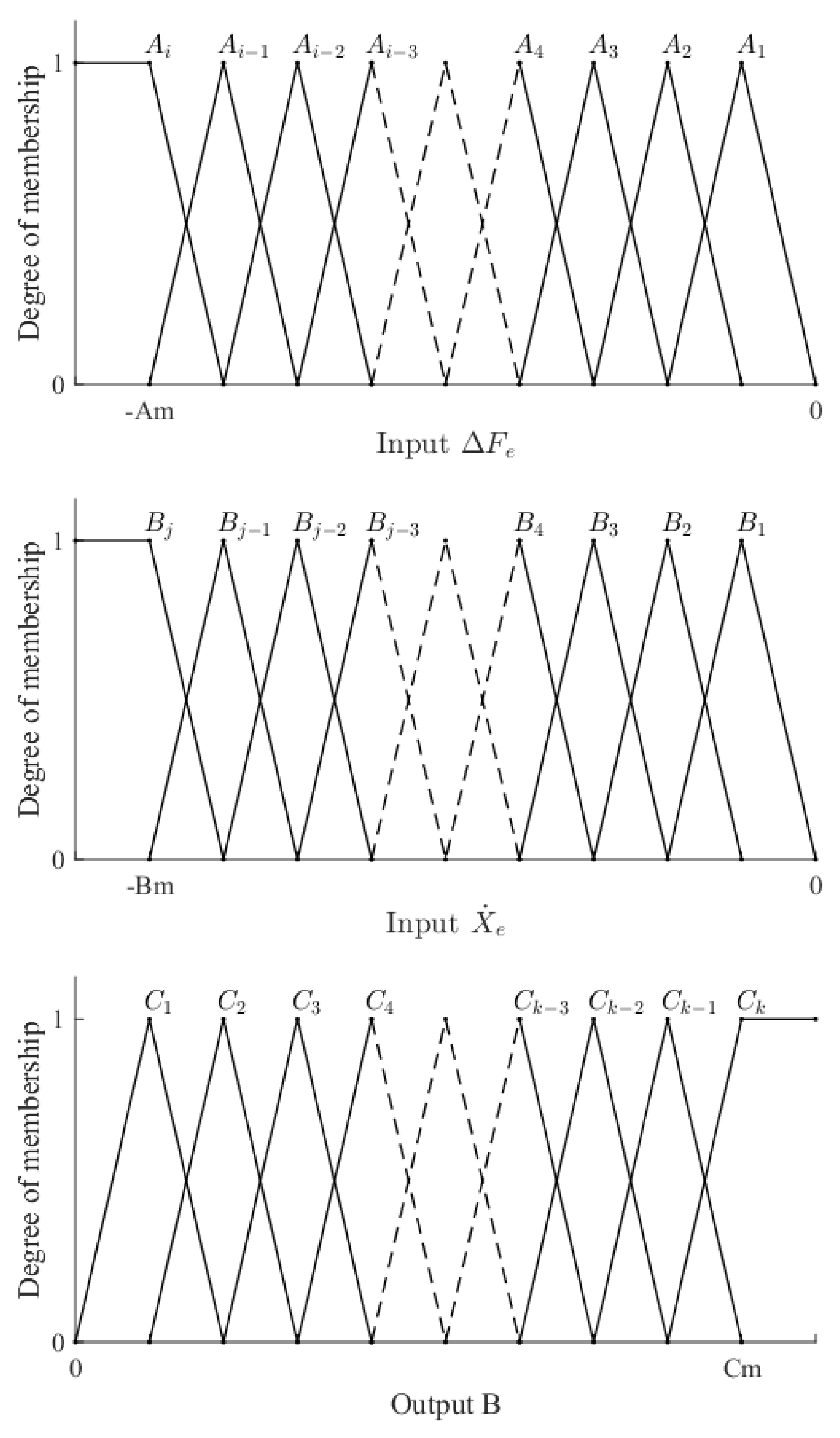

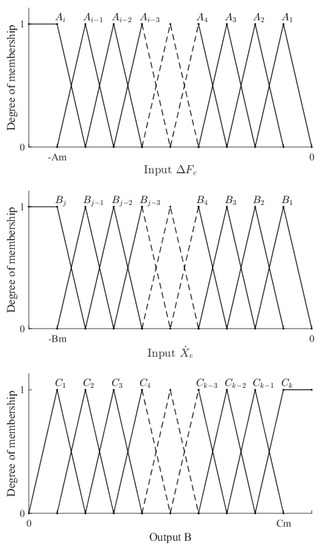

The main objective of the fuzzy impedance controller is to estimate the impedance parameter . Based on the learning law of ILC in Equation (7), the fuzzy system is designed consisting of two inputs: the gripping force error and the closing speed . The output is the damping . The parameter is calculated by Equation (2) after the damping is estimated.

Figure 4 shows the triangular membership functions of inputs and output. The number of fuzzy regions of inputs , , and output is , , , respectively. The inputs and are recorded at the time when the fingers just touched the object for the first time, so these parameters have negative values and magnitude depending on the closing speed and object hardness. The output is always positive. Based on the dataset collected from the data collection as presented in Section 4.1, the maximum magnitudes of the inputs and output are determined to set the values of , , and . The number of fuzzy regions , , and are experimentally adjusted so that the fuzzy controller achieves high accuracy.

Figure 4.

Membership functions of inputs and output.

The fuzzy impedance controller employs Mamdani If-Then rules as the following form:

The rule: If is and is then is , where ; ;

The dataset will be preprocessed to filter noise based on the maximum overshoot and the final force error . Its final data records will be calculated to create the rule base.

