Study on Reverse Logistics Focused on Developing the Collection Signal Algorithm Based on the Sensor Data and the Concept of Industry 4.0

Abstract

1. Introduction

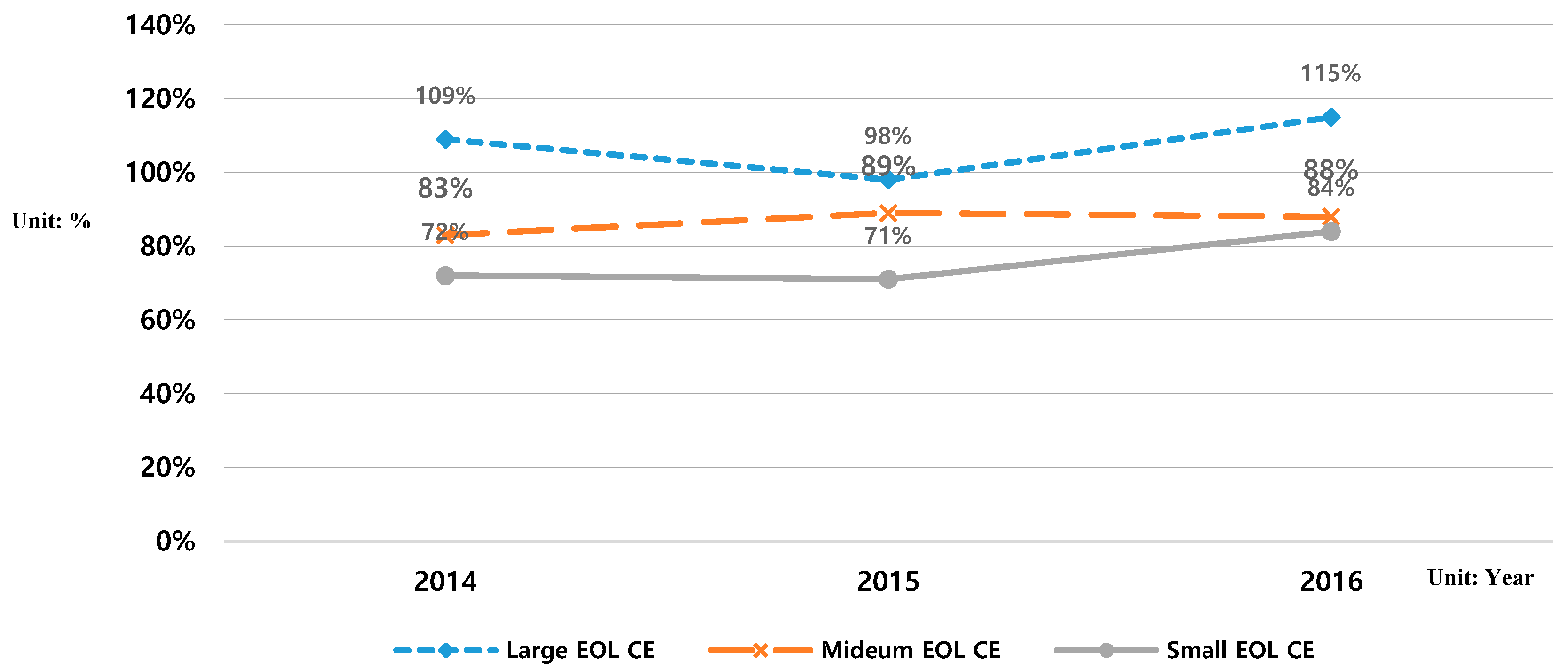

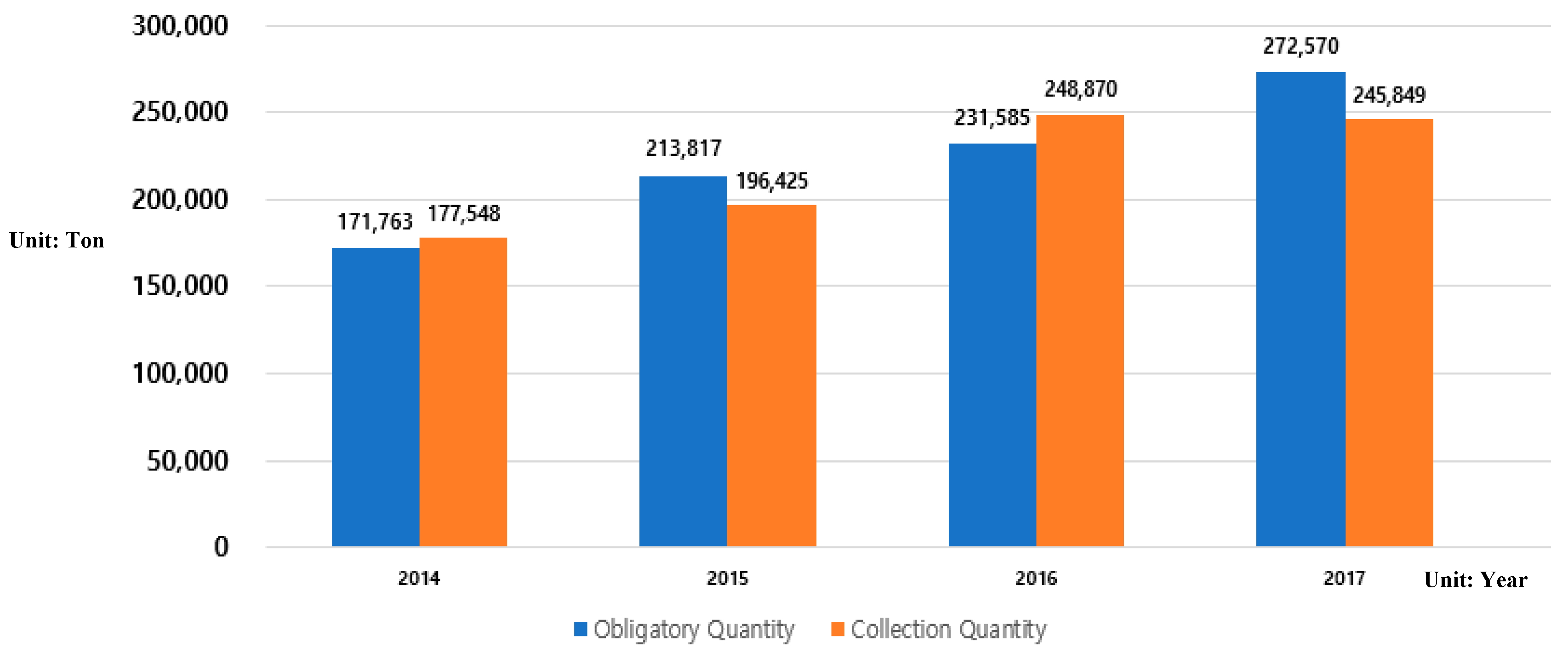

1.1. Background

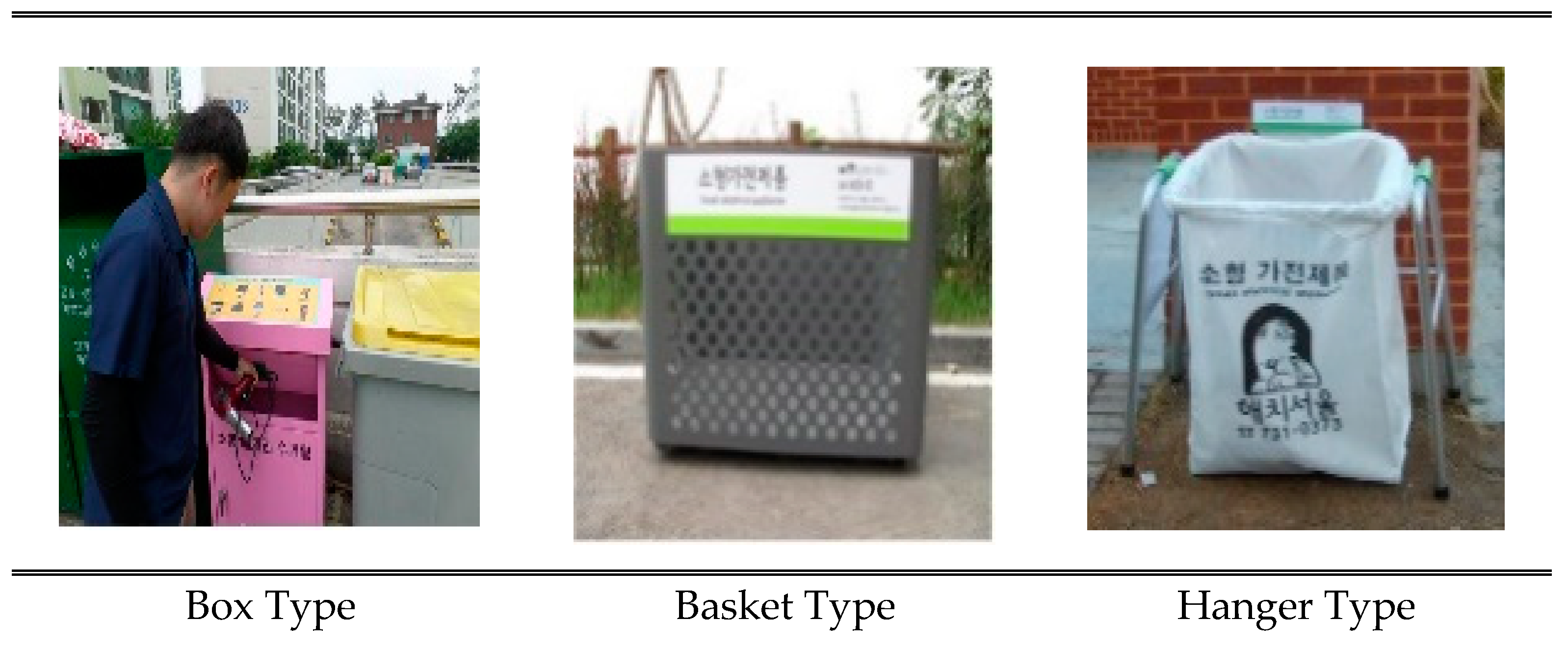

1.2. Domestic e-Waste Collection and Purpose of This Study

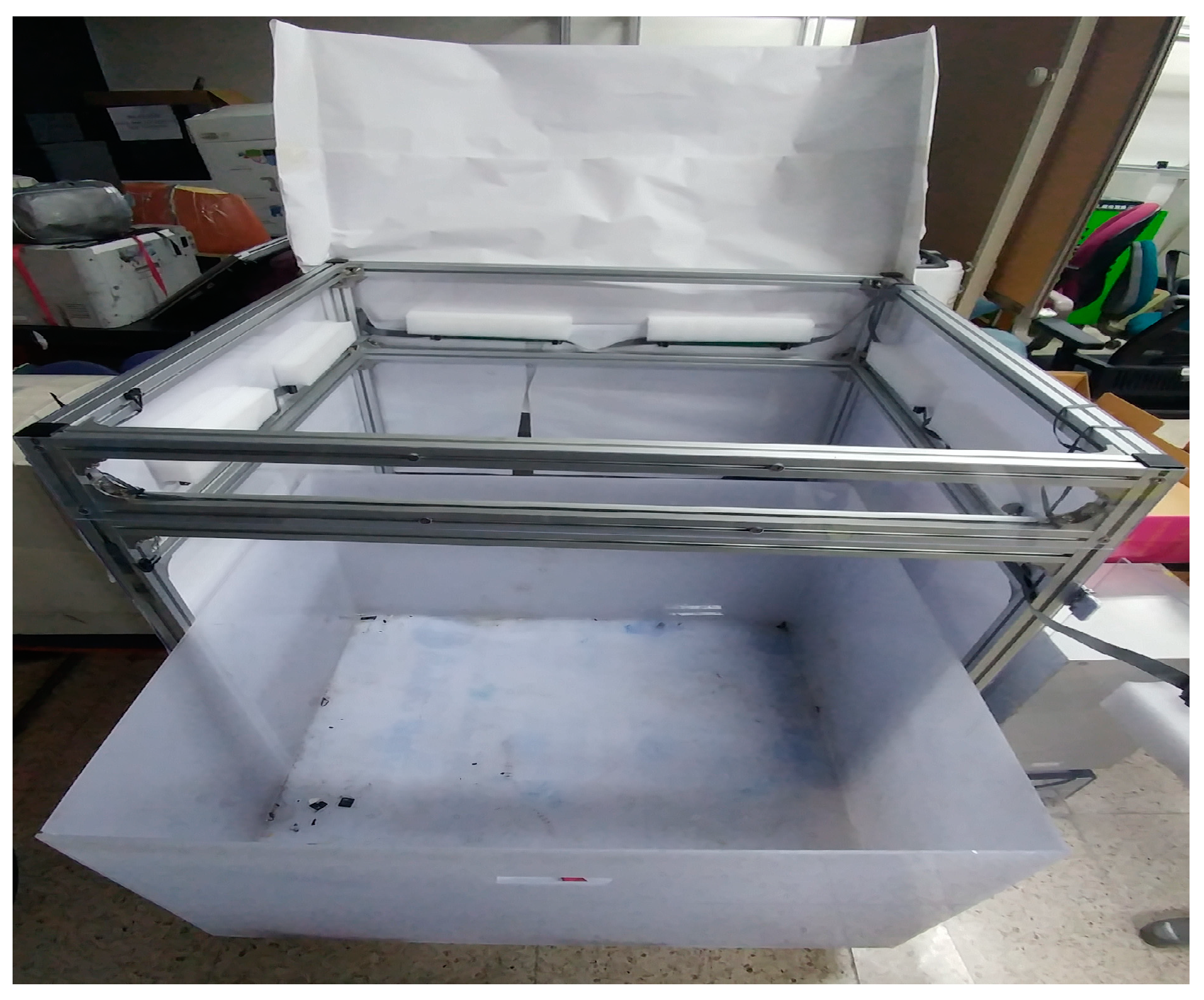

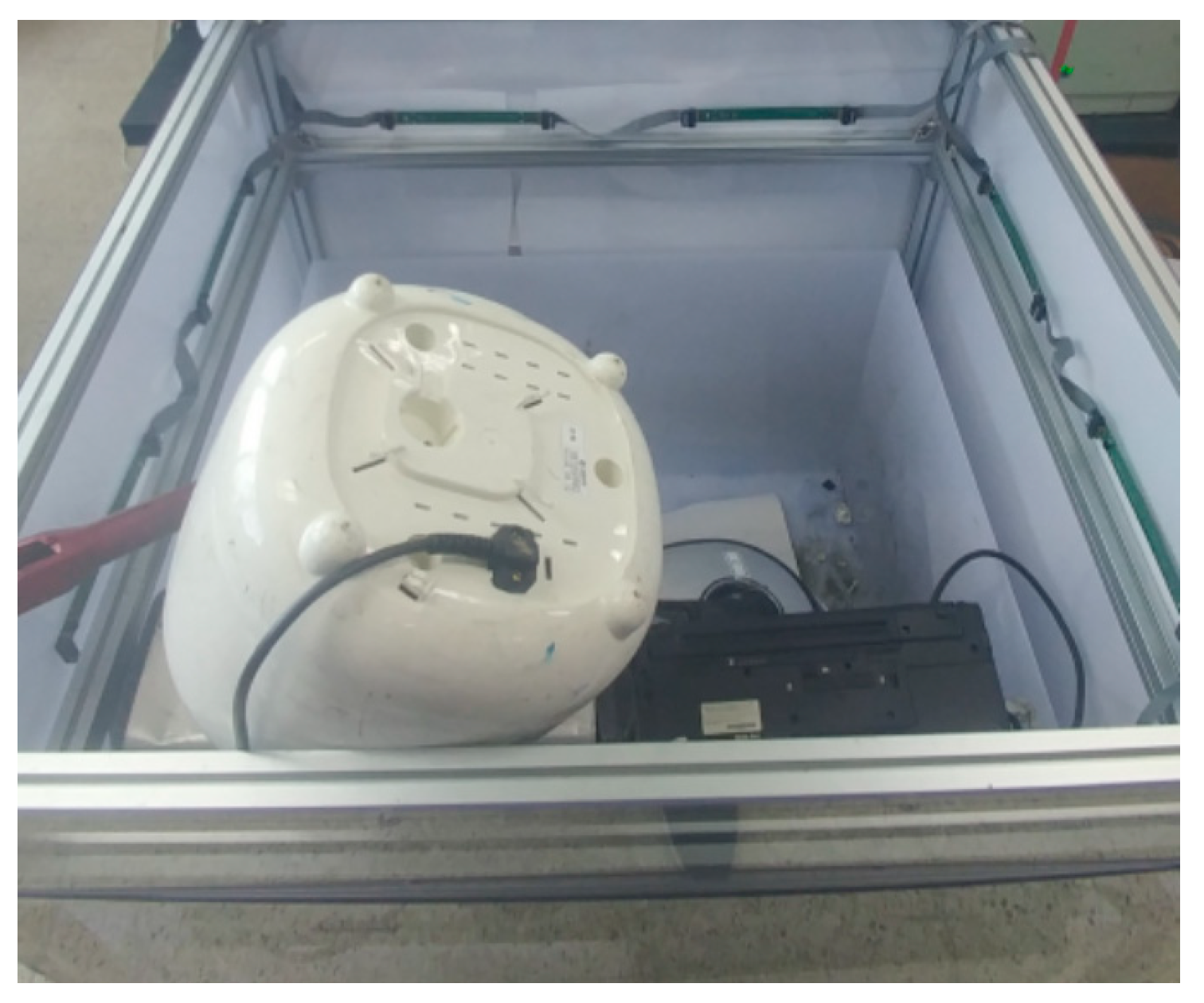

