Observation of Distribution of π-Orbital-Oriented Domains in PAN- and Pitch-Based Carbon Fibers Using Scanning Transmission X-ray Microscopy

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Miller, B.; Muri, P.; Rebenfeld, L. A microbond method for determination of the shear strength of a fiber/resin interface. Compos. Sci. Technol. 1987, 28, 17–32. [Google Scholar] [CrossRef]

- Otani, S.; Oya, A. Progress of Pitch-Based Carbon Fiber in Japan. ACS Symp. Ser. 1986, 303, 323–334. [Google Scholar]

- Soo-Jin, P. Carbon Fibers; Springer Singapore: Gateway East, Singapore, 2018; pp. 101–133. [Google Scholar]

- Dongxing, Y.; Velamakanni, A.; Bozoklu, G.; Park, S.; Stoller, M.; Piner, R.D.; Stankovich, S.; Jung, I.; Field, D.A.; Ventrice, C.A.; et al. Chemical analysis of graphene oxide films after heat and chemical treatments by X-ray photoelectron and Micro-Raman spectroscopy. Carbon 2009, 47, 145–152. [Google Scholar]

- Boudou, J.P.; Parent, P.; Suarez-Garcia, F.; Villar-Rodil, S.; Martinez-Alonso, A.; Tascon, J.M.D. Nitrogen in aramid-based activated carbon fibers by TPD, XPS and XANES. Carbon 2006, 44, 2452–2462. [Google Scholar] [CrossRef]

- Ponsonnet, L.; Donnet, C.; Varlot, K.; Martin, J.M.; Grill, A.; Patel, V. EELS analysis of hydrogenated diamond-like carbon films. Thin Solid Films 1998, 319, 97–100. [Google Scholar] [CrossRef]

- Hitchcock, A.P. Soft X-ray imaging and spectromicroscopy. In Handbook of Nanoscopy; Van Tendeloo, G., Dyck, D.V., Pennycook, S.J., Eds.; Wiley Online Library: Hoboken, NJ, USA, 2012; Volume 2, pp. 745–791. [Google Scholar]

- Fernandez, M.P.; Black, C.; Dawson, J.; Gibbs, D.; Kanczler, J.; Oreffo, R.O.C.; Tozzi, G. Exploratory full-field strain analysis of regenerated bone tissue from osteoinductive biomaterials. Materials 2020, 13. [Google Scholar]

- Minxiang, Z.; Shah, S.A.; Dali, H.; Parviz, D.; Yi-Hsien, Y.; Xuezhen, W.; Green, M.J.; Zhengdong, C. Aqueous exfoliation of graphite into graphene assisted by sulfonyl graphene quantum dots for photonic crystal applications. ACS Appl. Mater. Interfaces 2017, 9, 30797–30804. [Google Scholar]

- Jood, P.; Mehta, R.J.; Yanliang, Z.; Peleckis, G.; Xiaolin, W.; Siegel, R.W.; Borca-Tasciuc, T.; Dou, S.X.; Ramanath, G. Al-doped zinc oxide nanocomposites with enhanced thermoelectric properties. Nano Lett. 2011, 11, 4337–4342. [Google Scholar] [CrossRef] [PubMed]

- Minxiang, Z.; Yanliang, Z. Colloidal nanoparticle inks for printing functional devices: emerging trends and future prospects. J. Mater. Chem. A 2019, 7, 23301–23336. [Google Scholar]

- Rouzaud, J.-N. Conribution of Transmission Electron Microscopy to the study of the coal carbonization processes. Fuel Process. Technol. 1990, 24, 55–69. [Google Scholar] [CrossRef]

- Takeichi, Y.; Inami, N.; Suga, H.; Miyamoto, C.; Ueno, T.; Mase, K.; Takahashi, Y.; Ono, K. Design and performance of a compact scanning transmission X-ray microscope at the Photon Factory. Rev. Sci. Instrum. 2016, 87, 013704-1–013704-7. [Google Scholar] [CrossRef] [PubMed]