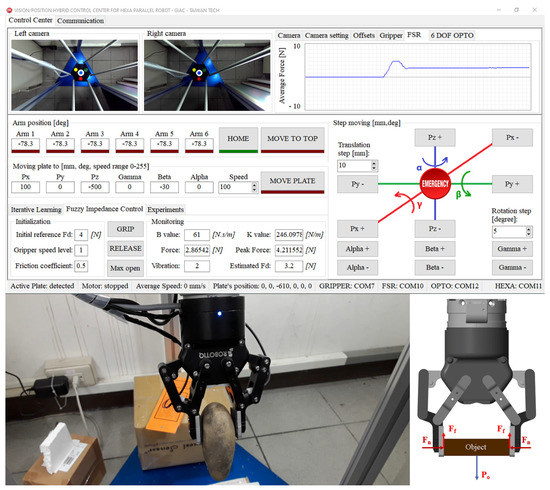

5. Simulation, Experiment, and Comparison

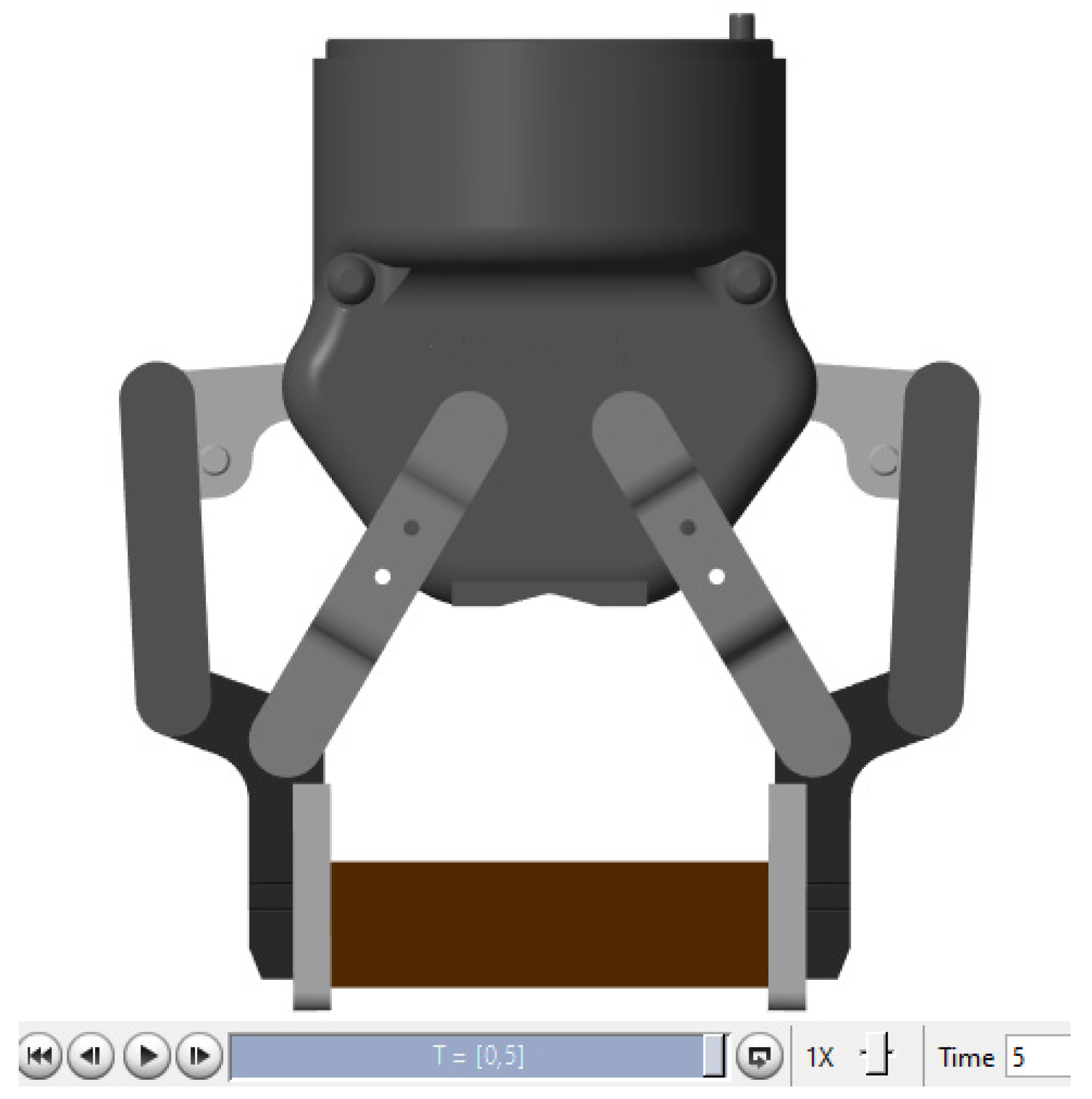

Figure 5 shows the two-finger gripper and control software interface used in the study. The control software is written in Delphi programming language. The position control of the gripper was modified to fit for the research purpose. Two FSRs have been added under the finger pads to control the gripping force. Figure 6 is the model of the gripper in SimMechanics (MATLAB) used in the simulation of ILC. The model was created with the same parameters and controls as the real model to ensure the simulation results are closest to reality. This section presents the simulation, experiment, and comparison. After that, Section 6 will discuss the results.

Figure 5.

The two-finger gripper and control software interface.

Figure 6.

The model of the gripper in SimMechanics.