2. Sensors Embedded in Collection Box

3. Empirical Studies

3.1. Experimental Procedure

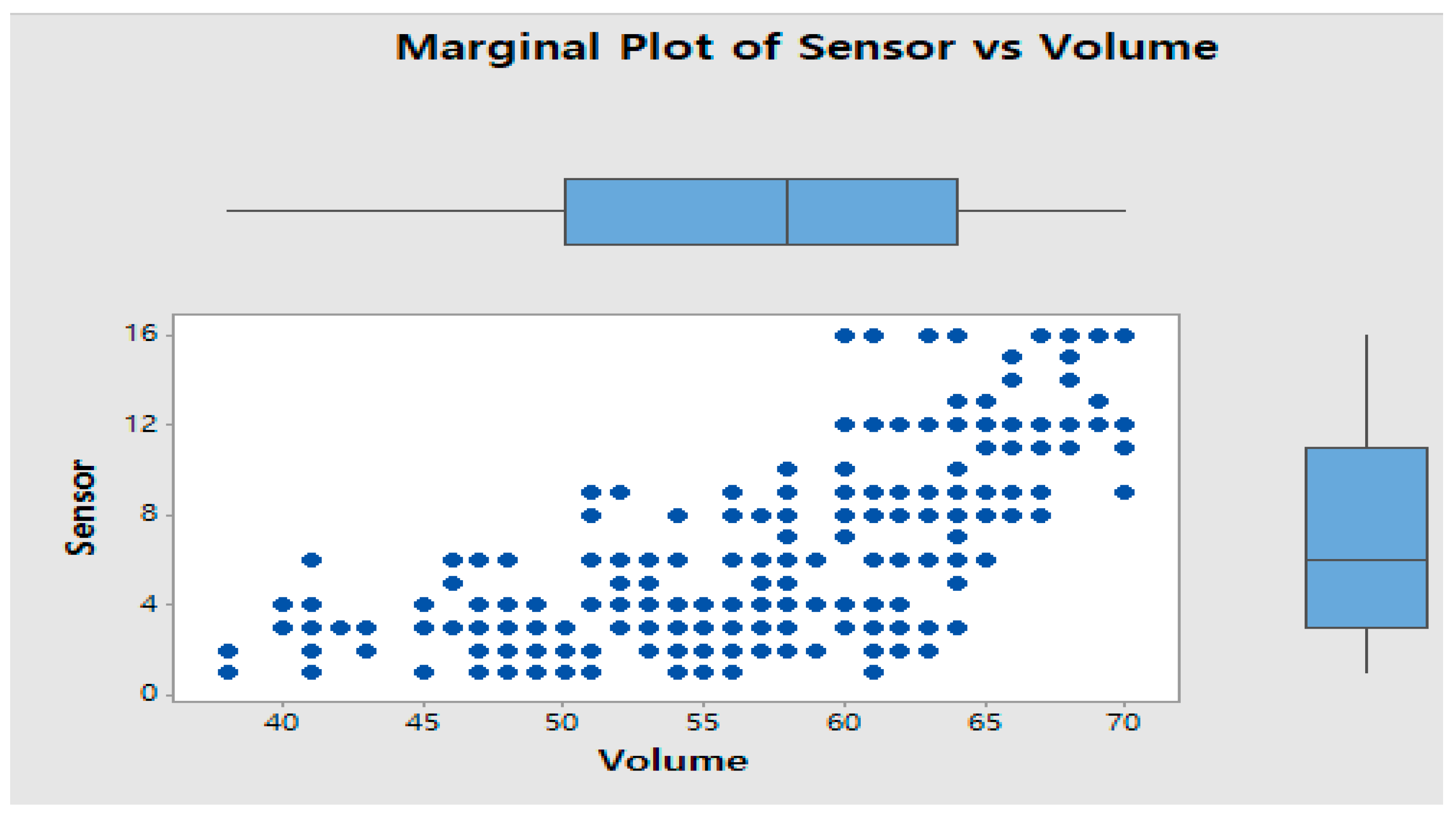

3.2. Experiment Results

3.3. Hypothesis Test with ANOVA

3.4. Collection Signal Algorithm

3.5. Validation Experiment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Group | Accumulated Order | Group | Accumulated Order |

|---|---|---|---|

| 1 | 24→21→4→16→15→14→8→22→27→32→31→2→6→29→26 | 11 | 31→10→25→19→13→28→6→5→23→22→26→2→29→16→15 |