- Sasaki, S.; Kakuno, K.; Takada, T.; Shimada, T.; Yanagida, K.; Miyahara, Y. Design of a new type of planar undulator for generating variably polarized radiation. Nucl. Instrum. Methods Phys. Res. Sect. A 1993, 331, 763–767. [Google Scholar] [CrossRef]

- Stöhr, J. NEXAFS Spectroscopy; Springer: Berlin, Germany, 1992; pp. 169–172; 96–126. [Google Scholar]

- Ohigashi, T.; Nagasaka, M.; Horigome, T.; Kosugi, N.; Rosendahl, S.M.; Hitchcock, A.P. Development of in-situ sample cells for scanning transmission X-ray microscopy. In Proceedings of the 12th International Conference on Synchrotron Radiation Instrumentation (SRI), New York, NY, USA, 6–10 July 2015; pp. 050002-1–050002-4. [Google Scholar]

- Watts, B.; Schuettfor, T.; McNeill, C.R. Mapping of Domain Orientation and Molecular Order in Polycrystalline Semiconducting Polymer Films with Soft X-ray Microscopy. Adv. Funct. Mater. 2011, 21, 1122–1131. [Google Scholar] [CrossRef]

- Watts, B.; McNeill, C.R.; Raabe, J. Imaging nanostructures in organic semiconductor films with scanning transmission X-ray spectro-microscopy. Synth. Met. 2012, 161, 2516–2520. [Google Scholar] [CrossRef]

- Harano, T.; Murao, R.; Takeichi, Y.; Kimura, M.; Takahashi, Y. Observation of the Interface between Resin and Carbon Fiber by Scanning Transmission X-ray Microscopy. In Proceedings of the 13th International X-Ray Microscopy Conference (XRM), Diamond Light Source, Oxford, UK, 15–19 August 2016; pp. 012023-1–012023-4. [Google Scholar]

- Hitchcock, A.P. aXis 2000. Available online: http://unicorn.mcmaster.ca/aXis2000.html (accessed on 25 December 2019).

- Halder, N.C.; Wagner, C.N.J. Separation of particle size and lattice strain in integral breadth measurements. Acta Crystallogr. 1966, 20, 312–313. [Google Scholar] [CrossRef]

- Howe, J.; Rawn, C.J.; Jones, L.E.; Ow, H. Improved crystallographic data for graphite. Powder Diffr. 2003, 18, 150–154. [Google Scholar] [CrossRef]