5.1. The Simulation

5.1.1. The Data Collection by ILC

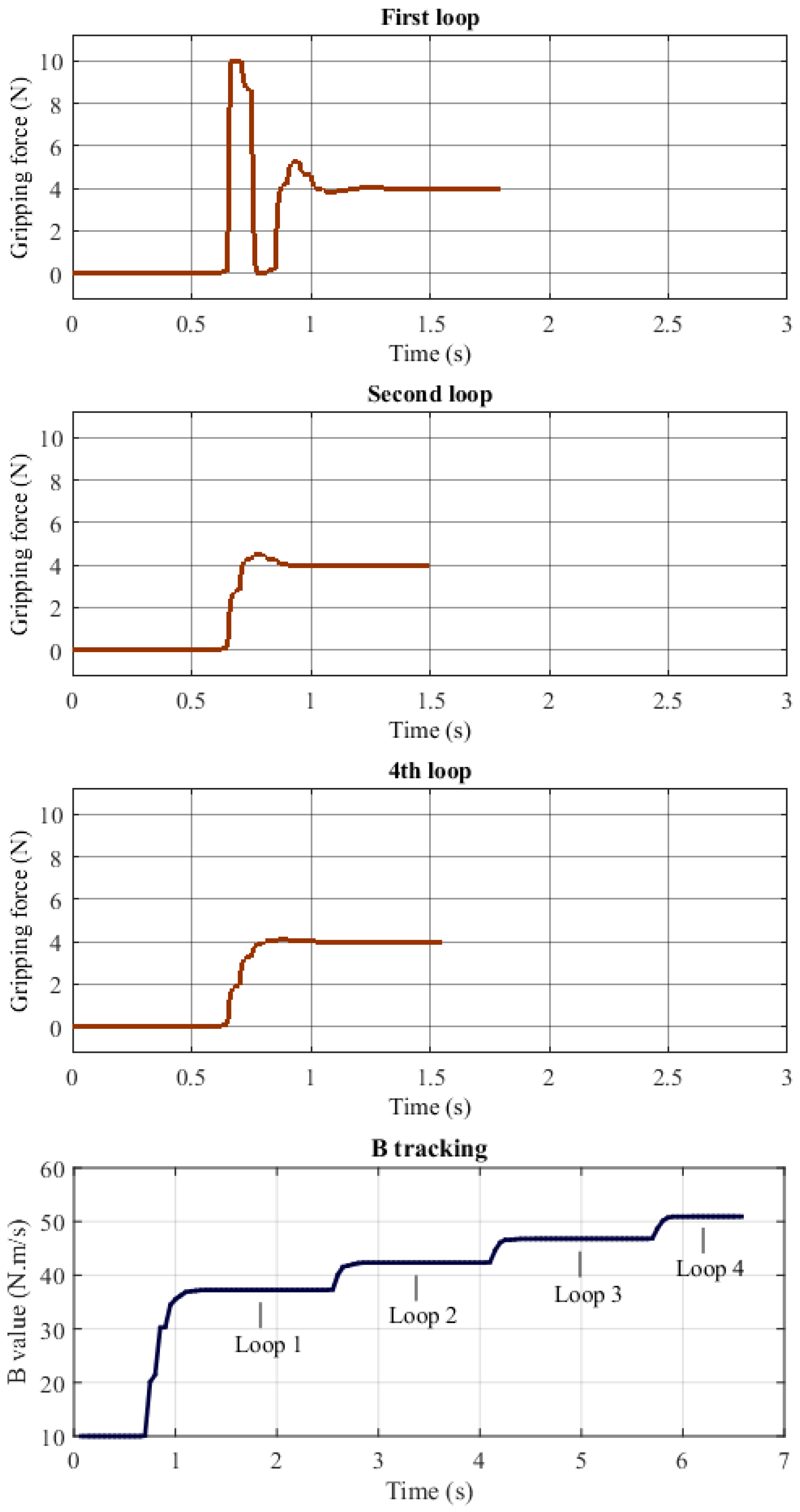

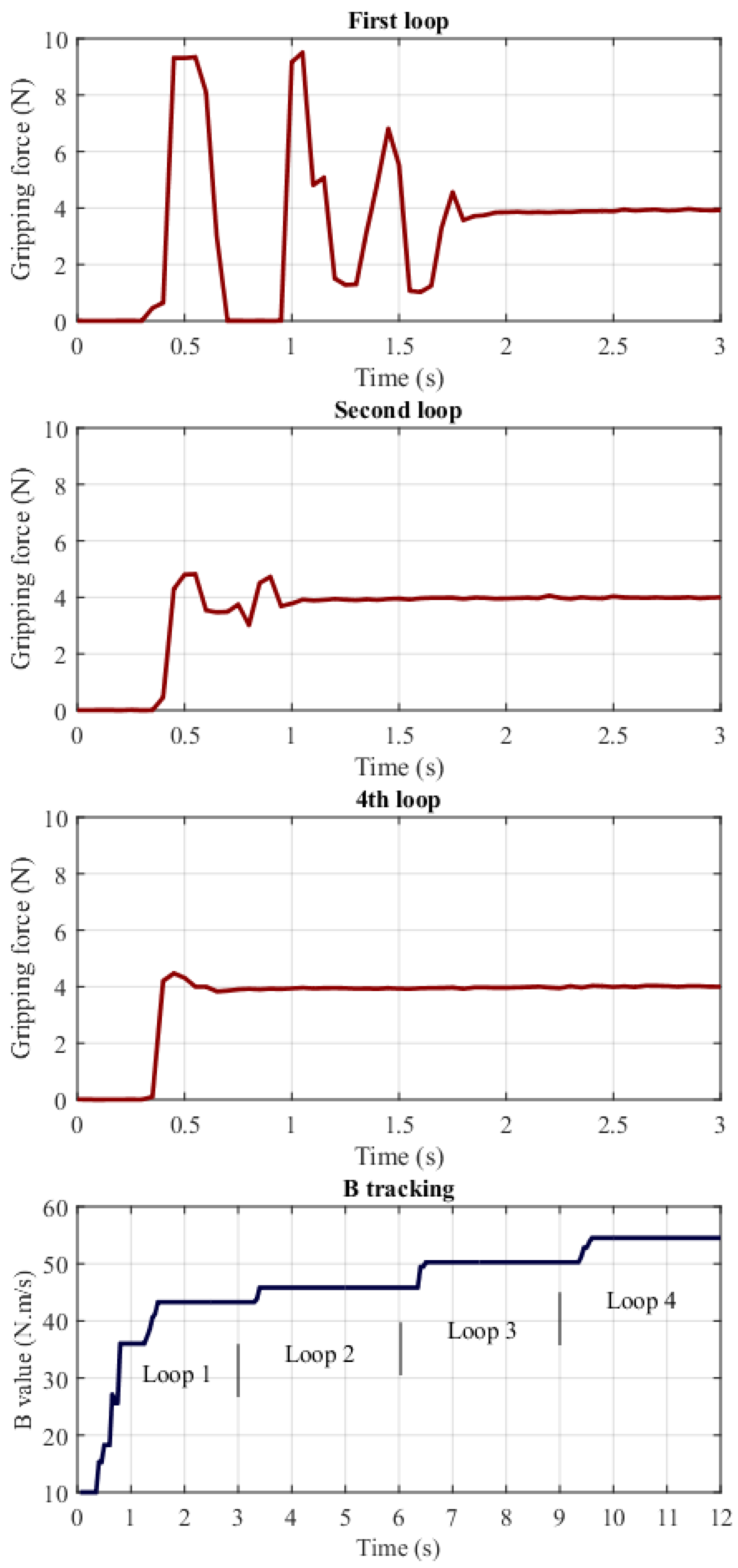

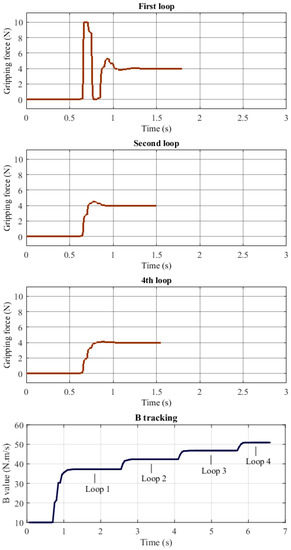

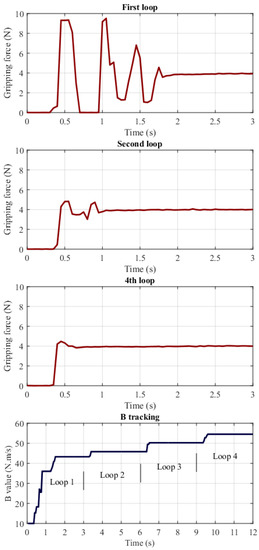

The model of the gripper is programmed to repeat the ILC process in Section 3.3 for different closing speeds and desired forces in different objects (environment). The closing speed varies from 5 to 10 mm/s, with each step being 1. The desired force varies from 1 to 8 N, with each step being 0.5. The initial value of is set at 10 N.m/s. The total number of experiments is 4200, so the dataset has 4200 records. The dataset is analyzed to evaluate the performance based on the parameters of the maximum overshoot and the final force error . Table 1 presents the analysis data from 4200 records of the dataset in the simulation. Figure 7 shows the tracking force of several loops in one case of the ILC process with a closing speed of 5 mm/s and the desired force of 4 N.

Table 1.

The resulted iterative learning control (ILC) quality parameters in the simulation.

Figure 7.

The tracking force and value through several loops in simulation.

5.1.2. The Fuzzy Logic Design

The dataset collected above is processed to create the rule base of the fuzzy impedance controller as presented in Section 4.2. The number of regions of inputs and output is , , and . The maximum magnitudes of the inputs and output are , , and . The total number of rules created is 45.

5.1.3. The Evaluation of Fuzzy Impedance Control

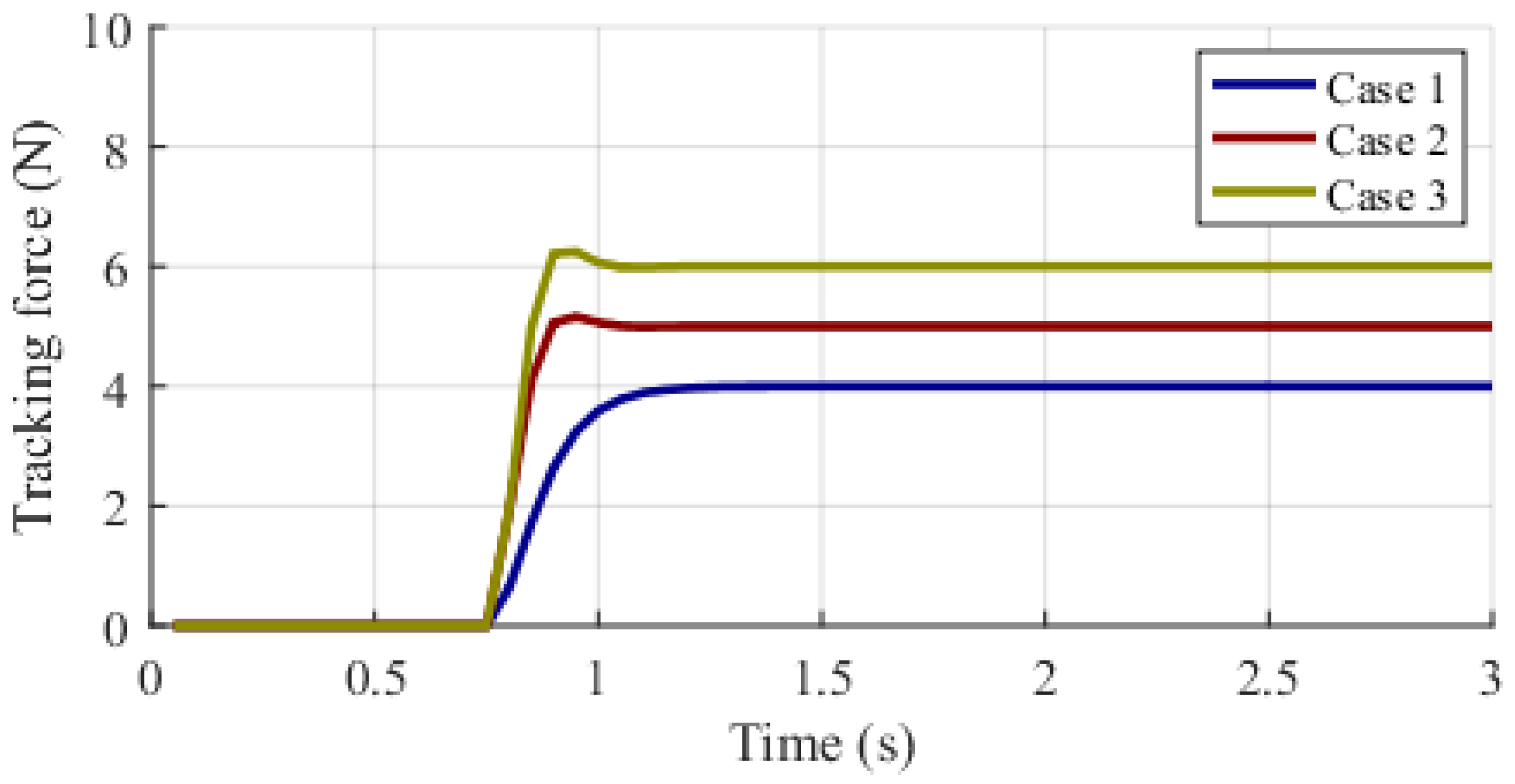

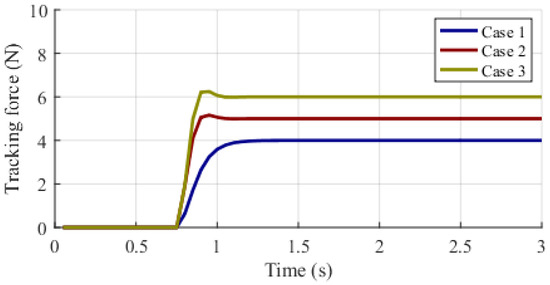

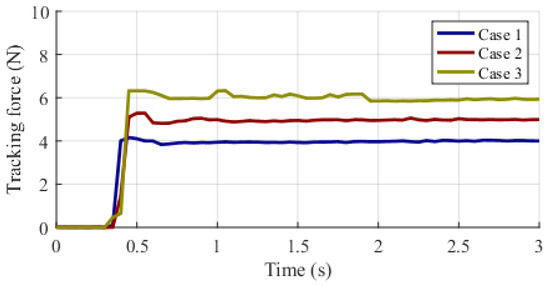

For evaluating the performance of the fuzzy impedance controller, a testing data is created including 300 records of different values of closing speed, desired force, and object hardness. The testing data does not coincide with the training dataset. The model runs 300 times with the parameters of the testing data. In each time, when the fingers have just touched the object for the first time, the values of , are calculated. The fuzzy impedance controller calculates the impedance parameters and . The program measures and records the parameters of the maximum overshoot and the final force error . Table 2 presents the analysis data from 300 tests. Figure 8 is the force monitoring data of some cases in the simulation testing. Section 6 will discuss in detail about this figure.