| 2 | 13→17→3→23→8→2→28→18→6→1→26→4 | 12 | 19→1→17→7→24→18→21→12→29→9→30→25→20→31→14→2→26 |

| 3 | 24→20→28→4→7→22→25→15→30→29→12→23→3→26→18 | 13 | 22→18→8→27→10→15→20→29→ 31→9→23→28→24→26→3→12 |

| 4 | 10→2→1→31→11→19→20→32→22→21→4→30→8→27→26→16→14→6→12 | 14 | 12→1→7→8→17→31→9→28→25→5→30→21→14→19→22→24→26→20→23→32 |

| 5 | 19→31→8→11→13→29→21→26→ 12→5→17→16→1→28→4→25→15→10→27 | 15 | 26→24→21→13→7→29→4→20→9→16→28→12→2→6→3 |

| 6 | 28→22→25→32→11→3→20→18→ 17→10→5→16→12→24→13→15→8→23 | 16 | 13→27→29→9→2→31→30→21→18→4→17→1→14→15→10→5 |

| 7 | 16→13→28→20→19→26→18→22→1→21→25→5→24→7→2→9→14 | 17 | 11→15→7→3→28→6→17→4→29→9→20→19→32→27→5→30→31 |

| 8 | 21→32→5→6→23→30→18→8→22→25→2→20→12→4 | 18 | 15→1→18→23→7→24→3→17→25→22→26→4→10→8 |

| 9 | 32→25→6→5→12→26→20→28→22→30→15→1→7→18 | 19 | 1→12→31→14→11→28→27→17→ 16→4→26→19→8→9→29→5→25→20→18 |

| 10 | 1→26→14→9→23→15→28→7→5→13→32→27→30→12→8 | 20 | 12→31→7→20→11→22→8→4→1→30→15→24→2→3→5→27→32→29 |