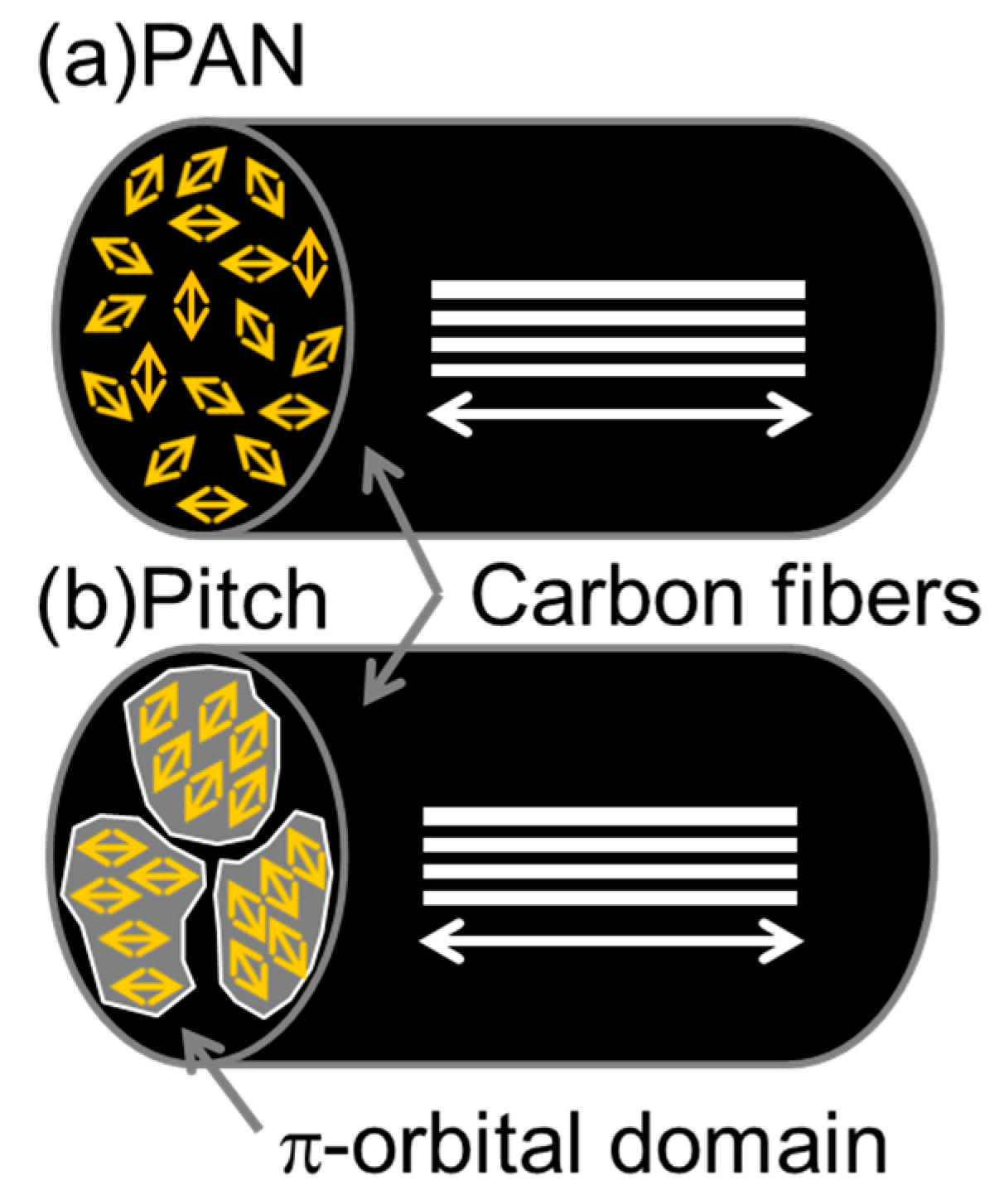

| PAN-Based CF | Pitch-Based CF | |

|---|---|---|

| Manufacturer | Toray Industries, Inc. | Nippon Graphite Fiber Corporation |

| Product name | M46J | YSH50A |

| Density (g/cm3) | 1.84 | 2.10 |

| Tensile strength (MPa) | 4210 | 3830 |

| Tensile modulus (GPa) | 436 | 520 |

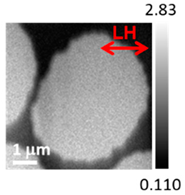

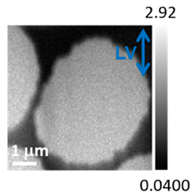

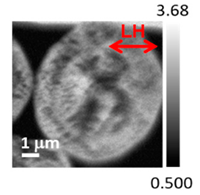

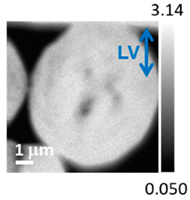

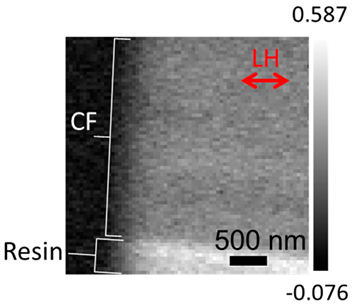

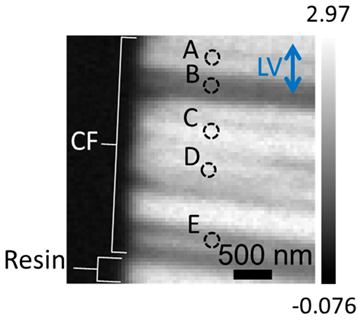