Table 2.

The quality parameters on the testing data of simulation.

Figure 8.

The force monitoring of some cases in simulation testing.

5.2. The Experiment

5.2.1. The Data Collection by ILC

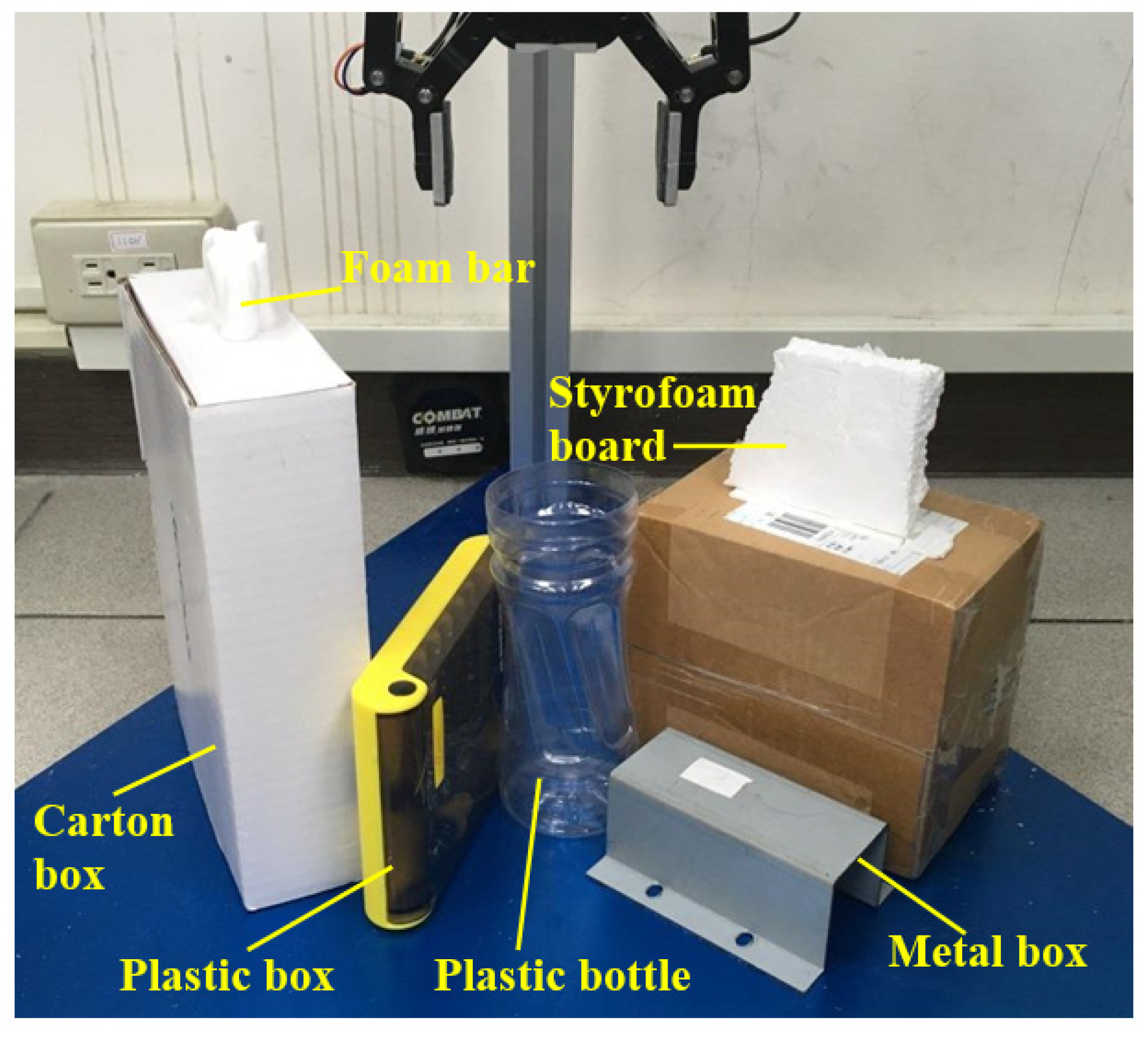

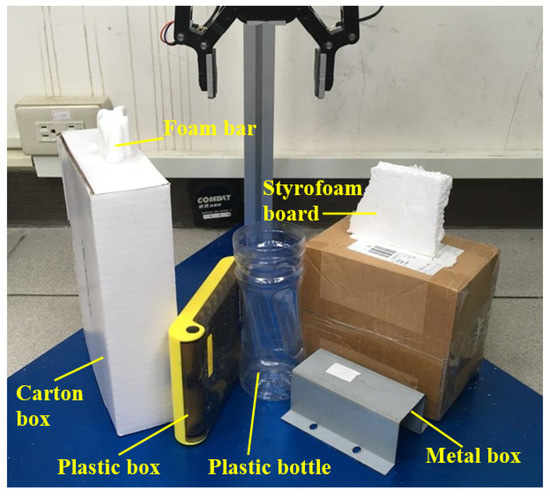

Similar to the simulation, the gripper is programmed to repeat the ILC process in Section 3.3 for different closing speeds, desired forces, and object hardness. However, from a practical perspective, it is hard to find many objects with different hardness, so six objects are used as shown in Figure 9. The closing speed varies from 5 to 10 mm/s, with each step being 1. The desired force varies from 1 to 8 N, with each step being 0.5. The initial value of is set at 10 N.m/s. The total number of experiments is 540, so the dataset has 540 records. The dataset is analyzed to evaluate the performance based on the parameters of the maximum overshoot and the final force error . Table 3 presents the analysis data from 540 records of the dataset in the simulation. Figure 10 shows the tracking force of several loops in one case of the ILC process with the closing speed of 5 mm/s and the desired force of 4 N (the same case as shown in the simulation).

Figure 9.

The objects used in the experiment of ILC.

Table 3.

The ILC quality parameters in the experiment.

Figure 10.

The tracking force and value through several loops in the experiment.

5.2.2. The Fuzzy Logic Design

The dataset collected above is processed to create the rule base of the fuzzy impedance controller as presented in Section 4.2. The number of regions of inputs and output is , , and . The maximum magnitudes of the inputs and output are , , and . The total number of rules created is 30.