References

- Dias, P.; Machado, A.; Huda, N.; Bernardes, A.M. Waste electric and electronic equipment (WEEE) management: A study on the Brazilian recycling routes. J. Clean. Prod. 2018, 174, 7–16. [Google Scholar] [CrossRef]

- Aguirre M, Á.; Hidalgo, M.; Canals, A.; Nóbrega, J.A.; Pereira-Filho, E.R. Analysis of waste electrical and electronic equipment (WEEE) using laser induced breakdown spectroscopy (LIBS) and multivariate analysis. Talanta 2013, 117, 419–424. [Google Scholar] [CrossRef] [PubMed]

- Ongondo, F.O.; Williams, I.D.; Cherrett, T.J. How are WEEE doing? A global review of the management of electrical and electronic wastes. Waste Manag. 2011, 31, 2553–2558. [Google Scholar] [CrossRef] [PubMed]

- Salhofer, S.; Steuer, B.; Ramusch, R.; Beigl, P. WEEE management in Europe and China–a comparison. Waste Manag. 2016, 57, 27–35. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, A.; Terazono, A.; Ballesteros, F.C., Jr.; Nguyen, D.Q.; Sukandar, S.; Kojima, M.; Sakata, S. E-waste recycling processes in Indonesia, the Philippines, and Vietnam: A case study of cathode ray tube TVs and monitors. Resour. Conserv. Recycl. 2016, 106, 48–58. [Google Scholar] [CrossRef]

- Min, D.K. A Study on the Evaluation and Improvement of EPR (Extended Producer Responsibility) System. Korea Soc. Environ. Adm. 2006, 12, 11–17. [Google Scholar]

- Samsung Global Environment Research Center. Improvement of Extended Producer Responsibility; Samsung Global Environment Research Center: Hwaseong, Korea, 2004; pp. 53–70. [Google Scholar]

- Sousa, R.; Agante, E.; Cerejeira, J.; Portela, M. EEE fees and the WEEE system–A model of efficiency and income in European countries. Waste Manag. 2018, 79, 770–780. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H. A Study on facilitating the EPR (Extended Producer Responsibility) in the EU Plastic Packaging Waste. J. Contemp. Eur. Stud. 2018, 36, 225–252. [Google Scholar]

- Korea Ministry of Environment. Enforcement Decree of the Act on Resource Circulation of Electrical and Electronic Equipment and Vehicles; Korea Ministry of Environment: Sejong, Korea, 2014; Available online: http://www.me.go.kr (accessed on 10 November 2019).

- Kim, H.; Lee, H.J. Quality improvement of FVP (free visit and pick-up) Services for Reverse Logistics of End-of-Life Consumer Electronics. Inf. Int. Interdiscip. J. 2012, 15, 6287–6296. [Google Scholar]

- Kim, Y.; Kim, H. The Study on the Efficiency of FVP (Free-Visit-Pickup) Service by changing Conditions. Korea Logist. Soc. 2018, 26, 77–90. [Google Scholar]

- Kim, H.; Park, K. Greenhouse Gas Emission Reduction on Collection Logistics of End-of-life Consumer Electronics Considering Environmental Information. Icic Express Lett. Part. B Appl. 2018, 9, 599–605. [Google Scholar]

- Zoeteman, B.C.; Krikke, H.R.; Venselaar, J. Handling WEEE waste flows: On the effectiveness of producer responsibility in a globalizing world. Int. J. Adv. Manuf. Technol. 2010, 47, 415–436. [Google Scholar] [CrossRef]

- Korea Electronics Recycling Cooperative. 2017. Available online: http://www.k-erc.or.kr/ (accessed on 10 November 2019).

- Statistics Korea. 2015. Available online: http://kostat.go.kr/portal/eng/index.action (accessed on 10 November 2019).

- Korea CEs Recycling Logistics. 2017. Available online: http://www.rcl.kr/ (accessed on 10 November 2019).

- Kim, H.; Park, K. Estimation of Disposal Trend of End-of-Life Consumer Electronics Considering Environmental Factors. In Proceedings of the 13th International Conference on Innovative Computing, Information and Control, Lianyungang, China, 20–23 August 2018; p. 10. [Google Scholar]

- Lee, J.; Yoon, J. A study on the Affordance factor for improvement of usability in recycling waste bin. Arch. Des. Res. 2008, 8, 219–228. [Google Scholar]

- Heo, G.; Lee, W.; Kim, M. Structural Health Monitoring System Employing Smart Sensor Technology Part 1: Development and Performance Test of Smart Sensor. J. Korea Inst. Struct. Maint. Insp. 2007, 11, 134–144. [Google Scholar]

- Dalkey, N.; Helmer, O. An experimental application of the Delphi method to the use of experts. Manag. Sci. 1963, 9, 458–467. [Google Scholar] [CrossRef]

- Frey, J.H.; Fontana, A. The group interview in social research. Soc. Sci. J. 1991, 28, 175–187. [Google Scholar] [CrossRef]

- Hogg, R.V.; Craig, A.T. Introduction to Mathematical Statistics; Pearson: Englewood Hills, NJ, USA, 1995. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Kim, T.; Choi, M.; Lee, H. P-value and Reduction to Absurdity. Quant. Bio-Sci. 2017, 36, 1–6. [Google Scholar]

| Year | 14 | 15 | 16 | 17 | Total | Ratio (%) |

|---|---|---|---|---|---|---|

| Computer (including Video player and Cassette) | 7,448,292.1 | 6,116,630.3 | 8,673,632.9 | 6,956,572.5 | 29,195,128 | 32.2 |

| Electric fan (including Humidifier) | 2,826,085.4 | 6,567,948.4 | 8,016,177.5 | 5,619,750.4 | 23,029,962 | 25.2 |

| Printer | 2,020,621.4 | 2,398,688.1 | 2,785,188.9 | 2,424,168.4 | 9,628,666.7 | 10.4 |