| TEM | STXM (OD) | ||||

|---|---|---|---|---|---|

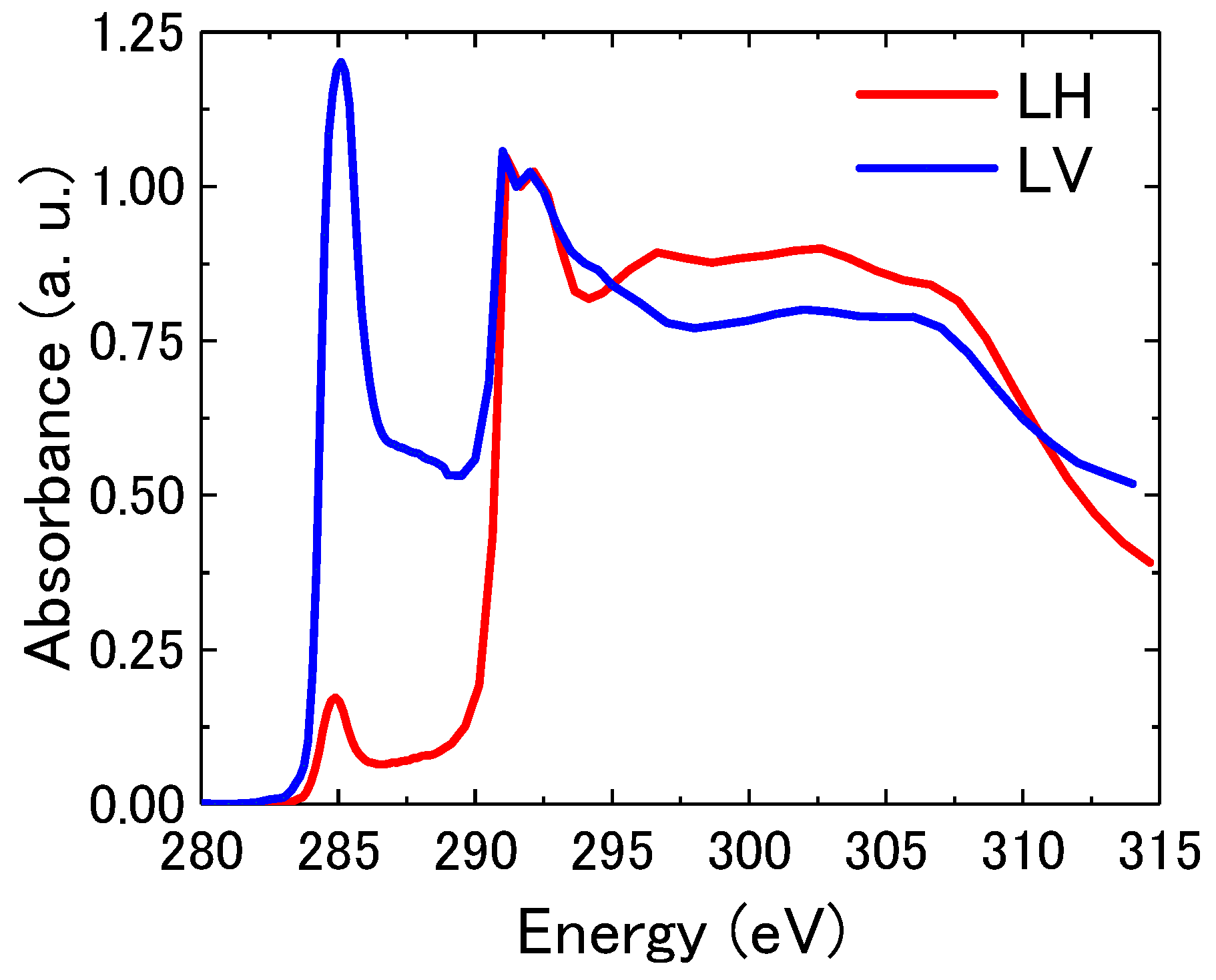

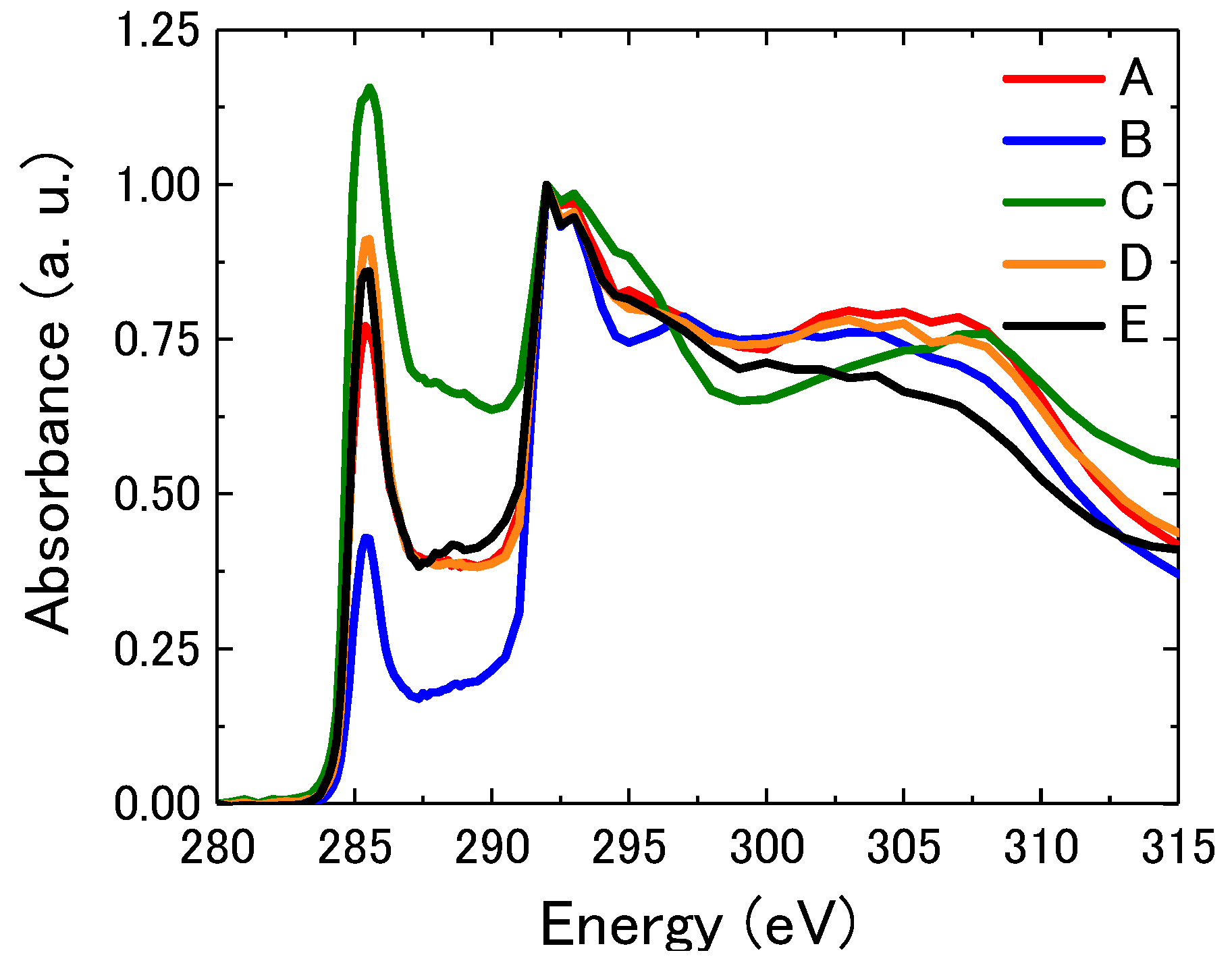

| E = 285.4 eV (1s→π* (C = C)) | E = 292.0 eV (1s→σ* (C-C)) | ||||

| LH | LV | LH | LV | ||

| PAN |  |  |  |  |  |

| (a) | (b) | (c) | (d) | (e) | |

| Pitch |  |  |  |  |  |

| (f) | (g) | (h) | (i) | (j) | |

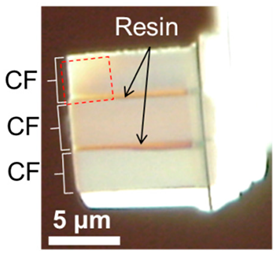

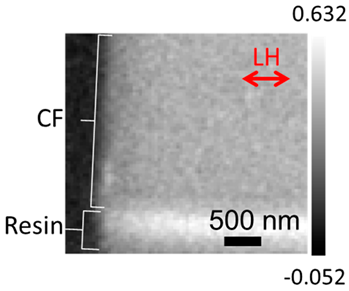

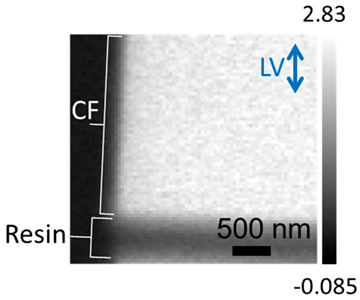

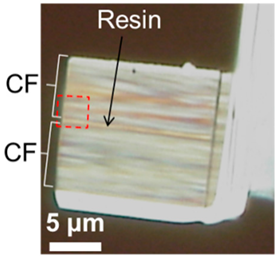