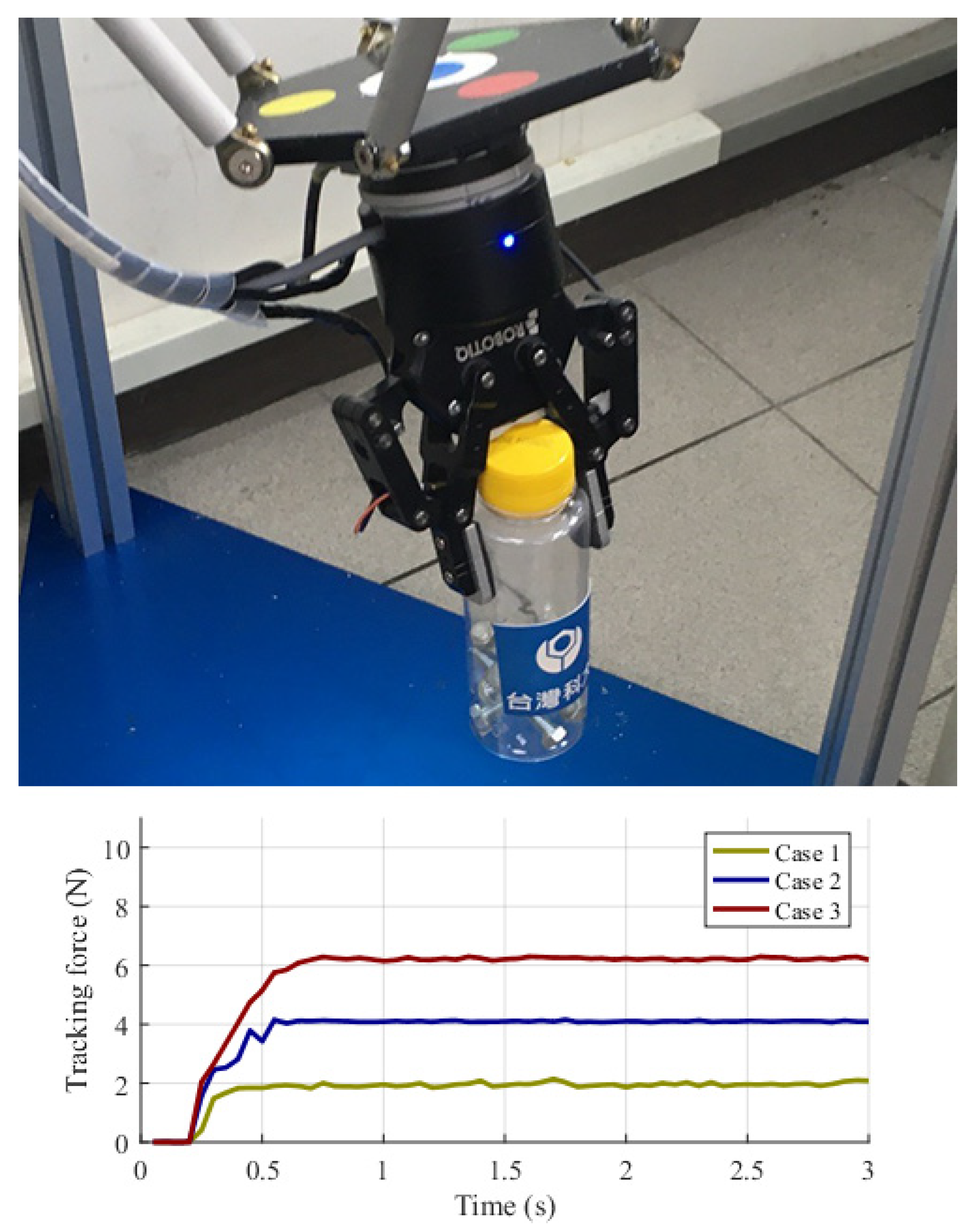

5.2.3. The Evaluation of Fuzzy Impedance Control

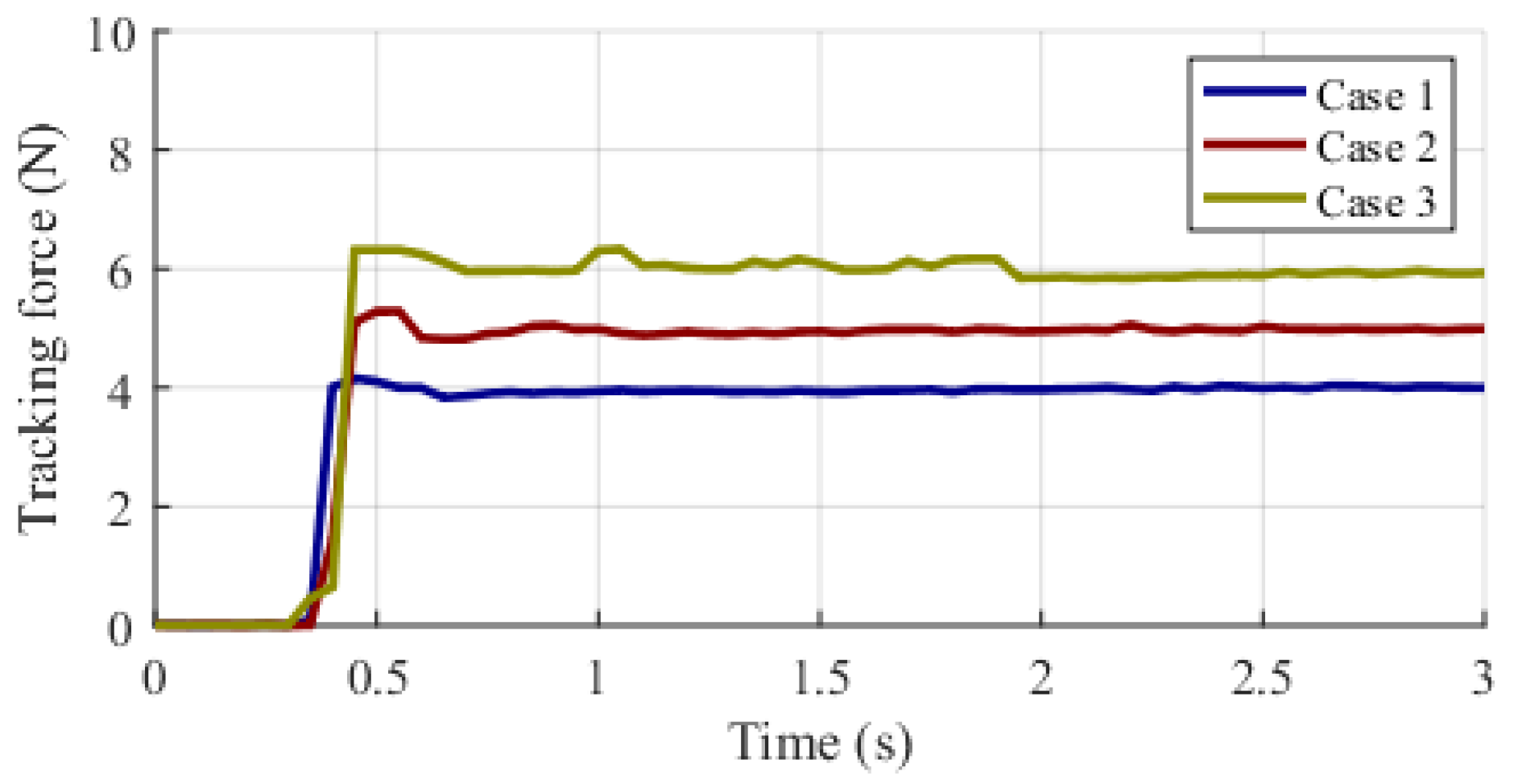

For evaluating the performance of the fuzzy impedance controller in the experiment, the gripper is controlled to grip the objects shown in Figure 9 with different values of closing speed and desired force, which are different from the set value in the data collection by ILC. The total number of experiments is 90. In each time, when the fingers have just touched the object for the first time, the values of , are calculated. The fuzzy impedance controller calculates the impedance parameters and . The program measures and records the parameters of the maximum overshoot and the final force error . Table 4 presents the analysis data from 90 experiments. Figure 11 is the force monitoring data of some cases in the experimental testing. Section 6 will discuss in details about this figure.

Table 4.

The quality parameters on the testing data of the experiment.

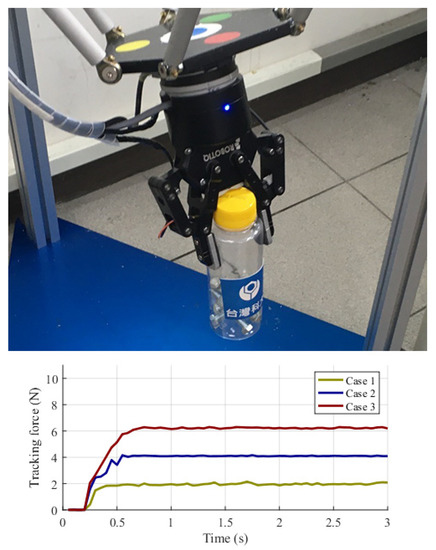

Figure 11.

The force monitoring of some cases in experimental testing.