| Copy machine | 1,249,540.6 | 2,401,901.8 | 3,614,162.3 | 2,164,052.7 | 9,429,657.3 | 10.2 |

| Vacuum cleaner | 1,413,397.7 | 1,674,767.6 | 1,929,575.5 | 1,136,867.6 | 6,154,608.5 | 6.7 |

| Electric rice cooker | 317,669.73 | 1,188,752.6 | 1,286,596.5 | 726,585.75 | 3,519,604.6 | 3.8 |

| Audio | 656,131.1 | 7,333,13.55 | 897,869.5 | 277,829.49 | 2,565,143.6 | 2.8 |

| Microwave | 500,852.5 | 490,693.06 | 666,786.36 | 226,604.69 | 1,884,936.6 | 2.1 |

| Dish dryer | 170,489.68 | 225,619.66 | 353,334.38 | 391,020.6 | 1,140,464.3 | 1.2 |

| Electric bidet | 117,841.21 | 245,677.76 | 323,774.6 | 337,259.51 | 1,024,553.1 | 1.1 |

| Electric oven | 180,893.39 | 229,145.88 | 275,871.51 | 206,647 | 892,557.78 | 1.0 |

| Air purifier | 132,998.57 | 156,827.96 | 227,499.27 | 294,756.42 | 812,082.22 | 0.9 |

| Mobile phone | 384,208.84 | 234,663.6 | 70,060.52 | 11,223.4 | 700,156.36 | 0.8 |

| Electric purifier | 145,651.64 | 143,979 | 187,227.42 | 61,235.74 | 538,093.8 | 0.6 |

| Facsimile | 90,205.83 | 65,780.48 | 98,828.69 | 43,214.24 | 298,029.24 | 0.3 |

| Blender | 69,112.11 | 80,017.74 | 83,965.44 | 53,019.2 | 286,114.49 | 0.3 |

| Food waste disposals | 33,038.46 | 31,648.4 | 39,889.03 | 29,836.35 | 134,412.24 | 0.2 |

| Water softener | 16,410.71 | 11,950.12 | 24,350.48 | 50,385.86 | 103,097.17 | 0.1 |

| Electric iron | 16,760.4 | 24,144.48 | 25,871.84 | 28,710.96 | 95,487.68 | 0.1 |

| ID | Product Type | Volume (m3) | ID | Product Type | Volume (m3) |

|---|---|---|---|---|---|

| 1 | Electric fan | 0.029 | 17 | Mini Cassette | 0.012 |

| 2 | Vacuum cleaner (1) | 0.067 | 18 | Vacuum cleaner (2) | 0.064 |

| 3 | Electric heater | 0.044 | 19 | Steam iron | 0.013 |

| 4 | Monitor (LCD) | 0.029 | 20 | Electric oven | 0.016 |

| 5 | Electric rice cooker (1) | 0.025 | 21 | Video player | 0.019 |

| 6 | Monitor (CRT) | 0.070 | 22 | Laptop | 0.004 |

| 7 | Microwave | 0.035 | 23 | Dishwasher | 0.040 |

| 8 | Electric rice cooker (2) | 0.024 | 24 | Keyboard | 0.003 |

| 9 | Mini refrigerator | 0.030 | 25 | Speaker | 0.041 |

| 10 | Toast machine | 0.007 | 26 | Wall fan | 0.041 |

| 11 | Electric iron | 0.004 | 27 | Humidifier (1) | 0.018 |

| 12 | Cassette | 0.022 | 28 | Juice extractor | 0.021 |

| 13 | Desktop computer | 0.015 | 29 | Frying machine | 0.024 |

| 14 | Printer | 0.026 | 30 | Mini frying machine (1) | 0.007 |

| 15 | Fax Printer (HP) | 0.070 | 31 | Mini frying machine (2) | 0.014 |

| 16 | Blender | 0.016 | 32 | Humidifier (2) | 0.024 |

| Group | Trial | Result | Group | Trial | Result |

|---|---|---|---|---|---|

| 1 | 1 | 3 (47%), 3 (58%), 12 (61%), 12 (67%) | 11 | 1 | 1 (54%), 4 (57%), 4 (60%), 9 (70%) |

| 2 | 3 (47%), 5 (58%), 9 (61%), 16 (67%) | 2 | 3 (54%), 3 (57%), 10 (60%), 9 (70%) | ||

| 3 | 6 (61%), 12 (67%) | 3 | 3 (54%), 6 (57%), 9 (60%), 16 (70%) | ||

| 4 | 3 (47%), 6 (58%), 9 (61%), 16 (67%) | 4 | 12 (70%) | ||

| 5 | 2 (47%), 2 (58%), 6 (61%), 12 (67%) | 5 | 19 (70%) | ||

| 2 | 1 | 6 (54%), 10 (58%), 16 (64%) | 12 | 1 | 1 (47%), 3 (49%), 6 (53%), 9 (60%), 12 (70%) |

| 2 | 3 (43%), 3 (54%), 9 (58%), 9 (64%), 12 (68%) | 2 | 2 (47%), 3 (49%), 3 (53%), 10 (60%), 16 (70%) | ||

| 3 | 8 (58%), 16 (64%) | 3 | 1 (47%), 4 (49%), 6 (53%), 16 (60%) | ||

| 4 | 3 (43%), 3 (54%), 8 (58%), 12 (64%), 16 (68%) | 4 | 1 (47%), 3 (49%), 6 (53%), 12 (60%), 12 (70%) | ||

| 5 | 2 (43%), 2 (54%), 6 (58%), 12 (64%), 16 (68%) | 5 | 3 (47%), 3 (49%), 6 (53%), 12 (60%), 12 (70%) | ||

| 3 | 1 | 1 (38%), 3 (41%), 6 (47%), 8 (54%), 12 (60%) | 13 | 1 | 1 (50%), 2 (56%), 6 (64%), 12 (66%) |

| 2 | 2 (38%), 4 (41%), 4 (47%), 4 (54%), 8 (60%), 12 (69%) | 2 | 1 (56%), 5 (64%), 9 (66%) | ||