| Visible Light Microscopy | SXTM (E = 285.4 eV) | ||

|---|---|---|---|

| LH | LV | ||

| PAN |  |  |  |

| (a) | (b) | (c) | |

| Pitch |  |  |  |

| (d) | (e) | (f) | |

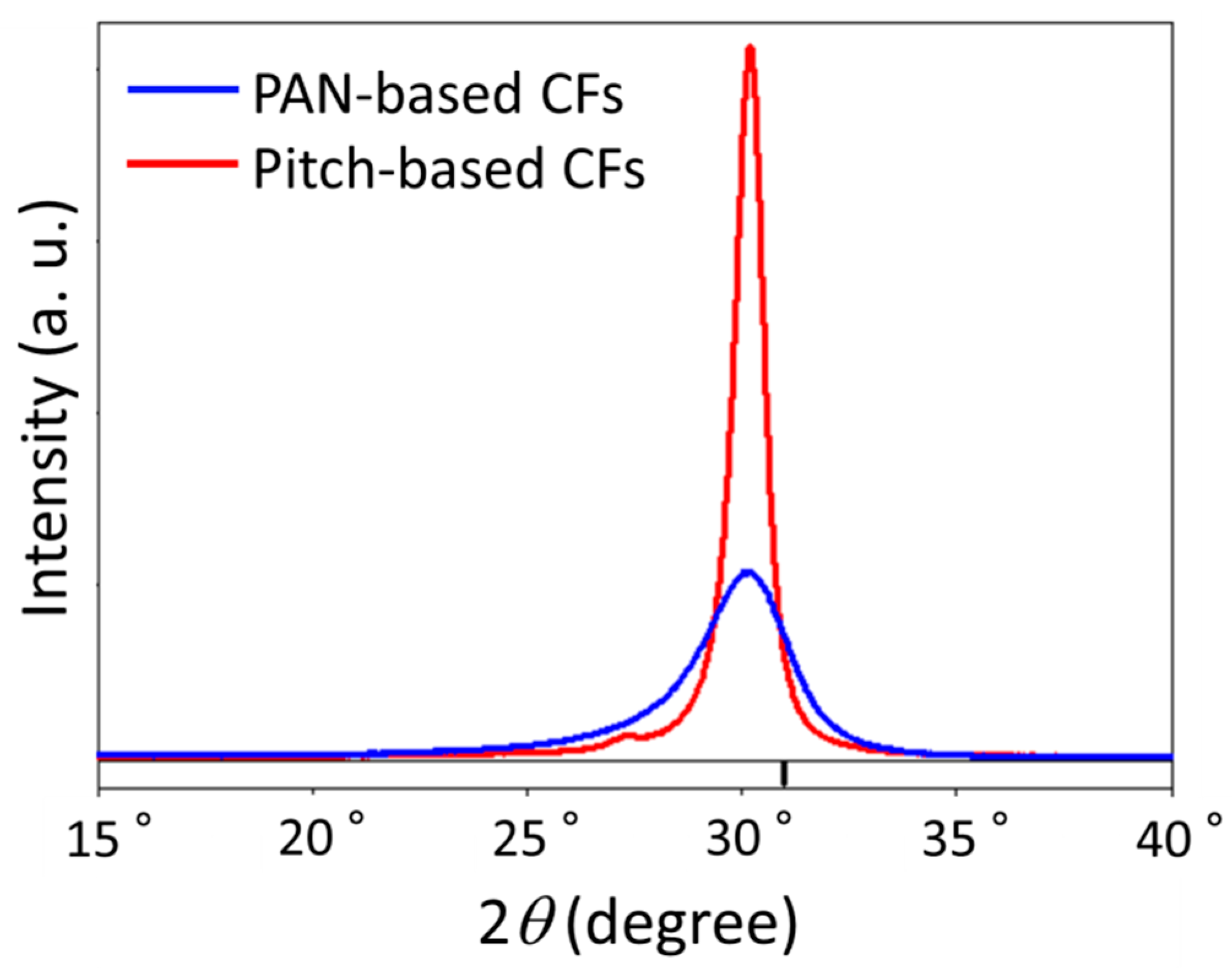

| PAN-Based CFs | Pitch-Based CFs | Graphite | |

|---|---|---|---|

| The lattice spacing of the (002) plane of the graphite (d(002)) (nm) | 0.346 | 0.344 | 0.335 [22] |

| Crystallite size (nm) | 4.1 | 12 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harano, T.; Takeichi, Y.; Usui, M.; Arai, Y.; Murao, R.; Negi, N.; Kimura, M. Observation of Distribution