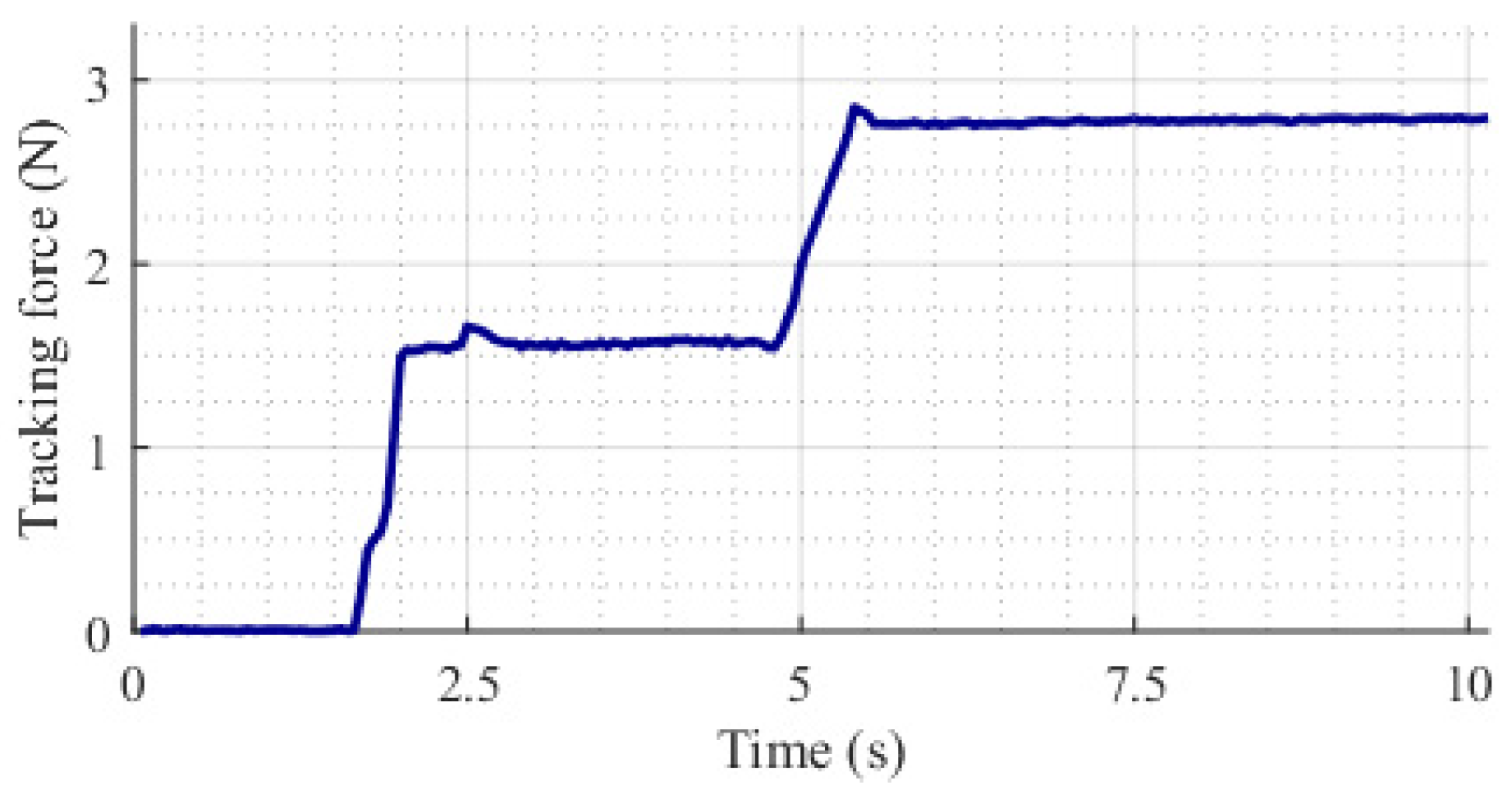

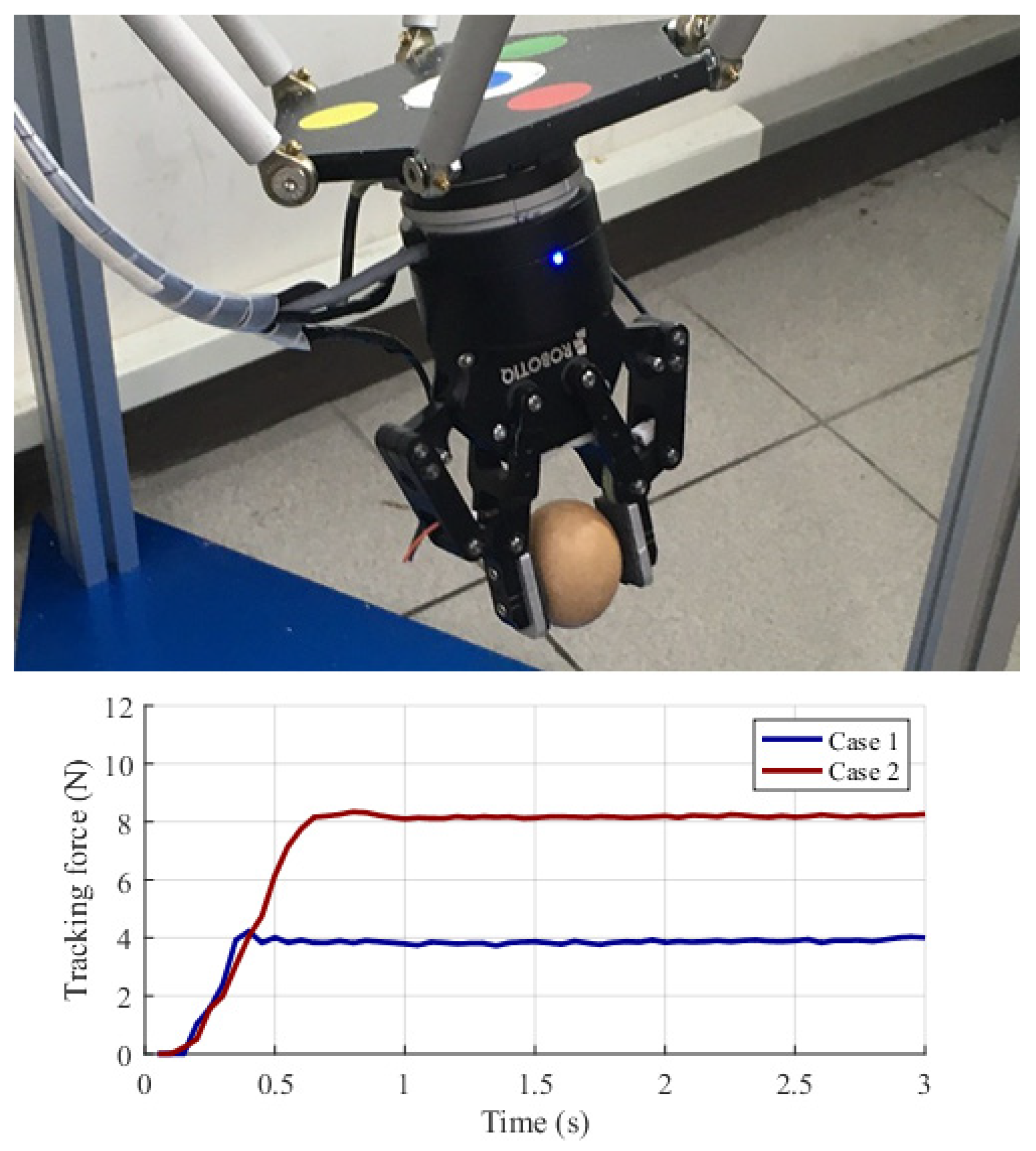

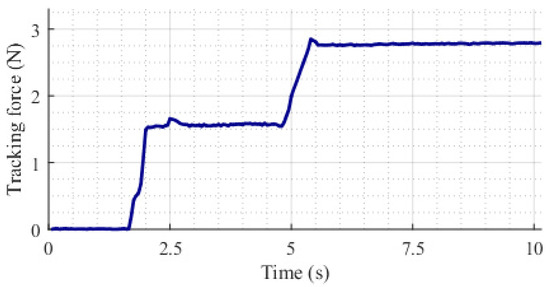

5.2.4. Testing the Gripping Force Estimator

For evaluating the gripping force estimator discussed in Section 3.4, the gripper is controlled to grip a plastic bottle, which weighs 115 g. The initial gripping force is set at 1.5 N. The friction coefficient is set as . The antisliding coefficient is set as . Once the plastic bottle has been gripped, the robot will move the end effector to pick the bottle up. The gripping force estimator will calculate the appropriate gripping force to keep the bottle from sliding down. Figure 12 shows the tracking force of this process.

Figure 12.

The tracking force in testing the gripping force estimator.