| 3 | 1 (38%), 4 (41%), 4 (47%), 6 (54%), 12 (60%), 12 (69%) | 3 | 1 (50%), 2 (56%), 6 (64%), 15 (66%) | ||

| 4 | 2 (38%), 4 (41%), 4 (47%), 6 (54%), 8 (60%), 16 (69%) | 4 | 1 (56%), 6 (64%), 12 (66%) | ||

| 5 | 1 (38%), 3 (41%), 6 (47%), 8 (54%), 12 (60%), 12 (69%) | 5 | 1 (56%), 6 (64%), 12 (66%) | ||

| 4 | 1 | 3 (48%), 3 (50%), 6 (54%), 8 (64%), 11 (67%) | 14 | 1 | 6 (63%), 12 (67%) |

| 2 | 3 (48%), 3 (50%), 6 (54%), 8 (64%), 12 (67%) | 2 | 1 (49%), 2 (55%), 4 (57%), 8 (63%), 16 (67%) | ||

| 3 | 9 (64%), 12 (67%) | 3 | 6 (63%), 12 (67%) | ||

| 4 | 2 (48%), 2 (50%), 6 (54%), 8 (64%), 12 (67%) | 4 | 1 (49%), 2 (55%), 2 (57%), 6 (63%), 8 (67%) | ||

| 5 | 3 (48%), 3 (50%), 3 (54%), 16 (64%, uncovered) | 5 | 1 (49%), 3 (55%), 5 (57%), 9 (63%), 16 (67%) | ||

| 5 | 1 | 3 (42%), 6 (46%), 9 (52%), 12 (63%, uncovered) | 15 | 1 | 2 (41%), 4 (51%), 9 (61%, uncovered) |

| 2 | 3 (42%), 6 (46%), 9 (52%), 12 (63%, uncovered) | 2 | 2 (41%), 4 (51%), 9 (61%, uncovered) | ||

| 3 | 3 (42%), 6 (46%), 9 (52%), 12 (63%, uncovered) | 3 | 1 (41%), 2 (51%), 6 (61%, uncovered) | ||

| 4 | 3 (42%), 3 (46%), 6 (52%), 12 (63%, uncovered) | 4 | 1 (41%), 2 (51%), 6 (61%, uncovered) | ||

| 5 | 3 (42%), 6 (46%), 9 (52%), 12 (63%, uncovered) | 5 | 1 (41%), 1 (51%), 6 (61%, uncovered) | ||

| 6 | 1 | 3 (45%), 6 (48%), 9 (58%), 9 (62%), 16 (68%) | 16 | 1 | 12 (64%, uncovered) |

| 2 | 3 (45%), 3 (48%), 6 (58%), 12 (62%), 16 (68%) | 2 | 9 (64%, uncovered) | ||

| 3 | 1 (45%), 3 (48%), 6 (58%), 12 (62%), 12 (68%) | 3 | 1 (47%), 3 (49%), 4 (53%), 8 (64%, uncovered) | ||

| 4 | 4 (45%), 6 (48%), 4 (58%), 12 (62%), 12 (68%) | 4 | 13 (64%, uncovered) | ||

| 5 | 4 (45%), 6 (48%), 9 (58%), 9 (62%), 12 (68%) | 5 | 9 (64%, uncovered) | ||

| 7 | 1 | 3 (45%), 6 (46%), 9 (51%), 12 (61%), 12 (66%) | 17 | 1 | 2 (61%), 6 (65%), 12 (66%), 14 (68%) |

| 2 | 3 (45%), 3 (46%), 6 (51%), 8 (61%), 11 (66%), 16 (70%) | 2 | 2 (61%), 6 (65%), 8 (66%), 12 (68%) | ||

| 3 | 4 (45%), 5 (46%), 8 (51%), 8 (61%), 15 (66%) | 3 | 2 (59%), 4 (61%), 9 (65%), 9 (66%), 12 (68%) | ||

| 4 | 8 (61%), 12 (66%), 16 (70%) | 4 | 1 (61%), 6 (65%), 14 (66%), 15 (68%) | ||

| 5 | 3 (45%), 3 (46%), 6 (51%), 8 (61%), 12 (66%), 16 (70%) | 5 | 2 (59%), 3 (61%), 8 (65%), 12 (66%), 16 (68%) | ||

| 8 | 1 | 9 (64%), 16 (68%) | 18 | 1 | 3 (62%), 6 (63%), 12 (67%) |

| 2 | 7 (64%), 11 (68%) | 2 | 1 (51%), 2 (57%), 6 (62%), 6 (63%), 9 (67%) | ||

| 3 | 8 (64%), 12 (68%) | 3 | 3 (63%), 12 (67%) | ||

| 4 | 6 (64%), 12 (68%) | 4 | 2 (62%), 2 (63%), 9 (67%) | ||

| 5 | 3 (60%), 3 (64%), 12 (68%) | 5 | 3 (62%), 6 (63%), 12 (67%) | ||

| 9 | 1 | 3 (40%), 3 (41%), 6 (51%), 9 (56%), 12 (61%) | 19 | 1 | 3 (48%), 5 (52%), 8 (58%), 9 (61%), 12 (70%) |

| 2 | 4 (40%), 6 (41%), 9 (51%), 9 (56%), 12 (61%) | 2 | 3 (48%), 3 (52%), 6 (58%), 9 (61%), 16 (70%) | ||

| 3 | 4 (40%), 6 (41%), 9 (51%), 9 (56%), 9 (61%) | 3 | 2 (48%), 4 (52%), 6 (58%), 8 (61%), 12 (70%) | ||

| 4 | 3 (40%), 3 (41%), 6 (51%), 9 (56%), 9 (61%) | 4 | 2 (48%), 4 (52%), 7 (58%), 12 (61%), 16 (70%) | ||

| 5 | 4 (40%), 6 (41%), 9 (51%), 9 (56%), 16 (61%) | 5 | 6 (61%), 11 (70%) | ||

| 10 | 1 | 1 (48%), 2 (50%), 5 (53%), 8 (56%), 8 (57%), 16 (60%) | 20 | 1 | 1 (55%), 2 (59%), 4 (62%), 9 (65%), 12 (69%) |