of π-Orbital-Oriented Domains in PAN- and Pitch-Based Carbon Fibers Using Scanning Transmission X-ray Microscopy. Appl. Sci. 2020, 10, 4836. https://doi.org/10.3390/app10144836

Harano T, Takeichi Y, Usui M, Arai Y, Murao R, Negi N, Kimura M. Observation of Distribution of π-Orbital-Oriented Domains in PAN- and Pitch-Based Carbon Fibers Using Scanning Transmission X-ray Microscopy. Applied Sciences. 2020; 10(14):4836. https://doi.org/10.3390/app10144836

Chicago/Turabian StyleHarano, Takayuki, Yasuo Takeichi, Masafumi Usui, Yutaka Arai, Reiko Murao, Noriyuki Negi, and Masao Kimura. 2020. "Observation of Distribution of π-Orbital-Oriented Domains in PAN- and Pitch-Based Carbon Fibers Using Scanning Transmission X-ray Microscopy" Applied Sciences 10, no. 14: 4836. https://doi.org/10.3390/app10144836

APA StyleHarano, T., Takeichi, Y., Usui, M., Arai, Y., Murao, R., Negi, N., & Kimura, M. (2020). Observation of Distribution of π-Orbital-Oriented Domains in PAN- and Pitch-Based Carbon Fibers Using Scanning Transmission X-ray Microscopy. Applied Sciences, 10(14), 4836. https://doi.org/10.3390/app10144836