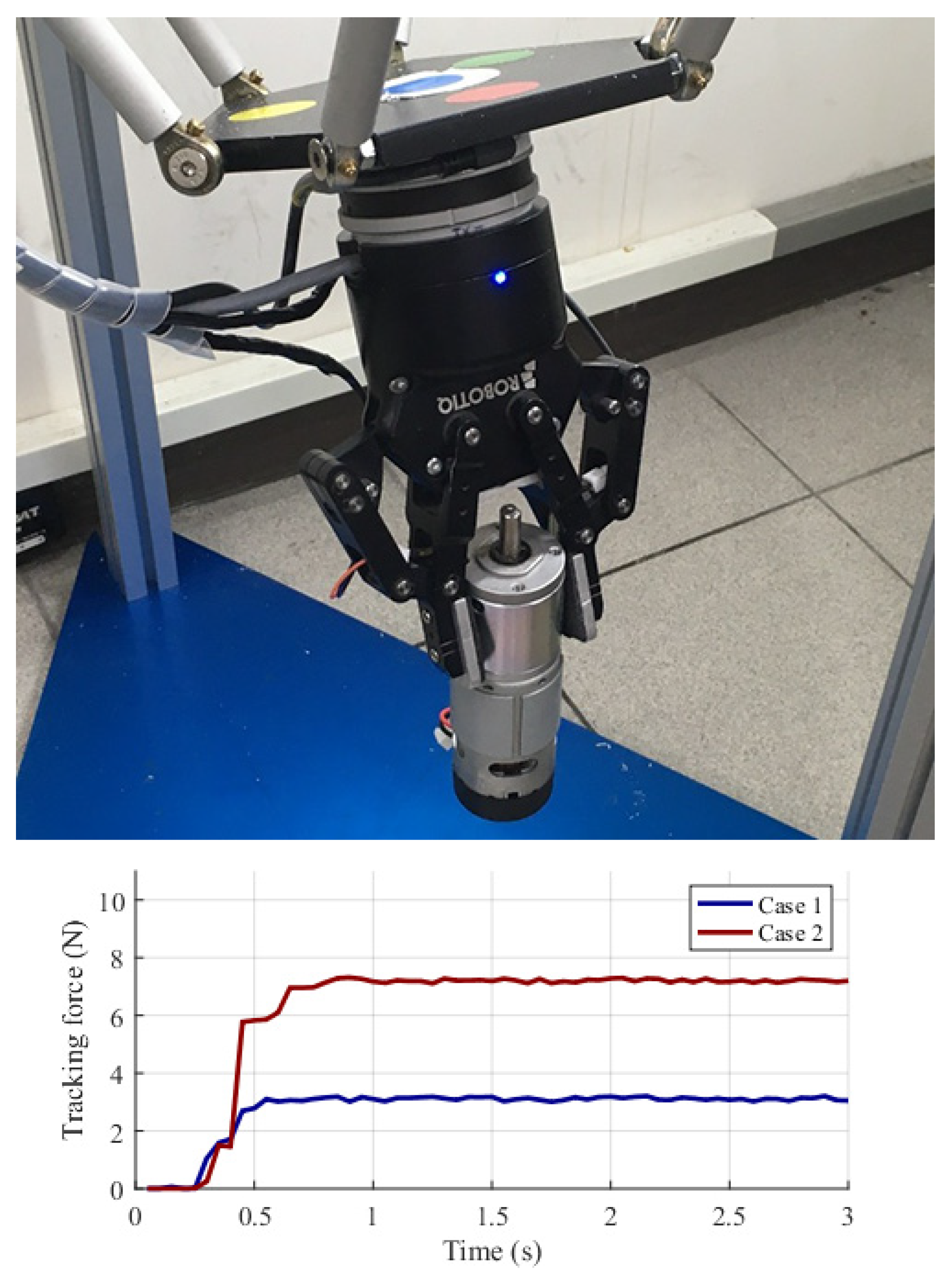

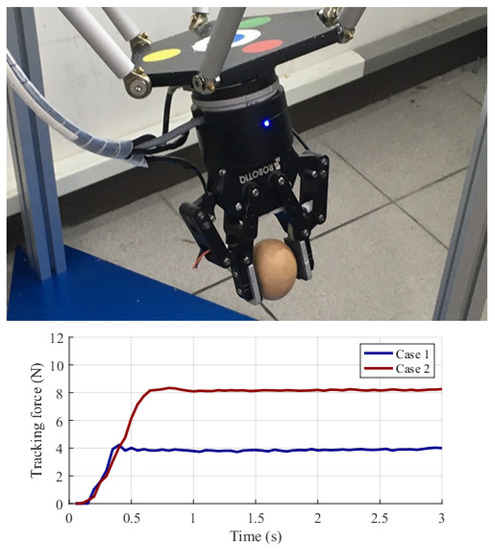

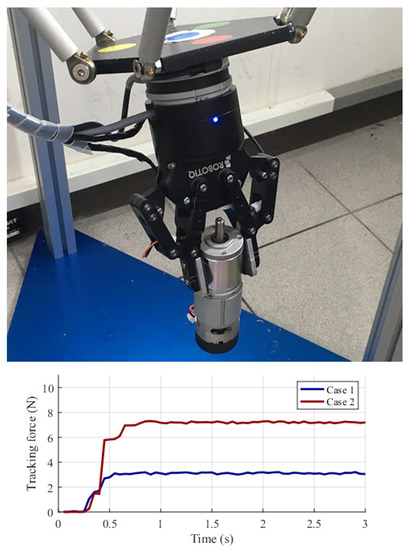

5.3. The Comparison

The performance of the proposed approach is compared with another state-of-art robot gripper and force control based on the PID control algorithm and objects tuning by experiment methods [6]. The experiments are repeated with the same parameters as summarized in Table 5. The tracking force data of experiments are shown in Figure 13, Figure 14 and Figure 15. The force errors of experiments are summarized in Table 6.

Table 5.

The experiments for the comparison.

Figure 13.

The tracking force of the comparative Experiment 1.

Figure 14.

The tracking force of the comparative Experiment 2.

Figure 15.

The tracking force of the comparative Experiment 3.

Table 6.

The force errors of comparative experiments.

6. Discussions

6.1. The ILC for Data Collection

By using ILC, the impedance parameter converges to an optimal value. As shown in Figure 7 and Figure 10, it takes approximately four loops of the ILC process in each case of both simulation and experiment. The fluctuation of force in the experiment is greater than in simulation. However, the process of convergence of the impedance parameter is consistent between simulation and experiment.

Table 1 and Table 3 are statistics of the resulted ILC quality parameters in simulation and experiment, respectively. The maximum overshoot and final error of the gripping force in the simulation are very small due to the ideality of the model. The maximum overshoot and final error of the gripping force in the experiment are 0.4827 N and 0.398 N, respectively. This result is quite good and it is safe to grip fragile objects such as eggs.

The ILC process provides the sample data for the fuzzy controller design. Each record in the data is optimized by ILC, so the fuzzy controller design will achieve higher accuracy.

6.2. The Fuzzy Impedance Control

Table 2 and Table 4 are statistics of testing the fuzzy impedance controller in simulation and experiment, respectively. It shows that the maximum overshoot and final error of gripping force are within the desired threshold. In the experimental testing, the final error of the gripping force is 0.3862 N. In Figure 8, the tracking forces in three cases of simulation testing reach the desired values with very high stability. In Figure 11, the tracking forces in three cases of experimental testing also reach the desired values with a little fluctuation. The fluctuation is mainly due to noise when reading the force value from the FSR. The results confirm that the fuzzy impedance controller can estimate the optimal value of the impedance parameter in different environments in real time without having to perform the ILC process again.

6.3. The Gripping Force Estimator

The gripping force estimator keeps the object from sliding down when picking it up. As shown in Figure 12, the adjustment of gripping force occurs continuously in a short period of about 0.5 s. Its application is described as follows: when gripping and picking an unknown object up, an initial gripping force is set small enough not to damage the object. The gripper will grip the object with this initial force. After that, the robot will move the end effector to pick the object up slowly. As soon as the object leaves the background, the estimator will be activated to adjust the gripping force to match the actual weight of the object. Throughout this process, the fuzzy impedance controller keeps the gripping force always at the desired value with high accuracy and stability to avoid damaging the object.

6.4. The Comparison

In all comparative experiments, the gripping force always reaches the desired value with high accuracy. The force at the steady-state has only a little fluctuation, mainly due to noise when reading the force value from the FSR. Figure 13, Figure 14 and Figure 15 show the result of the experiment presented in Section 5.3. Compared to the PID control algorithm and objects tuning by experiment methods [6], the proposed method has better stability. The final force error is also much smaller than the error in the other method as summarized in Table 6. This superiority is due to the gripping force being controlled in real time by the optimal fuzzy impedance controller.

7. Conclusions

In this study, an intelligent control approach for a robot gripper has been proposed to safely grasp and hold fragile and unknown objects of varying stiffness and shapes. The optimal fuzzy impedance hybrid controller of the gripper is the combining schema of the impedance control, fuzzy logic control, and ILC. The ILC is employed to optimize the sample dataset for designing the rule base to enhance the effectiveness of the fuzzy impedance controller, which is used in real time to estimate the optimal parameters in the impedance control. By using ILC, the impedance parameter converges to the optimal value. The experimental results confirm that the fuzzy impedance controller can estimate the optimal value of the impedance parameter in different environments in real time without having to perform the ILC process again. Besides, the design of the gripping force estimator based on a force/torque sensor is a simple but effective application proposal in keeping an unknown object from sliding down when picking it up. Throughout the experiment, the fuzzy impedance controller keeps the gripping force always at the desired value with high accuracy and stability to avoid damaging the object. Compared with the other methods, such as PID control, the proposed approach has advantages in that the control parameters are automatically estimated in real time and the force control has higher accuracy and stability. The proposed optimal fuzzy impedance controller could be used in common robotic applications such as egg handling, fruit harvesting, or sorting other fragile products.