| 2 | 1 (48%), 1 (50%), 2 (53%), 2 (56%), 6 (57%), 7 (60%), 10 (64%) | 2 | 3 (49%), 1 (55%), 2 (59%), 4 (62%), 9 (65%), 12 (69%) | ||

| 3 | 1 (48%), 1 (50%), 2 (53%), 3 (56%), 6 (57%), 12 (6%), 12 (64%) | 3 | 8 (62%), 11 (65%), 16 (69%) | ||

| 4 | 1 (48%), 1 (50%), 2 (53%), 6 (56%), 8 (57%), 12 (60%, uncovered) | 4 | 3 (49%), 4 (55%), 4 (59%), 8 (62%), 13 (65%), 13 (69%) | ||

| 5 | 1 (50%), 2 (53%), 4 (56%), 4 (57%), 9 (60%, uncovered) | 5 | 2 (49%), 3 (55%), 6 (59%), 9 (62%), 12 (65%), 12 (69%) |

| Increment (i) | Type A Error | Type B Error |

|---|---|---|

| 11 | 0.00 | 0.53 |

| 10 | 0.00 | 0.53 |

| 9 | 0.00 | 0.52 |

| 8 | 0.00 | 0.51 |

| 7 | 0.00 | 0.49 |

| 6 | 0.02 | 0.45 |

| 5 | 0.03 | 0.41 |

| 4 | 0.06 | 0.29 |

| 3 | 0.28 | 0.21 |

| Group | Accumulated Order | Group | Accumulated Order |

|---|---|---|---|

| 21 | 11→19→24→28→26→16→18→6→13→21→9→32→15→2→14 | 24 | 30→20→15→24→17→31→12→3→23→32→1→8→19→21→6→26→16 |

| 22 | 9→28→13→1→16→18→25→19→11→2→30→12→17→5→10→3→4 | 25 | 30→2→27→21→20→15→28→23→9→12→7→18→26→16→24→10 |

| 23 | 29→28→7→1→17→21→26→3→25→16→9→4→5→32→23→22→15 |

| Group | Trial | Result | Group | Trial | Result |

|---|---|---|---|---|---|

| 21 | 1 | 3 (48%), 6 (58%), 12 (68%), 12 (72%) | 24 | 1 | 6 (51%), 12 (61%), 12 (67%), 16 (71%) |

| 2 | 8 (58%), 16 (68%), 16 (72%) | 2 | 8 (51%), 12 (61%), 16 (67%), 16 (71%) | ||

| 3 | 6 (48%), 9 (58%), 12 (68%), 16 (72%) | 3 | 6 (51%), 12 (61%), 16 (67%), 16 (71%, uncovered) | ||

| 4 | 4 (48%), 6 (58%), 12 (68%), 12 (72%) | 4 | 6 (51%), 10 (61%), 12 (67%), 16 (71%, uncovered) | ||

| 5 | 6 (58%), 12 (68%), 12 (72%) | 5 | 5 (51%), 12 (61%), 12 (67%), 16 (71%, uncovered) | ||

| 22 | 1 | 6 (55%), 6 (56%), 12 (63%), 12 (67%), 16 (71%) | 25 | 1 | 2 (52%), 8 (61%), 10 (67%), 12 (70%), 12 (70%), 16 (71%) |

| 2 | 3 (55%), 6 (56%),10 (63%), 12 (67%), 16 (71%) | 2 | 4 (61%), 8 (67%), 12 (70%), 12 (70%), 12 (71%) | ||

| 3 | 6 (55%), 8 (56%),9 (63%), 12 (67%), 13 (7%) | 3 | 6 (61%), 8 (67%), 12 (70%), 12 (70%), 16 (71%) | ||

| 4 | 4 (56%), 12 (63%), 12 (67%), 16 (71%) | 4 | 3 (52%), 7 (61%), 8 (67%), 12 (70%), 16 (70%), 16 (71%) | ||

| 5 | 6 (56%), 9 (63%), 12 (67%), 16 (71%) | 5 | 2 (52%), 8 (61%), 10 (67%), 12 (70%), 12 (70%), 12 (71%) | ||

| 23 | 1 | 3 (55%), 6 (59%), 11 (65%), 12 (65%), 16 (76%) | |||

| 2 | 2 (55%), 5 (59%), 9 (65%), 9 (65%), 12 (76%) | ||||

| 3 | 8 (59%), 12 (65%), 12 (65%), 16 (76%) | ||||

| 4 | 2 (55%), 6 (59%), 12 (65%), 12 (65%), 16 (76%) | ||||

| 5 | 4 (59%), 6 (65%), 8 (65%), 12 (76%) | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sung, S.-I.; Kim, Y.-S.; Kim, H.-S. Study on Reverse Logistics Focused on Developing the Collection Signal Algorithm Based on the Sensor Data and the Concept of Industry 4.0. Appl. Sci. 2020, 10, 5016. https://doi.org/10.3390/app10145016

Sung S-I, Kim Y-S, Kim H-S. Study on Reverse Logistics Focused on Developing the Collection Signal Algorithm Based on the Sensor Data and the Concept of Industry 4.0. Applied Sciences. 2020; 10(14):5016. https://doi.org/10.3390/app10145016

Chicago/Turabian StyleSung, Si-Il, Young-Sun Kim, and Hyun-Soo Kim. 2020. "Study on Reverse Logistics Focused on Developing the Collection Signal Algorithm Based on the Sensor Data and the Concept of Industry 4.0" Applied Sciences 10, no. 14: 5016. https://doi.org/10.3390/app10145016

APA StyleSung, S.-I., Kim, Y.-S., & Kim, H.-S. (2020). Study on Reverse Logistics Focused on Developing the Collection Signal Algorithm Based on the Sensor Data and the Concept of Industry 4.0. Applied Sciences, 10(14), 5016. https://doi.org/10.3390/app10145016