Author Contributions

Conceptualization, B.-P.H. and Y.-L.K.; implementation, B.-P.H.; validation, B.-P.H. and Y.-L.K.; formal analysis, B.-P.H. and Y.-L.K.; writing—original draft preparation and editing, B.-P.H.; review and editing, Y.-L.K.; project administration, Y.-L.K. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported in part by the Ministry of Science and Technology, Taiwan, under Grant MOST 107-2221-E-011-135.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Monkman, G.-J.; Hesse, S.; Steimann, R.; Schunk, H. Robot Grippers; Wiley-VCH: Weinheim, Germany, 2006. [Google Scholar]

- Tai, K.; El-Sayed, A.-R.; Shahriari, M.; Biglarbegian, M.; Mahmud, S. State of the Art Robotic Grippers and Applications. Robotics 2016, 5, 11. [Google Scholar] [CrossRef]

- Petković, D.; Danesh, A.-S.; Dadkhah, M.; Misaghian, N.; Shamshirband, S.; Zalnezhad, E.; Pavlović, N.-D. Adaptive Control Algorithm of Flexible Robotic Gripper by Extreme Learning Machine. Robot. Comput. Integr. Manuf. 2016, 37, 170–178. [Google Scholar]

- Datta, R.; Pradhan, S.; Bhattacharya, B. Analysis and Design Optimization of a Robotic Gripper Using Multiobjective Genetic Algorithm. IEEE Trans. Syst. Man Cybern. 2016, 46, 16–26. [Google Scholar] [CrossRef]

- Sadun, A.-S.; Jalani, J.; Sukor, J.-A.; Jamil, F. Force Control for a 3-Finger Adaptive Robot Gripper by Using PID Controller. In Proceedings of the 2016 2nd IEEE International Symposium on Robotics and Manufacturing Automation (ROMA), Ipoh, Malaysia, 25–27 September 2016. [Google Scholar]

- Suebsomran, A. Development of Robot Gripper and Force Control. In Proceedings of the 2018 13th World Congress on Intelligent Control and Automation (WCICA), Changsha, China, 4–8 July 2018; pp. 433–437. [Google Scholar]

- Spiliotopoulos, J.; Michalos, G.; Makris, S. A Reconfigurable Gripper for Dexterous Manipulation in Flexible Assembly. Inventions 2018, 3, 4. [Google Scholar] [CrossRef]

- Ding, Z.; Paperno, N.; Prakash, K.; Behal, A. An Adaptive Control-Based Approach for 1-Click Gripping of Novel Objects Using a Robotic Manipulator. IEEE Trans. Control Syst. Technol. 2019, 27, 1805–1812. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Q. Adaptive Sliding Mode Control With Parameter Estimation and Kalman Filter for Precision Motion Control of a Piezo-Driven Microgripper. IEEE Trans. Control Syst. Technol. 2017, 25, 728–735. [Google Scholar] [CrossRef]

- Ikeura, R.; Inooka, H. Variable Impedance Control of a Robot for Cooperation with a Human. In Proceedings of the Proceedings of 1995 IEEE International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995; pp. 3097–3102. [Google Scholar]

- De Gea, J.; Kirchner, F. Modelling and Simulation of Robot Arm Interaction Forces Using Impedance Control. In Proceedings of the 17th World Congress the International Federation of Automatic Control, Seoul, Korea, 6–11 July 2008; pp. 15589–15594. [Google Scholar]

- Caccavale, F.; Chiacchio, P.; Marino, A.; Villani, L. Six-DOF Impedance Control of Dual-Arm Cooperative Manipulators. IEEE/ASME Trans. Mechatron. 2008, 13, 576–586. [Google Scholar] [CrossRef]

- Raiola, G.; Cardenas, C.-A.; Tadele, T.-S.; De Vries, T.; Stramigioli, S. Development of a Safety and Energy-Aware Impedance Controller for Collaborative Robots. IEEE Robot. Autom. Lett. 2018, 3, 1237–1244. [Google Scholar] [CrossRef]

- Park, J.; Choi, Y.-J. Input-to-State Stability of Variable Impedance Control for Robotic Manipulator. Appl. Sci. 2020, 10, 1271. [Google Scholar] [CrossRef]

- Jung, S.; Hsia, T.-C.; Bonitz, R.-G. Force Tracking Impedance Control of Robot Manipulators Under Unknown Environment. IEEE Trans. Control Syst. Technol. 2004, 12, 474–483. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.; Huang, Z.; Peng, Y.; Pu, H.; Ding, L. Adaptive Impedance Control of Human-Robot Cooperation Using Reinforcement Learning. IEEE Trans. Ind. Electron. 2017, 64, 8013–8022. [Google Scholar] [CrossRef]

- Kim, B.; Park, J.; Park, S.; Kang, S. Impedance Learning for Robotic Contact Tasks Using Natural Actor-Critic Algorithm. IEEE Trans. Syst. Man Cybern. Part B 2010, 40, 433–443. [Google Scholar]

- Li, Y.; Ge, S.-S. Impedance Learning for Robots Interacting with Unknown Environments. IEEE Trans. Control Syst. Technol. 2013, 22, 1422–1432. [Google Scholar] [CrossRef]

- Tran, H.-T.; Cheng, H.; Rui, H.; Lin, X.-C.; Duong, M.-K.; Chen, Q. Evaluation of a Fuzzy-Based Impedance Control Strategy on a Powered Lower Exoskeleton. Int. J. Soc. Robot. 2015, 8, 103–123. [Google Scholar] [CrossRef]

- Roveda, L.; Haghshenas, S.; Prini, A.; Dinon, T.; Pedrocchi, N.; Braghin, F.; Tosatti, L.-M. Fuzzy Impedance Control for Enhancing Capabilities of Humans in Onerous Tasks Execution. In Proceedings of the 2018 15th International Conference on Ubiquitous Robots (UR), Honolulu, HI, USA, 27–30 June 2018; pp. 406–411. [Google Scholar]

- Wong, C.-C.; You, S.-L.; Chen, R.-J.; Liu, Y.-T. Intuitive Teaching of Six-axis Robot Manipulator Based on Fuzzy Impedance Control. In Proceedings of the 2018 International Automatic Control Conference (CACS), Taoyuan, Taiwan, 4–7 November 2018. [Google Scholar]

- Li, M.; Wei, J.; Fang, J.; Shi, W.; Guo, K. Fuzzy Impedance Control of an Electro-Hydraulic Actuator with an Extended Disturbance Observer. Front. Inf. Technol. Electron. Eng. 2019, 20, 1221–1233. [Google Scholar] [CrossRef]

- Lin, C.-T.; Lee, C.-S.-G. Neural Fuzzy Systems-A Neuro-Fuzzy Synergism to Intelligent Systems; Prentice Hall PTR: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Freeman, C.-T.; Rogers, E.; Burridge, J.-H. Iterative Learning Control-An Overview. In Iterative Learning Control for Electrical Stimulation and Stroke Rehabilitation; Springer: London, UK, 2015; pp. 3–15. [Google Scholar]

- Moore, K.-L. Iterative Learning Control: An Expository Overview. In Applied and Computational Control, Signals, and Circuits; Springer Science and Business Media: New York, NY, USA, 1999; pp. 151–214. [Google Scholar]

- Morita, N.; Nogami, H.; Higurashi, E.; Sawada, R. Grasping Force Control for a Robotic Hand by Slip Detection Using Developed Micro Laser Doppler Velocimeter. Sensors 2018, 18, 326. [Google Scholar] [CrossRef] [PubMed]

- James, J.-W.; Pestell, N.; Lepora, N.-F. Slip Detection With a Biomimetic Tactile Sensor. IEEE Robot. Autom. Lett. 2018, 3, 3340–3346. [Google Scholar] [CrossRef]

- Su, Z.; Hausman, K.; Chebotar, Y.; Molchanov, A.; Loeb, G.-E.; Sukhatme, G.-S.; Schaal, S. Force Estimation and Slip Detection for Grip Control using a Biomimetic Tactile Sensor. In Proceedings of the 2015 IEEE-RAS 15th International Conference on Humanoid Robots (Humanoids), Seoul, Korea, 3–5 November 2015. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).